Evaluation of the Rheological Property of Binder-Filler Systems after Oxidation Based on a Simple Film Oven Aging Method

Abstract

:1. Introduction

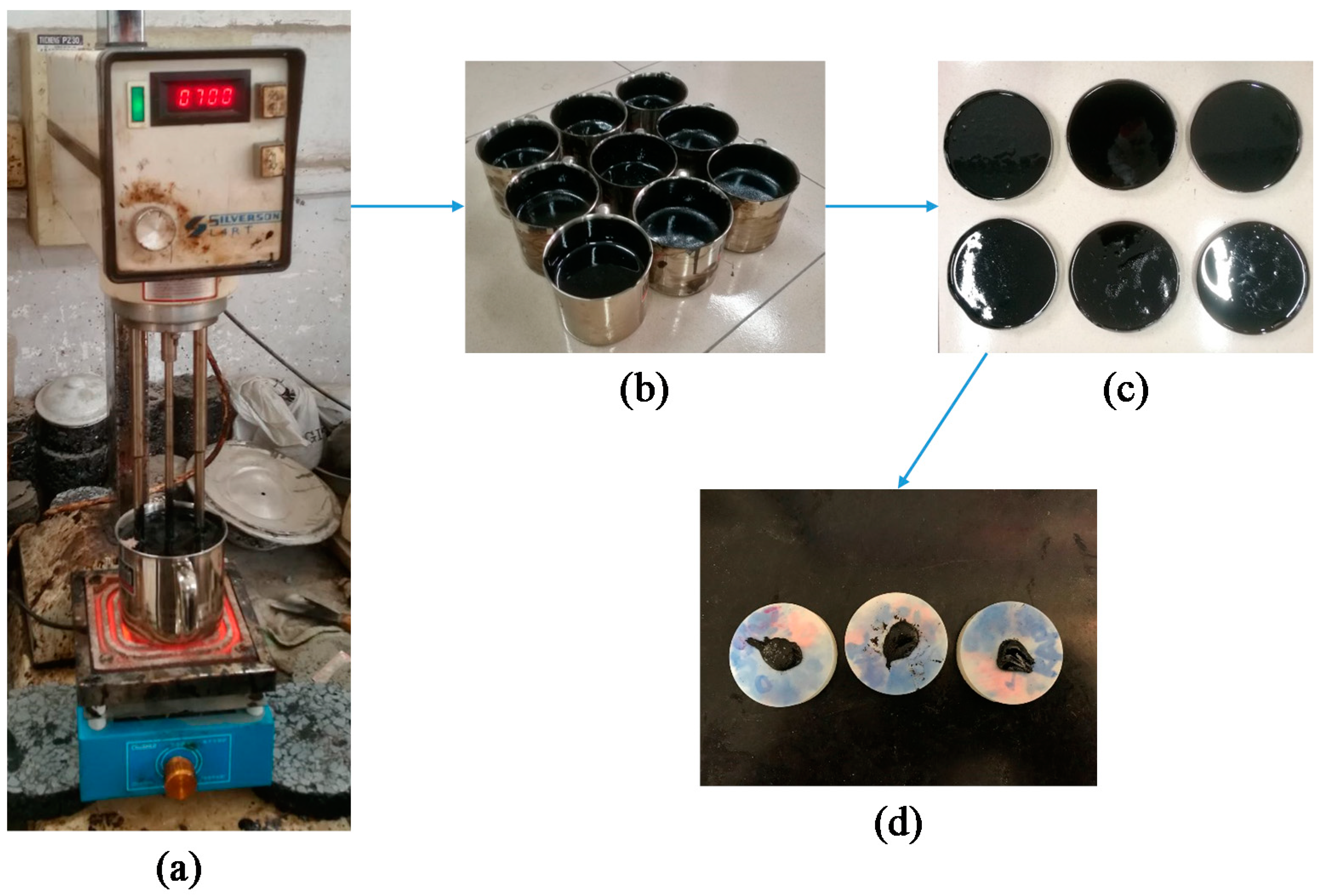

