Characterization of Copper–Graphite Composites Fabricated via Electrochemical Deposition and Spark Plasma Sintering

Abstract

1. Introduction

2. Experimental Procedure

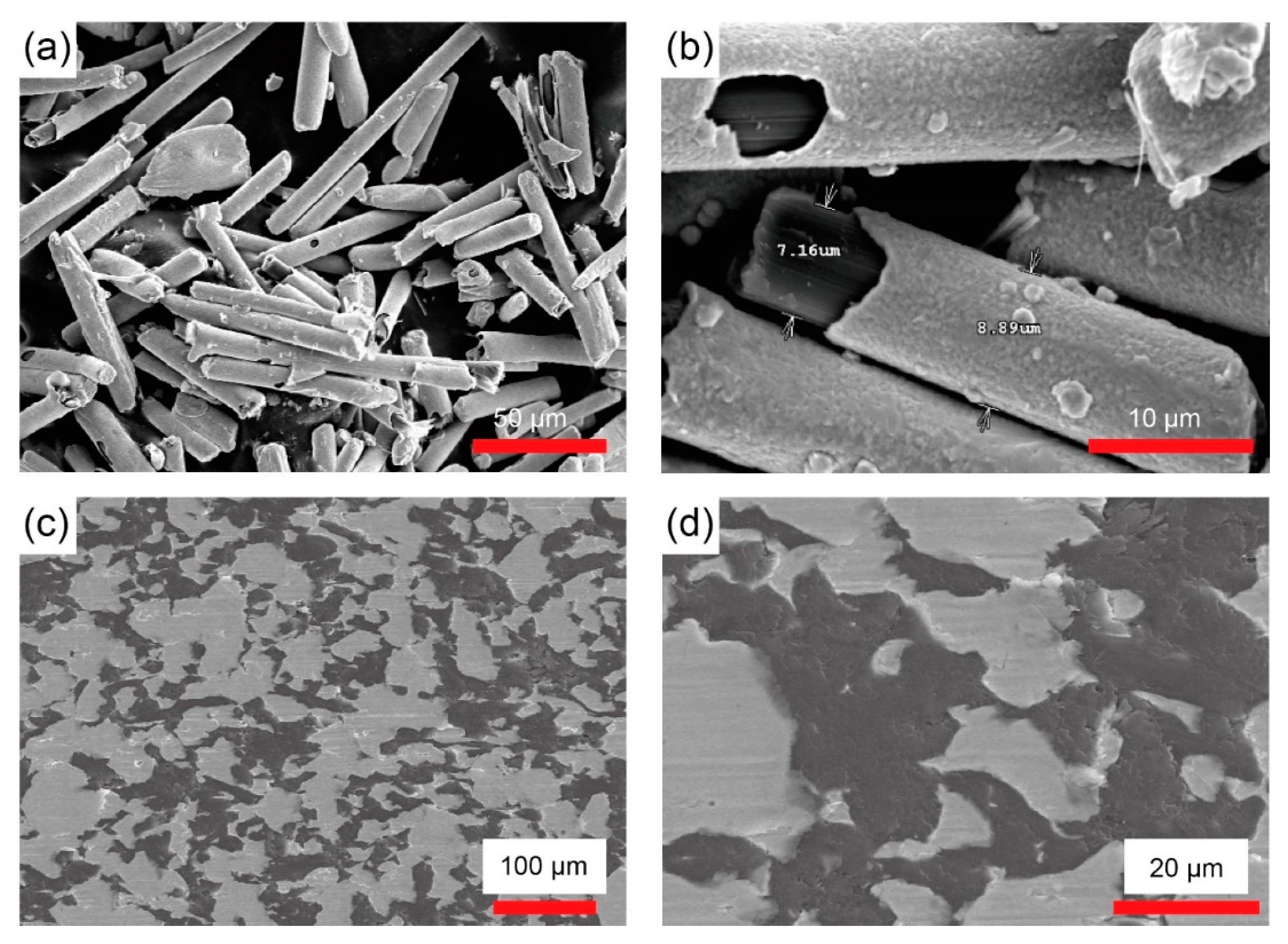

2.1. Preparation of Copper–Graphite Composite Materials

2.2. Spark Plasma Sintering

2.3. Characterization of Copper–Graphite Composites

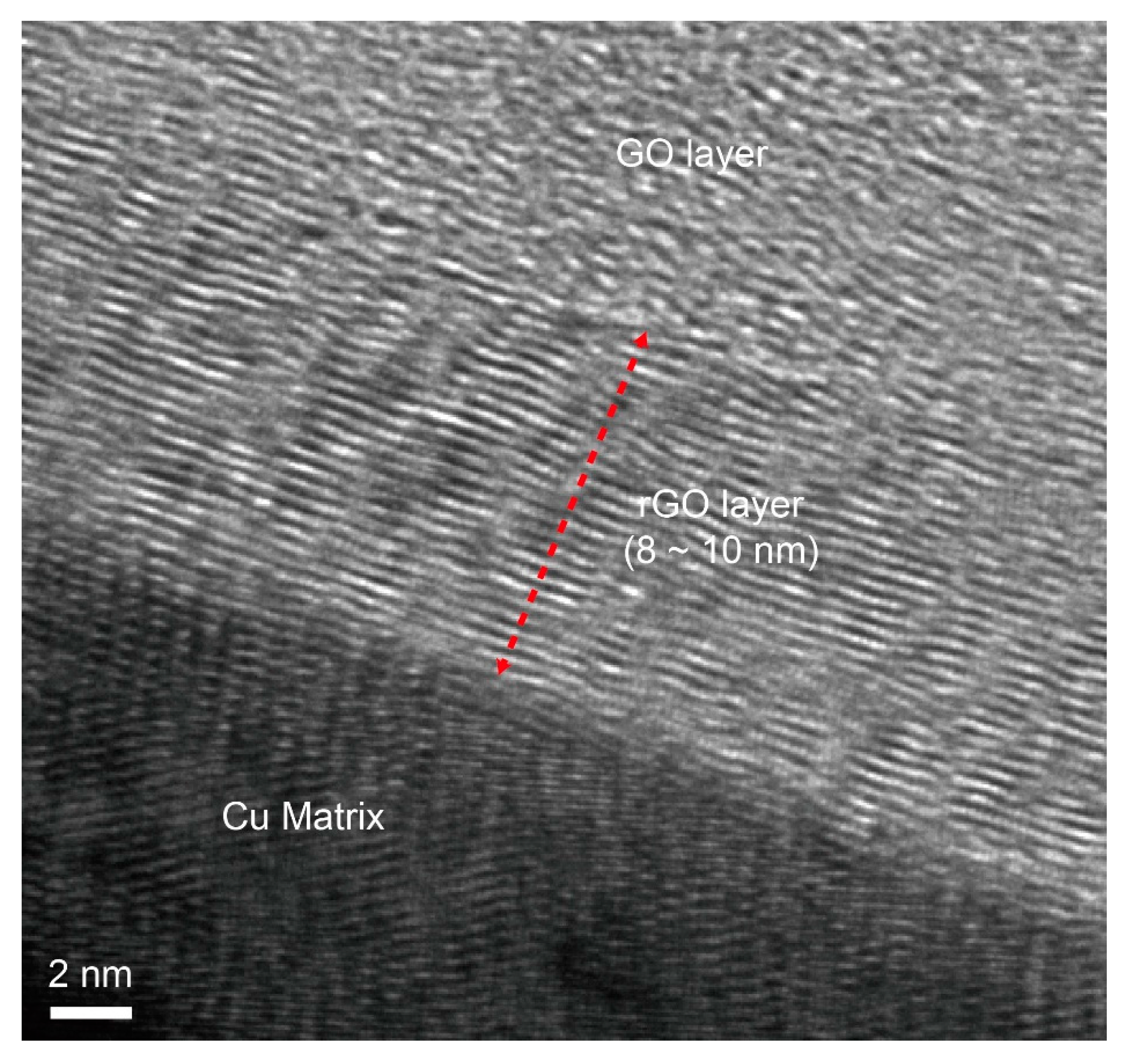

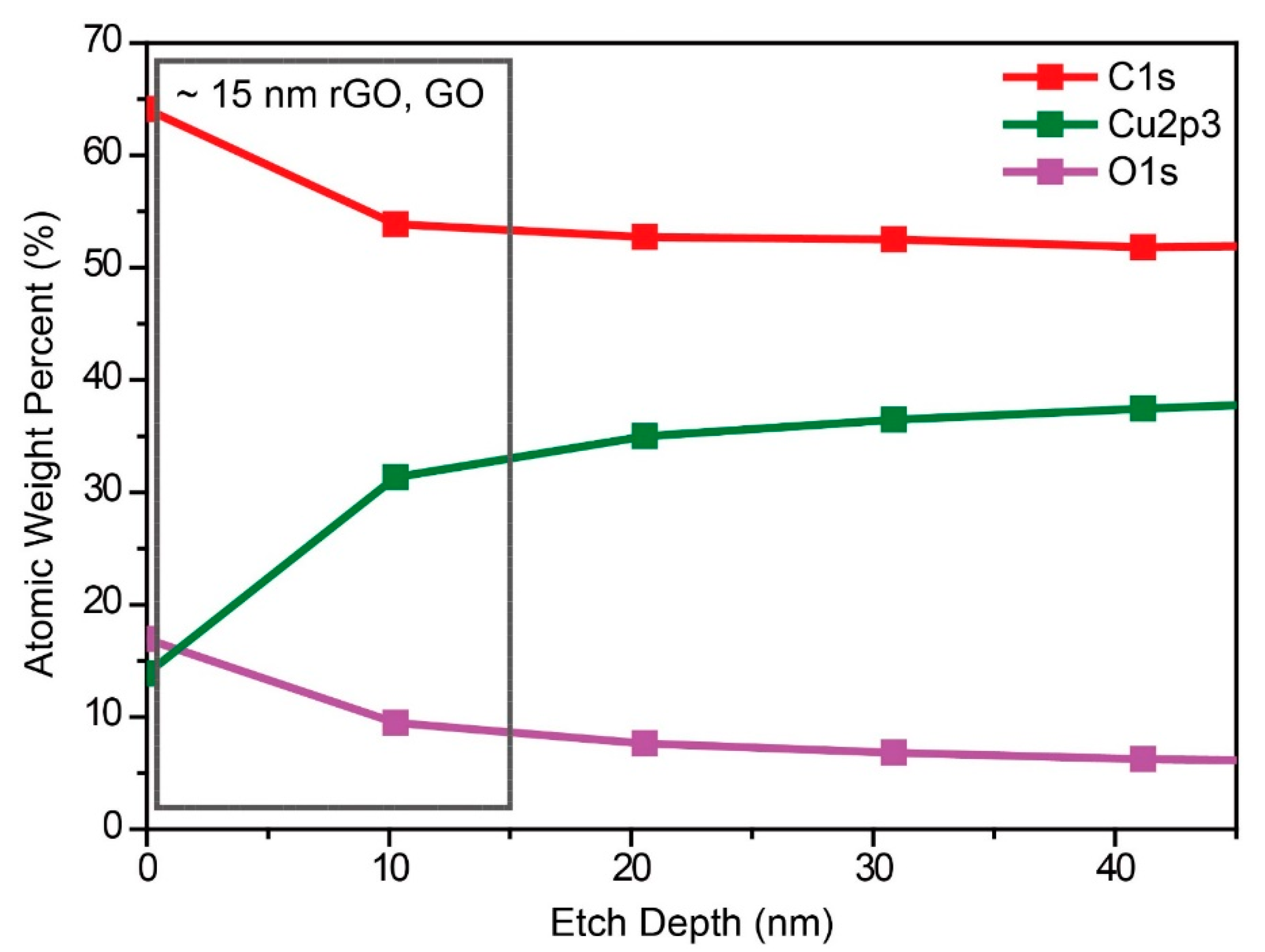

