Abstract

Due to the more powerful and miniaturized nature of modern devices, conventional heat-transfer working fluids are not capable of meeting the cooling needs of these systems. Therefore, it is necessary to improve the heat-transfer abilities of commonly used cooling fluids. Recently, nanoparticles with different characteristics have been introduced to base liquids to enhance the overall thermal conductivity. This paper studies the influence of various parameters, including base liquid, temperature, nanoparticle concentration, nanoparticle size, nanoparticle shape, nanoparticle material, and the addition of surfactant, on nanofluid thermal conductivity. The mechanisms of thermal conductivity enhancement by different parameters are discussed. The impact of nanoparticles on the enhanced thermal conductivity of nanofluids is clearly shown through plotting the thermal conductivities of nanofluids as a function of temperature and/or nanoparticle concentration on the same graphs as their respective base liquids. Additionally, the thermal conductivity of hybrid nanofluids, and the effects of the addition of carbon nanotubes on nanofluid thermal conductivity, are studied. Finally, modeling of nanofluid thermal conductivity is briefly reviewed.

1. Introduction

Conventional heat-transfer fluids, such as water, oil, and Ethylene Glycol, are widely used in numerous industries, including the fields of transportation, medicine, supply, heating, ventilation, and air conditioning (HVAC), power generation, chemical production and air-conditioning [1,2,3,4]. However, the low thermal conductivity of working fluids is a major limiting factor in design, limiting the compactness, efficiency, and capability of systems. High heat flux devices, including X-rays, high powered lasers, computers, and microelectronics are examples of technologies which are limited by the heat-transfer capabilities of currently available cooling fluids [2,5,6].

Miniaturization, power enhancement, and a possibility of increasing the efficiency of devices, motivated scientists to develop a new generation of working fluids, called suspension fluids. Initially, suspension fluids were fabricated by dispersing micro-scale particles within a base liquid. However, it has been found that suspending micro-scale sized solid particles in heat transfer fluids leads to problems such as sedimentation and erosion. By instead suspending nano-sized particles in heat transfer fluids, there is potential to avoid these problems while significantly enhancing the thermal conductivity [4]. Base fluids containing stably suspended nanoparticles, ranging from 1–100 nm in size, are called nanofluids [3,7]. Measurements of the thermal conductivities of micro-particle suspensions were first performed in the middle of the last century [8]. Generally, the nanofluid experiments need to be conducted with great care in a fume hood. It is necessary to be aware of particular dangers for humans and the environment before conducting any experiments using nanoparticles. Before conducting an experiment, the hazards identification, first aid measures, firefighting measures, accidental release measures, handling and storage, exposure controls and personal protection, physical and chemical properties, stability and reactivity, toxicological information, ecological information, disposal considerations, transport information and regulations need to be studied in detail, which nowadays can be found in Material Safety Data Sheets (MSDS).

Experimental data has shown that nanofluid thermal conductivity is a function of multiple parameters. This paper reviews and discusses the effects of different factors which influence the thermal conductivity of nanofluids, including the effects of characteristics of nanoparticles (size, shape, material), nanoparticle concentration, temperature, surfactant, and base liquid. The effects of the addition of carbon nanotubes on the thermal conductivity of a base liquid, along with the effects of adding multiple types of nanoparticles to a single base liquid to produce a hybrid nanofluid are also studied. Finally, the mechanisms which lead to increased nanofluid thermal conductivity are briefly discussed, along with the numerical models which describe these phenomena.

2. Nanofluid Thermal Conductivity

Experimentation has shown that nanofluid thermal conductivity is dependent upon base liquid [3,9,10,11,12,13,14,15], possible surfactant [16,17,18,19,20,21,22,23], concentration [1,3,4,7,8,9,10,11,13,15,16,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40], temperature [5,8,10,12,13,25,28,29,30,31,33,38,39,40,41], and characteristics of nanoparticles, such as nanoparticle size [3,4,7,11,20,25,28,32,35,36,42] and nanoparticle shape [16,25,43]. Interestingly, in some cases, experimental results are controversial. It has been observed that nanoparticle size and shape significantly influence the thermal conductivity of nanofluids whereas, surprisingly, nanoparticle material does not have a significant impact. It has been observed that temperature and nanoparticle volume concentration also significantly influence the thermal conductivity of nanofluids. The following section will discuss the aforementioned parameters which influence nanofluid thermal conductivity.

2.1. Effects of Nanoparticle Material on Nanofluid Thermal Conductivity

Researchers have conducted experiments to explore the effects of nanoparticle material on the thermal conductivity of nanofluids, interestingly finding that nanoparticle material alone is not an influential parameter and it does not significantly influence nanofluid thermal conductivity [8,26,32,36]. Several researchers have suggested that factors other than the intrinsic thermal conductivity of nanoparticles, such as nanoparticle size and clustering [26,32,36], have a more significant impact on nanofluid thermal conductivity. For example, Yoo et al. [36] studied the thermal conductivities of TiO2–water, Al2O3–water, Fe–Ethylene Glycol, and WO3–Ethylene Glycol nanofluids using the transient hot-wire method. It was observed that TiO2–water nanofluid had a higher thermal conductivity than Al2O3–water nanofluid, despite the higher intrinsic thermal conductivity of Al2O3 in comparison to TiO2. It was suggested that this was a result of the smaller size of the TiO2 nanoparticles (25 nm) in comparison to the Al2O3 nanoparticles (48 nm), resulting in a higher surface area to volume ratio in the TiO2–water nanofluid. It was also observed that Fe–Ethylene Glycol nanofluid had a higher thermal conductivity than WO3–Ethylene Glycol nanofluid. The size of the Fe nanoparticles (10 nm) was also smaller than that of the WO3 nanoparticles (38 nm). It was suggested that the thermal conductivity of the suspended nanoparticles does not have a primary effect on the thermal conductivity of nanofluids, but the surface area to volume ratio does have a strong influence on the thermal conductivity of a nanofluid. It was also suggested that the thermal conductivities of nanofluids containing metallic nanoparticles are higher than that of those containing ceramic nanoparticles. Using the same method, Pang et al. [32] measured the thermal conductivities of SiO2–methanol and Al2O3–methanol nanofluids. It was observed that SiO2–methanol nanofluid had a higher thermal conductivity despite alumina’s higher intrinsic thermal conductivity. It was suggested that this was a result of the formation of larger nanoparticle clusters in the SiO2–methanol nanofluid. These results agree with the idea that the thermal conductivity of nanofluids is impacted more significantly by factors other than the thermal conductivity of nanoparticles. In the same way, Xie et al. [26] measured the thermal conductivities of nanofluids composed of several oxide nanoparticles, including MgO, TiO2, ZnO, Al2O3 and SiO2, dispersed in Ethylene Glycol. Listed from highest to lowest, the intrinsic thermal conductivities of the nanoparticles were MgO, Al2O3, ZnO, SiO2, and TiO2. The thermal conductivities of the nanofluids, listed from highest to lowest, were MgO–Ethylene Glycol, Al2O3–Ethylene Glycol, TiO2–Ethylene Glycol, ZnO–Ethylene Glycol, and finally SiO2–Ethylene Glycol nanofluid. These results also support the idea that the thermal conductivity of nanofluids is affected more significantly by factors other than the intrinsic thermal conductivity of nanoparticles. However, in some cases experimental data has shown controversial results, in which nanofluid thermal conductivity increased with nanoparticle thermal conductivity. For example, using the transient hot-wire method, Iqbal et al. [37] measured the thermal conductivities of spherical Al2O3, SiO2, and ZrO2 nanoparticles dispersed in water. Due to the high density of ZrO2, yttrium oxide was used as a surfactant to aid in stability. The thermal conductivities of the nanoparticles listed from highest to lowest are Al2O3 > ZrO2 > SiO2. It was observed that Al2O3–water nanofluid had the highest thermal conductivity, and SiO2–water nanofluid had the lowest. Also, Chopkar et al. [4] measured the thermal conductivities of nanofluids composed of Ag2Al and Al2Cu dispersed in both water and Ethylene Glycol. They obtained measurements using a thermal comparator, which worked based on the principle that the total heat transferred by a hot probe was a function of both the thermal conductivity of the fluid and the thermal conductivity of the solid nanoparticles. When an electrically heated source was brought into contact with the fluid, a metallic copper probe sensed the temperature change through an attached thermocouple. The temperature was then measured and recorded through a circuit covering the probe assembly and nanofluid. Thermal conductivity values recorded were very high, with a thermal conductivity of 1.44 for Ag2Al–water nanofluid at nanoparticle volume concentration, and a thermal conductivity of 1.35 for Al2Cu nanofluid at the same nanoparticle volume concentration. Although no direct evidence was found, it was suggested that the formation of loose chain-like structures between nanoparticles may have caused the high thermal conductivity values by occupying more volume within the nanofluid than individual nanoparticles, thus allowing a greater area for heat transfer. It was observed that the nanofluids containing Ag2Al nanoparticles had higher thermal conductivities than those containing Al2Cu nanoparticles. Patel et al. [28] performed experiments to determine the thermal conductivities of Al2O3–water, Al2O3–Ethylene Glycol, CuO–transformer oil, Cu–water, Cu–Ethylene Glycol, Al–water, and Al–transformer oil nanofluids. The transient hot-wire method was used to obtain measurements for the oxide nanofluids, and temperature oscillation equipment was used for the metallic nanofluids. It was observed that nanofluids containing metallic nanoparticles had higher thermal conductivities than those containing oxide nanoparticles, which supports the observation made by Yoo et al. [36]. Additionally, using the transient hot-wire method, Sundar et al. [13] measured the thermal conductivity of magnetic Fe3O4 nanoparticles dispersed in a mixture of Ethylene Glycol and water. It was stated that an advantage to using magnetic nanoparticles is the possibility of separating the particles from the base fluid after the particles are fully dispersed. From the observations discussed above, it can be suggested that the intrinsic thermal conductivity of nanoparticles does not always have a significant influence on the thermal conductivity of nanofluids. However, further experimentation should be completed in order to determine the parameters which overpower the impact of nanoparticle material on nanofluid thermal conductivity.

