Abstract

This research developed a comprehensive computer model for a lab-scale Slurry Bubble Column Reactor (SBCR) (0.1 m Dt and 2.5 m height) for Fischer–Tropsch (FT) synthesis under flexible operation of synthesis gas load flow rates. The variable loads of synthesis gas are set at 3.5, 5, 7.5 m3/h based on laboratory adjustments at three different operating temperatures (483, 493 and 503 K). A set of Partial Differential Equations (PDEs) in the form of mass transfer and chemical reaction are successfully coupled to predict the behavior of all the FT components in two phases (gas and liquid) over the reactor bed. In the gas phase, a single-bubble-class-diameter (SBCD) is adopted and the reduction of superficial gas velocity through the reactor length is incorporated into the model by the overall mass balance. Anderson Schulz Flory distribution is employed for reaction kinetics. The modeling results are in good agreement with experimental data. The results of dynamic modeling show that the steady state condition is attained within 10 min from start-up. Furthermore, they show that step-wise syngas flow rate does not have a detrimental influence on FT product selectivity and the dynamic modeling of the slurry reactor responds quite well to the load change conditions.

1. Introduction

In the last decade, Carbon Capture Utilization (CCU) with the aid of Renewable Energy Source (RES) power has led to significant progress in the field of Power to Gas (PtG) and Power to Liquid (PtL) technologies. In order to reduce Greenhouse Gas (GHG) emissions, European Energy policy proposes that the share of renewable energy is 40% by 2020 and 80% by 2050 [1]. This electricity-to-fuel process stabilizes the electrical power grid by converting the fluctuating characteristics of Renewable Energy Sources into storable energy carrier e.g., gaseous hydrocarbons (H2 or CH4) in PtG. This process may also provide liquid fuel for the use of chemicals and transport in PtL technology [2]. In this respect, Power to Liquid is a strong candidate for the transformation of power into chemical electricity as there is no loss during long-term storage; it has wide-ranging applications in the transport sector, due to its high energy density which is compatible with existing infrastructures [3]. The main pathway in this transformation is Fischer–Tropsch Synthesis, which offers many advantages in the process design and for optimizing product selectivity. The feedstock of the FT process is attained using generated synthesis gas and steam/co-electrolysis can be employed for generating syngas out of water and carbon dioxide. This enables RES power to be coupled with electrolysis providing a carbon free cycle [4]. Other alternatives for syngas generation include biomass gasification and natural gas reforming. Syngas derived from autothermal reforming or gasification technology with an air separation unit must be employed in large scale FT facilities and those methods have the further benefit of generating a high syngas ratio (H2/CO) [5]. However, CO2 gasification using biomass technology is not able to provide a sufficient syngas ratio for producing liquid fuel. Therefore, steam electrolysis or a water gas shift reactor could be used for adjusting the H2/CO ratio so that it is equal to 2 (usage syngas ratio) [6].

In the field of power to fuel technology, flexible analysis of a Low Temperature Fischer–Tropsch (LTFT) reactor under variable operating conditions presents more challenges compared to other value-added processes such as methanation and the Dimethyl ether process. These challenges involve more complexity in FT product selectivity and lower feasibility in the dynamic analysis of an LTFT reactor compared to methanation and the DME synthesis [7]. In this respect, the most suitable FT reactors for analyzing under flexible operation are the Multi-Tubular Fixed Bed Reactor and the Slurry Bubble Column Reactor. In the Fixed Bed Reactor (FBR), dynamic analysis addresses the feasibility of reducing the size of H2 storage and optimizing the temperature profile along the catalyst bed [8], whereas, in the FT Slurry type, the analysis is focused on improving mass transfer phenomena (gas-to-liquid contact and interfacial mass transfer area), leading to enhanced selectivity and catalyst performance with regard to complex hydrodynamic features and scale up issues [9]. During recent years, the Slurry Bubble Column Reactor has been identified as the best option for Fischer–Tropsch synthesis due to its many advantages compared to the other reactors. These advantages include (1) flexible temperature control and excellent heat transfer; (2) efficient inter-phase contacting which results in higher productivity; (3) low pressure drop leading to reduced compression costs; (4) better use of catalyst surface (fine particles less than 100 μm) allowing suitable liquid-solid mass transfer [5,10].

However, this reactor presents several technical challenges in the design of the pilot plant as well as large scale due to following reasons: (1) potential formation of slug regime flow; (2) very little information on mass transfer data; (3) difficulty in scale up due to complex hydrodynamic features; (4) Obstacles to the separation of fine catalysts from the slurry phase.

This work focuses on the dynamic modeling of a Slurry Bubble Column Reactor for Fischer Tropsch synthesis in pilot plant scale under variable loads of synthesis gas. This transient calculation is performed in once-through conditions under a cobalt-supported catalyst to identify the effect of load change conditions on FT selectivity, CO conversion, the alpha value and temperature distribution of the slurry reactor in the Winddiesel Technology. Winddiesel technology developed by the Technical University of Vienna has already been tested at an FT demonstration plant based on synthesis gas from biomass steam gasification and steam electrolysis in cases of availability of renewable energy [11,12]. In the modeling of the Fischer–Tropsch Slurry Bubble Column reactor (FT-SBCR) in lab-scale, a set of appropriate hydrodynamic parameters is incorporated into coupled FT kinetics and mass transfer through MATLAB code. This new approach enables us to analyze the behavior of all species through the length of the reactor from start-up to steady state condition. Moreover, in this dynamic modeling, change in the superficial gas velocity due to chemical reaction is coupled to the set of PDEs using the overall species transport equations. This approach estimates the reliable calculation of the gradient of gas flow rate for bubbles which proposes a realistic prediction of the reactor performance [13]. However, the majority of slurry reactors models for superficial gas velocity within the reactor linearize the gas velocity with syngas conversion [14,15,16].

In dynamic modeling SBCR for FT process, a number of methodologies based on several well-developed hydrodynamic concepts such as the Axial dispersion model (ADM), Single bubble class (SBC), two bubble class (TBC), etc. with different FT kinetics have been proposed. In 2002, J.W.A de Swart and R. Krishna [14] developed a model to predict the steady state and dynamic behavior of a bubble column slurry reactor for Fischer Tropsch synthesis. Their numerical procedure was based on four partial differential equations solved using Method Of Lines (MOL). The results indicated that steady-state is achieved within about seven minutes from start-up and no thermal runways were observed in a reactor of commercial scale. Furthermore, the influence of the back-mixing of the liquid phase on hydrogen conversion for two different reactor diameters (1, 7.5 m) was compared. It was concluded that at 1 m diameter the axial dispersion coefficient decreased, leading to a flatter velocity profile in the liquid phase, which in turn results in higher conversions of hydrogen [14].