2. Materials and Design

3. Test Setup

4. Discussion of Results

4.1. Film Oven Aging Method

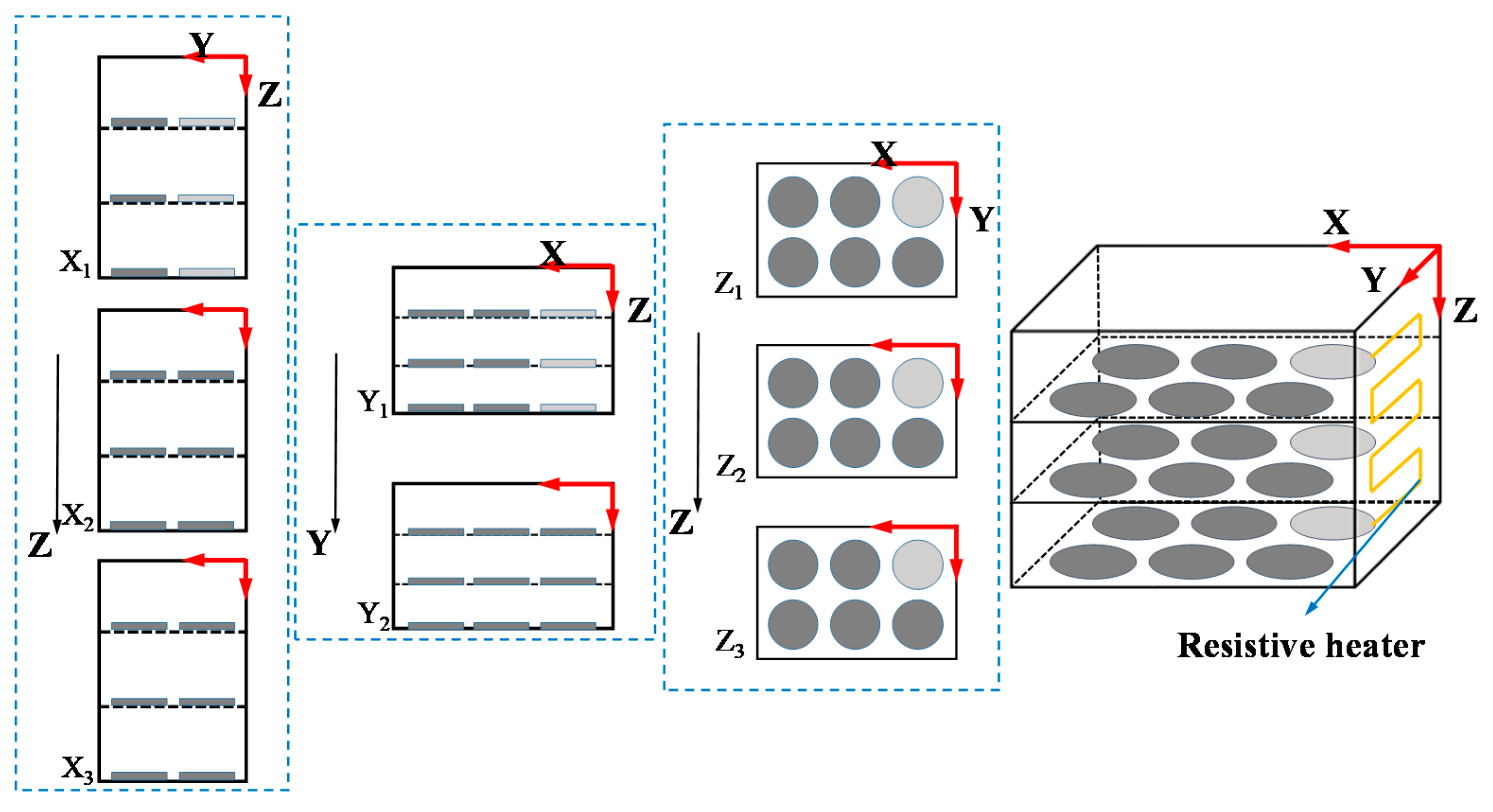

4.1.1. Effects of Position

