Multidisciplinary Design Optimization for a Centrifugal Compressor Based on Proper Orthogonal Decomposition and an Adaptive Sampling Method

Abstract

:Featured Application

Abstract

1. Introduction

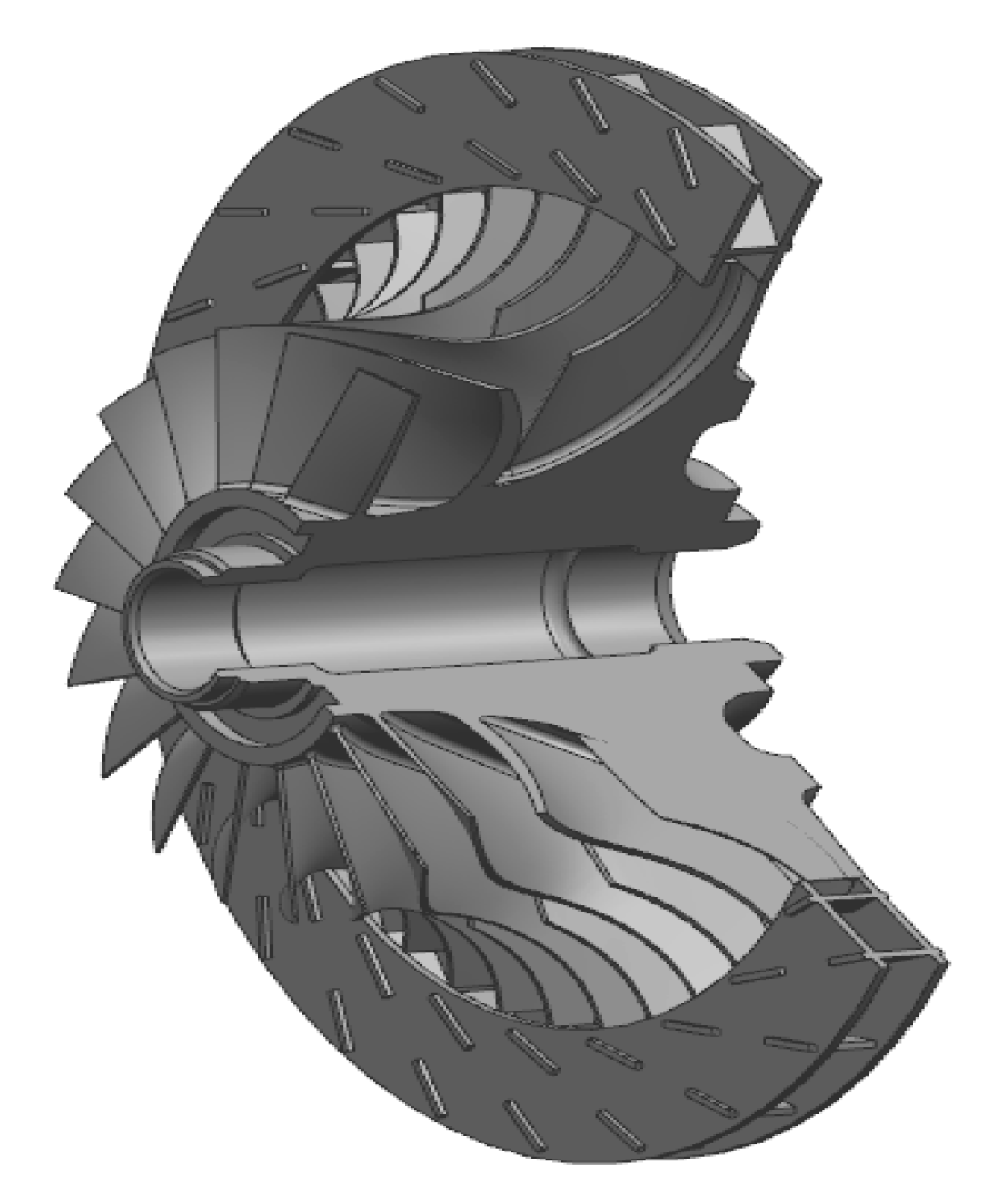

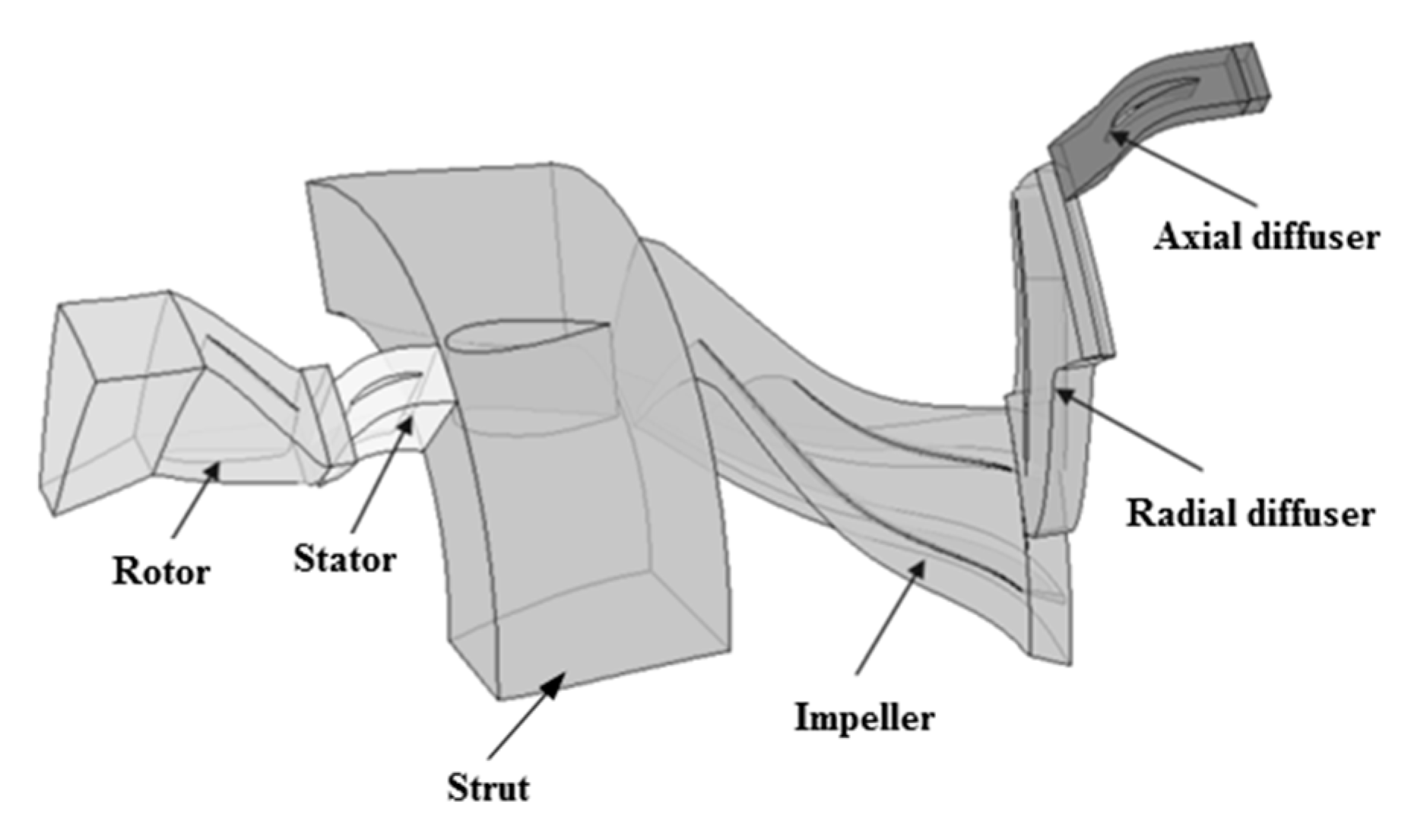

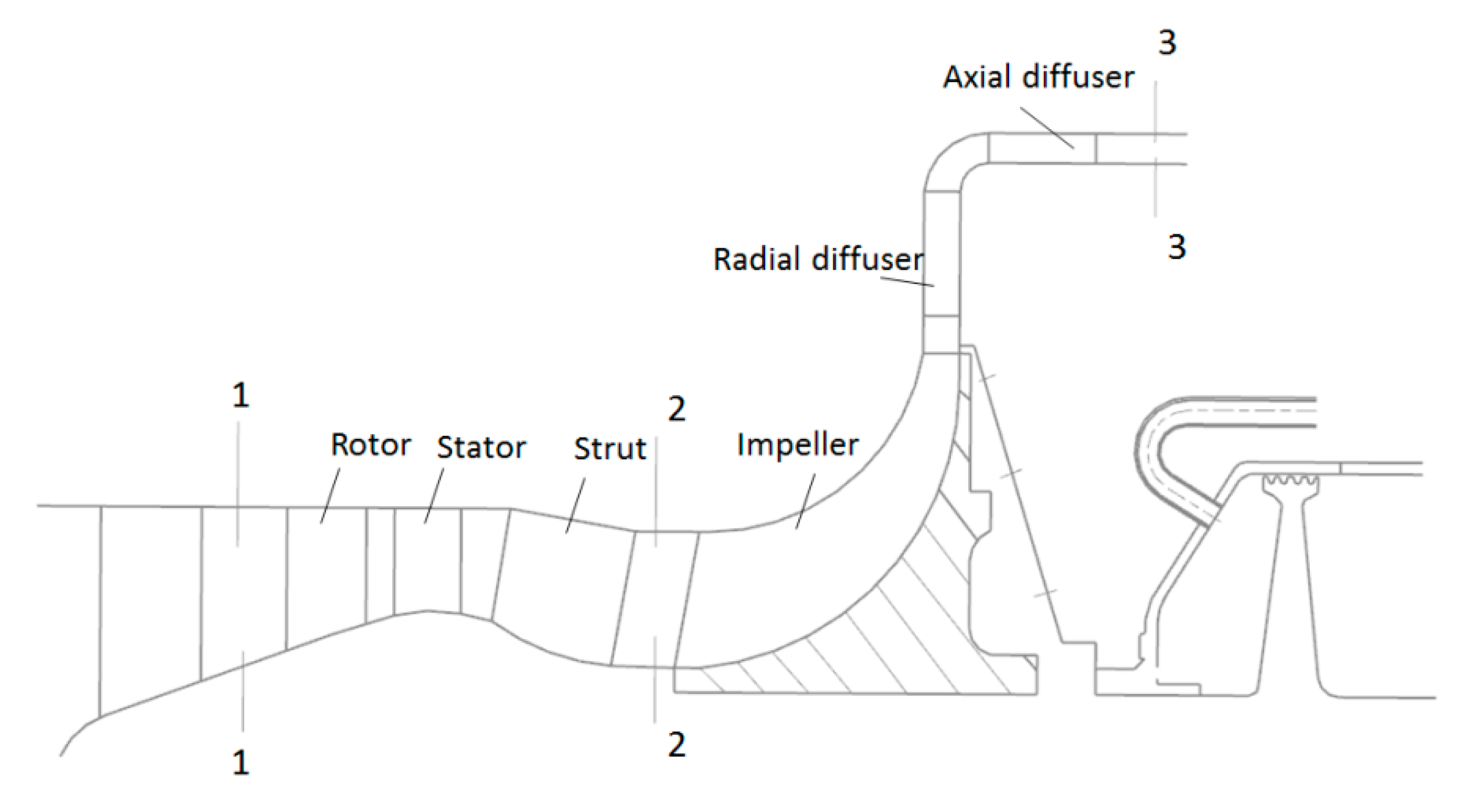

2. Researched Centrifugal Compressor

3. Optimization Framework

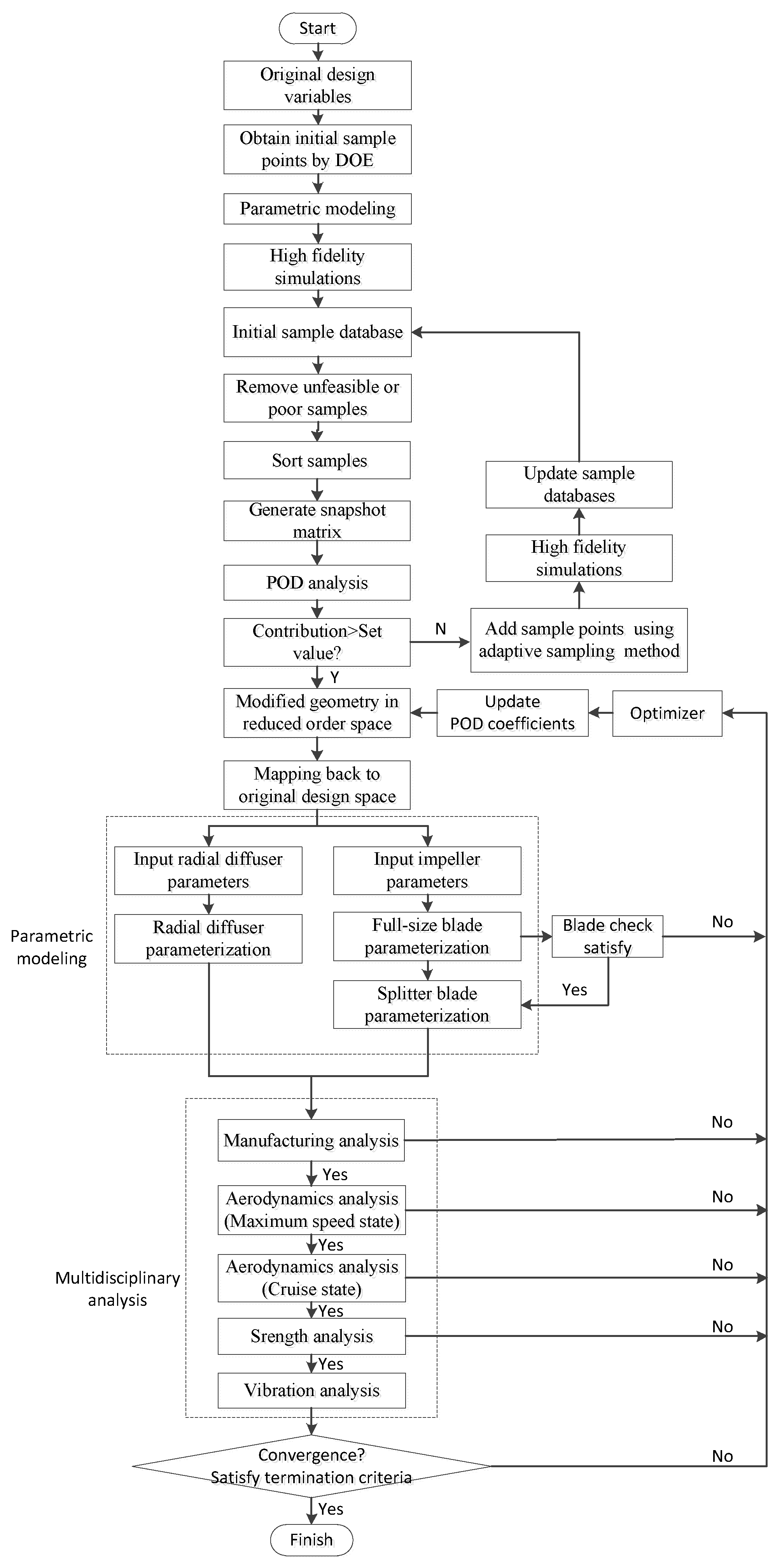

3.1. Optimization Process

- Select the design variables and determine their lower and upper bounds.

- Choose an appropriate design of experiment (DOE) to generate initial sample points. There are several types of DOEs, such as fractional factorial, full factorial, orthogonal array, Latin hypercube, and parameter study. In this study, the Latin hypercube was chosen to carry out 600 experiments, as it allows many points and more combinations can be studied for each factor, and the engineer has total freedom in selecting the number of designs to run as long as it is greater than the number of factors.

- Utilize the parametric modeling method to generate the new geometry of the impeller and radial diffuser for all the samples obtained from Step (2). Additionally, the mass of blades can be obtained during this process. The parametric modeling method will be introduced in Section 3.2.

- Conduct high-fidelity simulations such as computational fluid dynamics (CFD) and finite element analysis (FEA) and obtain the relevant responses (objectives and constraints) for all the sample points.

- Generate the initial sample database by combing the sample points and their relevant responses.

- Remove some of the samples (unfeasible or poor designs) and the samples are then sorted according to the satisfaction of the objectives and constraints. In other words, the best point in the samples is placed in the first place, and the suboptimal point is placed in the second place, and so on.

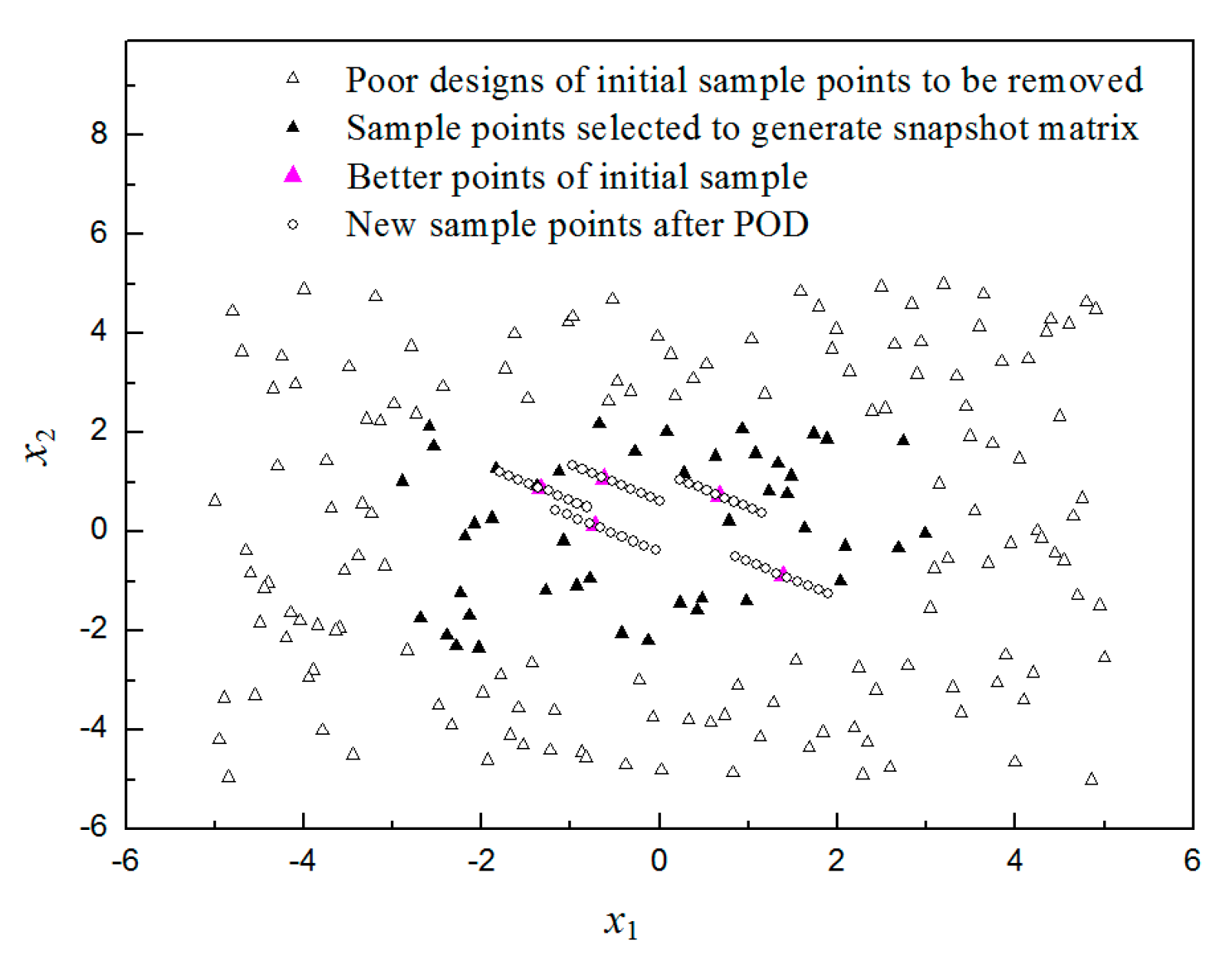

- Generate a snapshot matrix. The data were standardized to have a zero mean and unit variance. In this study, 120 sample points were chosen to generate the snapshot matrix.

- Conduct a POD analysis of the snapshot matrix, and determine the number of principal components to be retained. In this study, only four principal components were retained. The POD method will be introduced in Section 3.4.1.

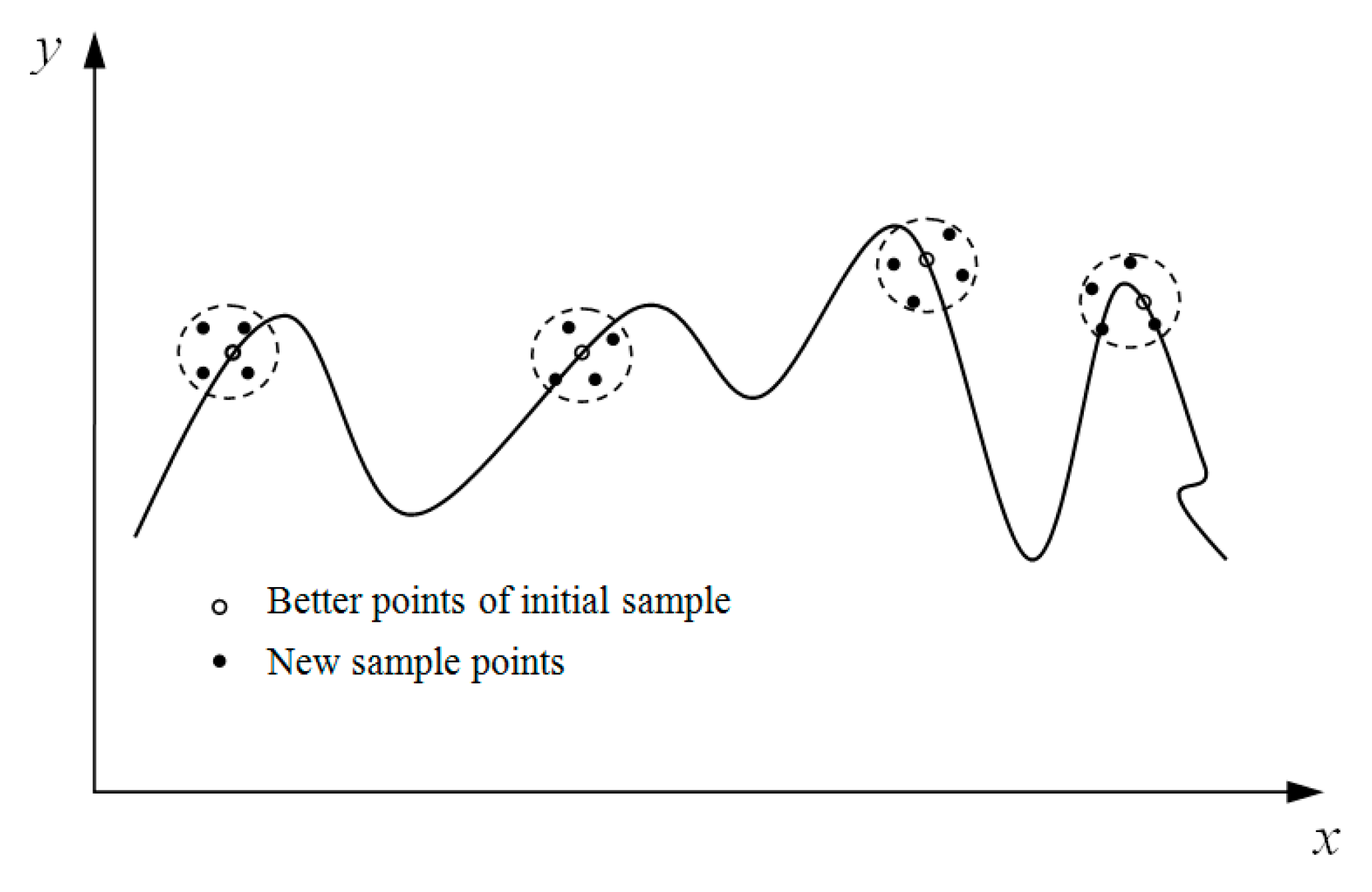

- Check whether the contribution rate is satisfied or not. If not, increase the sample points using an adaptive sampling method and then update the snapshot matrix. If yes, the cycle will continue. In this study, only one cycle of the sample point adding process is performed to satisfy the requirement of the set value for the contribution rate (85%), and 150 new sample points are added. The sample point adding strategy will be introduced in Section 3.4.2.