In 2005, Rados et al. [13] simulated an FT-SBCR with two chemical reaction systems. They analyzed the hydrodynamic behavior of two bubble class models by assuming linear first-order reaction kinetics. They also considered the influence of the Axial Dispersion Model (ADM) on conversion and reactor diameter and compared this effect in ideal reactors i.e., plug flow (PF) and completely stirred tank (CST) [13]. In 2009, Hooshyar et al. [15] developed a dynamic slurry FT for both single and double bubble class at churn turbulent flow regime. They concluded that there is no discrepancy between single and double class models in terms of concentration, temperature and conversion profile. Thus, they considered the single bubble class as a less complex reliable model to analyze the slurry bubble column reactors [15]. In 2008, Laurent Sehabiague [17] et al. developed a computer model for a large-scale FT slurry reactor. The simulator was used to optimize superficial gas velocity and reactor geometry for producing 10,000 (barrels/day) of liquid fuels. Different operating conditions were also used to find the maximum space time yield (STY). However, the condition for maximum productivity was considered as the optimum operating condition because of lower operating and capital cost [17].

Accordingly, almost all dynamic modeling of FT slurry reactors has focused on the commercial scale of slurry bubble column reactors and there has been no detailed transient computer model at pilot scale (reactor diameter < 1 m) for SBCR so far. In fact, the modeling of laboratory scale FT slurry is a more difficult task because of the wealth of dynamic features, such as the prediction of rise velocity of small bubbles and wall effects, which make hydrodynamic parameters quite sensitive to system properties, and the presence of impurities [18]. Thus, the present work investigates, for the first time, the transient analysis of a slurry FT reactor in lab-scale under supported catalyst cobalt for all key components of Fischer–Tropsch synthesis developed by a MATLAB code. This comprehensive modeling enables us to predict the behavior of several slurry reactor parameters such as CO conversion, FT selectivity, α-value and temperature profile under variable loads of synthesis gas. Furthermore, the results of the modeling are in good agreement with the experimental data. The experimental data is adopted from a Master of Science thesis which was conducted using the Fischer–Tropsch research plant. The plant is located in town of Güssing in Austria [11,12]. Appendix A and Appendix B reflect the experimental measurements for both base load (syngas flow rate of 5 m3/h) and change load conditions (syngas flow rate of 3.5 m3/h and 7.5 m3/h) in one specific run [12].

2. Fischer–Tropsch Reaction Scheme

Fischer–Tropsch synthesis consists of a set of polymerization reactions leading to a blend of linear paraffins of different carbon numbers. In the present investigation, the rate expression of Fischer–Tropsch synthesis under catalyst cobalt is employed based on Yates and Satterfield 1991 [19] (see the relation of reaction kinetics in Table 1). In this reaction kinetics (−Rco), by modifying parameters a and b, the model predictions of CO conversion correspond to the experimental measurements. Anderson-Schulz Flory model gives an indication of the distribution for n-paraffins based on their mass fraction (Wn) which can be expressed with the relation of ASF distribution of products as mentioned in Table 1 (Wn relation). Wn is defined by parameter α (Chain growth probability factor). In fact, α-value reflects the distribution of the weight percentage of products with regard to their carbon number [20]. Factor α strongly depends on temperature, pressure and the catalyst used in the process. Generally, in our model, alpha correlation is employed in terms of temperature as mentioned in the relation of chain growth probability factor (Table 1), which is described by Song et al. (2004) [21]. In the section of model comparison, in order to calculate α-value a semi-logarithmic plot of mass fraction against carbon number is considered (logarithmic relation in Table 1) producing a straight line. The slope of the line is given the α-value. The calculation is performed for different operating conditions based on both model and experimental data. The products of Fischer–Tropsch synthesis under catalyst cobalt are predominantly paraffins through the generic reaction in Table 1 (paraffin reaction form). Therefore, the rate of paraffin formation based on Anderson-Sculz-Flory (ASF) equation can be calculated from ri relation in Table 1 [22]. Also, Table 2 illustrates the operating conditions and several lab parameters. Details of the FT reactor and experimental setup are mentioned in references [11,12].

Table 1.

Kinetic Characteristics of Fischer–Tropsch Slurry Bubble Column reactor (FT-SBCR): reaction parameters, product distribution.

Table 2.

Operating conditions and liquid properties of lab-scale Fischer–Tropsch Slurry Bubble Column.

3. Modeling Activity

3.1. Model Framework

A detailed computer model for a pilot plant FT-SBCR (D = 0.1 m, H = 2.5 m) for all the key components of FT synthesis reactor was developed. A set of Partial Differential Equations (PDEs) of transport species including mass transfer and kinetics was successfully coupled with hydrodynamic parameters. In general, 10 equations for the gas phase (single bubble class) and 10 equations for the liquid phase need to be solved simultaneously. The reactor model was established with these assumptions: (1) an Axial Dispersion Model (ADM) in the form of a convection-diffusion phenomenon with a single class of gas bubble diameter is considered (ADM-SBCD); (2) the gas-liquid mass transfer resistance is positioned on both the gas and liquid side; (3) based on the non-dimensional form of Peng-Robinson equation-of-state (PR-EOS), the compressibility factor of the gas phase corresponds to near unity (Z ≈ 1). The PR-EOS is a suitable fluid model for FT systems to predict vapor-liquid compositions and flow rates inside the slurry reactor [23,24]; (4) considering a low pressure drop in the slurry reactor, the operating pressure is assumed to be constant along the reactor height; (5) the reactor operates under isothermal condition; (6) by assuming constant pressure and temperature, the overall continuity balance occurs at the inlet and outlet of the reactor (Equation (3)); (7) liquid-solid mass transfer resistance may be ignored and consequently solid suspension in liquid is simulated as a single pseudo-homogeneous slurry phase in this work; (8) chemical reaction through Langmuir Hinshelwood Hougen Watson (LHHW) kinetics in liquid phase is considered.

Based on these model assumptions, the mass balances of each component in gas and liquid phases can be derived as follows:

Gas phase equations:

Liquid phase equations:

Total concentration:

In the above equations, Ai denotes the Henry’s constant (Hi) for syngas and light hydrocarbons (CO, H2, H2O, C1 and C2). By employing Henry’s law solubility factor , the Henry’s constant for each reactant gas was calculated based on the heat of solution for each component and operating temperature [25].

where, the value of parameters and are listed in reference [25].

Ai = Hi/RT

For heavier components (), Ai was calculated using Raoult’s law for gas-liquid phase at the equilibrium as follows:

where, is the total concentration of liquid components, is the liquid density, is the average molecular weight of liquid components and is the Henry’s constant at infinite dilution which is defined as follow:

where is the activity coefficient for heavier components and Pi,sat is the vapor pressure of component i which is calculated from asymptotic behavior correlations (extension of the Antoine equations). By supposing ideal behavior of FT mixture due to long-chain n-paraffins, the Henry’s constant for the mixture can be expressed by:

where j is the components in the solvent. Since and is asymptotically linear with solute carbon number (m), the formula for calculating the infinite-dilution activity coefficient becomes as follow:

where n is the carbon number of solvent (n-paraffin) and r denotes the carbon number of reference solute (n-C6H14) in the same solvent. They are described in more detail in references [24,26].