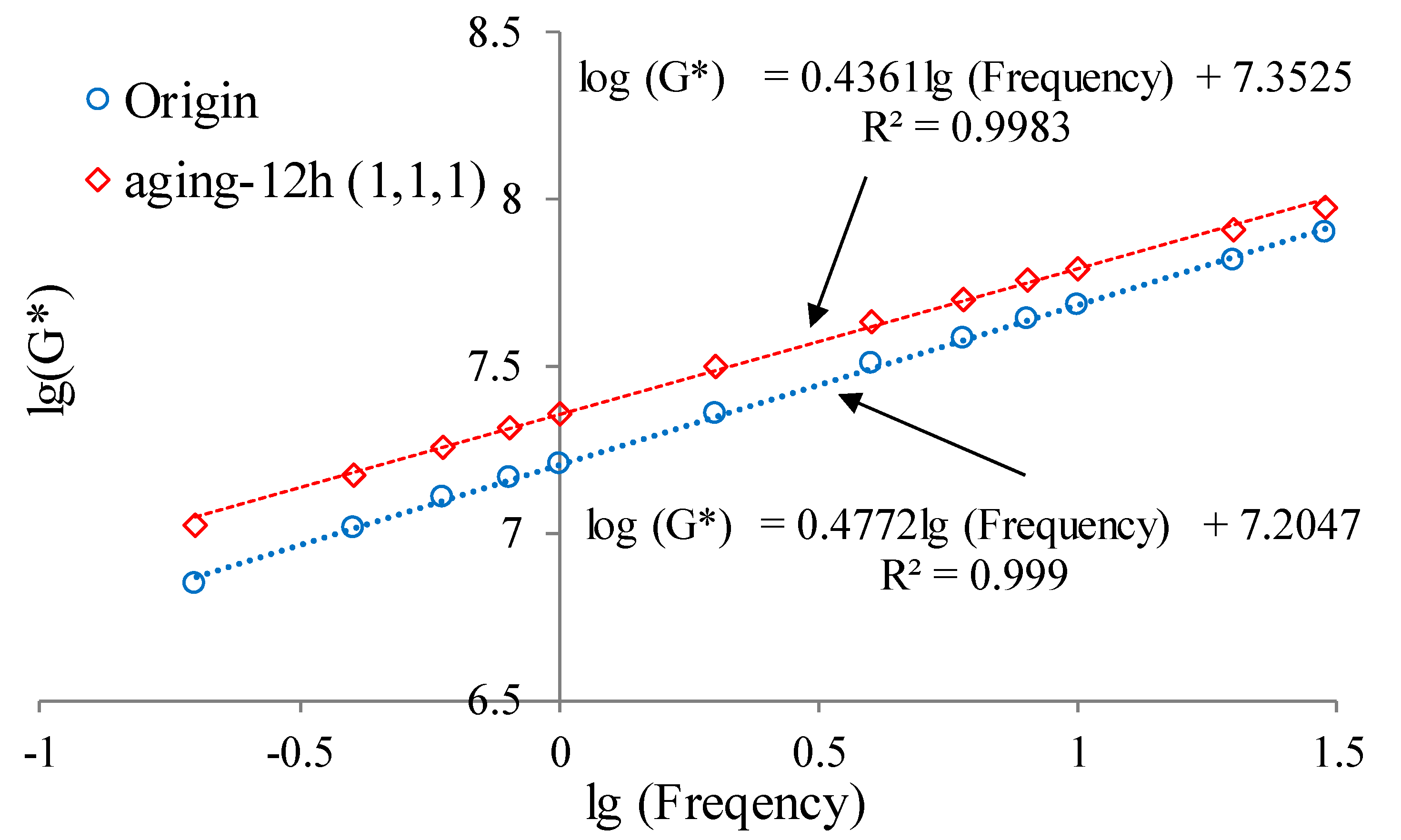

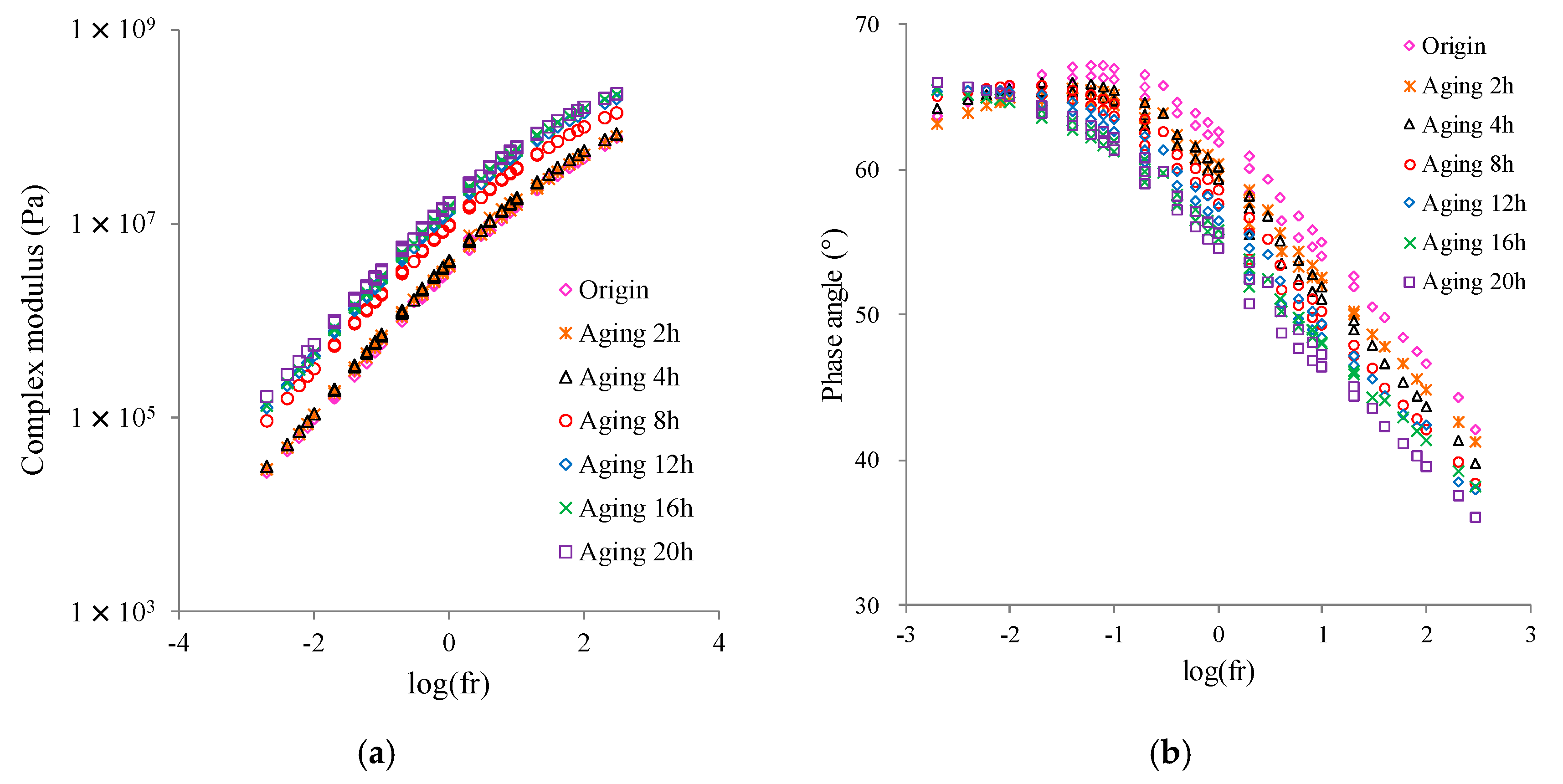

4.1.2. Effects of Time

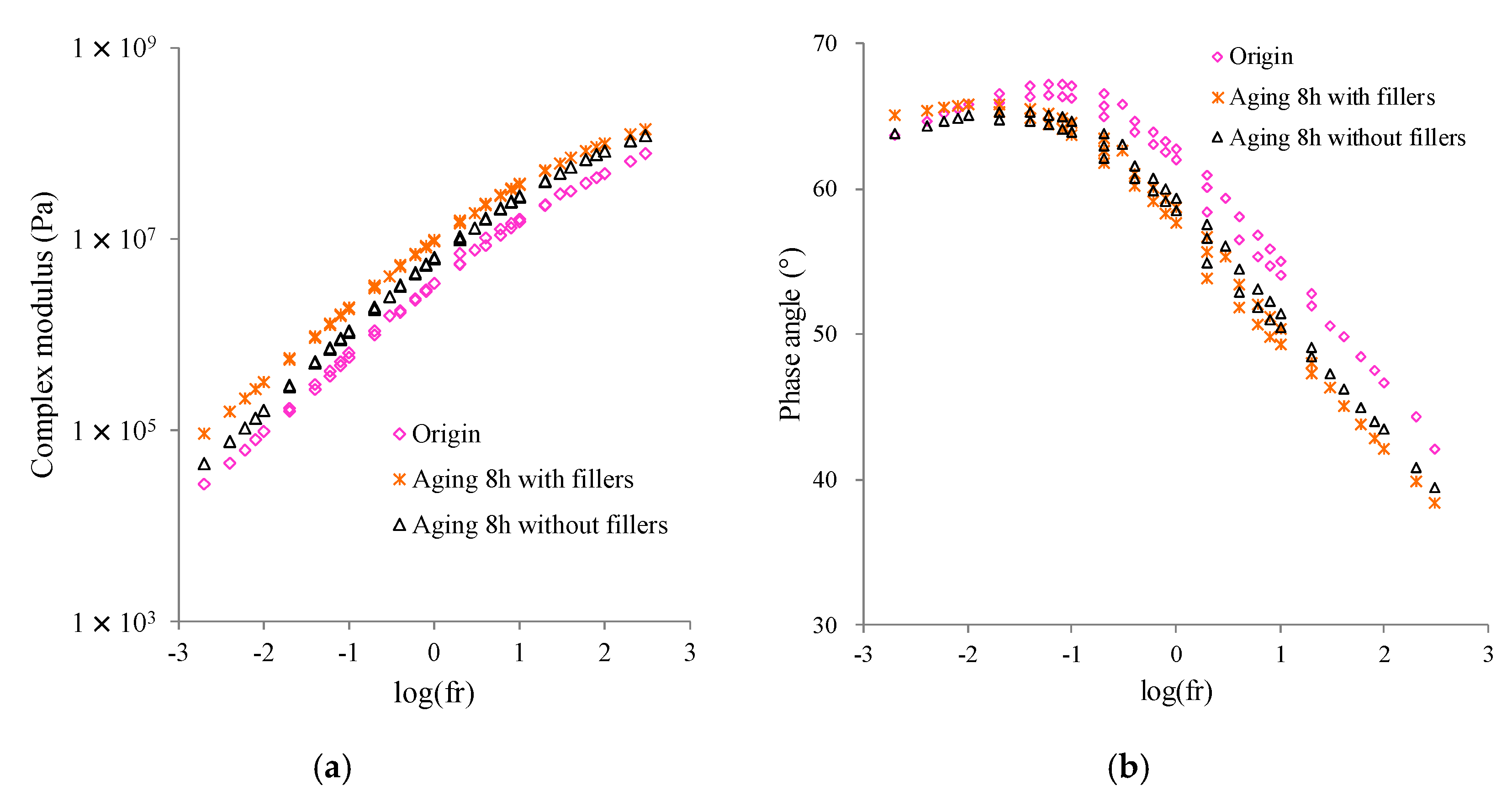

4.1.3. Effects of the Aging