Review of Machining Equipment Reliability Analysis Methods based on Condition Monitoring Technology

Abstract

1. Introduction

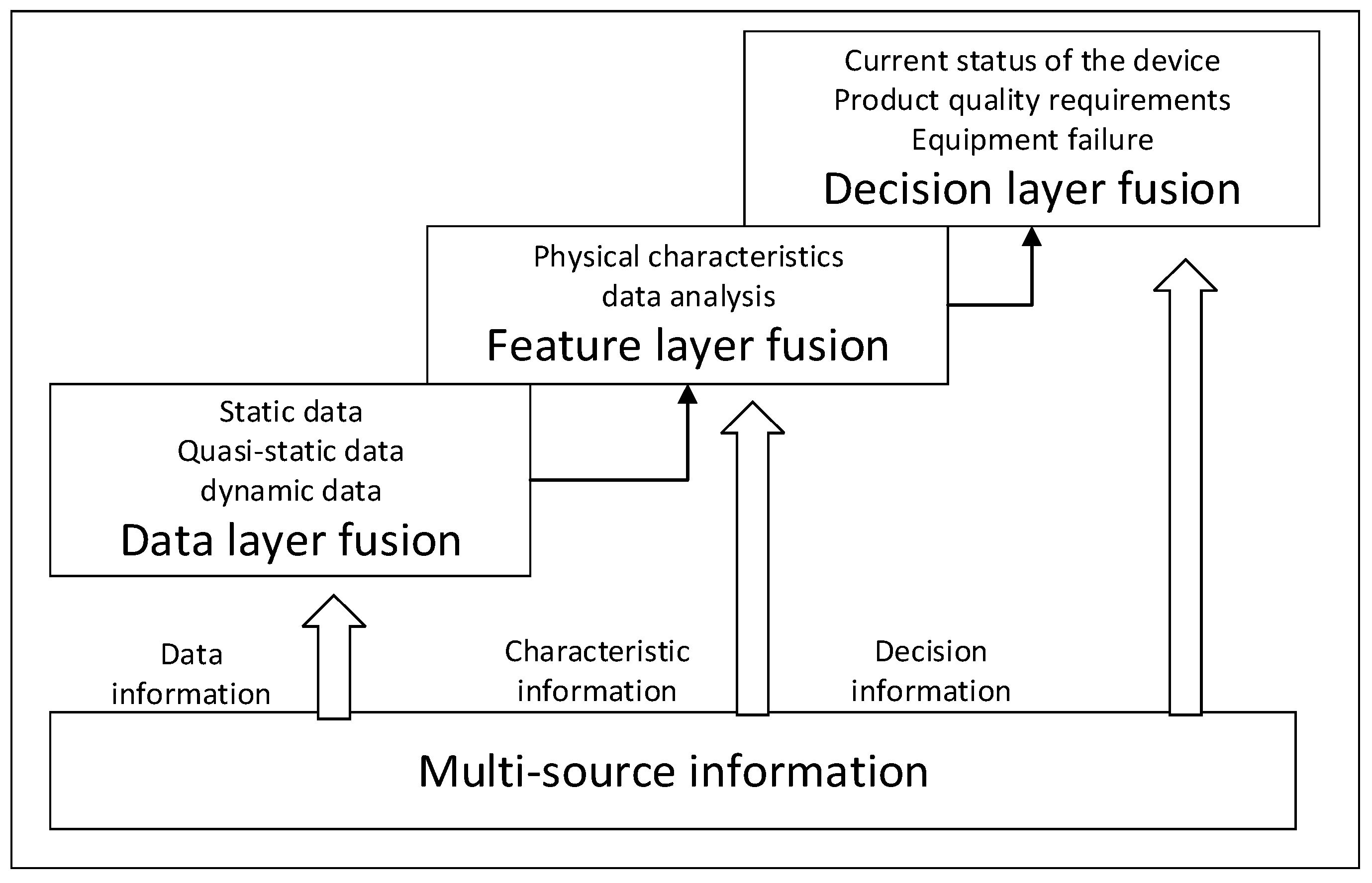

2. Multi-Source Information during Cutting Process

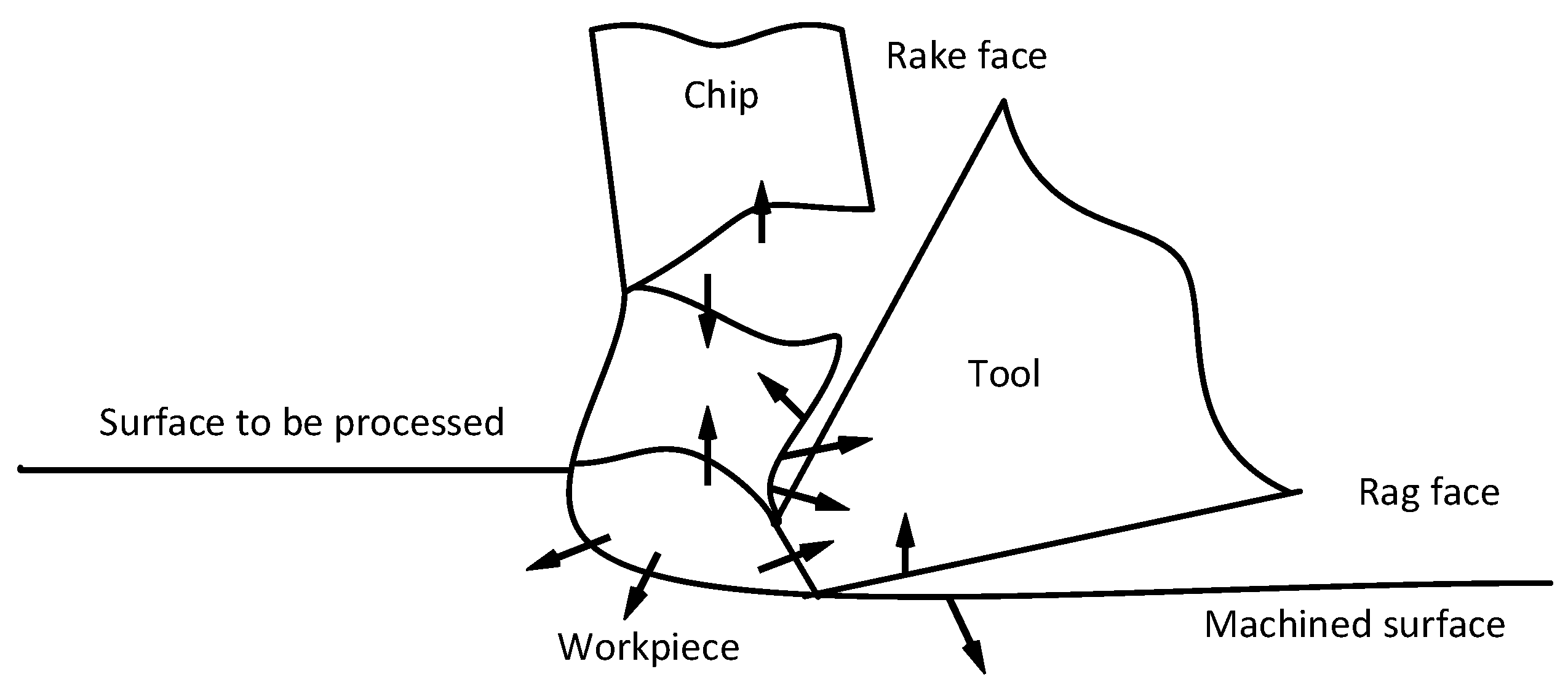

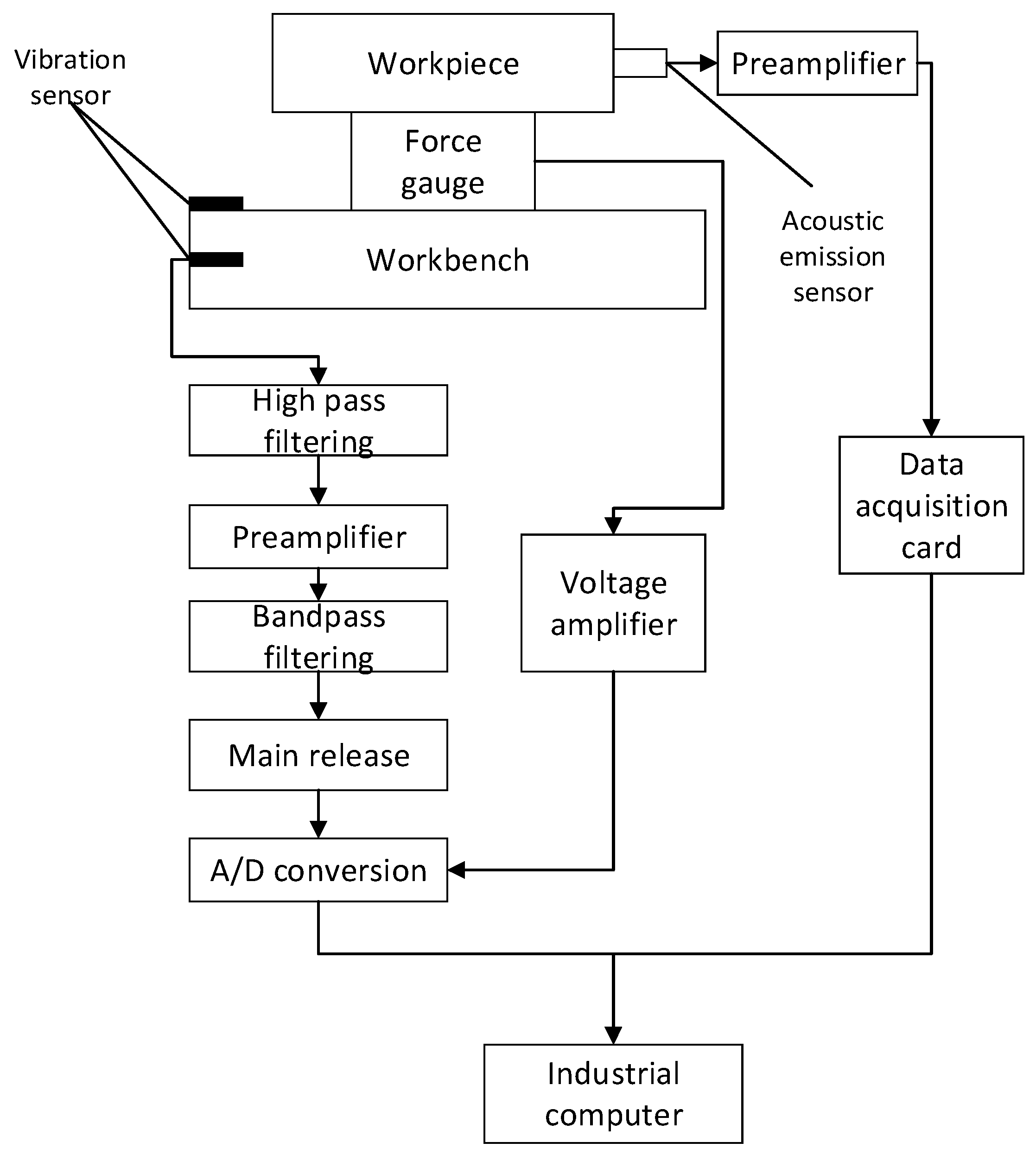

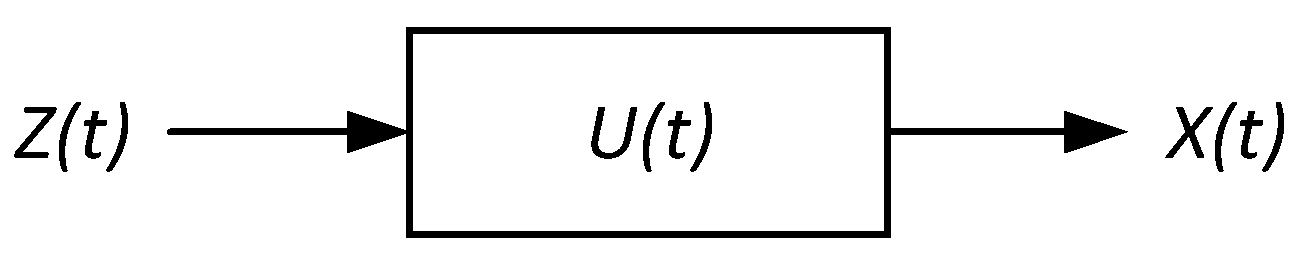

2.1. Cutting Process Information of Machining Equipment

2.2. Quality Characteristics Information of Processed Products

2.3. Process Flow and Parameter Information

3. Failure Physical Analysis for Signal Selection

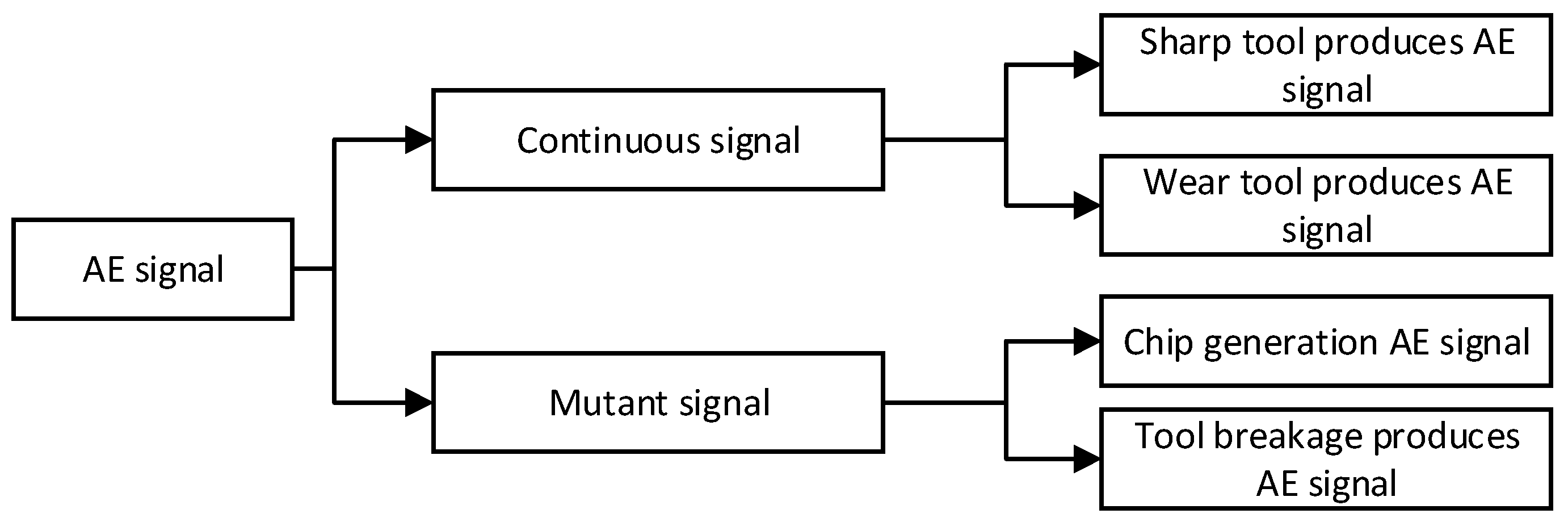

3.1. The Relevance Analysis between Failure Mechanism and Output Signal

3.1.1. Flutter

3.1.2. Breakage

3.1.3. Tool Wear

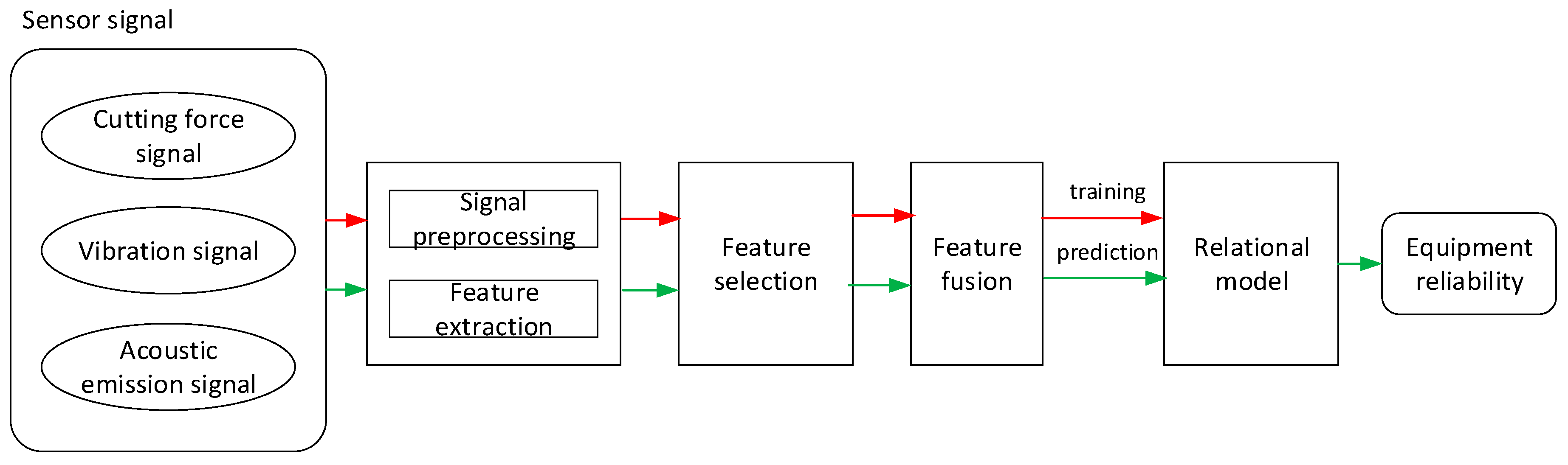

3.2. Application of Multi-Sensor Information Fusion

4. Reliability Assessment of Machining Equipment based on Condition Information