As mentioned in the model assumption, since the reactor is supposed to be operated under constant pressure and temperature, the total concentration is constant. As a consequence, the variation of the gas flow rate due to chemical reaction and mass transfer is determined by assuming the constant total concentration of components in single bubble gas diameter (Equation (3)). Therefore, the Equation (11) as a sub-model in the form of a gas state equation is incorporated into the SBCD model. This sub-model used for behavior of superficial gas velocity inside the reactor is a reliable approach since it considers the concentrations of all gaseous components [13].

Table 3 depicts the initial and boundary conditions of Equations (1), (2) and (11). The initial values in the model are set based on pressure, temperature and concentration of species. The boundary conditions adopted from Danckwerts’ type are defined for the gas and liquid at the inlet and outlet of the reactor. For the gas phase at the reactor inlet, the concentration is taken from a syngas composition under the operating conditions of the laboratory, calculated based on Table 3. The inlet superficial gas velocity for single bubble gas diameter is calculated from Equation (14).

Table 3.

Initial and boundary conditions for the slurry reactor model.

The effective gas-liquid interfacial area for mass transfer of small bubbles between two phases can be expressed as follows [27]:

a = 6 × ɛg/dB

The mass transfer coefficient (Kl) is calculated from the following empirical correlation. It is applicable in a wide range of operating conditions which leads to a good prediction of gas-liquid mass transfer [27]:

The superficial gas velocity is defined as the volumetric gas flow rate divided by the cross-sectional area of the reactor above the gas distributor [28]:

The initial bubble size depending on buoyancy forces and surface tension is derived by the theoretical Davidson and Schuler expression [29]:

The gas hold up can be expressed as the volume of the gas phase divided by the reactor volume consisting of gas volume, liquid volume and volume of catalyst used [28]:

This is calculated to be 0.161 and the catalyst volume fraction (ɛcat) is calculated to be 0.34 It should be noted that in the Equations (1) and (2), ɛL is the liquid holdup and ri denotes reaction rate of FT species . Moreover, the velocity of liquid inside the reactor is assumed to be 0.00089 m/s.

In the slurry bubble column reactors, the gas bubble coalescence occurs in a short time with an increase of the column diameter, and the large bubbles collect around the center of the column in the operation of a churn turbulent regime. This is called heterogeneous flow, which usually occurs when the superficial gas velocity is greater than 0.05 m/s. When the gas-liquid mixture reaches the surface, the bubbles disengage, allowing the degassed liquid to recirculate. Therefore, the main cause of back-mixing and liquid dispersion in the lab-scale slurry FT reactor is attributed to downward velocity of the liquid in the wall region and upward direction (VL(r)) in the central axis [30]. Based on Riquarts correlation [31] the magnitude of VL(0) depends on the column diameter, superficial gas velocity and kinematic viscosity of the liquid phase as described in Equation (17). The experimental data [30,31] show that the liquid phase axial dispersion coefficient (Dax,L) has a direct proportionality to column reactor diameter and centre-line liquid velocity as mentioned in Equation (18).

VL(0) = 0.2 × (g Dt)1/2 × (U3g,in/g νL)1/8

Dax,L = 0.31 × VL(0) × Dt

According to reference [30,31], the two correlations given above are the most appropriate ones for the estimation of axial dispersion coefficient which was recommended in all systems (including slurry). The axial dispersion coefficient of the gas phase for the small bubbles is equal to that of the liquid phase according to the relationship which was proposed by Sehabiague et al. [10].

3.2. Computer Solution Procedure

In this transient calculation, a MATLAB pdepe (Partial Differential Equations Parabolic Elliptic) solver is implemented. The solver converts a set of PDEs to ODEs (Ordinary Differential equations) using an accurate spatial discretization based on a specified grid size. The solution domain is equal to the length scale of the reactor and the optimized discretization is chosen based on a balance between the desired level of accuracy and the affordable CPU time [8].

For solving equations, the mass balance of 10 components of H2, CO, H2O, CO2, CH4, C2H6, C4H10, C10H22, C18H38, and C30H62 in two phases, gas and liquid, are considered.

4. Results and Discussions

The simulation of the FT slurry reactor begins with the start-up after all heating devices are switched on and the alarm values are set. Once an operating parameter such as temperature or pressure, attains its alarm value, the research plant is automatically switched off and this is called an alarm shut down (ASD). The alarm values are vitally important since they ensure a safe operation of the plant. Then, the FT plant is started under N2 flow as an inert gas in the manual mode until the FT reactor reaches a temperature of 453 K, at which the wax in the FT reactor is liquid. Afterwards, the plant is switched to the automatic mode and the FT reactor reaches the required operating temperature of 503 K and the plant starts to operate under syngas. The time required for the start-up stage before switching the plant to automatic mode is about 2–3 h.

4.1. Species Distribution

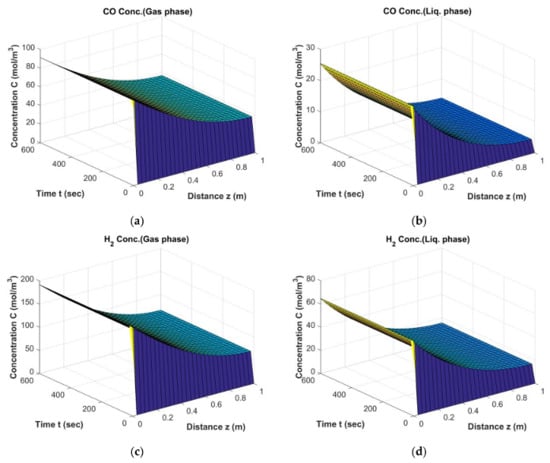

4.1.1. The Behavior of Components H2, CO

Firstly, the aforementioned hydrodynamic parameters are implemented in the computer model then the equations related to small bubbles of gas species and the liquid phase are coupled to obtain the concentration behavior of all FT key components from the beginning to the steady state conditions through the length of the reactor. As Figure 1 shows, at τ = 0 there is no carbon monoxide and hydrogen in either of the two phases. At normal operation (τ > 0), these species enter the reactor with their own inlet values (which are already calculated based on the boundary conditions in Table 3; Cg,in), initiating the reaction. At the reactor inlet a maximum value is seen and liquid is supposed to be saturated with gas phase. The CO and H2 are consumed due to the chemical reaction and their concentration decreases across the reactor length to the equilibrium values in two phases. In this respect, “wall effects” cause small bubbles to dissolve faster into the liquid phase before reaching steady state values. The concentration behavior of species (mol/m3gas for gaseous components and mol/m3liquid for liquid components) shows that the steady state values are reached at 10 min, as expected from the experimental data [12]. The CO conversion in this base load condition equals 58%, which is slightly overestimated compared to the experimental data. The run is performed for T = 503 K, P = 20 bar, Ug = 0.17 m/s, = 0.34.

Figure 1.

Results of Fischer–Tropsch (FT) Simulation; The behavior of CO, H2 in gas phase (a,c) and liquid phase (b,d) from start-up to steady state conditions (Dt = 0.1 m, H = 2.5 m, = 0.34, Ug,in = 0.17 m/s).

