Compaction Characteristics and Minimum Void Ratio Prediction Model for Gap-Graded Soil-Rock Mixture

Abstract

Featured Application

Abstract

1. Introduction

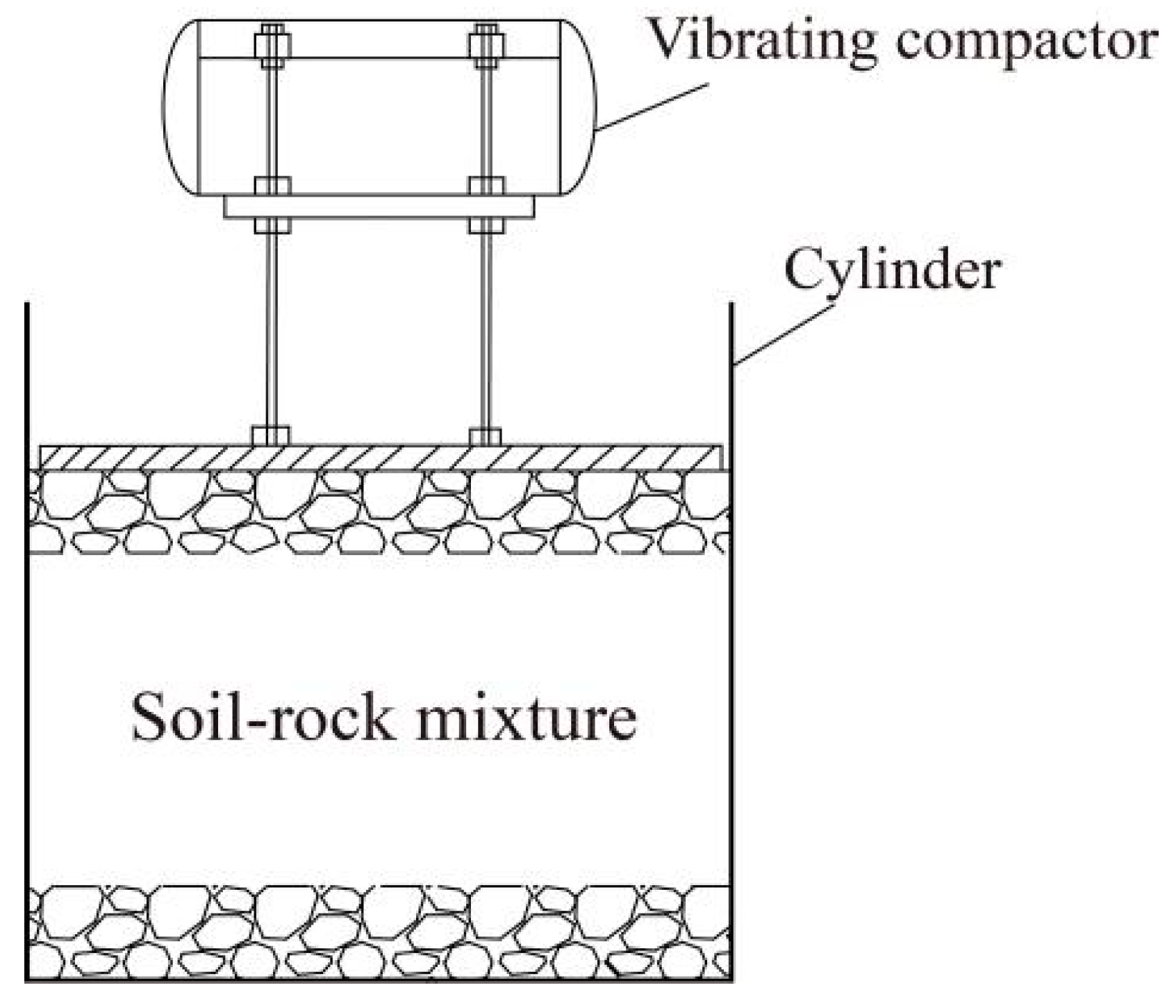