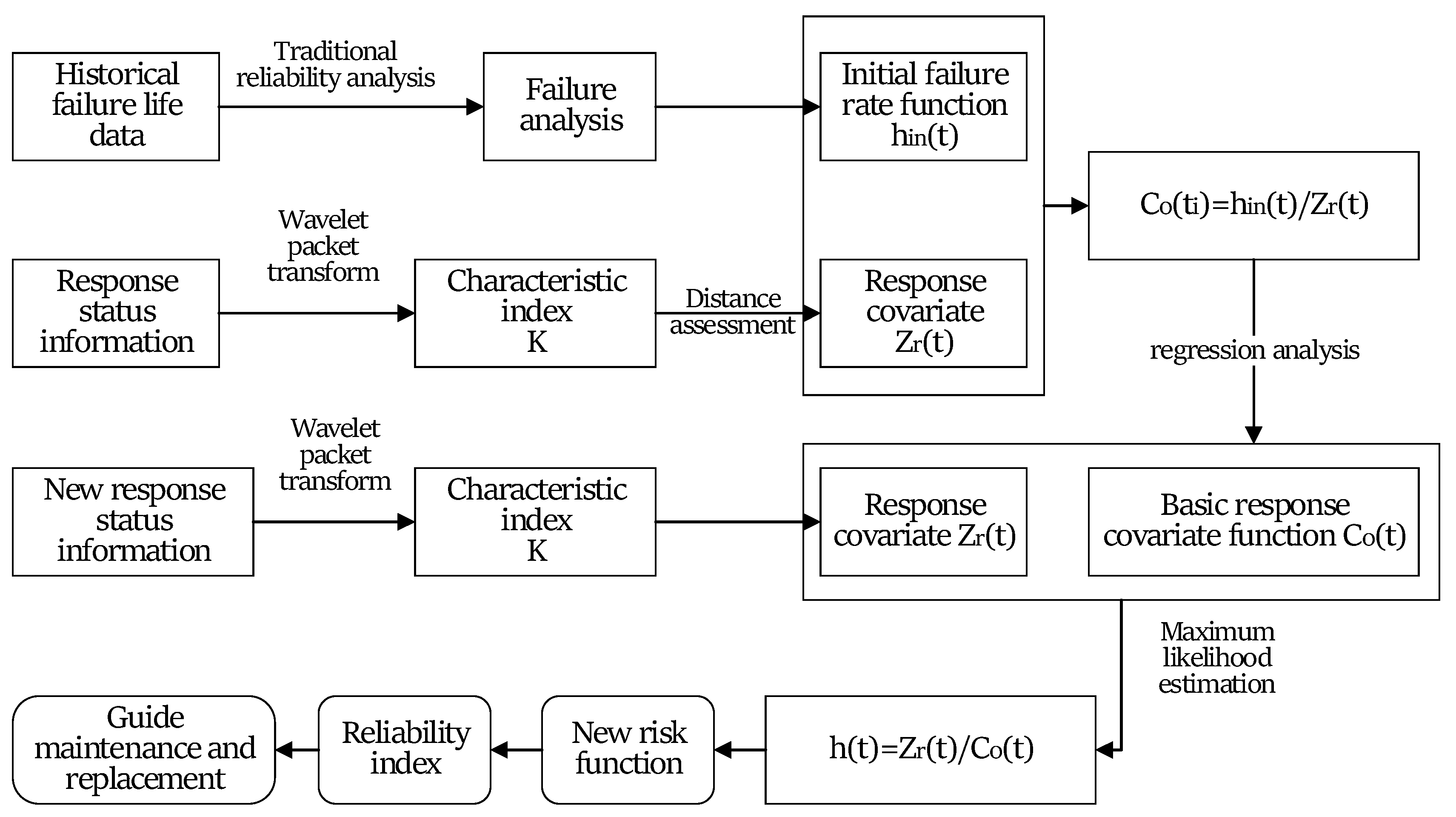

4.1. Operational Reliability Assessment Method of Machining Equipment

4.1.1. Probability and Statistics Method

4.1.2. Artificial Intelligence Method

4.2. Mission Reliability Assessment Method of Machining Equipment

5. Summary and Outlook

5.1. Outlook on Future Challenges and Trends

5.2. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Chen, H.T.; Huang, S.; Li, D.W. Study on the cutting force prediction of CNC turning. Mod. Manuf. Eng. 2010, 06, 36–39. [Google Scholar]

- Oraby, S.E.; Hayhurst, D.R. Tool life determination based on the measurement of wear and tool force ratio variation. Int. J. Adv. Manuf. Technol. 2004, 44, 1261–1269. [Google Scholar] [CrossRef]

- Zhang, S.M.; Mao, D.; Wang, B.Y. Application of big data processing technology in fault diagnosis and early warning of wind turdine cearbox. Autom. Electr. Power Syst. 2016, 40, 129–134. [Google Scholar]