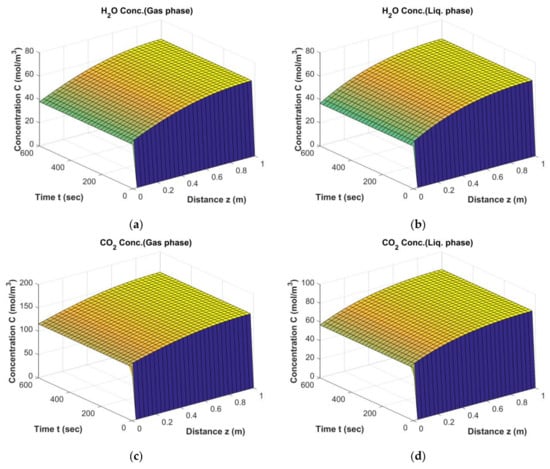

4.1.2. The Behavior of Components H2O, CO2

As Figure 2 illustrates, water vapor, which is one of the products of FT synthesis, increases over the reactor height and over the time. Since the FT reaction occurs under a co-supported catalyst, no water gas shift reaction is promoted and the inlet CO2 acts as an inert through the process. The CO2 concentration increases due to the volume reduction of off-gas and syngas consumption. It is worth noting that the presence of diluents such as CO2, CH4 or N2 has a beneficial influence in slurry bubble column reactors. The inert (here as carbon dioxide) enables supplementary mixing energy to the slurry system to maintain catalyst suspension. On the other hand, in FBRs we need to avoid diluents since they elevate the pressure drop across the reactor bed [32].

Figure 2.

Results of FT Simulation; The behavior of H2O and CO2 in gas phase (a,c) and liquid phase (b,d) from start-up to steady state conditions (Dt = 0.1 m, H = 2.5 m, = 0.34, Ug,in = 0.17 m/s).

4.1.3. The Behavior of Components CH4, C2H6, C4H10

Methane, ethane and butane increase over time and achieve their highest concentration at the final time in the reactor outlet. These highest values in the gas phase reach around 85, 35 and 50 mol/m3 for CH4, C2H6 and C4H10, respectively as shown in Figure 3.

Figure 3.

Results of FT Simulation; The behavior of CH4, C2H6 and C4H10 in gas phase (a,c,e) and liquid phase (b,d,f) from start-up to steady state conditions (Dt = 0.1 m, H = 2.5 m, = 0.34, Ug,in = 0.17 m/s).

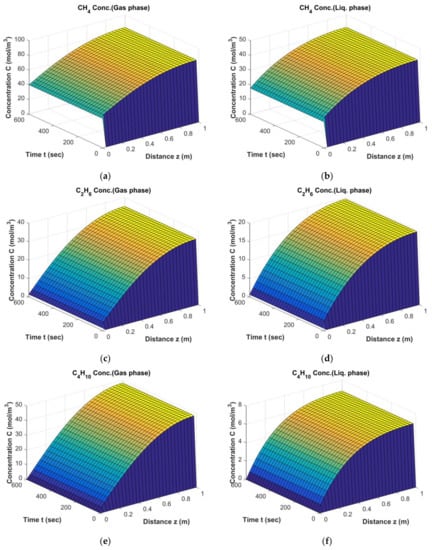

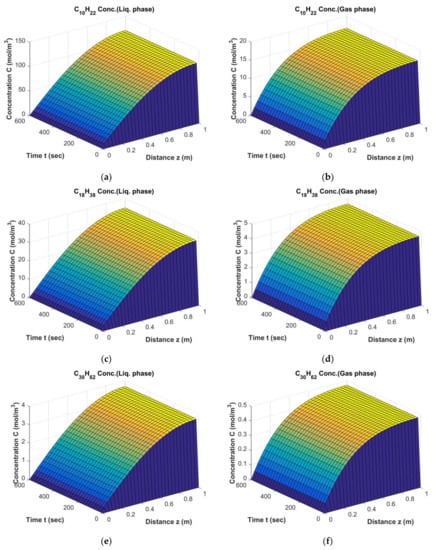

4.1.4. The Behavior of Liquid Products C10H22, C18H38, C30H62

In this mathematical modeling, three components are considered as representatives of each specific carbon cut. C10H22, C18H38 and C30H62 were introduced as naphtha, diesel and wax respectively, which are derived from three condensers with reaction water in each condenser and collected in each related drum [12]. The results of modeling show that all three sets of products have a similar profile through the slurry reactor. As illustrated in Figure 4, the liquid products have an upward trend over time through the reactor height and the highest magnitude belongs to the middle distillate whereas diesel and wax stand at lower values respectively.

Figure 4.

Results of FT simulation; The behavior of C10H22, C18H38 and C30H62 in liquid phase (a,c,e) and gas phase (b,d,f) from start-up to steady state conditions (Dt = 0.1 m, H = 2.5 m, = 0.34, Ug,in = 0.17 m/s).

These simulations results relate to base load conditions (volumetric gas flow rate 5 m3/h). The computer model is also able to work quite well under variable loads of synthesis gas. Therefore, the flow rate in the model was changed in the range of 3.5–7.5 m3/h to find maximum CO conversion and FT product selectivity.

