Procedural Method for Fast Table Mountains Modelling in Virtual Environments

Abstract

Featured Application

Abstract

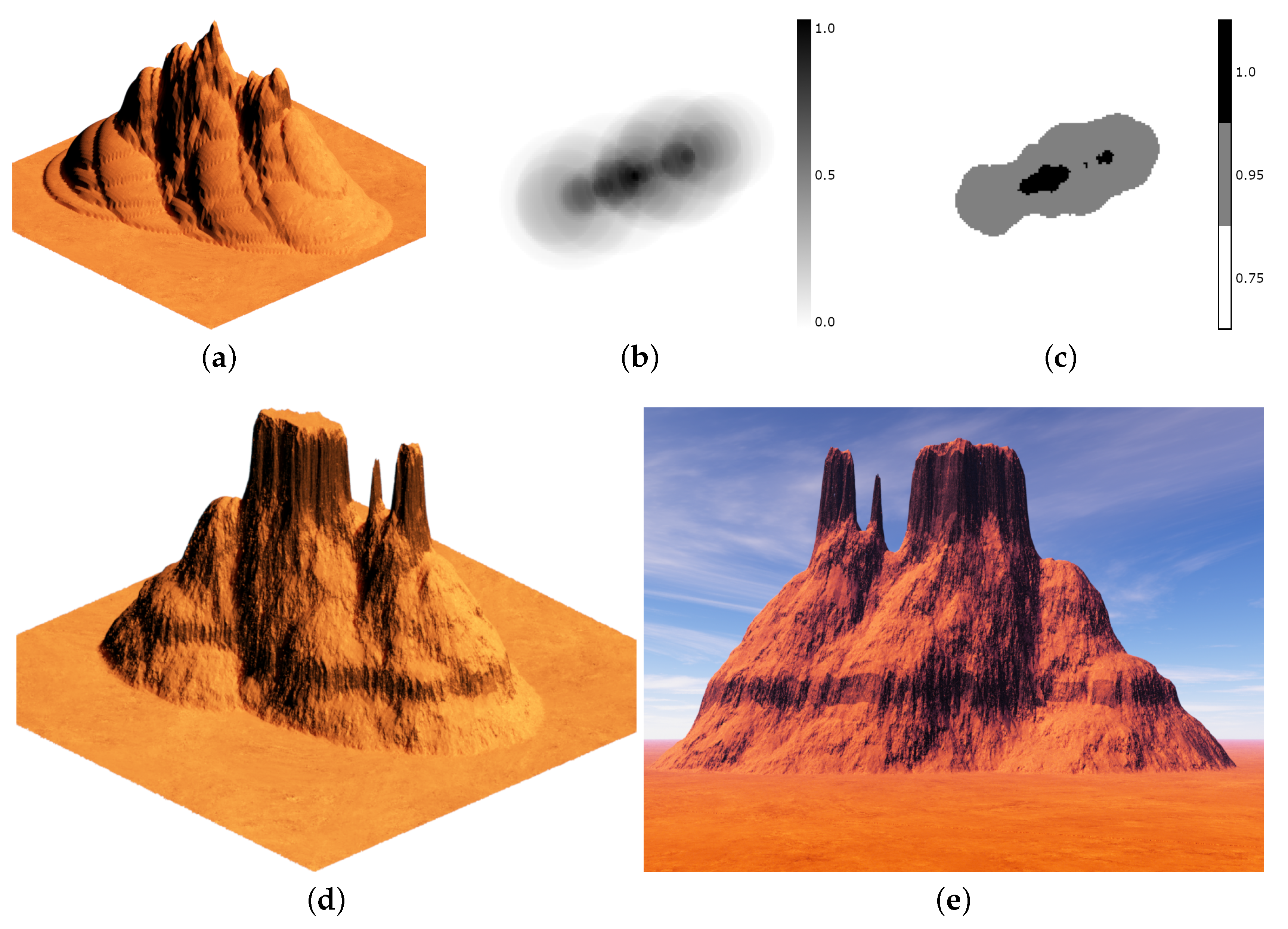

1. Introduction

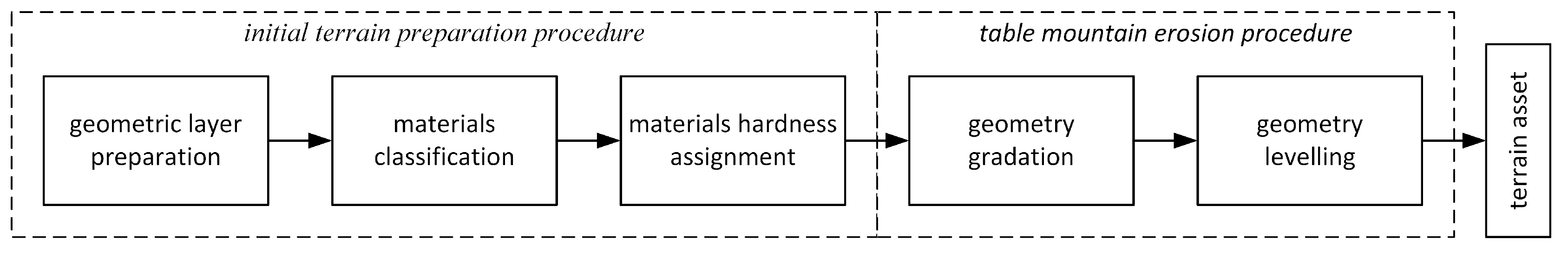

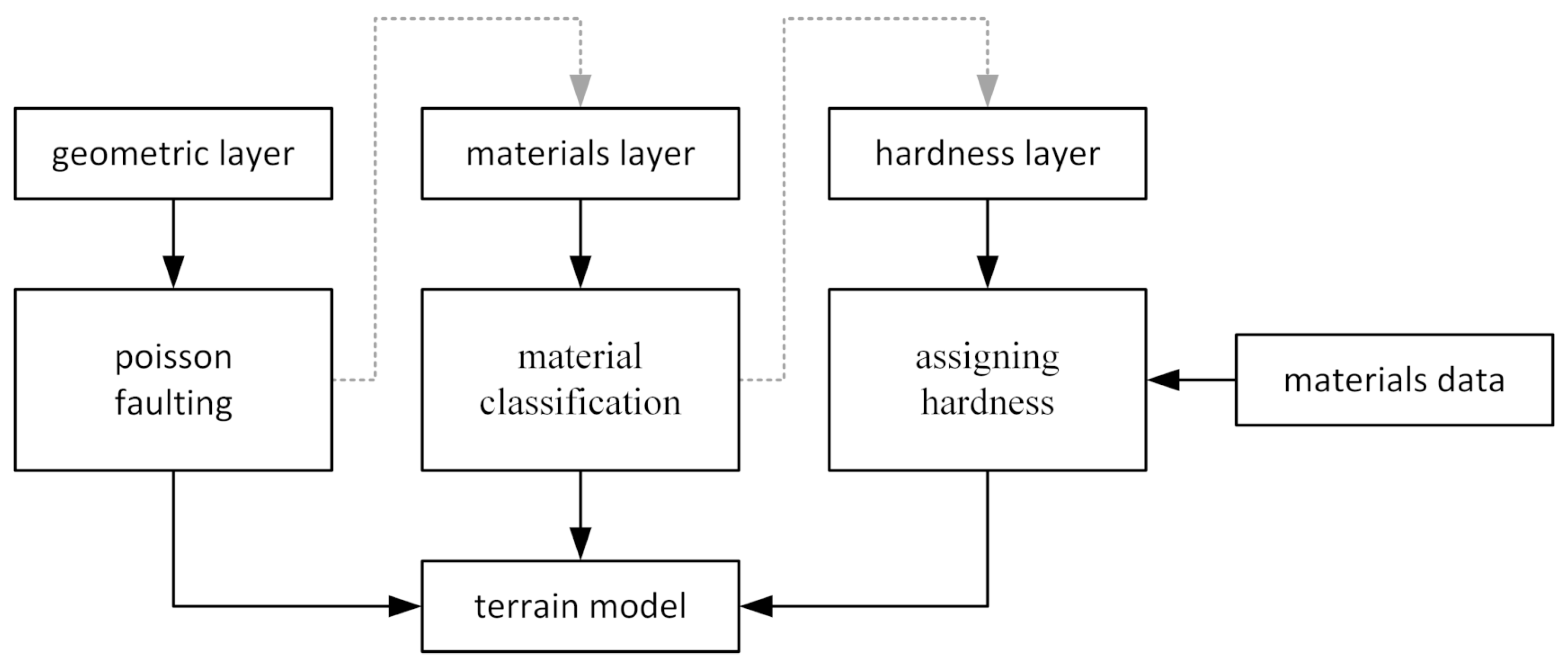

2. Terrain Model

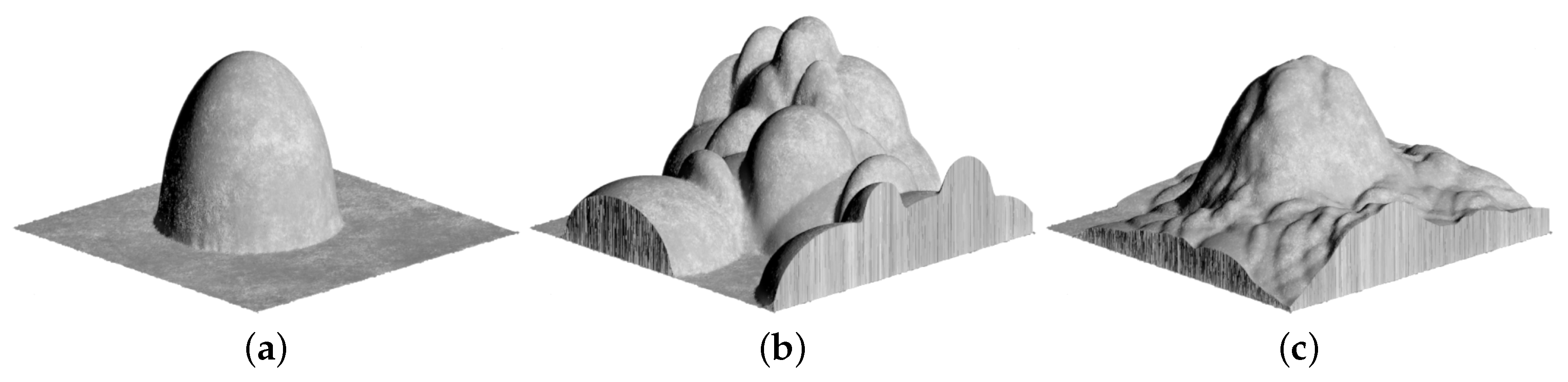

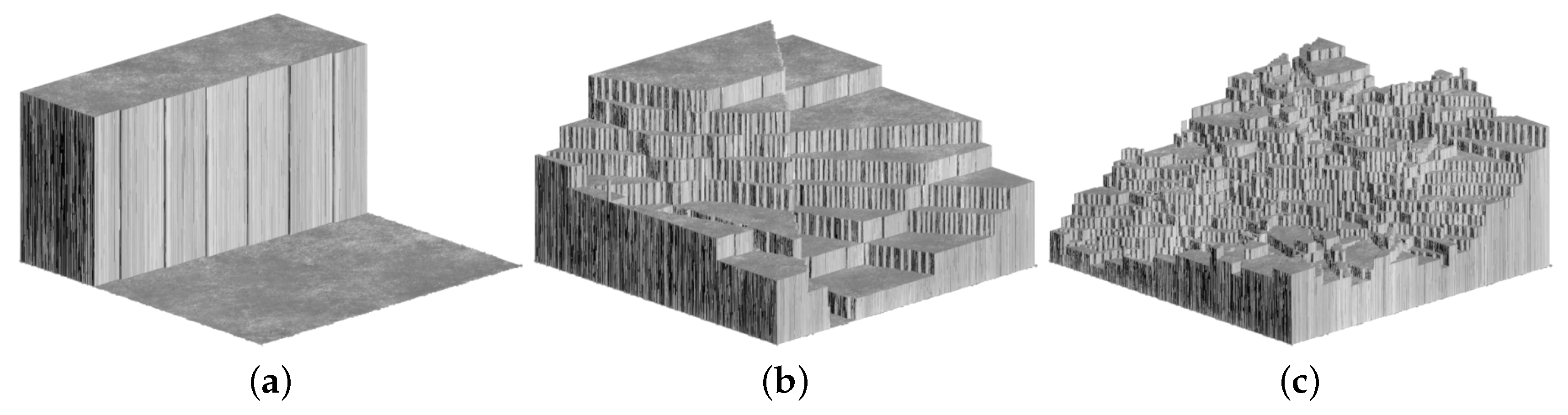

