Experimental Study on the Static Behavior of Reinforced Warren Circular Hollow Section (CHS) Tubular Trusses

Abstract

1. Introduction

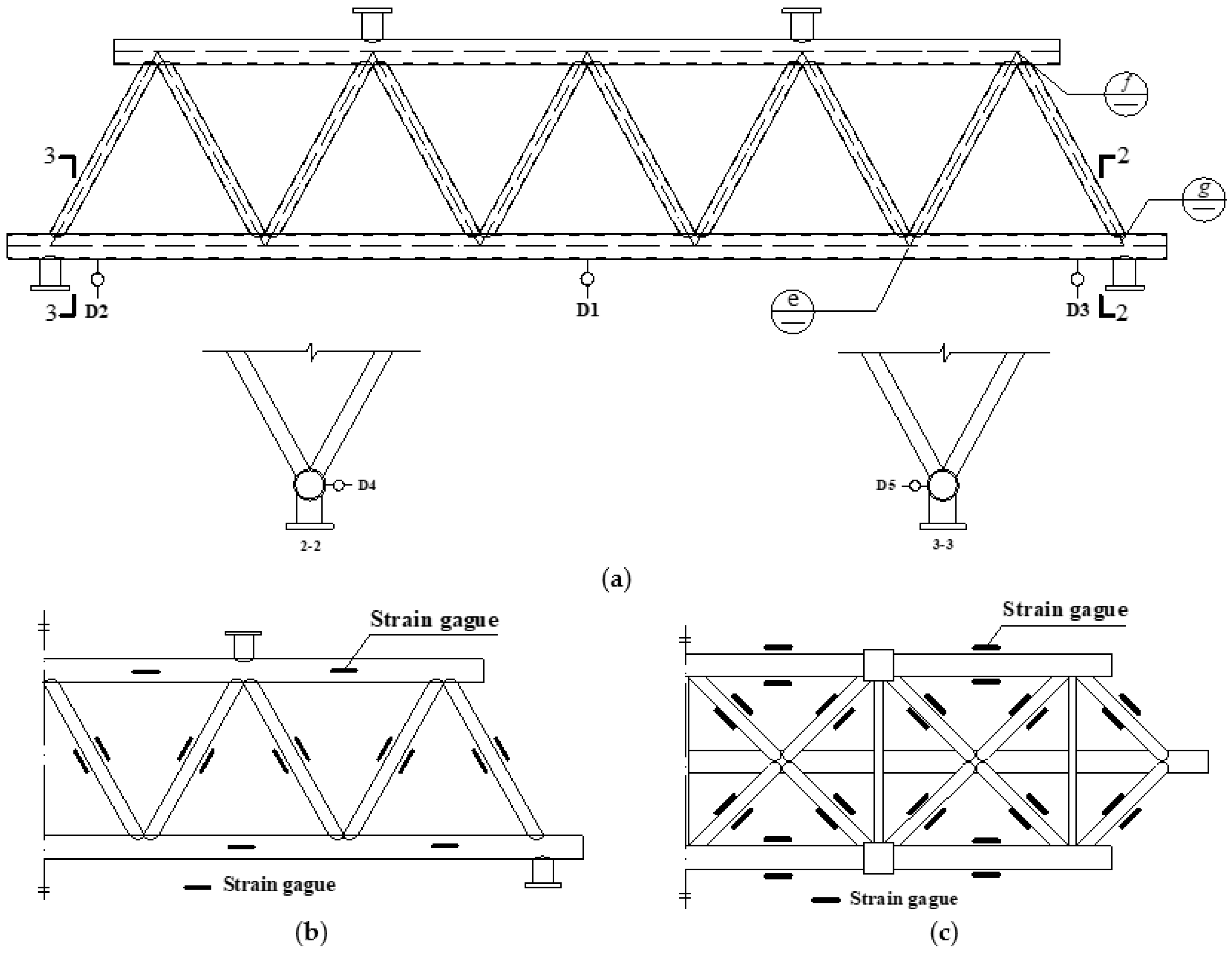

2. Experimental Study

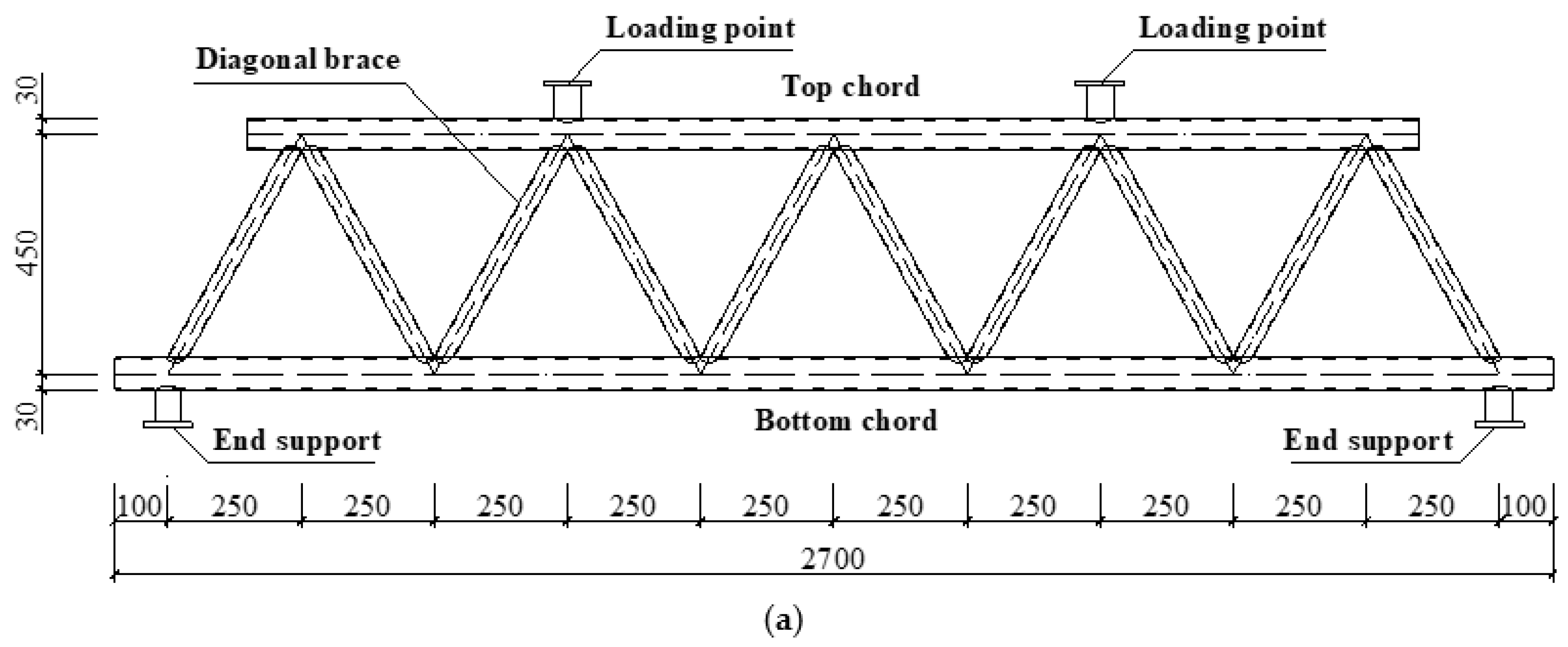

