1. Introduction

Climate change is a global challenge due to an increase of average global annual temperature of 0.99 °C, with CO

2 levels reaching 400 ppm, breaking the 1950s’ level threshold of 300 ppm [

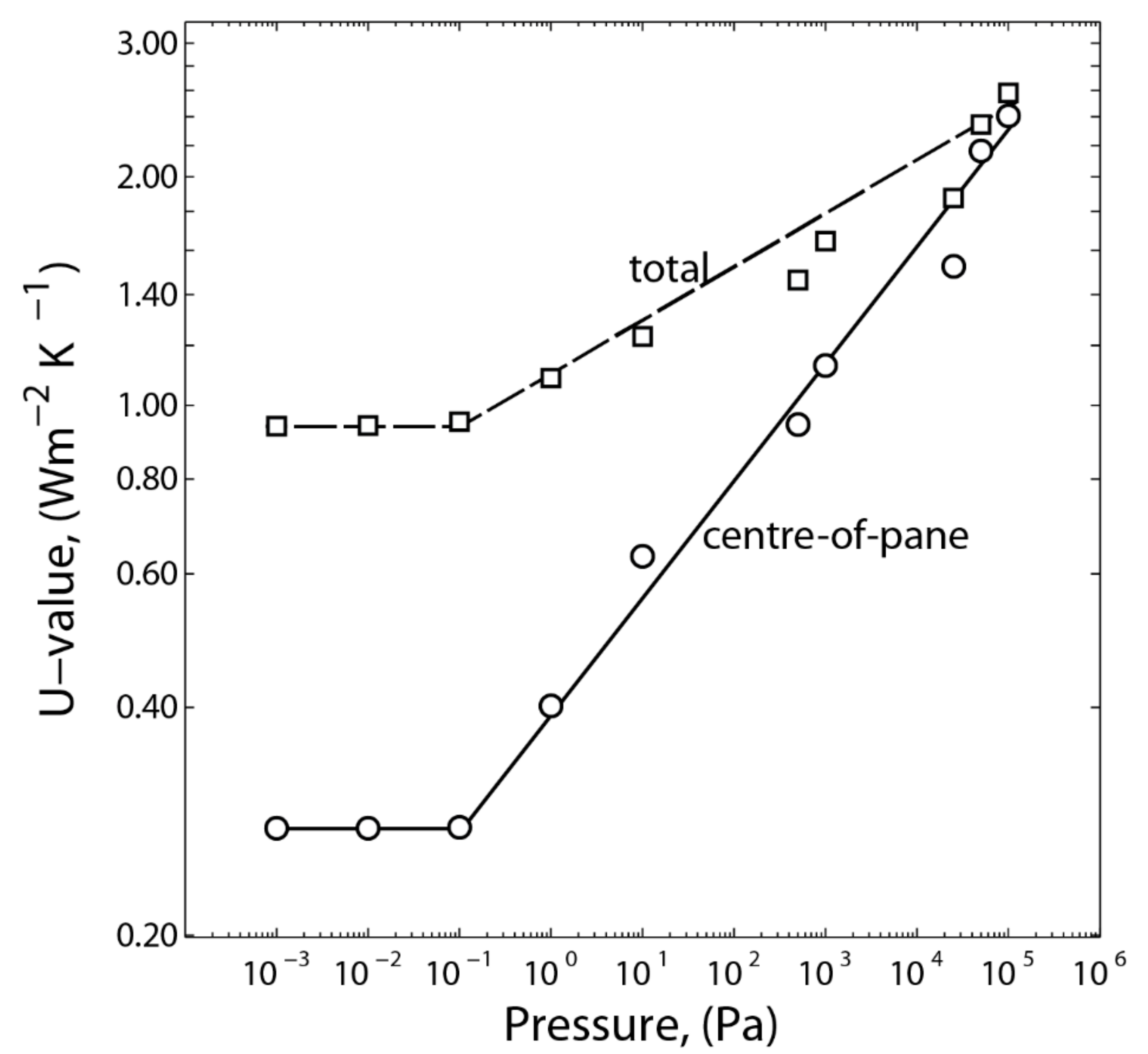

1]. In buildings, the thermal transmittance (U value) is the combination of thermal conductance (i.e., the rate of heat flow between the higher-temperature area and lower-temperature area) and the thermal transfer coefficients. The total U value accounts for the effect of frames and edges, and the centre-of-pane U values do not account for the aforementioned effects. Vacuum insulation as a retrofit solution to existing buildings plays a momentous role in the reduction of carbon emissions and bringing our building sector towards a zero-energy building (ZEB) target [

