Study on the Thermal Distribution Characteristics of High-Speed and Light-Load Rolling Bearing Considering Skidding

Abstract

1. Introduction

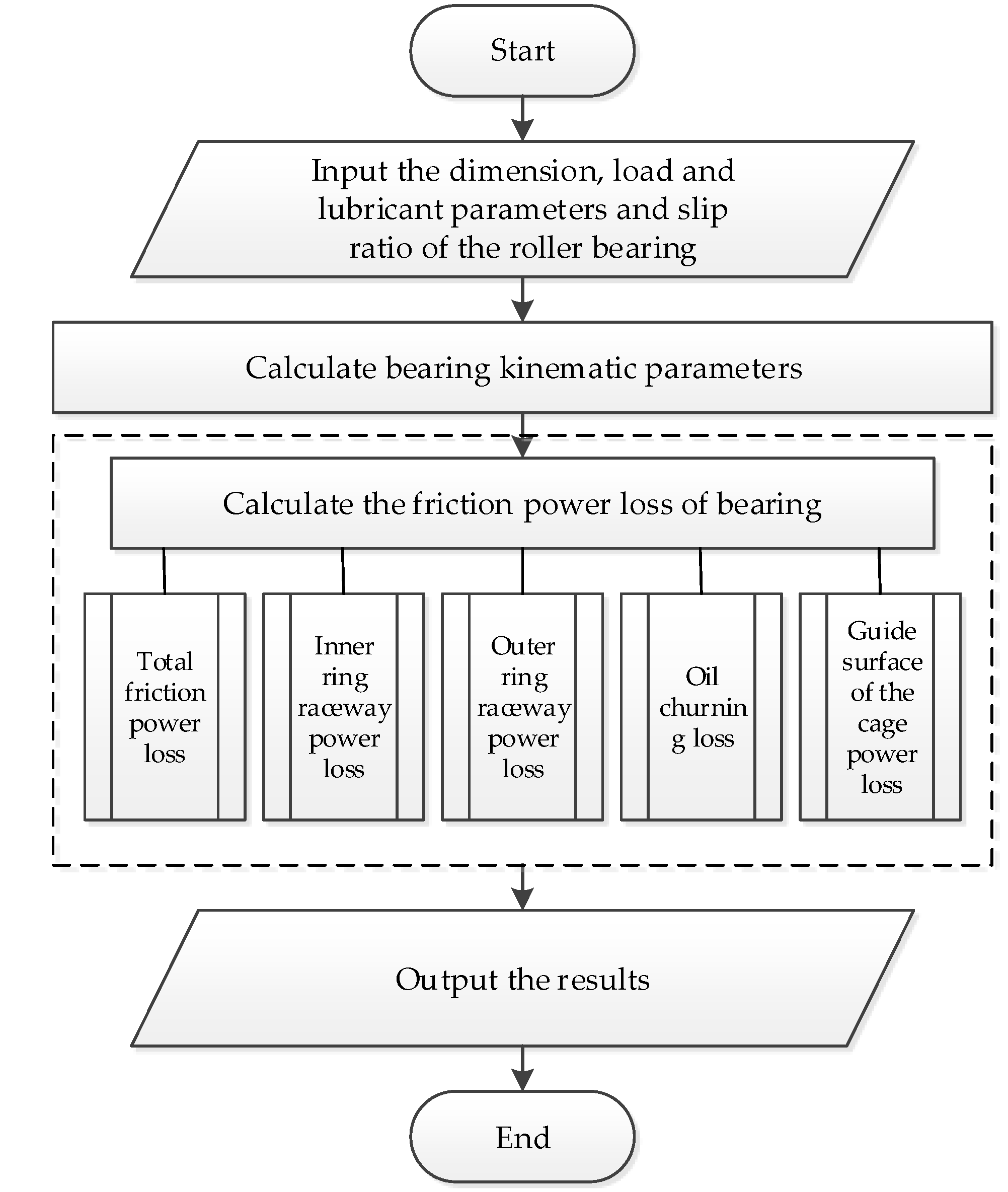

2. Numerical Model

2.1. Skidding

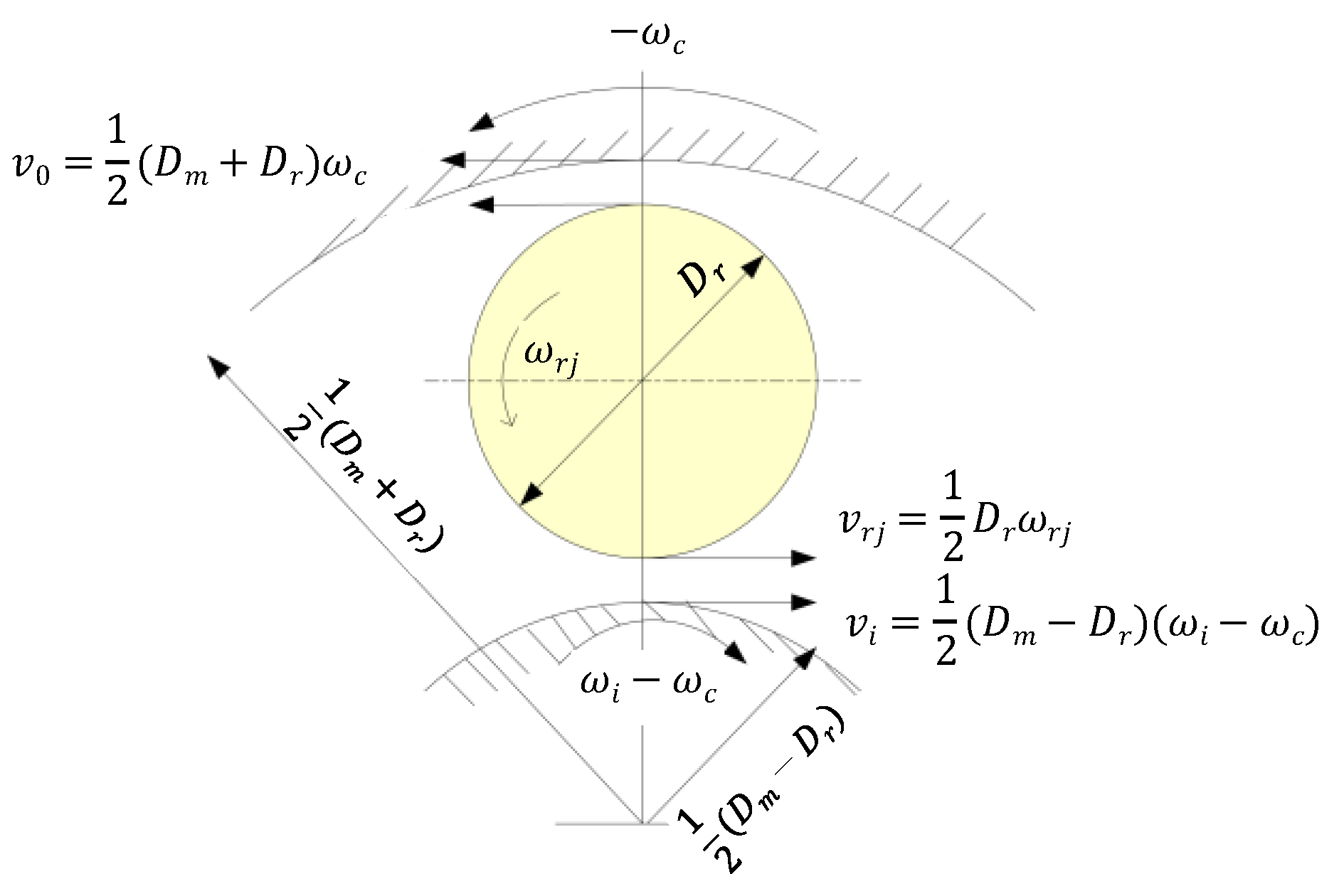

2.2. Kinematics Models of the Roller

2.3. Friction Power Loss Analysis Model

2.3.1. Friction Power Loss between the Roller and Inner Ring Raceway

2.3.2. Friction Power Loss between the Roller and Outer Ring Raceway

2.3.3. Oil Stirring Friction Power Loss

2.3.4. Friction Power Loss between the Cage and Guide Edge of the Rings