- Select POD coefficients to act as new design variables and a modified geometry in the reduced order space by changing the POD coefficients. Then, project the data back to the original space.

- Utilize the parametric modeling method to generate the new geometry of the impeller and radial diffuser as Step (3).

- Conduct a multidisciplinary analysis in sequence. The analysis includes aerodynamics analysis, strength analysis, and vibration analysis, which will be introduced in Section 3.3.

- Optimize the POD coefficients using an appropriate algorithm. The formulation of the optimization problem will be introduced in Section 3.5. In this study, a hybrid optimization searching algorithm was adopted. The genetic algorithm (GA) was firstly used to search the optimized point and then sequential quadratic programming (SQP) was employed for local optimization. The whole process was integrated and optimized by commercial software iSIGHT (Version 5.9.4, Dassault Systems, Vélizy-Villacoublay, France, 2015) [28].

- Check whether a convergence or termination criterion is satisfied or not. If not, repeat Steps (10)–(13). If yes, the cycle will be finished, and an optimal design will be obtained.

- The feedbacks are set up in the process to reduce searching time, which is stated as follows:

- ●

- Parameterization part: Check the requirements of the exit lean angle. The given condition is as follows: 0° ≤ exit lean angle ≤ 15°.

- ●

- Aerodynamics analysis part: Check the requirements of the adiabatic aerodynamic efficiency, the mass flow, and the pressure ratio.

- ●

- Strength analysis part: Check the requirements of the blade stress.

- ●

- Termination criteria: Reach the maximum number of iterations (for the present case: 200 steps).

