Prototype Design and Performance Tests of Beijing Astronaut Robot

Abstract

:Featured Application

Abstract

1. Introduction

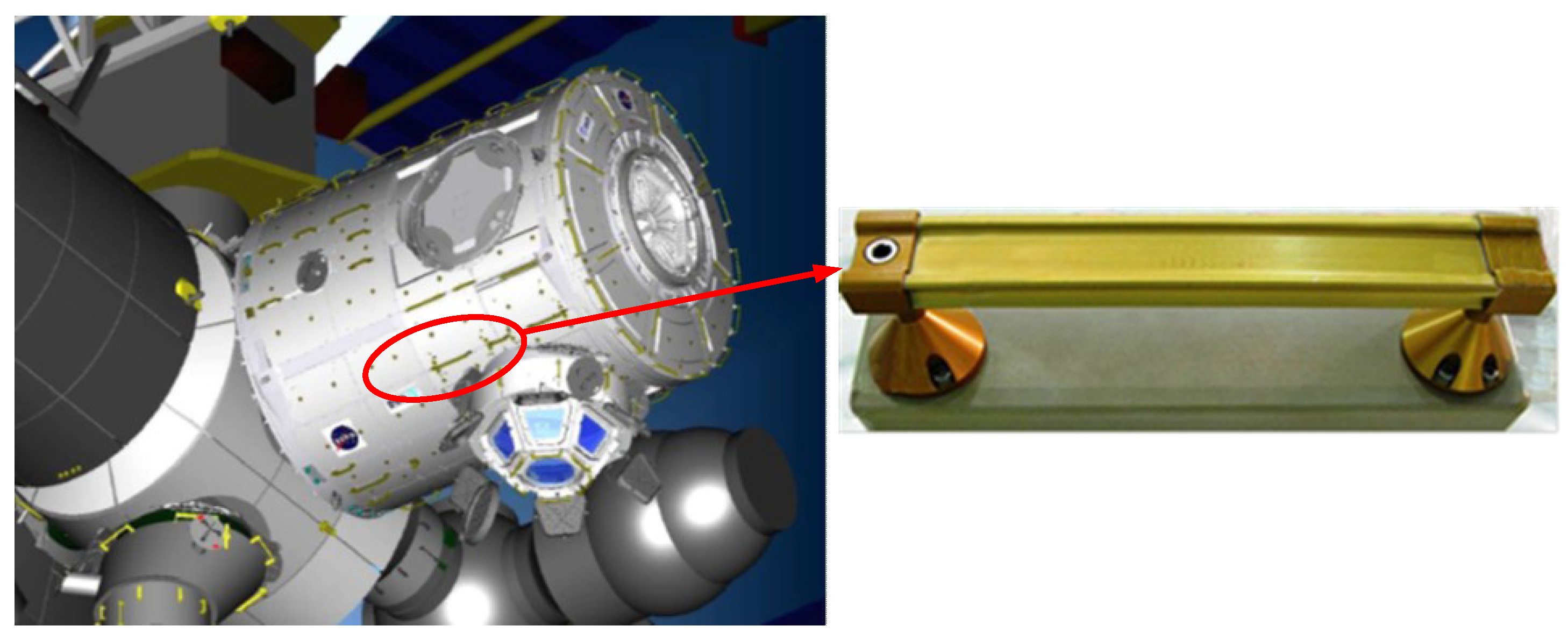

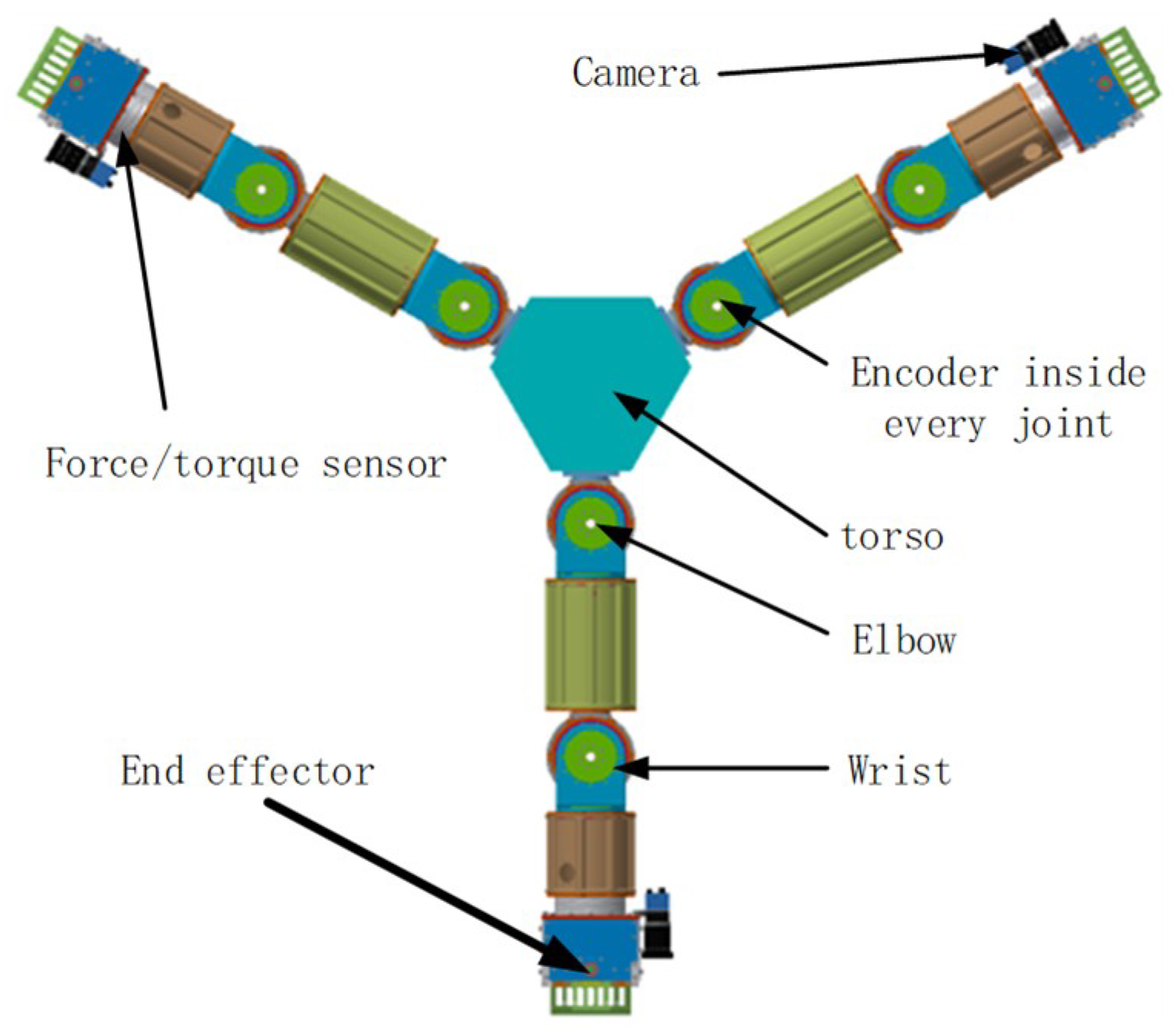

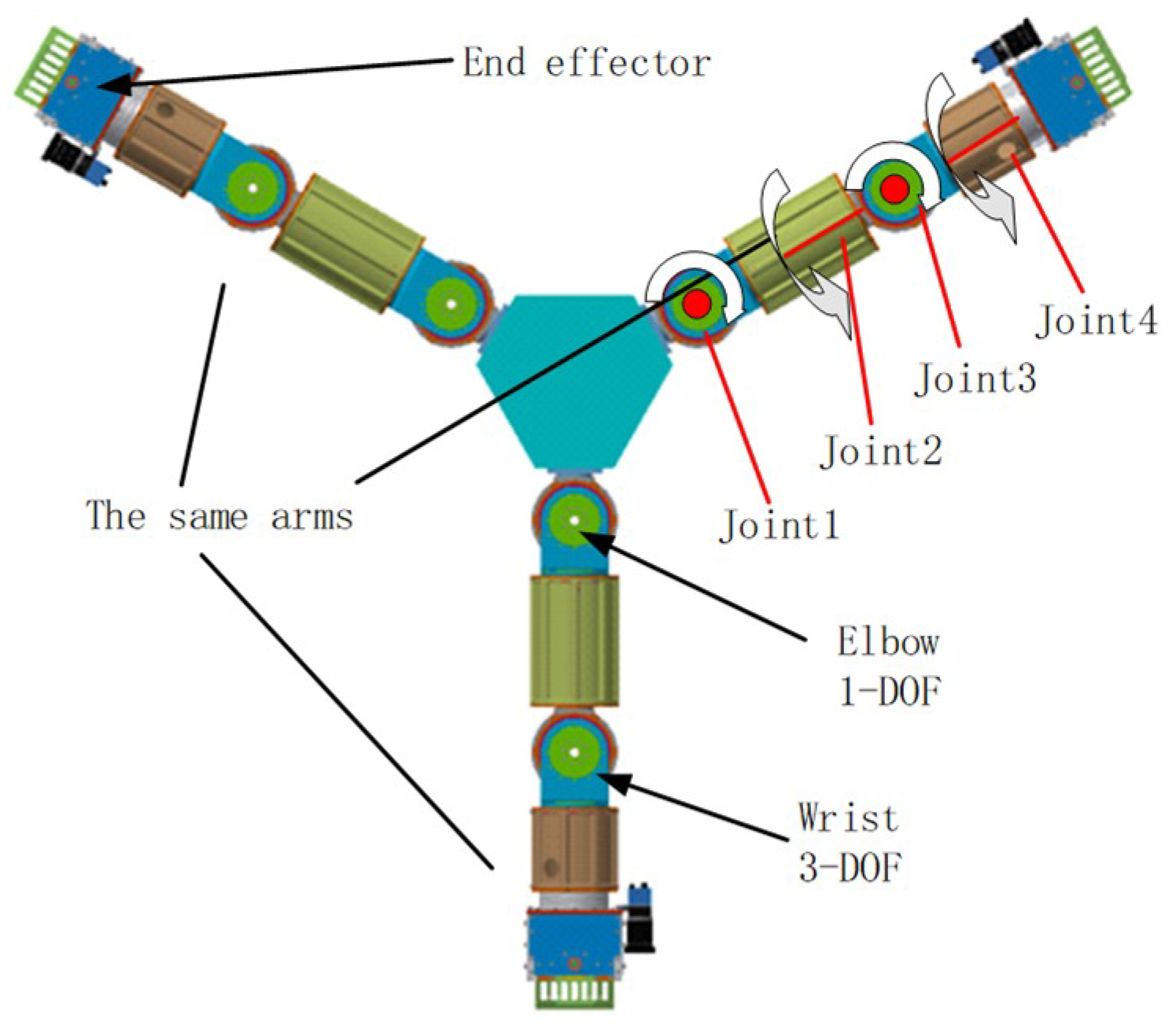

2. The Mechanical Structure and Test System Design of the Robot

2.1. Design Indicators

- The total mass of the robot is less than 30 kg;

- The total degrees of freedom (DOF) of the robot is no less than 12;

- The robot has at least three arms, each arm has no less than 4-DOF;

- The robot arm length is not more than 700 mm.

- Walking mode, the stride of the robot is not less than 30 cm, the robot movement speed is not less than 0.1 m/s;

- Rolling mode, the robot's stride is not less than 60 cm, the robot movement speed of not less than 0.2 m/s; and

- Sliding mode, the moving speed of the robot is not less than 0.5 m/s.

- Visual measurement accuracy not less than 1 mm in the range of 200 mm;

- End effector’s positioning accuracy within 2 mm;

- End effector’s force control accuracy within 2 N.