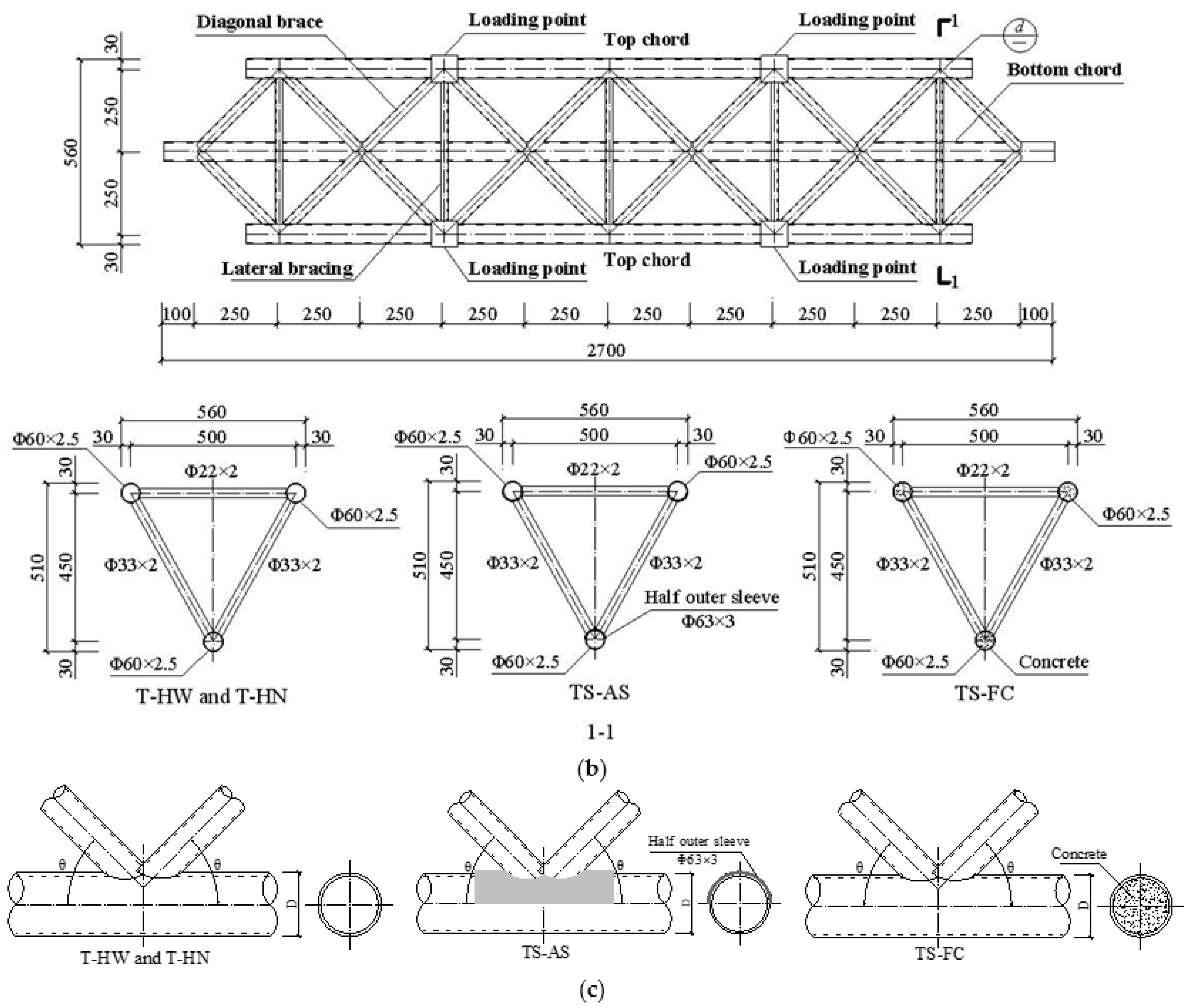

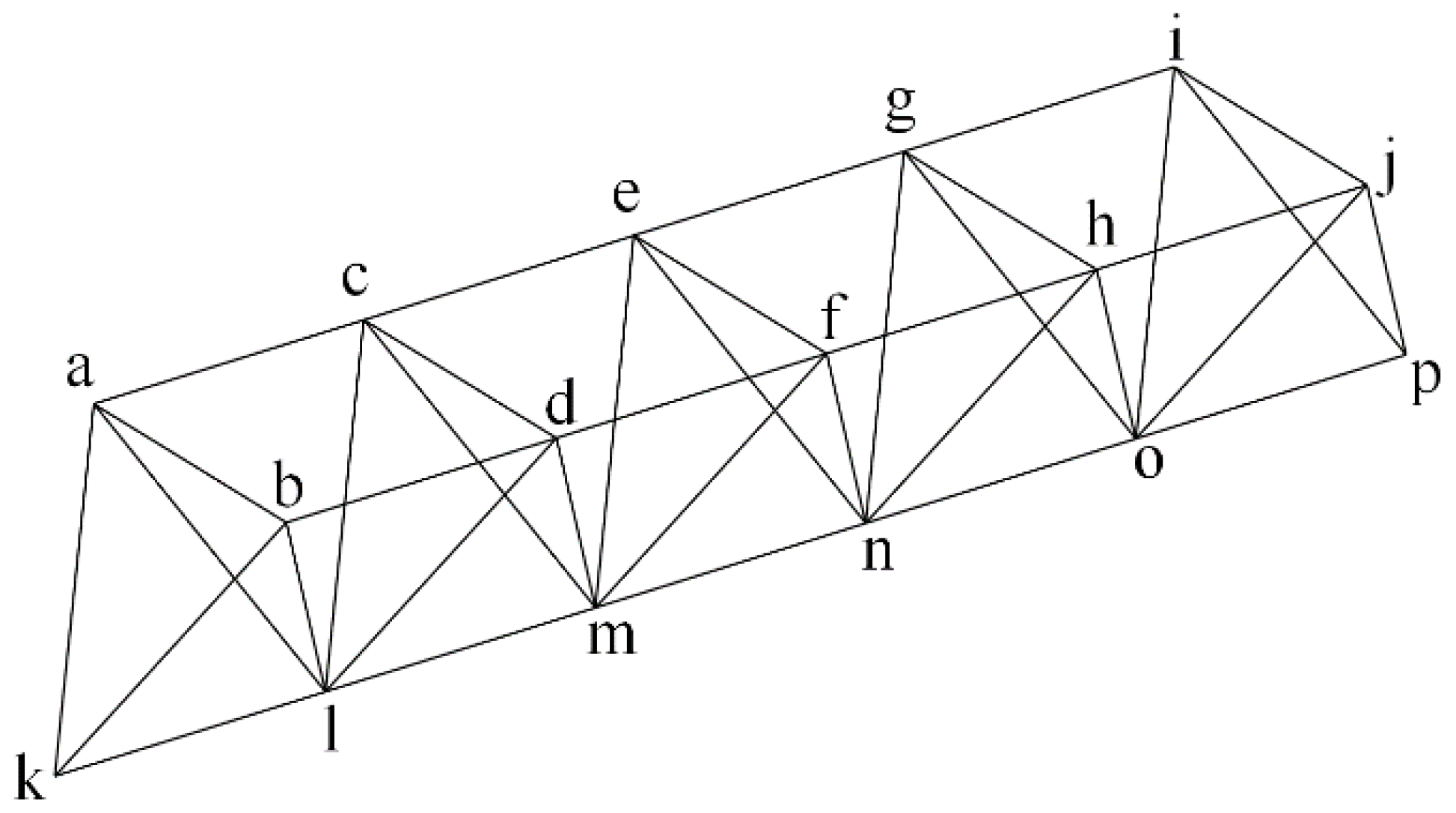

2.1. Test Specimens

2.2. Material Properties