Process With or Without Fillers

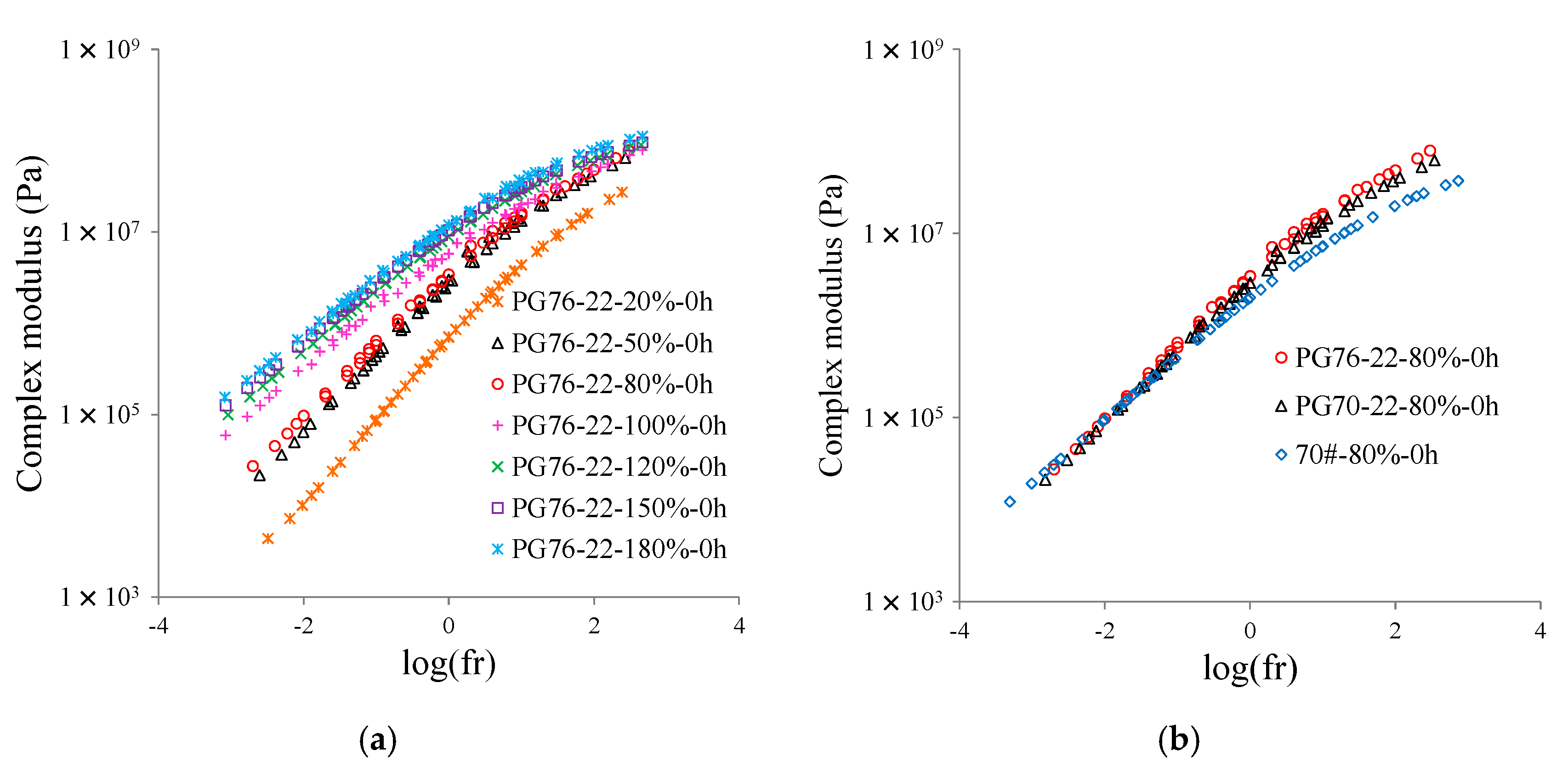

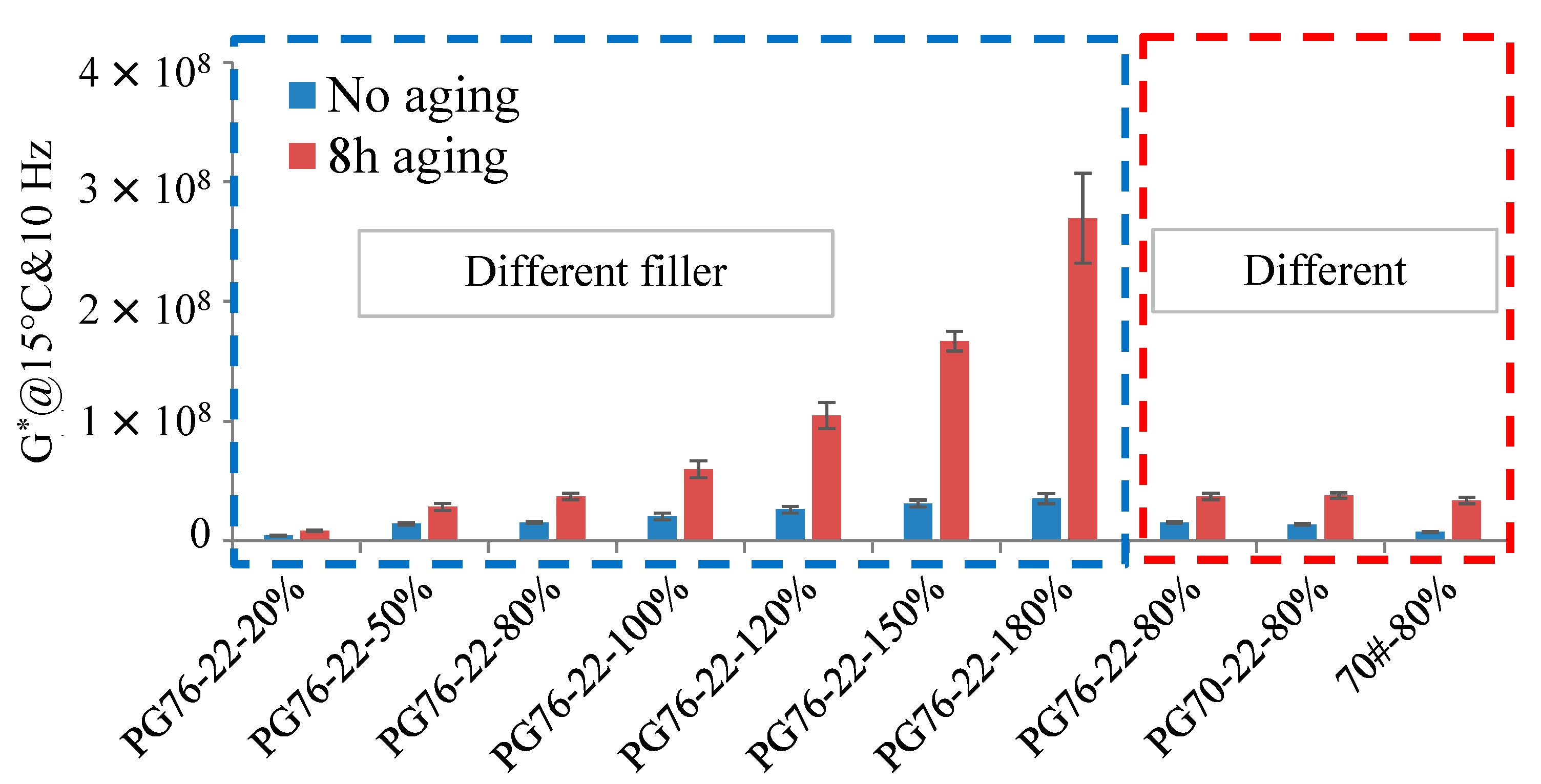

4.2. Influence of Filler Contents and Binder Types