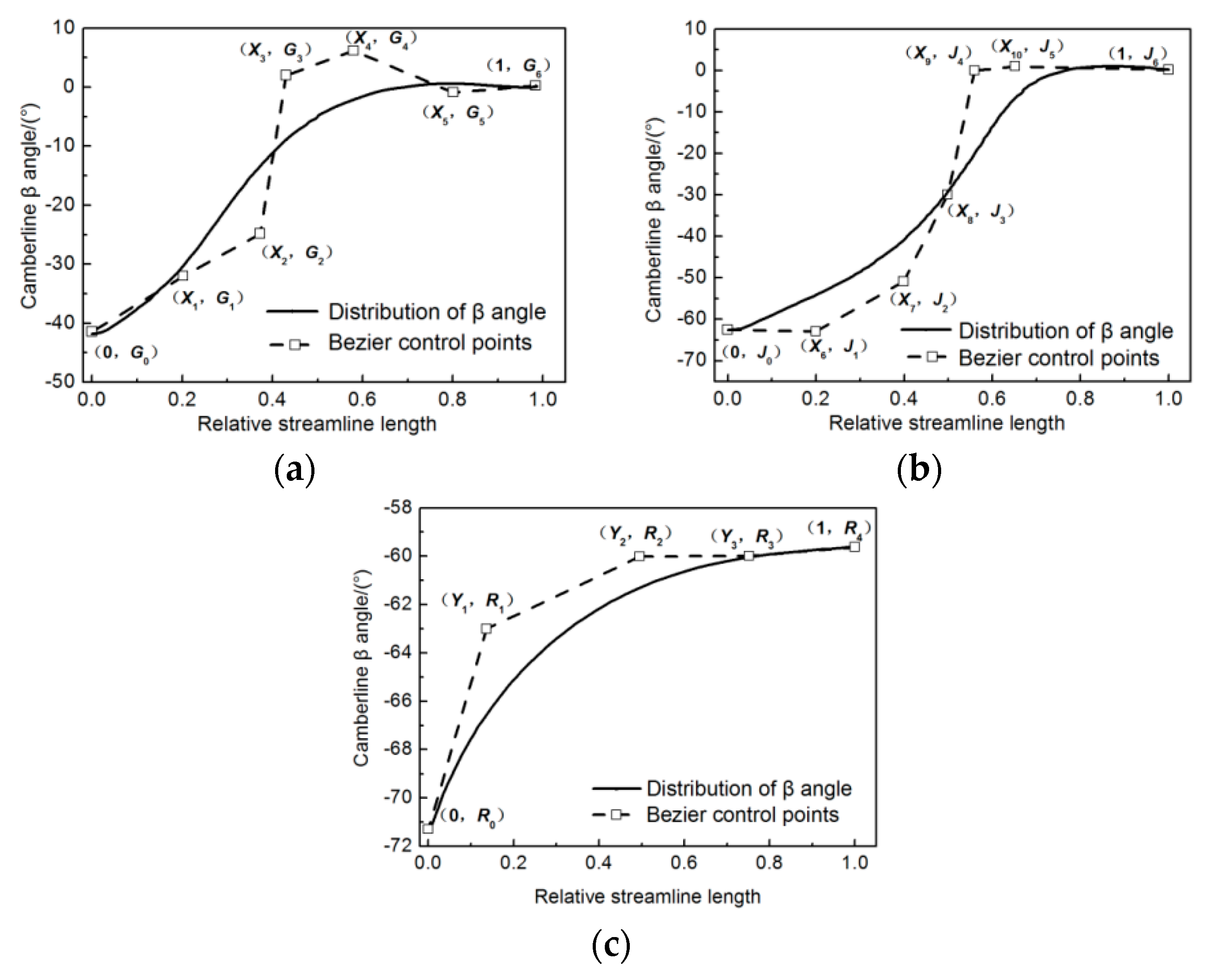

3.2. Geometrical Parameterization

3.3. Multidisciplinary Analysis

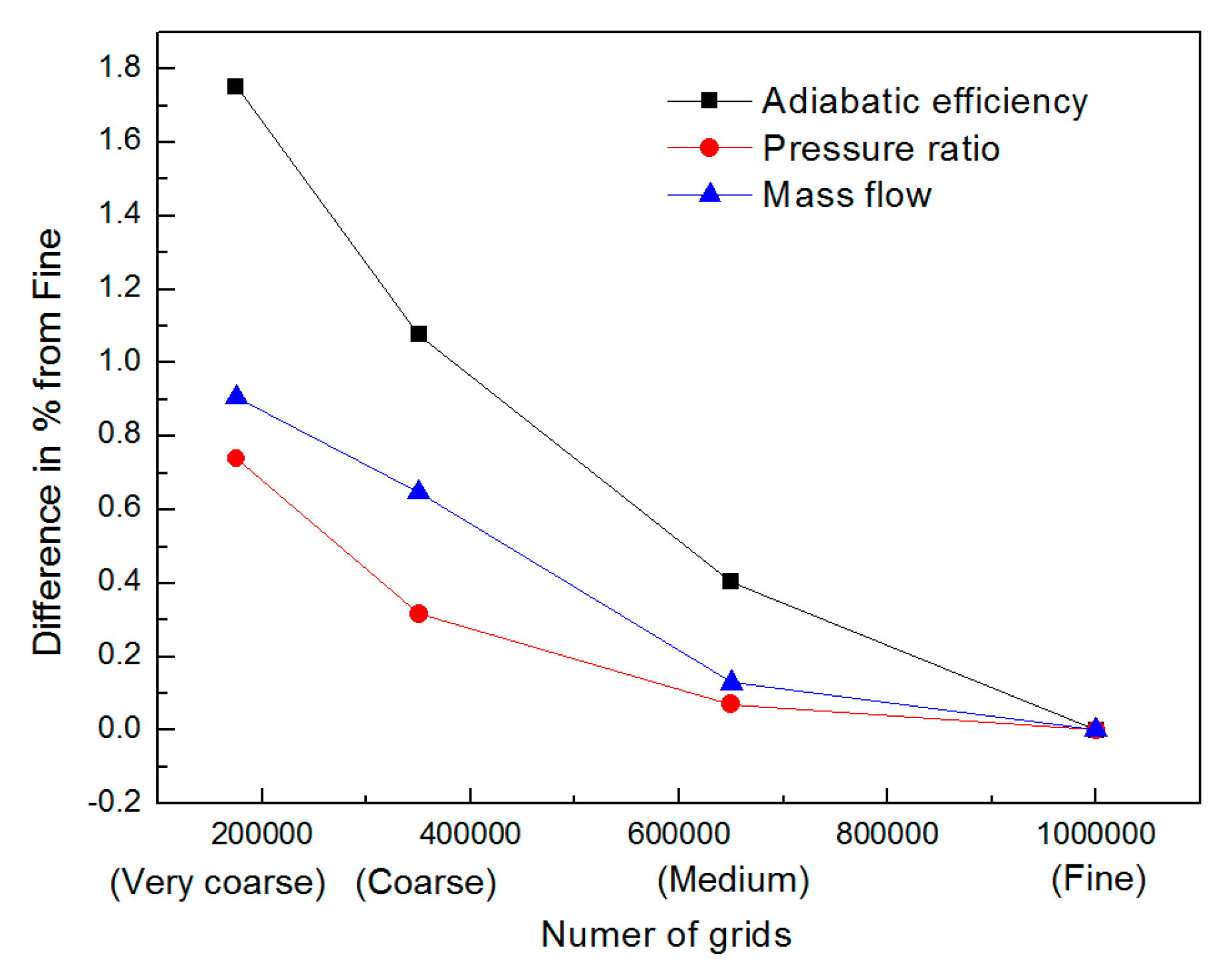

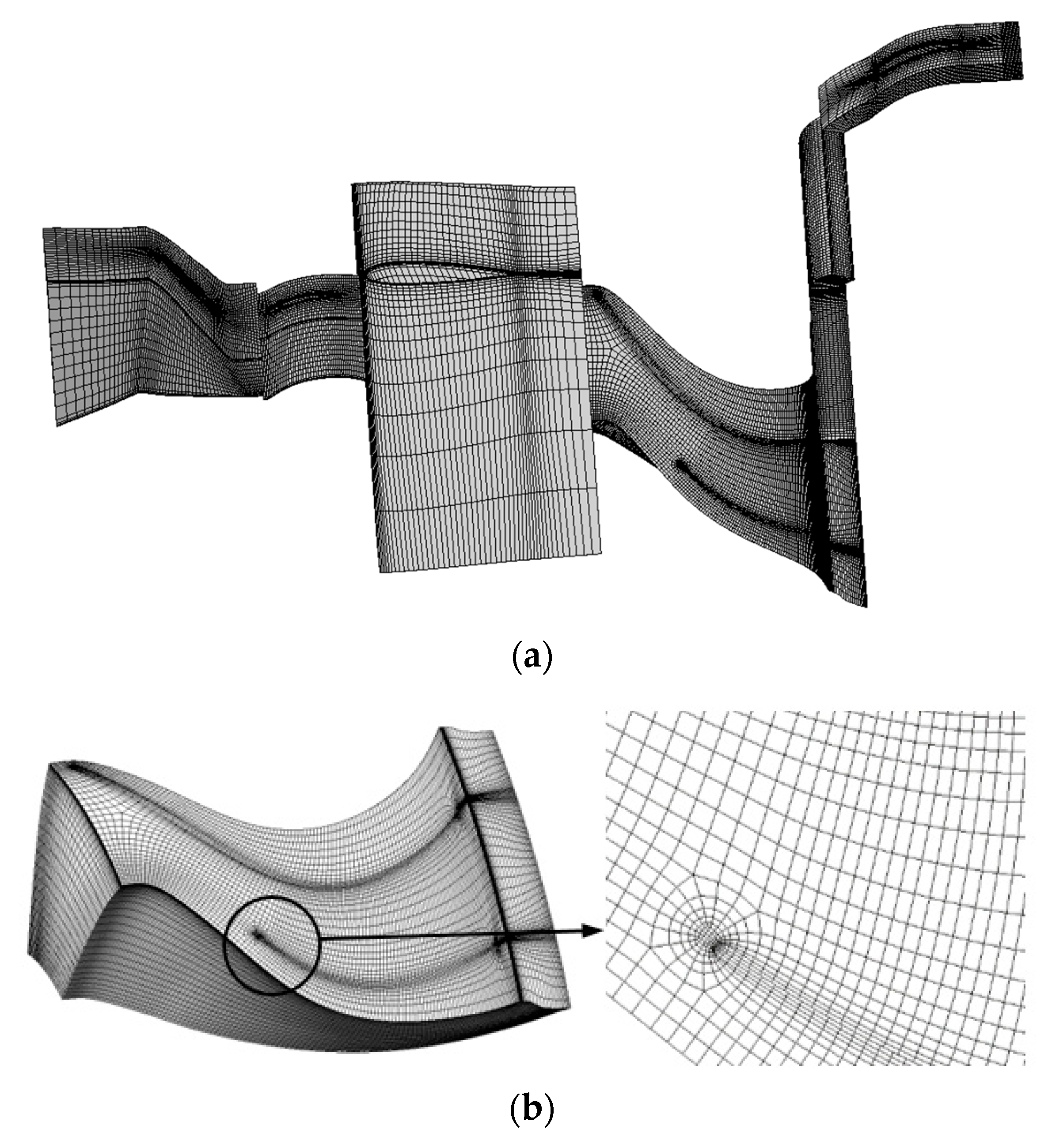

3.3.1. Aerodynamic Analysis

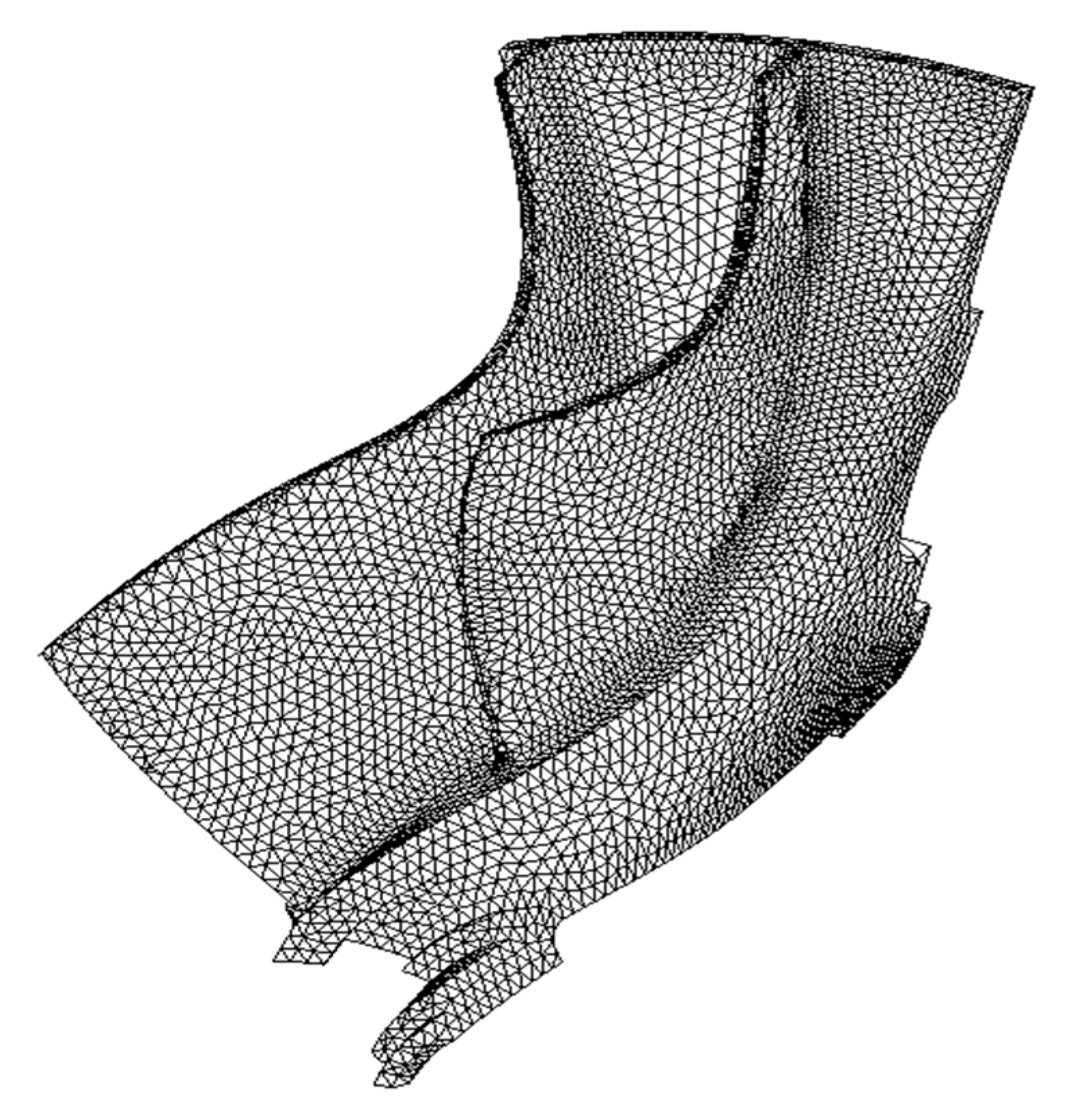

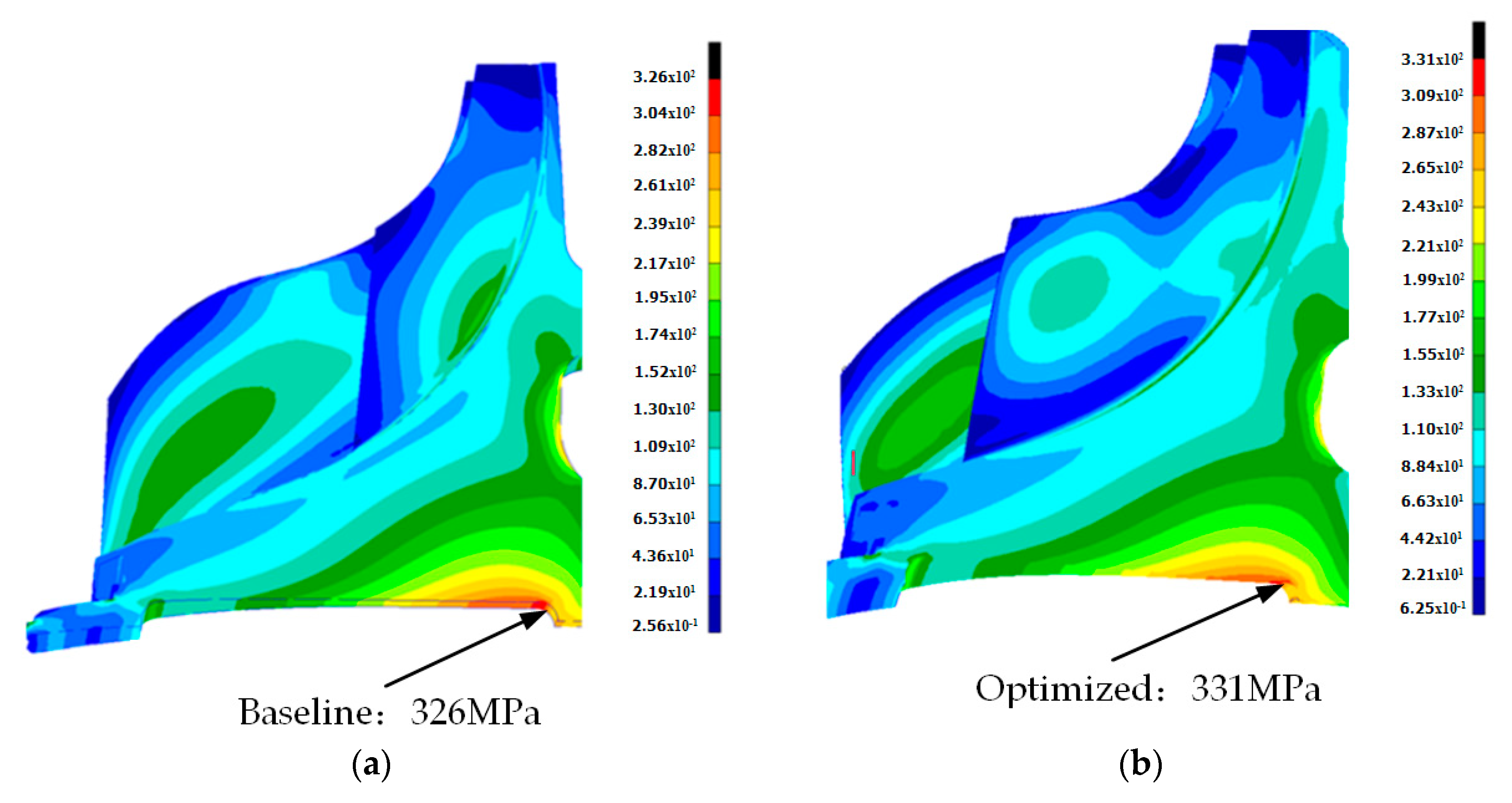

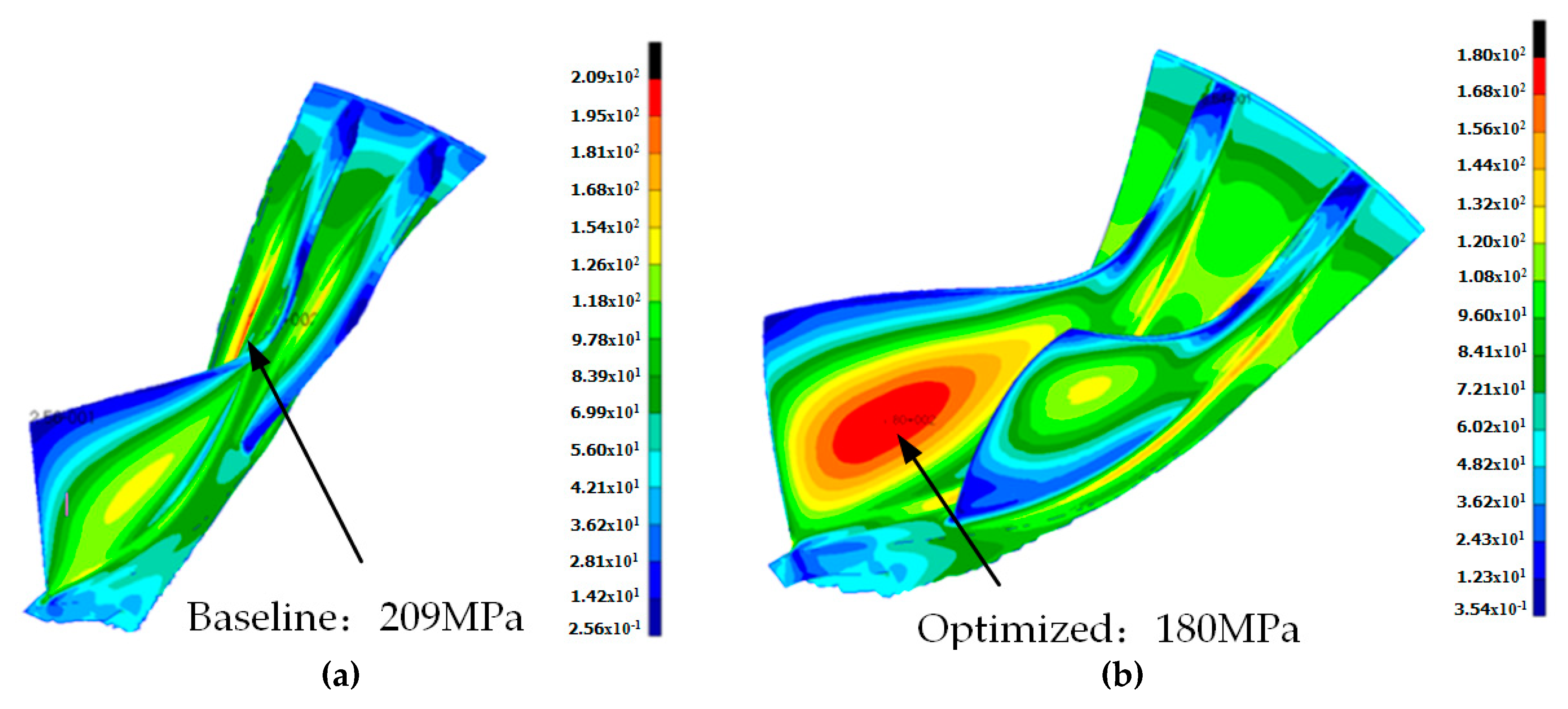