4.2. Model Comparison with Experimental Data

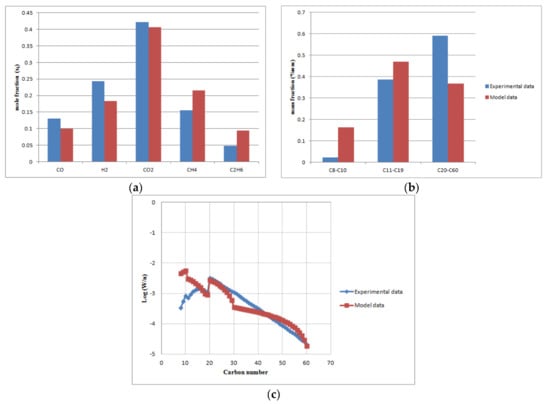

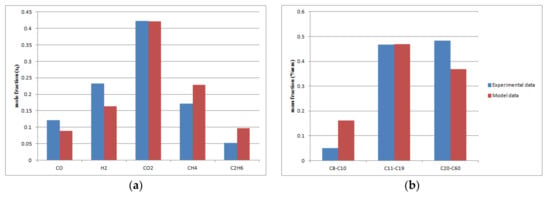

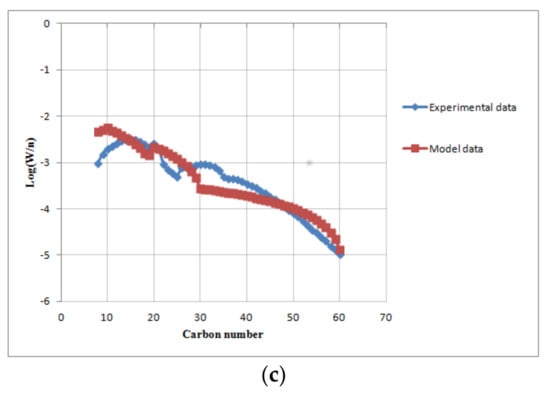

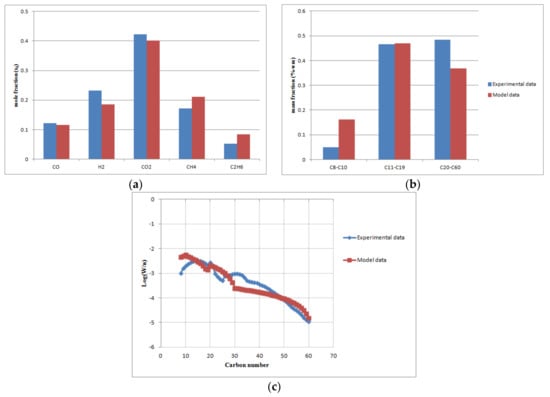

The comparison of the model results with experimental data was conducted based on the composition (volume %) of syngas and off-gas which were measured by a GC device under base load and change load conditions. Figure 5, Figure 6 and Figure 7 show a comparison of the predicted values by the computer model with the measured data from the conducted experiments. In general, the results show that the predicted model is in good agreement with the experimental data. When compared with FT products only in the case of naphtha (C8–C10) is there a noticeable difference between model and laboratory data in all three operating conditions. This is due to the volatility of this carbon cut and difficulty in collecting them together. In product distribution (Figure 5c, Figure 6c and Figure 7c) only, two groups (C8–C15) and (C30–C40) show a deviation as well as discontinuities in the model prediction. The deviation is probably due to the neglect of olefin formation in the reactor modeling and the discontinuities can be attributed to the model equations which were solved for specific classes of FT species (C1, C2, C4, C10, C18 and C30). As mentioned earlier, the α-value can be derived from the slope of the drawn line in all three load conditions. In the model, the α-value for volumetric flow rate of 3.5, 5 and 7.5 m3/h is calculated to be 0.89, 0.9 and 0.88 respectively. It shows that change load conditions have almost no influence on the α-value or catalyst selectivity as predicted from the experiment.

Figure 5.

The comparison of the predicted model with experimental data at base load conditions (volumetric gas flow rate 5 m3/h, T = 503 K, = 0.34, P = 20 bar): (a) off-gas molar fractions; (b) FT products (naphta, diesel, wax); (c) ASF distribution.

Figure 6.

The comparison of the predicted model with experimental data at change load conditions (volumetric gas flow rate 3.5 m3/h, T = 503 K, = 0.34, P = 20 bar): (a) off-gas molar fractions; (b) FT products (naphta, diesel, wax); (c) ASF distribution.

Figure 7.

The comparison of the predicted model with experimental data at change load conditions (volumetric gas flow rate 7.5 m3/h, T = 503 K, = 0.34, P = 20 bar): (a) off-gas molar fractions; (b) FT products (naphtha, diesel, wax); (c) ASF distribution.

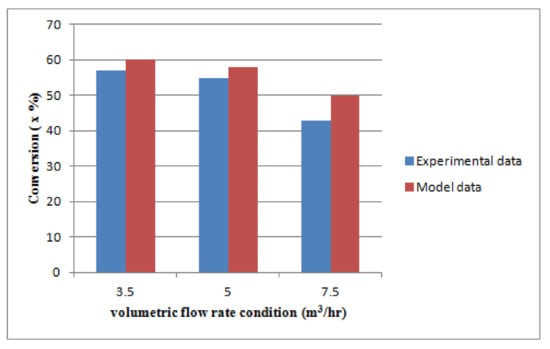

The results show that the CO conversion both in the model and experiments has lower values at a higher superficial velocity of syngas. This is due to the decreasing residence time of reactants at higher values of velocity. Thus, the maximum CO conversion occurs at 3.5 m3/h which is equal to 60%. As Figure 8 shows, the CO conversion also is in good agreement with the experimental data; however, the model values are slightly overestimated. This is due to larger area for gas-liquid mass transfer in the result of the assumption of the single bubble class diameter.

Figure 8.

CO Conversion at base and change load condition based on experimental and model data.

4.3. The Effect of Temperature on Product Selectivity

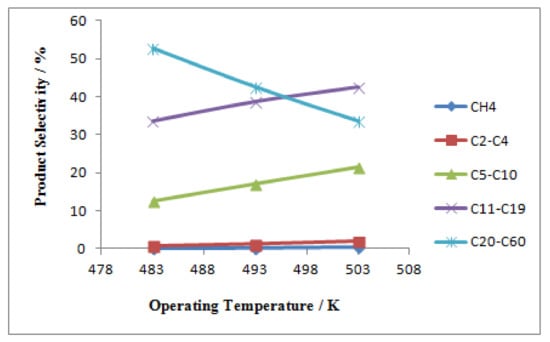

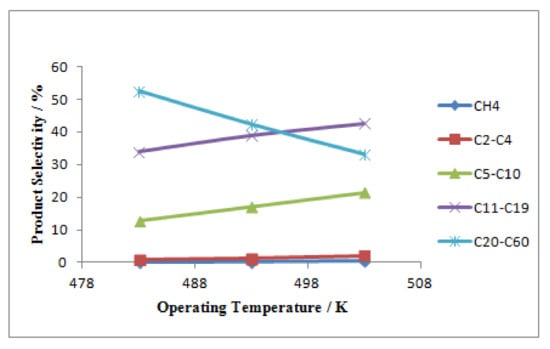

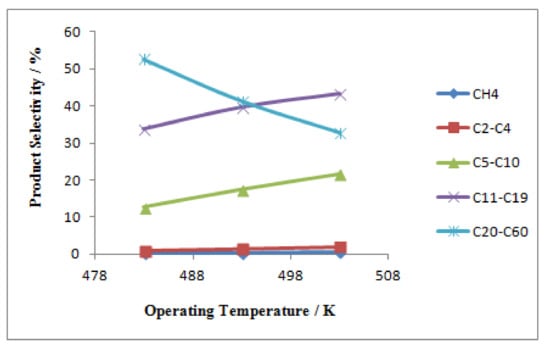

One strength of FT reactor modeling is that analysis of the product selectivity with reaction temperatures can be carried out to find the desired operating conditions. Figure 9, Figure 10 and Figure 11 illustrate the variation of product selectivity based on mass fraction with operating temperature at three loads of volumetric flow rates (3.5, 5, 7.5 m3/h), respectively. As shown in these figures, for all three loads with increasing temperature the light gaseous (C1–C4), naphtha (C5–C10) and diesel increase whereas, heavier liquid fuels such as wax (C20–C60) tend to decrease. This trend can be expected since higher temperatures tend to shift the α-parameter to lower values thus producing more light hydrocarbons (C1–C4). In the design of the lab-scale SBCR for the FT process, it is advisable to operate the reactor under a narrow temperature range (483–503 K). This prevents catalyst deactivation, avoiding higher increases in methane as well as obtaining selectivity of diesel products [12].

Figure 9.

Influence of operating temperature on product selectivity; Dt = 0.1 m, H = 2.5 m, Vf = 3.5 m3/h, P = 20 bar, = 0.34.

Figure 10.