2.3.5. Total Friction Power Loss

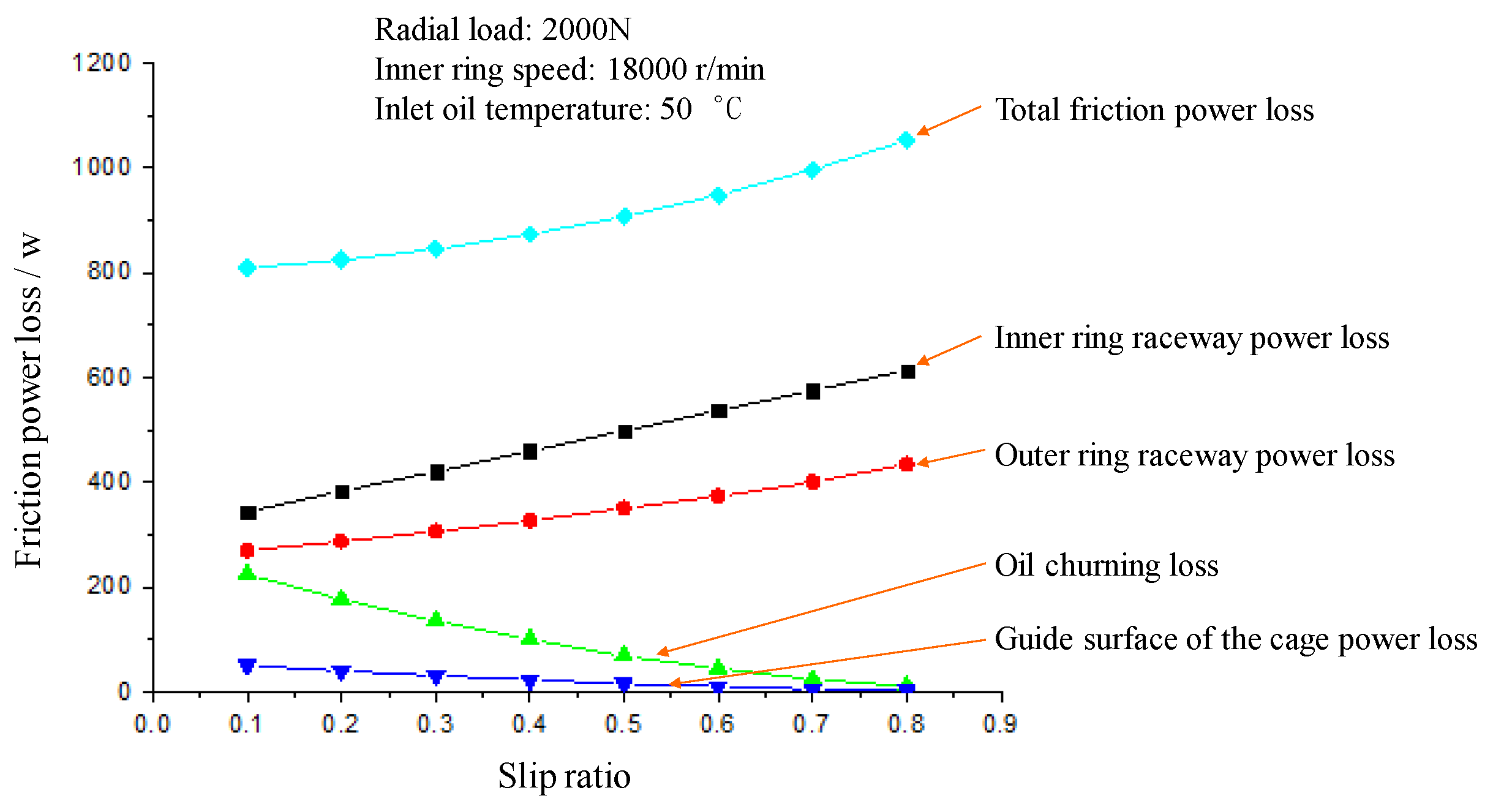

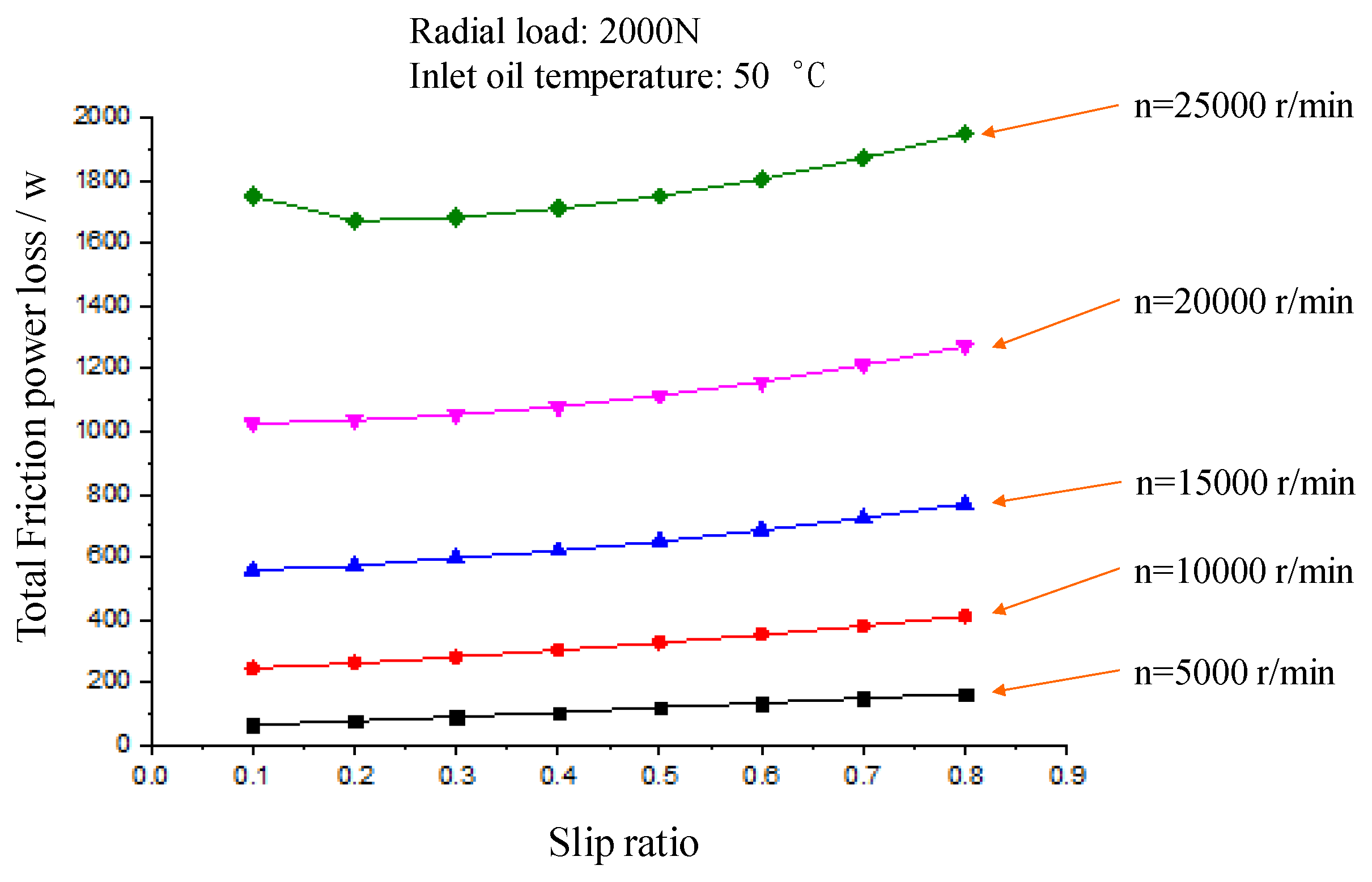

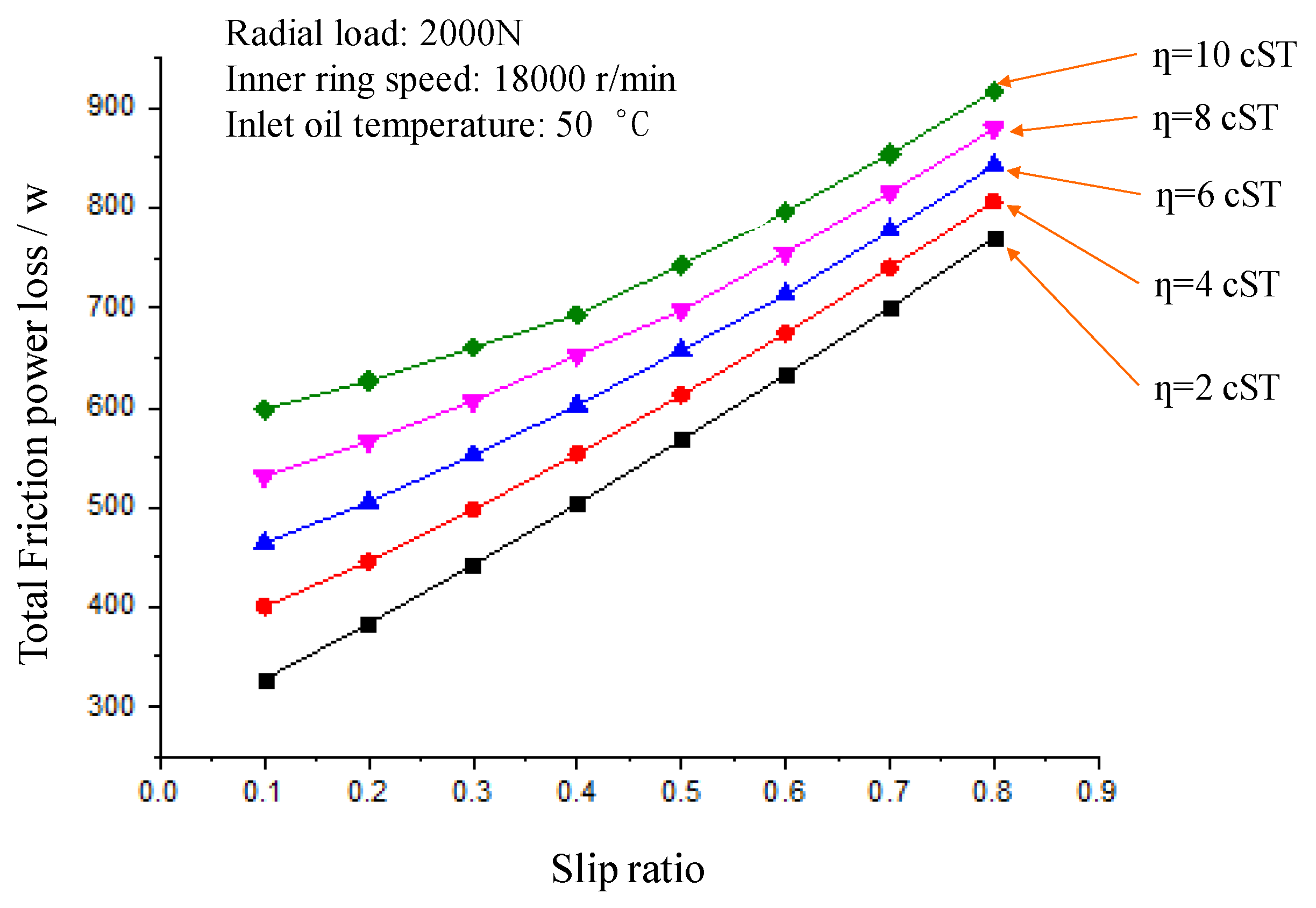

3. Theoretical Analysis of Friction Power Loss Distribution in HSLLRBs

4. Finite Element Analysis of Temperature Distribution Characteristics in HSLLRBs

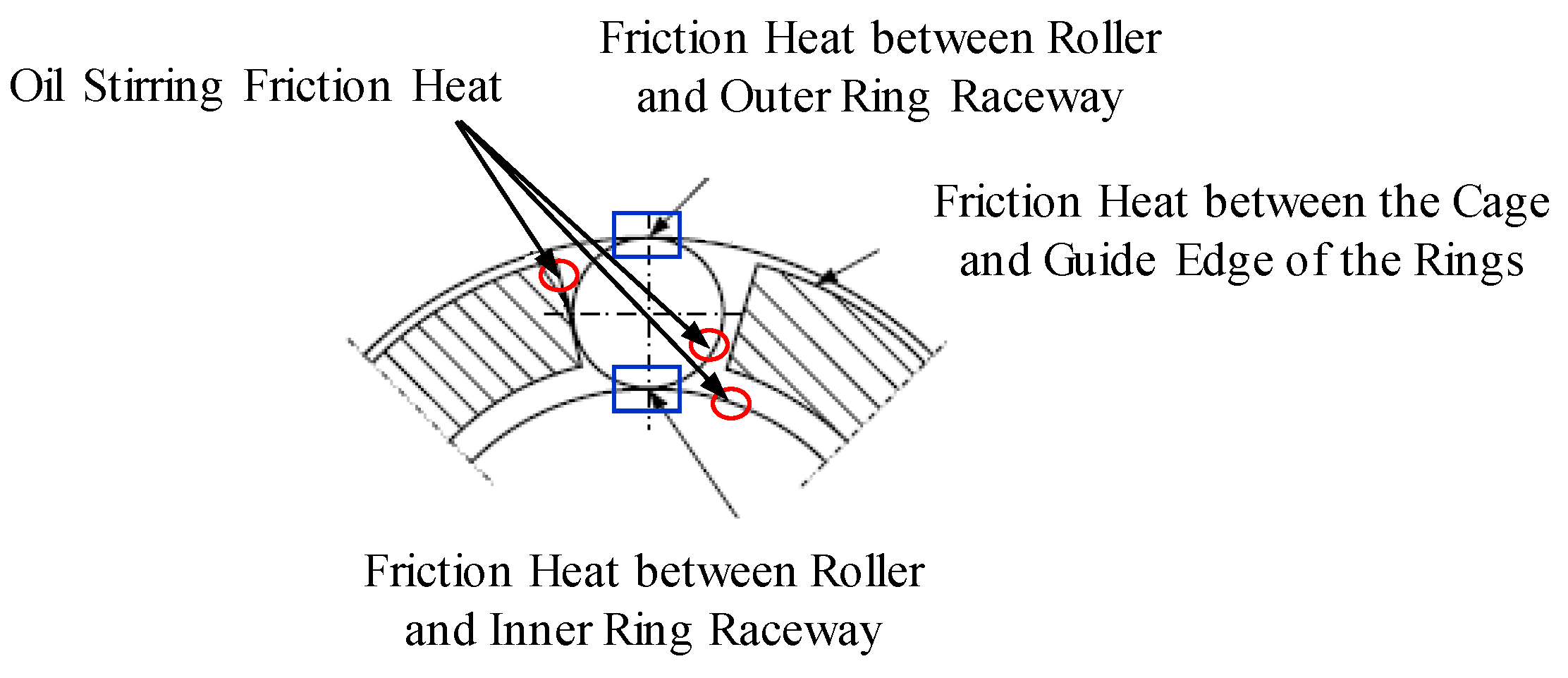

4.1. Friction Heat Source

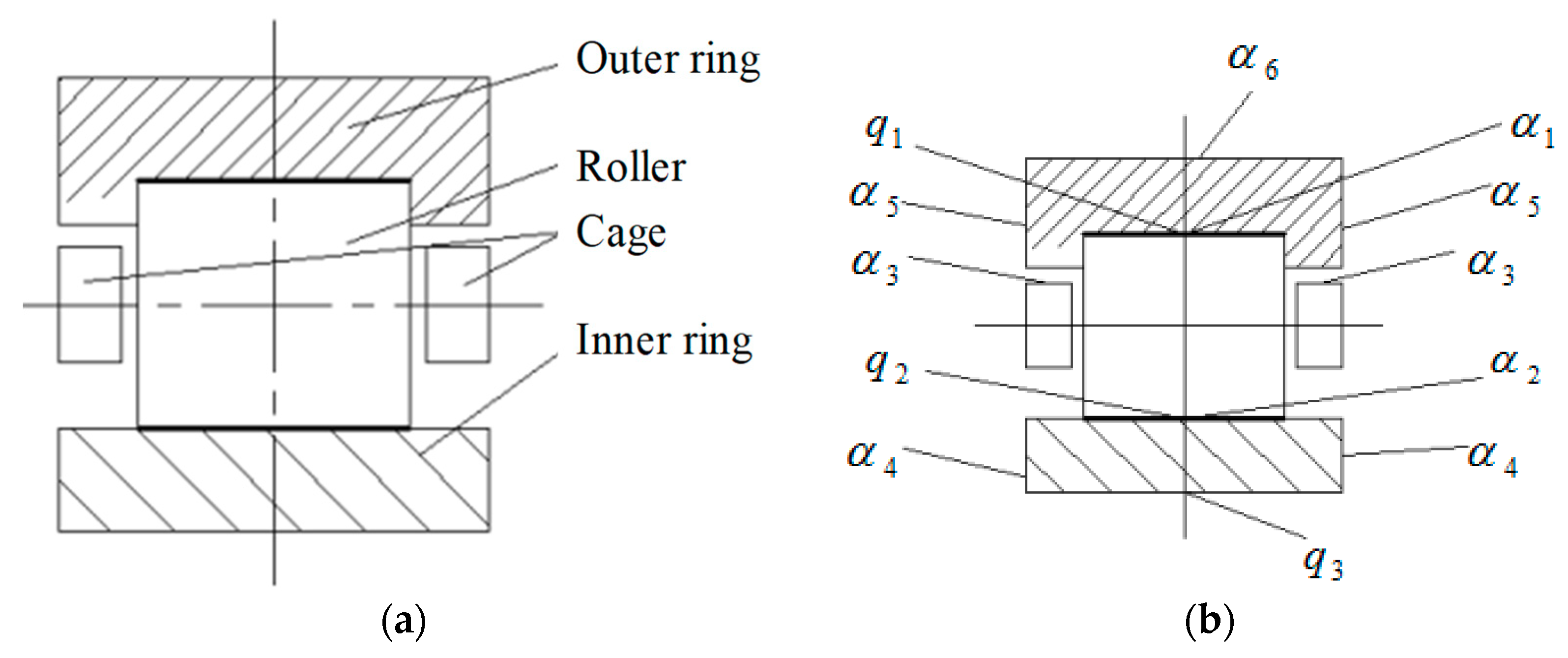

4.2. Temperature Field Analysis Model

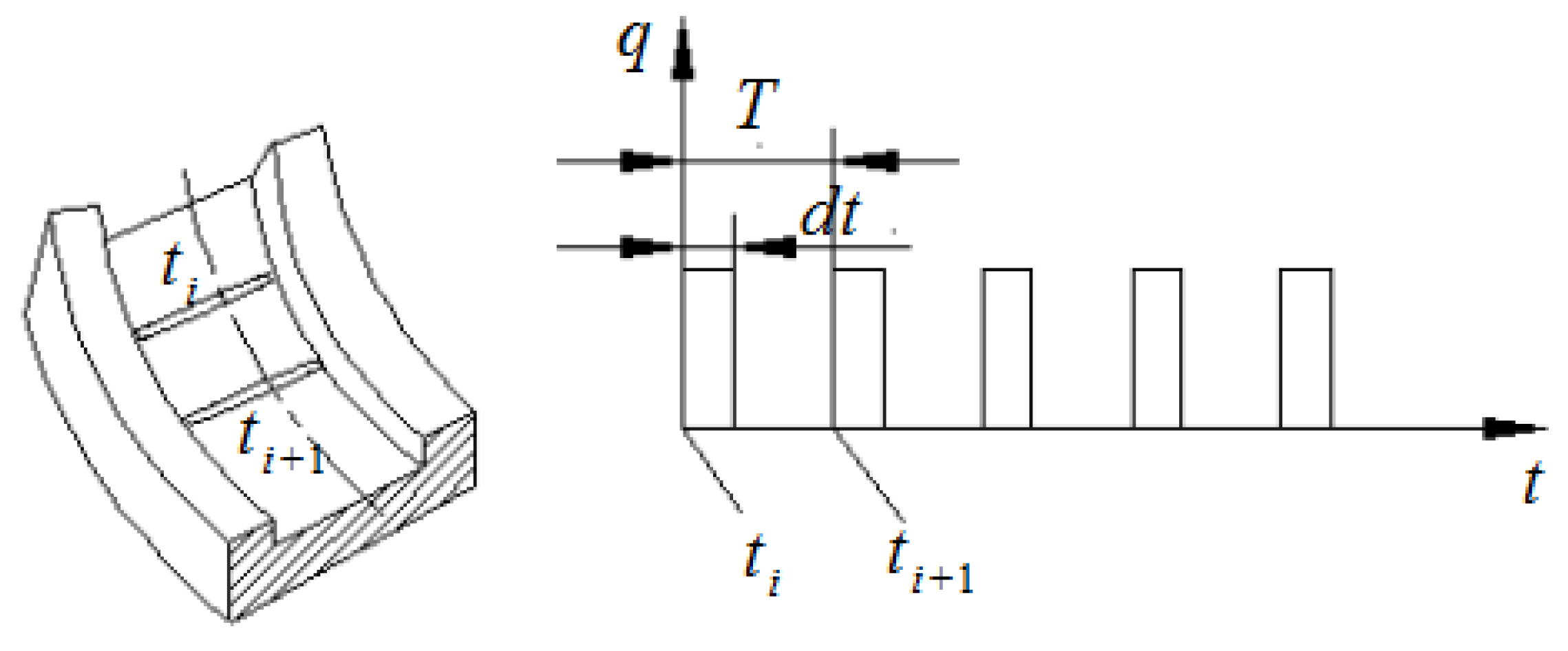

4.2.1. Contact and Heat Flux

4.2.2. Heat Transfer Model

4.3. Temperature Distribution Analysis