2. Vibrating Compaction Test

2.1. Test Programs

2.2. Results and Discussion

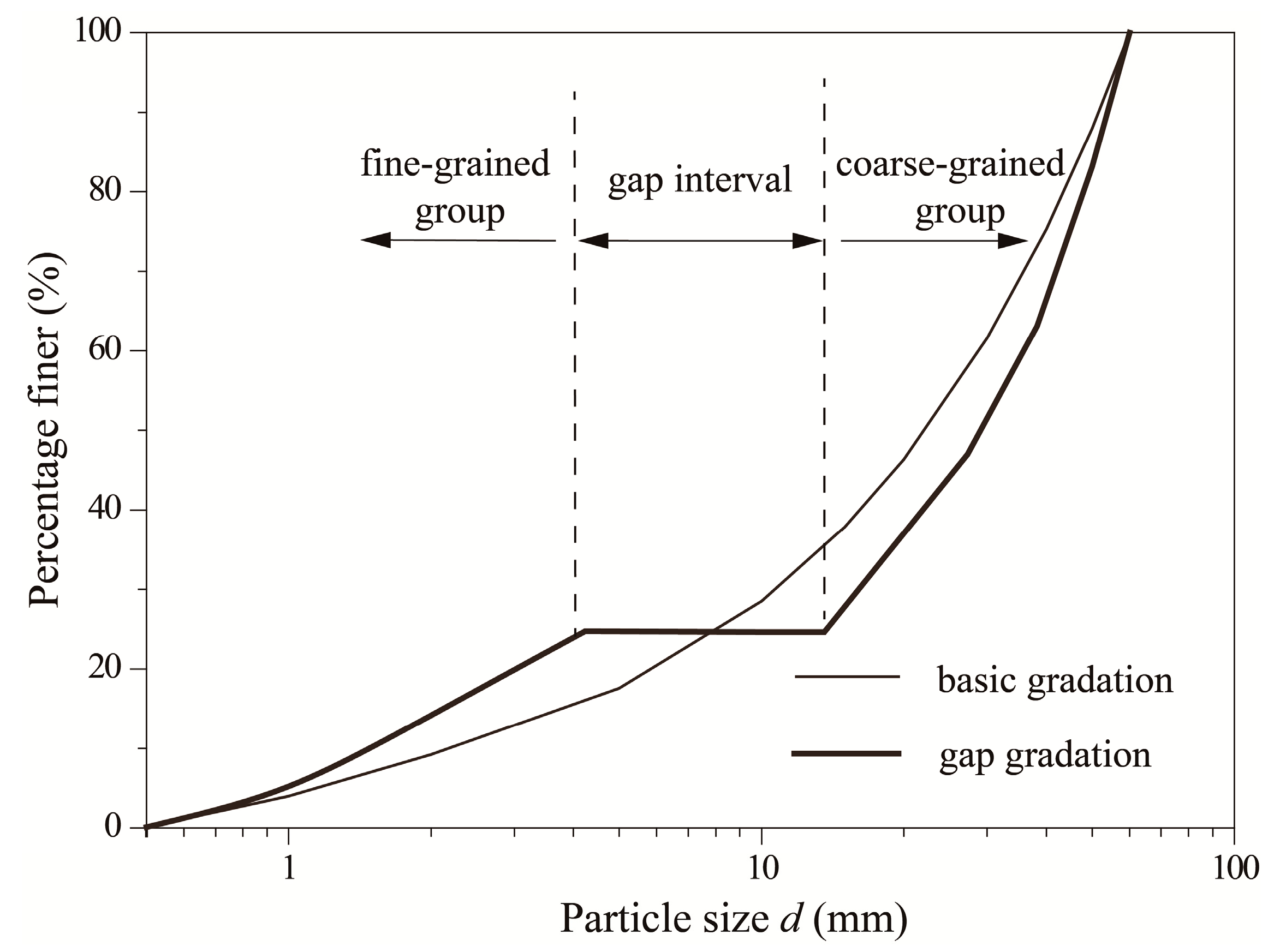

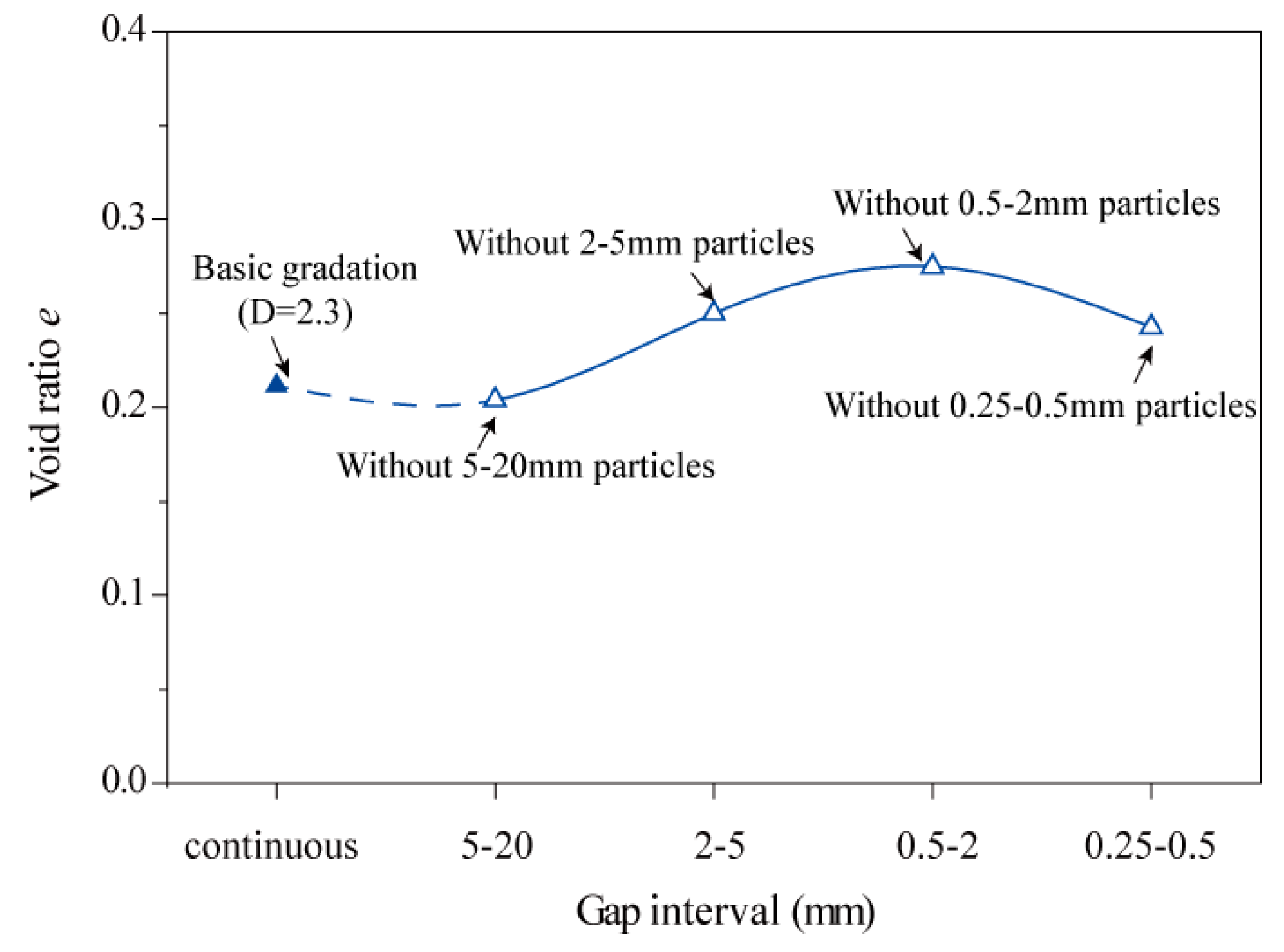

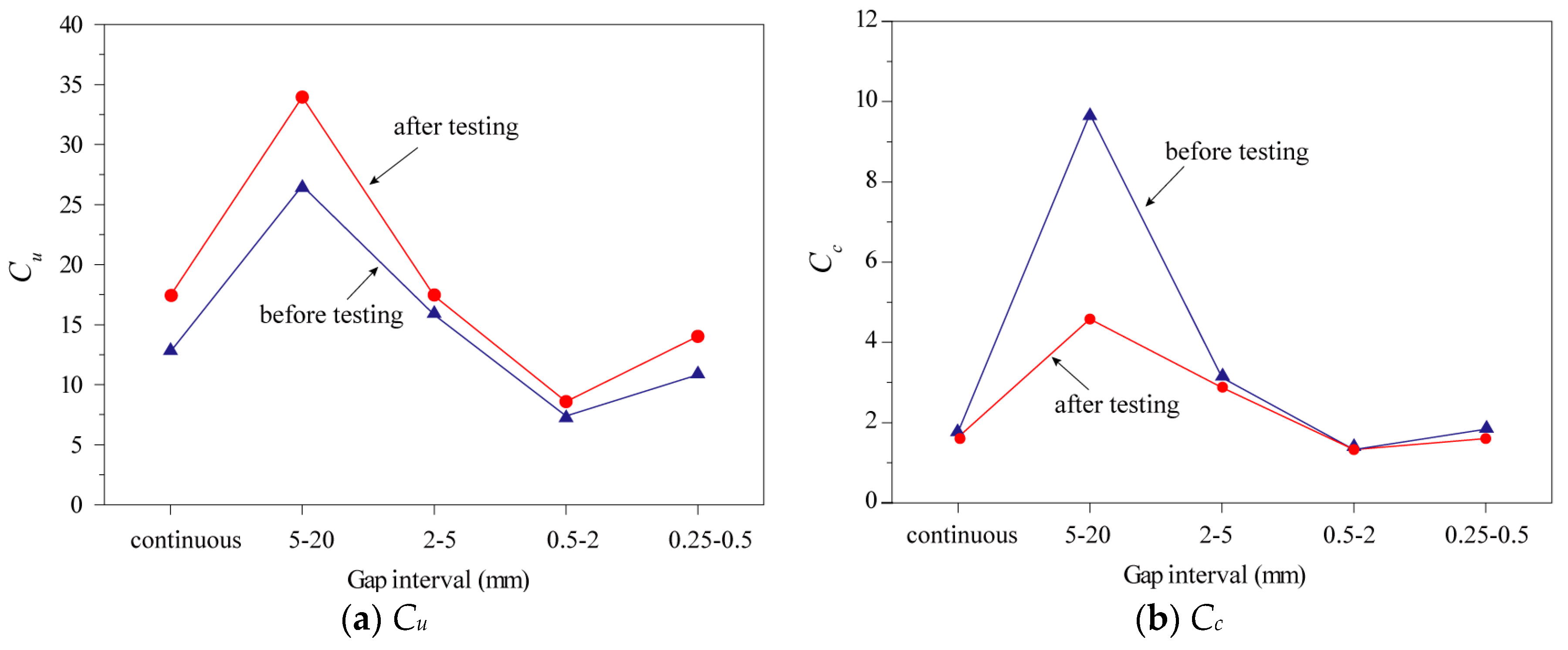