2], because buildings are accountable for at least 30% of the overall global final energy consumed [

3,

4]. Although a number of retrofitting measures to improve building insulation have already made the building sector more energy-efficient [

5], it requires advanced technologies to bring the building sector towards a ZEB target. Triple vacuum glazing (TVG) has the ability to curtail heat flow between the warm side and cold side of a window, i.e., to provide preeminent thermal insulation, so-called thermal transmittance (U value) [

6]. TVG consists of three panes of 4 mm thick glass, with an evacuated gap 0.13 mm high, separated by 0.13 mm high and 0.3 mm diameter stainless-steel support pillars. TVG edges are sealed with airtight material such as solder glass, indium alloy, or Cerasolzer CS186. The reason TVG has the potential for retrofitting to existing buildings is because its U value is less than 0.5 Wm

−2 K

−1, compared to triple air-filled glazing, which has a U value of 2.8 Wm

−2 K

−1. It also would allow increasing the window-to-wall area ratios because of its U value being closer to that of cavity wall insulation. Nevertheless, TVG has associated challenges; this paper presents the findings of the effects of diminution of vacuum pressure on the U value. The U value of TVG primarily depends on the thickness of the glass panes, vacuum pressure in the space between the glass panes, emissivity of the coatings on the glass panes, frame, and type of spacers that separate the panes of glass and type of window frame. The total U value consists of the influence of the frame and the area of the edge seal. The edge seal area is dependent on the width and the type of edge-sealing material. The airtight edge seal of a TVG must be able to perpetuate a vacuum pressure below 0.1 Pa for quelling gaseous heat conduction for long-term duration [

7]. Benson et al. [

8] investigated laser technology in a vacuum chamber to seal the edges of two glass panes. This achieved an airtight edge seal, but the cavity vacuum pressure was not below 0.1 Pa because the laser seal instigated particles such as moisture and notorious gases [

9]. The first successful fabrication method of double vacuum glazing (i.e., an evacuated cavity between two panes of glass) relied on a lead-based solder glass material sealed at around 450 °C (it was recognised as a high-temperature sealing method because of its melting temperature) [

10,

11]. This method achieved a centre-of-pane U value of 0.8 Wm

−2 K

−1 and progressed to the commercial scale with a trade name of SPACIA. The problems with the high-temperature method of sealing are: the degradation of soft (low emissivity) coatings, meaning only hard coatings can be used [

12]; and if using annealed glass, then loss of toughness, and requirement of higher amounts of heat energy for the construction. Investigations on a low-temperature solder glass material showed a hermetic edge seal, but durability was a problem due to the absorption of moisture [

9]. The second successful fabrication method of double vacuum glazing used indium or an indium alloy, which was sealed in a low-temperature process, at about 160 °C. It required a secondary adhesive seal to prevent moisture access [

13]. A low-temperature sealing process enables the use of low-emittance soft coatings, reducing radiative heat transfer between glass panes, and annealed glass allows to increase support pillar spacing, reducing conductive heat transfer [

14]. The problem with the low-temperature fabrication method is the use of semiprecious indium alloys. It is a hindrance in advancing indium-sealed vacuum glazing at a commercial level [

15]. Recently, a new low-temperature composite material and method of fabrication were reported by Memon et al. [

16], in which the CS-186 type of Cerasolzer and steel-reinforced epoxy resin [

17] were used for the development of composite edge-sealed triple vacuum glazing.

Despite the aforementioned successful constructions of double and triple vacuum glazing, there is always an uncertainty of the degradation/leakage of the cavity vacuum pressure. It is also pertinent that during the evacuation process or after sealing the pump-out tube of the TVG, there is a propensity of some gas molecules remaining in the cavity to react when exposed to sunlight and/or under extreme climate conditions for longer time periods due to the production of carbon monoxide inside the cavity that degrades the vacuum layer. It is obvious that TVG is exposed to sunlight and thus must be designed to withstand different climates and temperatures in order to avoid degradation of the vacuum. The heat conductance and internal pressure due to ageing (for over 250 days) of a vacuum glazing, with a temperature increased from ambient (21 °C) to 150 °C, was reported by Turner and Collins in 1997 [

18]. It showed that both pressure inside the cavity and heat conductance rose upon heating. It identified that the increase in the thermal conductance from the glass bulk due to the water vapour evolved into the gap was negligible; it was less than 0.1 Wm

−2 K

−1 over a period of 25 years at 30 °C for the samples baked out at about 180 °C for 1 h. The result from mass spectroscopy showed that 95% of the total remaining gas on the internal glass surfaces is water vapour, whereas the remaining 5% includes H