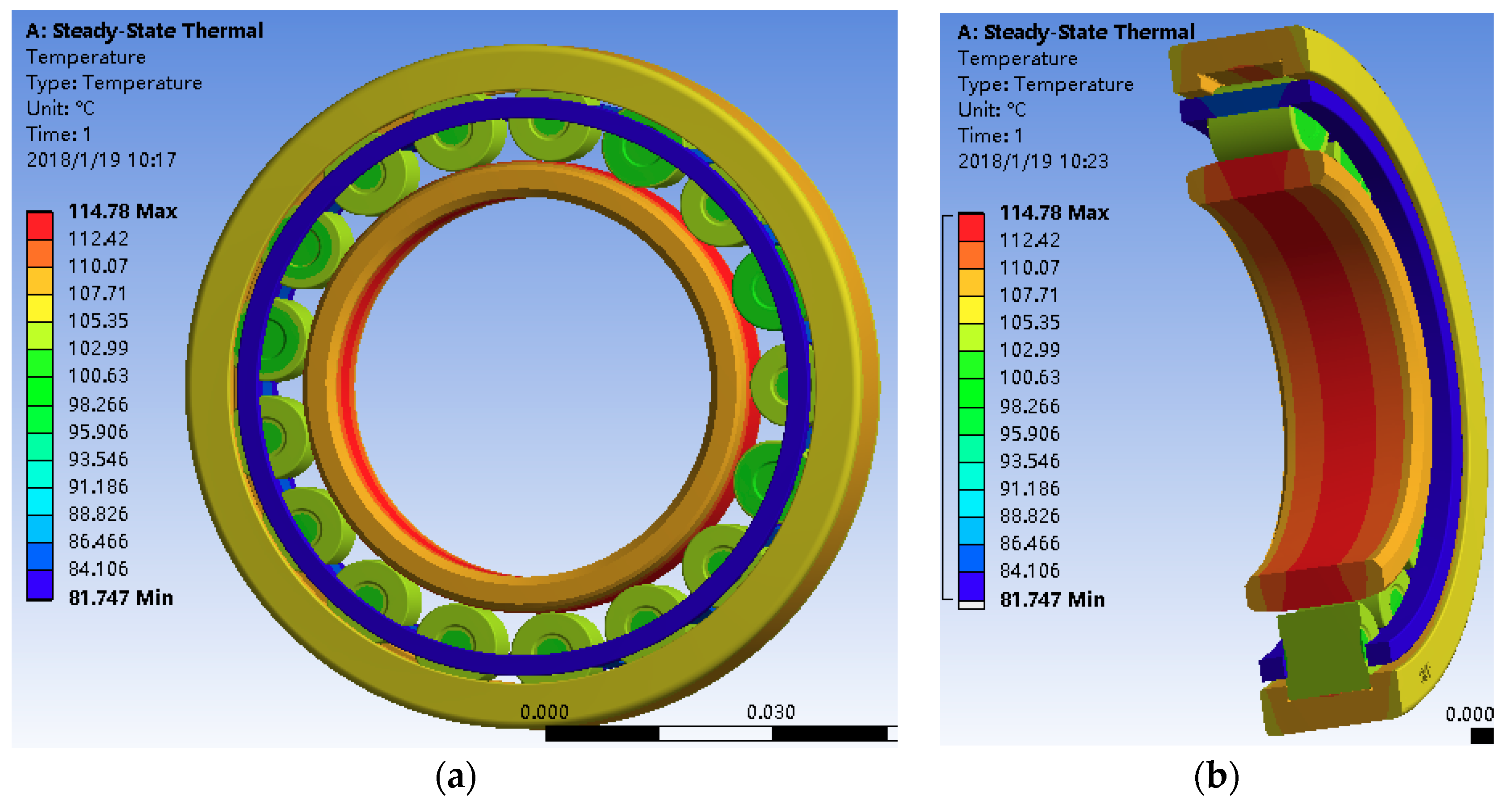

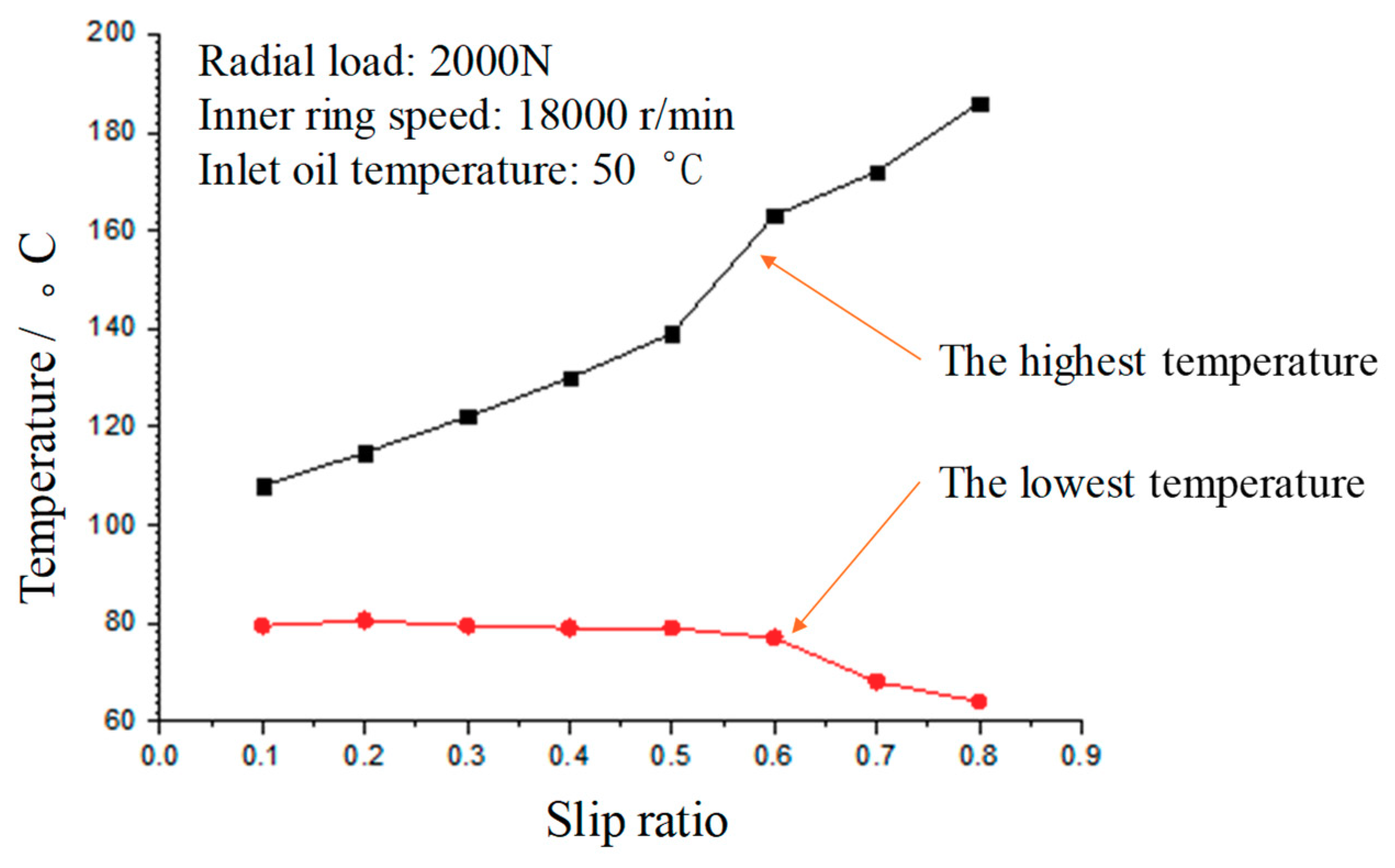

4.3.1. Steady-State Thermal Analysis

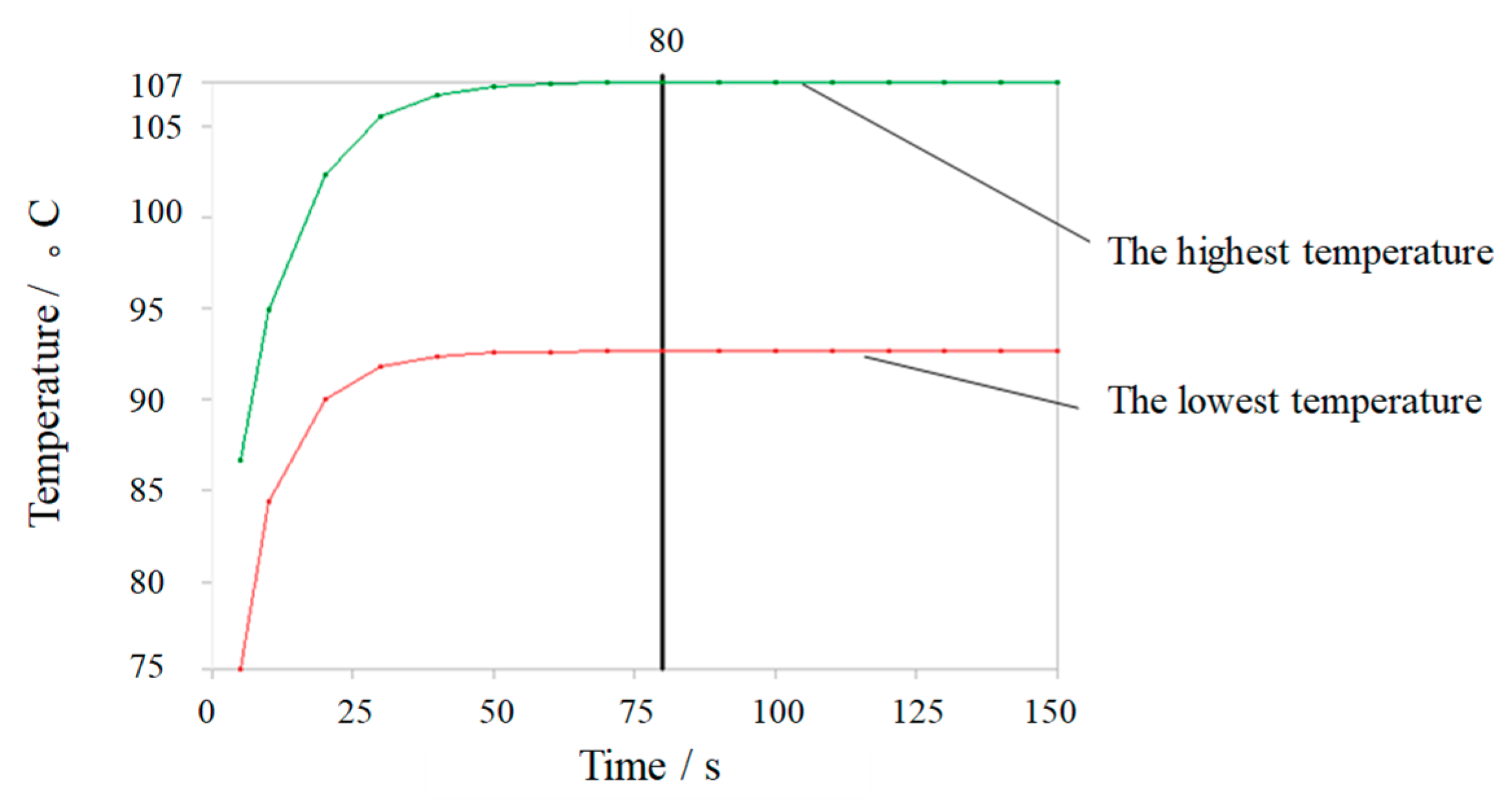

4.3.2. Transient Thermal Analysis

5. Experimental Validation

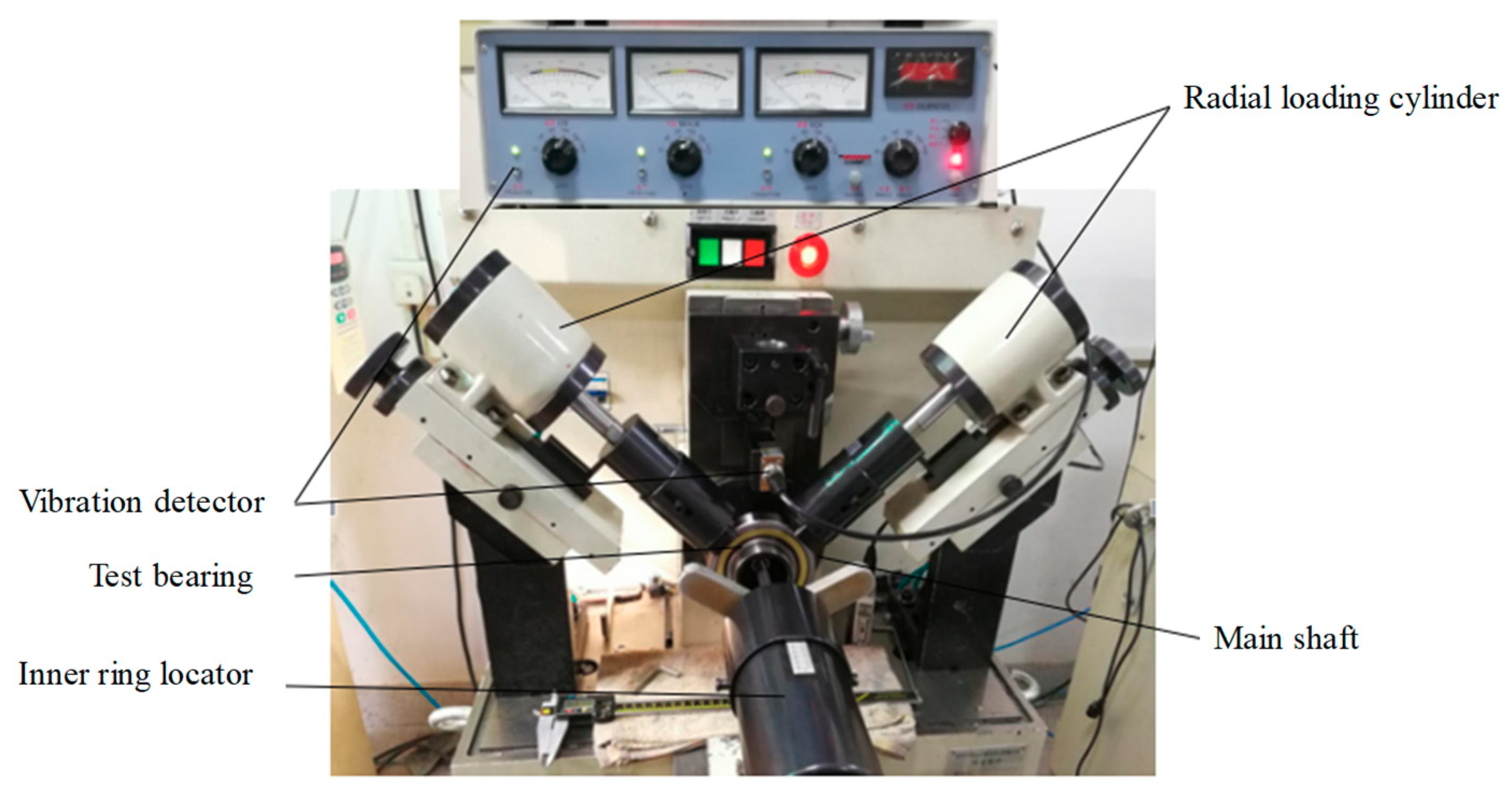

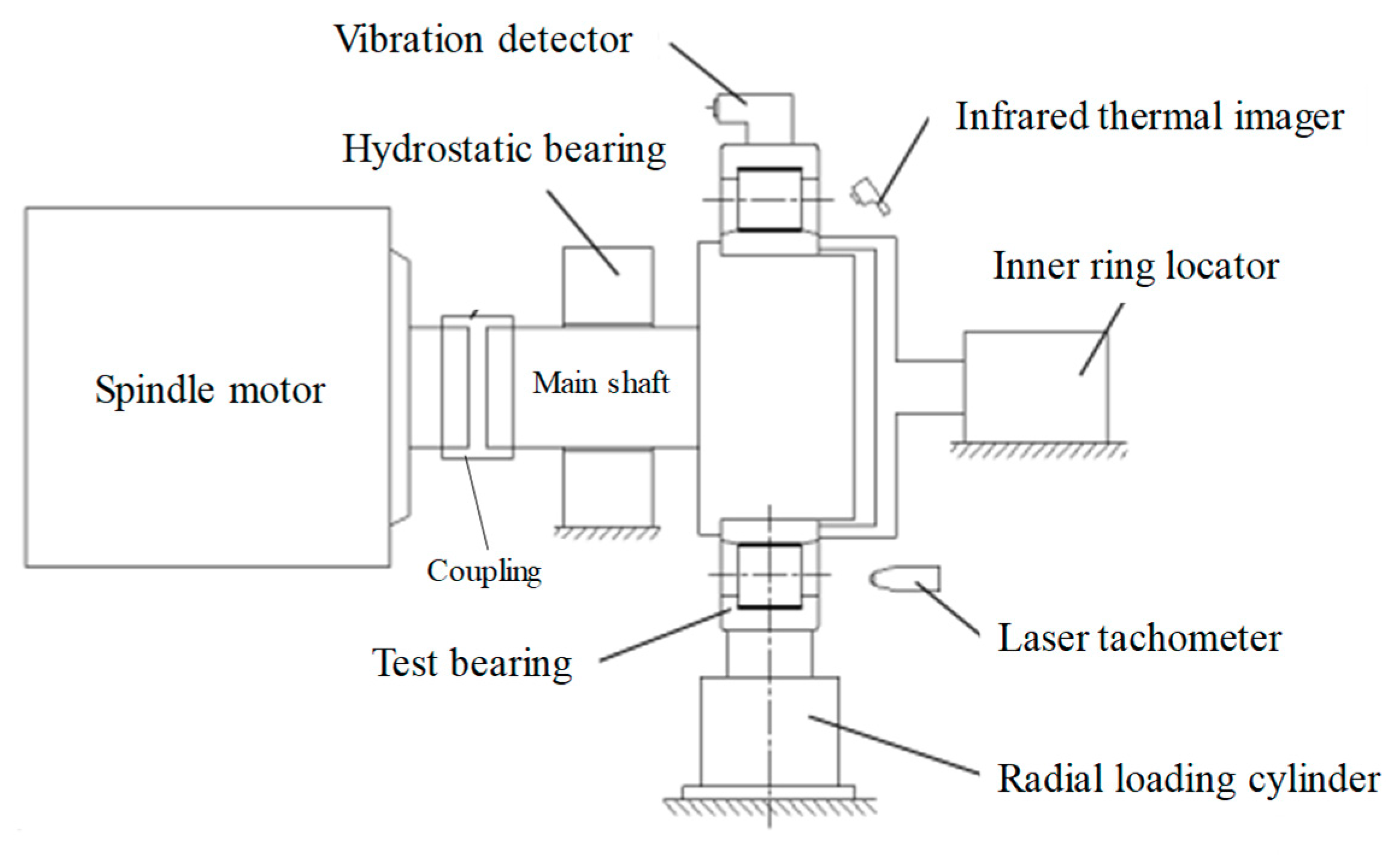

5.1. Test Rig and Test Method

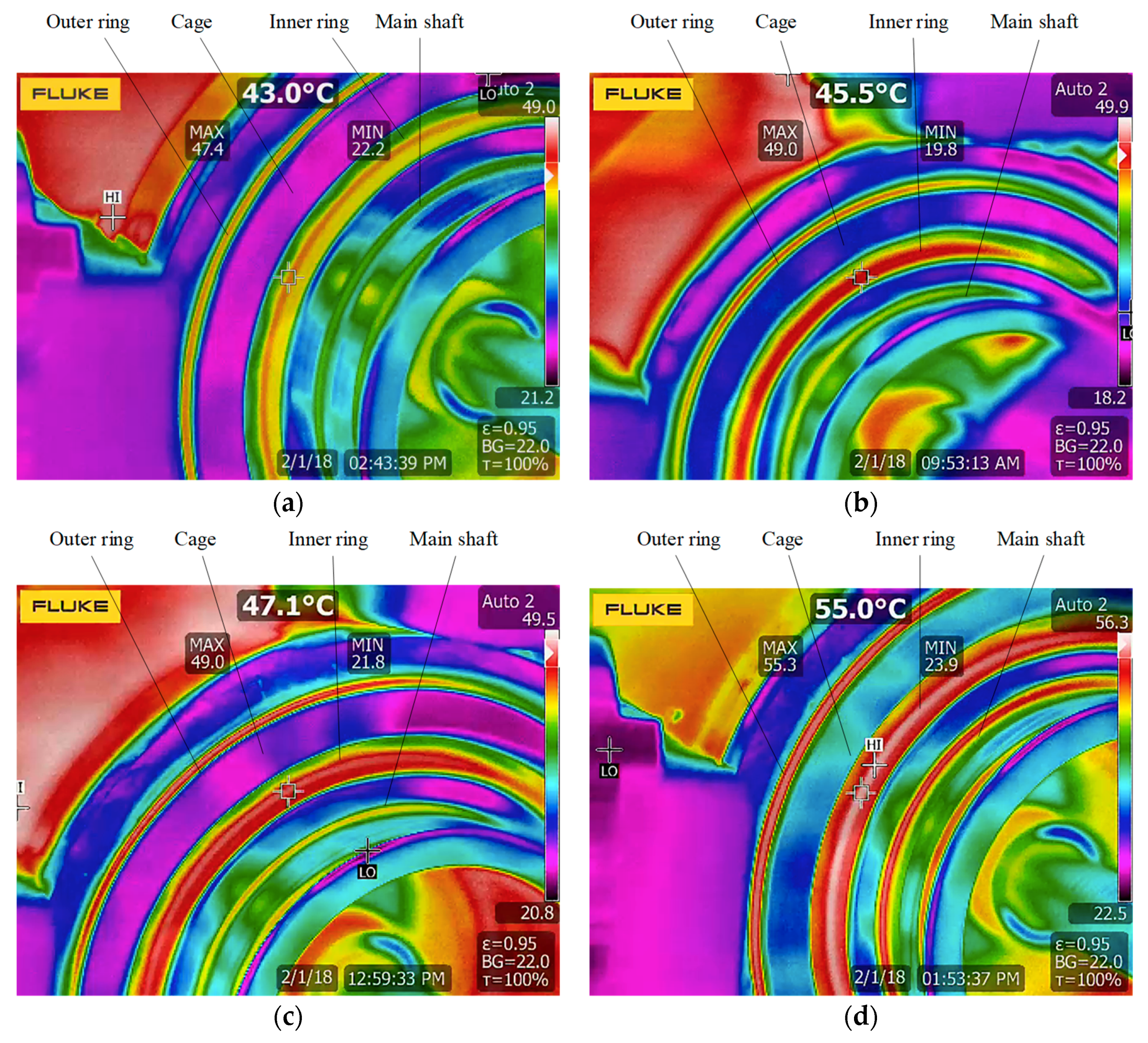

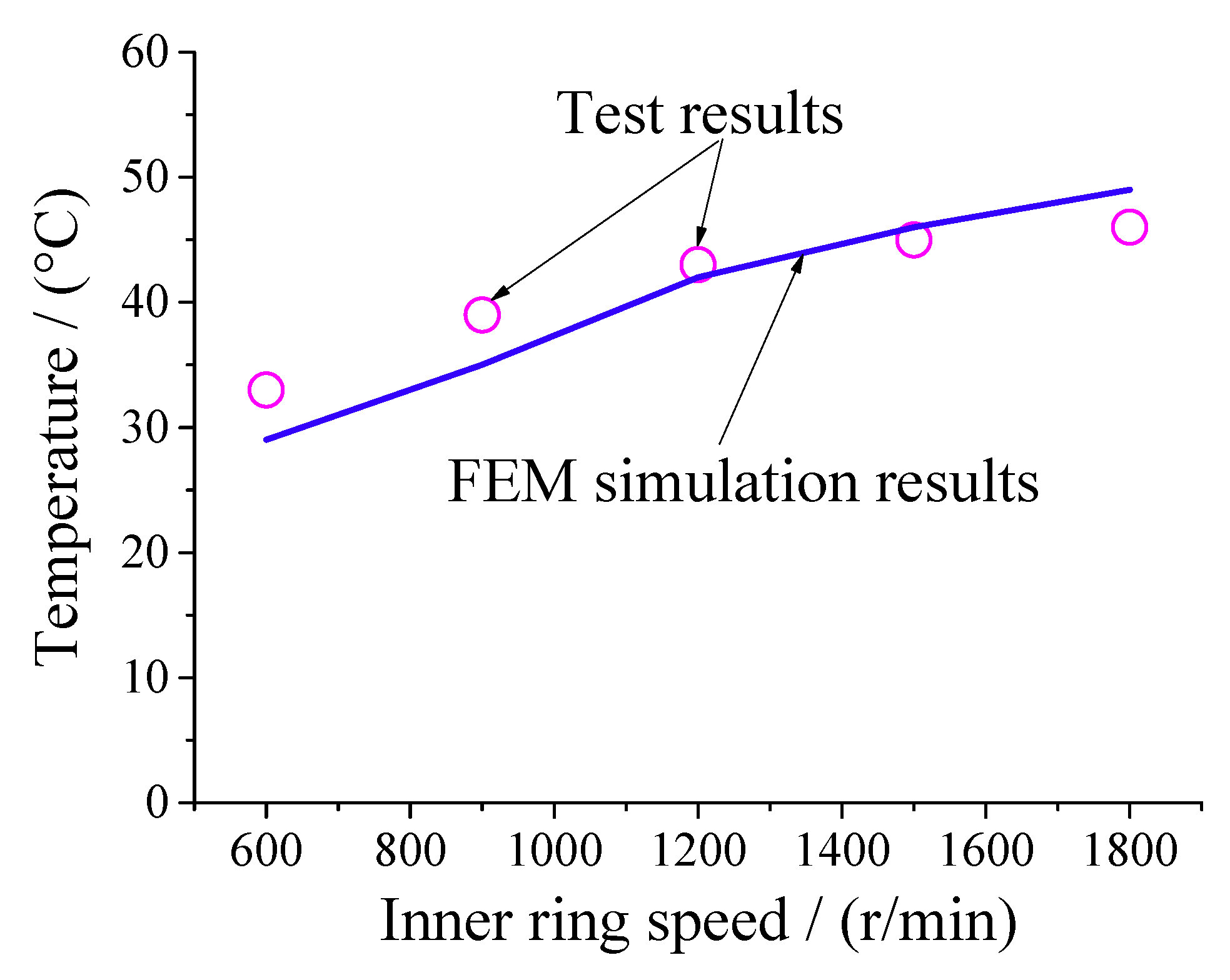

5.2. Results and Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

Parameters and Variables

| A | surface area, m2 |