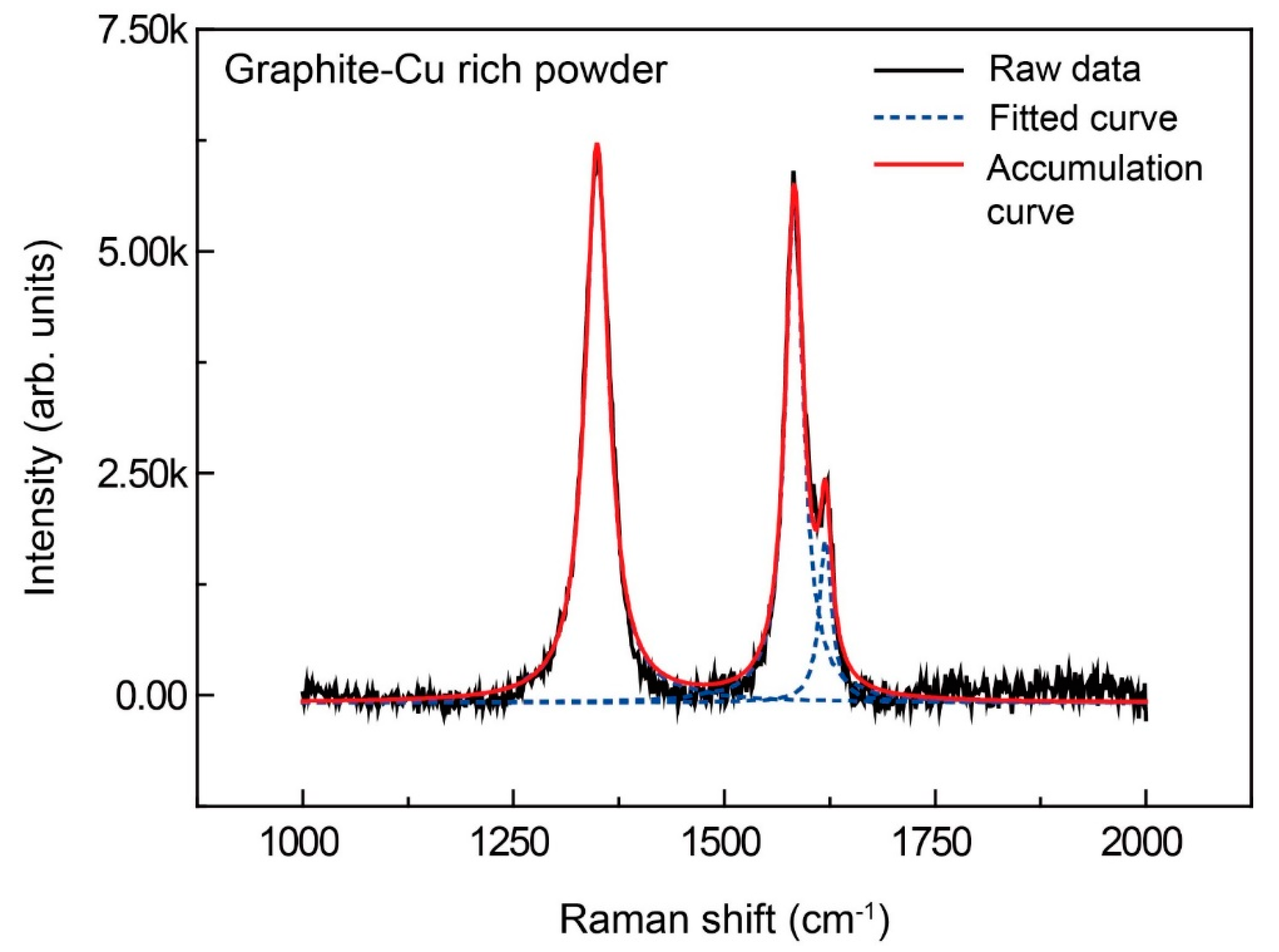

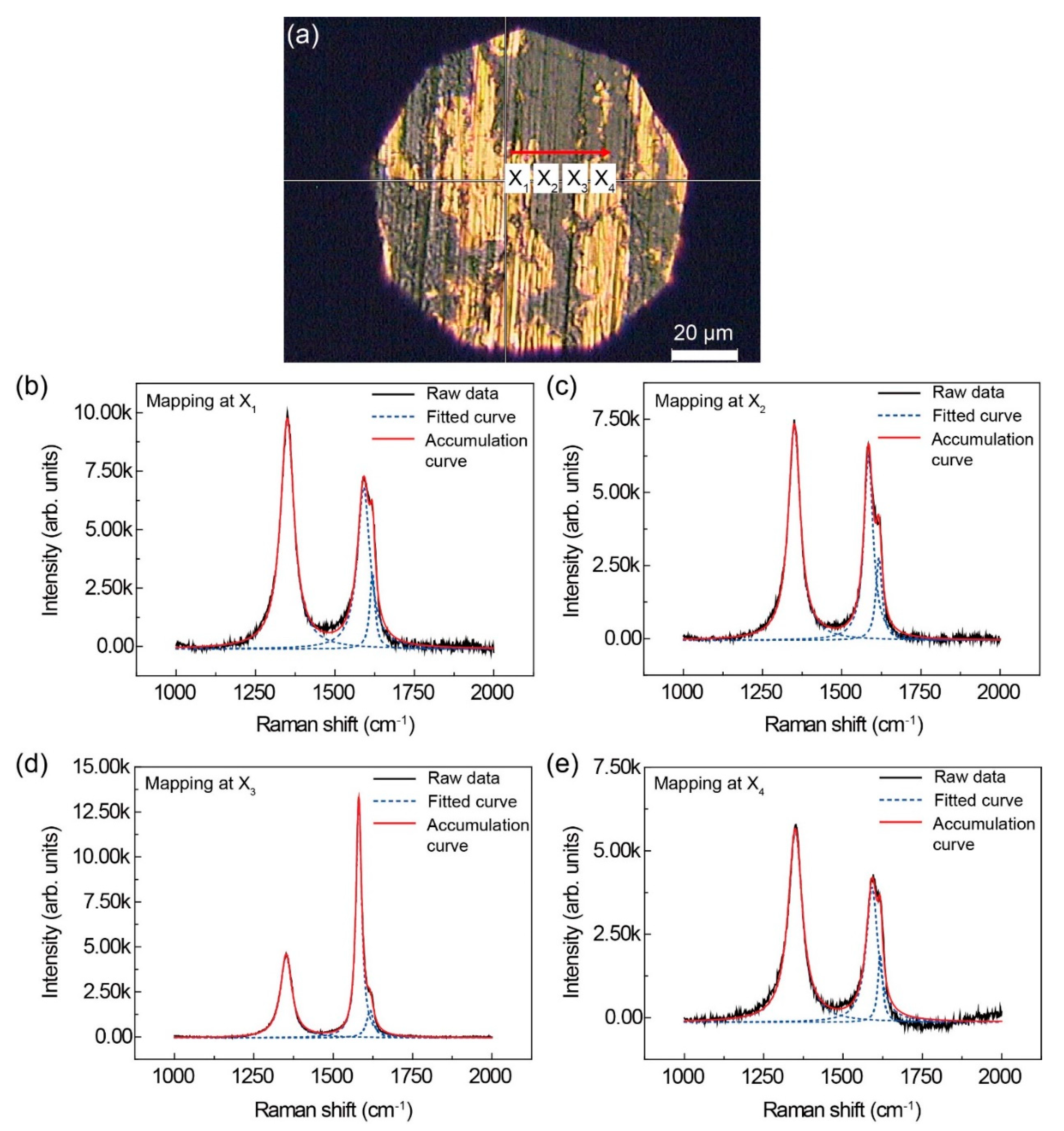

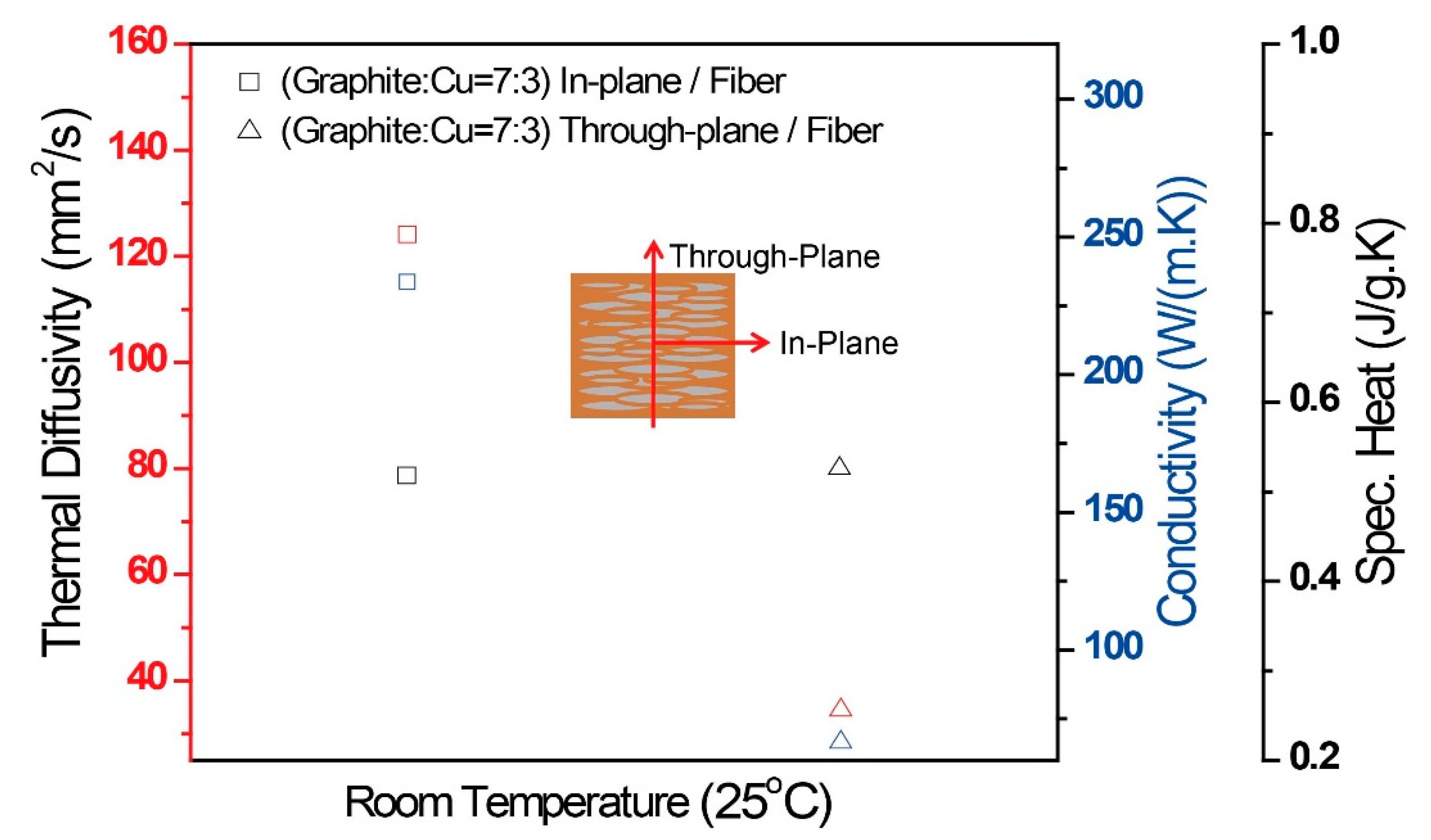

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed]

- Inagaki, M.; Kaburagi, Y.; Hishiyama, Y. Thermal Management Material: Graphite. Adv. Eng. Mater. 2014, 16, 494–506. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, H.; Wen, G.; Wang, E.; Fang, X.; Liu, G.; Zhou, W. Copper–graphite–copper sandwich: Superior