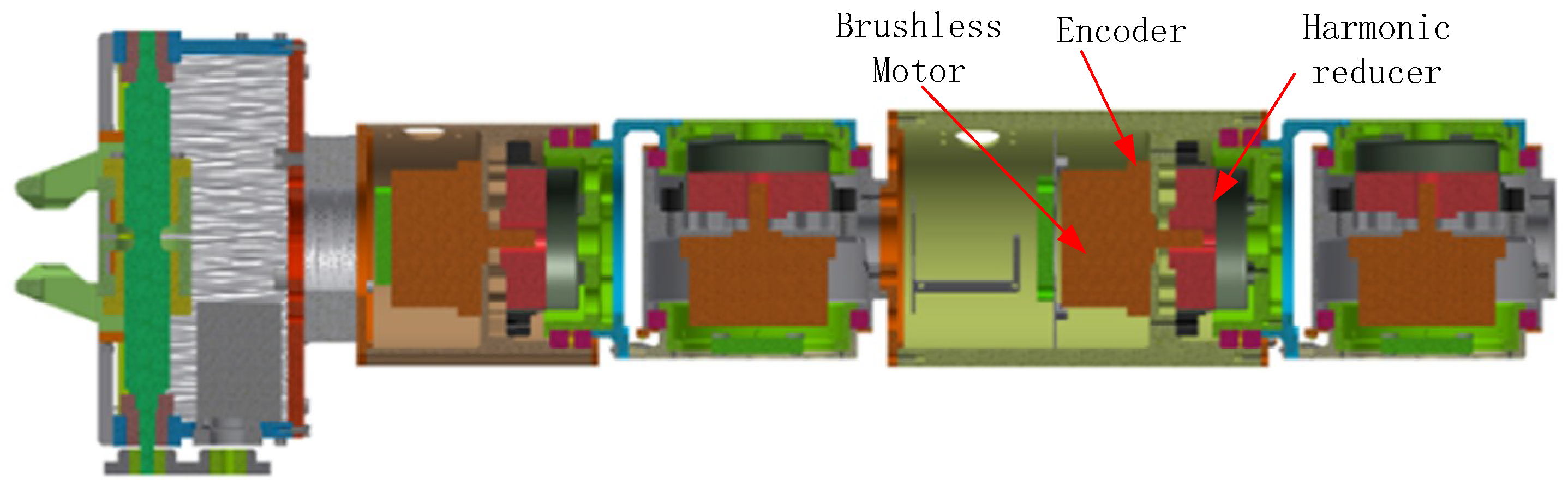

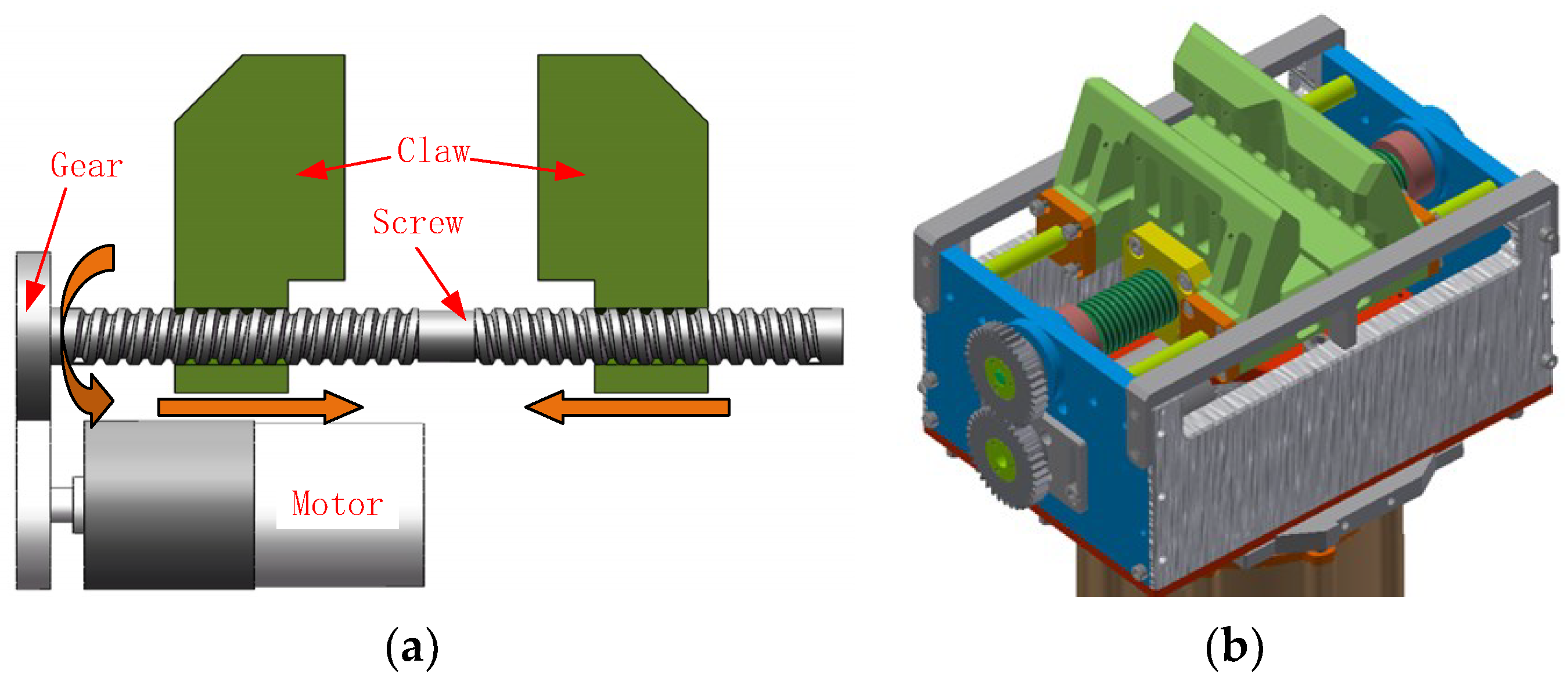

2.2. Structural Design and Key Technologies

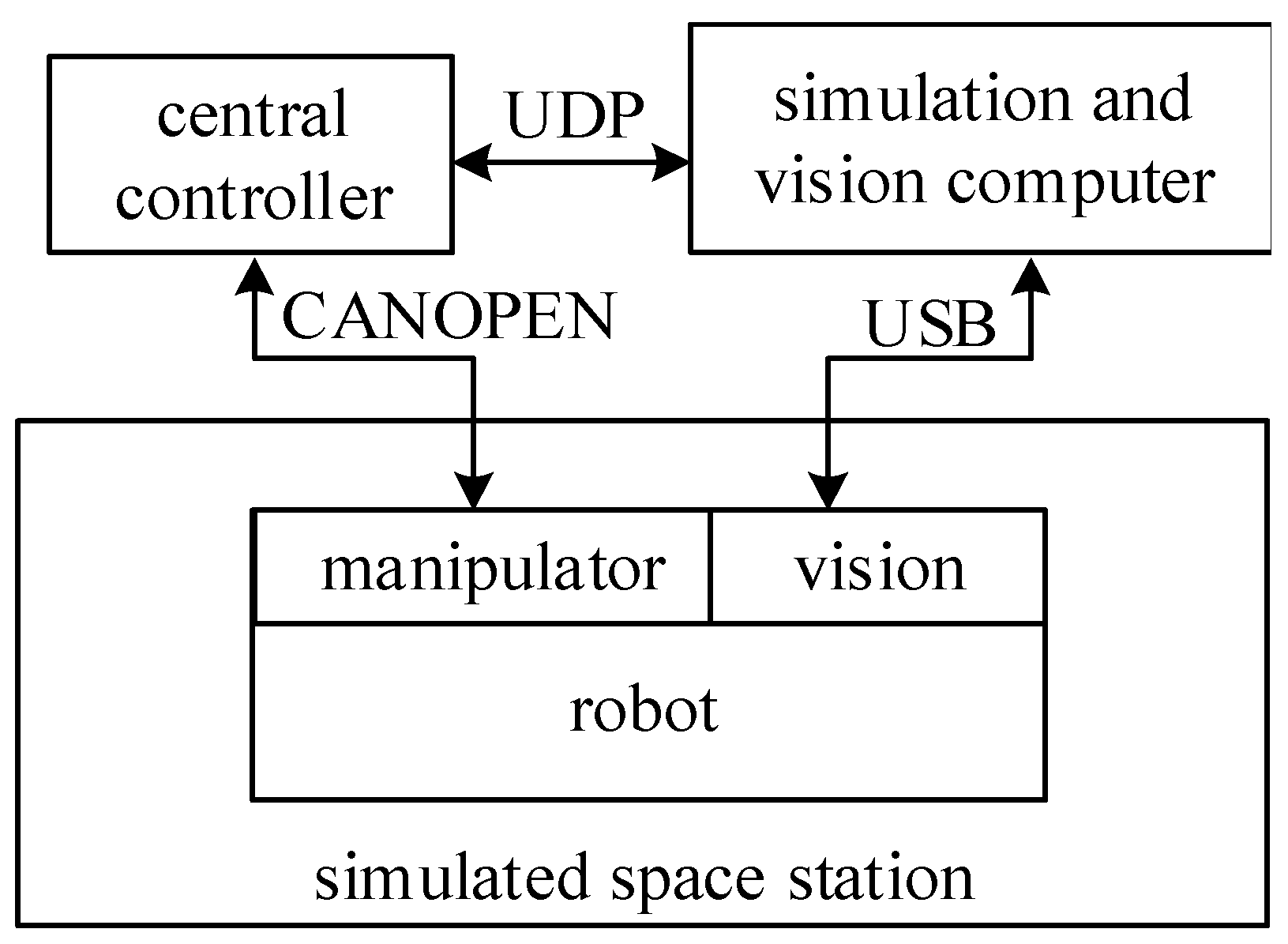

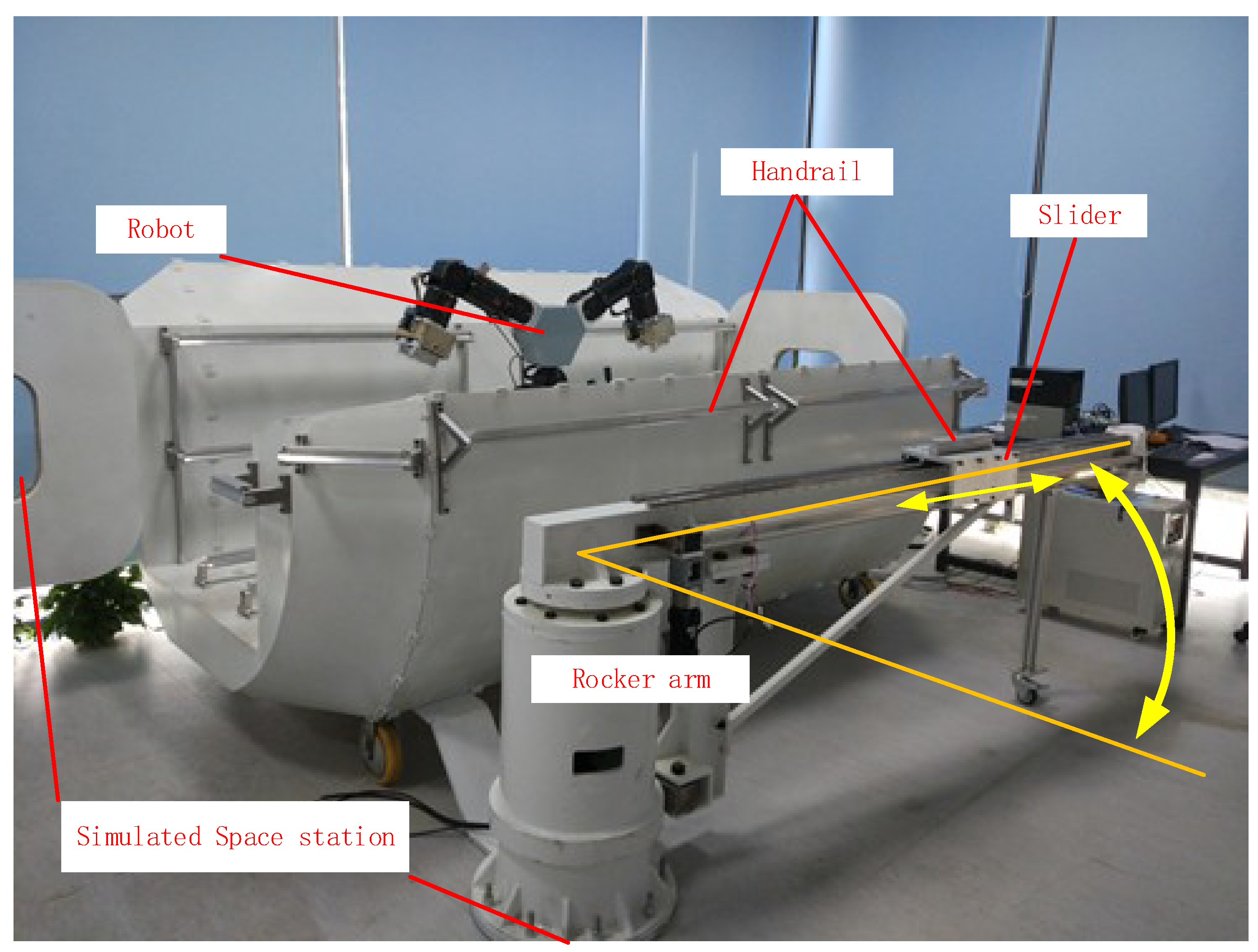

2.3. Testing Layout

3. Testing Results

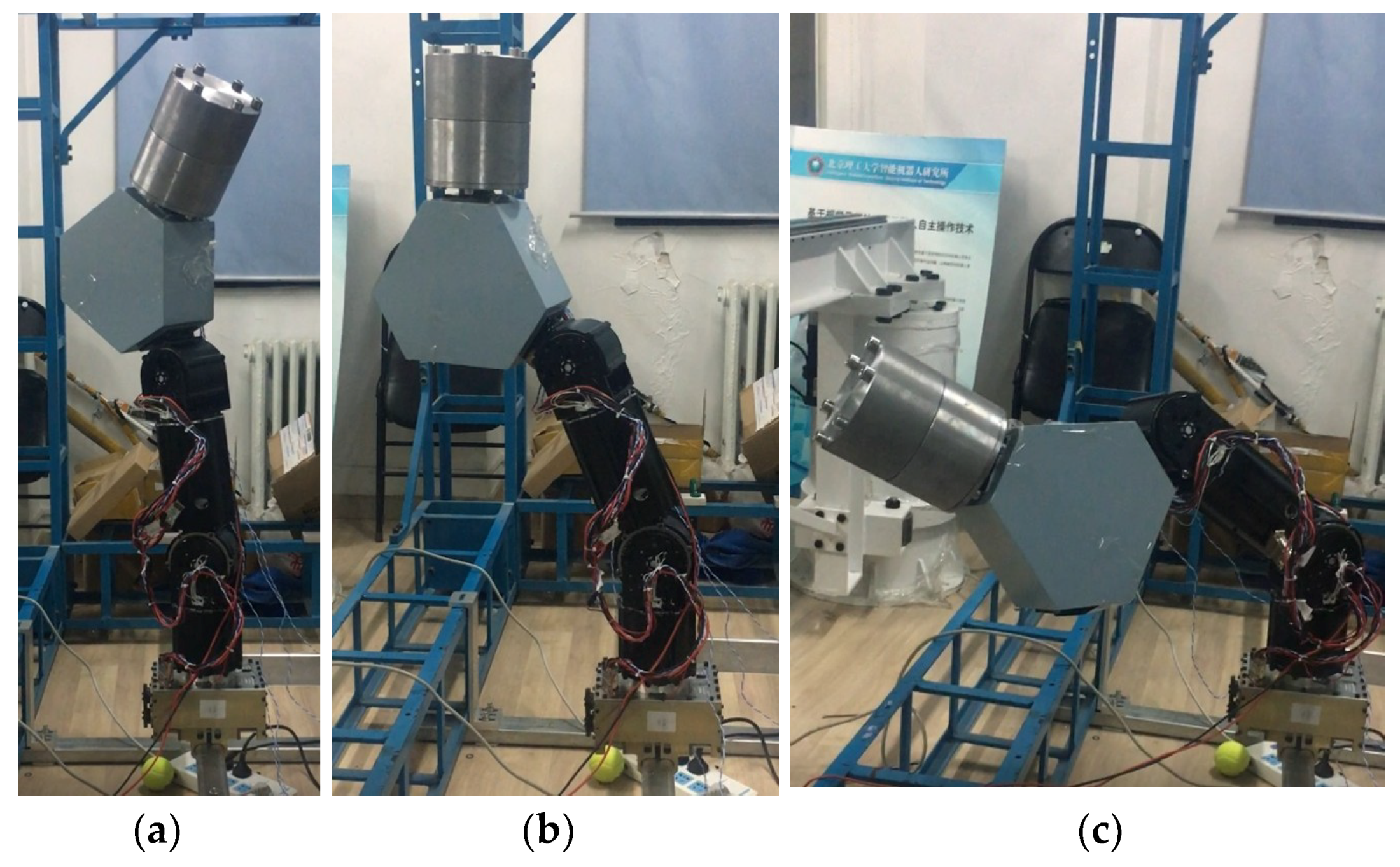

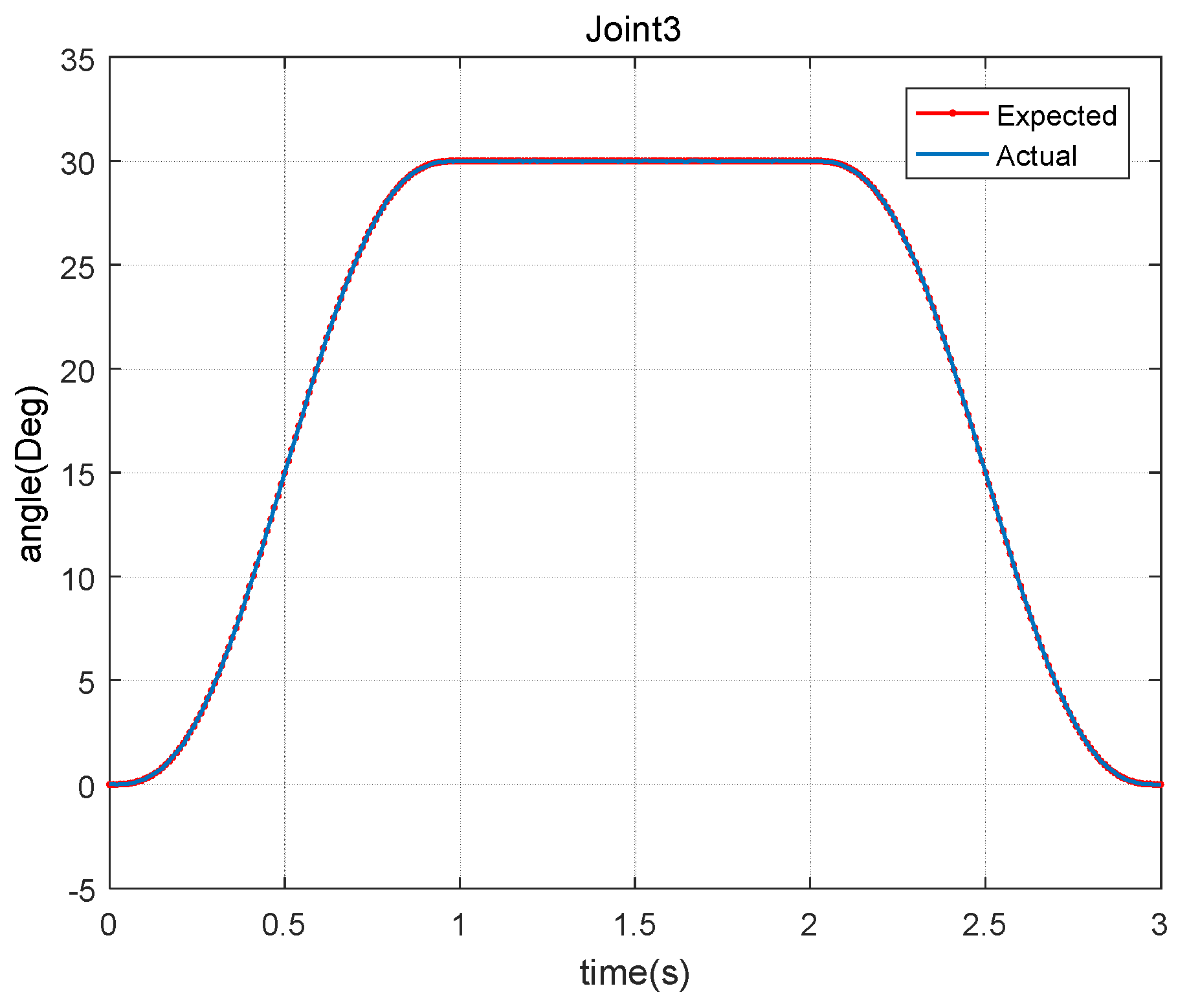

3.1. Motion Performance Test of A Single Arm

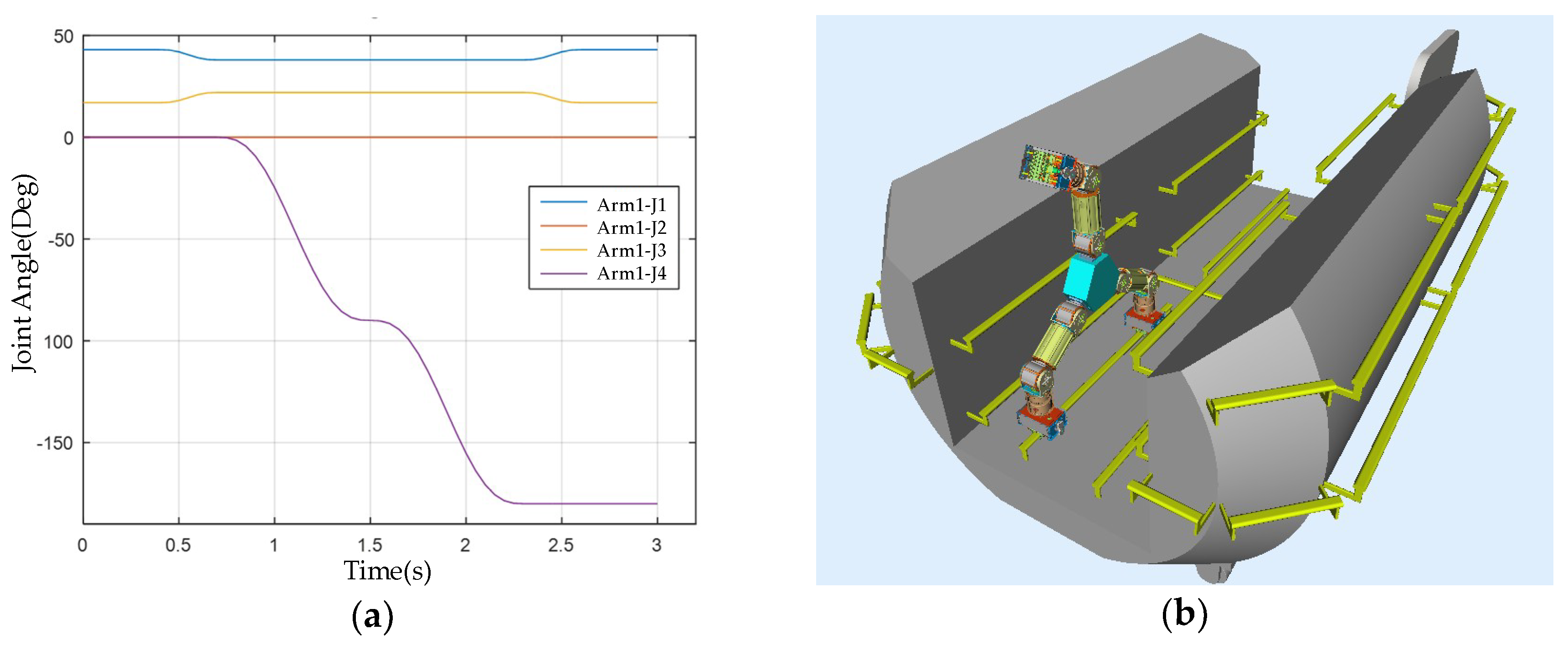

3.2. System Simulation Test

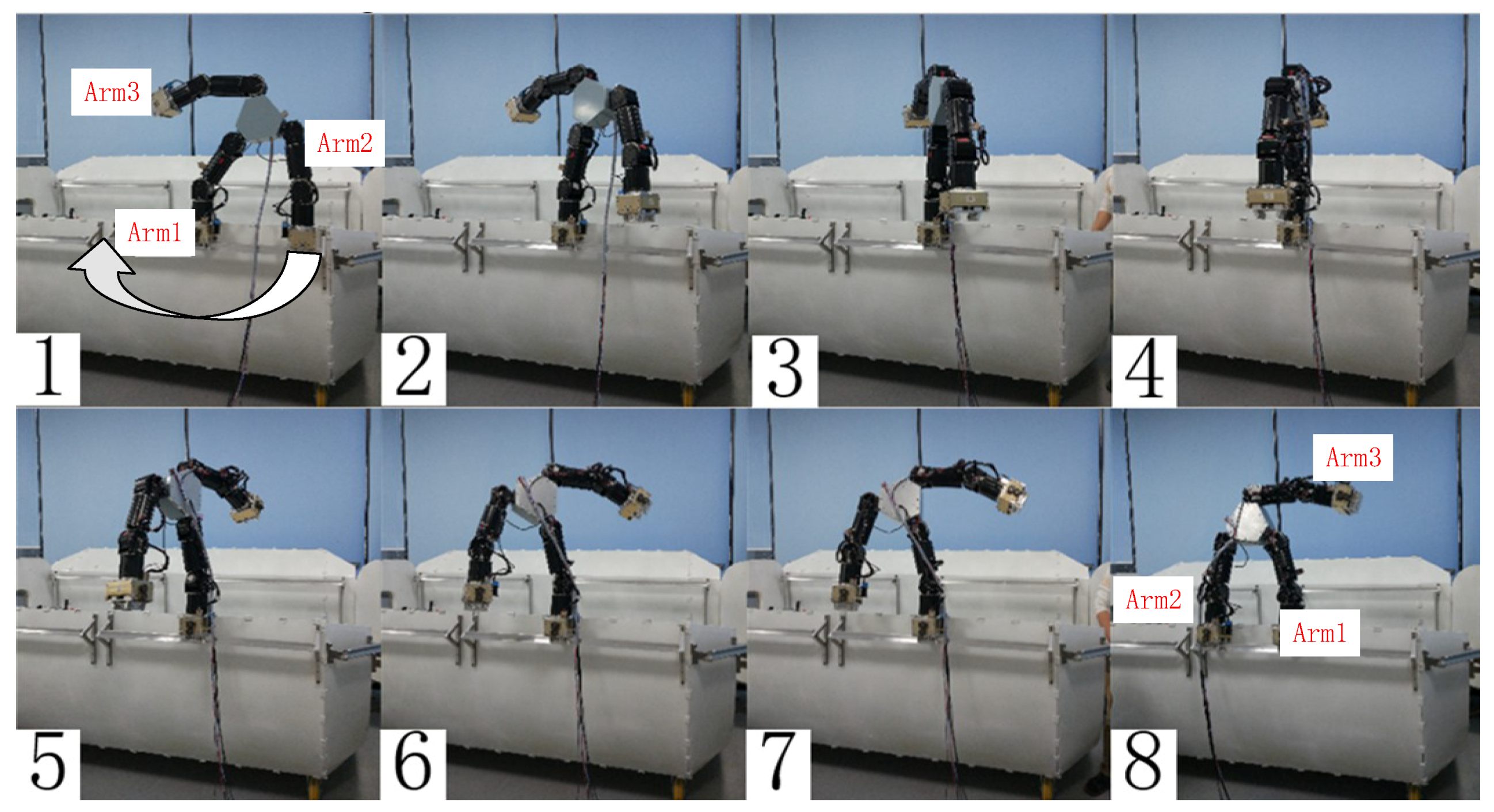

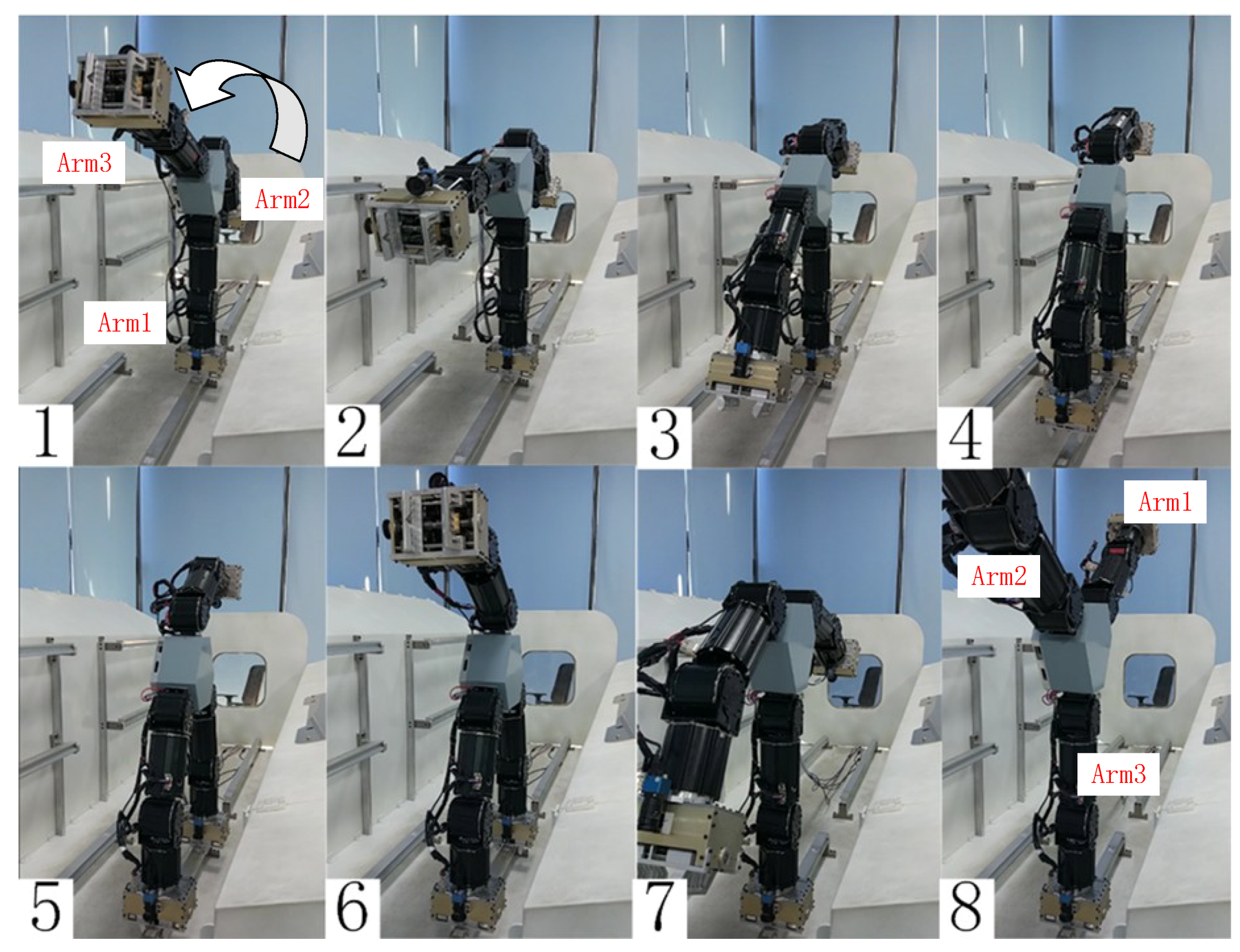

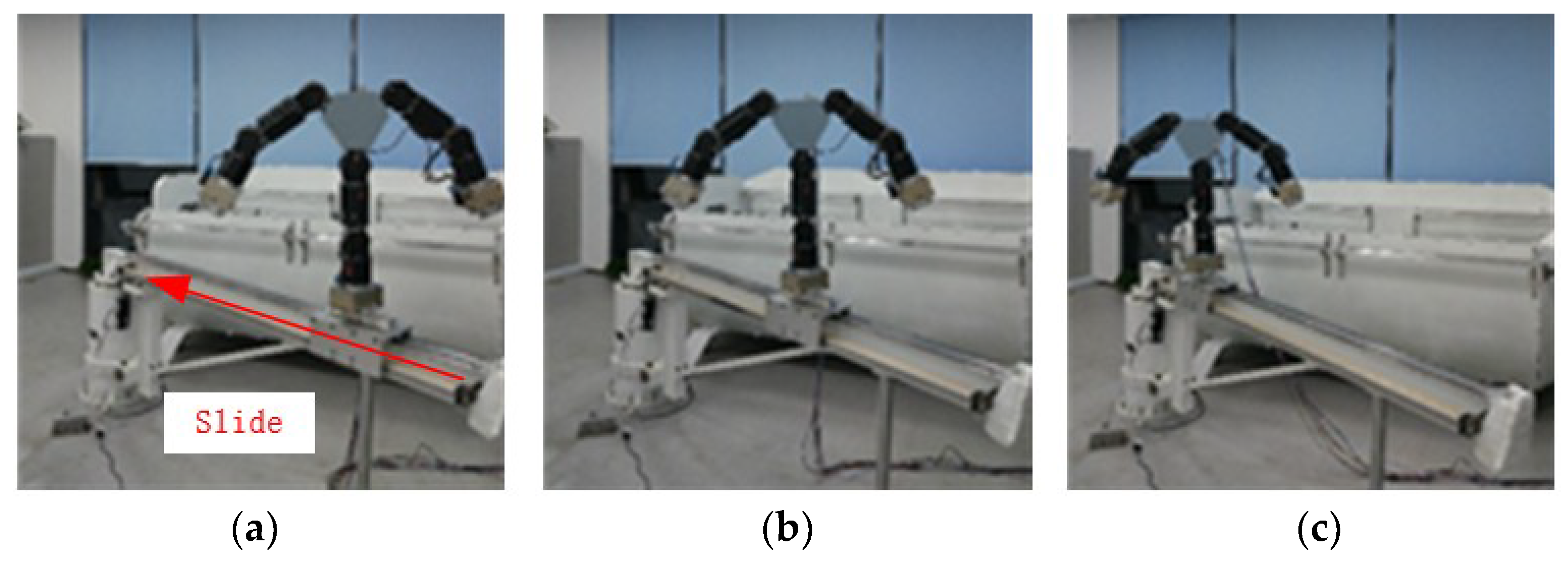

3.3. Motion Performance Test of the Robot

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thuot, P.J.; Harbaugh, G.J. Extravehicular activity training and hardware design consideration. Acta Astronaut. 1995, 36, 13–16. [Google Scholar] [CrossRef]