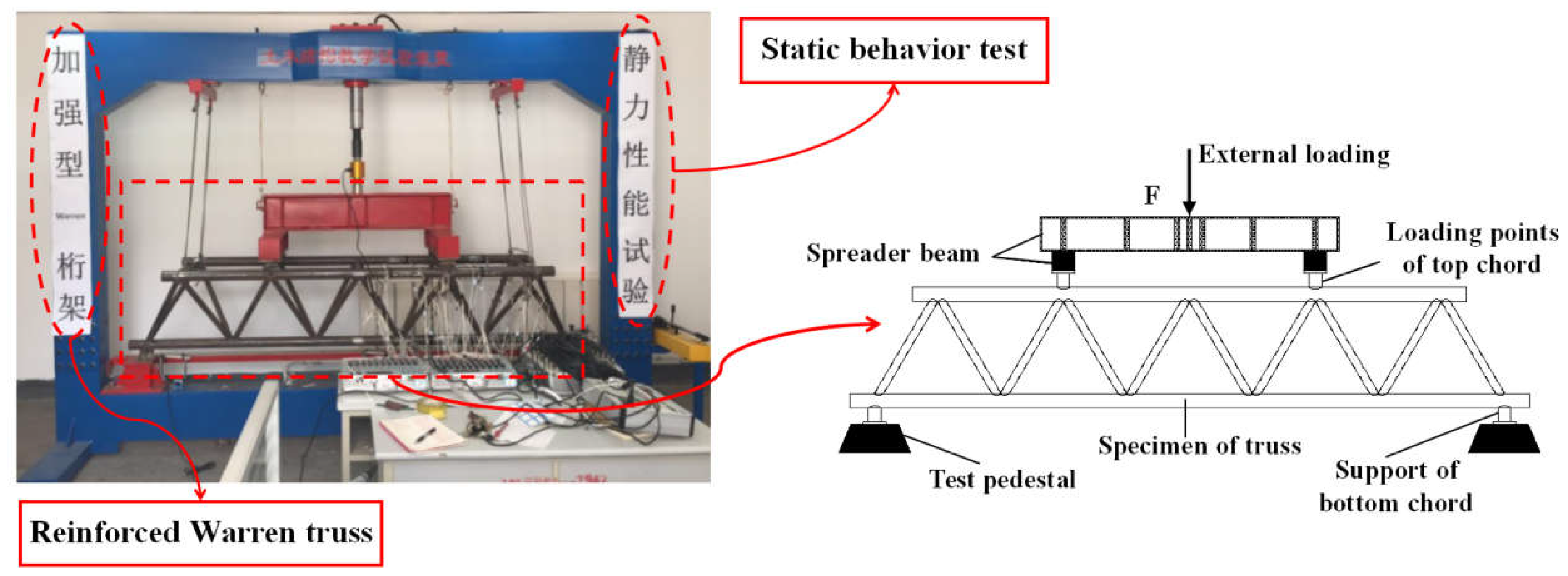

2.3. Test Program

3. Test Results

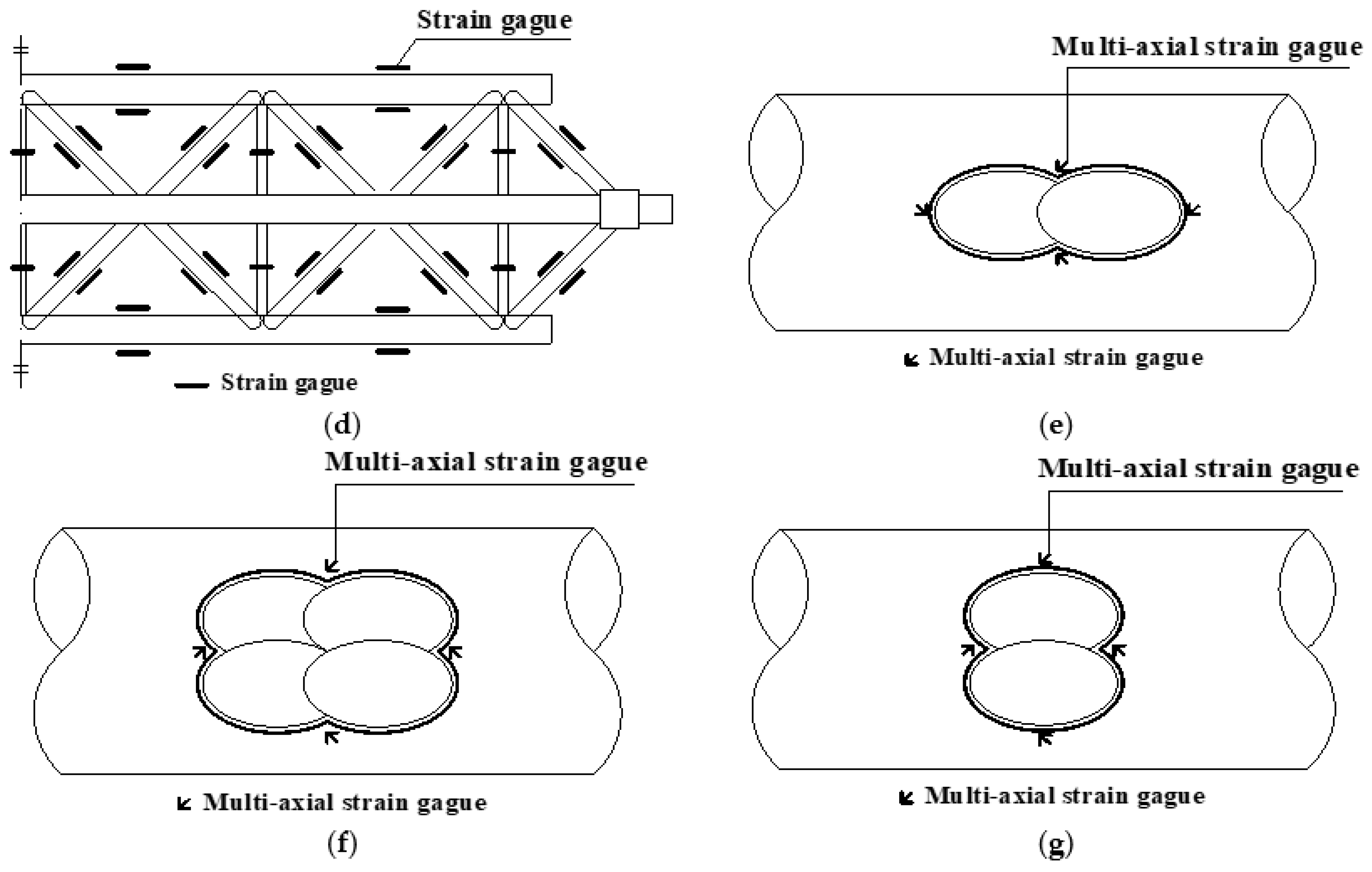