2, H

2O, CO/N

2, O

2, and CO

2. Fang et al. [

19] investigated the extreme temperature cycling effect, for which the heat conductance at the centre-of-pane was found to be increased by about 10.2% (1.18 Wm

−2 K

−1 to 1.30 Wm

−2 K

−1) when the cavity vacuum pressure inside the vacuum glazing had increased from 0.1 Pa to 0.16 Pa. Ng et al. [

20] conducted an investigation of gases evolved into the evacuated gaps in vacuum glazing, in which the samples of vacuum glazing were aged by exposing them to high temperatures and sunlight for a long period of time, and their internal pressure and the existing gases were studied using a vacuum gauge and a mass spectrometer, respectively. However, there is no literature available on the influence of cavity vacuum pressure diminution on triple vacuum glazing (TVG). Thus, this paper reports the effects of vacuum pressure on the thermal transmittance of TVG by developing a mathematical model using the finite element method in predicting their thermal performance.

This paper contributes to the new understanding of the effects of cavity vacuum pressure diminution on the thermal performance (heat-transfer characteristics) of triple vacuum glazing. In this paper, a 3D finite element method with details of the governing equations utilised and modelled heat-transfer mechanisms of the 10-mm wide edge-sealed triple vacuum glazing is reported. The influence of vacuum pressure diminution on the thermal transmittance (U value) of a triple vacuum glazing when the vacuum space (cavity) pressure decreases from 0.001 Pa (high vacuum pressure) to 101.321 kPa (atmospheric pressure) is investigated. This study enables the future prospects of improving the edge sealing of TVG and presenting significant findings on understanding how the diminution of vacuum pressure may affect the heat loss through TVG.

2. Materials and Methods

To analyse TVG thermal performance or the prediction of U values, a 3D finite element model was developed using a validated approach based on the boundary conditions. The U value was quantified with the boundary conditions of: Temperature,

; heat flux (surface) per unit area,

; heat flux (volumetric) per volume,

; heat-transfer convection (surface),

, where the film coefficient

and temperature (sink)

; and heat-transfer radiation,

, where

is the radiation constant and the

value is absolute zero on the temperature scale used. The heat conduction occurred as a solid body in which the conductivity is subjected to the temperature, internal energy with effects of latent heat, and convection and radiation equations. According to Green and Naghdi [

21], the energy balance approach used is stated in Equation (1), and with the Fourier law Equation (2), is acquired by applying the standard Galerkin spatial discretisation method.

where

is the volume of the glazing components having:

, area of the surface;

r, the heat supplied externally per volume;

, the density of the materials;

, the material time rate of the internal energy; and

, the heat flux per unit area. It is an adopted assumption that iterative solutions are disjoined in such a way that only

, where

is the temperature of the material.

is the arbitrary differential field satiating the essential boundary conditions. The body is estimated geometrically with finite elements, so the temperature is interpolated as in Equation (3):

where

TN are nodal temperatures. The Galerkin approach presumes

, that the variation field is interpolated by the same functions as

, and that

is arbitrarily chosen. First- and second-order polynomials consist of 1D, 2D, and 3D for

NN. With these interpolations, the variation of Equation (2) is rewritten as:

The 8-node brick in a second-order heat-transfer element method [

22] used a numerical Gaussian integration rule, because by using this for the TVG, a smooth solution can be achieved.

The heat transfer mechanisms through conduction elements are proposed and are based on the combination of piecewise quadratic interpolations of TN via the breadth of the element. The isoparametric interpolation functions for the element associated with the heat-conduction reference surface are utilised. TN are coupled at a set of points via the breadth at each node of the element (nodes ). For computational numerical integration of the finite element equations, a 2 × 2 Gauss integration scheme with a 2 × 2 nodal integration scheme is used for the internal energy and specific heat term used for the quadrilateral element with a 3 × 3 Gauss integration method.