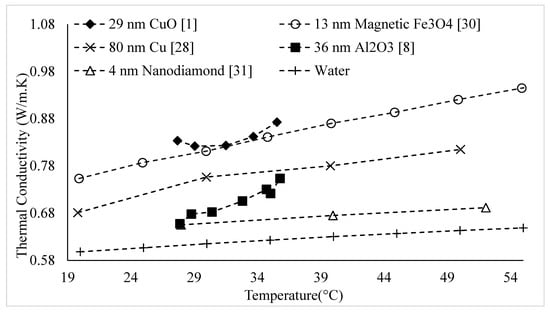

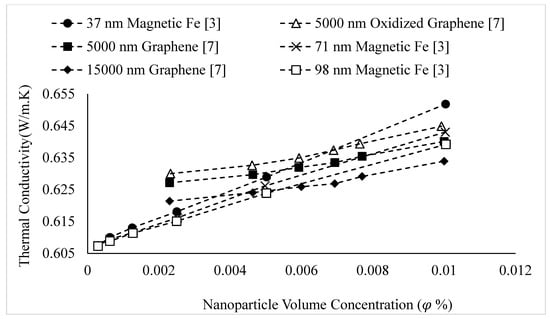

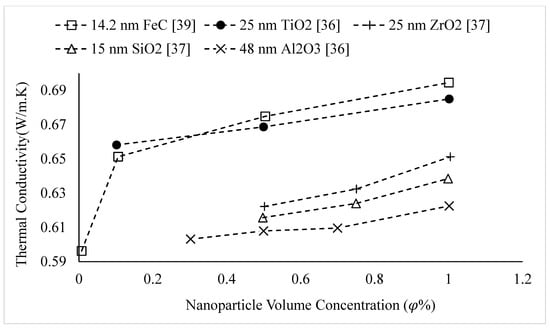

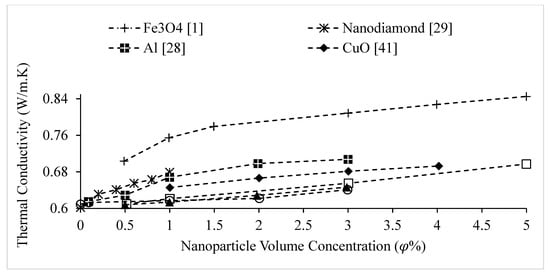

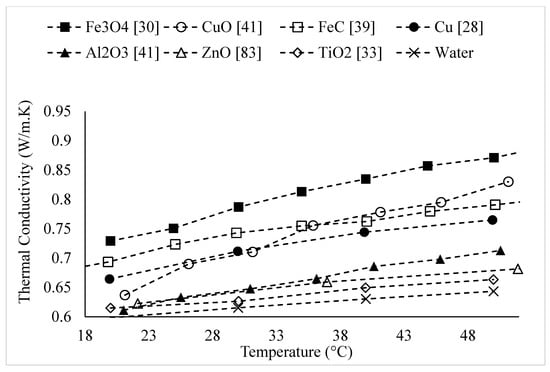

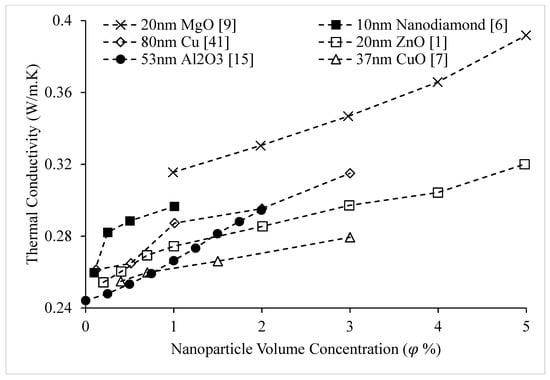

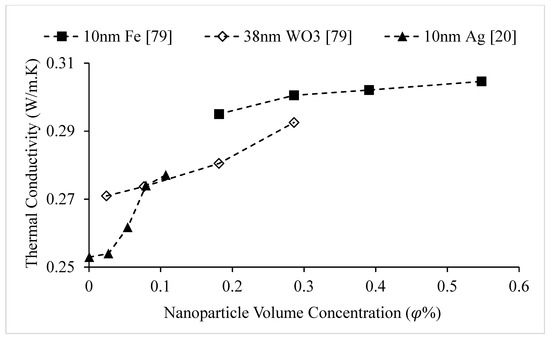

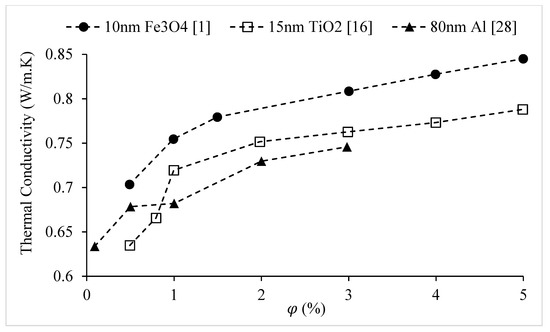

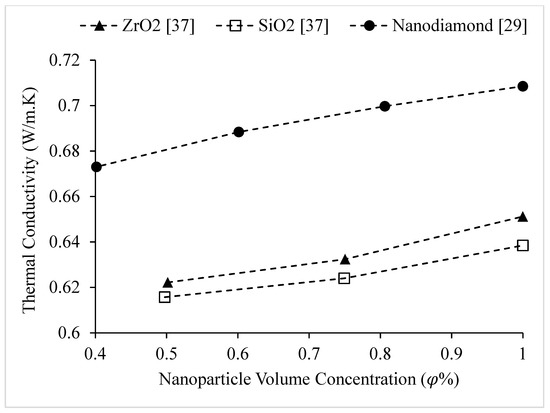

The thermal conductivities of water-based nanofluids containing various nanoparticles, are shown in Figure 1 as a function of temperature, at a nanoparticle volume concentration of It is observed that for a given temperature, the thermal conductivity of CuO–water nanofluid is higher than the thermal conductivity of Cu–water nanofluid. These results contradict -the observations made by Milanese et al. [44], who observed a thermal conductivity of 0.706 for 50 nm Cu nanoparticles dispersed in water, and a thermal conductivity of 0.67 for 30 nm CuO nanoparticles dispersed in water, at a nanoparticle volume concentration and a temperature of 30 °C. It is also observed that the thermal conductivity of nanodiamond–water nanofluid is very low despite the high intrinsic thermal conductivity of nanodiamond 1000 within the temperature range of 27–52 °C, for the thermal conductivity of nanodiamond–water nanofluid ranged from 0.66–0.69 . Yegameha et al. [29] also observed relatively low values for the thermal conductivity of nanodiamond–water nanofluids. Within the temperature range of 20–60 °C, for the thermal conductivity of nanodiamond–water nanofluid ranged from 0.67–0.80 . The thermal conductivities of nanofluids composed of various nanoparticles dispersed in water at room temperature are shown in Figure 2 as a function of nanoparticle volume concentration, for concentrations below It is observed that for a given nanoparticle concentration, 5000 nm oxidized graphene nanofluid has higher thermal conductivity than the nanofluid composed of unoxidized graphene nanoparticles having the same size, despite the nanoparticles having the same thermal conductivity. This may be a result of the greater stability of the nanofluid containing oxidized graphene nanoparticles. It is also observed that the thermal conductivity of 5000 nm graphene–water nanofluid is higher than that of 15,000 nm graphene–water nanofluid, which is likely caused by the smaller size of the 5000 nm particles. The thermal conductivities of nanofluids composed of various nanoparticles dispersed in water at room temperature are shown in Figure 3 as a function of nanoparticle volume concentration, for concentrations below It is observed that the thermal conducitivity of TiO2–water nanofluid is higher than that of Al2O3–water nanofluid. This may be a result of the smaller size of the TiO2 nanoparticles. The thermal conductivities of nanofluids composed of various nanoparticles dispersed in water at room temperature are shown in Figure 4 as a function of nanoparticle volume concentration, for concentrations below Despite the low thermal conductivity of Fe3O4 in comparison to other oxide nanoparticles, it is observed that the thermal conductivity of Fe3O4–water nanofluid is unexpectedly high. This may be a result of more significant clustering and alignment of the Fe3O4 nanoparticles in comparison to other oxide nanoparticles dispersed in water [1]. It is also observed that the thermal conductivity of Al–water nanofluid is higher than the thermal conductivities of nanofluids containing oxide nanoparticles, other than Fe3O4. This may be a result of the higher intrinsic thermal conductivity of metals in comparison to metal oxides. The thermal conductivities of water-based nanofluids containing various nanoparticles are shown in Figure 5 as a function of temperature, at a nanoparticle volume concentration of It is observed that for a given temperature, the thermal conductivity of Fe3O4–water nanofluid is higher than that of the CuO–water nanofluid. This observation is inconsistent with Figure 1, in which it is observed that the thermal conductivity of CuO–water nanofluid is slightly higher than that of Fe3O4–water nanofluid for a given temperature, at The thermal conductivities of nanofluids composed of various nanoparticles dispersed in Ethylene Glycol at room temperature are shown in Figure 5 as a function of nanoparticle volume concentration, for concentrations below . It is observed that nanodiamond–Ethylene Glycol nanofluid has a higher thermal conductivity than other nanofluids, besides MgO–Ethylene Glycol nanofluid, for a given nanoparticle volume concentration. The higher thermal conductivity of nanodiamond–Ethylene Glycol nanofluid may be a result of the combination of the high thermal conductivity of nanodiamond, and the strong compatibility between nanodiamond particles and Ethylene Glycol base fluid, which is caused by the carboxyl and hydroxyl groups on the surfaces of the nanodiamond particles having strong interactions with polar Ethylene Glycol in an alkaline environment (having a PH value higher than 7.0) [45]. It was also observed that for concentrations greater than the thermal conductivity of Al2O3–Ethylene Glycol nanofluid was higher than that of CuO–ethylene nanofluid. The opposite was observed for Al2O3–water and CuO–water in Figure 4. The thermal conductivities of nanofluids composed of various nanoparticles dispersed in Ethylene Glycol at room temperature are shown in Figure 6 and Figure 7 as a function of nanoparticle volume concentration, for concentrations below The Fe–Ethylene Glycol and WO3–Ethylene Glycol nanofluids contained no surfactant, whereas Gum Arabic surfactant was used in the Ag–Ethylene Glycol nanofluid. It was observed that the Gum Arabic surfactant did not have a significant impact on the thermal conductivity of the Ag–Ethylene Glycol nanofluid. The thermal conductivity of Ag–Ethylene Glycol nanofluid was not able to be tested at concentrations higher than those shown due to agglomeration and settling. The settling of nanoparticles resulted in lower concentrations of particles dispersed near the hot wire, leading to measurements showing a lower rate of increase in thermal conductivity at higher nanoparticle volume concentrations [23]. It is also observed that the thermal conductivity of Fe–Ethylene Glycol nanofluid is higher than that of WO3–Ethylene Glycol nanofluid. This may be a result of the smaller size of the Fe nanoparticles, and the metallic properties of the Fe nanoparticles. The thermal conductivity of nanoparticles is given in Table 1.