2.1. Initial Geometry

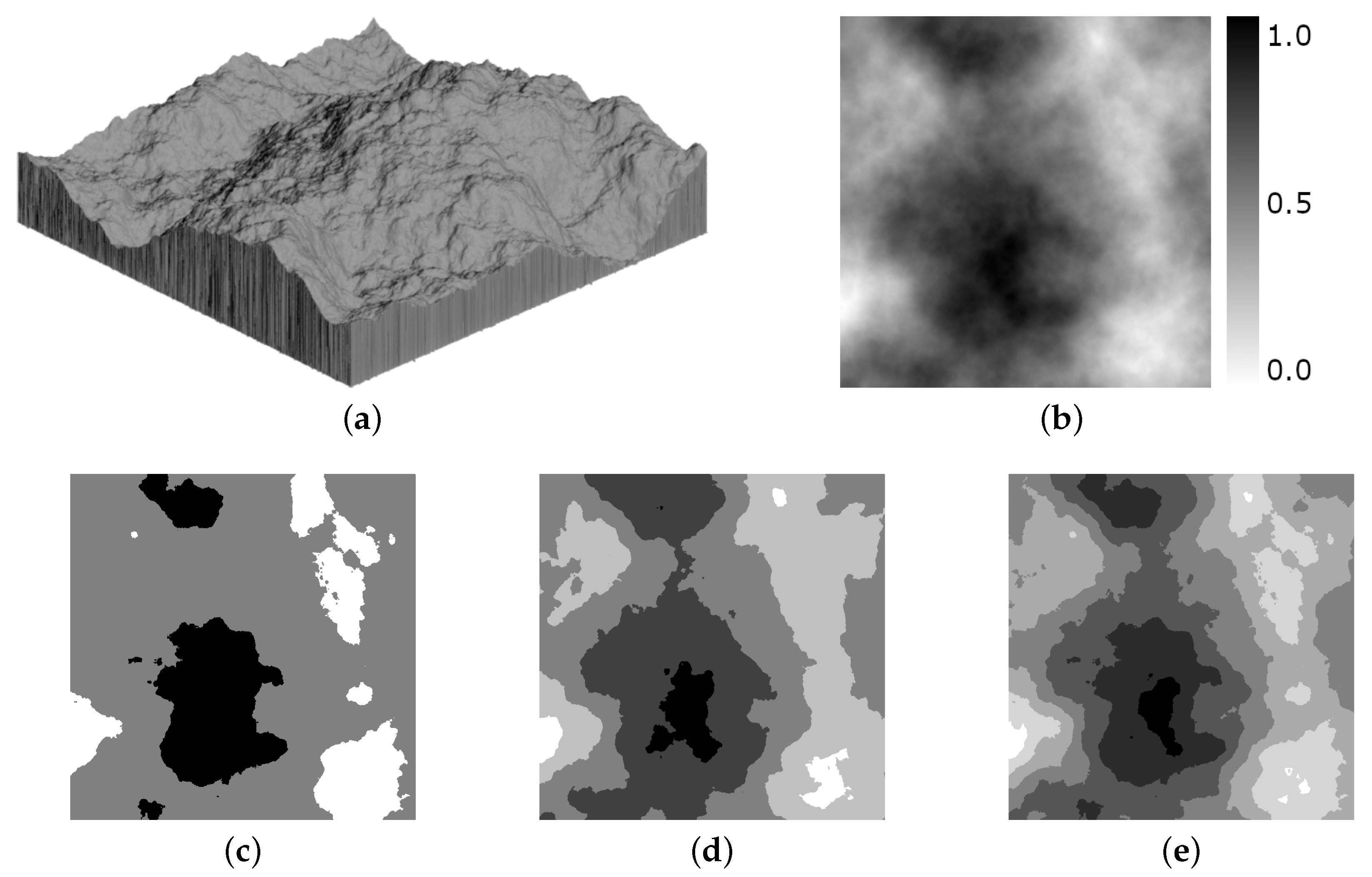

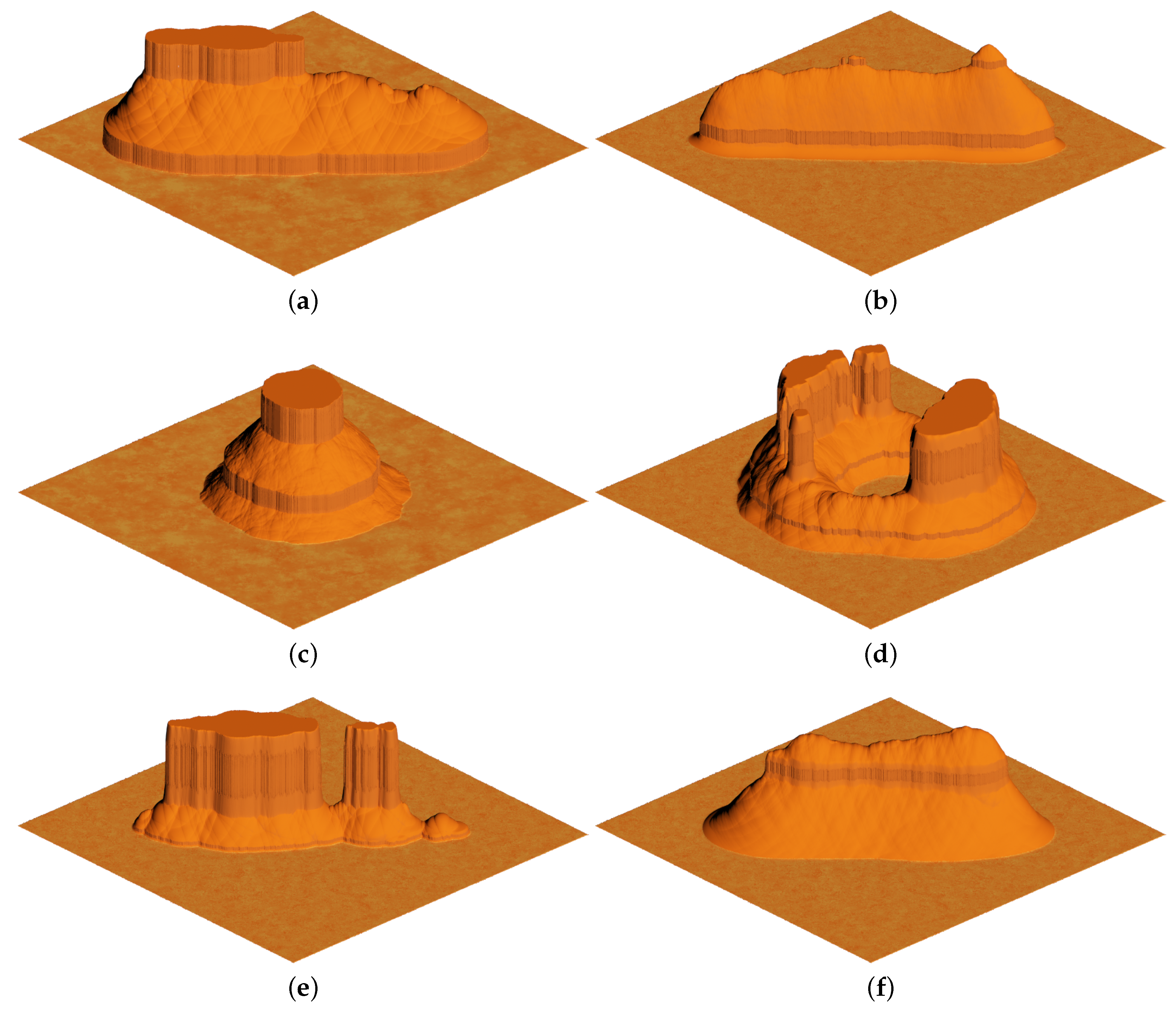

- The LFF combined with a step-based height modifier introduces sharp transitions between points lying on the fault sides, resulting in a rough surface, more adequate in irregular arrangement of rocks and stones than in structured terrain [42];