Let

be individual TVG elements directing to the reference surface point of the element related with heat conduction, and

measures the position through the thickness of the heat conduction object, such as the edge seal, glass panes, and support pillars, so that

, where

is the thickness of the element and

z0 is the offset of the reference surface from the mid-surface. The position of any point in the element is given by Equation (5).

where

is the locus and

is the unit normal of a point in the reference surface. The interpolation of the temperature is written as in Equation (6):

where

is a piecewise parabolic interpolation,

is the interpolator in the reference surface, and

are nodal temperature values (at node

, point

via the breadth). The thermal energy balance Equation (2) is now rewritten as Equation (7), which accounts for the heat conduction of each element with the approximate Jacobian matrix for the Newton method.

where

is the correction to the temperature solution at time

. The form of these terms for the elemental heat conduction, e.g., through the edge seal and support pillars, is obtained by introducing the interpolator and neglecting the change in area with respect to

of surfaces parallel to the reference surface. The piecewise quadratic interpolation through the breadth of finite elements is represented by Equation (8).

where

is a one-step operator for stabilising the heat-transfer processes and the elemental heat transfer through convection modelled with a nonsymmetric Jacobian matrix, thus both transient and steady-state capabilities are incorporated. The transient capability introduces a limit on the time increment; the time increment is adjusted to satisfy this limit. Equation (9) is matched to the work by Yu and Heinrich [

23,

24].

where

is the temperature distribution;

is the arbitrary variation field;

is the fluid density;

is the specific heat of the air molecules, which can then be reduced for the perfect vacuum;

is the conductivity of the air molecules at a particular pressure;

is the auxiliary heat distribution in the volume;

is the surface heat distribution per volume where temperature is not prescribed

);

is the outward normal to the surface;

is the spatial position; and

is time. Low-pressure air in the cavity will have isotropic conductivity, so that

(where

is a scalar and

is the unit matrix). The boundary conditions are such that

is coupled to

and heat flux inflowing to the domain across the rest of the surface,

, is associated by convection and/or radiation conditions and is expressed in Equation (10).

where

is the heat flux linked to the conduction through the surface only, and any convection of energy across the surface is not included in

. It makes negligible variance if the surface is part of a solid body (where

is defined by heat transfer into the adjacent body), since then, the normal velocity (v.n.) into that body is equal to 0, due to no continuous fluid crossing the surface, and here is assumed as static conditions in a TVG.

The elemental heat transfer through radiation is dependent on the surfaces that are comprised of facets with radiation boundary conditions. In this 3D FEM, a facet is a face of a solid element of TVG and each facet is presumed to be isothermal, having unvarying emissivity. Cavity heat radiation elements, calculated through Abaqus, produce a series of matrices, since they couple the temperature degrees-of-freedom of every node on the cavity surface. Such a method of surface radiation is followed according to Holman [

25] and Howell et al. [

26]. Radiation flux density

into a cavity facet

stated in Equation (11) depends on the grey body radiation theory, in which the monochromatic emissivity of the facets is independent of the wavelength of propagation of the radiation and only nondirectional reflection is applied with the approximation of isothermal and isoemissive cavity facets.

where

are the surface emissivities of facets

,

;

is the Stefan–Boltzmann constant;

is the geometrical view factor matrix;

are the temperatures of facets

,

;

is the value of absolute zero on the temperature scale being used; and

is the Kronecker delta. Distinctively, in the blackbody radiation, where no reflection takes place, the addition of all emissivities is equal to one and Equation (11) is condensed to Equation (12).

The radiation flux

is made up of finite element facets, which occurs when the heat is exchanged in a way that is dependent on view factors, which is a dimensionless factor

between two elementary areas,

and

, satisfying the relation of Equation (13).

where

is the gap between two areas and

,

are the angles between

. The dimensionless view factor is a geometrical number, and for the validation of the accuracy of the calculations used in Equation (14), it is a result of the fact that all rays from facet

i collide with other the surface

j in an enclosed cavity.