| C | clearance between the cage and the inner ring, m |

| DCL | cage land diameter, m |

| DCR | cage rail diameter, m |

| Dh | diameter of the bearing seat surface, |

| Di | bore diameter, m |

| Dm | bearing pitch diameter, m |

| Dr | roller diameter, m |

| Fc | roller centrifugal force, N |

| FcL | friction force in the guide edge of the cage, N |

| Fr | radial load, N |

| Fv | viscous friction force, N |

| f | friction coefficient |

| fv | viscous friction coefficient |

| HcL | friction power loss between the cage and the guide edge of the rings, W |

| Hd | oil stirring friction power loss, W |

| Hi | friction power loss between the roller and inner ring raceway, W |

| Hidrag | friction power loss of oil stirring for the inner ring Hidrag, W |

| Ho | friction power loss between the roller and outer ring raceway, W |

| Hrdrag | friction power loss of oil stirring for the roller, W |

| K | oil heat conductivity coefficient |

| k | air heat conductivity coefficient |

| lCL | cage land width, m |

| le | roller length, m |

| li | inner ring width, m |

| n | inner ring speed, r/min |

| nc | cage speed, r/min |

| Q | contact force of each roller, N |

| R | bearing pitch radius, m |

| Re | Reynolds number |

| Ri | inner ring radius, m |

| r | reference radius, m |

| Sf | cage slip ratio |

| T | friction force, N |

| Ta | Taylor number |

| U | entrainment velocity, m/s |

| V | sliding velocity, m/s |

| v | absolute viscosity, pa·s |

| w | width of a lamina, m |

| Z | number of rollers per row |

| γ | Dr /Dm |

| Ɛ | load distribution coefficient |

| η | kinematic viscosity, cSt |

| ξ | density of the air oil mixture, kg/m3 |

| ωc | cage angular velocity, rad/s |

| ωcm | cage theoretical angular velocity, rad/s |

| ωi | shaft angular velocity, rad/s |

| ωrj | roller angular velocity about its own axis, rad/s |

| [C] | specific heat matrix |

| [T] | temperature vector |

| [K] | heat conduction matrix |

| [Q] | heat flux matrix |

| Subscripts: | |

| c | cage |

| i | inner raceway |

| j | roller located at φj |

| o | outer raceway |

| r | roller |

| u | unloaded roller |

| 0 | the most heavily loaded roller |

References

- Cao, H.; Niu, L.; Xi, S.; Chen, X. Mechanical model development of rolling bearing-rotor systems: A review. Mech. Syst. Signal Process. 2018, 102, 37–58. [Google Scholar] [CrossRef]