3.3.2. Strength Analysis

3.3.3. Vibration Analysis

3.4. POD-Based Dimension Reduction Technique and an Adaptive Sampling Method

3.4.1. POD-Based Dimension Reduction Technique

3.4.2. The Adaptive Sampling Method

3.5. Formulation of the Optimization Problem

4. Method Validation

4.1. Numerical Experiments

4.2. Numerical Results

5. Results and Discussion

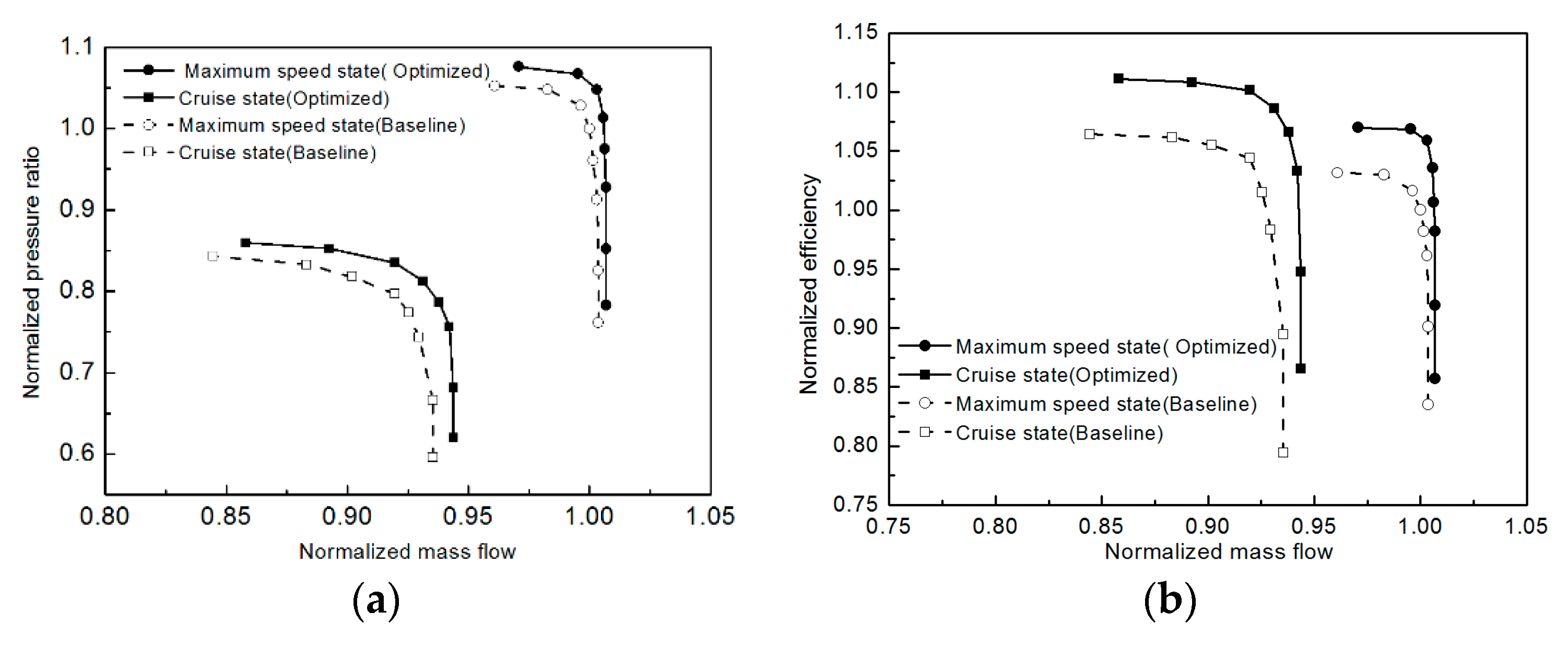

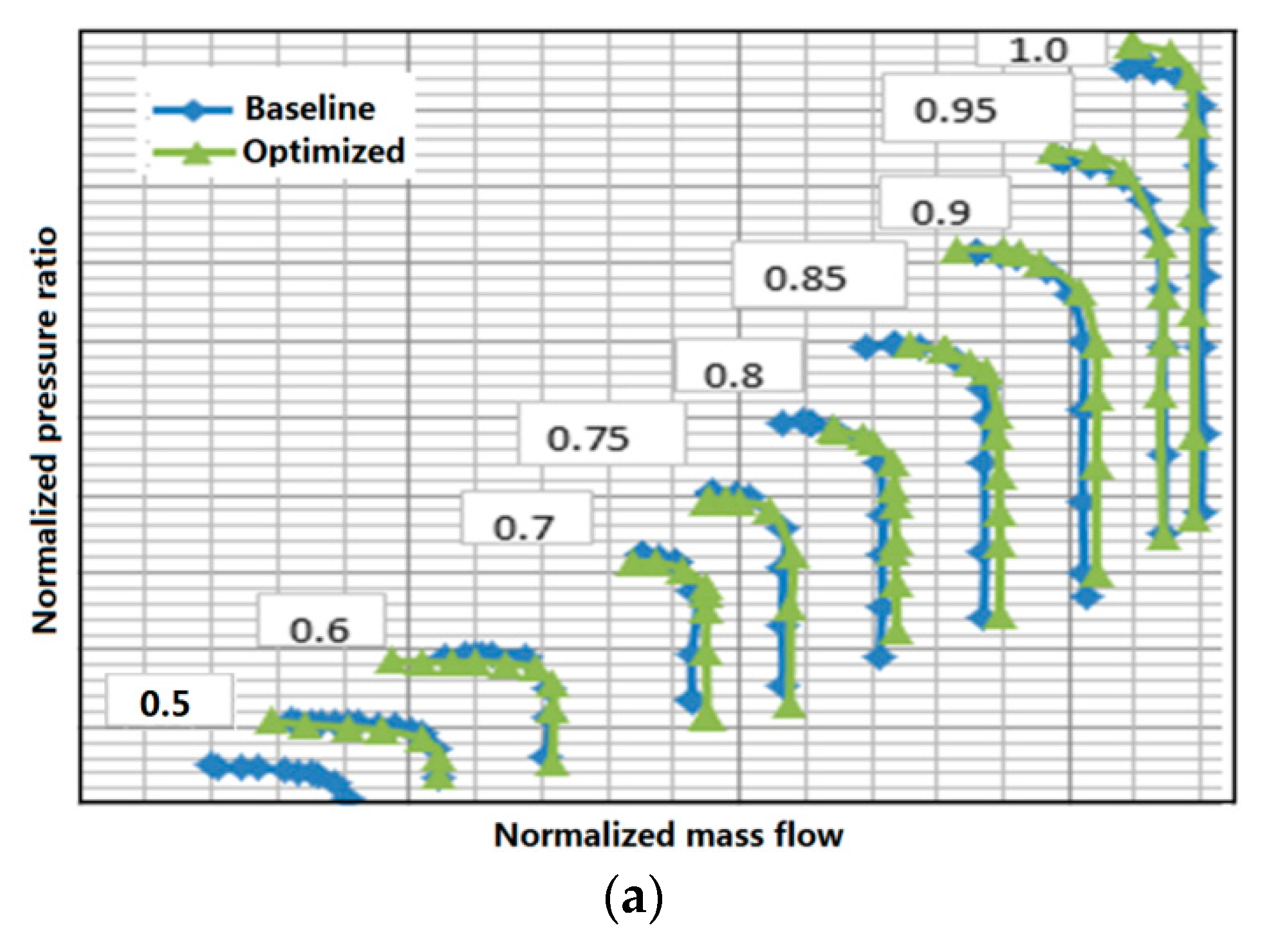

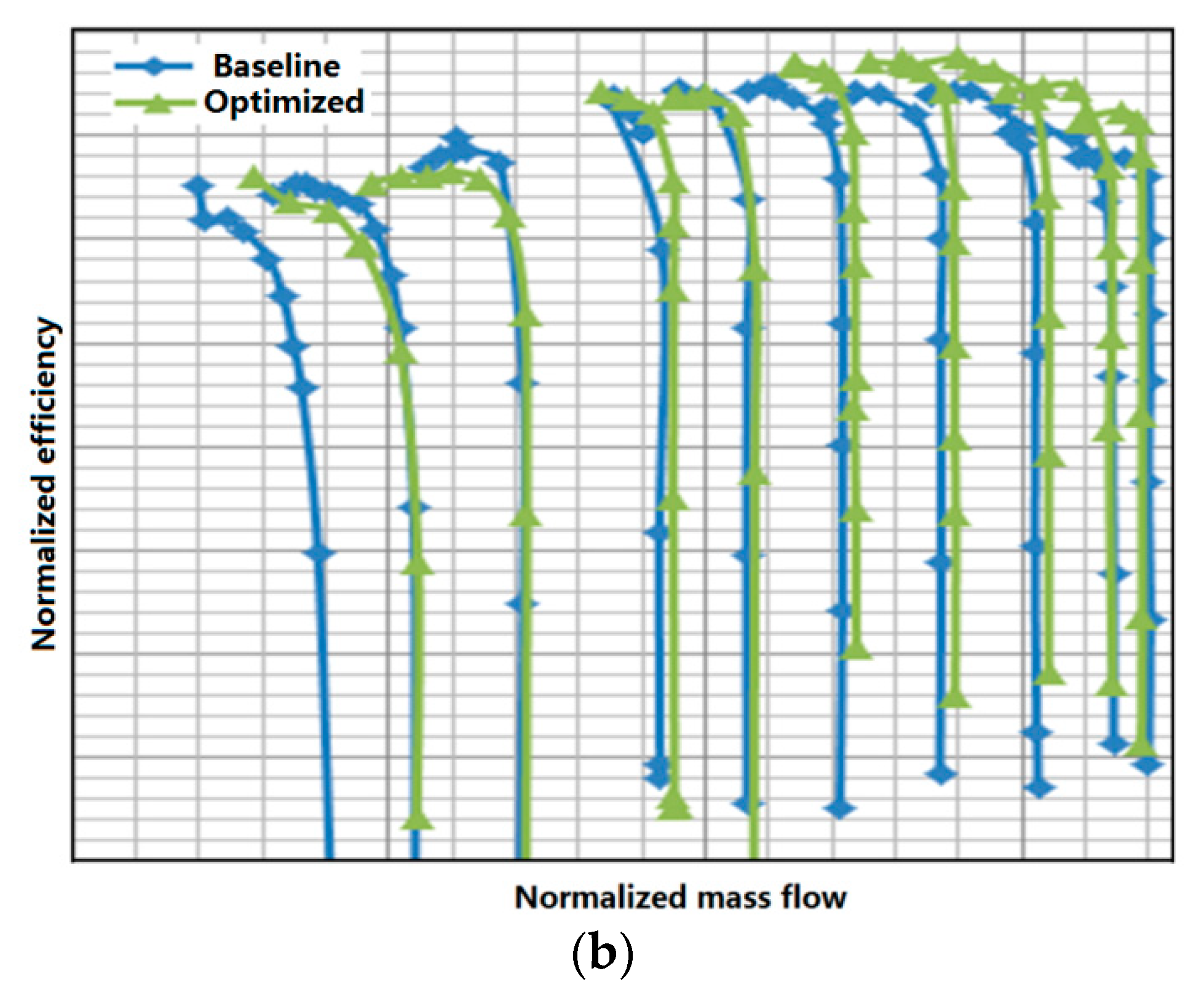

5.1. Optimization Results

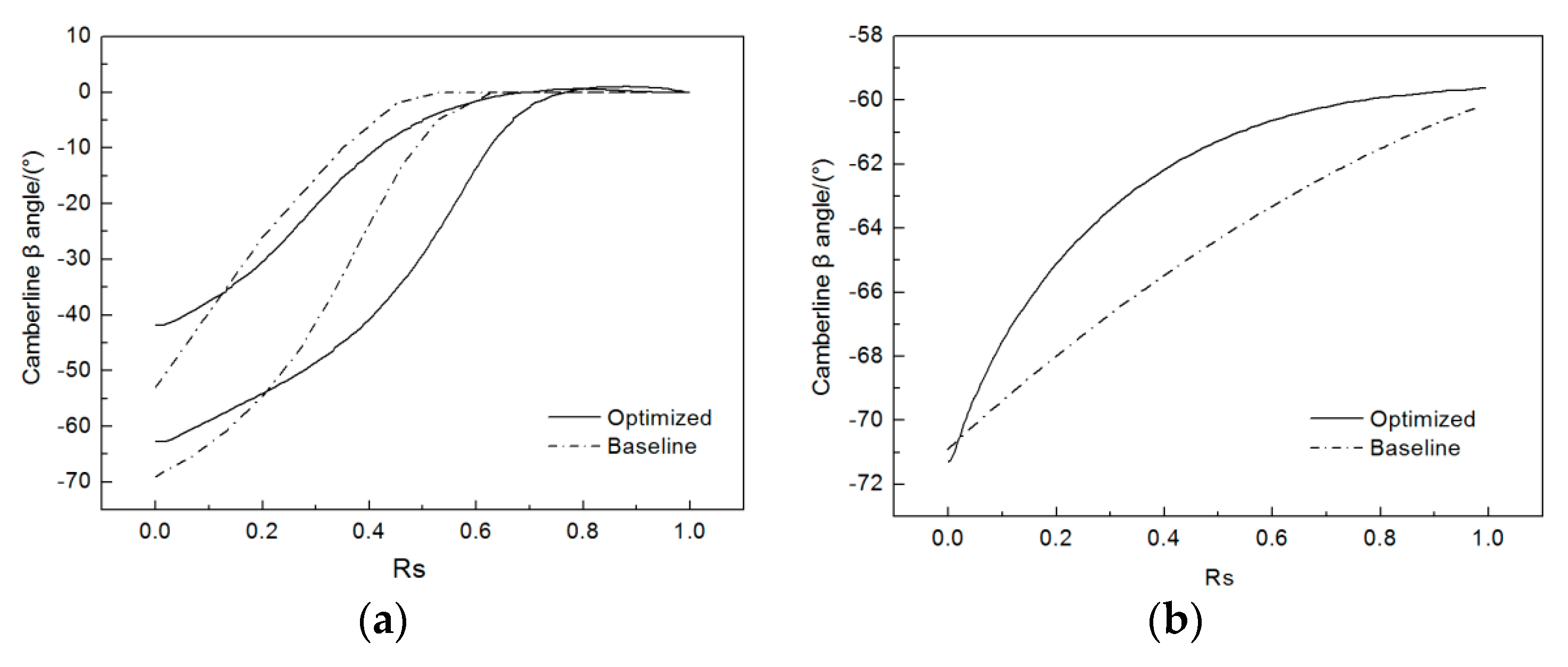

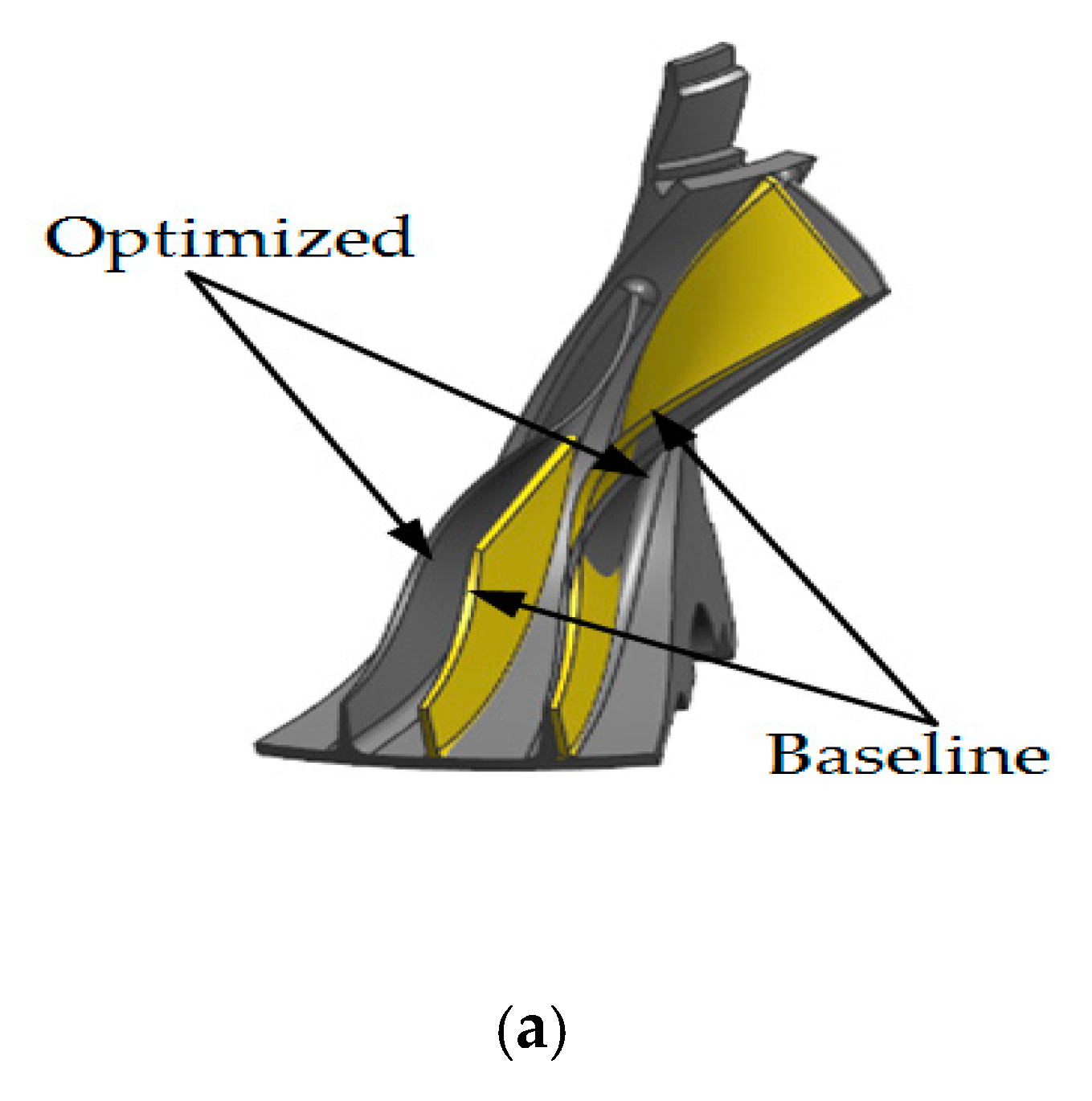

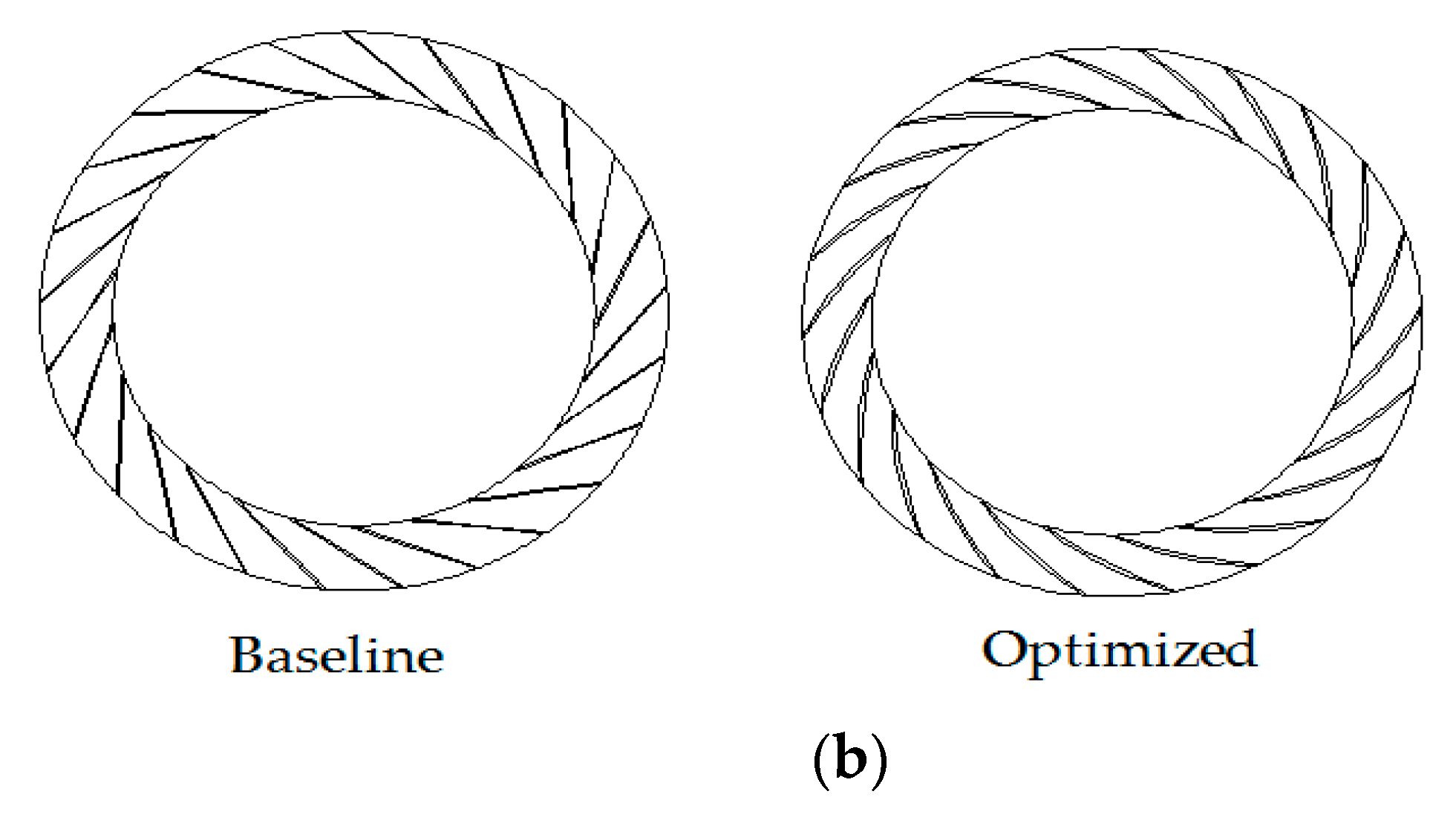