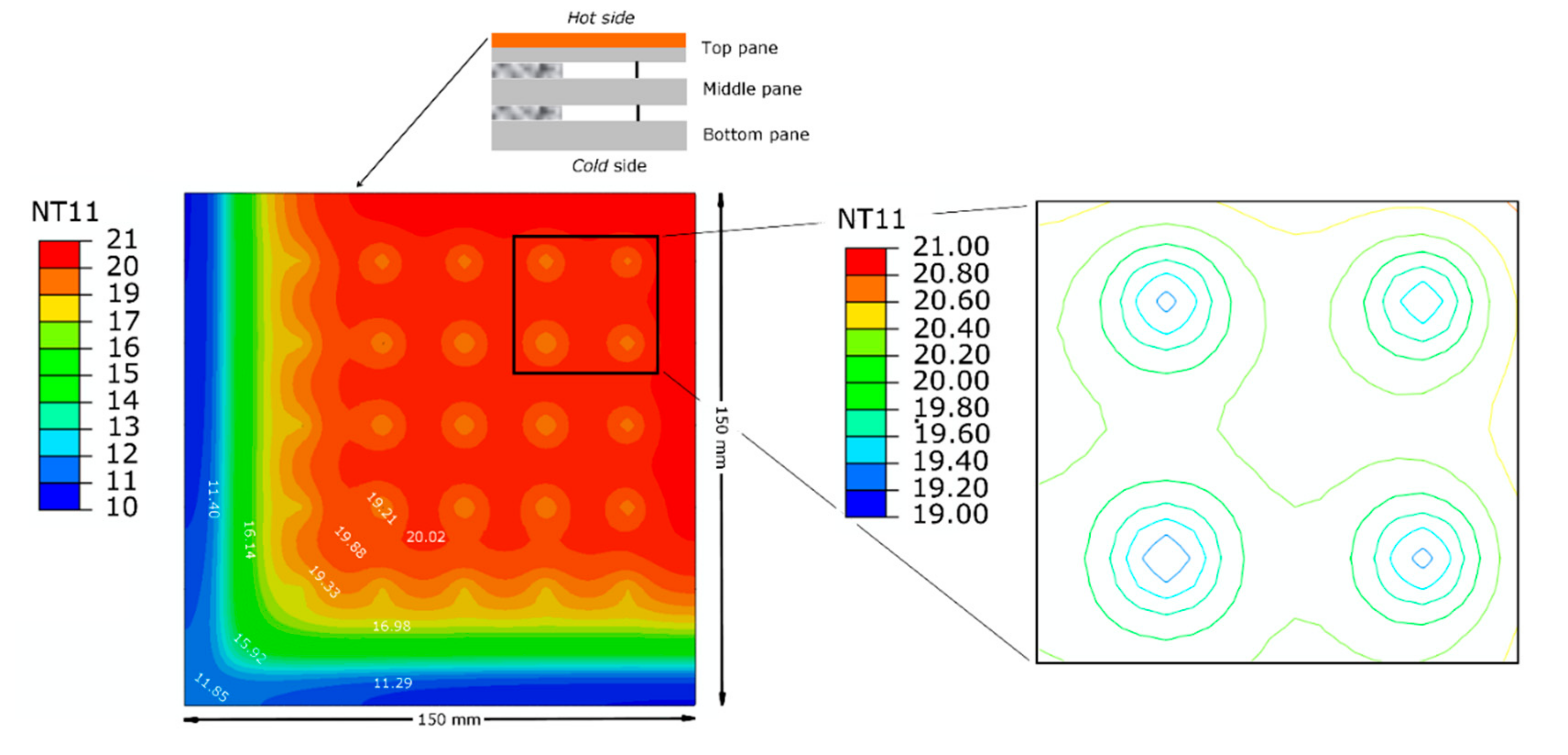

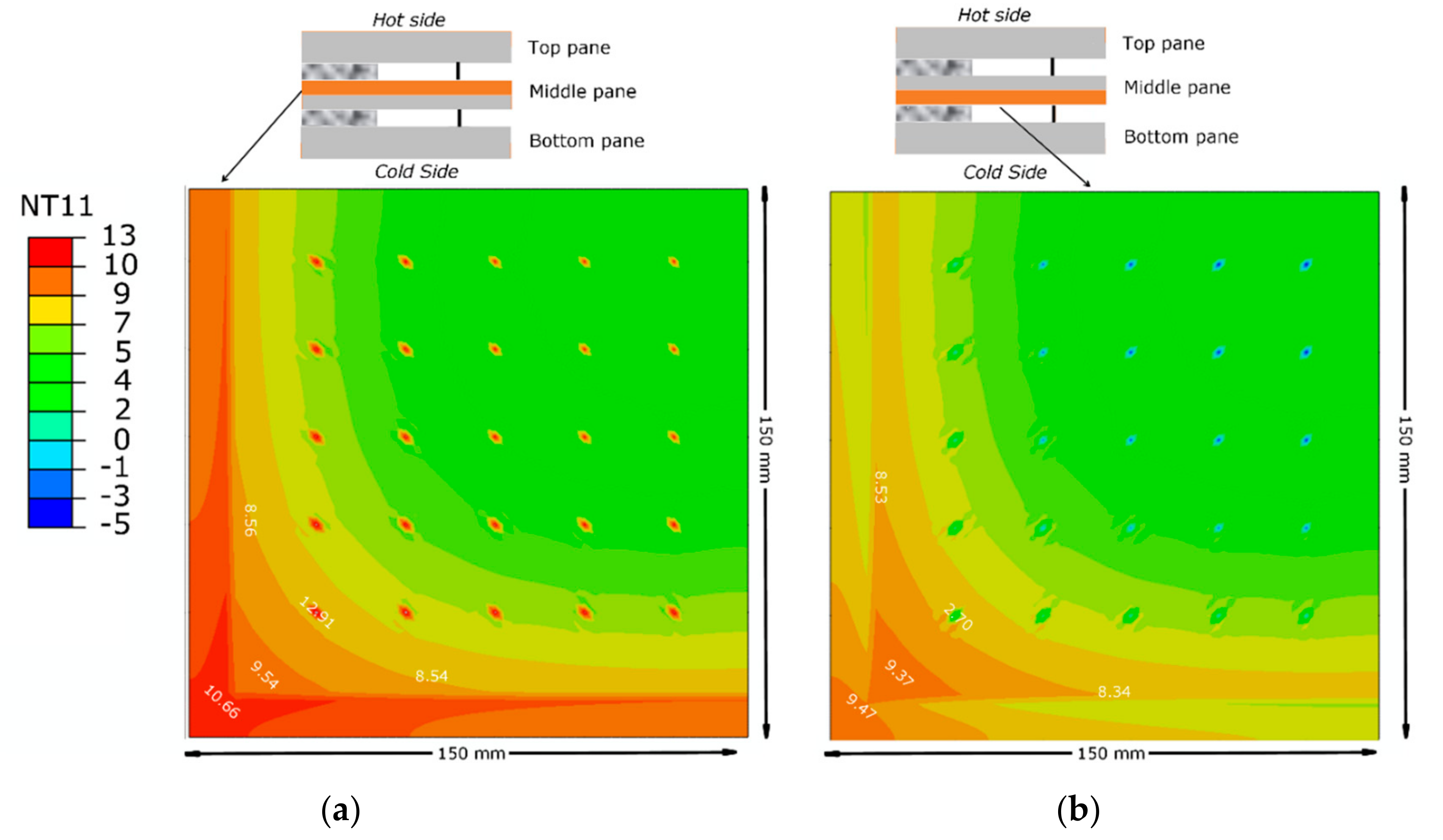

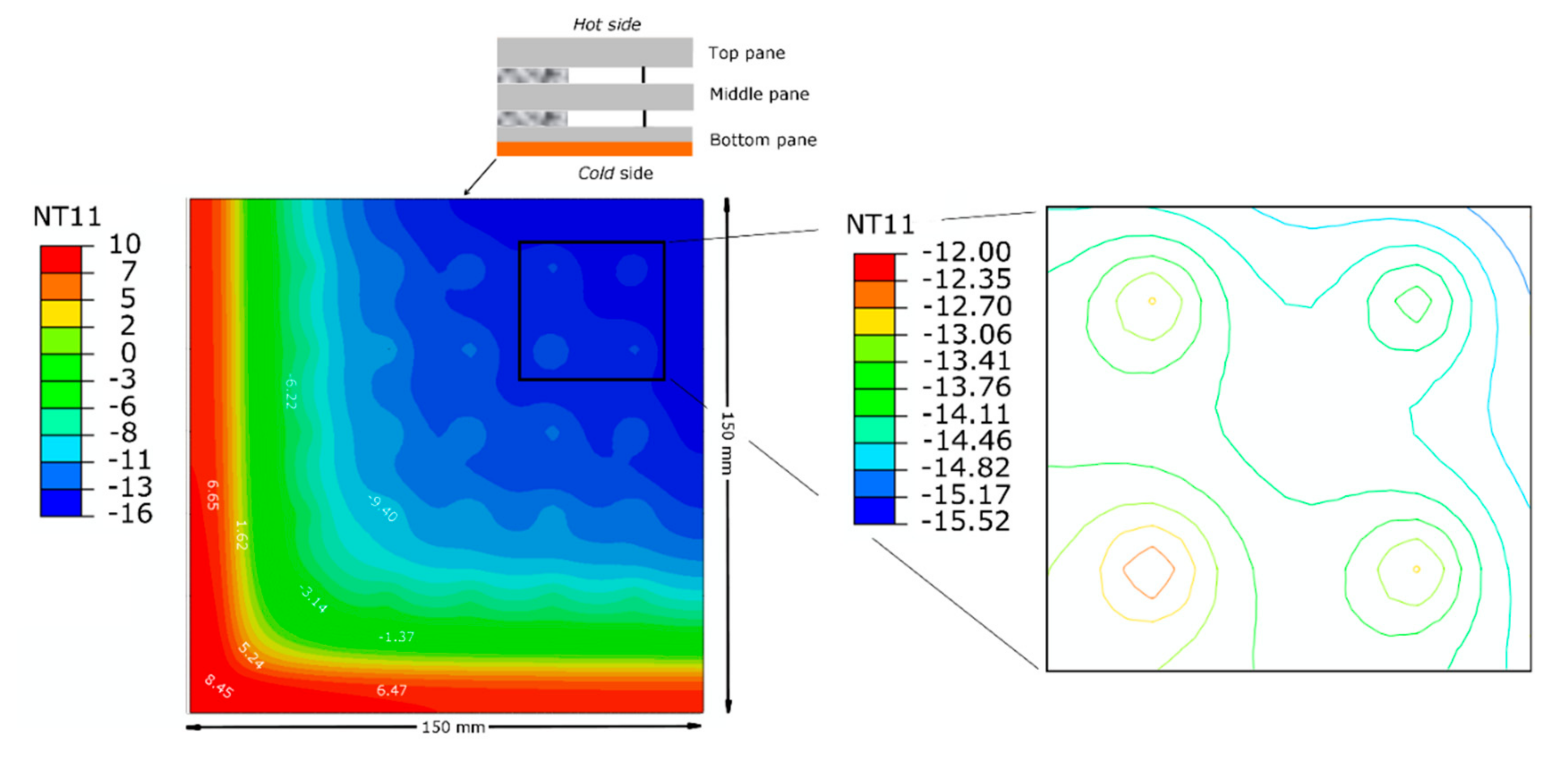

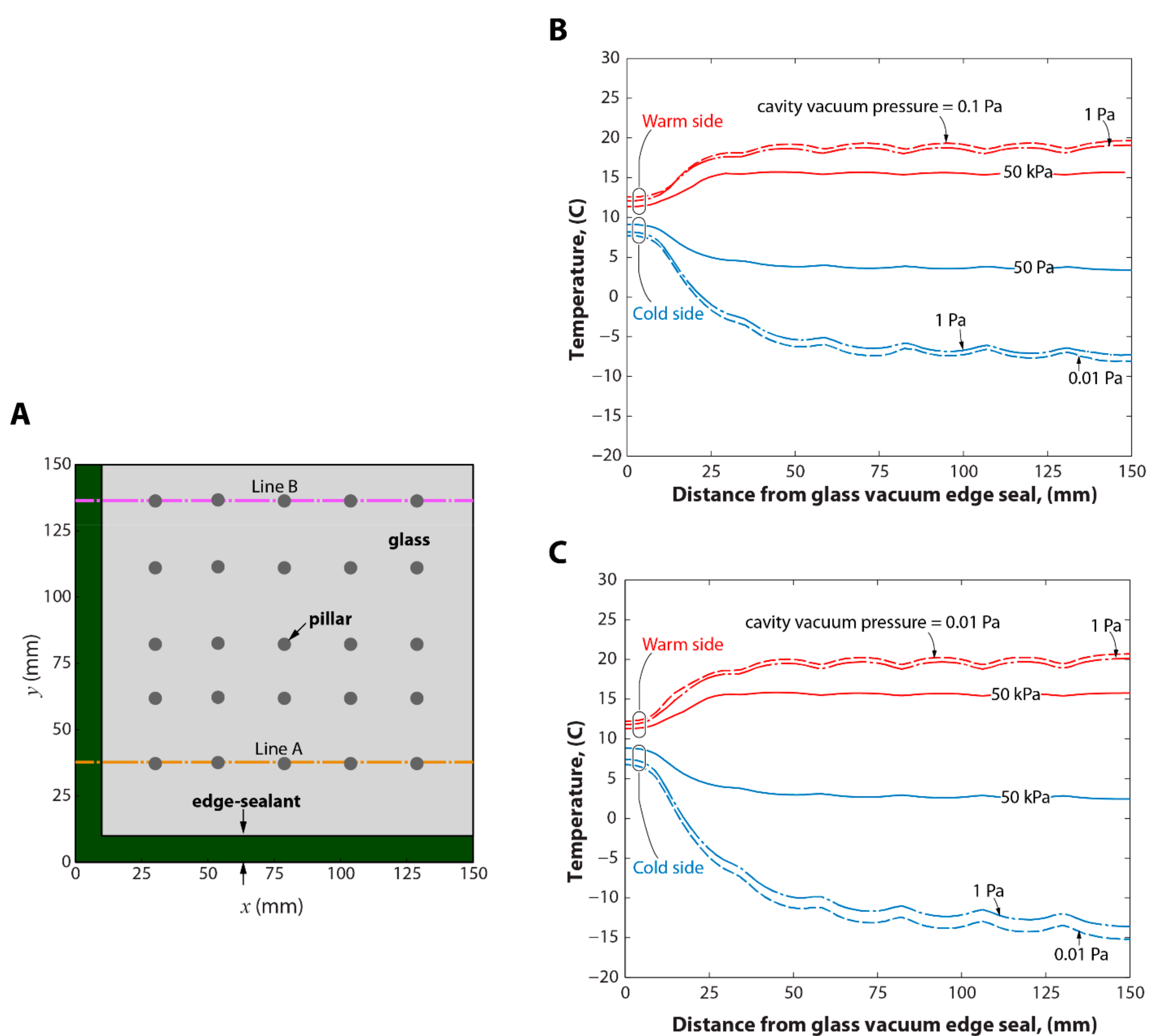

To reduce the computational time and due to symmetrical conditions, one quarter (150 mm × 150 mm) of the TVG size of 300 mm × 300 mm × 4 mm was simulated. The model was designed using an eight-node linear brick diffusion element, with a total of 174,100 elements and 204,226 nodes, used to model a quarter of the TVG as shown in

Figure 1. The vacuum cavity is modelled as a material with thermal conductivity dynamically dependent on the air molecules and its mean free path as most of the thermal conduction occurs due to molecules adsorbed on the surfaces and/or left in the cavity of the vacuum gap. A 6 μm layer on the inner surface of the glass panes with the emissivity of tin oxide is the coating modelled for radiation heat-transfer simulations. The stainless-steel support pillars, modelled as a square with the side length of 1.78

r, represented the same heat transfer as of the cylindrical type used; this approach was used by Fang et al. [

27] and Zhao et al. [