heat spreader with excellent heat-dissipation ability and good weldability. RSC Adv. 2016, 6, 25128–25136. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, G.; Khan, J.M.; Balandin, A.A. Graphene quilts for thermal management of high-power GaN transistors. Nat. Commun. 2012, 3, 827. [Google Scholar] [CrossRef] [PubMed]

- Park, C.G.; Lee, T.H.; Lee, T.K.; Jeong, M.Y. A Study on the Optimization of Heat Dissipation in Flip-chip Package. J. Microelectron. Packag. Soc. 2013, 20, 75–80. [Google Scholar] [CrossRef][Green Version]

- Ko, Y.-H.; Choi, K.; Kim, S.W.; Yu, D.-Y.; Bang, J.; Kim, T.-S. Trends of Researches and Technologies of Electronic Packaging Using Graphene. J. Microelectron. Packag. Soc. 2016, 23, 1–10. [Google Scholar] [CrossRef]

- Abyzov, A.M.; Kidalov, S.V.; Shakhov, F.M. High thermal conductivity composite of diamond particles with tungsten coating in a copper matrix for heat sink application. Appl. Therm. Eng. 2012, 48, 72–80. [Google Scholar] [CrossRef]

- Boden, A.; Boerner, B.; Kusch, P.; Firkowska, I.; Reich, S. Nanoplatelet Size to Control the Alignment and Thermal Conductivity in Copper–Graphite Composites. Nano Lett. 2014, 14, 3640–3644. [Google Scholar] [CrossRef]

- Firkowska, I.; Boden, A.; Boerner, B.; Reich, S. The Origin of High Thermal Conductivity and Ultralow Thermal Expansion in Copper–Graphite Composites. Nano Lett. 2015, 15, 4745–4751. [Google Scholar] [CrossRef]

- Slack, G.A. Thermal Conductivity of Pure and Impure Silicon, Silicon Carbide, and Diamond. J. Appl. Phys. 1964, 35, 3460. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, Q.; Shi, J.; Zhai, G.; Liu, L. Graphite blocks with high thermal conductivity derived from natural graphite flake. Carbon 2008, 46, 414–421. [Google Scholar] [CrossRef]