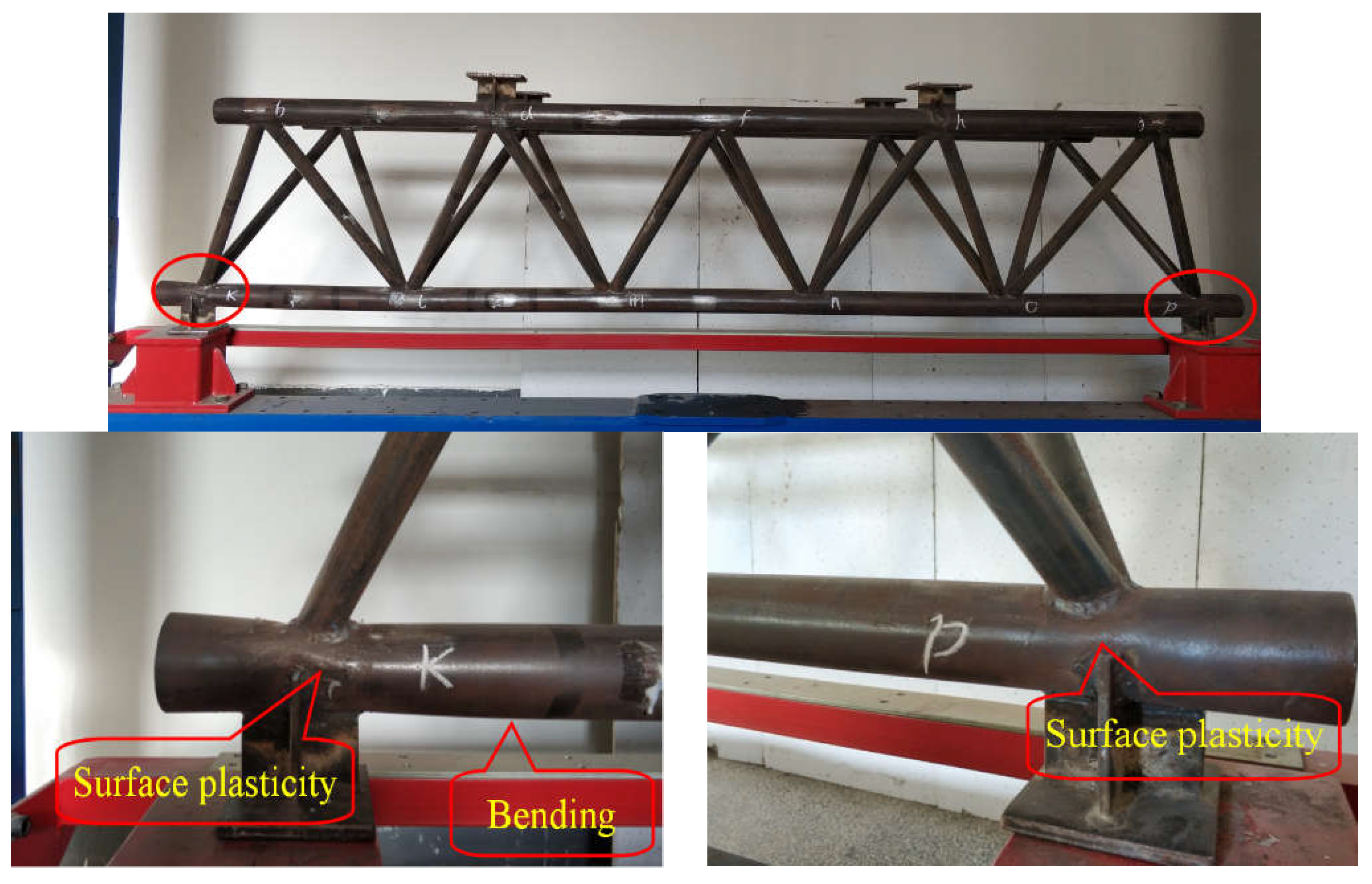

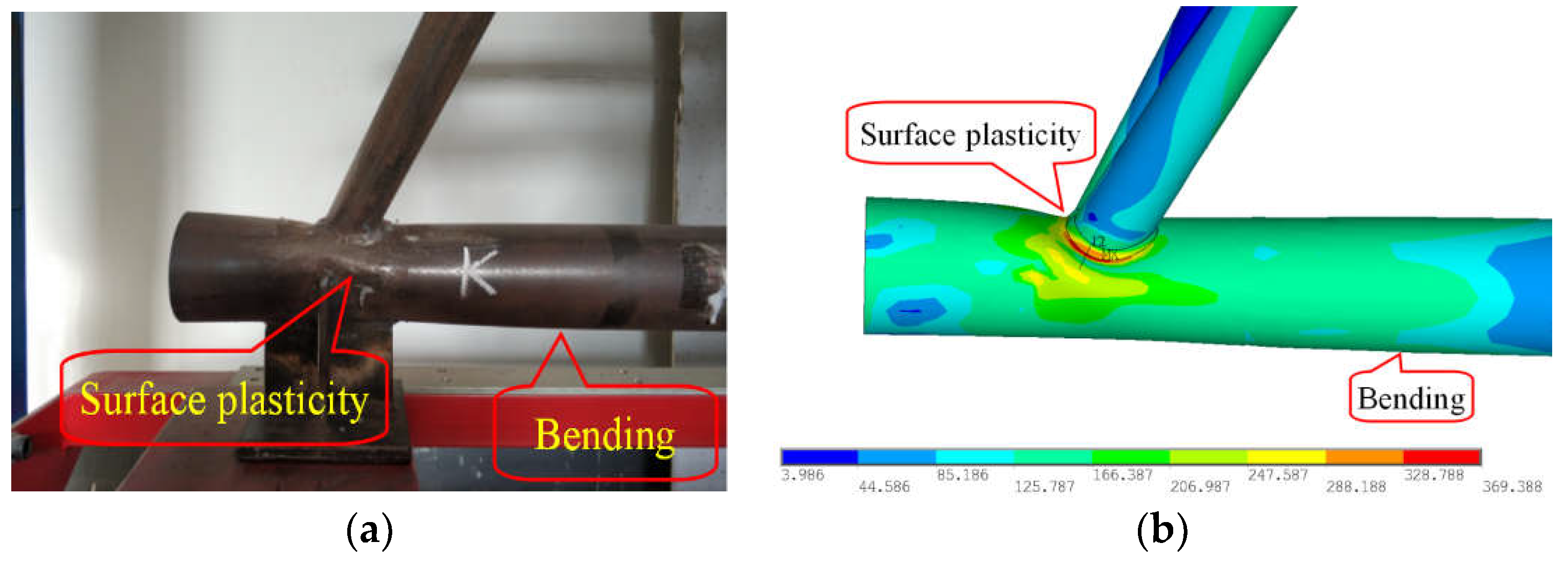

3.1. Failure Mode