28]. A graded mesh with a higher number of elements in the pillars was employed to achieve adequate representation of the heat transfer [

6,

17]. An example of the finite element mesh employed is shown in

Figure 1. A series of 15 convergence tests were performed to ensure that the density of the elements used was sufficient to predict the thermal performance with an accuracy of more than 97%. It is vital in the 3D finite element model to perform the simulation with repetitive results and confirm with the literature. In the convergence tests, the error found was less than 0.4% and found to be precisely repeatable. The material properties and parameters of the simulated triple vacuum glazing are listed in

Table 1.

A thermal contact between glass interfaces with a cavity gap between them is specified by incorporating the gap conductance coefficient between two closely adjacent surfaces with small clearance (similar to glass surfaces separated by support pillars). Thermal gap conductance between two surfaces is represented by nodes 1 and 2 with temperatures

and

(

>

), and the clearance

d between them is shown in

Figure 2.

The gap heat transfer is defined by the summation of gaseous conductance heat transfer and radiation heat transfer between two adjacent surfaces, i.e., Equation (15).

where

is the gap heat transfer,

is the gas conductance heat transfer, and

is the radiation heat transfer. The gas conductance heat transfer over a fixed gap clearance

is given by Equation (16).

where

is the conductance coefficient of the gas and

and

are the temperatures at nodes 1 and 2, respectively. Subroutine GAPCON can help to define the dependency of

on different variables, including temperature, distance, and pressure between the bodies. In this study, it is used to define the

as a function of pressure between the glass surfaces [

22].

The radiation heat transfer (

) between two nodes in contact is given by Equation (17).

where

is the Stefan–Boltzmann constant and

and

are the temperatures at nodes 1 and 2, respectively. The theoretical model of the thermal gap conductance is implemented into Abaqus using the user-defined GAPCON subroutine. When the GAPCON subroutine is called, it provides the pressure and temperatures

and

for the contacting nodes 1 and 2 on adjacent glass surfaces for defining the thermal gap conductance.

The thermal transmittance U value consists of the centre-of-pane and total glazing area values. The total glazing area contains the edge effects, whilst the centre-of-pane does not [

30]. The ASTM [

31] testing conditions are followed, in which the internal and external surface heat-transfer coefficients

were set to 8.3 Wm

−2 K

−1 and 30 Wm

−2 K

−1, respectively [

32], and the internal and external surface air temperatures were set to be at 21.1 °C and −17.8 °C, respectively. The glass surface-to-surface thermal transmittance of the total glazing

and the centre-of-pane glazing

is defined by Equations (18) and (19).

where

and

are the centre-of-pane and total internal surface thermal resistances, respectively, and

and

are the centre-of-pane and total external surface thermal resistances, respectively.

and

are the centre-of-pane and total average heat flux by conduction, convection, and radiation, simulated using Abaqus as per the preceding equations, respectively. Similarly,

and

are the calculated centre-of-pane internal and external average surface temperatures, respectively.

and

are the total internal and external average surface temperatures, respectively.