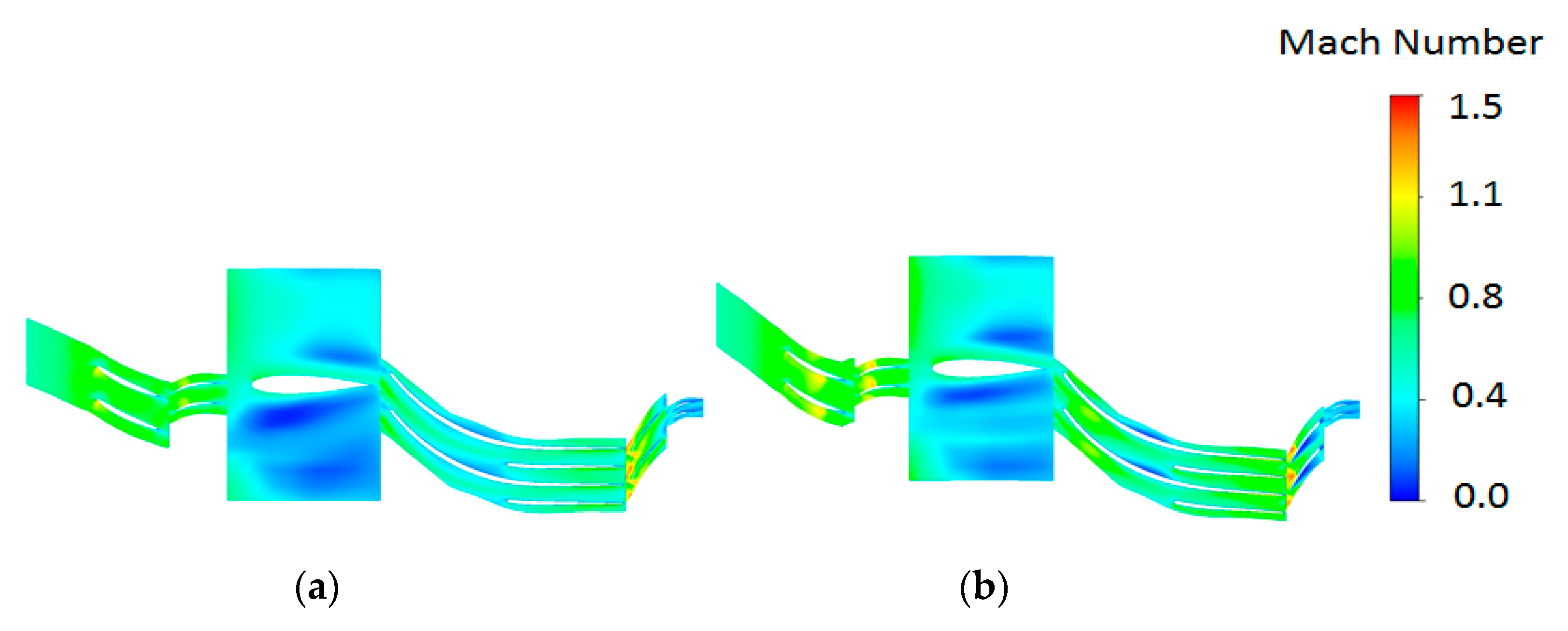

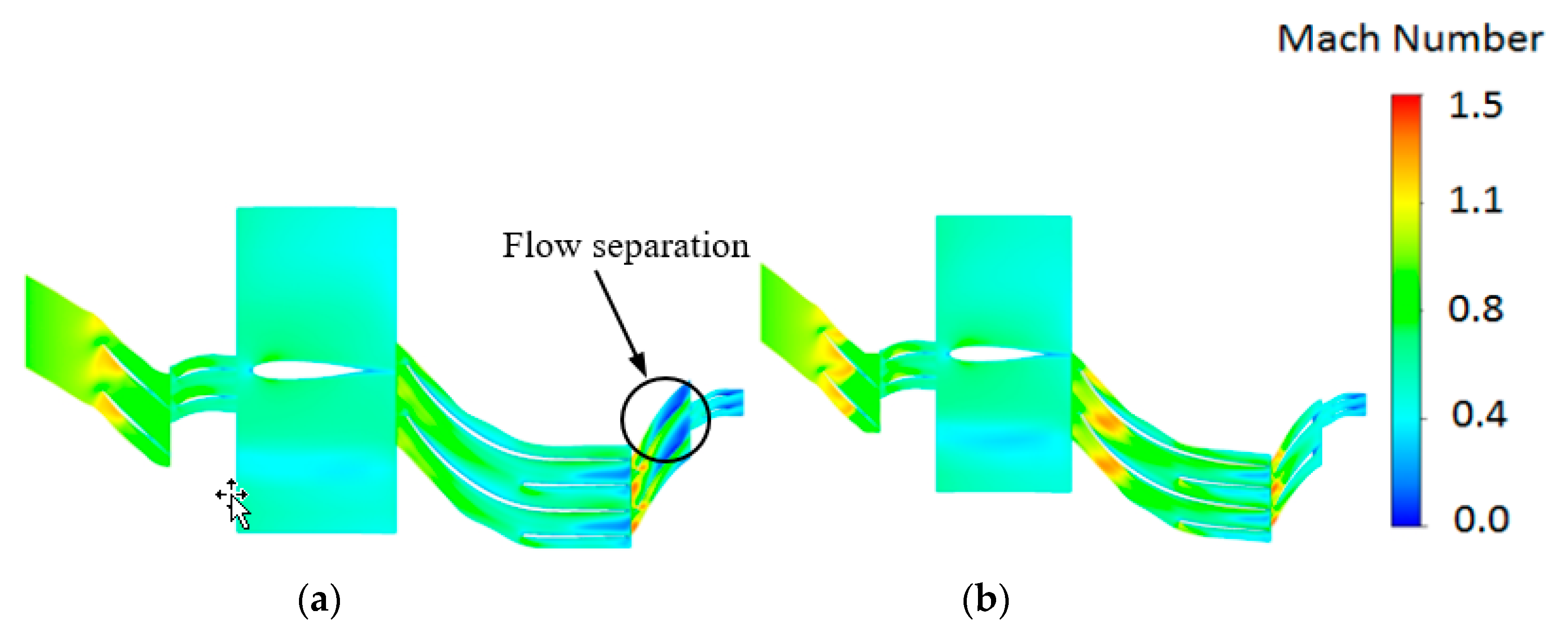

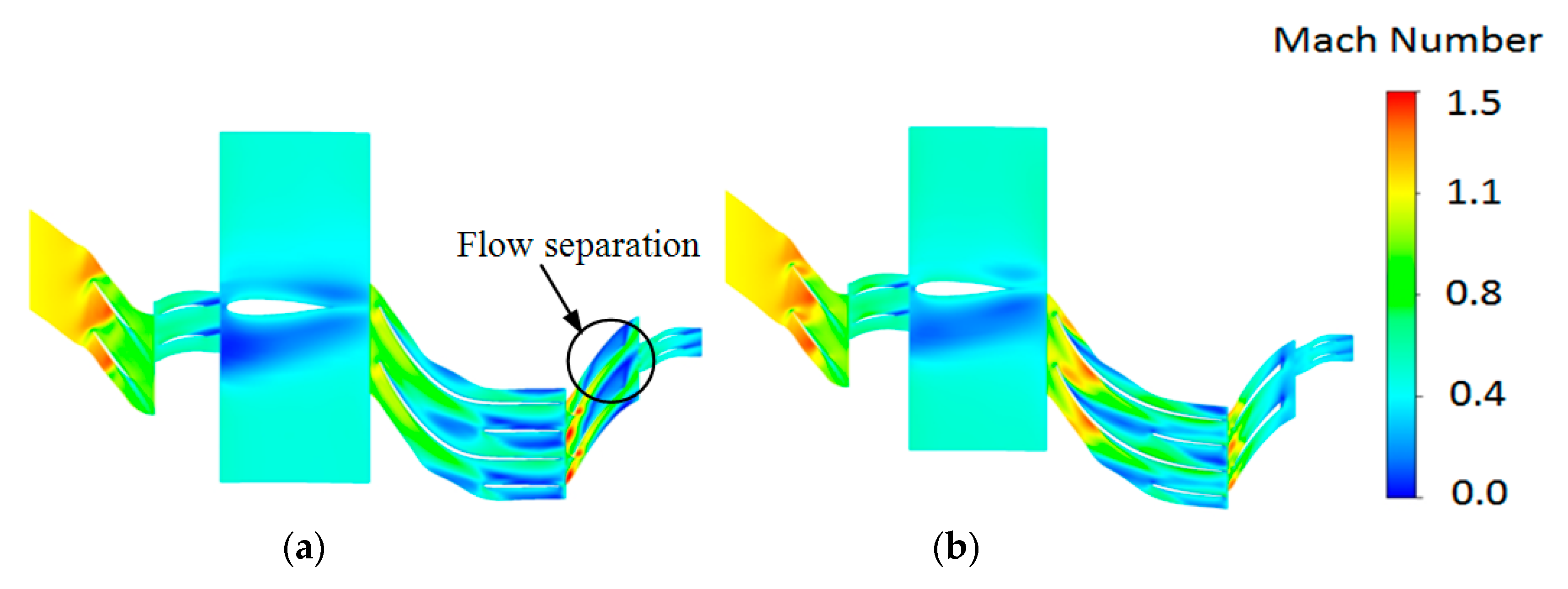

5.2. Details Analysis

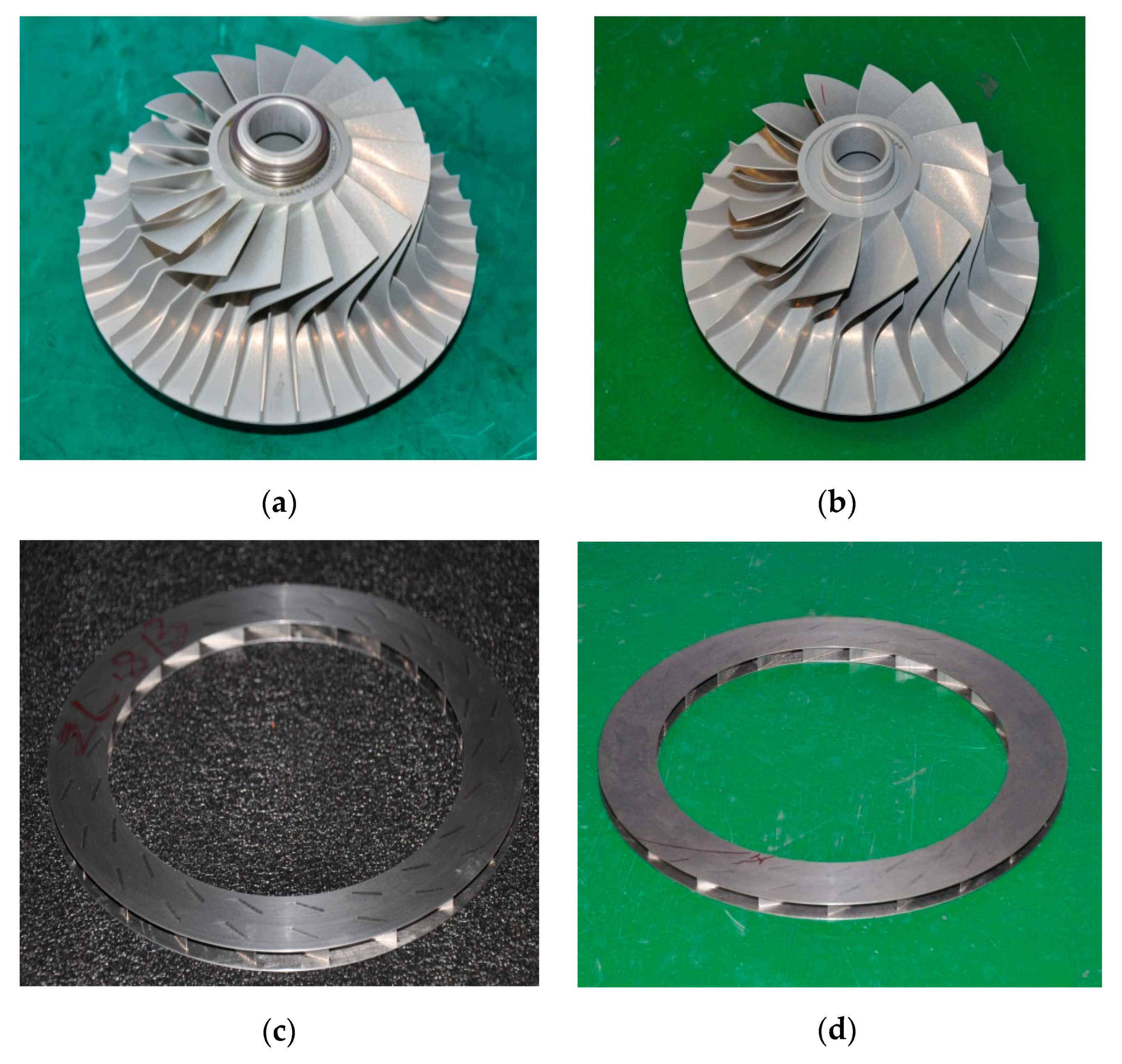

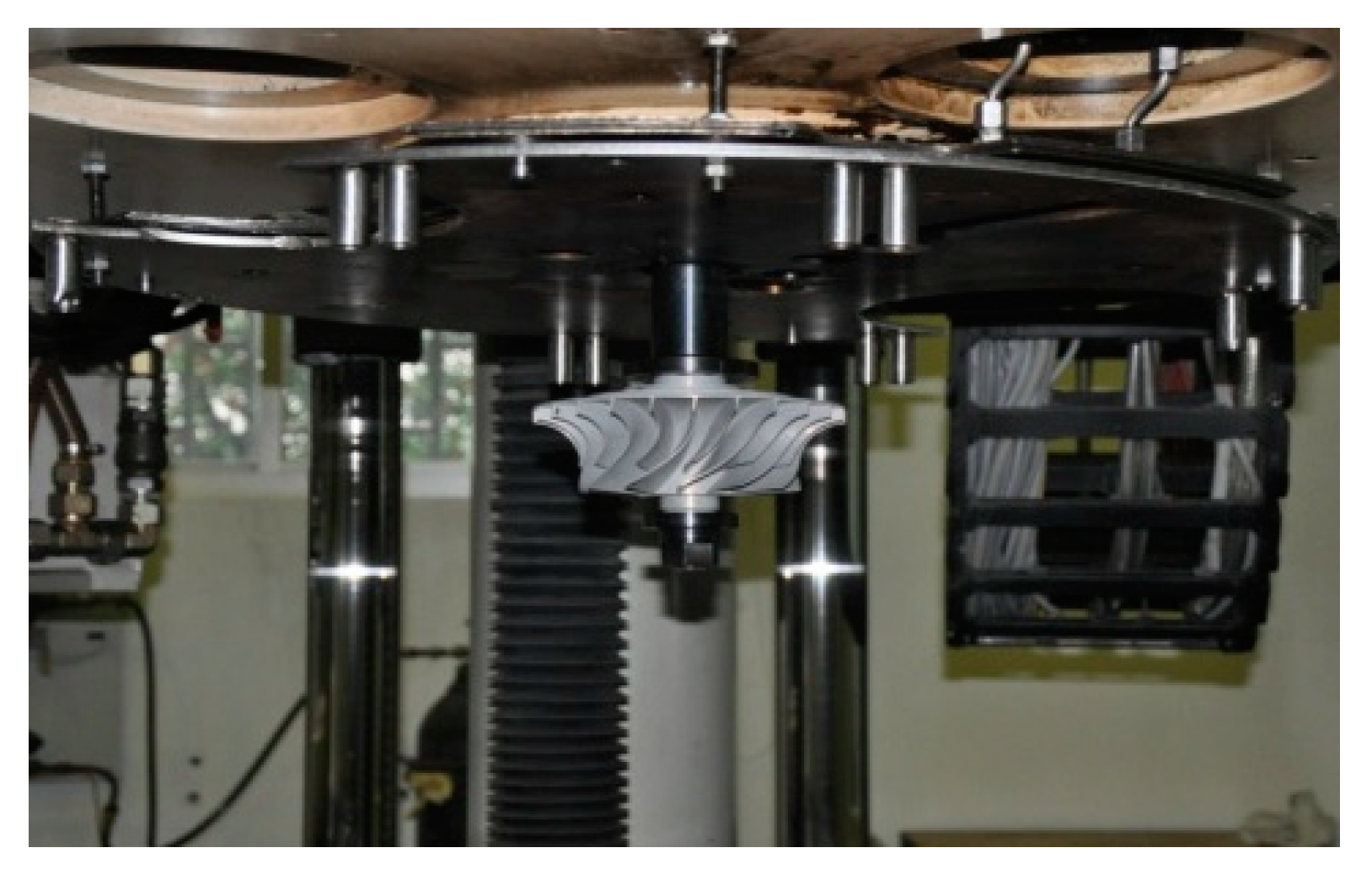

6. Test Verification

6.1. Test Part

6.2. Performance Test Verification

6.3. Structure Strength Test Verification

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barsi, D.; Costa, C.; Cravero, C.; Ricci, G. Aerodynamic design of a centrifugal compressor stage using an automatic optimization strategy. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Dusseldorf, Germany, 16–20 June 2014; pp. 1–11. [Google Scholar] [CrossRef]