- Henriquez, P.; Alonso, J.B.; Ferrer, M.A.; Travieso, C.M.; Alonso-Hernández, J.B.; Travieso-González, C.M. Review of Automatic Fault Diagnosis Systems Using Audio and Vibration Signals. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 642–652. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Chen, J.C. Tool condition monitoring in an end-milling operation based on the vibration signal collected through a microcontroller-based data acquisition system. Int. J. Adv. Manuf. Technol. 2008, 39, 118–128. [Google Scholar] [CrossRef]

- Renede Jesus, R.T.R.; Gilberto, H.R.; Ivan, T.V.; Carlos, J.C.J. Driver current analysis for senseless tool breakage monitoring of CNC milling machines. Int. J. Mach. Tools Manuf. 2003, 43, 1529–1534. [Google Scholar] [CrossRef]

- Wang, J.P.; Jing, Z.L.; Wang, A. Tool wear estimation by soft-sensing technology based on stochastic fuzzy neural network. Inf. Control 2002, 31, 534–537. [Google Scholar]

- Guan, S. Technology of Classification and Forecast of Tools Wear Based on Muti-Feature Analysis and Fusion of AE.; Jilin University: Changchun, China, 2011. [Google Scholar]

- Ghosh, N.; Ravi, Y.; Patra, A.; Mukhopadhyay, S.; Paul, S.; Mohanty, A.; Chattopadhyay, A.; Mohanty, A. Estimation of tool wear during CNC milling using neural network-based sensor fusion. Mech. Syst. Signal Process. 2007, 21, 466–479. [Google Scholar] [CrossRef]

- Chen, P. AE-Based Fault Diagnosis of Milling Cutter; Nanchang Hangkong University: Nanchang, China, 2011. [Google Scholar]

- Liu, T.; Veidt, M. Single mode Lamb waves in composite laminated plates generated by piezoelectric transducers. Compos. Struct. 2002, 58, 381. [Google Scholar] [CrossRef]

- Chen, X.; Li, B. Acoustic emission method for tool condition monitoring based on wavelet analysis. Int. J. Adv. Manuf. Technol. 2007, 33, 968–976. [Google Scholar] [CrossRef]