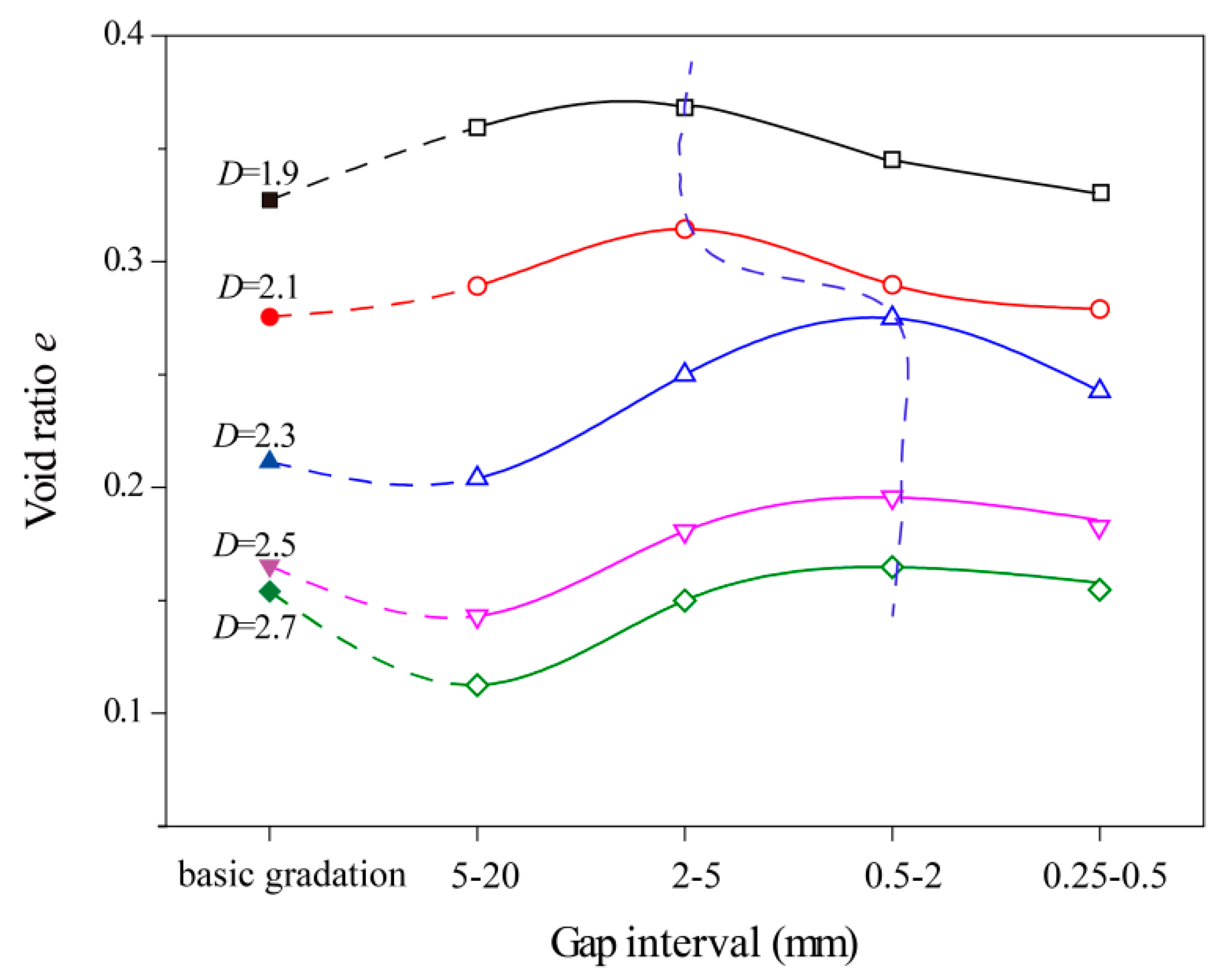

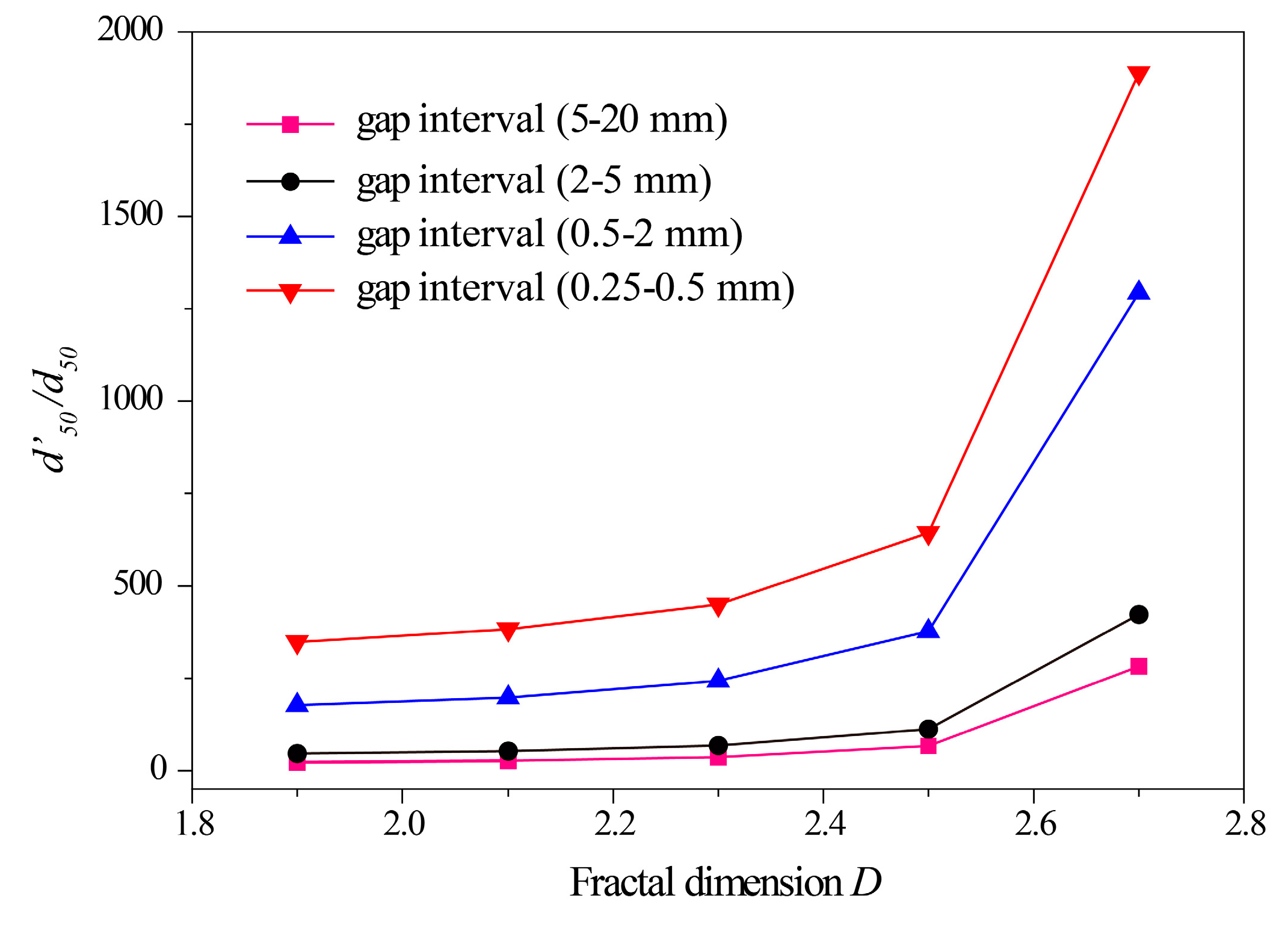

2.2.1. Influence of gap intervals

2.2.2. Influence of basic gradations

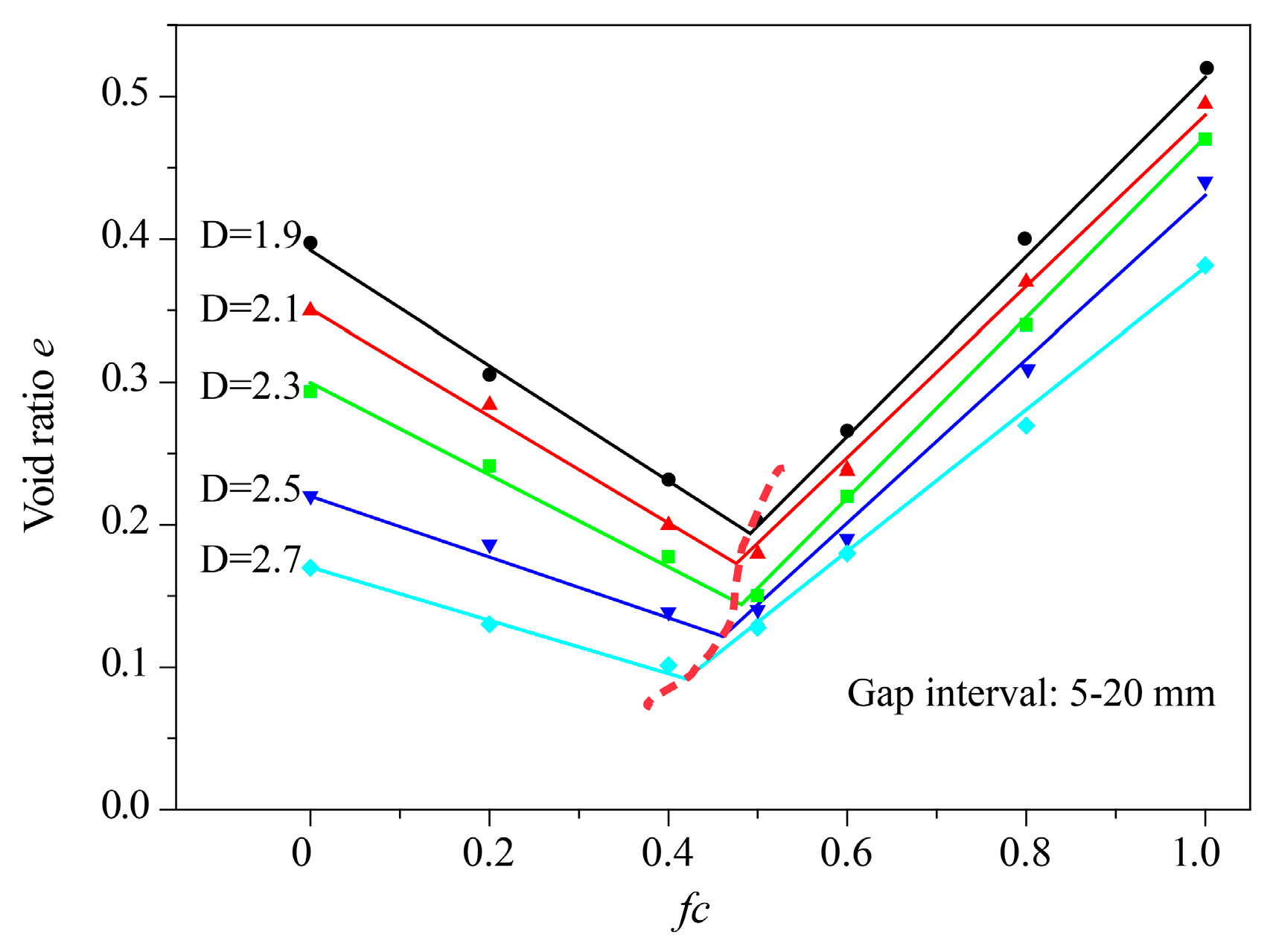

2.2.3. Influence of mass content in fine-grained group (fc)