Influence of operating temperature on product selectivity; Dt = 0.1 m, H = 2.5 m, Vf = 5 m3/h, P = 20 bar, = 0.34.

Figure 11.

Influence of operating temperature on product selectivity; Dt =0.1 m, H = 2.5 m, Vf = 7.5 m3/h, P = 20 bar, = 0.34.

It was concluded that by increasing the load of syngas flow rate, the selectivity of wax and diesel remain constant in each corresponding temperature. It was also concluded that there is a homogenous temperature profile within the reactor.

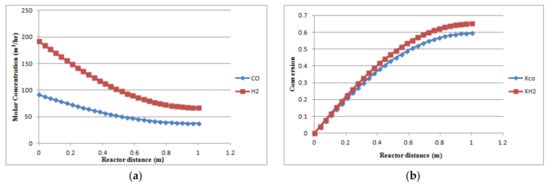

4.4. The Behavior of the Species Inside the Reactor

The experimental data of the research FT reactor in laboratory scale is only able to reflect information about the reactor outlet. However, this mathematical modeling attempts to predict the dynamic behavior of the system through the height of the reactor which includes the concentration change of all species along the reactor length. Figure 12a,b show the molar concentration and conversion of syngas (CO and H2) along the reactor bed at base load condition, respectively. The slightly higher values of H2 conversion compared to CO conversion is attributed to the stochiometric ratio of H2/CO taking the value 3 for producing methane, which then shifts to 2 in paraffin formation.

Figure 12.

The syngas variation on the reactor inside, (a) Molar concentration of CO and H2; (b) CO and H2 conversion.

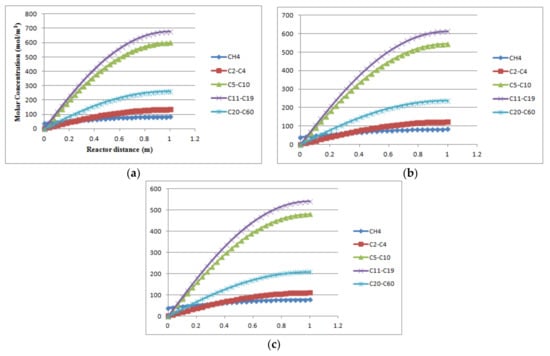

The molar concentration of other FT species along the reactor height at three load conditions is also investigated as shown in Figure 13. It shows that all products increase with more or less the same intensity apart from naphtha (C5–C10) and diesel (C11–C19) which shift to lower values at higher syngas flow rate loads.

Figure 13.

The molar concentration of the FT products along the reactor bed at three load conditions: (a) T = 503 K, P = 20 bar, Vf = 3.5 m3/h; (b) T = 503 K, P = 20 bar, Vf =5 m3/h; (c) T = 503 K, P = 20 bar, Vf = 7.5 m3/h.

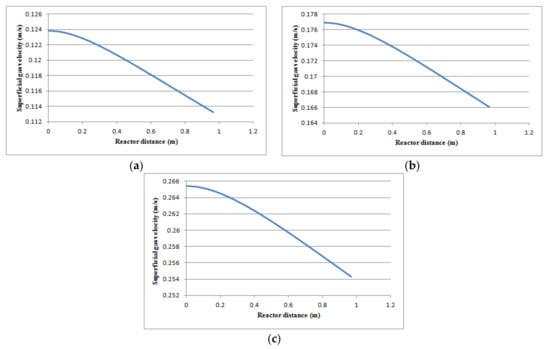

Furthermore, Figure 14 illustrates the reduction of superficial gas velocity at three different loads of conditions based on the overall mass balance (Equation (11)).

Figure 14.

Reduction of superficial gas velocity as a function of reactor height at three different operating load conditions: (a) T = 503 K, P = 20 bar, Vf = 3.5 m3/h; (b) T = 503 K, P = 20 bar, Vf = 5 m3/h; (c) T = 503 K, P = 20 bar, Vf = 7.5 m3/h.

5. Conclusions

A rigorous computer model for a lab-scale FT slurry reactor was developed to investigate flexible reactor operation. This flexibility was performed by a step-change of syngas flow rate load (3.5, 5, 7.5 m3/h) in a low-temperature Fischer–Tropsch synthesis. It was found that the dynamic simulation is not only able to predict all Fischer–Tropsch components over the reactor bed but can also describe the behavior of superficial gas velocity as a sub-model using the overall gas mass balance.

The effect of a step-change volumetric syngas flow on the performance of FT slurry reactor was investigated. The results show that the temperature distribution of the slurry reactor remains constant under base load and change load conditions. It can be concluded that load change conditions do not have a negative influence on the temperature distribution inside the reactor and the presented dynamic model of the slurry reactor responds quite well to the load change conditions.

Acknowledgments

The authors acknowledge financial support by the Austrian government through the “Klima und Energiefonds” financed Project Winddiesel_klienIF within the “e!Mission.at” funding scheme. The project Winddiesel_klienIF is executed in cooperation with Energie Burgenland AG, Bilfinger SEBUR, Güssing Energy Technologies GmbH, Renewable Power Technologies Umwelttechnik GmbH, Energy & Chemical Engineering GmbH and the Institute of Chemical Engineering from TU WIEN.

Author Contributions

R.R., H.H. and G.W. prepared the materials and designed the experiments and S.S., R.R., S.B. and G.S. contributed to the paper writing.

Conflicts of Interest

The authors declare no conflict of interests.