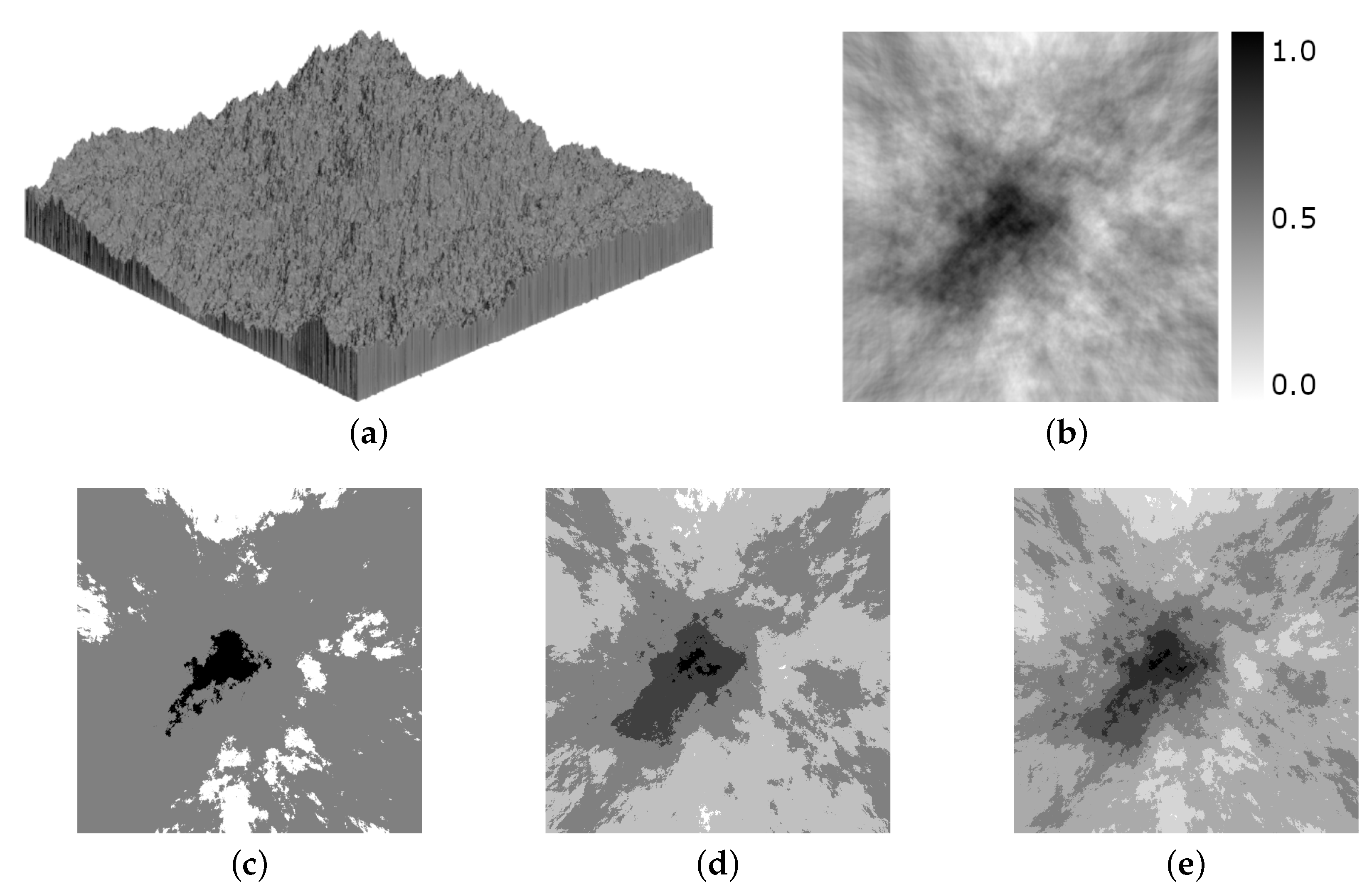

- The CFF in combination with a new height modifier emulates the distribution of the sediments at the terrain base in the further described erosive procedure;

- The CFF can be limited to a certain area of the height-field, thus the generation of buttes is simplified.