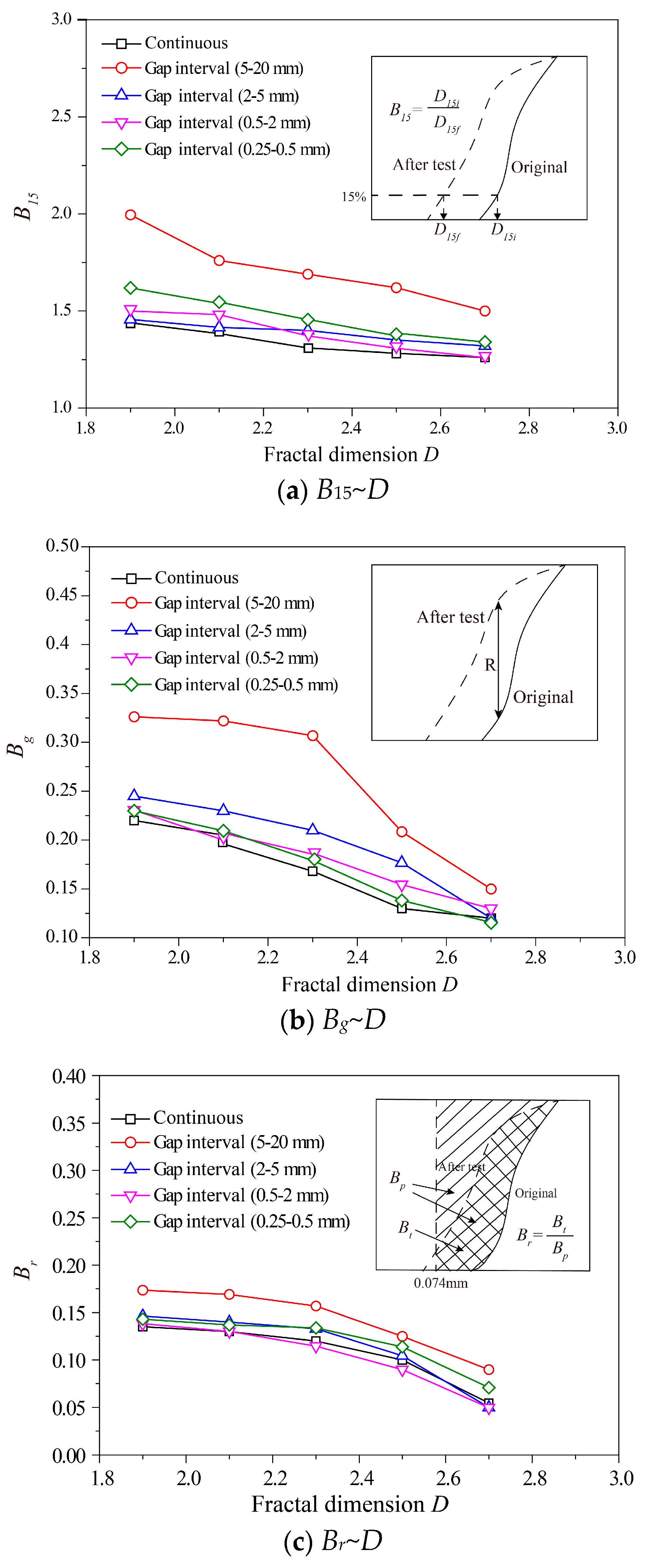

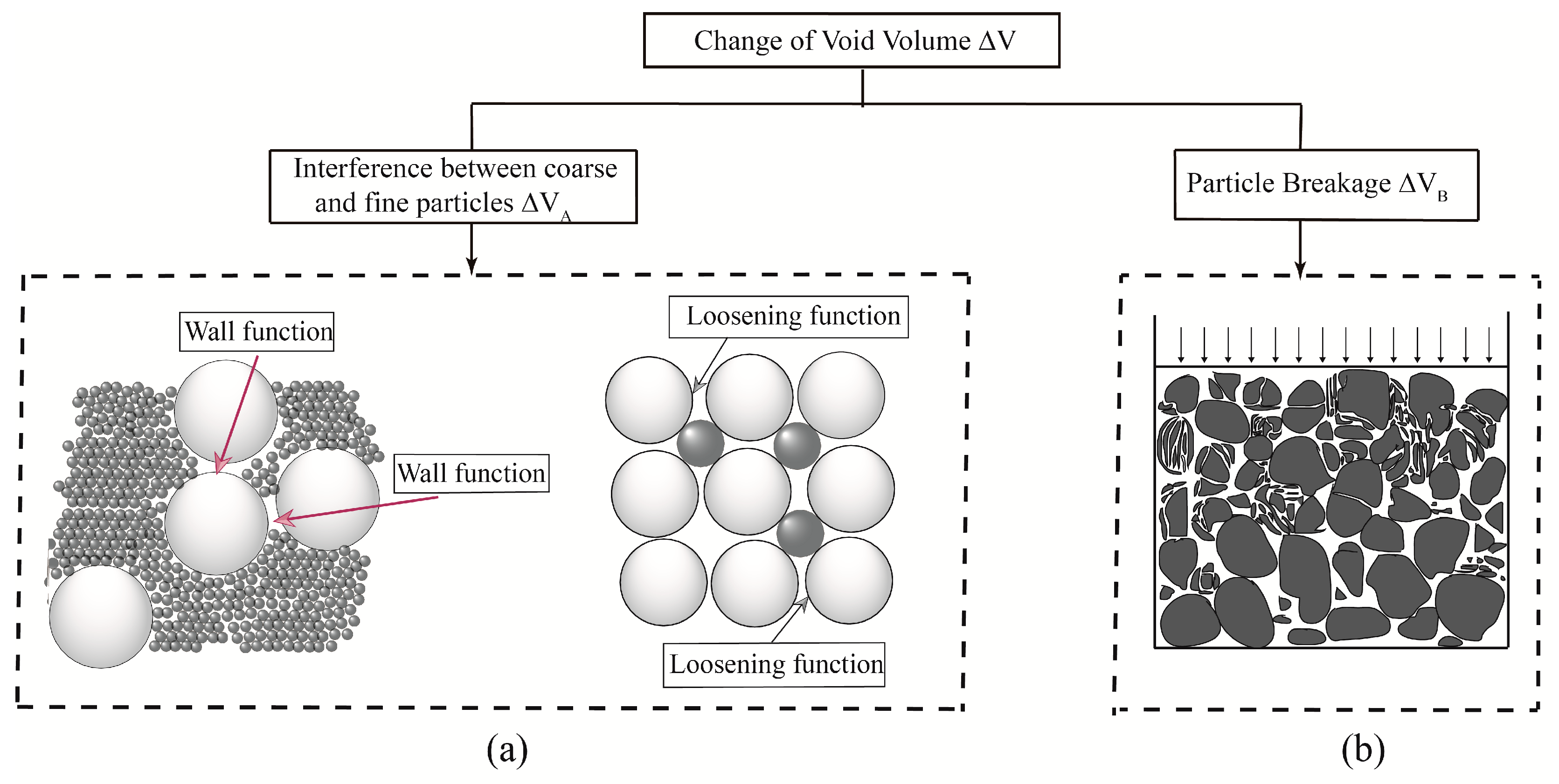

3. A New Model for Predicting Minimum Void Ratio of Gap-Graded SRMs Incorporating Particle Breakage