- Tansel, I.; Trujillo, M.; Nedbouyan, A.; Velez, C.; Bao, W.Y.; Arkan, T.T.; Tansel, B. Micro-end-milling—III. Wear estimation and tool breakage detection using acoustic emission signals. Int. J. Mach. Tools Manuf. 1998, 38, 1449–1466. [Google Scholar]

- Xie, J.F.; Wang, H.L. Tool Breakage Feature Extraction and Optimization in Milling Using Acoustic Emission. Modul. Mach. Tool Autom. Manuf. Tech. 2011, 10, 14–17. [Google Scholar]

- Gómez, M.P.; Hey, A.M.; Ruzzante, J.E. Tool wear evaluation in drilling by acoustic emission. Phys. Procedia 2010, 3, 819–825. [Google Scholar] [CrossRef]

- Jemielniak, K.; Kossakowska, J.; Urbański, T. Application of wavelet transform of acoustic emission and cutting force signals for tool condition monitoring in rough turning of Inconel 625. Proceedings of the Institution of Mechanical Engineers. part B. J. Eng. Manuf. 2011, 225, 123–129. [Google Scholar] [CrossRef]

- Zhang, D.L.; Mo, F.; Sun, H.B. Tool wear state recognition based on chaotic time series analysis and support vector machine. Comput. Integr. Manuf. Syst. 2015, 21, 2138–2146. [Google Scholar]

- Hu, J.L.; Zhang, S.W.; Li, L. Research on Tool Wear Monitoring by Acoustic Emission Technology. Tool Eng. 2012, 03, 67–69. [Google Scholar]

- Neslušan, M.; Mičieta, B.; Mičietová, A.; Čilliková, M.; Mrkvica, I. Detection of tool breakage during hard turning through acoustic emission at low removal rates. Measurement 2015, 70, 1–13. [Google Scholar] [CrossRef]

- Nie, P.; Xu, T. State recognition of tool wear based on wavelet neural network. J. Beijing Univ. Aeronaut. Astronaut. 2011, 37, 106–109. [Google Scholar]

- Zhou, Y.M. Tool Wear Monitoring Based on Acoustic Emission Technology; Henan University of Science and Technology: Luoyang, China, 2014. [Google Scholar]

- Maia, L.H.; Abrao, A.M.; Vasconcelos, W.L. A new approach for detection of wear mechanisms and determination of tool life in turning using acoustic emission. Tribol. Int. 2015, 92, 519–532. [Google Scholar] [CrossRef]

- Salgado, D.R.; Alonso, F.J. An approach based on current and sound signals for in-process tool wear monitoring. Int. J. Mach. Tools Manuf. 2007, 47, 2140–2152. [Google Scholar] [CrossRef]

- Li, X.; Djordjevich, A.; Venuvinod, P.K. Current-Sensor-Based Feed Cutting Force Intelligent Estimation and Tool Wear Condition Monitoring. Ind. Electron. IEEE Trans. 2000, 47, 697–702. [Google Scholar] [CrossRef]

- Shao, H.; Wang, H.L.; Zhao, X.M. A cutting power model for tool wear monitoring in milling. Int. J. Mach. Tools Manuf. 2004, 44, 1503–1509. [Google Scholar] [CrossRef]

- Low, K.S.; Win, W.N.N.; Er, M.J. Wireless Sensor Networks for Industrial Environments. In Proceedings of the International Conference on International Conference on Computational Intelligence for Modelling, Monterrey, Mexico, 14–18 November 2005. [Google Scholar]

- Prasan, K.S. Efficient security mechanisms for mHealth applications using wireless body sensor networks. Sensors 2012, 12, 12606–12633. [Google Scholar]

- Mecocci, A.; Abrardo, A. Monitoring architectural heritage by wireless sensors networks: San Gimignano—A case study. Sensors 2014, 14, 770–778. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Yao, X.; Zhang, J. Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors 2016, 16, 795. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.Y.; Hecker, R.L.; Landers, R.G. Machining Process Monitoring and Control: The State–of–the–Art. In Proceedings of the ASME 2002 International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; pp. 599–610. [Google Scholar]

- Pham, D.; Oztemel, E. Control chart pattern recognition using learning vector quantization networks. Int. J. Prod. Res. 1994, 32, 721–729. [Google Scholar] [CrossRef]

- Gauri, S.K.; Chakraborty, S. Feature-based recognition of control chart patterns. Comput. Ind. Eng. 2006, 51, 726–742. [Google Scholar] [CrossRef]

- Hassan, A.; Baksh, M.S.N.; Shaharoun, A. Improved SPC chart pattern recognition using statistical features. Int. J. Prod. Res. 2003, 41, 1587–1603. [Google Scholar] [CrossRef]

- Wang, C.-H.; Kuo, W. Identification of control chart patterns using wavelet filtering and robust fuzzy clustering. J. Intell. Manuf. 2007, 18, 343–350. [Google Scholar] [CrossRef]

- Jiang, P.; Liu, D.; Zeng, Z. Recognizing control chart patterns with neural network and numerical fitting. J. Intell. Manuf. 2009, 20, 625. [Google Scholar] [CrossRef]

- Ebrahimzadeh, A.; Addeh, J.; Rahmani, Z. Control chart pattern recognition using K-MICA clustering and neural networks. ISA Trans. 2012, 51, 111–119. [Google Scholar] [CrossRef]

- Zhou, X.; Jiang, P.; Wang, X. Recognition of control chart patterns using fuzzy SVM with a hybrid kernel function. J. Intell. Manuf. 2015, 29, 51–67. [Google Scholar] [CrossRef]

- Nowicki, B.; Jarkiewicz, A. The in-process surface roughness measurement using fringe field capacitive (FFC) method. Int. J. Mach. Tools Manuf. 1998, 38, 725–732. [Google Scholar] [CrossRef]

- Ertekin, Y.M.; Kwon, Y.; Tseng, T.-L.B. Identification of common sensory features for the control of CNC milling operations under varying cutting conditions. Int. J. Mach. Tools Manuf. 2003, 43, 897–904. [Google Scholar] [CrossRef]

- Lee, K.-C.; Ho, S.-J.; Ho, S.-Y. Accurate estimation of surface roughness from texture features of the surface image using an adaptive neuro-fuzzy inference system. Precis. Eng. 2005, 29, 95–100. [Google Scholar] [CrossRef]