4.2.1. TTS Test Results

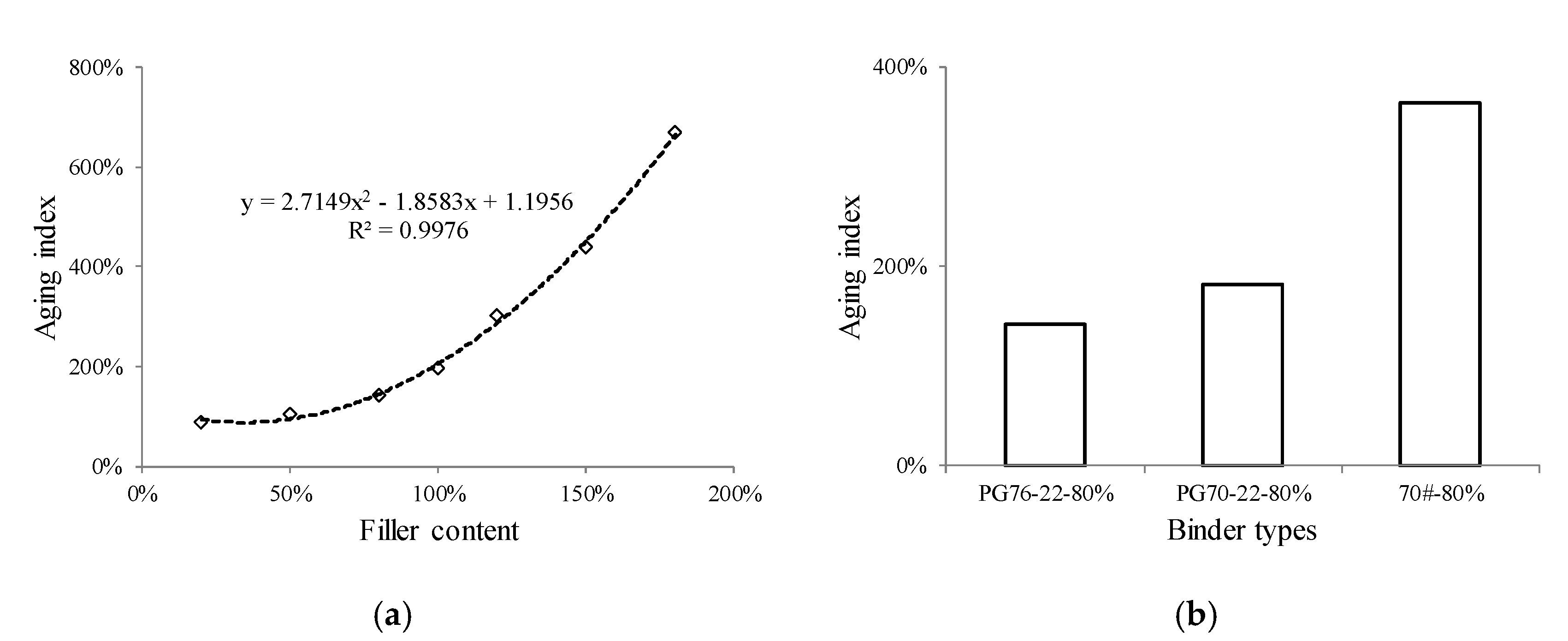

4.2.2. Analysis of Aging Index

5. Conclusions

- Based on the statistical analysis, the oven study shows that the oxidation level of the asphalt mastics in the oven is influenced significantly by the distance from the plate to the resistive heater in X-axis since the limitation of the circulation.