Figure 1.

Variation of water-based nanofluid thermal conductivity as a function of temperature for different nanoparticles at .

Figure 2.

Variation of water-based nanofluid thermal conductivity as a function of nanoparticle volume concentration, , for different nanoparticles at room temperature.

Figure 3.

Variation of water-based nanofluid thermal conductivity as a function of nanoparticle volume concentration, , for different nanoparticles at room temperature.

Figure 4.

Variation of water-based nanofluid thermal conductivity as a function of nanoparticle volume concentration, , for different nanoparticles at room temperature.

Figure 5.

Variation of water-based nanofluid thermal conductivity as a function of temperature for different nanoparticles at .

Figure 6.

Variation of Ethylene Glycol-based nanofluid thermal conductivity as a function of nanoparticle volume concentration, , for different nanoparticles at room temperature.

Figure 7.

Variation of Ethylene Glycol-based nanofluid thermal conductivity as a function of nanoparticle volume concentration, , for different nanoparticles at room temperature.

Table 1.

Nanoparticle thermal conductivity.

2.2. Effects of Nanoparticle Size on Nanofluid Thermal Conductivity

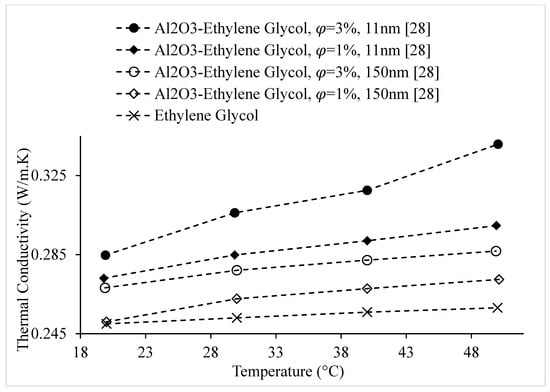

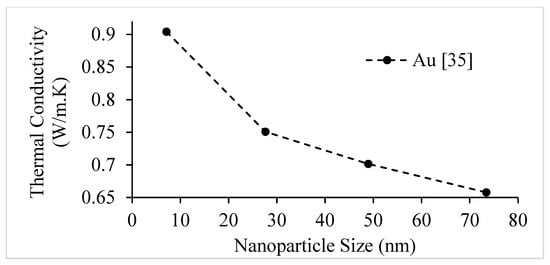

Researchers have observed that a greater surface area to volume ratio in nanofluids, resulting from nanoparticles of smaller sizes, leads to increased thermal conductivity [3,4,28,35,36]. Wang et al. [11] measured the thermal conductivities of Al2O3 and CuO nanoparticles dispersed in water, Ethylene Glycol, engine oil, and vacuum pump fluid. Measurements were obtained using the one-dimensional steady-state parallel-plate method. An increase in thermal conductivity with the decrease of nanoparticle size was observed. It was suggested that this relationship could be partially explained by stochastic and electrostatic forces only, having a strong influence on very small particles. Also, Park et al. [7] measured the thermal conductivity of graphene–water nanofluid, using 5000 nm graphene, 15,000 nm graphene, and oxidized 5000 nm graphene. The thermal conductivity of the 5000 nm graphene nanofluid was higher for a given nanoparticle volume concentration. It was suggested that the thermal conductivity of nanofluids increases with the decrease of nanoparticle size. In addition, Patel et al. [28] measured the thermal conductivities of Al2O3–water and Al2O3–Ethylene Glycol nanofluids as a function of nanoparticle size. The results, which are shown in Figure 8, indicated an increase in thermal conductivity with the decrease of nanoparticle size. It was suggested that the thermal conductivity enhancement was a result of the increased surface area to volume ratio, A/V, with the decrease of nanoparticle size, allowing more effective heat transfer to the base fluid. It was also suggested that increased Brownian motion with smaller nanoparticles led to the increased thermal conductivity. It was observed that the magnitude of Brownian motion was on the order of 10−4 for Al2O3–water nanofluid containing 150 nm particles and increased to the order of 10−2 for Al2O3–water nanofluid containing 11 nm particles. Using a KD2 Pro Thermal Property Analyzer, Esfe et al. [3] measured the thermal conductivity of Fe–water nanofluid as a function of nanoparticle volume concentration (, using 37 nm, 71 nm, and 98 nm Fe particles. The KD2 Pro Thermal Property Analyzer works based on the transient short hot-wire method. It was observed that for a given the thermal conductivity increased with the decrease of nanoparticle size. It was suggested that this increase was caused by the increased interfacial area between nanoparticles and base liquid for smaller particle sizes. Using the same method, Sharifpur et al. [42] studied the thermal conductivity of Al2O3–glycerol nanofluid. Experiments were conducted using Al2O3 nanoparticles of three different diameters, including 31 nm, 55 nm, and 134 nm. The results showed a relatively significant increase in thermal conductivity with the decrease in nanoparticle size. It was suggested that this increase was related to increased Brownian motion in nanofluids containing smaller nanoparticles. The Brownian motion diffusion coefficient was calculated using the Einstein–Stokes equation. The coefficient increased as the nanoparticle size decreased, indicating more significant collisions between the nanoparticles and base liquid molecules for smaller nanoparticles, resulting in enhanced thermal conductivity. Moreover, using the KD2 Pro Thermal Analyzer, Paul et al. [35] measured the thermal conductivity of Au–water nanofluid as a function of nanoparticle size. It was observed that the thermal conductivity increased with the decrease of nanoparticle size, which is shown in Figure 9. It was suggested that this increase was a result of increased Brownian motion and greater surface area to volume ratio for smaller nanoparticles. The thermal conductivities of Ag2Al–water, Ag2Al–Ethylene Glycol, Al2Cu–water, and Al2Cu–Ethylene Glycol nanofluids were measured by Chopkar et al. [4], as a function of nanoparticle size, within the range of 30–120 nm. The results indicated an increase in thermal conductivity with the decrease of nanoparticle size. It was suggested that this was a result of the larger surface area of nanoparticles and greater stability in suspensions in comparison to coarse particles. Pang et al. [32] measured the thermal conductivities of SiO2–methanol and Al2O3–methanol nanofluids as a function of nanoparticle volume concentration, . The SiO2 nanoparticles had diameters of 10–20 nm, and the Al2O3 nanoparticles had diameters of 40–50 nm. Dynamic light scattering was used to measure the cluster sizes of the nanoparticles dispersed in methanol, and it was observed that the clustering size of SiO2 nanoparticles was 280–401nm, while that of the Al2O3 nanoparticles was 120–148 nm for a given condition. It was suggested that the larger formation of clusters in the SiO2 nanofluid was a result of the smaller size of SiO2 nanoparticles in comparison to the Al2O3 nanoparticles. It was observed that for a given the SiO2–methanol nanofluid had a higher thermal conductivity. It was suggested that the higher thermal conductivity of SiO2–methanol nanofluid was a result of the larger cluster size of the nanoparticles in comparison to the clusters formed in the Al2O3–methanol nanofluid. Yoo et al. [36] measured the thermal conductivities of TiO2–water, Al2O3–water, Fe–Ethylene Glycol, and WO3–Ethylene Glycol nanofluids as a function of nanoparticle volume concentration. It was observed that TiO2–water nanofluid had a higher thermal conductivity than Al2O3–water nanofluid for a given It was also observed that Fe–Ethylene Glycol nanofluid had a higher thermal conductivity than WO3–Ethylene Glycol nanofluid for a given . TiO2 has a lower intrinsic thermal conductivity than Al2O3; however, the TiO2 nanoparticles (25 nm) were smaller in size than the Al2O3 nanoparticles (48 nm), resulting in a higher thermal conductivity for TiO2 nanofluid. It was also suggested that the smaller size of the Fe nanoparticles (10 nm) in comparison to that of the WO3 nanoparticles (38 nm) contributed to the higher thermal conductivity of Fe–Ethylene Glycol nanofluid in comparison to that of WO3–Ethylene Glycol nanofluid. It was stated that these results showed the strong effect of surface area-to-volume ratio of nanoparticles on the thermal conductivity of nanofluids [36]. Using the transient hot-wire method, Maheshwary et al. [25] conducted experiments to determine the thermal conductivity of TiO2–water nanofluid. It was observed that the thermal conductivity increased with decrease in nanoparticle size. It was suggested that this relationship was related to greater Brownian motion for smaller nanoparticles. Xia et al. [20] measured the thermal conductivities of Al2O3–water nanofluids, using 13 nm and 20 nm Al2O3 particles, containing both sodium dodecyl sulphate (SDS) and polyvinyl pyrrolidone (PVP) as surfactants. For a given surfactant concentration, it was observed that the nanofluids containing 13 nm particles had higher thermal conductivities. However, in some cases, researchers found that the thermal conductivity of nanofluids did not increase with the decrease in nanoparticle size. Xie et al. [48] measured the thermal conductivities of Al2O3–Ethylene Glycol nanofluids containing 5 nm, 25 nm, 58 nm, and 101 nm particles using the transient hot-wire method. It was observed that the thermal conductivities of the nanofluids, from highest to lowest, were those containing 25 nm particles, 5 nm particles, 58 nm particles, and finally 101 nm particles. It was suggested that these results were caused by a combination of the surface area to volume ratio and phonon scattering. The scattering of the primary carriers of energy at the boundaries of nanoparticles is called phonon scattering [48]. As the nanoparticle size decreases, the surface area to volume ratio increases, which allows for more effective heat transfer at the solid–liquid interface, leading to increased thermal conductivity. However, the intrinsic thermal conductivity of the nanoparticles decreases due to phonon scattering when the nanoparticle size is close to that of the mean free path, which was estimated to be around 35 nm. Although existing experimental data indicates that the effect of nanoparticle material on the thermal conductivity of nanofluids is not very strong [26,32,36], it was suggested that phonon scattering had a significant impact on these experimental results. Beck et al. [49] measured the thermal conductivities of nanofluids composed of 8 nm, 12 nm, 16 nm, 46 nm, 71 nm, 245 nm, and 282 nm Al2O3 particles dispersed in water, and 12 nm, 16 nm, 245 nm, and 282 nm Al2O3 particles dispersed in Ethylene Glycol using a liquid metal transient hot-wire device. It was observed that the thermal conductivity was almost constant with the decrease in nanoparticle size for nanofluids containing nanoparticles with a size greater than 50 nm. For nanofluids containing particles having a size smaller than approximately 50 nm, it was observed that the thermal conductivity of the nanofluid decreased with decrease in nanoparticle size. It was suggested that this was a result of the decreased intrinsic thermal conductivity of nanoparticles when the nanoparticles became small enough to be affected by phonon scattering. Nisha et al. [50] measured the thermal conductivities of nanofluids composed of TiO2 nanoparticles dispersed in water and polyvinyl alcohol (PVA) as a function of nanoparticle size, for nanoparticles, ranging from 5–100 nm. It was observed that the thermal conductivity of TiO2–PVA nanofluid increased with the decrease of nanoparticle size. It was suggested that this increase was a result of liquid adsorption layers forming around the surfaces of the nanoparticles. At smaller nanoparticles sizes, the adsorption layers formed an easy path for heat transfer, due to the large surface area to volume ratio of the nanoparticles and the high viscosity of the base fluid. As the nanoparticle size increased, the adsorption layers became thinner, making a less effective heat transfer path. It was also suggested that Kapitza resistance led to the decrease in thermal conductivity at larger nanoparticle sizes, due to thermal waves scattering at the base liquid-nanoparticle boundaries. However, it was observed that the thermal conductivity of TiO2–water nanofluid increased with increased nanoparticle size. It was suggested that this increase was caused by nanoparticle clustering. The conflicting relationships between PVA- and water-based nanofluids were explained by the higher viscosity of PVA in comparison to water allowing a thicker adsorption layer to form around the nanoparticles. From the experimental observations discussed above, it can be suggested that smaller nanoparticle size leads to increased thermal conductivity. However, more experimentation should be completed to determine the significance of phonon scattering in nanofluid thermal conductivity.