- Tsai, Y.-H.; Chen, J.C.; Lou, S.-J. An in-process surface recognition system based on neural networks in end milling cutting operations. Int. J. Mach. Tools Manuf. 1999, 39, 583–605. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Chen, J.C.; Kirby, E.D. The development of an in-process surface roughness adaptive control system in turning operations. J. Intell. Manuf. 2007, 18, 301–311. [Google Scholar] [CrossRef]

- Chang, H.-K.; Kim, J.-H.; Kim, I.H.; Jang, D.Y.; Han, D.C. In-process surface roughness prediction using displacement signals from spindle motion. Int. J. Mach. Tools Manuf. 2007, 47, 1021–1026. [Google Scholar] [CrossRef]

- Samanta, B.; Erevelles, W.; Omurtag, Y. Prediction of workpiece surface roughness using soft computing. Intell. Prod. Mach. Syst. 2006, 222, 344–349. [Google Scholar]

- Correa, M.; Bielza, C.; Teixeira, J.P. Comparison of Bayesian networks and artificial neural networks for quality detection in a machining process. Expert Syst. Appl. 2009, 36, 7270–7279. [Google Scholar] [CrossRef]

- Benardos, P.; Vosniakos, G.-C.; Benardos, P. Predicting surface roughness in machining: A review. Int. J. Mach. Tools Manuf. 2003, 43, 833–844. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Wiackiewicz, M.; Krolczyk, G. Study on metrological relations between instant tool displacements and surface roughness during precise ball end milling. Measurement 2018, 129, 686–694. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Maruda, R.; Barrans, S.; Nieslony, P.; Krolczyk, G.; Krolczyk, G. Optimisation of machining parameters during ball end milling of hardened steel with various surface inclinations. Measurement 2017, 111, 18–28. [Google Scholar] [CrossRef]

- Yang, P. Research on Online Condition Monitoring Based Prognostics of Key Parts and Components of Mechnicanic Equipment; University of Electronic Science and Technology of China: Chengdu, China, 2016. [Google Scholar]

- Gu, T.R.; Xiao, F.Z.; Guo, W. Cutting flutter mechanism and control. Metal. Work. 2010, 26, 36–38. [Google Scholar]

- Tangjitcharoen, S. Development of Chatter Detection in Milling Process. Int. J. Adv. Manuf. Technol. 2013, 65, 919–927. [Google Scholar] [CrossRef]

- Altintas, Y.; Chan, P.K. In-process Detection and Suppression of Chatter in Milling. Int. J. Mach. Tool Manuf. 1992, 32, 329–347. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Senguptaa, D.; Mukhopadhyay, S. Cutting force-based real-time estimation of tool wear in face milling using a combination of signal processing techniques. Mech. Syst. Signal Process. 2007, 21, 2665–2683. [Google Scholar] [CrossRef]

- Li, X.L.; Ouyang, G.X.; Liang, Z.H.X.L. Complexity measure of motor current signals for tool flute breakage detection in end milling. Int. J. Mach. Tools Manuf. 2008, 48, 371–379. [Google Scholar] [CrossRef]

- Prickett, P.; Johns, C. An overview of approaches to end milling tool monitoring. Int. J. Mach. Tools Manuf. 1999, 39, 105–122. [Google Scholar] [CrossRef]

- Marinescu, I.; Axinte, D. A time–frequency acoustic emission-based monitoring technique to identify workpiece surface malfunctions in milling with multiple teeth cutting simultaneously. Int. J. Mach. Tools Manuf. 2009, 49, 53–65. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A. Coatings tribology-properties, techniques and applications insSurface engineering. In Coatings Tribology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 1994; pp. 354–358. [Google Scholar]

- Chen, H.T. Study on Tool Wear Monitoring and Prediction Technology Based on Multi-Parameter Information Fusion; Southwest Jiaotong University: Chengdu, China, 2013. [Google Scholar]

- Niu, Z.Y. Research on Multi-sensor Information Fusion Technology in Modern Warfare. Computer and Information Technology, China, 2006; 71–73. [Google Scholar]

- Yang, Z.Y.; Han, Q.S.; Sun, Z.Y. A review about multi-sensor information fusion and its application in machining process. Mod. Manuf. Eng. 2007, 10, 55–62. [Google Scholar]

- Bertok, P.; Takata, S.; Matsushima, K.; Ootsuka, J.; Sata, T. A System for Monitoring the Machining Operation by Referring to a Predicted Cutting Torque Pattern. CIRP Ann. 1983, 32, 439–444. [Google Scholar] [CrossRef]

- Liang, J.C.; Li, S.Y.; Wen, X.S. Research on Quantitative Monitoring of Tool Wear Based on Neural Network and Multi-sensor Fusion. Mech. Sci. Technol. Aerosp. Eng. 1995, 6, 125–130. [Google Scholar]

- Lu, Z.-J.; Xiang, Q.; Xu, L. An Application Case Study on Multi-sensor Data fusion System for Intelligent Process Monitoring. Procedia CIRP 2014, 17, 721–725. [Google Scholar] [CrossRef]

- Yan, C. Degradation Assessment and Residual Life Prediction of Rolling Bearings Based on Multiple Features; School of Mechatronics Engineering: Chengdu, China, 2016. [Google Scholar]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Anderson, P.M.; Mann, D.S. Application of the weibull proportional hazards model to aircraft and marine engine failure data. Qual. Reliab. Eng. Int. 1987, 3, 77–82. [Google Scholar] [CrossRef]

- Liao, H.; Zhao, W.; Guo, H. Predicting remaining useful life of an individual unit using proportional hazards model and logistic regression model. In Proceedings of the 2006 Annual Reliability and Maintainability Symposium—Product Quality & Integrity (RAMS), Newport Beach, CA, USA, 23–26 January 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 127–132. [Google Scholar]

- Caesarendar, W.; Widodo, A.; Yang, B.S. Application of relevance vector machine and logistic regression for machine degradation assessment. Mech. Syst. Signal Process. 2010, 24, 1161–1171. [Google Scholar] [CrossRef]

- Chen, B.J.; Chen, X.F.; Li, B. Reliability Estimation for Cutting Tool Based on Logistic Regression Model. J. Mech. Eng. 2011, 47, 158–164. [Google Scholar] [CrossRef]

- Yu, J.B. Bearing performance degradation assessment using locality preserving projections and Gaussian mixture models. Mech. Syst. Signal. Process. 2011, 25, 2573–2588. [Google Scholar] [CrossRef]