- The mastics could become stiffer, the phase angle and relaxation spectrum decreases with the increasing aging times, and it was observed that 8 h of aging could change the rheological properties of the mastics significantly by visualization.

- When compared to the aging process of mastics with and without fillers, it was found that the addition of fillers could accelerate the aging of mastics dramatically. The hypothesis is the addition of filler would shorter the binder film thickness and therefore speed up the aging process.

- From the analysis of aging index, it could be found that both the modification of binder and filler contents inside the mastics could influence the aging of mastics. The mastic produced by SBS modified asphalt present a lower aging rate when compared to the mastic from the neat binder. The aging index of the mastics increases with the filler content in a quadratic function, which may be attributed to the changing binder distribution within the mastics with a different volume of fillers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Elwardany, M.D.; Rad, F.Y.; Castorena, C.; Kim, Y.R. Evaluation of asphalt mixture laboratory long-term ageing methods for performance testing and prediction. Road Mater. Pavement Des. 2017, 18, 28–61. [Google Scholar] [CrossRef]

- Safaei, F.; Lee, J.; Nascimento, L.A.H.; Hintz, C.; Kim, Y.R. Implications of warm-mix asphalt on long-term oxidative ageing and fatigue performance of asphalt binders and mixtures. Road Mater. Pavement Des. 2014, 15, 45–61. [Google Scholar] [CrossRef]

- Alavi, M.Z.; Morian, N.E. Influence of asphalt binder oxidative aging on critical thermal cracking characteristics of asphalt mixtures. In Proceedings of the 90th Association of Asphalt Paving Technologists’ Annual Meeting, Portland, OR, USA, 8–13 March 2015. [Google Scholar]

- Xiao, F.; Amirkhanian, A.N.; Amirkhanian, S.N. Influence of carbon nanoparticles on the rheological characteristics of short-term aged asphalt binders. Mater. Civ. Eng. 2010, 23, 423–431. [Google Scholar] [CrossRef]

- Banerjee, A.; de Fortier Smit, A.; Prozzi, A. The effect of long-term aging on the rheology of warm mix asphalt binders. Fuel 2012, 97, 603–611. [Google Scholar] [CrossRef]

- Li, Q.; Chen, X.; Li, G.; Zhang, S. Fatigue resistance investigation of warm-mix recycled asphalt binder, mastic, and fine aggregate matrix. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 400–411. [Google Scholar] [CrossRef]

- Kandhal, P.; Chakraborty, S. Effect of asphalt film thickness on short-and long-term aging of asphalt paving mixtures. Trans. Res. Rec. J. Trans. Res. Board 1996, 1535, 83–90. [Google Scholar] [CrossRef]

- Das, P.; Balieu, R.; Kringos, N.; Birgisson, B. On the oxidative ageing mechanism and its effect on asphalt mixtures morphology. Mater. Struct. 2015, 48, 3113–3127. [Google Scholar] [CrossRef]

- Luo, X.; Gu, F.; Lytton, R.L. Prediction of field aging gradient in asphalt pavements. Trans. Res. Rec. 2015, 2507, 19–28. [Google Scholar] [CrossRef]

- Airey, G.D. State of the art report on ageing test methods for bituminous pavement materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Dondi, G.; Mazzotta, F.; Simone, A.; Vignali, V.; Sangiorgi, C.; Lantieri, C. Evaluation of different short term aging procedures with neat, warm and modified binders. Construc. Build. Mater. 2016, 106, 282–289. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, C.; Wan, M.; Zhou, X.; Wang, Y.; Wu, S. Study of the diffusion of rejuvenators and its effect on aged bitumen binder. Appl. Sci. 2017, 7, 397. [Google Scholar] [CrossRef]

- Glover, C.; Davison, R.R.; Domke, C.H. Development of a new method for assessing asphalt binder durability with field validation. Texas Dept. Trans. 2005, 1872, 1–334. [Google Scholar]

- Qin, Q.; Schabron, J.F.; Boysen, R.B.; Farrar, M.J. Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 2014, 121, 86–94. [Google Scholar] [CrossRef]

- Lesueur, D.; Teixeira, A.; Lázaro, M.M.; Andaluz, D.; Ruiz, A. A simple test method in order to assess the effect of mineral fillers on bitumen ageing. Constr. Build. Mater. 2016, 117, 182–189. [Google Scholar] [CrossRef]

- Jiang, J.; Ni, F.; Dong, Q.; Yao, L.; Ma, X. Investigation of the internal structure change of two-layer asphalt mixtures during the wheel tracking test based on 2D image analysis. Constr. Build. Mater. 2019, 209, 66–76. [Google Scholar] [CrossRef]

- Guo, M.; Bhasin, A.; Tan, Y. Effect of mineral fillers adsorption on rheological and chemical properties of asphalt binder. Constr. Build. Mater. 2017, 141, 152–159. [Google Scholar] [CrossRef]

- Moraes, R.; Bahia, H.U. Effect of mineral filler on changes in molecular size distribution of asphalts during oxidative ageing. Road Mater. Pavement Des. 2015, 16, 55–72. [Google Scholar] [CrossRef]

- Moraes, R.; Bahia, H. Effect of Mineral Fillers on the Oxidative Aging of Asphalt Binders: Laboratory Study with Mastics. Trans. Res. Rec. J. Trans. Res. Board 2015, 2506, 19–31. [Google Scholar] [CrossRef]