Figure 8.

Variation of Al2O3–Ethylene Glycol nanofluid thermal conductivity as a function of temperature, for with 11 nm diameter and 150 nm diameter particles.

Figure 9.

Variation of Au–water nanofluid thermal conductivity at room temperature as a function of nanoparticle size, for a nanoparticle volume concentration of .

2.3. Effects of Nanoparticle Shape on Nanofluid Thermal Conductivity

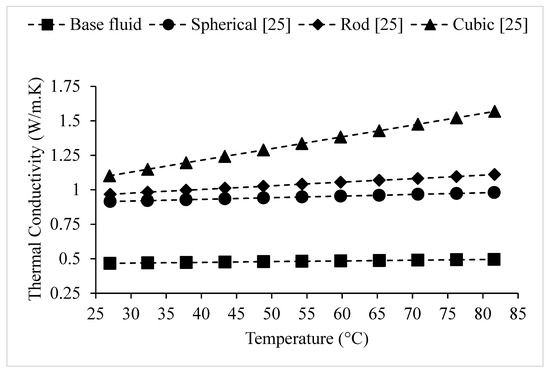

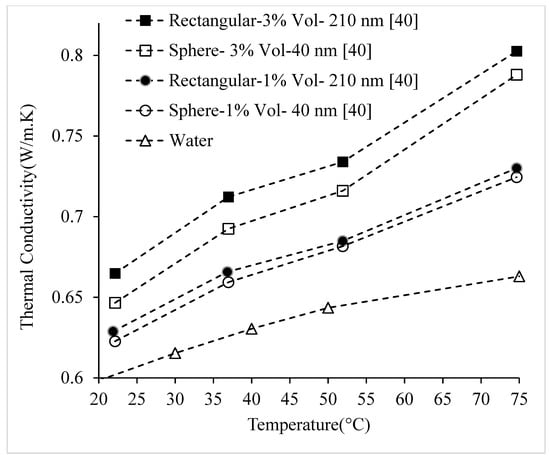

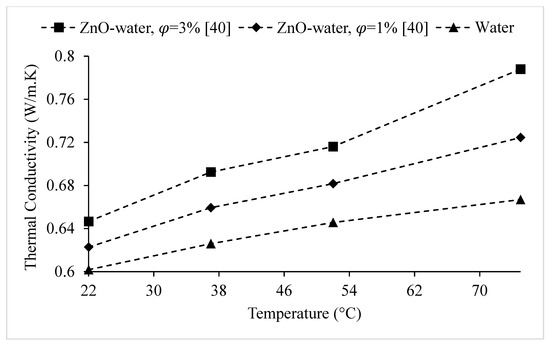

Researchers have observed that nanofluids having nanoparticles with greater surface area to volume ratios, have higher thermal conductivities [25,43]. Maheshwary et al. [25] studied the thermal conductivity of TiO2–water nanofluid using cubic (51.87 nm), rod (43.08 nm), and spherical (22.9 nm) nanoparticles. It was observed that the nanofluid containing cubic nanoparticles had the highest thermal conductivity and that containing spherical nanoparticles had the lowest, which is shown in Figure 10. It was suggested that the significant impact of nanoparticle shape on thermal conductivity was related to the difference in surface area. Some benefits of using spherical nanoparticles in nanofluids include their superior stability to other shapes and fewer issues with clogging. A downside to using cubic nanoparticles is high cost. Similarly, using the transient hot-wire method, Murshed et al. [16] tested the thermal conductivity of TiO2–water nanofluid containing rod-shaped and spherical nanoparticles. The spherical nanoparticles had an average diameter of 15 nm. The rod-shaped nanoparticles had an average diameter of 10 nm and an average length of 40 nm. Cetyl trimethyl ammonium bromide (CTAB) was used as a surfactant to create a more stable nanofluid. For a given particle concentration, it was observed that the nanofluid containing rod-shaped nanoparticles had a higher thermal conductivity. It was suggested that this difference was related to the larger size of the rod-shaped nanoparticles in comparison to the spherical nanoparticles. Kim et al. [24] measured the thermal conductivity of Al2O3–water nanofluid, using brick, platelet, and blade shaped nanoparticles. It was observed that nanofluid containing brick-shaped nanoparticles had the highest enhancement in thermal conductivity, while nanofluid containing blade-shaped nanoparticles had the lowest. It was suggested that thermal conductivity is related to suspension stability which is affected by nanoparticle shape. The nanofluid containing brick-shaped nanoparticles had the highest stability, while nanofluid containing blade-shaped nanoparticles had the lowest stability. Timofeeva et al. [43] measured the thermal conductivity of nanofluid composed of Al2O3 nanoparticles dispersed in 50:50 volume Ethylene Glycol–water using the transient hot-wire method. It was observed that nanofluid containing cylinder-shaped nanoparticles (80 × 10 nm) had the highest thermal conductivity, followed by that containing brick-shaped nanoparticles (40 nm). The nanofluid containing blade-shaped (60 × 10 nm) nanoparticles had a lower thermal conductivity than those of cylindrical and brick-shaped nanofluids. It was suggested that increased nanoparticle surface area leads to higher thermal conductivity. Jeong et al. [40] conducted experiments to determine the thermal conductivity of ZnO–water nanofluid using both spherical and rectangular nanoparticles. The results are shown in Figure 11. The spherical nanoparticles had an average size of 20–40 nm, and rectangular nanoparticles had an average size of 90–210 nm. For a given volume fraction and temperature, the thermal conductivity of nanofluid containing rectangular nanoparticles was higher. It was suggested that the relationship between thermal conductivity and nanoparticle shape was related to the change in effective aggregate radius of the nanofluid with the change of nanoparticle shape. It was suggested that nanoparticle shape has a stronger influence on thermal conductivity than nanoparticle size. From the above discussed experimental observations, it can be concluded the nanoparticles having greater surface area lead to higher nanofluid thermal conductivity. However, further experimentation should be completed in order to determine the effects of nanoparticle shape on nanofluid stability.

Figure 10.

Effect of nanoparticle shape on the thermal conductivity of TiO2–water nanofluid at %, as a function of temperature.

Figure 11.

Effect of nanoparticle shape on the thermal conductivity of ZnO–water nanofluid as a function of temperature.