- Hui, C.; Zhang, Y.; Zhang, L.; Sun, R.; Liu, F. Crumpling of a pyrolytic graphite sheet. J. Appl. Phys. 2013, 114, 163512. [Google Scholar] [CrossRef]

- Wen, C.-Y.; Huang, G.-W. Application of a thermally conductive pyrolytic graphite sheet to thermal management of a PEM fuel cell. J. Power Sources 2008, 178, 132–140. [Google Scholar] [CrossRef]

- Kim, P.; Shi, L.; Majumdar, A.; McEuen, P.L. Thermal Transport Measurements of Individual Multiwalled Nanotubes. Phys. Rev. Lett. 2001, 87, 215502. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Seol, J.H.; Jo, I.; Moore, A.L.; Lindsay, L.; Aitken, Z.H.; Pettes, M.T.; Li, X.; Yao, Z.; Huang, R.; Broido, D.; et al. Two-Dimensional Phonon Transport in Supported Graphene. Science 2010, 328, 213–216. [Google Scholar] [CrossRef]

- Song, W.-L.; Veca, L.M.; Kong, C.Y.; Ghose, S.; Connell, J.W.; Wang, P.; Cao, L.; Lin, Y.; Meziani, M.J.; Qian, H.; et al. Polymeric nanocomposites with graphene sheets—Materials and device for superior thermal transport properties. Polymer 2012, 53, 3910–3916. [Google Scholar] [CrossRef]

- Xiang, C.; Young, C.C.; Hwang, C.-C.; Cerioti, G.; Tour, J.M.; Wang, X.; Yan, Z.; Hwang, C.; Lin, J.; Kono, J.; et al. Large Flake Graphene Oxide Fibers with Unconventional 100% Knot Efficiency and Highly Aligned Small Flake Graphene Oxide Fibers. Adv. Mater. 2013, 25, 4592–4597. [Google Scholar] [CrossRef]

- Gwinn, J.; Webb, R. Performance and testing of thermal interface materials. Microelectron. J. 2003, 34, 215–222. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, L.; Peng, K.; Zhu, J.; Wan, L. Effect of tungsten addition on thermal conductivity of graphite/copper composites. Compos. Part B Eng. 2013, 55, 1–4. [Google Scholar] [CrossRef]

- Kang, Q.; He, X.; Ren, S.; Zhang, L.; Wu, M.; Liu, T.; Liu, Q.; Guo, C.; Qu, X. Preparation of high thermal conductivity copper–diamond composites using molybdenum carbide-coated diamond particles. J. Mater. Sci. 2013, 48, 6133–6140. [Google Scholar] [CrossRef]

- Prieto, R.; Molina, J.; Narciso, J.; Louis, E. Fabrication and properties of graphite flakes/metal composites for thermal management applications. Scr. Mater. 2008, 59, 11–14. [Google Scholar] [CrossRef]

- Jagannadham, K. Orientation dependence of thermal conductivity in copper-graphene composites. J. Appl. Phys. 2011, 110, 74901. [Google Scholar] [CrossRef]

- Jagannadham, K. Thermal Conductivity of Copper-Graphene Composite Films Synthesized by Electrochemical Deposition with Exfoliated Graphene Platelets. Metall. Mater. Trans. B 2012, 43, 316–324. [Google Scholar] [CrossRef]

- Liu, Q.; He, X.-B.; Ren, S.-B.; Zhang, C.; Ting-Ting, L.; Qu, X.-H. Thermophysical properties and microstructure of graphite flake/copper composites processed by electroless copper coating. J. Alloys Compd. 2014, 587, 255–259. [Google Scholar] [CrossRef]

- Goli, P.; Ning, H.; Li, X.; Lu, C.Y.; Novoselov, K.S.; Balandin, A.A. Thermal Properties of Graphene–Copper–Graphene Heterogeneous Films. Nano Lett. 2014, 14, 1497–1503. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.-D.; Zhan, Z.-J. Experimental investigation of interfaces in graphene materials/copper composites from a new perspective. RSC Adv. 2016, 6, 52219–52226. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Z.; Cui, Y.; Wei, B.; Xu, S.; Sheng, J.; Wang, M.; Zhu, Y.; Fei, W. Graphene-copper composite with micro-layered grains and ultrahigh strength. Sci. Rep. 2017, 7, 41896. [Google Scholar] [CrossRef]