- Huang, S.C.; Zeng, M. Characterization of aging effect on rheological properties of asphalt-filler systems. Int. J. Pavement Eng. 2007, 8, 213–223. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SBS-and SBS/sulfur-modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Lin, M.S.; Chaffin, J.M.; Liu, M.; Glover, C.; Davison, R.; Bullin, J. The effect of asphalt composition on the formation of asphaltenes and their contribution to asphalt viscosity. Fuel Sci. Technol. Int. 1996, 14, 139–162. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Hasan, M.R.M.; Lei, Y.; Irfan, M. Rheological behavior and sensitivity of wood-derived bio-oil modified asphalt binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef]

- Zeng, M.; Bahia, H.U.; Zhai, H.; Andson, M.R.; Turner, P. Rheological modeling of modified asphalt binders and mixtures (with discussion). J. Assoc. Asph. Paving Technol. 2001, 70, 403–441. [Google Scholar]

- Liu, G.; Glover, C. A study on the oxidation kinetics of warm mix asphalt. Chem. Eng. J. 2015, 280, 115–120. [Google Scholar] [CrossRef]

- Zhang, Y.; Leng, Z. Quantification of bituminous mortar ageing and its application in ravelling evaluation of porous asphalt wearing courses. Mater. Des. 2017, 119, 1–11. [Google Scholar] [CrossRef]

| Properties | 70# | PG70-22 | PG76-22 |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) (0.1 mm) | 70 | 65 | 51 |

| Ductility (cm, 5 cm/min, 5 °C) | 25 | 38.1 | 33 |

| Softening point (°C) | 47 | 62.4 | 82 |

| ∣G*∣/sinδ (Original sample) | 1.513 (58 °C) 0.773 (64 °C) | 1.991 (70 °C) 0.956 (76 °C) | 1.880 (76 °C) 0.652 (82 °C) |

| ∣G*∣/sinδ (After RTFOT) | 5.027 (58 °C) 1.923 (64 °C) | 2.881 (70 °C) 1.194 (76 °C) | 2.831 (76 °C) 1.321 (82 °C) |

| Filler content | 20% | 50% | 80% | 100% | 120% | 150% | 180% |

| Weight of the mastics (g) | 31.9 | 36.4 | 41.3 | 43.5 | 44.3 | 46.9 | 88.7 |

| Position ID | X1 | X2 | X3 | Y1 | Y2 | Z1 | Z2 | Z3 | |

|---|---|---|---|---|---|---|---|---|---|

| G*(5 °C &10 Hz, 107 Pa) | Mean | 6.21 | 5.86 | 5.42 | 5.97 | 5.85 | 5.79 | 5.72 | 5.74 |

| St.d | 0.31 | 0.34 | 0.38 | 0.24 | 0.32 | 0.27 | 0.24 | 0.31 | |

| St.d (multiple positions) | 0.062 | 0.031 | 0.026 | ||||||

| ANOVA | P value | 0.0002* | 0.5288 | 0.6931 | |||||

| Parameters | Origin | Aging 2 h | Aging 4 h | Aging 8 h | Aging 12 h | Aging 16 h | Aging 20 h |

|---|---|---|---|---|---|---|---|

| Ge | 3.9 × 103 | 4.3 × 103 | 5.5 × 103 | 6.5 × 103 | 9.2 × 103 | 9.5 × 103 | 9.8 × 103 |

| Gg | 2.7 × 108 | 3.0 × 108 | 3.1 × 108 | 3.9 × 108 | 5.2 × 108 | 5.4 × 108 | 5.5 × 108 |

| fc | 55.50 | 56.58 | 50.28 | 31.01 | 30.88 | 29.86 | 28.55 |

| k | 0.33 | 0.32 | 0.31 | 0.32 | 0.33 | 0.34 | 0.33 |

| me | 0.95 | 0.93 | 0.91 | 0.85 | 0.85 | 0.85 | 0.84 |

| R | 0.88 | 0.87 | 0.87 | 0.79 | 0.77 | 0.75 | 0.75 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Jiang, J.; Li, S.; Ma, X. Evaluation of the Rheological Property of Binder-Filler Systems after Oxidation Based on a Simple Film Oven Aging Method. Appl. Sci. 2019, 9, 2542. https://doi.org/10.3390/app9122542

Li H, Jiang J, Li S, Ma X. Evaluation of the Rheological Property of Binder-Filler Systems after Oxidation Based on a Simple Film Oven Aging Method. Applied Sciences. 2019; 9(12):2542. https://doi.org/10.3390/app9122542

Chicago/Turabian StyleLi, Hongmei, Jiwang Jiang, Song Li, and Xiang Ma. 2019. "Evaluation of the Rheological Property of Binder-Filler Systems after Oxidation Based on a Simple Film Oven Aging Method" Applied Sciences 9, no. 12: 2542. https://doi.org/10.3390/app9122542

APA StyleLi, H., Jiang, J., Li, S., & Ma, X. (2019). Evaluation of the Rheological Property of Binder-Filler Systems after Oxidation Based on a Simple Film Oven Aging Method. Applied Sciences, 9(12), 2542. https://doi.org/10.3390/app9122542