2.4. Effects of Base Liquid on Nanofluid Thermal Conductivity

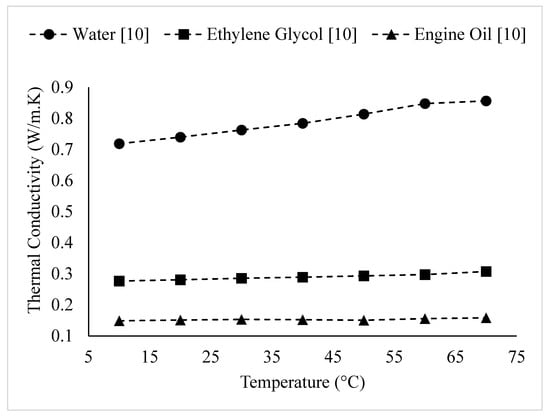

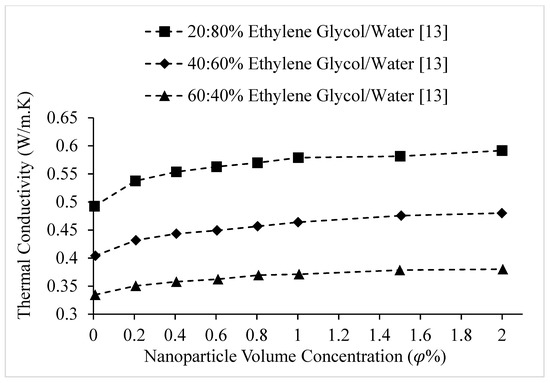

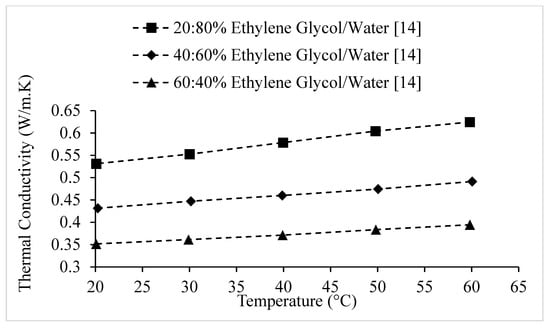

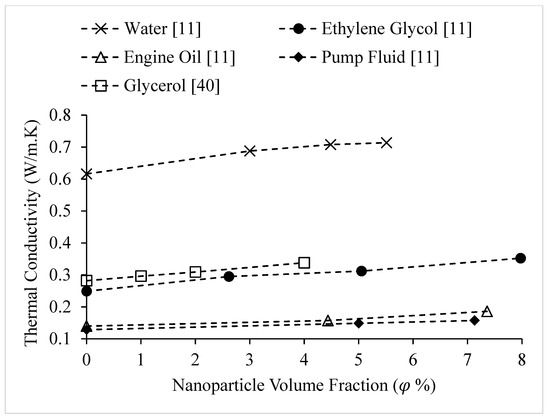

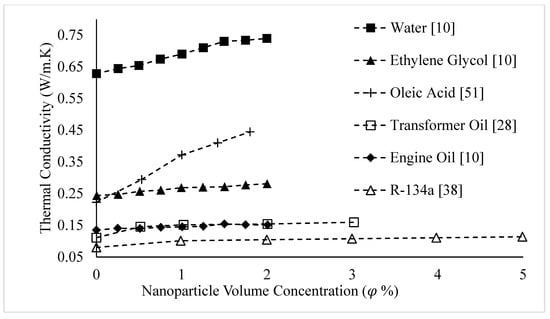

Researchers have observed that the thermal conductivity of nanofluids increases with the thermal conductivity of the base liquid [3,9,10,11,12,13,14,15]. For example, Barbés et al. [9] measured the thermal conductivities of CuO–water and CuO–Ethylene Glycol nanofluids. It was observed that for a given volume fraction and temperature, the thermal conductivity of CuO–water nanofluid was higher. Also, Agarwal et al. [10] measured the thermal conductivities of CuO nanofluids, mixing CuO nanoparticles with water, Ethylene Glycol, and engine oil. The results are shown in Figure 12. The observations agreed with those of Barbés et al. [9], with the thermal conductivity of CuO–water nanofluid being higher than that of CuO–Ethylene Glycol nanofluid. The results showed that CuO–engine oil nanofluid had the lowest thermal conductivity. It was suggested that the variation in nanofluid thermal conductivity with different base fluids was related to the different thermal conductivities of the base fluids and the strength of interactions between the CuO nanoparticles and base fluids [10]. Wang et al. [11] measured the thermal conductivities of CuO–water, CuO–Ethylene Glycol, Al2O3–water, Al2O3–Ethylene Glycol, Al2O3–pump fluid, and Al2O3–engine oil nanofluids. The observations also reinforced the findings of Barbés et al. [9] and Agarwal et al. [10], with the thermal conductivities of water-based nanofluids being higher than those of Ethylene Glycol-based nanofluids for both CuO and Al2O3 nanoparticles, at a given volume fraction. Al2O3–engine oil and Al2O3-Pump Fluid nanofluids had lower thermal conductivities than Al2O3-Ethylene Glycol nanofluid. The thermal conductivity of Al2O3–engine oil nanofluid was slightly higher than that of the pump fluid-based nanofluid. It was suggested that the thermal conductivity of a nanofluid increases with the thermal conductivity of the base liquid [11]. Additionally, Agarwal et al. [12] observed that the thermal conductivity of Al2O3–water nanofluid was higher than that of Al2O3–Ethylene Glycol nanofluid, which agrees with the findings of Wang et al. [11]. Chopkar et al. [4] measured the thermal conductivities of Al2Cu and Ag2Al nanoparticles dispersed in Ethylene Glycol and water. It was again observed that water-based nanofluids had higher thermal conductivities than Ethylene Glycol-based nanofluids [4]. Sundar et al. [13] measured the thermal conductivity of magnetic Fe3O4 nanoparticles dispersed in 20%:80%, 40%:60% and 60%:40% by weight Ethylene Glycol–water mixtures. The results, shown in Figure 13, indicated that the thermal conductivity decreased as the amount of Ethylene Glycol in the mixture increased. It was suggested that this was a result of the lower thermal conductivity of Ethylene Glycol in comparison to water. Additionally, Sundar et al. [14] measured the thermal conductivity of nanodiamond particles dispersed in 20%:80%, 40%:60% and 60%:40% by weight Ethylene Glycol–water mixtures. The results, shown in Figure 14, reinforce the results shown in Figure 13 for nanofluid containing Fe3O4 particles. Yu et al. [15] studied the variation of thermal conductivity as a function of temperature for aluminum nitride–Ethylene Glycol and aluminum nitride–propylene glycol nanofluids in comparison to that of the base liquids (Ethylene Glycol and propylene glycol). The thermal conductivity of aluminum nitride–Ethylene Glycol nanofluid was higher for a given temperature, which is consistent with the conclusion that the thermal conductivity of a nanofluid increases with the thermal conductivity of the base liquid. The thermal conductivities of the nanofluids were higher than that of the base fluids for a given temperature. The slope of the thermal conductivity as a function of temperature for each nanofluid and respective base fluid were nearly the same.

Figure 12.

Variation of CuO nanofluid thermal conductivity as a function of temperature for different base liquids, at

Figure 13.

Variation of Fe3O4 nanofluid thermal conductivity as a function of nanoparticle volume fraction, for different weight concentrations of Ethylene Glycol/water base liquid, at 20 °C.

Figure 14.

Variation of nanodiamond nanofluid thermal conductivity as a function of temperature, for different weight concentrations of Ethylene Glycol/water base liquid, at .

Figure 15 and Figure 16 show that the thermal conductivity of the base liquid has a significant impact on nanofluid thermal conductivity enhancement. The thermal conductivities of nanofluids composed of CuO nanoparticles dispersed in various base liquids are shown in Figure 16 as a function of nanoparticle volume concentration, . The thermal conductivities of the base fluids are shown at . It is observed that the thermal conductivity of nanofluids increases with the thermal conductivity of the base fluid. The low rate of increase in thermal conductivity with concentration for engine oil-based nanofluid may be a result of weak interactions between the CuO nanoparticles and engine oil causing a weak interfacial layer. The observations of Figure 16 are reinforced by Figure 15. Figure 15 shows the thermal conductivities of nanofluids composed of Al2O3 nanoparticles dispersed in various base liquids as a function of nanoparticle volume concentration, . The thermal conductivity of base liquids is given in Table 2.

Figure 15.

Variation of alumina nanofluid thermal conductivity as a function of nanoparticle volume fraction,, for different base liquids, at room temperature.

Figure 16.

Variation of CuO nanofluid thermal conductivity as a function of nanoparticle volume fraction,, for different base liquids, at room temperature.

Table 2.

Thermal conductivity of base liquids.