- Zhang, Q.; Hua, C.; Xu, G. A mixture Weibull proportional hazard model for mechanical system failure prediction utilising lifetime and monitoring data. Mech. Syst. Signal Process. 2014, 43, 103–112. [Google Scholar] [CrossRef]

- Bi, X.M.; Bi, R.H. Summary of KNN Algorithm. Sci. Technol. Innov. Her. 2009, 14, 31. [Google Scholar]

- Li, Y.C. Research on Remote Intelligent Fault-Diagnosis of CNC Machine Tools Based on BN.; Zhejiang University: Hangzhou, China, 2010. [Google Scholar]

- Liu, J.; Lv, Y. Fault Diagnosis for Rolling Bearing Based on the Variational Mode Decomposition De-Noising. Mech. Des. Manuf. 2015, 10, 21–25. [Google Scholar]

- Song, G.; Hu, D.J. The Fault Diagnostic Method of Numerical Controlled Machine Based on Sugeno Fuzzy Model. J. Shanghai Jiaotong Univ. 2005, 39, 91–94. [Google Scholar]

- Jia, G.F. Rolling Bearing Faults Diagnosis Based on Hilbert-Huang Transform and Decision Tree; Huazhong Agricultural University: Wuhan, China, 2011. [Google Scholar]

- Guifeng, J.; Shengfa, Y.; Chengwen, T.; Jie, X. Fault diagnosis of roller bearing using feedback EMD and decision tree. In Proceedings of the International Conference on Electric Information & Control Engineering, Wuhan, China, 15–17 April 2011. [Google Scholar]

- Wang, J.S.; Yu, J.X.; Huang, W.G. Application of Wavelet Package Analysis and Support Vector Machine to Fault Diagnosis of Cutting Too. J. Vib. Meas. Diagn. 2008, 28, 273–276. [Google Scholar]

- Hu, L. Research on Novelty Detection Methods Oriented to Flight Vehicle Health Management; National University of Defense Technology: Changsha, China, 2010. [Google Scholar]

- Chang, Q. Research on the Key Technologies of Knowledge Based Structural Health Management; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2011. [Google Scholar]

- Long, X.Y. System Design of Intelligent NC Machine Tool Fault Diagnosis Syetem; Southwest Jiaotong University: Chengdu, China, 2014. [Google Scholar]

- Li, S.M.; Gou, H.D.; Li, D.R. Review of vibration signal processing methods. Chin. J. Sci. Instrum. 2013, 34, 1907–1915. [Google Scholar]

- Mei, Z.J.; Shi, H.M.; Chang, S. Time domain rapid diagnosis of signal power spectrum characteristics. J. Huazhong Univ. Sci. Technol. 1988, 16, 55–90. [Google Scholar]

- Ding, Y.M.; Kuo, Y.H.; Gao, X.B. Digital Signal Processing-Time Domain Discrete Random Signal Processing; Xi’an University of Electronic Science and Technology Press: Xi’an, China, 2002. [Google Scholar]

- Chen, H.F.; Feng, H.H.; Xu, H.D. Performance of STFT in speech processing used for cochlear implant. Tech. Acoust. 2007, 26, 442–446. [Google Scholar]

- Hu, C.H.; Li, H.H.; Liu, T. System Analysis and Design Based on Matlab6.x—Wavelet Analysis; Xi’an University of Electronic Science and Technology Press: Xi’an, China, 2004. [Google Scholar]

- Li, X.; Dong, S.; Yuan, Z. Discrete wavelet transform for tool breakage monitoring. Int. J. Mach. Tools Manuf. 1999, 39, 1935–1944. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.C.; Tung, C.C.; Liu, H.H. The Empirical Mode Decomposition and the Hilbert Spectrum for Nonlinear and Non-Stationary Time Series Analysis. Proc. R. Soc. Lond. Ser. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Toliyat, H.; Abbaszadeh, K.; Rahimian, M.; Olson, L. Rail defect diagnosis using wavelet packet decomposition. IEEE Trans. Ind. Appl. 2003, 39, 1454–1461. [Google Scholar] [CrossRef]

- Rzeszucinski, P.; Juraszek, M.; Ottewill, J.R. Ensemble Empirical Mode Decomposition and Sparsity Measurement as Tools Enhancing the Gear Diagnostic Capabilities of Time Synchronous Averaging. Adv. Data Sci. Adapt. Anal. 2017, 9, 1750004. [Google Scholar] [CrossRef]

- Dong, S.; Wang, J.; Tang, B.; Xu, X.; Liu, J. Bearing faults recognition based on the local mode decomposition morphological spectrum and optimized support vector machine. In Proceedings of the 2016 13th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Xian, China, 19–22 August 2016; pp. 1012–1016. [Google Scholar]

- Gritli, Y.; Rossi, C.; Zarri, L.; Filippetti, F.; Chatti, A.; Casadei, D.; Stefani, A. Advanced diagnosis of broken bar fault in induction machines by using discrete wavelet transform under time-varying condition. In Proceedings of the 2011 IEEE International Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011. [Google Scholar]

- Zhao, Z.H. Research on Mechanical Fault Feature Extraction and Diagnosis Based on Vibration Signal; Beijing Jiaotong University: Beijing, China, 2012. [Google Scholar]

- Ren, S. Research on Fault Diagnosis Technology of Rolling Bearing Based on Vibration Signal; Nanchang Aeronautical University: Nanchang, China, 2014. [Google Scholar]

- Qiao, H. Fault Diagnosis of Key Parts of CNC Machine Tools Based on Wavelet Neural Network; Southwest Jiaotong University: Chengdu, China, 2011. [Google Scholar]

- Xu, D.; Liu, Q. High-performance XY table fault diagnosis based on wavelet multi-resolution analysis. China Mech. Eng. 2007, 18, 573–577. [Google Scholar]

- Yu, J.X.; Wang, J.S.; Liu, Z.H. Fault Diagnosis of CNC Machine Tool Based on Acoustic Emission and Neural Network. Mach. Tool Hydraul. 2012, 40, 165–168. [Google Scholar]

- Zhang, P. Research on Aeroengine Fault Diagnosis Technology Based on Kalman Filter; Nanjing Aerospace University: Nanjing, China, 2009. [Google Scholar]