- Macelroy, R.D.; Smernoff, D.T. Controlled Ecological Life Support System: Regenerative Life Support Systems in Space. Available online: https://ntrs.nasa.gov/search.jsp?R=19880002869 (accessed on 1 September 1987).

- Zhang, T.; Chen, Z.; Wang, X.; Liang, B. Overview and Prospect of Key Technologies of Teleoperation of Space Robot. Aerosp. Control Appl. 2014, 40, 1–9. [Google Scholar]

- Doetsch, K. Canada’s role on space station. Acta Astronaut. 2005, 57, 661–675. [Google Scholar] [CrossRef] [PubMed]

- Diftler, M.A.; Culbert, C.J.; Ambrose, R.O.; Platt, R.J. Evolution of the NASA/DARPA Robonaut control system. IEEE ICRA 2003, 2, 2543–2548. [Google Scholar]

- Gibbs, G.; Sachdev, S. Canada and the international space station program: overview and status. Acta Astronaut. 2002, 51, 591–600. [Google Scholar] [CrossRef]

- Abramovici, A. The Special Purpose Dexterous Manipulator (SPDM) Systems Engineering Effort—A successful exercise in cheaper, faster and (hopefully) better systems engineering. J. Reduc. Space Mission Cost 1998, 1, 177–199. [Google Scholar] [CrossRef]

- Robotics, M.D. Mobile Servicing System—Data Sheet. MD Robotics, Brampton, Ontario, Canada 2002. Available online: http://www.spacenet.on.ca/data/pdf/canada-in-space/mss-ds.pdf (accessed on 23 January 2002).

- Ni, W.; Zhang, B.; Yang, H.; Li, H.; Jiang, Z.; Huang, Q. Foot/hand design for a chameleon-like service robot in space station. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12–14 December 2013; pp. 215–220. [Google Scholar]