3.2. Load Carrying Capacity

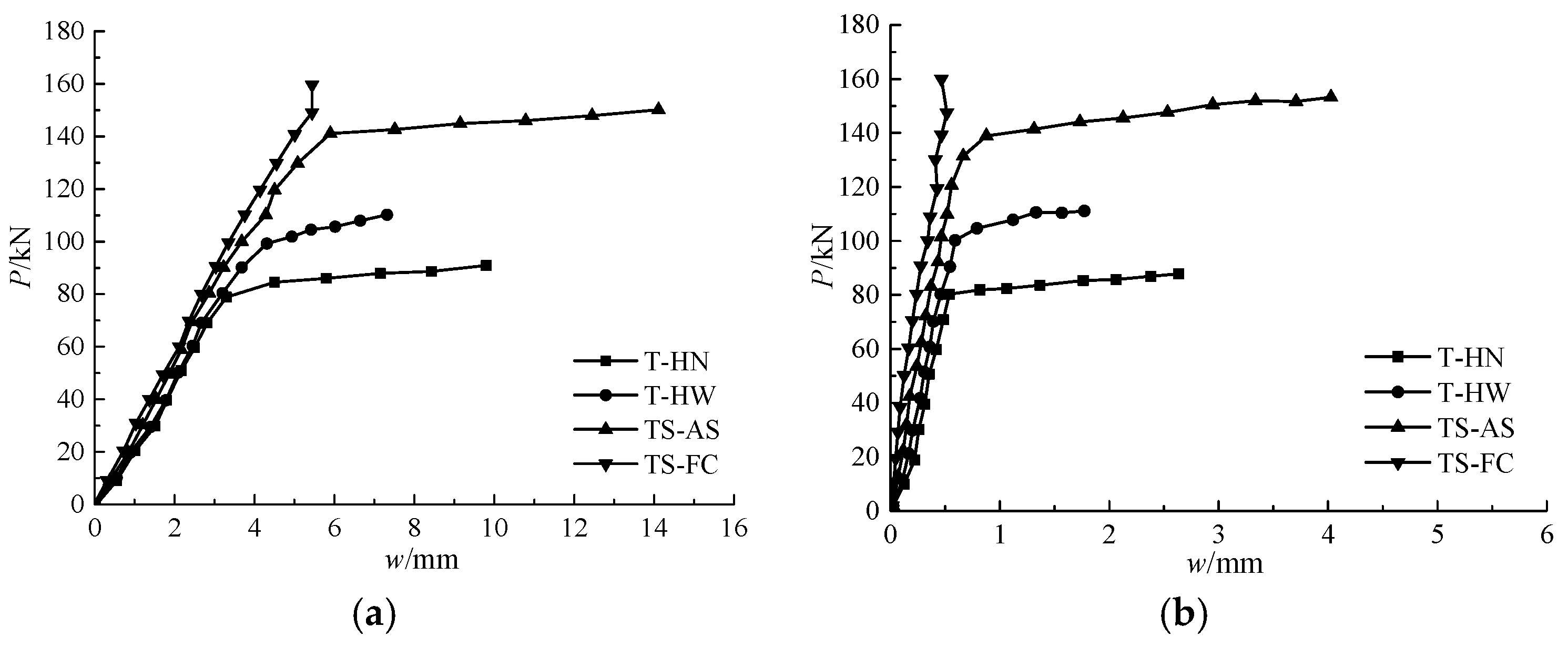

3.3. Overall Deflection

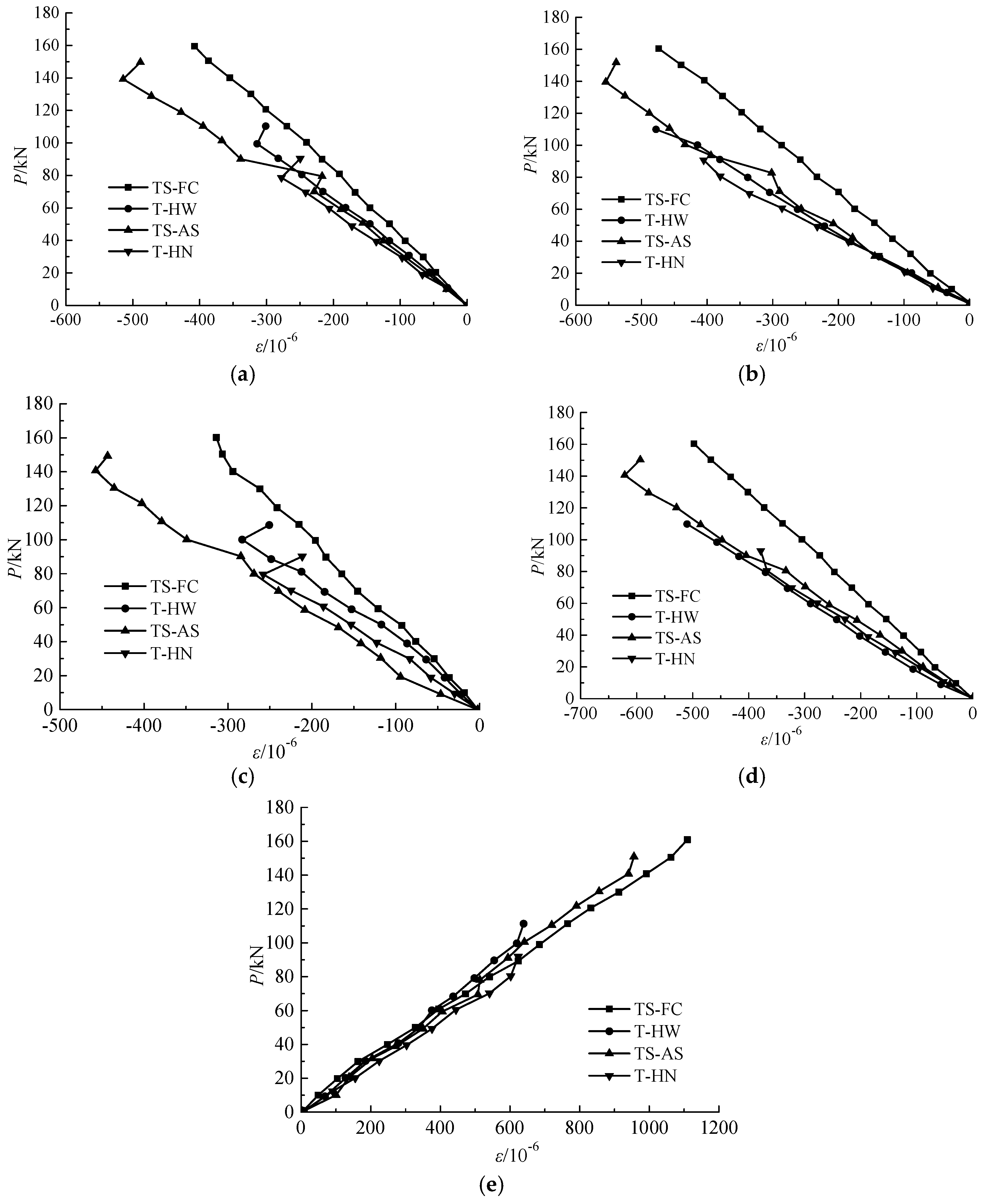