- Younus, A.M.; Yang, B.-S. Wavelet co-efficient of thermal image analysis for machine fault diagnosis. In Proceedings of the Prognosties & System Health Management Conference, Macao, China, 12–14 January 2010. [Google Scholar]

- Atoui, I.; Meradi, H.; Boulkroune, R.; Saidi, R.; Grid, A. Fault detection and diagnosis in rotating machinery by vibration monitoring using FFT and Wavelet techniques. In Proceedings of the 8th International Workshop on Systems, Signal Processing and their Applications (WoSSPA), Algiers, Algeria, 12–15 May 2013. [Google Scholar]

- Cheng, Z. Research on Damage Modeling and Fault Prediction Theory and Method of Planetary Gear Train in Helicopter Transmission System; National University of Defense Technology: Changsha, China, 2011. [Google Scholar]

- Kira, K.; Rendell, L.A. The feature selection problem: Traditional methods and a new algorithm. In Proceedings of the 9th National Conference on Artificial Intelligence, Anaheim, CA, USA, 14–19 July 1991; pp. 129–134. [Google Scholar]

- John, G.H.; Kohavi, R.; Pfleger, K. Irrelevant Features and the Subset Selection Problem. In Machine Learning Proceedings 1994; Elsevier: Amsterdam, The Netherlands, 1994; pp. 121–129. [Google Scholar]

- Koller, D.; Sahami, M. Toward Optimal Feature Selection; Stanford InfoLab.: Stanford, CA, USA, 1996; pp. 284–292. [Google Scholar]

- Dash, M.; Liu, H. Feature selection for classification. Intell. Data Anal. 1997, 1, 131–156. [Google Scholar] [CrossRef]

- Chinnam, R.B. On-line reliability estimation of individual components, using degradation signals. Reliab. IEEE Trans. 1999, 48, 403–412. [Google Scholar] [CrossRef]

- Lu, H.; Kolarik, W.J.; Lu, S.S. Real-time performance reliability prediction. IEEE Trans. Reliab. 2001, 50, 353–357. [Google Scholar]

- Gebraeel, N.Z.; Lawley, M.A. A Neural Network Degradation Model for Computing and Updating Residual Life Distributions. IEEE Trans. Autom. Sci. Eng. 2008, 5, 154–163. [Google Scholar] [CrossRef]

- Gašperin, M.; Juričić, Đ.; Boškoski, P.; Vižintin, J. Model-based prognostics of gear health using stochastic dynamical models. Mech. Syst. Signal Process. 2011, 25, 537–548. [Google Scholar] [CrossRef]

- Fong, B.; Li, C. Methods for Assessing Product Reliability: Looking for enhancements by adopting condition-based monitoring. IEEE Consum. Electron. Mag. 2012, 1, 43–48. [Google Scholar] [CrossRef]

- Fang, M.J.; Zhou, G.H.; Cheng, Y.S. Reliability prediction for hydraulic system of CNC honing machine based on the operational status information. Appl. Sci. Technol. 2013, 39, 30–33. [Google Scholar]

- He, Z.J.; Cai, G.G.; Shen, Z.J. Study of operation reliability based on diagnosis information for mechanical equipment. Eng. Sci. 2013, 15, 9–14. [Google Scholar]

- Hua, C.; Zhang, Q.; Xu, G.; Zhang, Y.; Xu, T. Performance reliability estimation method based on adaptive failure threshold. Mech. Syst. Signal Process. 2013, 36, 505–519. [Google Scholar] [CrossRef]

- Wu, J.; Shou, X.Y.; Deng, C. A HMC-based Equipment Operation Reliability Prediction with Multiple Observation Sequences. China Mech. Eng. 2010, 21, 2345–2349. [Google Scholar]

- Dong, M. A Tutorial on Nonlinear Time-Series Data Mining in Engineering Asset Health and Reliability Prediction: Concepts, Models, and Algorithms. Math. Probl. Eng. 2010, 2010, 175936. [Google Scholar] [CrossRef]

- Miriyala, K.; Viswanadham, N. Reliability analysis of flexible manufacturing systems. Int. J. Flex. Manuf. Syst. 1989, 2, 145–162. [Google Scholar] [CrossRef]

- Bao, W.W. Research on Reliability Analysis Framework and Evaluation Model of Manufacturing System; Jilin University: Changchun, China, 2018. [Google Scholar]

- Chi, Y.J. Research on Equipment Condition Recognition and Prediction Method Based on Process Information Fusion; Beihang University: Beijing, China, 2018. [Google Scholar]

| Key Words | 2014 | 2015 | 2016 | 2017 | 2018 |

|---|---|---|---|---|---|

| Machining Equipment and Reliability and Quality | 10 | 15 | 15 | 16 | 16 |

| Multi-Source Data Fusion | 17 | 14 | 18 | 41 | 49 |

| Cutting process and Failure mechanism | 22 | 32 | 47 | 49 | 55 |

| Equipment and Reliability Assessment | 65 | 65 | 70 | 58 | 89 |

| Condition Monitoring Technology | 531 | 587 | 678 | 748 | 887 |

| Cutting Process and Quality Control | 116 | 149 | 150 | 172 | 180 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, W.; Sun, J.; Chi, Y.; Lu, Z.; Xu, D.; Jiang, N. Review of Machining Equipment Reliability Analysis Methods based on Condition Monitoring Technology. Appl. Sci. 2019, 9, 2786. https://doi.org/10.3390/app9142786

Dai W, Sun J, Chi Y, Lu Z, Xu D, Jiang N. Review of Machining Equipment Reliability Analysis Methods based on Condition Monitoring Technology. Applied Sciences. 2019; 9(14):2786. https://doi.org/10.3390/app9142786

Chicago/Turabian StyleDai, Wei, Jiahuan Sun, Yongjiao Chi, Zhiyuan Lu, Dong Xu, and Nan Jiang. 2019. "Review of Machining Equipment Reliability Analysis Methods based on Condition Monitoring Technology" Applied Sciences 9, no. 14: 2786. https://doi.org/10.3390/app9142786

APA StyleDai, W., Sun, J., Chi, Y., Lu, Z., Xu, D., & Jiang, N. (2019). Review of Machining Equipment Reliability Analysis Methods based on Condition Monitoring Technology. Applied Sciences, 9(14), 2786. https://doi.org/10.3390/app9142786