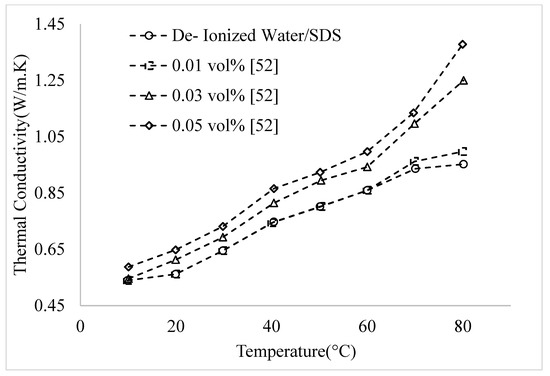

2.5. Effects of Surfactant on Nanofluid Thermal Conductivity

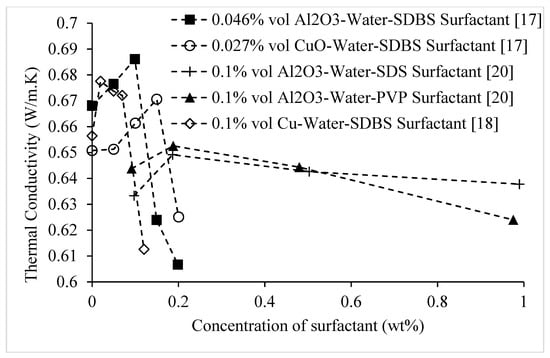

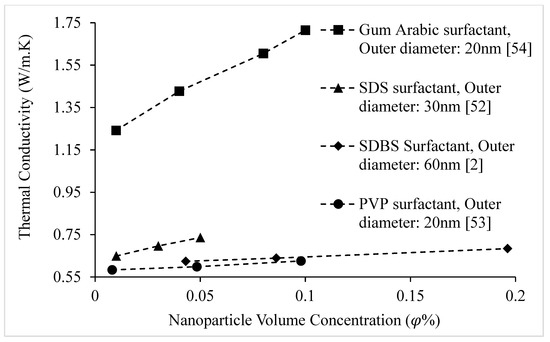

Scientists have studied the effects of various surfactants on the thermal conductivity of nanofluids [16,17,18,19,20,21,22,23]. Surfactant was mixed with the base liquid of various nanofluids in order to produce a uniform distribution of nanoparticles, and to prevent the agglomeration of nanoparticles. The high surface energy of nanoparticles leads to agglomeration and settling, thus resulting in a lack of stability in nanofluids. Low stability in nanofluids leads to low thermal conductivity. Thus, surfactants are added with the goal of creating more stable nanofluids, and in turn increasing the thermal conductivity [18]. Several researchers have observed that surfactants aid in preventing the agglomeration of nanoparticles but can lead to decrease thermal conductivity at higher concentrations. Using the transient hot-wire method, Murshed et al. [16] measured the thermal conductivity of TiO2–water nanofluid using oleic acid (OA) and CTAB as surfactants. The surfactants were used at very low concentrations, between 0.01 and 0.02 volume percent, in order to avoid altering the heat transfer characteristics of the nanofluid. CTAB was found to be a more effective surfactant in producing a stable nanofluid, by preventing nanoparticle clustering and in turn creating a homogeneous distribution of nanoparticles throughout the base liquid. Using a KD2 Pro Thermal Property Analyzer, Khairul et al. [17] measured the thermal conductivities of CuO–water and Al2O3–water nanofluids containing sodium dodecyl benzene sulfonate (SDBS) surfactant as a function of surfactant weight concentration. The addition of the negatively charged surfactant altered the surface charges of the positively charged CuO and Al2O3 nanoparticles, creating repulsion forces between the nanoparticles. The repulsion forces prevented clustering of the nanoparticles, and in turn led to a more stable nanofluid with higher thermal conductivity. It was suggested that ideal thermo-physical properties can be obtained by creating optimal surface charges on the nanoparticles. It was observed that the thermal conductivity of the nanofluid increased up to 0.1 W% for Al2O3–water nanofluid, and up to 0.15 W% for CuO–water nanofluid. Above these concentrations, the thermal conductivity of the nanofluid decreased significantly. It was suggested that this decrease was caused by the greater amount of surfactant on the surfaces of the nanoparticles leading to a narrower available area for heat transfer. Wang et al. [18] measured the thermal conductivities of Al2O3–water and Cu–water nanofluids containing SDBS surfactant. Measurements were obtained using a hot-disk thermal constant analyzer, which worked based on the transient plane source method. It was observed that higher stability in a nanofluid leads to higher thermal conductivity. It was suggested that finding the optimal pH and surfactant concentration can lead to increased thermal conductivity by altering the surface charges of the nanoparticles to prevent agglomeration. The thermal conductivity was measured as a function of surfactant concentration. It was observed that the thermal conductivity increased with surfactant concentration up to approximately 0.03 W% surfactant for both nanofluids. Above this concentration, the thermal conductivity decreased with the increase of surfactant concentration. It was suggested that this decrease was caused by the amount of surfactant on the surfaces of the nanoparticles allowing a narrow area for heat transfer. Using a KD2 Pro Thermal Property Analyzer, Adabi et al. [19] measured the thermal conductivity of Mg (OH)2–water nanofluid. The stability of the nanofluid was tested using CTAB, SDS, and OA as surfactants at volume fractions of 0.02%. It was observed that CTAB surfactant produced the most stable nanofluid. The nanofluid containing CTAB surfactant remained stable over a 30 days period, during which it was observed. Mg (OH)2–water nanofluid without surfactant only remained stable for 1 day. The thermal conductivity of the nanofluid without surfactant was not measured. However, it was suggested that due to the increase in stability of the nanofluid with the addition of surfactant, the thermal conductivity of Mg (OH)2–water nanofluid containing CTAB surfactant would be higher than that without. Xia et al. [20] measured the thermal conductivity of Al2O3–water nanofluid containing SDS and polyvinylpyrrolidone (PVP) as surfactants. Measurements were obtained using a hot-disk thermal constant analyzer. It was observed that the thermal conductivity of the base liquid, water, decreased with increasing surfactant concentration, for both SDS and PVP. The thermal conductivity of water decreased more rapidly with the increased concentration of PVP surfactant, in comparison to the addition of SDS surfactant. It was suggested that this difference was caused by the longer alkyl chain in the PVP solution. It was observed that the thermal conductivity of Al2O3–water nanofluid increased with the surfactant concentration up to a maximum point, and then began to decrease. It was suggested that this decrease was caused by supersaturated adsorption leading to weaker heat transfer between the nanoparticles, and greater amounts of surfactant on the nanoparticle surfaces, allowing a narrower area for heat transfer. It was observed that both surfactants improved the stability of the nanofluid by forming a layer on the surfaces of the nanoparticles which prevented agglomeration. Using the transient hot-wire method, Colangelo et al. [21] measured the thermal conductivities of Al2O3–therminol 66 nanofluid containing no surfactant and containing OA surfactant. Therminol 66 is usually applied in high temperature solar energy systems. It was observed that for the nanoparticle volume concentrations of , the thermal conductivities of nanofluids containing surfactant were higher than those containing no surfactant, with a greater difference between the nanofluids with and without surfactant at However, for the thermal conductivity of the nanofluid containing no surfactant was higher than the thermal conductivity of the nanofluid containing surfactant. It was stated that the differences between the thermal conductivities of the nanofluids with and without surfactants were within the error of the measuring instrument for all nanoparticle volume concentrations tested. Therefore, it was suggested that the effect of surfactant on the thermal conductivity of nanofluids is negligible. It was stated that adding larger amounts of surfactant would not be beneficial in Al2O3–oil nanofluids, because it leads to a narrower heat transfer area, due to the amount of surfactant on the surfaces of the nanoparticles. It was observed that over a time period of 8 days, the nanofluid containing surfactant remained stable, while greater sedimentation was observed in the nanofluid containing no surfactant. It was suggested that the surfactant molecules on the surfaces of the nanoparticles created bonds between the nanoparticles and the base liquid, and limited aggregation, leading to more stable suspensions. Using a KD2 Pro Thermal Property Analyzer, Huminic et al. [39] measured the thermal conductivity of FeC–water nanofluid as a function of temperature and nanoparticle volume concentration. Due to the carbon-rich nature of FeC particles, low viscosity carboxymethyl cellulose sodium salt was used as a surfactant. The surfactant was used in a concentration of 3 g/L. It was observed that the surfactant itself did not have a significant effect on the thermal conductivity of the base fluid. However, it was suggested that the surfactant may have indirectly influenced the thermo-physical properties of the nanofluid by improving the stability. Das et al. [33] tested the stability of TiO2–water nanofluid using CTAB, acetic acid (AA), OA, and SDS as surfactants. It was observed that only AA and CTAB surfactants produced stable nanofluids. In some cases, researchers have observed negative effects of surfactants on the thermal conductivity of nanofluids. Using a KD2 Pro Thermal Property Analyzer, Das et al. [22] measured the thermal conductivity of Al2O3–water nanofluid as a function of temperature and nanoparticle volume concentration. The stability of the nanofluid was tested using CTAB, SDBS, and SDS as surfactants. It was observed that SDS and CTAB surfactants did not increase stability of the nanofluid. SDBS surfactant showed the highest stability, yielding a more homogeneous distribution of nanoparticles within the base liquid. It also aided in the reduction of particle clustering. However, it was observed that the effective nanoparticle sizes were larger, due to surfactant layers on the surfaces of the nanoparticles. At a given temperature and volume fraction, the nanofluid containing SDBS surfactant had slightly lower thermal conductivity than the nanofluid containing no surfactant. Using the transient hot-wire method, Seyhan et al. [23] measured the thermal conductivities of Ag–Ethylene Glycol, Ag–hexane, and Ag–water nanofluids. OA, oleylamine, and Gum Arabic were used as surfactants to aid in stability. It was observed that surfactant had no effect on the thermal conductivities of Hexane and Ethylene Glycol. The thermal conductivity of water decreased with the addition of Gum Arabic surfactant, due to the lower thermal conductivity of the surfactant in comparison to water. From the experimental observations discussed above, it can be suggested that surfactant, when used at an optimum concentration, can create uniform, stable suspensions in a nanofluid, which in turn leads to increased thermal conductivity. However, further experimentation should be completed in order to determine the optimum surfactant concentration.

The effects of various surfactants on the thermal conductivities of nanofluids composed of CuO, Cu, and Al2O3 nanoparticles dispersed in water at room temperature are shown in Figure 17. It is observed that the thermal conductivity of nanofluids increases with surfactant concentration up to a maximum value, and then decreases. The decrease in thermal conductivity at higher concentrations of surfactant may be a result of the greater amount of surfactant present on the surfaces of the nanoparticles allowing a narrower area for heat transfer. Brief discussion of effects of surfactant on thermal conductivity of nanofluids is given in Table 3.

Figure 17.

Effect of surfactant on the thermal conductivity of CuO–water and Al2O3–water nanofluids at room temperature, as a function of surfactant weight concentration.

Table 3.

Effects of surfactant on nanofluids.