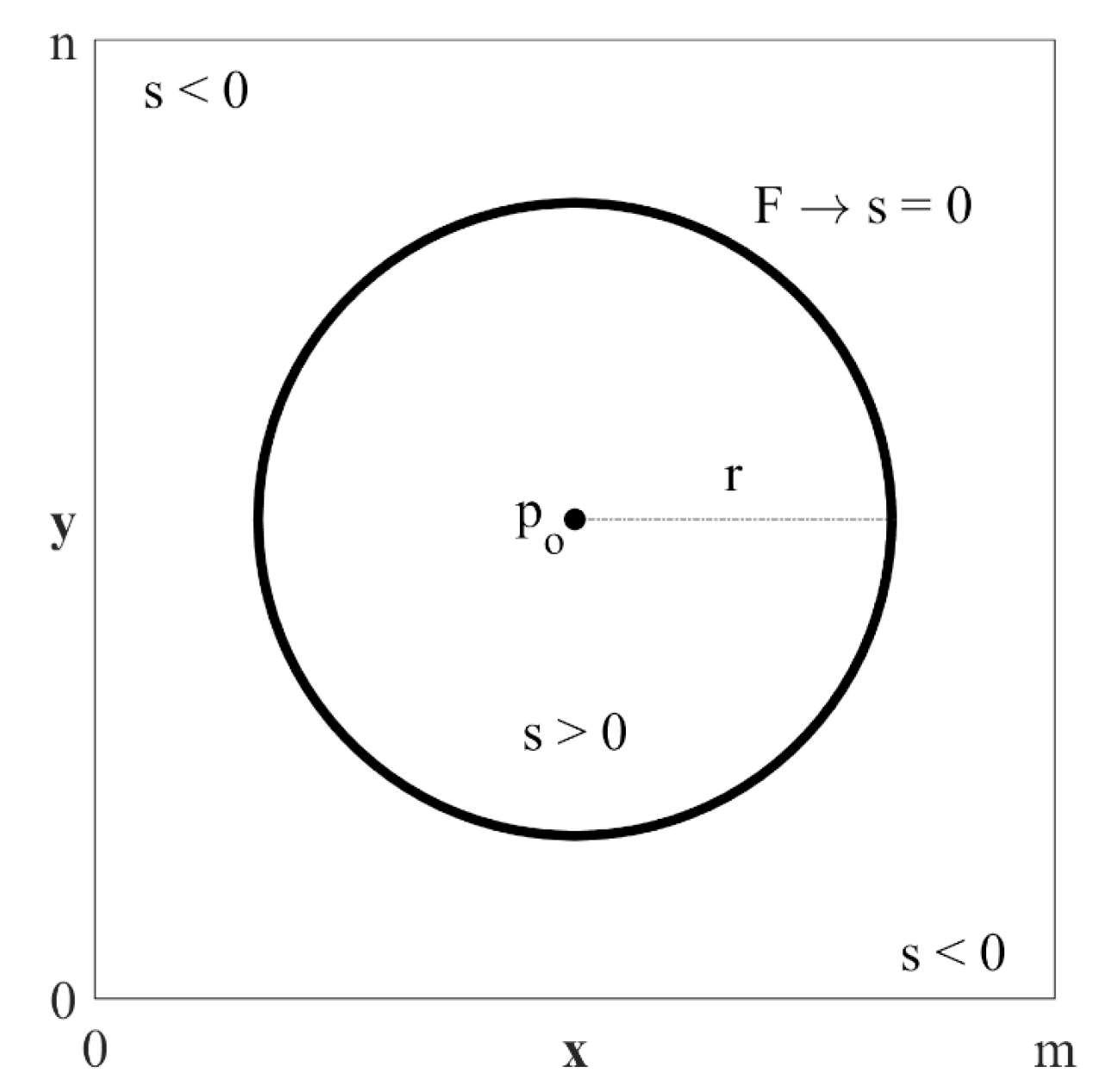

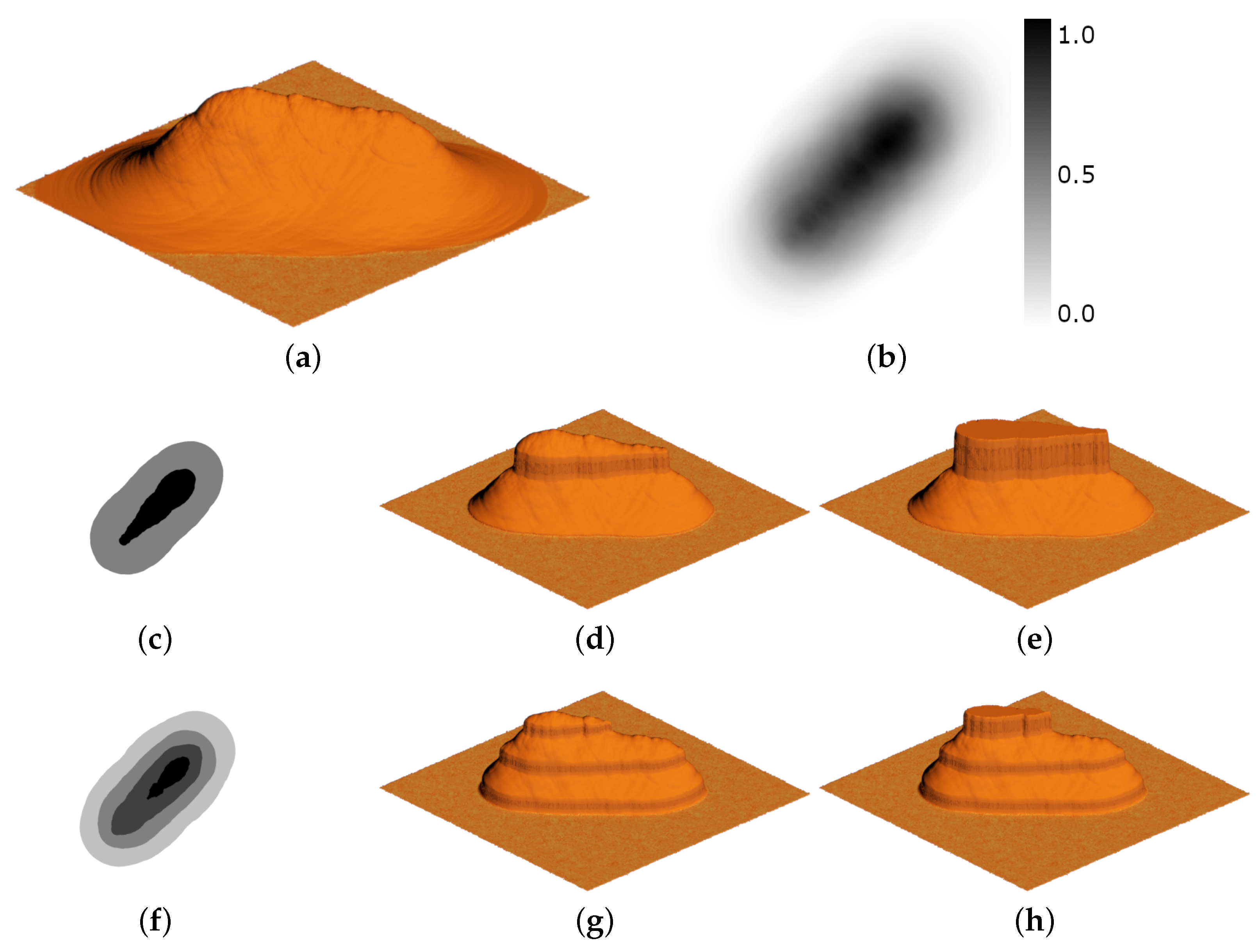

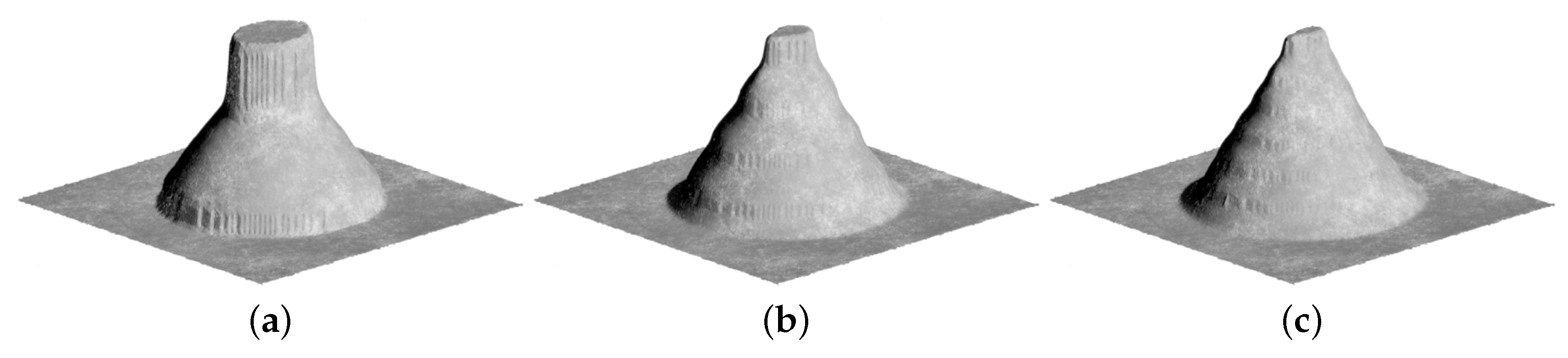

2.1.1. Circular Edge of Fault

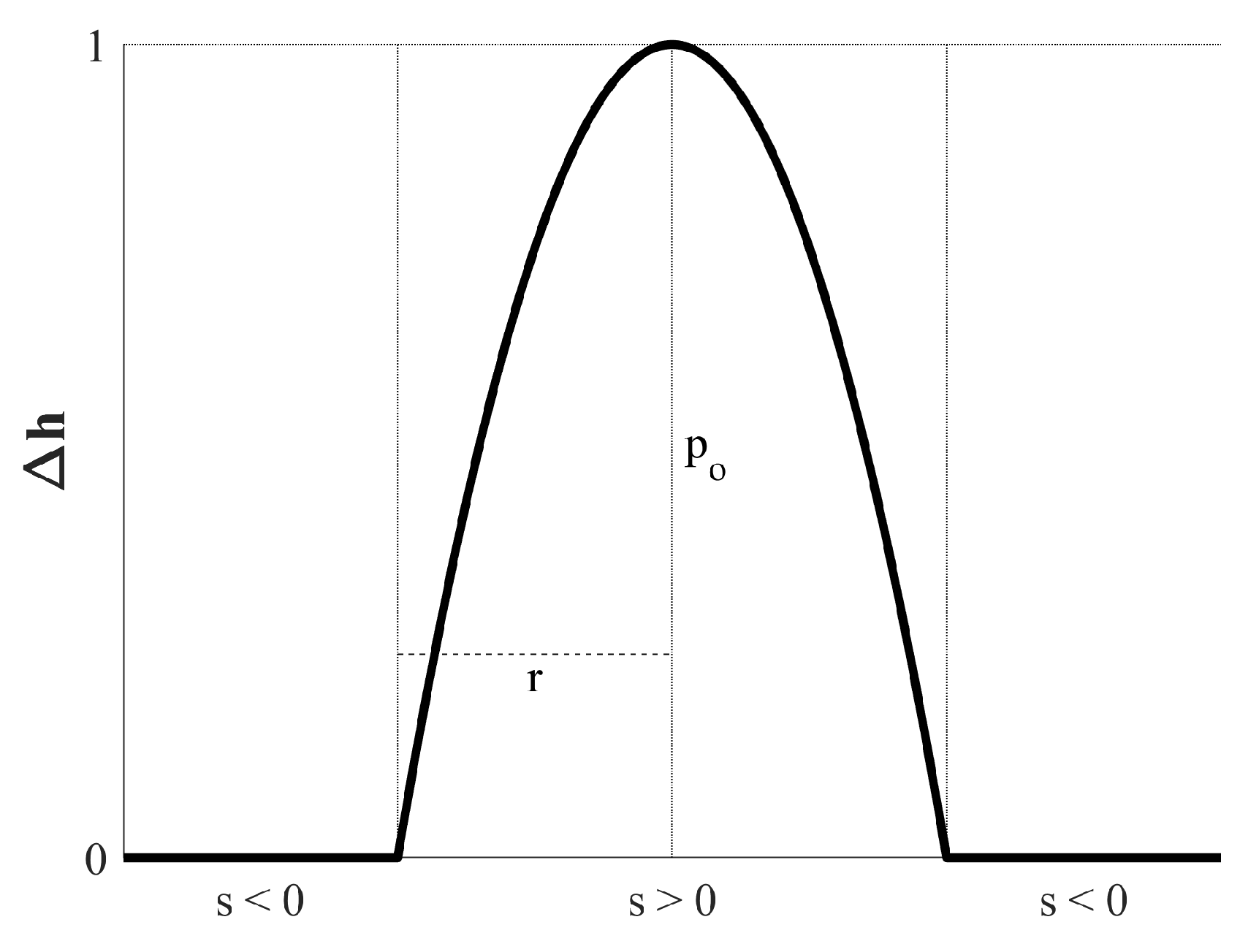

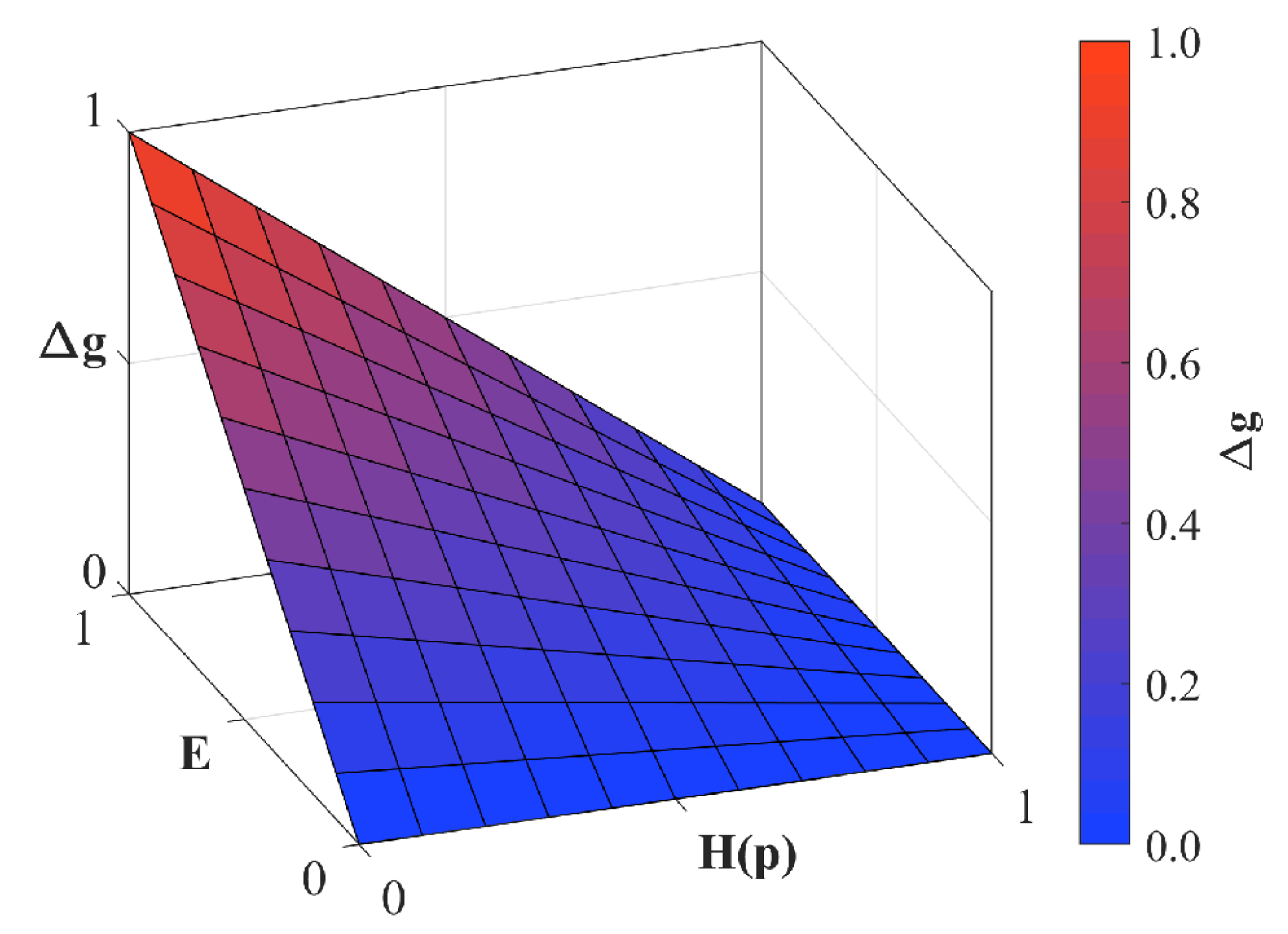

2.1.2. Height Modifier

2.2. Material Classification

2.3. Hardness Data

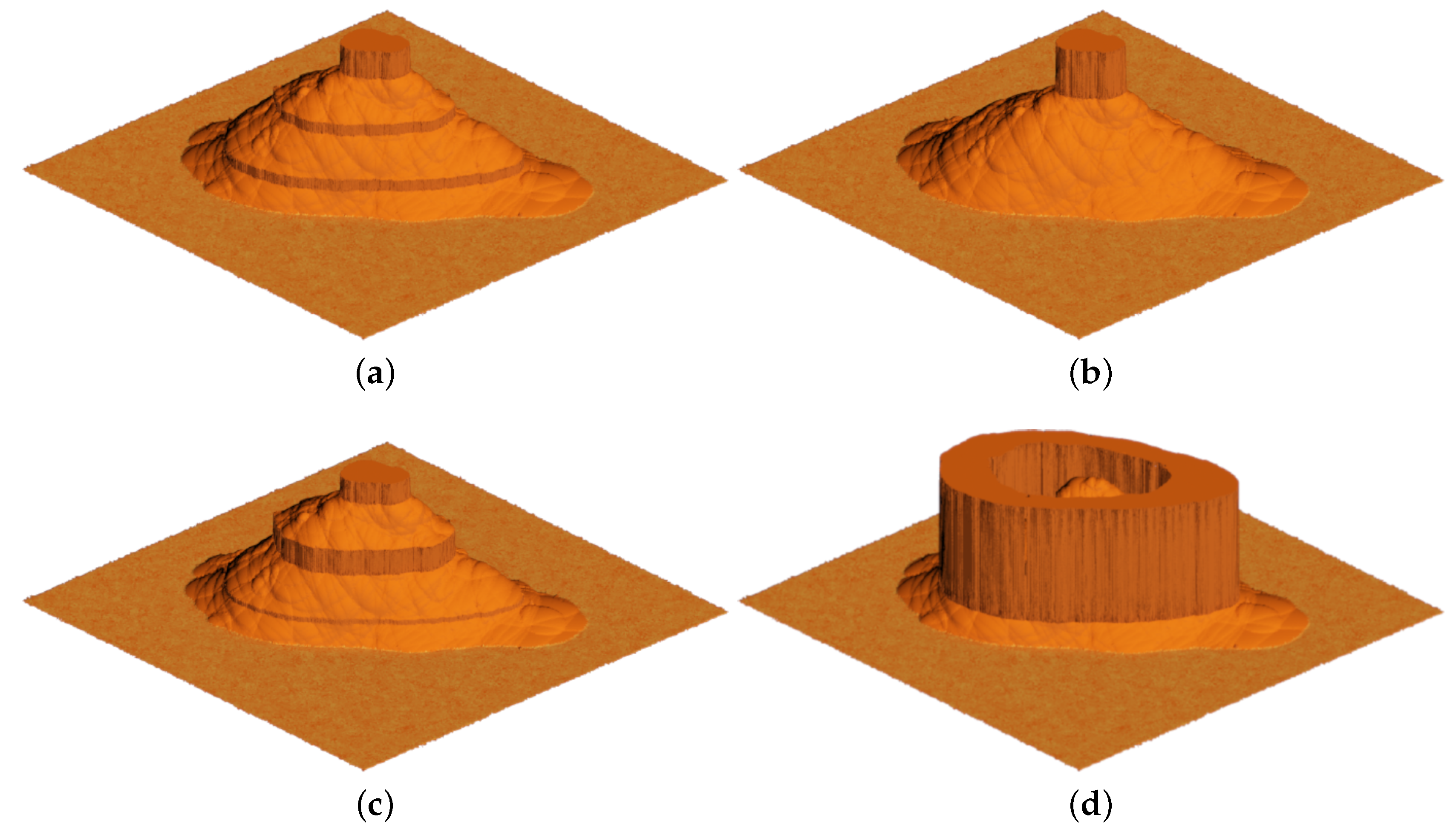

3. Table Mountain Erosion

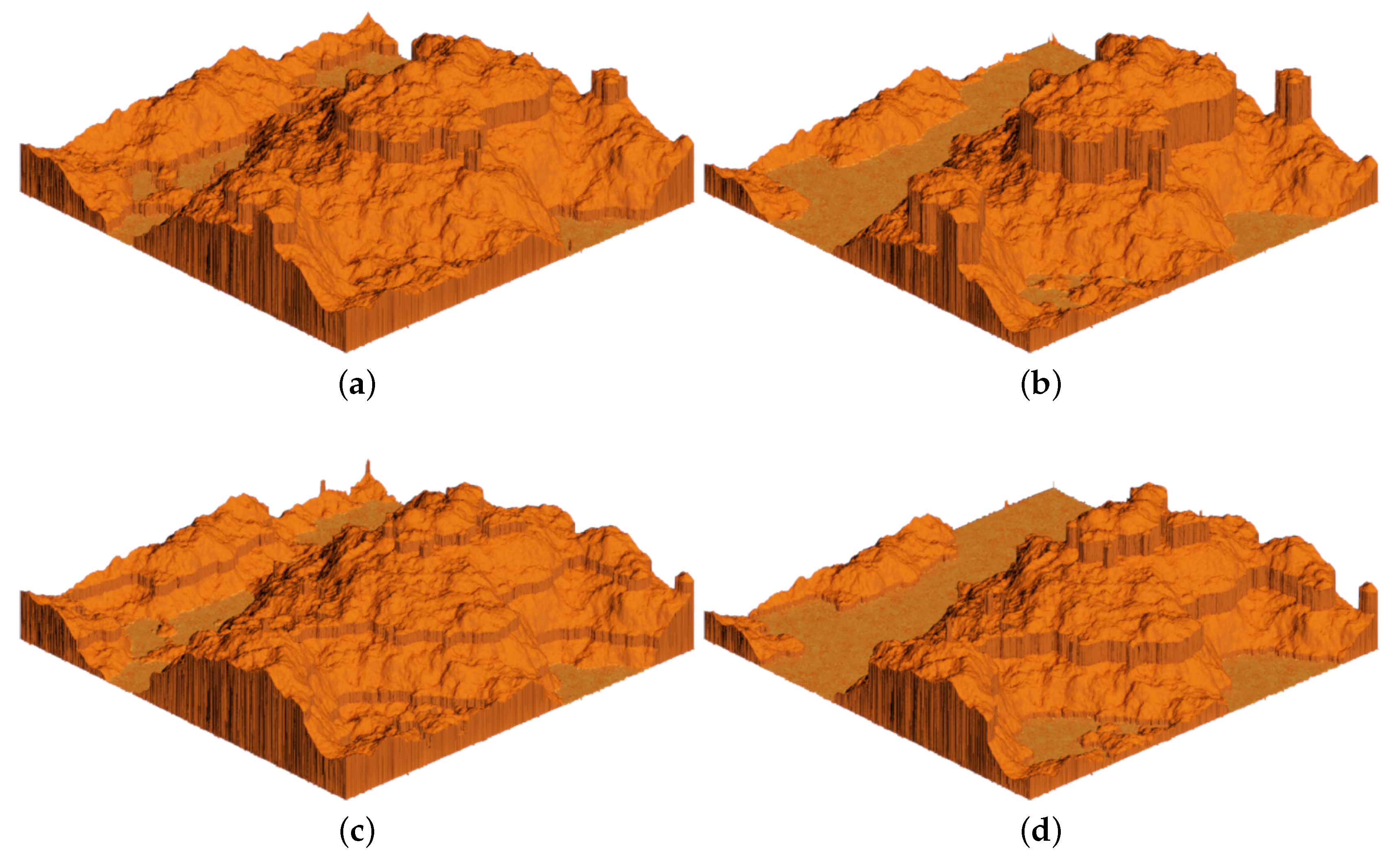

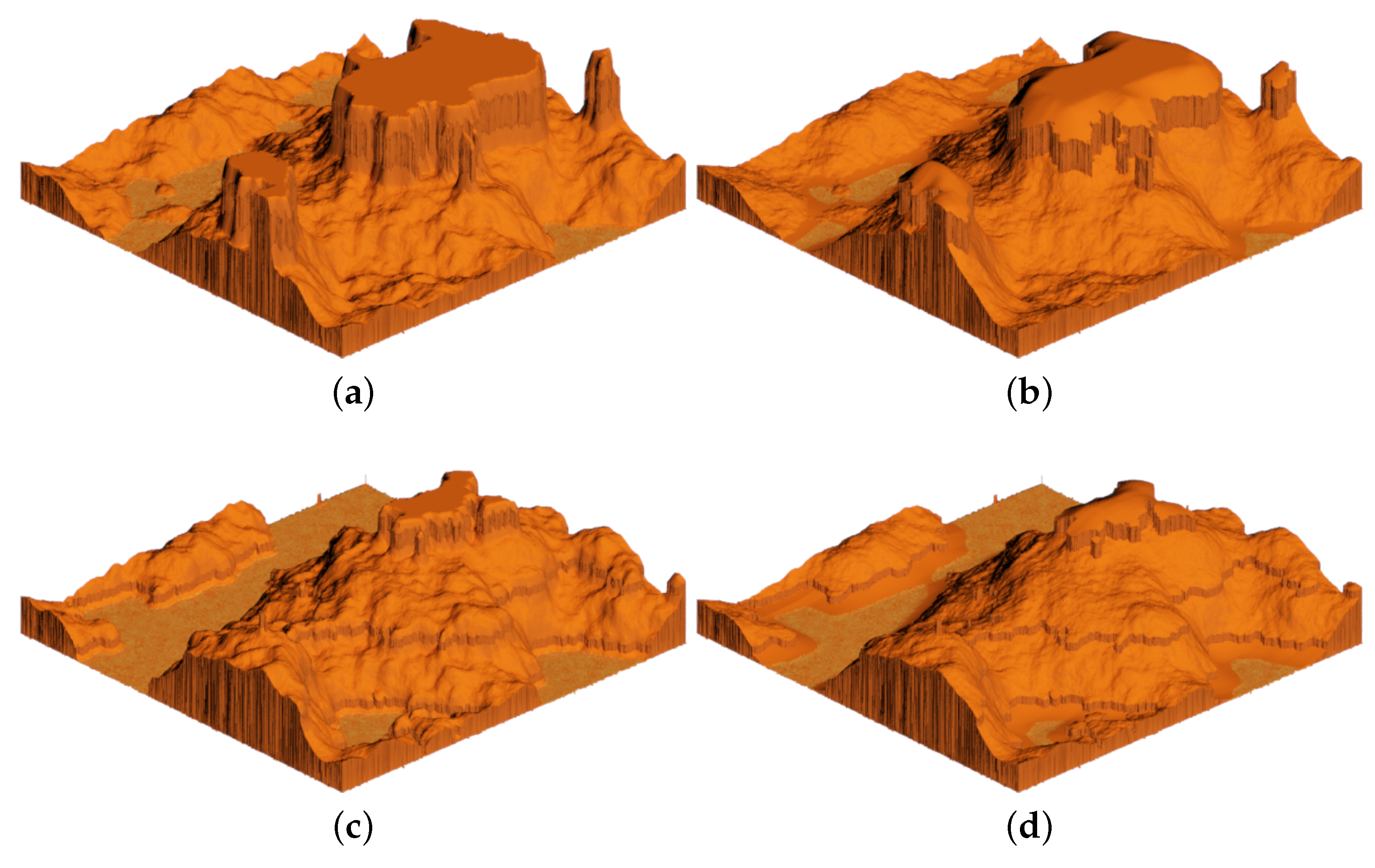

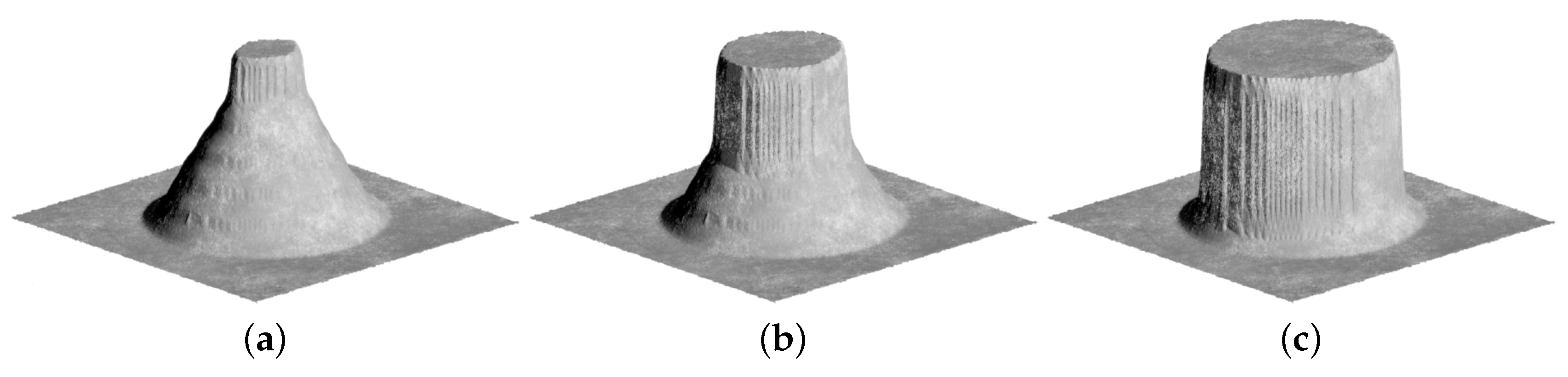

3.1. Geometry Gradation

Caprock

3.2. Geometry Levelling

3.3. Butte Modification

4. Results

4.1. Testing Workstation and Applications

4.2. Computational Efficiency

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CFF | Circular Fault Formation |

| DEM | Digital Elevation Model |

| fBs | fractional Brownian surface |

| LFF | Linear Fault Formation |

References

- Frade, M.; de Vega, F.; Cotta, C. Modelling Video Games’ Landscapes by Means of Genetic Terrain Programming: A New Approach for Improving Users’ Experience. In