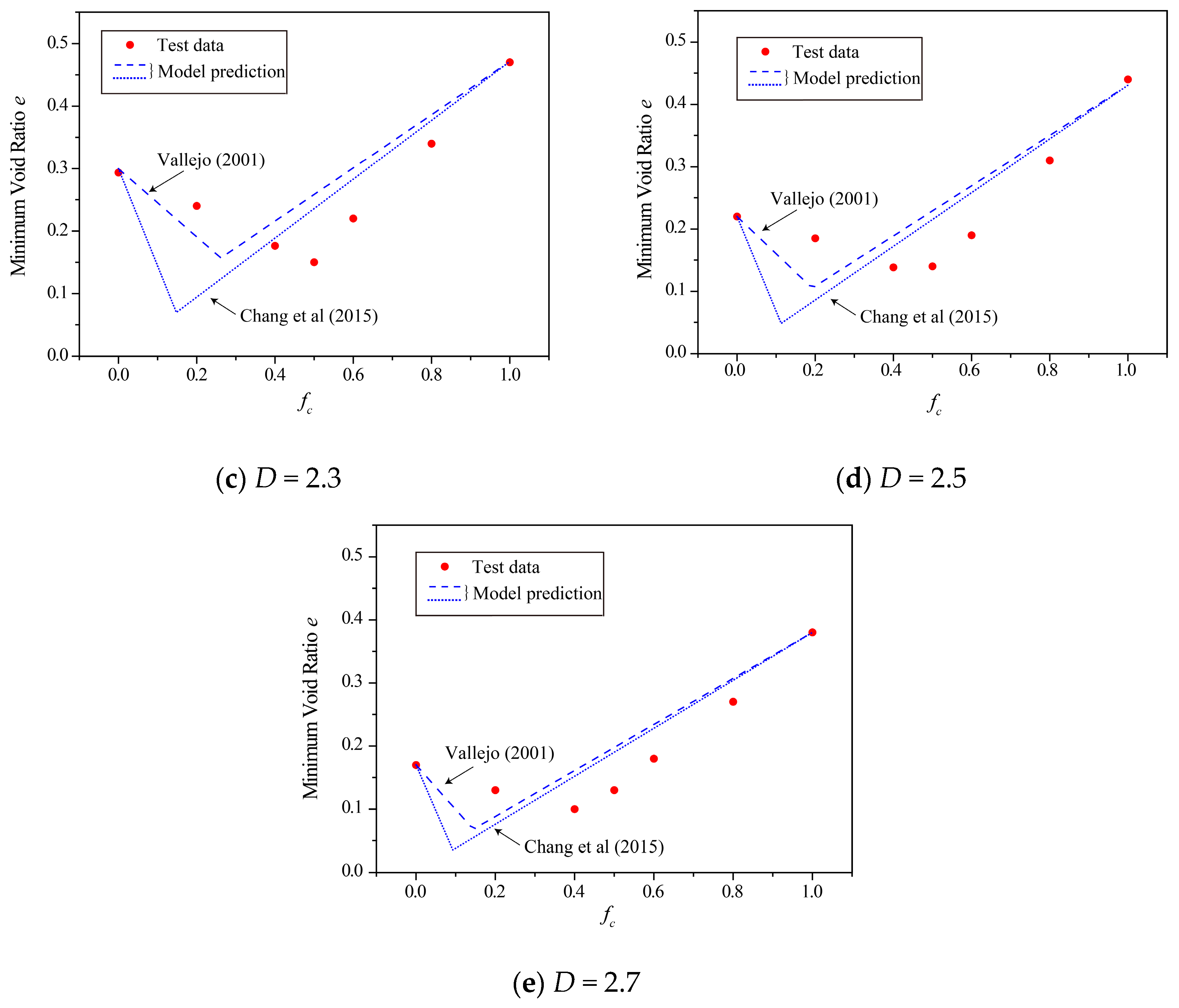

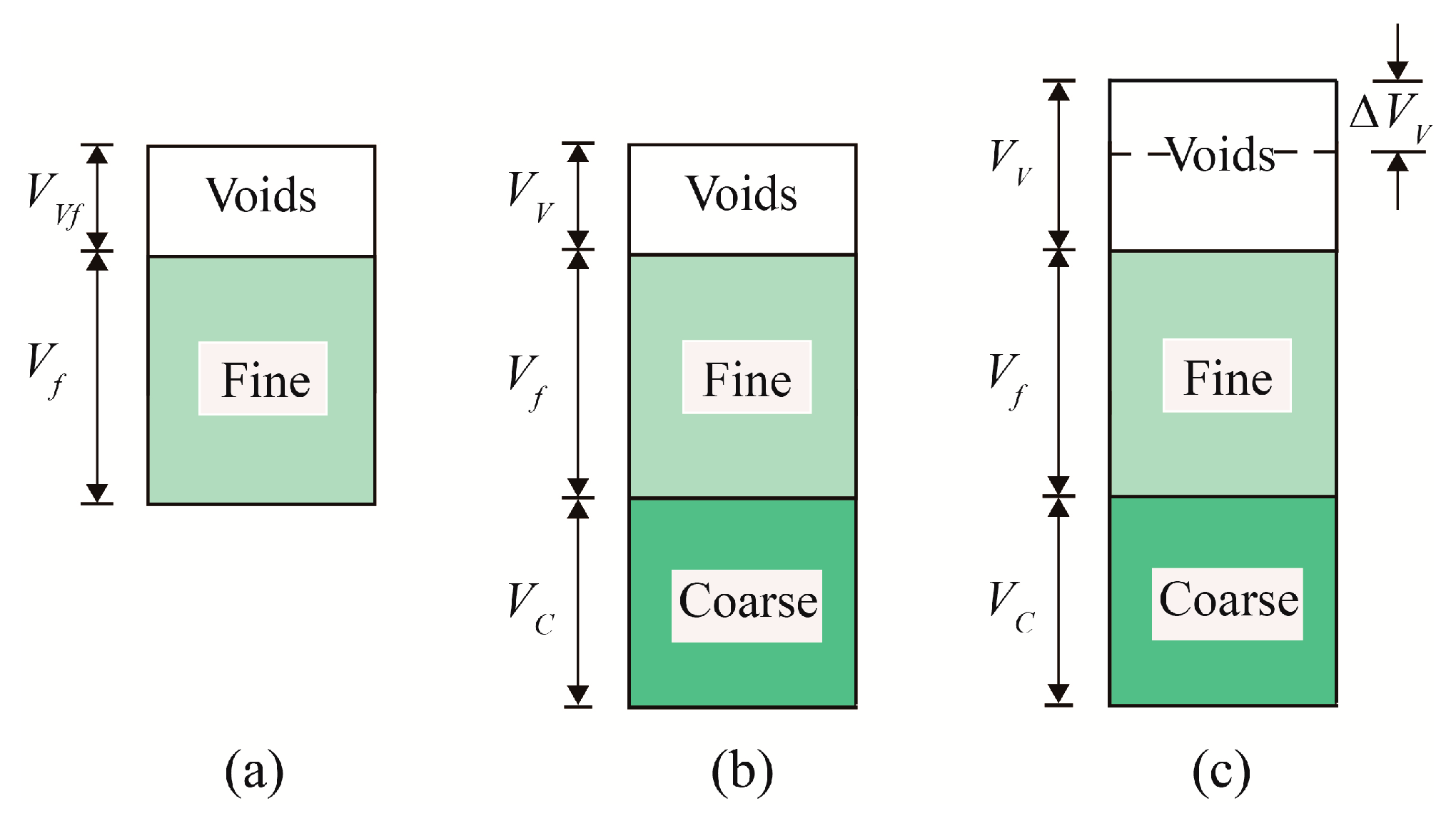

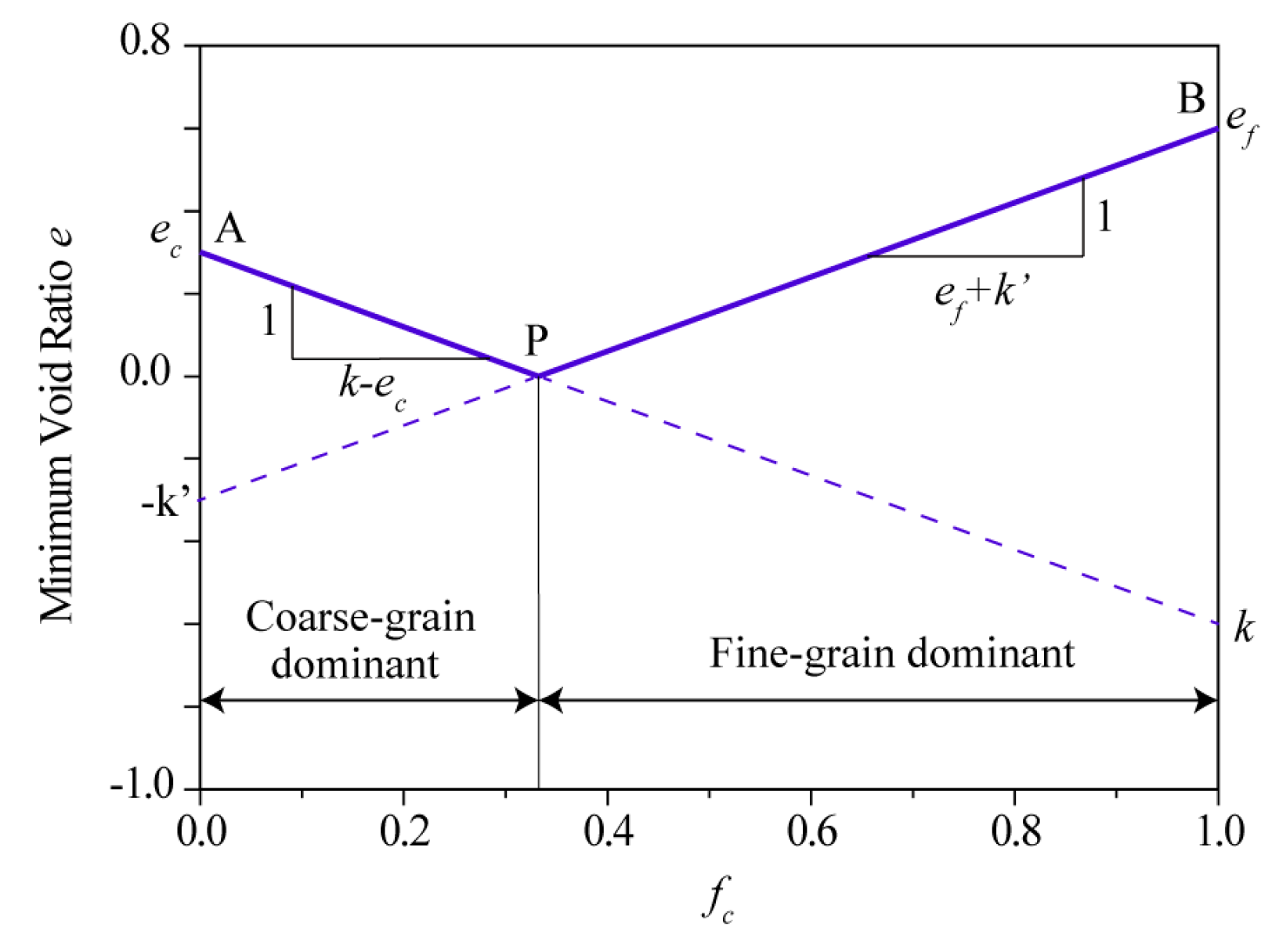

3.1. Existing Model

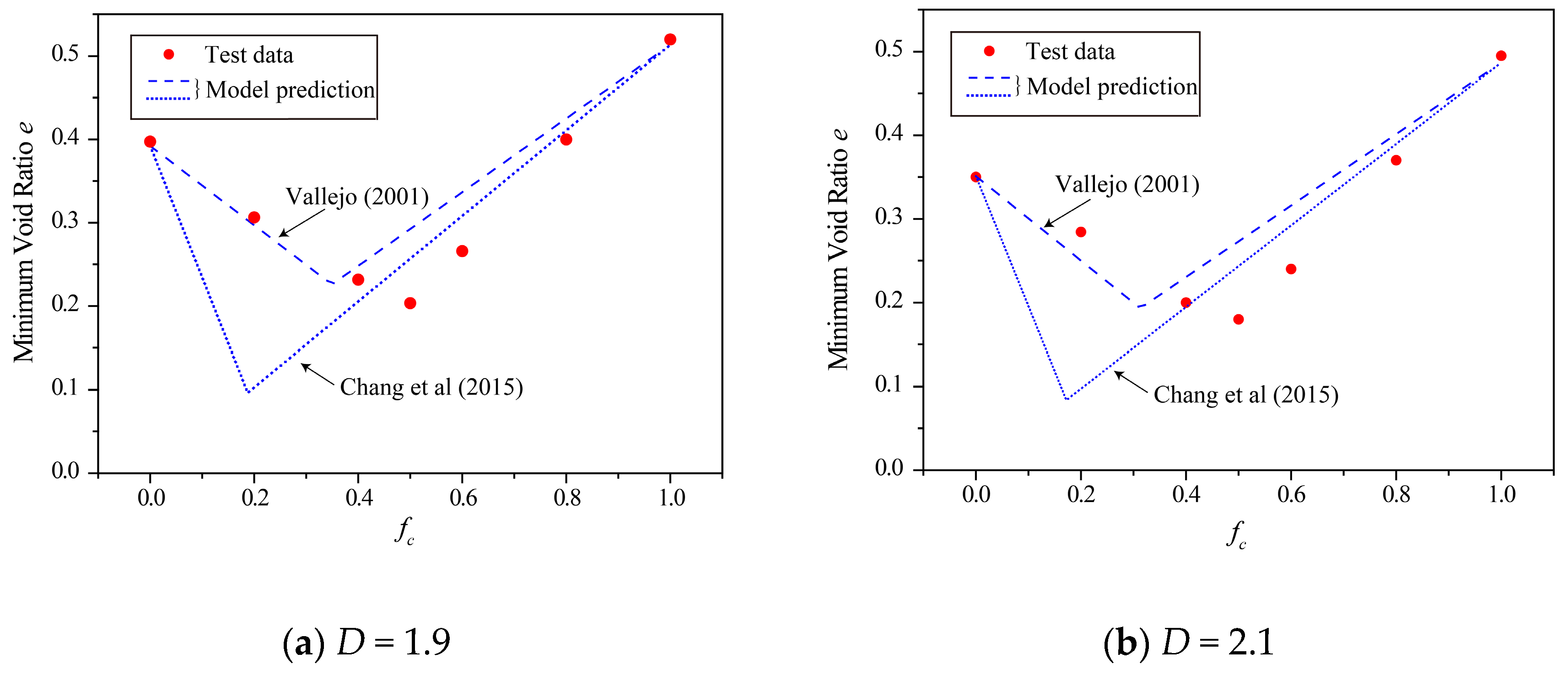

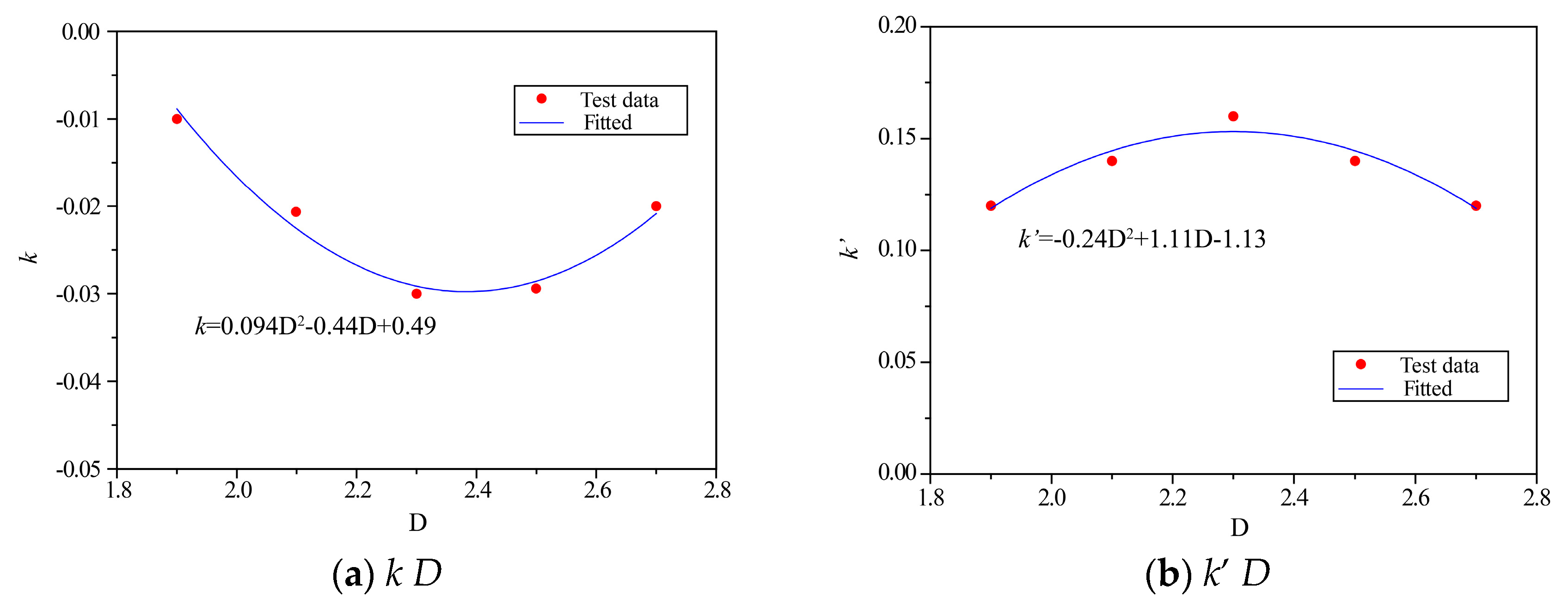