2.6. Effects of Concentration of Nanoparticles on Nanofluid Thermal Conductivity

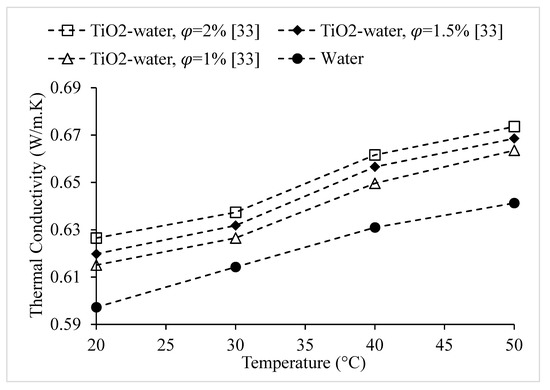

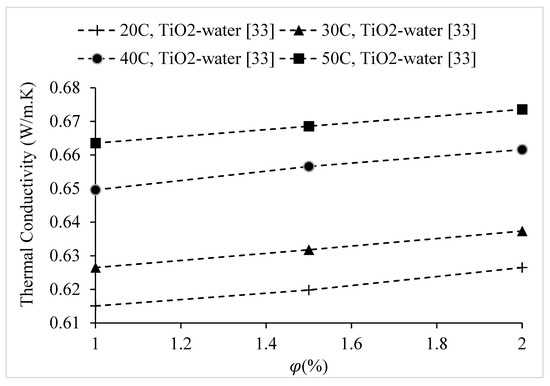

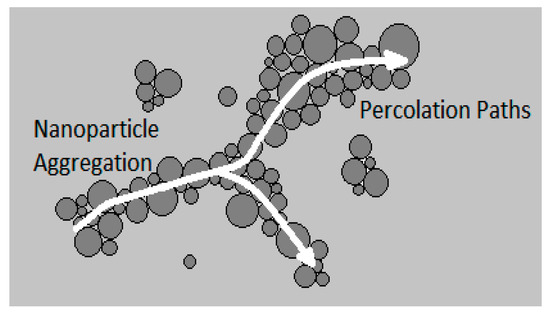

In general, experimental data has shown that nanofluid thermal conductivity increases with nanoparticle volume fraction [1,3,4,7,8,9,10,11,13,15,16,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40]. However, in some cases researchers have observed a linear relationship between thermal conductivity and nanoparticle concentration [3,9,15,22,37,38,39,40], whereas in other cases a non-linear relationship has been observed [1,4,7,8,11,13,16,23,26,27,28,29,30,31,32,33,34,35,36]. Using the transient line heat source method, Agarwal et al. [10] measured the thermal conductivities of CuO–water, CuO–Ethylene Glycol, and CuO–engine oil nanofluids. For all nanofluids tested, the thermal conductivity increased with concentration. It was suggested that this relationship was a result of increased available surface area for heat transfer at higher nanoparticle concentrations. Using the transient hot-wire method, Kim et al. [24] studied the thermal conductivity of Al2O3–water nanofluid containing brick, platelet and blade nanoparticles. For all nanoparticle shapes, the thermal conductivity increased with the increase of nanoparticle concentration. Maheshwary et al. [25] measured the thermal conductivity of TiO2–water nanofluid as a function of nanoparticle volume concentration using nanoparticles of irregular shape with the same average size. It was observed that the thermal conductivity increased with particle concentration. It was suggested that nanoparticle concentration had a more significant effect on thermal conductivity than particle shape and size. In many experiments, a non-linear relationship between the concentration of nanoparticles and nanofluid thermal conductivity has been observed, which is likely due to greater agglomeration at higher nanoparticle concentrations. Xie et al. [26] measured the thermal conductivity of MgO–Ethylene Glycol nanofluid as a function of nanoparticle concentration. It was observed that at concentrations below change in thermal conductivity for the nanofluid was more rapid than at higher concentrations. This result was attributed to increased particle agglomeration at higher concentrations. Using the transient hot-wire method, Seyhan et al. [23] measured the thermal conductivity of hydrophobic Ag–hexane and hydrophilic Ag–Ethylene Glycol nanofluids as a function of nanoparticle concentration. For both nanofluids, the thermal conductivity increased with the increase of particle concentration, however, the rate of increase in thermal conductivity slowed at higher concentrations. It was suggested that the decelerated rate of increase was related to agglomeration and settling of nanoparticles at higher concentrations. Using the same method, Yu et al. [27] studied the thermal conductivity of ZnO–Ethylene Glycol nanofluid. A non-linear increase in thermal conductivity with nanoparticle concentration was observed. Two different linear relationships were found, one at lower concentrations, and one at higher concentrations. The linear relationship at lower concentrations had a higher slope than the linear relationship at higher concentrations. Patel et al. [28] measured the thermal conductivities of CuO–transformer oil, Al2O3–water, Cu–Ethylene Glycol, and Al–water nanofluids as a function of nanoparticle concentration. For all nanofluids tested, the thermal conductivity increased with concentration. However, it was observed that the increase in thermal conductivity was relatively higher at low nanoparticle concentrations, which reinforces the observations of Xie et al. [26], Seyhan et al. [23], and Yu et al. [27]. Sundar et al. [29] measured the thermal conductivity of nanodiamond–water nanofluid using the transient hot-wire method. It was observed that the thermal conductivity increased with concentration. However, contrary to the previously discussed observations, it was observed that the enhancement in thermal conductivity was greater at higher concentrations. It was suggested that this was caused by agglomeration of the nanodiamond particles. Agarwal et al. [12] measured the thermal conductivities of Al2O3–water and Al2O3–Ethylene Glycol nanofluids using KD2 Pro equipment which worked based on the transient line heat source method. For both nanofluids, the thermal conductivity increased with nanoparticle concentration. The Ethylene Glycol-based nanofluid showed a more rapid increase. At higher concentrations, the results showed a more significant increase in thermal conductivity with nanoparticle concentration, which agrees with the observations of Sundar et al. [29]. It was suggested that Ethylene Glycol-based nanofluid would be a more appropriate choice for applications involving rapid changes in particle concentration. Harikrishnan et al. [51] measured the thermal conductivity of CuO–oleic acid nanofluid using the LFA 447 NanoFlash Analyzer. It was observed that at low concentrations, the thermal conductivity increased linearly with concentration. At higher concentrations, the thermal conductivity increased non-linearly with concentration. It was suggested that this relationship was a result of nanoparticle agglomeration at high concentrations. Murshed et al. [16] measured the thermal conductivity of TiO2–water nanofluid containing CTAB surfactant. The results showed a non-linear increase in thermal conductivity with the increase of particle concentration at concentrations below and a linear increase at higher concentrations. It was suggested that the non-linear relationship at lower particle concentrations was caused by the surfactant. Using the transient line heat source method, Yeganeha at al [31] measured the thermal conductivity of nanodiamond–water nanofluid. It was observed that the thermal conductivity increased non-linearly with nanoparticle volume fraction. At higher volume concentrations, a stronger non-linear relationship was observed. It was suggested that the thermal conductivity could be improved by increasing the dispersion quality of the nanofluid. In the same way, Zhu et al. [1] measured the thermal conductivity of Fe3O4–water nanofluid. A non-linear increase in thermal conductivity with nanoparticle volume fraction was observed. Pang et al. [32] conducted experiments to determine the thermal conductivities of SiO2–methanol and Al2O3–methanol nanofluids. A non-linear increase in thermal conductivity with the increase of volume fraction was observed. Li et al. [8] measured the thermal conductivities of CuO–water and Al2O3–water nanofluids as a function of volume fraction. It was observed that the thermal conductivity of both nanofluids increased non-linearly with nanoparticle volume concentration. Using a KD2 Pro Thermal Property Analyzer, Das et al. [33] measured the thermal conductivity of TiO2–water nanofluid. The results are shown in Figure 18. It was observed that for a given temperature, the thermal conductivity increased non-linearly with nanoparticle concentration. Using the same method, Lee et al. [34] measured the thermal conductivity of SiC–water nanofluid as a function of nanoparticle volume concentration. The results showed a non-linear increase in thermal conductivity with increased nanoparticle volume fraction. Using the transient hot-wire method, Sundar et al. [13] measured the thermal conductivity of nanofluids composed of magnetic Fe3O4 nanoparticles dispersed in 20%:80%, 40%:60% and 60%:40% by weight Ethylene Glycol–water. The results indicated a non-linear increase in thermal conductivity with the increase of nanoparticle concentration. Additionally, Sundar et al. [30] measured the thermal conductivity of magnetic Fe3O4–water nanofluid containing CTAB surfactant. The results showed a non-linear increase in thermal conductivity with nanoparticle concentration. Paul et al. [35] studied the thermal conductivity of Ag–water nanofluid. The results showed a non-linear increase in the thermal conductivity with nanoparticle concentration. Park et al. [7] measured the thermal conductivity of Graphene–water nanofluid using 5000 nm graphene, 15,000 nm graphene, and oxidized 5000 nm graphene. The thermal conductivity increased non-linearly with increased nanoparticle volume fraction for all, with the oxidized 5000 nm graphene having the highest rate of increase. Yoo et al. [36] measured the thermal conductivities of TiO2–water, Al2O3–water, Fe–Ethylene Glycol, and WO3–Ethylene Glycol nanofluids as a function of nanoparticle volume fraction. For each nanofluid, the thermal conductivity increased non-linearly with the nanoparticle concentration. Wang et al. [11] measured the thermal conductivities of nanofluids composed of Al2O3 and CuO nanoparticles dispersed in water, Ethylene Glycol, engine oil, and vacuum pump fluid. It was observed that the thermal conductivity increased non-linearly with the nanoparticle concentration for all nanofluids tested. Chopkar et al. [4] measured the thermal conductivities of Ag2Al–water, Ag2Al–Ethylene Glycol, Al2Cu–water, and Al2Cu–Ethylene Glycol nanofluids. The results showed a non-linear increase in thermal conductivity with nanoparticle concentration. However, some researchers have observed a linear relationship between nanoparticle concentration and thermal conductivity [3,9,15,22,37,38,39,40]. Iqbal et al. [37] studied the thermal conductivities of Al2O3–water, SiO2–water and ZrO2–water nanofluids. It was observed that the thermal conductivity increased almost linearly with the nanoparticle concentration for all tested nanofluids. It was suggested that this increase was related to increased activity between nanoparticles and the base fluid. Esfe et al. [3] measured the thermal conductivity of Fe–water nanofluid as a function of nanoparticle concentration. An almost linear increase in thermal conductivity with the increase of nanoparticle volume concentration was observed. It was suggested that this relationship was a result of the agglomeration of nanoparticles creating particle-free areas in the base liquid with high thermal resistance [3]. Alawi et al. [38] measured the thermal conductivity of CuO-R-134a nanofluid. The results showed a linear increase in thermal conductivity with concentration. It was observed that the increase in thermal conductivity with concentration was much sharper than the increase with temperature. Using a KD2 Pro Thermal Properties Analyzer, Huminic et al. [39] studied the thermal conductivity of FeC–water nanofluid as a function of nanoparticle weight concentration. It was observed that for a given temperature, the thermal conductivity increased almost linearly with nanoparticle concentration. It was suggested that this increase could be partially explained by the increased interaction between particles at higher concentrations. Barbe´s et al. [9] measured the thermal conductivities of CuO–water and CuO–Ethylene Glycol nanofluids using a differential heat-flow C80D microcalorimeter containing special calorimetric vessels, which worked based on the steady-state coaxial cylinder method. It was found that for a given temperature, the relative thermal conductivity increased almost linearly with volume fraction. Using the transient short hot-wire method, Yu et al. [15] measured the thermal conductivities of aluminum nitride (AIN)–Ethylene Glycol and AIN–propylene glycol nanofluids. An almost linear increase in thermal conductivity with nanoparticle concentration was observed. Das et al. [22] measured the thermal conductivity of Al2O3–water nanofluid using a KD2 Pro Thermal Property Analyzer. It was observed that the thermal conductivity increased almost linearly with nanoparticle volume concentration. Using the transient hot-wire method, Jeong et al. [40] measured the thermal conductivity of ZnO–water nanofluid as a function of nanoparticle concentration. The results showed an almost linear increase in thermal conductivity with nanoparticle concentration. It can be concluded from the experimental findings, discussed above that the thermal conductivity of nanofluids increases with nanoparticle volume concentration. However, the rate of increase is different for various nanofluids due to the degree of agglomeration.

Figure 18.

Variation of thermal conductivity of TiO2–water nanofluid at nanoparticle volume concentrations of , as a function of temperature, °C.

The effect of nanoparticle concentration on the thermal conductivity of water-based nanofluids at room temperature is shown in Figure 19. For all nanofluids, the thermal conductivity increases with nanoparticle volume concentration (, while the rate of increase in thermal conductivity becomes smaller at higher concentrations. This decrease may be a result of nanoparticle clustering at higher concentrations. Figure 20 further reinforces the observations of Figure 19, showing that the thermal conductivity increases with nanoparticle volume concentration (. It is observed that the rate of increase in thermal conductivity becomes slightly smaller at higher concentrations for nanodiamond nanofluids, whereas the rate of increases becomes larger at higher concentrations for SiO2 and ZrO2 nanofluids.