Applications of Evolutionary Computing; Giacobini, M., Brabazon, A., Cagnoni, S., Di Caro, G.A., Drechsler, R., Ekárt, A., Esparcia-Alcázar, A.I., Farooq, M., Fink, A., McCormack, J., et al., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2008; Volume 4974, pp. 485–490. [Google Scholar]

- Roman, P.A.; Brown, D. Games—Just how serious are they? In Proceedings of the Interservice/Industry Training, Simulation, and Education Conference (I/ITSEC ’08), Orlando, FL, USA, 1–5 December 2008; pp. 1–11. [Google Scholar]

- Wells, W.D.; Darken, C.J. Generating enhanced natural environments and terrain for interactive combat simulations (GENETICS). In Proceedings of the ACM Symposium on Virtual Reality Software and Technology (VRST ’05), Monterey, CA, USA, 7–9 November 2005; pp. 184–191. [Google Scholar]

- Wilkowski, A.; Kornuta, T.; Stefańczyk, M.; Kasprzak, W. Efficient generation of 3D surfel maps using RGB–D sensors. Int. J. Appl. Math. Comput. Sci. 2016, 26, 99–122. [Google Scholar] [CrossRef]

- Guérin, E.; Digne, J.; Galin, E.; Peytavie, A.; Wolf, C.; Beneš, B.; Martinez, B. Interactive Example-based Terrain Authoring with Conditional Generative Adversarial Networks. ACM Trans. Graph. 2017, 36, 228. [Google Scholar] [CrossRef]

- Bézin, R.; Crespin, B.; Skapin, X.; Terraz, O.; Meseure, P. Generalized Maps for Erosion and Sedimentation Simulation. Comput. Graph. 2014, 45, 1–16. [Google Scholar] [CrossRef]

- Génevaux, J.D.; Galin, E.; Guérin, E.; Peytavie, A.; Beneš, B. Terrain Generation Using Procedural Models Based on Hydrology. In Proceedings of the Annual Conference on Computer Graphics and Interactive Techniques (SIGGRAPH ’13), Anaheim, CA, USA, 21–25 July 2013; pp. 1–13. [Google Scholar]

- Beneš, B.; Forsbach, R. Layered data representation for visual simulation of terrain erosion. In Proceedings of the Spring Conference on Computer Graphics (SCCG ’01), Budmerice, Slovakia, 25–28 April 2001; pp. 80–85. [Google Scholar]

- Musgrave, F.K. Methods for Realistic Landscape Imaging. Ph.D. Thesis, Yale University, New Haven, CT, USA, 1993. [Google Scholar]