- Hwang, J.; Yoon, T.; Jin, S.H.; Lee, J.; Kim, T.-S.; Hong, S.H.; Jeon, S. Enhanced Mechanical Properties of Graphene/Copper Nanocomposites Using a Molecular-Level Mixing Process. Adv. Mater. 2013, 25, 6724–6729. [Google Scholar] [CrossRef]

- Wang, L.; Cui, Y.; Li, B.; Yang, S.; Liu, Z.; Vajtai, R.; Fei, W. High apparent strengthening efficiency for reduced graphene oxide in copper matrix composites produced by molecule-lever mixing and high-shear mixing. RSC Adv. 2015, 5, 51193–51200. [Google Scholar] [CrossRef]

- Choi, I.; Jeong, H.Y.; Jung, D.Y.; Byun, M.; Choi, C.-G.; Hong, B.H.; Choi, S.-Y.; Lee, K.J. Laser-Induced Solid-Phase Doped Graphene. ACS Nano 2014, 8, 7671–7677. [Google Scholar] [CrossRef]

- Choi, I.; Jeong, H.Y.; Shin, H.; Kang, G.; Byun, M.; Kim, H.; Chitu, A.M.; Im, J.S.; Ruoff, R.S.; Choi, S.-Y.; et al. Laser-induced phase separation of silicon carbide. Nat. Commun. 2016, 7, 13562. [Google Scholar] [CrossRef] [PubMed]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Liu, X.-W.; Mao, J.-J.; Liu, P.-D.; Wei, X.-W. Fabrication of metal-graphene hybrid materials by electroless deposition. Carbon 2011, 49, 477–483. [Google Scholar] [CrossRef]

- Sato, K.; Saito, R.; Oyama, Y.; Jiang, J.; Cançado, L.; Pimenta, M.; Jorio, A.; Samsonidze, G.; Dresselhaus, G.; Dresselhaus, M.; et al. D-band Raman intensity of graphitic materials as a function of laser energy and crystallite size. Chem. Phys. Lett. 2006, 427, 117–121. [Google Scholar] [CrossRef]

- Barcena, J.; Maudes, J.; Coleto, J.; Baldonedo, J.L.; De Salazar, J.M.G. Microstructural study of vapour grown carbon nanofibre/copper composites. Compos. Sci. Technol. 2008, 68, 1384–1391. [Google Scholar] [CrossRef]

- Mai, Y.; Zhang, D.; Qiao, Y.; Gu, C.; Wang, X.; Tu, J. MnO/reduced graphene oxide sheet hybrid as an anode for Li-ion batteries with enhanced lithium storage performance. J. Power Sources 2012, 216, 201–207. [Google Scholar] [CrossRef]

- Song, H.; Wang, B.; Zhou, Q.; Xiao, J.; Jia, X. Preparation and tribological properties of MoS2/graphene oxide composites. Appl. Surf. Sci. 2017, 419, 24–34. [Google Scholar] [CrossRef]

- Schmidt, A.J.; Collins, K.C.; Minnich, A.J.; Chen, G. Thermal conductance and phonon transmissivity of metal–graphite interfaces. J. Appl. Phys. 2010, 107, 104907. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Byun, M.; Kim, D.; Sung, K.; Jung, J.; Song, Y.-S.; Park, S.; Son, I. Characterization of Copper–Graphite Composites Fabricated via Electrochemical Deposition and Spark Plasma Sintering. Appl. Sci. 2019, 9, 2853. https://doi.org/10.3390/app9142853

Byun M, Kim D, Sung K, Jung J, Song Y-S, Park S, Son I. Characterization of Copper–Graphite Composites Fabricated via Electrochemical Deposition and Spark Plasma Sintering. Applied Sciences. 2019; 9(14):2853. https://doi.org/10.3390/app9142853

Chicago/Turabian StyleByun, Myunghwan, Dongbae Kim, Kildong Sung, Jaehan Jung, Yo-Seung Song, Sangha Park, and Injoon Son. 2019. "Characterization of Copper–Graphite Composites Fabricated via Electrochemical Deposition and Spark Plasma Sintering" Applied Sciences 9, no. 14: 2853. https://doi.org/10.3390/app9142853

APA StyleByun, M., Kim, D., Sung, K., Jung, J., Song, Y.-S., Park, S., & Son, I. (2019). Characterization of Copper–Graphite Composites Fabricated via Electrochemical Deposition and Spark Plasma Sintering. Applied Sciences, 9(14), 2853. https://doi.org/10.3390/app9142853