- Bellis, F.D.; Guidotti, E.; Rubino, D.T. Centrifugal compressors return channel optimization by means of advanced 3D CFD. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Hehn, A.; Mosdzien, M.; Grates, D.; Jeschke, P. Aerodynamic optimization of a transonic centrifugal compressor by using arbitrary blade surface. J. Turbomach. 2018, 140, 051011. [Google Scholar] [CrossRef]

- Demeulenaere, A.; Bonaccorsi, J.-C. Multi-disciplinary multi-point optimization of a turbocharger compressor wheel. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Geller, M.; Schemmann, C.; Kluck, N. Optimization the operation characteristic of a highly stressed centrifugal compressor impeller using automated optimization and metamodeling methods. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; pp. 1–11. [Google Scholar] [CrossRef]

- Salnikov, A.; Danilov, M. A centrifugal compressor impeller: A multidisciplinary optimization to improve its mass, strength, and gas-dynamic characteristics. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017; pp. 1–10. [Google Scholar] [CrossRef]

- Mattia, O.; David, P.; Antonio, G.; Stefano, R. Three-dimensional turbulent optimization of vane diffusers for centrifugal compressors based on metamodel-assisted genetic algorithms. Optim. Eng. 2014, 15, 973–992. [Google Scholar] [CrossRef]

- Chen, J.; Wu, G. Kriging-assisted design optimization of the impeller geometry for an automotive torque converter. Struct. Multidiscip. Optim. 2018, 57, 2503–2514. [Google Scholar] [CrossRef]

- Khalfallah, S.; Ghenaiet, A.; Benini, E.; Bedon, G. Surrogate-based shape optimization of stall margin and efficiency of centrifugal compressor. J. Propul. Power 2015, 31, 1607–1620. [Google Scholar] [CrossRef]

- Derakhshan, S.; Bashiri, M. Investigation of an efficient shape optimization procedure for centrifugal pump impeller using eagle strategy algorithm and ANN (case study: Slurry flow). Struct. Multidiscip. Optim. 2018, 58, 459–473. [Google Scholar] [CrossRef]

- Yan, C.; Shen, X.; Guo, F. Novel two-stage method for low-order polynomial model. Math. Probl. Eng. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Yan, C.; Shen, X.; Guo, F. An improved support vector regression using least squares method. Struct. Multidiscip. Optim. 2018, 57, 2431–2445. [Google Scholar] [CrossRef]

- Bonaiuti, D.; Zangeneh, M. On the Coupling of inverse design and optimization techniques for the multiobjective, multipoint design of turbomachinery blades. J. Turbomach. 2009, 131, 021014. [Google Scholar] [CrossRef]

- Zangeneh, M.; Mendonca, F. 3D multidisciplinary inverse design based optimization of a centrifugal compressor impeller. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Dusseldorf, Germany, 16–20 June 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Luo, J.; Zhu, Y.; Tang, X.; Liu, F. Flow reconstructions and aerodynamic shape optimization of turbomachinery blades by POD-based hybrid models. Sci. China Technol. Sci. 2017, 60, 1658–1673. [Google Scholar] [CrossRef]

- Tan, B.T.; Damodaran, M.; Willcox, K.E. Aerodynamic data reconstruction and inverse design using proper orthogonal decomposition. AIAA J. 2004, 42, 1505–1516. [Google Scholar] [CrossRef]

- Bai, J.; Qiu, Y.; Hua, J. Improved airfoil inverse design method based on Gappy POD. Acta Aeronaut. Astronaut. Sin. 2013, 34, 762–771. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, B.; Cao, Z.; Zou, W.; Yu, G. A comparative study of POD interpolation and POD projection methods for fast and accurate prediction of heat transfer problems. Int. J. Heat. Mass. Trans. 2012, 55, 4827–4836. [Google Scholar] [CrossRef]

- Braconnier, T.; Ferrier, M.; Jouhaud, J.C.; Montagnac, M.; Sagaut, P. Towards an adaptive POD/SVD surrogate model for aeronautic design. Comput. Fluids 2011, 40, 195–209. [Google Scholar] [CrossRef]

- Filomeno Coelho, R.; Breitkopf, P.; Knopf-Lenoir, C. Model reduction for multidisciplinary optimization-application to a 2D wing. Struct. Multidiscip. Optim. 2008, 37, 29–48. [Google Scholar] [CrossRef]

- Filomeno Coelho, R.; Breitkopf, P.; Knopf-Lenoir, C.; Villon, P. Bi-level model reduction for coupled problems-application to a 3D wing. Struct. Multidiscip. Optim. 2009, 39, 401–418. [Google Scholar] [CrossRef]

- Luliano, E.; Quagliarella, D. Proper Orthogonal decomposition, surrogate modeling and evolutionary optimization in aerodynamic design. Comput. Fluids 2013, 84, 327–350. [Google Scholar] [CrossRef]

- Molinari, M.; Jarrett, J.; Clarkson, P.; Dawes, W. Characterizing the design space in multiobjective axial compressor blade optimization. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conf., Newport, RI, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Total, D.J.; Bressloff, N.W.; Keane, A.J.; Holden, C.M.E. Geometric filtration using proper orthogonal decomposition for aerodynamic design optimization. AIAA J. 2010, 48, 916–928. [Google Scholar] [CrossRef]

- Viswanath, A.; Forrester, A.I.J.; Keane, A.J. Dimension reduction for aerodynamic design optimization. AIAA J. 2011, 49, 1256–1266. [Google Scholar] [CrossRef]

- Ghoman, S.; Wang, Z.; Chen, P.; Kapania, R. A POD-based reduced order design scheme for shape optimization of air vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar] [CrossRef]

- Ghoman, S.; Wang, Z.; Chen, P.; Kapania, R. Hybrid optimization framework with Proper-Orthogonal-Decomposition-based Order Reduction and Design space Evolution scheme. J. Aircr. 2013, 50, 1776–1786. [Google Scholar] [CrossRef]

- Dassault. Dassault Systems, Isight, Simulia Execution Engine, version 5.9.4; Dassault Systems: Vélizy-Villacoublay, France, 2015. [Google Scholar]

- ANSYS. Ansys Products, Ansys Icem CFX, version 10.0 64-bit; ANSYS: Canonsburg, PA, USA, 2010. [Google Scholar]

- MSC.Software. Patran, version 2012 64-bit; MSC Software: Santa Ana, CA, USA, 2012.

- ANSYS. Ansys Products, Ansys Icem Mechnical, version 15.0 64-bit; ANSYS: Canonsburg, PA, USA, 2015. [Google Scholar]

- Jamil, M.; Yang, X.-S. A literature survey of benchmark functions for global optimization problems. Int. J. Math. Model. Numer. Optim. 2013, 4, 151–194. [Google Scholar] [CrossRef]

- Duan, X.; Wang, G.G.; Kang, X.; Niu, Q.; Naterer, G.; Peng, Q. Performance study of model-pursuing sampling method. J. Eng. Optim. 2009, 41, 1–21. [Google Scholar] [CrossRef]

| Design Variable | Lower Bound | Upper Bound | Design Variable | Lower Bound | Upper Bound | Design Variable | Lower Bound | Upper Bound |

|---|---|---|---|---|---|---|---|---|

| G0 | −55 | −38 | J4 | −15 | 15 | X9 | 0.4 | 0.8 |

| G1 | −47 | −17 | J5 | −10 | 10 | X10 | 0.6 | 1.0 |

| G2 | −41 | −11 | X1 | 0.1 | 0.3 | R0 | −74 | −68 |

| G3 | −13 | 17 | X2 | 0.2 | 0.5 | R1 | −67 | −37 |

| G4 | −9 | 21 | X3 | 0.3 | 0.6 | R2 | −76 | −46 |

| G5 | −10 | 10 | X4 | 0.4 | 0.8 | R3 | −75 | −45 |

| J0 | −68 | −62 | X5 | 0.6 | 1.0 | R4 | −65 | −58 |

| J1 | −78 | −48 | X6 | 0.1 | 0.3 | Y1 | 0 | 0.5 |

| J2 | −66 | −36 | X7 | 0.2 | 0.5 | Y2 | 0.25 | 0.75 |

| J3 | −45 | −15 | X8 | 0.3 | 0.6 | Y3 | 0.5 | 1.0 |

| Problem | Number of Initial Sample Points | Number of Sample Points Selected to Generate Snapshot Matrix | Number of Design Variables Retained | Number of New Sample Points |

|---|---|---|---|---|

| TF1 | 200 | 50 | 1 | 50 |

| TF2 | 1000 | 300 | 2 | 200 |

| TF3 | 5000 | 1000 | 5 | 500 |

| Problem | Optimum f-Value | Number of Total Sample Points | Average f-Value | ||

|---|---|---|---|---|---|

| POD | M-POD | RBF | |||

| TF1 | −1.0316 | 250 | −0.9998 | −1.0315 | −0.9682 |

| TF2 | −195.831 | 1200 | −177.5 | −188.3 | −174.1 |

| TF3 | 0 | 5500 | 250.3 | 74.7 | 608.9 |

| Main Performance Indexes | Baseline | Optimized |

|---|---|---|

| η1* | 1.000 | 1.036 |

| η2* | 1.044 | 1.086 |

| m1* | 1.000 | 1.006 |

| m2* | 0.920 | 0.931 |

| π1* | 1.000 | 1.014 |

| π2* | 0.771 | 0.782 |

| n1* | 1.000 | 0.6315 |

| n2* | 1.000 | 0.8800 |

| δ1 | 14.5 | 12.7 |

| δ2 | 18.6 | 23.1 |

| σblade | 209 | 180 |

| σdisc | 326 | 331 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Mi, D.; Yan, C.; Tang, F. Multidisciplinary Design Optimization for a Centrifugal Compressor Based on Proper Orthogonal Decomposition and an Adaptive Sampling Method. Appl. Sci. 2018, 8, 2608. https://doi.org/10.3390/app8122608

Zhang L, Mi D, Yan C, Tang F. Multidisciplinary Design Optimization for a Centrifugal Compressor Based on Proper Orthogonal Decomposition and an Adaptive Sampling Method. Applied Sciences. 2018; 8(12):2608. https://doi.org/10.3390/app8122608

Chicago/Turabian StyleZhang, Lizhang, Dong Mi, Cheng Yan, and Fangming Tang. 2018. "Multidisciplinary Design Optimization for a Centrifugal Compressor Based on Proper Orthogonal Decomposition and an Adaptive Sampling Method" Applied Sciences 8, no. 12: 2608. https://doi.org/10.3390/app8122608

APA StyleZhang, L., Mi, D., Yan, C., & Tang, F. (2018). Multidisciplinary Design Optimization for a Centrifugal Compressor Based on Proper Orthogonal Decomposition and an Adaptive Sampling Method. Applied Sciences, 8(12), 2608. https://doi.org/10.3390/app8122608