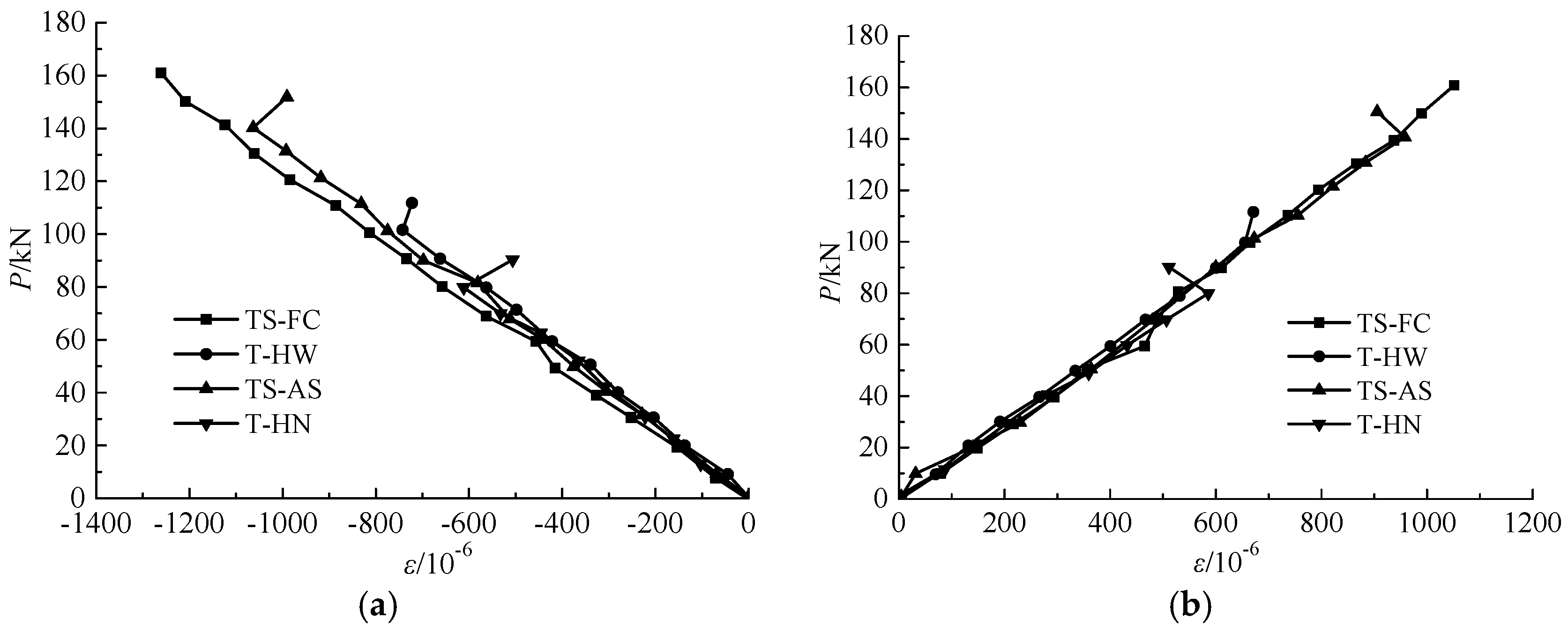

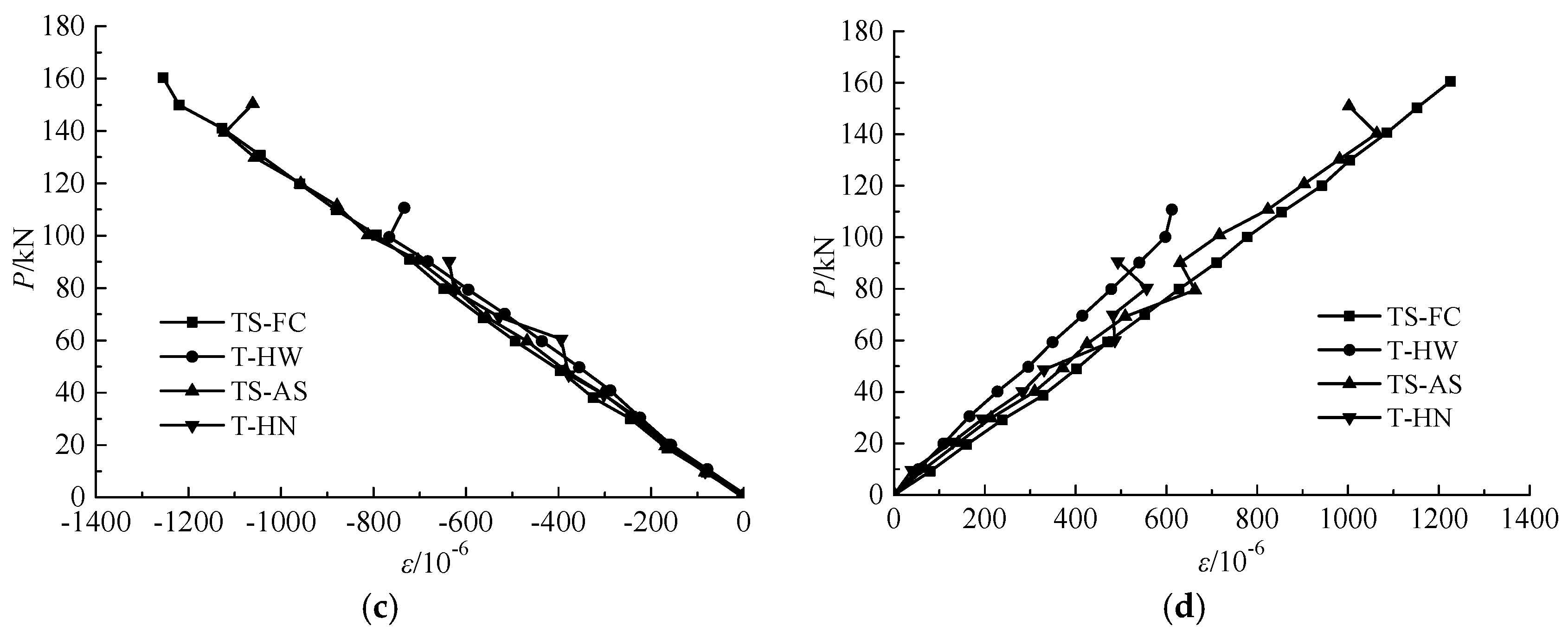

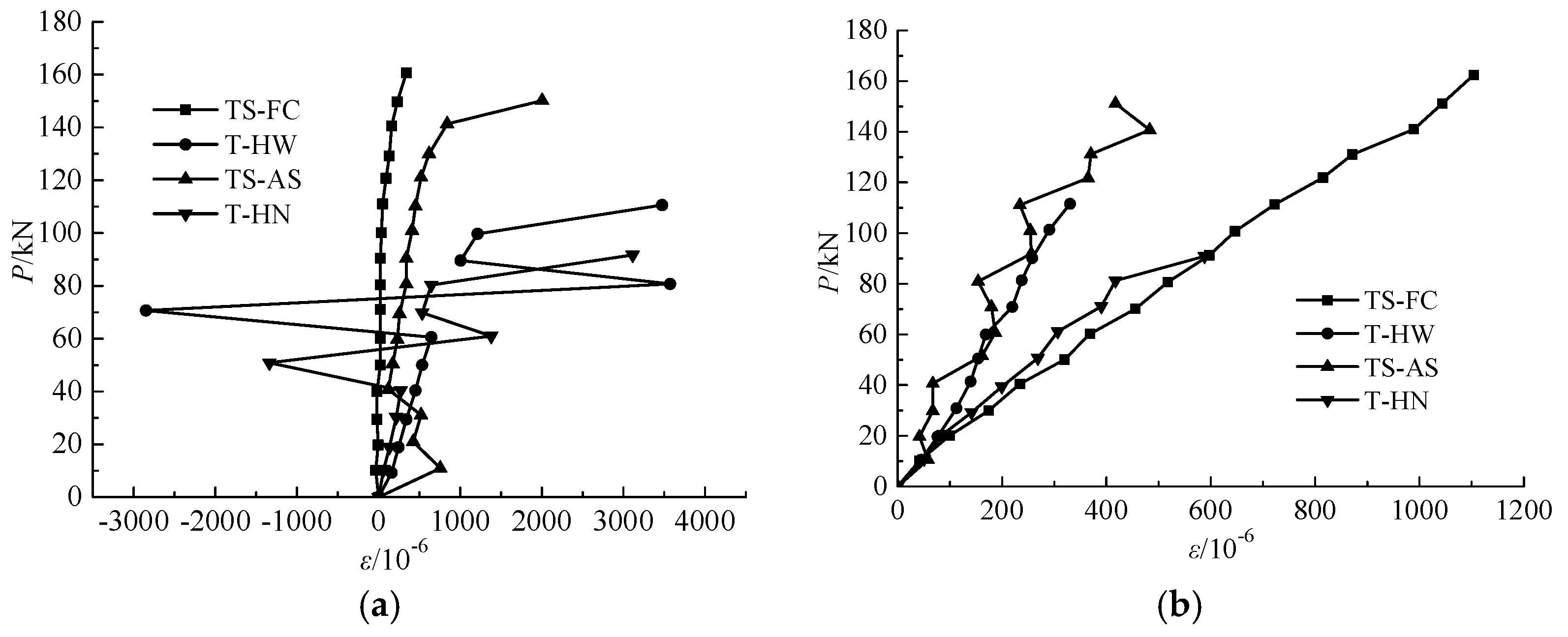