Nomenclature

| Ar (m3) | Reactor cross sectional area |

| a (m2 m−3) | Effective gas-liquid interfacial area per unit bed volume |

| Ci (mol/m3) | Concentration of component i |

| Ctot (mol/m3) | Total concentration of gaseous components |

| (mol/m3) | Total concentration of liquid components |

| Dax,L (m2/s) | Liquid phase axial dispersion coefficient |

| Dg (m2/s) | Gas phase axial dispersion coefficient |

| Dt (m) | Reactor diameter |

| d0 (m) | Gas distributor diameter |

| dB (m) | Bubble diameter |

| g (m/s2) | Acceleration due to gravity |

| H (m) | Reactor height |

| Hi | Henry’s solubility constant of gaseous component i |

| (MPa. m3/kmol) | Coefficient in Henry’s law for gaseous component i |

| −ΔHs,i (kJ/kmol) | Heat of solution for gaseous component i |

| Kl a (s−1) | Volumetric Mass transfer coefficient |

| MWave,L (kg mol−1) | Average molecular weight of liquid components |

| P (Pa or bar) | Pressure |

| Pi,sat (bar) | Vapor pressure of component i |

| R (J mol−1 K−1) | Gas constant |

| Rco () | Carbon monoxide consumption rate |

| ri () | Chemical reaction rate of component i |

| T (K) | Temperature |

| t (s) | Time |

| Ug (m/s) | Superficial gas velocity |

| Ul (m/s) | Liquid velocity |

| Vcat (m3) | Volume of catalyst in column |

| Vf (m3/h) | Volumetric gas flow rate |

| Vgas (m3) | Volume of gas in column |

| Vliquid (m3) | Volume of liquid in column |

| VL(0) (m/s) | Center-line liquid velocity |

| z (m) | Axial coordinate |

| Z | Compressibility factor, dimensionless |

| Greek Letters | |

| Chain growth probability factor, dimensionless | |

| Gas holdup, dimensionless | |

| Liquid holdup, dimensionless | |

| Catalyst volume fraction | |

| Activity coefficient for component i, dimensionless | |

| (kg/m3) | Catalyst density |

| (kg/m3) | Slurry density |

| μl (Pa.s) | Liquid viscosity |

| (N/m) | Surface tension |

| (kg/m3) | Gas density |

| (m2/s) | Kinematic viscosity of phase |

| τ | Dimensionless time coordinate |

Abbreviations

| ADM-SBCD | Axial Dispersion Model- Single Bubble Class Diameter |

| ASF | Anderson-Sculz-Flory |

| CCU | Carbon Capture Unit |

| CPU | Central Processing Unit |

| FBR | Fixed Bed Reactor |

| FT | Fischer–Tropsch |

| GHG | Greenhouse Gas |

| MOL | Method Of Lines |

| ODE | Ordinary Differential Equation |

| PDE | Partial Differential Equation |

| PDEPE | Partial Differential Equations Parabolic Elliptic |

| RES | Renewable Energy Sources |

| SBCR | Slurry Bubble Column Reactor |

Appendix A

Table A1.

Average composition of Inlet/Outlet Gases under BL condition [12].

Table A1.

Average composition of Inlet/Outlet Gases under BL condition [12].

| Inlet/Outlet Gas | N2 | CO2 | CH4 | C2H4 | C2H6 | CO | C3H6 | C3H8 | H2 |

|---|---|---|---|---|---|---|---|---|---|

| Syngas (vol. %) | 4.6 | 24.2 | 8.4 | 2.5 | 0.3 | 19.1 | ~0 | ~0 | 40.1 |

| Off-gas (vol. %) | 7.0 | 39.0 | 14.4 | 0.1 | 4.5 | 12.1 | ~0 | 0.1 | 22.6 |

Table A2.

Average composition of Inlet/Outlet Gases under CL condition [12].

Table A2.

Average composition of Inlet/Outlet Gases under CL condition [12].

| Inlet/Outlet Gas | N2 | CO2 | CH4 | C2H4 | C2H6 | CO | C3H6 | C3H8 | H2 |

|---|---|---|---|---|---|---|---|---|---|

| Syngas (vol. %) | 2.5 | 25.1 | 9.5 | 2.8 | 0.2 | 19.2 | ~0 | ~0 | 40.1 |

| Off-gas (vol. %) | 3.6 | 40.6 | 16.5 | ~0 | 5.0 | 11.7 | ~0 | 0.1 | 22.4 |

Appendix B

Table A3.

Mass fraction of the FT products measured by off-line device [12].

Table A3.

Mass fraction of the FT products measured by off-line device [12].

| Products | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 |

| BL | 0.0039 | 0.0072 | 0.012 | 0.0186 | 0.0271 | 0.0361 | 0.0442 | 0.0506 | 0.0536 |

| CL | 0.0095 | 0.0167 | 0.0238 | 0.0323 | 0.0405 | 0.0487 | 0.0555 | 0.0606 | 0.0624 |

| Products | C17 | C18 | C19 | C20 | C21 | C22 | C23 | C24 | C25 |

| BL | 0.0538 | 0.0524 | 0.0505 | 0.048 | 0.0454 | 0.0427 | 0.0395 | 0.0364 | 0.0334 |

| CL | 0.0604 | 0.0564 | 0.0498 | 0.0415 | 0.0333 | 0.0262 | 0.0206 | 0.0177 | 0.016 |

| Products | C26 | C27 | C28 | C29 | C30 | C31 | C32 | C33 | C34 |

| BL | 0.0307 | 0.0285 | 0.0265 | 0.0244 | 0.0229 | 0.0214 | 0.0193 | 0.0178 | 0.0158 |

| CL | 0.016 | 0.0161 | 0.0181 | 0.0202 | 0.0218 | 0.0227 | 0.0222 | 0.0213 | 0.0177 |

| Products | C35 | C36 | C37 | C38 | C39 | C40 | C41 | C42 | C43 |

| BL | 0.0143 | 0.0127 | 0.0115 | 0.0107 | 0.0098 | 0.0088 | 0.0081 | 0.0072 | 0.0063 |

| CL | 0.0135 | 0.0128 | 0.0129 | 0.0126 | 0.0122 | 0.011 | 0.0103 | 0.0094 | 0.0083 |

| Products | C44 | C45 | C46 | C47 | C48 | C49 | C50 | C51 | C52 |

| BL | 0.0059 | 0.0053 | 0.0046 | 0.0043 | 0.0039 | 0.0034 | 0.0031 | 0.0028 | 0.0025 |

| CL | 0.0075 | 0.0065 | 0.0058 | 0.0049 | 0.0043 | 0.0036 | 0.0032 | 0.0027 | 0.0022 |

| Products | C53 | C54 | C55 | C56 | C57 | C58 | C59 | C60 | |

| BL | 0.0022 | 0.002 | 0.0018 | 0.0016 | 0.0014 | 0.0012 | 0.0011 | 0.0009 | |

| CL | 0.0018 | 0.0015 | 0.0013 | 0.0011 | 0.0009 | 0.0007 | 0.0006 | 0.0005 |

BL: Base Load condition (Vf =5 m3/h). CL: Change Load condition (Vf =3.5, 7.5 m3/h).

References

- Varone, A.; Ferrari, M. Power to liquid and Power to gas: An option for the German Energiewende. J. Renew. Sustain. Energy Rev. 2015, 45, 207–218. [Google Scholar] [CrossRef]

- Eilers, H.; González, M.I.; Schaub, G. Lab-scale experimental studies of Fischer–Tropsch kinetics in a three-phase slurry reactor under transient reaction conditions. Catal. Today 2015, 275, 164–171. [Google Scholar] [CrossRef]

- König, D.H.; Freiberg, M.; Dietrich, R.-U.; Wörner, A. Techno-economic study of the storage of fluctuating renewable. Fuel 2015, 159, 289–297. [Google Scholar] [CrossRef]

- Cinti, G.; Baldinelli, A.; di Michele, A.; Desideri, U. Integration of Solid Oxide Electrolyzer and Fischer-Tropsch: A sustainable pathway for synthetic fuel. Appl. Energy 2016, 162, 308–320. [Google Scholar] [CrossRef]

- Maitlis, P.M.; de Klerk, A. Greener Fischer Tropsch Process for Fuels and Feedstocks; John Wiley & Sons: Weinheim, Germany, 2013; pp. 40–58. ISBN 9783527326051. [Google Scholar]

- Gross, P.; Rauch, R.; Hofbauer, H.; Aichering, C.; Zweiler, R. Winddiesel Technology—An alternative to power to gas systems. In Proceedings of the 23rd European Biomass Conference and Exhibition, Vienna, Austria, 1–4 June 2015. [Google Scholar]