- Fischer, M.S.; Krause, C.; Lilje, K.E. Evolution of chameleon locomotion, or how to become arboreal as a reptile. Zoology 2010, 113, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Coleshill, E.; Oshinowo, L.; Rembala, R.; Bina, B.; Rey, D.; Sindelar, S. Dextre: Improving maintenance operations on the international space station. Acta Astronaut. 2009, 64, 869–874. [Google Scholar] [CrossRef]

- Prahlad, H.; Pelrine, R.; Stanford, S.; Marlow, J.; Kornbluh, R. Electroadhesive Robots—Wall Climbing Robots Enabled by a Novel, Robust, and Electrically Controllable Adhesion Technology. In Proceedings of the IEEE ICRA and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 3028–3033. [Google Scholar]

- Hui, L.; Marco, C.; Qiang, H.; Giuseppe, C. A Chameleon-Like Service Robot for Space Station. In Proceedings of the International Workshop on Bio-Inspired Robots, Nantes, France, 6–8 April 2011. [Google Scholar]

- Marco, C. Grasping in Robotics; Springer: Berlin, Germany, 2013; pp. 117–120. ISBN 978-1-4471-4664-3. [Google Scholar]

- Sabatini, M.; Palumbo, N.; Gasbarri, P. Virtual and Rapid Prototyping of an Underactuated Space End Effector. J. Robot. Autom. 2017, 1, 10–21. [Google Scholar]

- Farsi, M.; Ratcliff, K.; Barbosa, M. An introduction to CANopen. Comput. Control Eng. J. 1999, 10, 161–168. [Google Scholar] [CrossRef]

- Postel, J. User Datagram Protocol. Available online: https://tools.ietf.org/html/rfc768 (accessed on 28 August 1980).

- Baglio, S.; Castorina, S.; Fortuna, L.; Savalli, N. Modeling and design of novel photo-thermo-mechanical microactuators. Sens. Actuators A 2002, 101, 185–193. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Li, H.; Jiang, Z.; Song, Z.; Mo, Y.; Ceccarelli, M. Prototype Design and Performance Tests of Beijing Astronaut Robot. Appl. Sci. 2018, 8, 1342. https://doi.org/10.3390/app8081342

Sun Z, Li H, Jiang Z, Song Z, Mo Y, Ceccarelli M. Prototype Design and Performance Tests of Beijing Astronaut Robot. Applied Sciences. 2018; 8(8):1342. https://doi.org/10.3390/app8081342

Chicago/Turabian StyleSun, Zeyuan, Hui Li, Zhihong Jiang, Zhenzi Song, Yang Mo, and Marco Ceccarelli. 2018. "Prototype Design and Performance Tests of Beijing Astronaut Robot" Applied Sciences 8, no. 8: 1342. https://doi.org/10.3390/app8081342

APA StyleSun, Z., Li, H., Jiang, Z., Song, Z., Mo, Y., & Ceccarelli, M. (2018). Prototype Design and Performance Tests of Beijing Astronaut Robot. Applied Sciences, 8(8), 1342. https://doi.org/10.3390/app8081342