- Musgrave, F.K.; Kolb, C.E.; Mace, R.S. The synthesis and rendering of eroded fractal terrains. In Proceedings of the Annual Conference on Computer Graphics and Interactive Techniques (SIGGRAPH ’89), Boston, MA, USA, 31 July– 4 August 1989; pp. 41–50. [Google Scholar]

- Št’ava, O.; Beneš, B.; Brisbin, M.; Křivánek, J. Interactive Terrain Modeling Using Hydraulic Erosion. In Proceedings of the ACM SIGGRAPH/Eurographics Symposium on Computer Animation (SCA ’08), Dublin, Ireland, 7–9 June 2008; pp. 201–210. [Google Scholar]

- Cordonnier, G.; Braun, J.; Cani, M.P.; Beneš, B.; Galin, E.; Peytavie, A.; Guérin, E. Large Scale Terrain Generation from Tectonic Uplift and Fluvial Erosion. Comput. Graph. Forum 2016, 35, 165–175. [Google Scholar] [CrossRef]

- Cordonnier, G.; Cani, M.P.; Beneš, B.; Braun, J.; Galin, E. Sculpting Mountains: Interactive Terrain Modeling Based on Subsurface Geology. IEEE Trans. Vis. Comput. Graph. 2018, 24, 1756–1769. [Google Scholar] [CrossRef] [PubMed]

- Beneš, B.; Arriaga, X. Table Mountains by Virtual Erosion. In Proceedings of the Eurographics Workshop on Natural Phenomena (NPH ’05), Dublin, Ireland, 30 August 2005; pp. 33–39. [Google Scholar]

- Smelik, R.M.; de Kraker, K.J.; Tutenel, T.; Bidarra, R.; Groenewegen, S.A. A survey of procedural methods for terrain modelling. In Proceedings of the CASA Workshop on 3D Advanced Media in Gaming and Simulation (3AMIGAS ’09), Amsterdam, The Netherlands, 16 June 2009; pp. 25–34. [Google Scholar]

- Smelik, R.M.; Tutenel, T.; Bidarra, R.; Beneš, B. A Survey on Procedural Modelling for Virtual Worlds. Comput. Graph. Forum 2014, 33, 31–50. [Google Scholar] [CrossRef]

- Lengyel, E.S. Voxel-Based Terrain for Real-Time Virtual Simulations. Ph.D. Thesis, University of California, Davis, CA, USA, 2010. [Google Scholar]

- Galin, E.; Guérin, E.; Peytavie, A.; Cordonnier, G.; Cani, M.P.; Beneš, B.; James, G. A Review of Digital Terrain Modeling. Comput. Graph. Forum 2019, 38, 553–577. [Google Scholar] [CrossRef]

- Schmitter, D.; García-Amorena, P.; Unser, M. Smooth Shapes with Spherical Topology: Beyond Traditional Modeling, Efficient Deformation, and Interaction. Comput. Vis. Media 2017, 3, 199–215. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Van Ness, J.W. Fractional Brownian motions, fractional noises and applications. SIAM Rev. 1968, 10, 422–437. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. Stochastic models for the earth’s relief, the shape and fractal dimension of coastlines, and the number area rule for islands. Proc. Natl. Acad. Sci. USA 1975, 72, 2825–2828. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature, 2nd ed.; H.W. Freeman and Co.: San Francisco, CA, USA, 1982. [Google Scholar]

- Voss, R.F. Random Fractal Forgeries. In Fundamental Algorithms for Computer Graphics; Earnshaw, R.A., Ed.; NATO ASI Series; Springer: Berlin, Germany, 1991; Volume 17, pp. 805–835. [Google Scholar]

- Ebert, D.S.; Musgrave, F.K.; Peachery, D.; Perlin, K.; Worley, S. Texture & Modeling: A Procedural Approach, 3rd ed.; The Morgan Kaufmann Series in Computer Graphics and Geometric Modeling; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2003. [Google Scholar]

- Prusinkiewicz, P.; Hammel, M. A Fractal Model of Mountains with River. In Proceedings of the Graphics Interface (GI ’93), Toronto, ON, Canada, 19–21 May 1993; pp. 174–180. [Google Scholar]

- Nagashima, K. Computer generation of eroded valley and mountain terrains. Vis. Comput. 1997, 13, 456–464. [Google Scholar] [CrossRef]

- Van Lawick van Pabst, J.; Jense, H. Dynamic Terrain Generation Based on Multifractal Techniques. In Proceedings of the International Workshop on High Performance Computing for Computer Graphics and Visualisation, Swansea, UK, 3–4 June 1995; pp. 186–203. [Google Scholar] [CrossRef]

- Zuo, C.; Wu, L.; Zeng, Z.F.; Wei, H.L. Stochastic fractal based multiobjective fruit fly optimization. Int. J. Appl. Math. Comput. Sci. 2017, 27, 417–433. [Google Scholar] [CrossRef]

- Kristof, P.; Beneš, B.; Krivanek, J.; Stava, O. Hydraulic Erosion Using Smoothed Particle Hydrodynamics. Comput. Graph. Forum 2009, 28, 219–228. [Google Scholar] [CrossRef]

- Beneš, B.; Těšínský, V.; Hornyš, J.; Bhatia, S.K. Hydraulic erosion. Comput. Animat. Virtual Worlds 2006, 17, 99–108. [Google Scholar] [CrossRef]

- Beneš, B. Real-Time Erosion Using Shallow Water Simulation. In Proceedings of the Workshop in Virtual Reality Interactions and Physical Simulation (VRIPHYS ’07), Dublin, Ireland, 9–10 November 2007; pp. 43–50. [Google Scholar]

- Beneš, B.; Forsbach, R. Visual Simulation of Hydraulic Erosion. In Proceedings of the International Conferences in Central Europe on Computer Graphics, Visualization and Computer Vision (WSCG ’02), Plzen-Bory, Czech Republic, 4–8 February 2002; pp. 79–86. [Google Scholar]

- Natali, M.; Lidal, E.M.; Parulek, J.; Viola, I.; Patel, D. Modeling Terrains and Subsurface Geology. In Proceedings of the EUROGRAPHICS State of the Art Reports (STAR ’12), Cagliary, Italy, 13–18 May 2012; pp. 155–173. [Google Scholar] [CrossRef]

- Frade, M.; de Vega, F.F.; Cotta, C. Breeding terrains with genetic terrain programming: The evolution of terrain generators. Int. J. Comput. Games Technol. 2009, 83–96. [Google Scholar] [CrossRef]

- Golubev, K.; Zagarskikh, A.; Karsakov, A. Dijkstra-based Terrain Generation Using Advanced Weight Functions. In Proceedings of the 5th International Young Scientist Conference on Computational Science (YSC ’16), Kraków, Poland, 26–28 October 2016; pp. 152–160. [Google Scholar]

- Génevaux, J.D.; Galin, E.; Peytavie, A.; Guérin, E.; Briquet, C.; Grosbellet, F.; Beneš, B. Terrain Modelling from Feature Primitives. Comput. Graphics Forum 2015, 34, 198–210. [Google Scholar] [CrossRef]

- Zawadzki, T.; Nikiel, S.; Warszawski, K. Hybrid of shape grammar and morphing for procedural modeling of 3D caves. Trans. GIS 2012, 16, 619–633. [Google Scholar] [CrossRef]

- Shankel, J. Fractal terrain generation—Particle deposition. In Game Programming Gems; DeLoura, M.A., Ed.; Charles River Media: Rockland, MA, USA, 2000; Volume 1, pp. 508–511. [Google Scholar]

- Warszawski, K.; Nikiel, S. A proposition of particle system-based technique for automated terrain surface modeling. In Proceedings of the 5th International North American Conference on Intelligent Games and Simulation (Game-On-NA ’09), Atlanta, GA, USA, 26–28 August 2009; pp. 17–19. [Google Scholar]

- Fournier, A.; Fussell, D.; Carpenter, L. Computer rendering of stochastic models. Commun. ACM 1982, 25, 371–384. [Google Scholar] [CrossRef]

- Mukherjee, S. Applied Mineralogy: Applications in Industry and Environment; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar]

- Migoń, P.; Różycka, M.; Jancewicz, K.; Duszyński, F. Evolution of sandstone mesas—Following landform decay until death. Prog. Phys. Geogr. 2018, 42, 588–606. [Google Scholar] [CrossRef]

- Waters, R. Differential Weathering and Erosion on Oldlands. R. Geogr. Soc. 1957, 123, 503–509. [Google Scholar] [CrossRef]

- Lewis, R.Q.; Trimble, D.E. Geology and and Uranium Deposits of Monument Valley, San Juan County, Utah; Technical Report 1087, Geological Survey Bulletin; United States Department of the Interior: Washington, DC, USA, 1959.

- Baker, A.A. Geology of the Monument Valley–Navajo Mountain Region, San Juan County, Utah; Technical Report 865, Geological Survey Bulletin; United States Department of the Interior: Washington, DC, USA, 1936.