- Gonzalez, M.I. Gaseous Hydrocarbon Synfuels from H2/CO2 based on Renewable Electricity-Kinetics, Selectivity and Fundamentals of Fixed-Bed Reactor Design for Flexible Operation. Ph.D. Thesis, Karlsruher Institute für Technologie (KIT), Karlsruher, Germany, 2016. [Google Scholar]

- Gonzalez, M.I.; Eilers, H.; Schaub, G. Flexible Operation of Fixed bed Reactors for a Catalytic Fuel Synthesis-CO2 Hydrogenation as Example Reaction. Energy Technol. 2016, 4, 90–103. [Google Scholar] [CrossRef]

- Lucero, A. Improved Fischer Tropsch Slurry Reactors; Worked Performed under Cooperative Agreement JSR Task 26 Under DE-FC26-98FT40323; PowerEnerCat, Inc.: Lakewood, CO, USA, 2009. [Google Scholar]

- Sehabiague, L.; Morsi, B.I. Modeling and Simulation of Fischer-Tropsch Slurry Bubble Column Reactor Using different kinetic rate expressions for Iron and Cobalt Catalysts. Int. J. Chem. React. Eng. 2013, 11, 309–330. [Google Scholar] [CrossRef]

- Sauciuc, A.; Abosteif, Z.; Weber, G.; Potetz, A.; Rauch, R.; Hofbauer, H.; Schaub, G.; Dumitrescu, L. Influence of operating conditions on the performance of biomass-based Fischer-Tropsch synthesis. Biomass Convers. 2012, 2, 253–263. [Google Scholar] [CrossRef]

- Abulmfalfel, R. Winddiesel: Power to Liquids Assisted by Biomass Steam Gasification. Master’s Thesis, Karlsruhe Institute of Technology, Karlsruher, Germany, March 2017. [Google Scholar]

- Novica, R.; Al-Dahhan, M.H.; Duduković, M.P. Dynamic modeling of slurry bubble column reactors. Ind. Eng. Chem. Res. 2005, 16, 6086–6094. [Google Scholar] [CrossRef]

- De Swart, J.W.A.; Krishna, R. Simulation of transient and steady state behavior of a bubble column slurry reactor for Fischer-Tropsch synthesis. Chem. Eng. Process. 2002, 41, 35–47. [Google Scholar] [CrossRef]

- Hooshyar, N.; Fatemi, S.; Rahmani, M. Mathematical Modeling of Fischer-Tropsch Synthesis in an industrial Slurry Bubble Column. Chem. React. Eng. 2009, 7. [Google Scholar] [CrossRef]

- Maretto, C.; Krishna, R. Modelling of a bubble column slurry reactor for Fischer-Tropsch synthesis. Catal. Today 1999, 52, 279–289. [Google Scholar] [CrossRef]

- Sehabiague, L.; Lemoine, R.; Behkish, A.; Heintz, Y.J.; Sanoja, M.; Oukaci, R.; Morsi, B.I. Modeling and optimization of a large-scale slurry bubble column reactor for producing 10,000 bbl/day of Fischer–Tropsch liquid hydrocarbons. J. Chin. Inst. Chem. Eng. 2008, 39, 169–179. [Google Scholar] [CrossRef]

- Krishna, R.; Urseanu, M.I.; van Baten, J.M.; Ellenberger, J. Liquid phase dispersion in bubble columns operating in the churn-turbulent flow regime. Chem. Eng. J. 2000, 78, 43–51. [Google Scholar] [CrossRef]

- Ian, C.Y.; Satterfield, C.N. Intrinsic kinetics of the Fischer-Tropsch synthesis on a cobalt catalyst. Energy Fuels 1991, 5, 168–173. [Google Scholar] [CrossRef]

- Baliban, R.C.; Elia, J.A.; Floudas, C.A. Toward Novel Hybrid Biomass, Coal, and Natural Gas Processes for Satisfying Current Transportation Fuel Demands, 1: Process Alternatives, Gasification Modeling, Process Simulation, and Economic Analysis. Ind. Eng. Chem. Res. 2010, 49, 7343–7370. [Google Scholar] [CrossRef]

- Song, H.-S.; Ramkrishna, D.; Trinh, S.; Wright, H. Operating Strategies for Fischer-Tropsch Reactors: A Model-Directed Study. Korean J. Chem. Eng. 2004, 21, 308–317. [Google Scholar] [CrossRef]

- Joseph William, P. A Fischer-Tropsch Synthesis Reactor Model Framework for Liquid Biofuels Production; Sandia National Laboratories: Livermore, CA, USA, 2012.

- Watson, L.A. Solar-Boosted Biomass-to-Liquid (BtL) Process Modelling. Bachelor Thesis, Australian National University, Canberra, Australia, 2011. [Google Scholar]

- Marano, J.J.; Holder, G.D. Characterization of Fischer-Tropsch liquids for vapor-liquid equilibria calculations. Fluid Phase Equilib. 1997, 138, 1–21. [Google Scholar] [CrossRef]

- Shah, Y.T.; Dassori, C.G.; Tierney, J.W. Multiple steady states in non-isothermal FT slurry reactor. Chem. Eng. Commun. 1990, 88, 49–61. [Google Scholar] [CrossRef]

- Marano, J.J.; Holder, G.D. General equation for correlating the thermophysical properties of n-paraffins, n-olefins, and other homologous series. 2. Asymptotic behavior correlations for PVT properties. Ind. Eng. Chem. Res. 1997, 36, 1895–1907. [Google Scholar] [CrossRef]

- Lau, R.; Peng, W.; Velazquez-Vargas, L.G.; Yang, G.Q.; Fan, L.S. Gas-liquid mass transfer in high-pressure bubble columns. Ind. Eng. Chem. Res. 2004, 43, 1302–1311. [Google Scholar] [CrossRef]

- Loipersböck, J.; Weber, G.; Gruber, H.; Kratky, J.; Capistrano, R.; Hofbauer, H.; Rauch, R. Upscaling and operation of a biomass-derived Fischer-Tropsch pilot plant producing one barrel per day. In Proceedings of the 25th European Biomass Conference and Exhibition, Stockholm, Sweden, 12–15 June 2017; pp. 1088–1093. [Google Scholar] [CrossRef]

- Behkish, A. Hydrodynamic and Mass Transfer Parameters in Large-Scale Slurry Bubble Column Reactors. Ph.D. Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2005. [Google Scholar]

- Krishna, R.; Sie, S.T. Design and Scale up of the Fischer Tropsch Bubble Column Slurry Reactor. Fuel Process. Technol. 2000, 64, 73–105. [Google Scholar] [CrossRef]

- Krishna, R. A Scale-up Strategy for a Commercial Scale Bubble Column Slurry Reactor for Fischer-Tropsch Synthesis. Oil Gas Sci. 2000, 4, 359–393. [Google Scholar] [CrossRef][Green Version]

- Eric, H.; Iglesia, E. Slurry Bubble Column (C-2391). U.S. Patent No. 5,348,982, 20 September 1994. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).