Figure 19.

Variation of the thermal conductivity of water-based nanofluids at room temperature as a function of nanoparticle volume concentration,.

Figure 20.

Variation of thermal conductivity of water-based nanofluids at room temperature as a function of nanoparticle volume concentration, , at concentrations below

2.7. Effects of Temperature on Nanofluid Thermal Conductivity

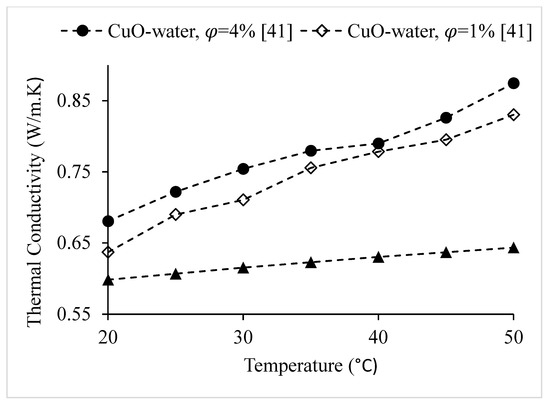

Researchers have conducted experiments to determine the effects of temperature on the thermal conductivity of nanofluids, concluding that the thermal conductivity of nanofluids increases with temperature [5,8,10,12,13,22,25,28,30,31,33,38,39,40,41]. For example, the thermal conductivity of Al2O3–water and CuO–water nanofluids was measured and the results indicated that the rate of enhancement of the effective thermal conductivity increased significantly with respect to increasing temperature [8,41]. Also, Sundar et al. [13] measured the thermal conductivities of magnetic Fe3O4 nanoparticles dispersed in 20%:80%, 40%:60% and 60%:40% by weight Ethylene Glycol/water-based nanofluids. It was observed that the thermal conductivity increased with temperature [13]. In addition, using a KD2 Pro analyzer which worked based on the transient line heat source method, Yeganeh et al. [31] measured the thermal conductivity of nanodiamond–water nanofluid as a function of temperature. A significant increase in thermal conductivity with the increase of temperature was observed. In the same way, Huminic et al. [39] studied the thermal conductivity of FeC–water nanofluid. An increase in thermal conductivity with temperature was observed. Similarly, Das et al. [22] measured the thermal conductivity of Al2O3–water nanofluid and observed an increase with the increase of temperature. It was suggested that this increase was a result of intensified Brownian motion at higher temperatures. Brownian motion is caused by the random collisions of liquid molecules resulting in the random motion of nanoparticles within the base liquid, which in turn leads to greater heat transfer. It was also suggested that the increased microscopic motion caused by Brownian, van der Waals, and electrostatic forces had a significant impact on the increase in thermal conductivity. Also, using a KD2 Pro instrument, Das et al. [33] measured the thermal conductivity of TiO2–water nanofluid as a function of temperature. The results are shown in Figure 21. For each tested nanoparticle volume fraction, the thermal conductivity increased with temperature. The results showed that the temperature had a stronger influence on thermal conductivity at higher temperatures. It was suggested that this relationship was related to enhanced Brownian motion at higher temperatures. Using the same method, Agarwal et al. [12] measured the thermal conductivities of Al2O3–water and Al2O3-Ethylene Glycol nanofluids at temperatures ranging from 10–70 °C. For both nanofluids, at a given nanoparticle volume concentration, the thermal conductivity increased with temperature. The increase was less significant for Ethylene Glycol-based nanofluid. It was suggested that the increase in thermal conductivity with temperature was related to more significant Brownian motion at higher temperatures. It was suggested that water-based nanofluid would be a more appropriate choice for applications involving a significant temperature increase, because the thermal conductivity increased almost constantly with the increase of both temperature and nanoparticle concentration. Using the transient hot-wire method, Raja et al. [5] measured the thermal conductivity of Ag–water nanofluids having nanoparticle volume concentrations less than 1%. It was observed that the thermal conductivity increased with the increase of temperature. It was suggested that the thermal conductivity of nanofluids has a stronger dependence on temperature than base fluid thermal conductivity. Using the same method, Maheshwary et al. [25] measured the thermal conductivity of TiO2–water nanofluid as a function of temperature. For every combination of nanoparticle shape and concentration tested, it was observed that the thermal conductivity increased with temperature. Similarly, Sundar et al. [30] measured the thermal conductivity of magnetic Fe3O4–water nanofluid, containing CTAB surfactant. It was observed that the thermal conductivity increased with temperature. It was suggested that this increase was caused by increased Brownian motion at higher temperatures. Also, using the transient hot-wire method, Jeong et al. [40] measured the thermal conductivity of ZnO–water nanofluid. An increase in thermal conductivity with temperature was observed. In the same way, Sundar et al. [29] measured the thermal conductivity of nanodiamond–water nanofluid and observed an increase with temperature. It was suggested that this was a result of Brownian motion and micro-convection of the nanoparticles. Alawi et al. [38] measured the thermal conductivity of nanofluid composed of CuO nanoparticles dispersed in R-134a refrigerant. The results showed an increase in thermal conductivity with temperature. It was suggested that this increase was a result of increased Brownian motion at higher temperatures. It was also noted that the contribution of microconvection to heat transfer increases with the increase of Brownian motion, which also leads to enhanced thermal conductivity. Patel et al. [28] studied the thermal conductivities of Al2O3–Ethylene Glycol, Cu–water, and Al–transformer oil nanofluids. It was observed that the thermal conductivity increased with temperature. It was suggested that this increase was a result of increased Brownian motion at higher temperatures. Also, using the transient line heat source method, Agarwal et al. [10] measured the thermal conductivities of CuO–water, CuO–Ethylene Glycol, and CuO–engine oil nanofluids as a function of temperature. The results showed an increase in thermal conductivity with temperature for each nanofluid tested. It was suggested that this increase was caused by increased Brownian motion at higher temperatures. However, several researchers have suggested that the effect of temperature on the thermal conductivity of nanofluids is solely a result of the increase in thermal conductivity of the base liquid [15,26,42]. Using the transient short hot-wire method, Yu et al. [15] measured the thermal conductivities of AIN–Ethylene Glycol and AIN–propylene glycol nanofluids within the temperature range on 10–60 °C. A negligible change in thermal conductivity with the increase of temperature was observed. At a given temperature, the thermal conductivity of the nanofluid was almost identical to that of the base fluid. Additionally, Xie et al. [26] observed that the thermal conductivity of MgO–Ethylene Glycol nanofluid increased slightly with temperature. However, the thermal conductivity enhancement ratio remained almost constant. It was suggested that the change in thermal conductivity of nanofluids with temperature follows the trend of increase in the thermal conductivity of their respective base fluid. Also, Sharifpur et al. [42] measured the thermal conductivity of Al2O3–glycerol nanofluid as a function of temperature. The thermal conductivity did not vary significantly with temperature, and followed the pattern of the base fluid, glycerol. It was suggested that the effect of temperature on the thermal conductivity of nanofluids is dependent on the characteristics of the nanofluid. Seyhan et al. [23] measured the thermal conductivity of Ag–Ethylene Glycol, Ag–hexane, and Ag–water nanofluids as a function of temperature. The thermal conductivity of Ag-Hexane nanofluid decreased with temperature. The thermal conductivity of Ag–water nanofluid increased with temperature at lower concentrations, but decreased with the increase of temperature at higher concentrations. It was suggested that this change in the behavior of water-based nanofluid at higher temperatures was related to the presence of Gum Arabic surfactant. Water generally does not transfer energy between molecules, but rather the energy is stored within hydrogen bonds in large clusters of molecules that occur at lower temperatures [23]. The thermal conductivity of water then increases with temperature, unlike other liquids. The Gum Arabic surfactant created new places in which hydrogen bonding could occur, by adding several –OH groups to the mixture. This led to a decrease in the amount of hydrogen bonds between water molecules, creating a critical concentration above which the thermal conductivity of the nanofluid decreased. By the above discussed experimental results, it can be concluded that the thermal conductivity of nanofluids increases with the thermal conductivity of their respective base liquids. Through plotting various nanofluids along with their respective base liquids in Figure 21, Figure 22 and Figure 23 below, it was observed that the thermal conductivity of nanofluids generally does not increase at the same rate as the thermal conductivity of base liquids. Thus, it can be suggested that the increase in nanofluid thermal conductivity with temperature is not solely a result of the increased thermal conductivity of the base liquid, but is also a result of Brownian motion and micro-convection due to the addition of nanoparticles.

Figure 21.

Variation of the thermal conductivity of TiO2–water nanofluid at various temperatures, as a function of nanoparticle volume concentration,

Figure 22.

Variation of the thermal conductivity of ZnO–water nanofluid at various nanoparticle volume concentrations, as a function of temperature.

Figure 23.

Variation of the thermal conductivity of CuO–water nanofluid at various nanoparticle volume concentrations, as a function of temperature.

The thermal conductivities of various water-based nanofluids, at , are shown in Figure 5 as a function of temperature, in comparison to the thermal conductivity of water as a function of temperature. It is observed that the thermal conductivity of nanofluids increases with temperature, however not all nanofluids increase at the same rate. It is observed that for all nanofluids, other than nanodiamond–water nanofluid, the slopes of the nanofluid thermal conductivities as a function of temperature are different from the slope of increase in the thermal conductivity of water. Therefore, it can be suggested that the increase in thermal conductivity with temperature of a nanofluid is not only caused by the base liquid, but by the nanofluid as a whole. The data shown in Figure 14 further reinforces this suggestion, by showing that the thermal conductivities of Al2O3–Ethylene Glycol nanofluids also did not increase with temperature at the same rate as the base liquid, Ethylene Glycol.

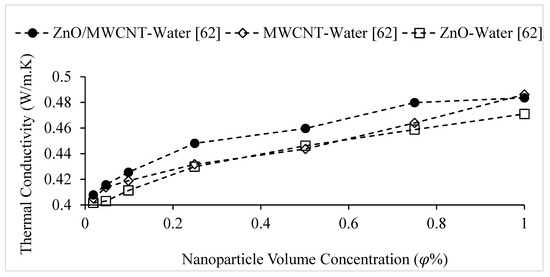

2.8. Effects of Carbon Nanotubes on Nanofluid Thermal Conductivity