- Chen, X.; Sun, Q.; Hu, J. Generation of Complete SAR Geometric Distortion Maps Based on DEM and Neighbor Gradient Algorithm. Appl. Sci. 2018, 8, 2206. [Google Scholar] [CrossRef]

- Shankel, J. Fractal terrain generation—Fault formation. In Game Programming Gems; DeLoura, M.A., Ed.; Charles River Media: Rockland, MA, USA, 2000; Volume 1, pp. 499–502. [Google Scholar]

- Vollmer, J.; Mencl, R.; Müller, H. Improved Laplacian Smoothing of Noisy Surface Meshes. Comput. Graph. Forum 1999, 18, 131–138. [Google Scholar] [CrossRef]

- Park, S.; Kim, J. Landslide Susceptibility Mapping Based on Random Forest and Boosted Regression Tree Models, and a Comparison of Their Performance. Appl. Sci. 2019, 9, 942. [Google Scholar] [CrossRef]

| Type | Scale of Mineral Hardness | |

|---|---|---|

| Absolute | Normalised | |

| none | 0 | 0.0 |

| talc | 1 | 0.001 |

| gypsum | 3 | 0.002 |

| calcite | 9 | 0.006 |

| fluorite | 21 | 0.014 |

| apatite | 48 | 0.032 |

| orthoclase | 72 | 0.048 |

| quartz | 100 | 0.067 |

| topaz | 200 | 0.133 |

| corundum | 400 | 0.267 |

| diamond | 1500 | 1.0 |

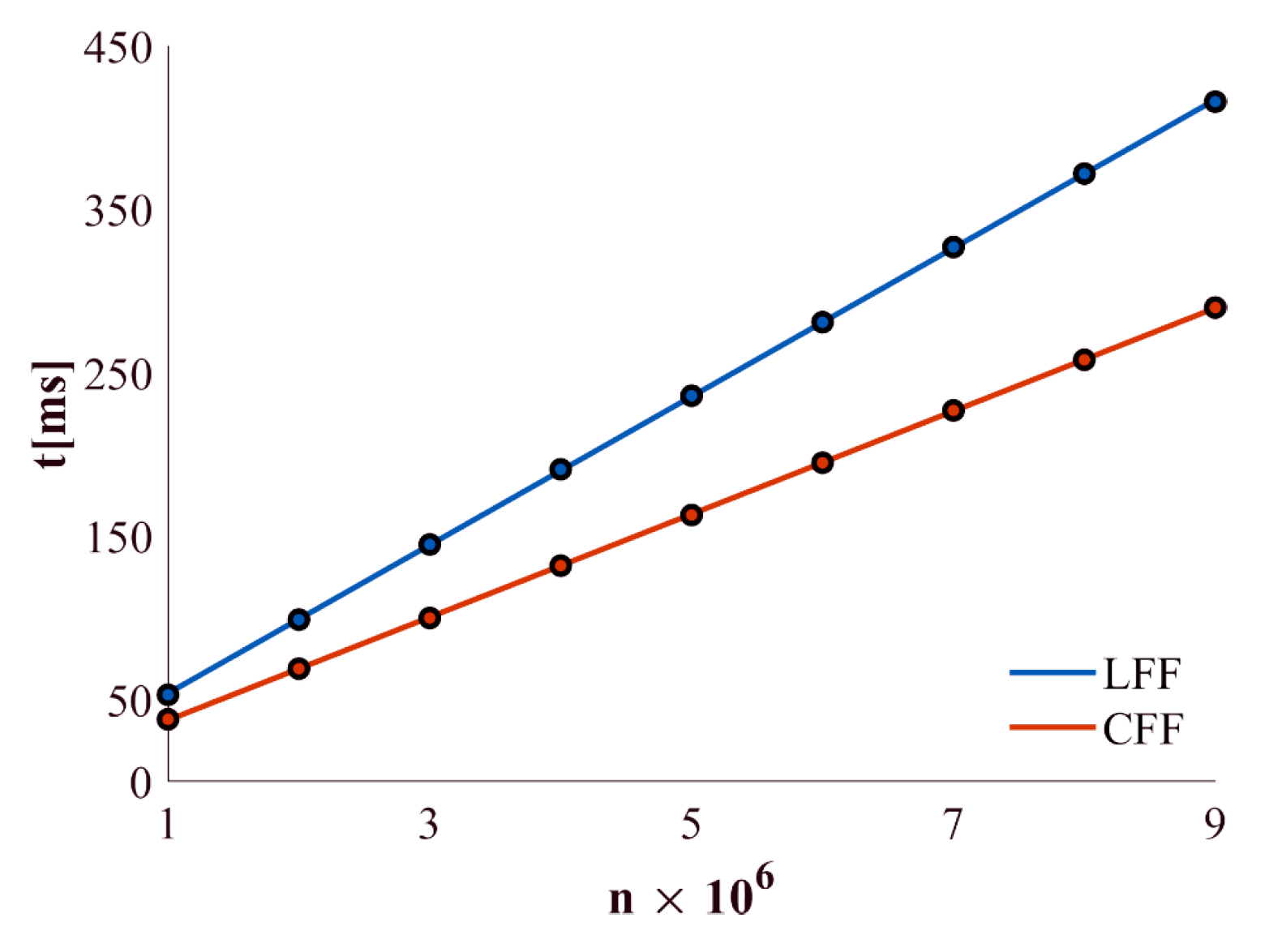

| Model Size | Geometry | ||

|---|---|---|---|

| Elements | Resolution | LFF | CFF |

| t [ms] | t [ms] | ||

| 1 | 53 | 38 | |

| 2 | 99 | 69 | |

| 3 | 145 | 100 | |

| 4 | 191 | 132 | |

| 5 | 236 | 163 | |

| 6 | 281 | 195 | |

| 7 | 327 | 227 | |

| 8 | 372 | 258 | |

| 9 | 416 | 290 | |

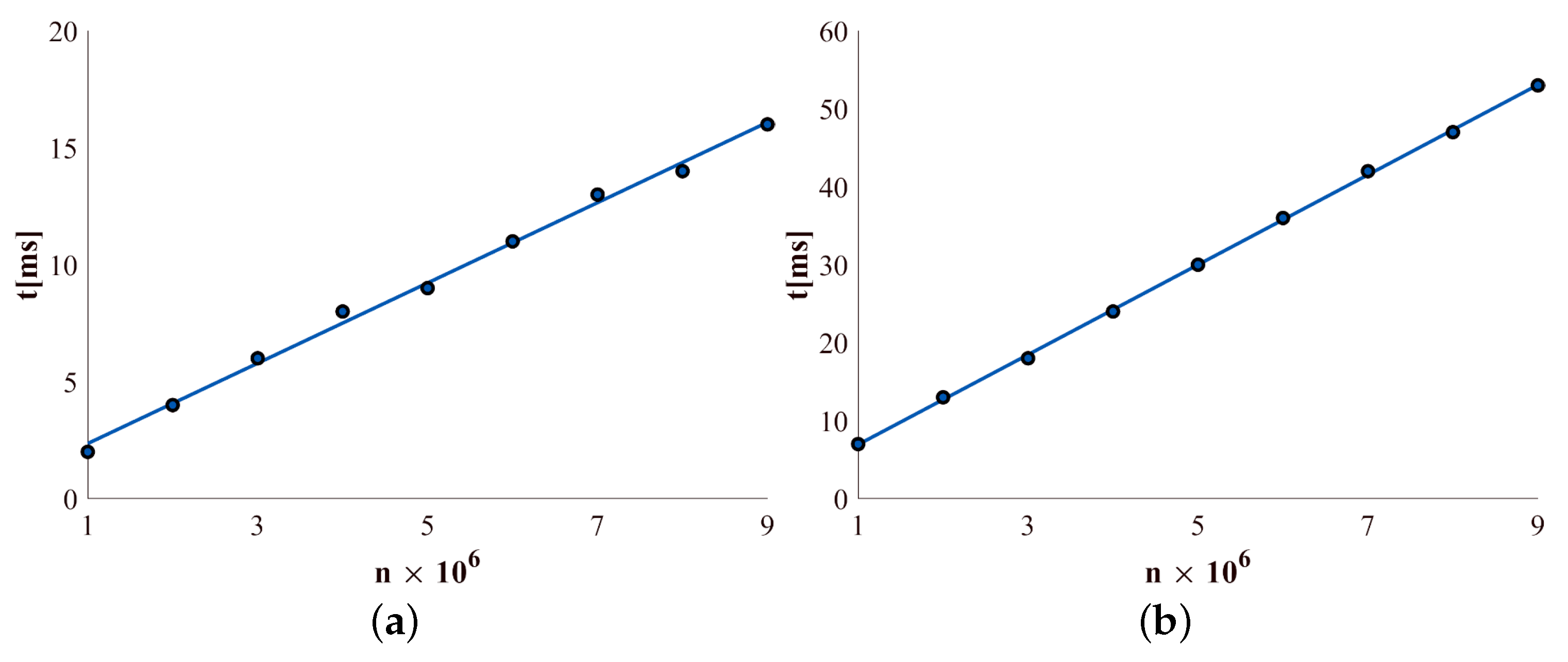

| Model Size | |||

|---|---|---|---|

| Elements | Resolution | Materials | Erosion |

| t [ms] | t [ms] | ||

| 1 | 2 | 7 | |

| 2 | 4 | 13 | |

| 3 | 6 | 18 | |

| 4 | 8 | 24 | |

| 5 | 9 | 30 | |

| 6 | 11 | 36 | |

| 7 | 13 | 42 | |

| 8 | 14 | 47 | |

| 9 | 16 | 53 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warszawski, K.K.; Nikiel, S.S.; Mrugalski, M. Procedural Method for Fast Table Mountains Modelling in Virtual Environments. Appl. Sci. 2019, 9, 2352. https://doi.org/10.3390/app9112352

Warszawski KK, Nikiel SS, Mrugalski M. Procedural Method for Fast Table Mountains Modelling in Virtual Environments. Applied Sciences. 2019; 9(11):2352. https://doi.org/10.3390/app9112352

Chicago/Turabian StyleWarszawski, Korneliusz K., Sławomir S. Nikiel, and Marcin Mrugalski. 2019. "Procedural Method for Fast Table Mountains Modelling in Virtual Environments" Applied Sciences 9, no. 11: 2352. https://doi.org/10.3390/app9112352

APA StyleWarszawski, K. K., Nikiel, S. S., & Mrugalski, M. (2019). Procedural Method for Fast Table Mountains Modelling in Virtual Environments. Applied Sciences, 9(11), 2352. https://doi.org/10.3390/app9112352