3.2. A Model for Predicting Minimum Void Ratio of Gap-Graded SRMs Incorporating Particle Breakage

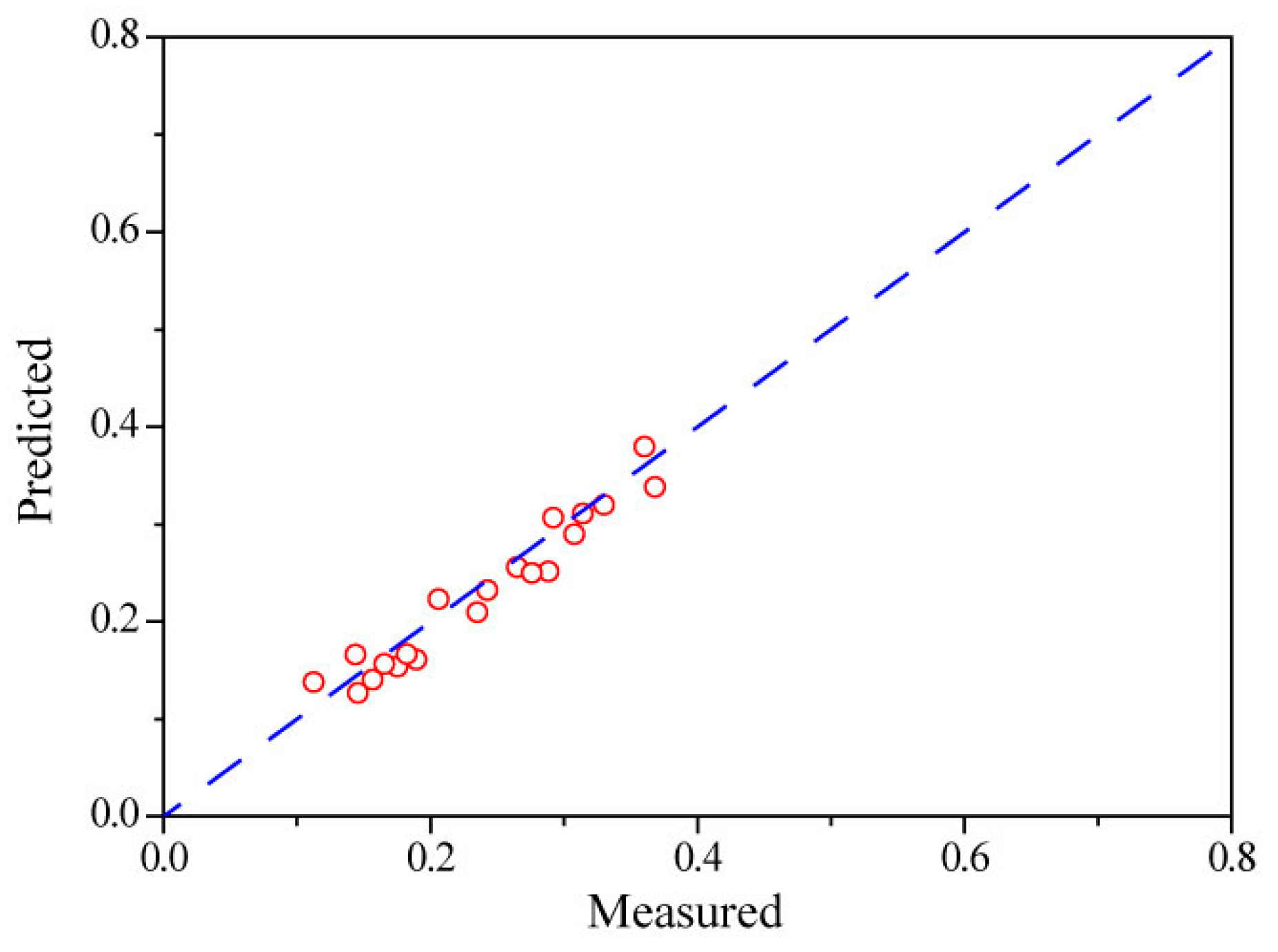

3.3. Validation of the Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Li, X.; Zheng, B.; Mao, T.Q.; Hu, R.L. Investigation of the effect of soil matrix on flow characteristics for soil and rock mixture. Géotech. Lett. 2016, 6, 226–233. [Google Scholar] [CrossRef]