- Bercea, I.; Cretu, S.; Nélias, D. Analysis of double-row tapered roller bearings, Part I-Model. Tribol. Trans. 2003, 46, 228–239. [Google Scholar] [CrossRef]

- Takabi, J.; Khonsari, M.M. On the influence of traction coefficient on the cage angular velocity in roller bearings. Tribol. Trans. 2014, 57, 793–805. [Google Scholar] [CrossRef]

- Palmgren, A. Ball and Roller Bearing Engineering, 3rd ed.; SKF industries: Philadelphia, PA, USA, 1959. [Google Scholar]

- Astridge, D.G.; Smith, C.F. Heat Generation in High-speed Cylindrical Roller Bearings, In Proceedings of the Inst. Mech. Eng. Elasto-hydrodynamic Lubrication Symposium, Leeds, UK, 11–13 April 1972. [Google Scholar]

- Aramaki, H.; Shoda, Y.; Morishita, Y.; Sawamoto, T. The performance of ball bearings with silicon nitride ceramic balls in high speed spindles for machine tools. J. Tribol. 1988, 110, 693–698. [Google Scholar] [CrossRef]

- Rumbarger, J.H.; Filetti, E.G.; Gubemick, D. Gas turbine engine mainshaft roller bearing-system analysis. J. Lubr. Technol. 1973, 95, 401–416. [Google Scholar] [CrossRef]

- Harris, T.A.; Kotzalas, M.N. Advanced Concepts of Bearing Technology: Rolling Bearing Analysis, 5th ed.; CRC Press: Boca Raton, FL., USA, 2006. [Google Scholar]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Friction torque in grease lubricated thrust ball bearings. Tribol. Int. 2011, 44, 523–531. [Google Scholar] [CrossRef]

- Doki-Thonon, T.; Fillot, N.; Vergne, P.; Espejel, G.E.M. Numerical insight into heat transfer and power losses in spinning EHD non-Newtonian point contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 226, 23–25. [Google Scholar] [CrossRef]

- Doki-Thonon, T.; Fillot, N.; Espejel, G.E.M.; Querry, M.; philippon, D.; Devaux, N.; Vergne, P. A Dual Experimental/Numerical Approach for Film Thickness Analysis in TEHL Spinning Skewing Circular Contacts. Tribol. Lett. 2015, 50, 115–126. [Google Scholar] [CrossRef]

- Mizuta, K.; Inoue, T.; Takahashi, Y.; Huangm, S.; Ueda, K.; Omokawa, H. Heat transfer characteristics between inner and outer rings of an angular ball bearing. Heat Trans. Asian Res. 2003, 32, 42–57. [Google Scholar] [CrossRef]

- Ai, S.; Wang, W.; Wang, Y.; Zhao, Z. Temperature rise of double-row tapered roller bearings analyzed with the thermal network method. Tribol. Int. 2015, 87, 11–22. [Google Scholar] [CrossRef]

- Wu, W.; Li, X.; Xu, F. Investigating effects of non-uniform preload on the thermal characteristics of angular contact ball bearings through simulations. Proc. IMechE Part J J. Eng. Tribol. 2014, 228, 667–681. [Google Scholar] [CrossRef]

- Yan, K.; Wang, N.; Zhai, Q.; Zhu, Y.; Zhang, J.; Niu, Q. Theoretical and experimental investigation on the thermal characteristics of double-row tapered roller bearings of high speed locomotive. Int. J. Heat Mass Transfer 2015, 84, 1119–1130. [Google Scholar] [CrossRef]

- Takabi, J.; Khonsari, M.M. Experimental testing and thermal analysis of ball bearings. Tribol. Int. 2013, 60, 93–103. [Google Scholar] [CrossRef]

- Wang, L.; Chen, G.; Gu, L. Study on heat generation of high-speed cylindrical roller bearings. Lubr. Eng. 2007, 32, 8–11. [Google Scholar]

- Wang, L.; Chen, G.; Gu, L.; Zheng, D. Study on operating temperature of high-speed cylindrical roller bearings. J. Aerosp. Power 2008, 23, 179–183. [Google Scholar]

- Tarawneh, C.M.; Cole, K.D.; Wilson, B.M.; Fadi, A. Experiments and models for the thermal response of railroad tapered-roller bearings. Int. J. Heat Mass Transfer 2008, 51, 5794–5803. [Google Scholar] [CrossRef]

- Than, V.; Huang, J. Nonlinear thermal effects on high-speed spindle bearings subjected to preload. Tribol. Int. 2016, 96, 361–372. [Google Scholar] [CrossRef]

- Harris, T.A. An Analytical Method to Predict Skidding in High Speed Roller Bearings. ASLE Trans. 1966, 9, 229–241. [Google Scholar] [CrossRef]

- Laniado-Jacome, E.; Meneses-Alonso, J.; Diaz-Lopez, V. A study of sliding between rollers and races in a roller bearing with a numerical model for mechanical event simulations. Tribol. Int. 2010, 43, 2175–2182. [Google Scholar] [CrossRef]

- Tu, W.; Shao, Y.; Mechefske, C.K. An analytical model to investigate skidding in rolling element bearings during acceleration. J. Mech. Sci. Technol. 2012, 26, 2451–2458. [Google Scholar] [CrossRef]

- Han, Q.; Chu, F. Nonlinear dynamic model for skidding behavior of angular contact ball bearings. J. Sound. Vib. 2015, 354, 219–235. [Google Scholar] [CrossRef]

- Han, Q.; Li, X.; Chu, F. Skidding behavior of cylindrical roller bearings under time-variable load conditions. Int. J. Mech. Sci. 2018, 135, 203–214. [Google Scholar] [CrossRef]

- Li, J.; Chen, W.; Xie, Y. Experimental study on skid damage of cylindrical roller bearing considering thermal effect. Proc. IMechE Part J J. Eng. Tribol. 2014, 228, 1036–1046. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, P.; Shen, Y. Thermal analysis models of high speed cylindrical roller bearing. J. Mech. Sci. Technol. 1997, 16, 607–611. [Google Scholar]

- Parker, R.J. Comparison of Predicted and Experimental Thermal Performance of Angular-Contact Ball Bearings; National Aeronautics and Space Administration, Scientific and Technical Information Branch: Washington, DC, USA, 1984.

- Stribeck, R. Ball bearing for various loads. Trans. ASME 1907, 29, 420–463. [Google Scholar]

- Kannel, J.W.; Barber, S.A. Estimate of surface temperature during rolling contact. Tribol. Trans. 1989, 32, 305–310. [Google Scholar] [CrossRef]

- Burton, R.A.; Staph, H.E. Thermally Activated Seizure of Angular Contact Bearings. Tribol. Trans. 1967, 10, 408–417. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Inner ring (mm) | 50 | Roller length (mm) | 12 |

| Outer ring (mm) | 90 | Roller number | 16 |

| Pitch diameter (mm) | 70 | Inner ring speed (r/min) | 18,000 |

| Roller diameter (mm) | 12 | Radial load (N) | 2000 |

| Parameter | Density (kg/m3) | Elastic Modulus (GPa) | Thermal Conductivity (W/(m·k)) |

|---|---|---|---|

| Cage | 8430 | 100 | 108.9 |

| Roller | 7830 | 208 | 46 |

| Rings | 7830 | 208 | 46 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Xue, J.; Ma, Z. Study on the Thermal Distribution Characteristics of High-Speed and Light-Load Rolling Bearing Considering Skidding. Appl. Sci. 2018, 8, 1593. https://doi.org/10.3390/app8091593

Li J, Xue J, Ma Z. Study on the Thermal Distribution Characteristics of High-Speed and Light-Load Rolling Bearing Considering Skidding. Applied Sciences. 2018; 8(9):1593. https://doi.org/10.3390/app8091593

Chicago/Turabian StyleLi, Junning, Jiafan Xue, and Zhitao Ma. 2018. "Study on the Thermal Distribution Characteristics of High-Speed and Light-Load Rolling Bearing Considering Skidding" Applied Sciences 8, no. 9: 1593. https://doi.org/10.3390/app8091593

APA StyleLi, J., Xue, J., & Ma, Z. (2018). Study on the Thermal Distribution Characteristics of High-Speed and Light-Load Rolling Bearing Considering Skidding. Applied Sciences, 8(9), 1593. https://doi.org/10.3390/app8091593