- Xu, W.J.; Xu, Q.; Hu, R.L. Study on the shear strength of soil–rock mixture by coarse scale direct shear test. Int. J. Rock Mech. Min. Sci. 2011, 48, 1235–1247. [Google Scholar]

- Kumara, J.J.; Hayano, K.; Kikuchi, Y. Deformation behaviour of gap-graded fouled ballast evaluated by a 3D discrete element method. KSCE J. Civ. Eng. 2016, 20, 2345–2354. [Google Scholar] [CrossRef]

- Zhong, Q.M.; Chen, S.S.; Deng, Z. A simplified physically-based breach model for a high concrete-faced rockfill dam: A case study. Water Sci. Eng. 2018, 11, 46–52. [Google Scholar] [CrossRef]

- Li, L.K.; Wang, Z.J.; Liu, S.H.; Bauer, E. Calibration and performance of two different constitutive models for rockfill materials. Water Sci. Eng. 2016, 9, 227–239. [Google Scholar] [CrossRef]

- Khalili, A.; Wijewickreme, D.; Wilson, G.W. Mechanical response of highly gap-graded mixtures of waste rock and tailings. Part I: Monotonic shear response. Can. Geotech. J. 2010, 47, 552–565. [Google Scholar] [CrossRef]

- Vallejo, L.E. Interpretation of the limits in shear strength in binary granular mixture. Can. Geotech. J. 2001, 38, 1097–1104. [Google Scholar] [CrossRef]

- Fei, K. Experimental study of the mechanical behavior of clay–aggregate mixtures. Eng. Geol. 2016, 210, 1–9. [Google Scholar] [CrossRef]

- Ma, C.; Zhan, H.B.; Yao, W.M.; Li, H.Z. A new shear rheological model for a soft interlayer with varying water content. Water Sci. Eng. 2016, 11, 131–138. [Google Scholar] [CrossRef]

- Wan, C.F.; Fell, R. Assessing the Potential of Internal Instability and Suffusion in Embankment Dams and Their Foundations. J. Geotech. Geoenviron. Eng. 2008, 134, 401–407. [Google Scholar] [CrossRef]

- Langroudi, M.F.; Soroush, A.; Shourijeh, P.T.; Shafipour, R. Stress transmission in internally unstable gap-graded soils using discrete element modeling. Powder Technol. 2013, 247, 161–171. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Baudet, B.A. Particle breakage in gap-graded soil. Géotech. Lett. 2013, 3, 72–77. [Google Scholar] [CrossRef]

- Le, M.V.T.; Marot, D.; Rochim, A.; Bendahmane, F.; Nguyen, H.H. Suffusion susceptibility investigation by energy based method and stat. Can. Geotech. J. 2018, 55, 57–68. [Google Scholar] [CrossRef]

- Chen, S.K.; He, Q.D.; Cao, J.G. Seepage simulation of high concrete-faced rockfill dams based on generalized equivalent continuum model. Water Sci. Eng. 2018, 11, 250–257. [Google Scholar] [CrossRef]

- Slangen, P.; Fannin, R.J. The role of particle type on suffusion and suffosion. Géotech. Lett. 2017, 7, 1–5. [Google Scholar] [CrossRef]

- Wang, S.; Chen, J.S.; He, H.Q.; He, W.Z. Experimental study on piping in sandy gravel foundations considering effect of overlying clay. Water Sci. Eng. 2016, 9, 165–171. [Google Scholar] [CrossRef]

- Shen, C.M.; Liu, S.H.; Wang, Y.S. Microscopic interpretation of one-dimensional compressibility of granular materials. Comput. Geotech. 2017, 91, 161–168. [Google Scholar] [CrossRef]

- Alam, M.F.; Haque, A.; Ranjith, P.G. A Study of the Particle-Level Fabric and Morphology of Granular Soils under One-Dimensional Compression Using Insitu X-ray CT Imaging. Materials 2018, 11, 919. [Google Scholar] [CrossRef] [PubMed]

- Sandeep, C.S.; Senetakis, K. Effect of Young’s Modulus and Surface Roughness on the Inter-Particle Friction of Granular Materials. Materials 2018, 11, 217. [Google Scholar] [CrossRef]

- Chang, C.S.; Meidani, M.; Deng, Y. A compression model for sand-silt mixtures based on the concept of active and inactive voids. Acta Geotech. 2017, 12, 1301–1317. [Google Scholar] [CrossRef]

- Fragaszy, R.J.; Su, J.; Siddiqi, F.H. Modeling Strength of Sandy Gravel. J. Geotech. Eng. 1992, 118, 920–935. [Google Scholar] [CrossRef]

- Zhou, Z.; Fu, H.L.; Liu, B.C. Orthogonal tests on permeability of soil-rock-mixture. Chin. J. Geotech. Eng. 2006, 28, 1134–1138. [Google Scholar]

- Chang, C.S.; Wang, J.Y.; Ge, L. Modeling of minimum void ratio for sand–silt mixtures. Eng. Geol. 2015, 196, 293–304. [Google Scholar] [CrossRef]

- Jiang, Q.; Cui, J.; Chen, J. Time-Dependent Damage Investigation of Rock Mass in an In Situ Experimental Tunnel. Materials 2012, 5, 1389–1403. [Google Scholar] [CrossRef]

- Tyler, S.W. Fractal scaling of soil particle size distributions: Analysis and limitations. Soil Sci. Soc. Am. J. 1992, 56, 362–369. [Google Scholar] [CrossRef]

- Mcgeary, R.K. Mechanical Packing of Spherical Particles. J. Am. Ceram. Soc. 1961, 44, 513–522. [Google Scholar] [CrossRef]

- Lee, K.L.; Farhoomand, I. Compressibility and crushing of granular soil in anisotropic triaxial. Can. Geotech. J. 1967, 4, 68–86. [Google Scholar] [CrossRef]

- Marsal, R.J. Coarse-scale testing of rockfills materials. J. Soil Mech. Found. Eng. ASCE 1967, 93, 27–44. [Google Scholar]

- Hardin, B.O. Crushing of Soil Particles. J. Geotech. Eng. 1985, 111, 1177–1192. [Google Scholar] [CrossRef]

- De Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; Taylor & Francis: London, UK, 1999. [Google Scholar]

| Fractal dimension D of basic gradation | 1.9, 2.1, 2.3, 2.5, 2.7 |

| Gap interval (mm) | 5–20, 2–5, 0.5–2, 0.25–0.5 |

| fc for the gap interval of 5–20 mm | 0, 0.2, 0.4, 0.5, 0.6, 0.8, 1.0 |

| Gap Interval | ec | ef | k | k’ |

|---|---|---|---|---|

| 2–5 mm | 0.433 | 0.442 | k = 0.094D2 − 0.44D + 0.49 | k’ = −0.24D2 + 1.11D − 1.13 |

| 0.5–2 mm | 0.413 | 0.467 | ||

| 0.25–0.5 mm | 0.403 | 0.472 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Liu, S.; Feng, Y.; Yu, J. Compaction Characteristics and Minimum Void Ratio Prediction Model for Gap-Graded Soil-Rock Mixture. Appl. Sci. 2018, 8, 2584. https://doi.org/10.3390/app8122584

Wang T, Liu S, Feng Y, Yu J. Compaction Characteristics and Minimum Void Ratio Prediction Model for Gap-Graded Soil-Rock Mixture. Applied Sciences. 2018; 8(12):2584. https://doi.org/10.3390/app8122584

Chicago/Turabian StyleWang, Tao, Sihong Liu, Yan Feng, and Jidu Yu. 2018. "Compaction Characteristics and Minimum Void Ratio Prediction Model for Gap-Graded Soil-Rock Mixture" Applied Sciences 8, no. 12: 2584. https://doi.org/10.3390/app8122584

APA StyleWang, T., Liu, S., Feng, Y., & Yu, J. (2018). Compaction Characteristics and Minimum Void Ratio Prediction Model for Gap-Graded Soil-Rock Mixture. Applied Sciences, 8(12), 2584. https://doi.org/10.3390/app8122584