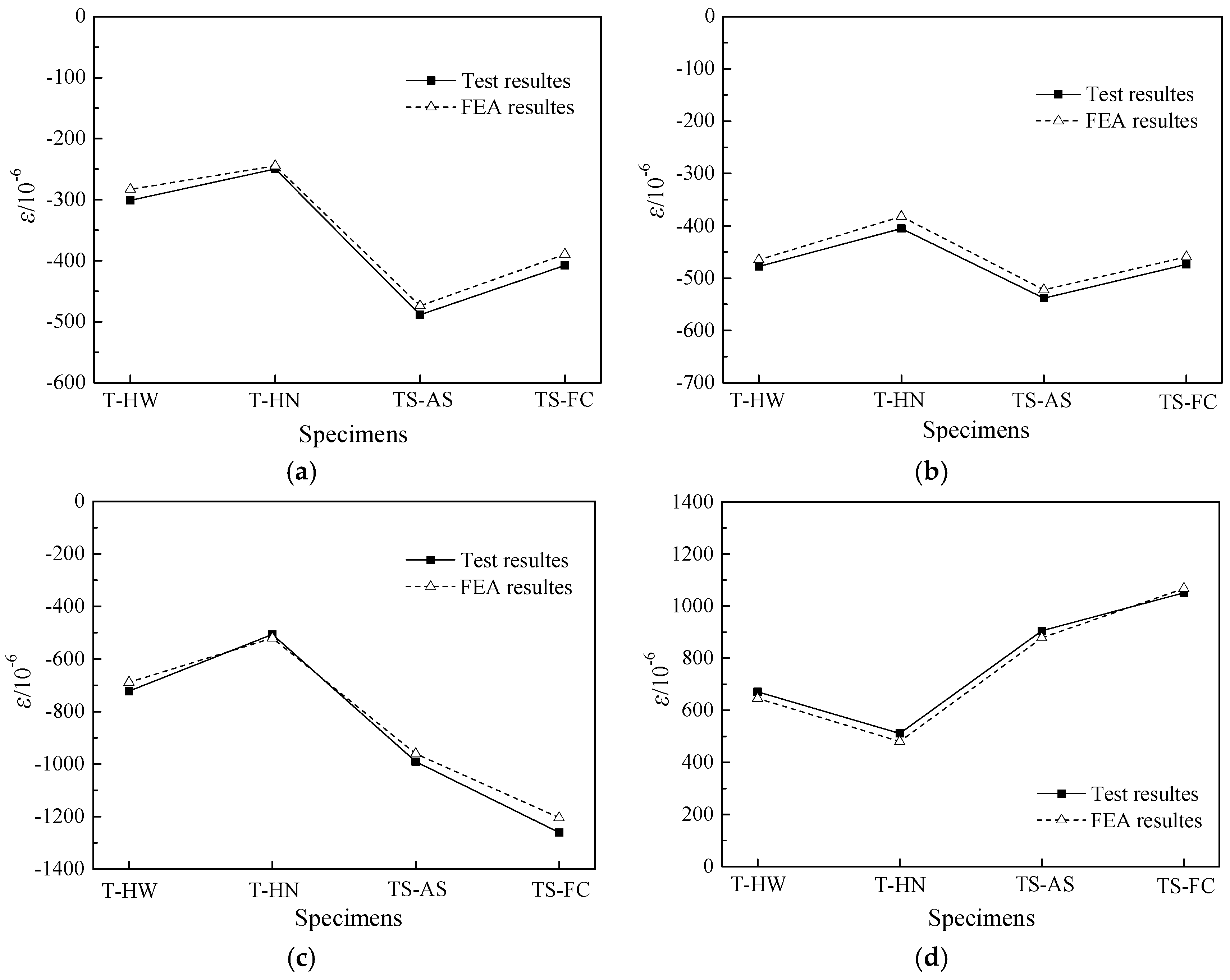

3.4. Strain Intensity

4. Finite Element Analysis

4.1. General

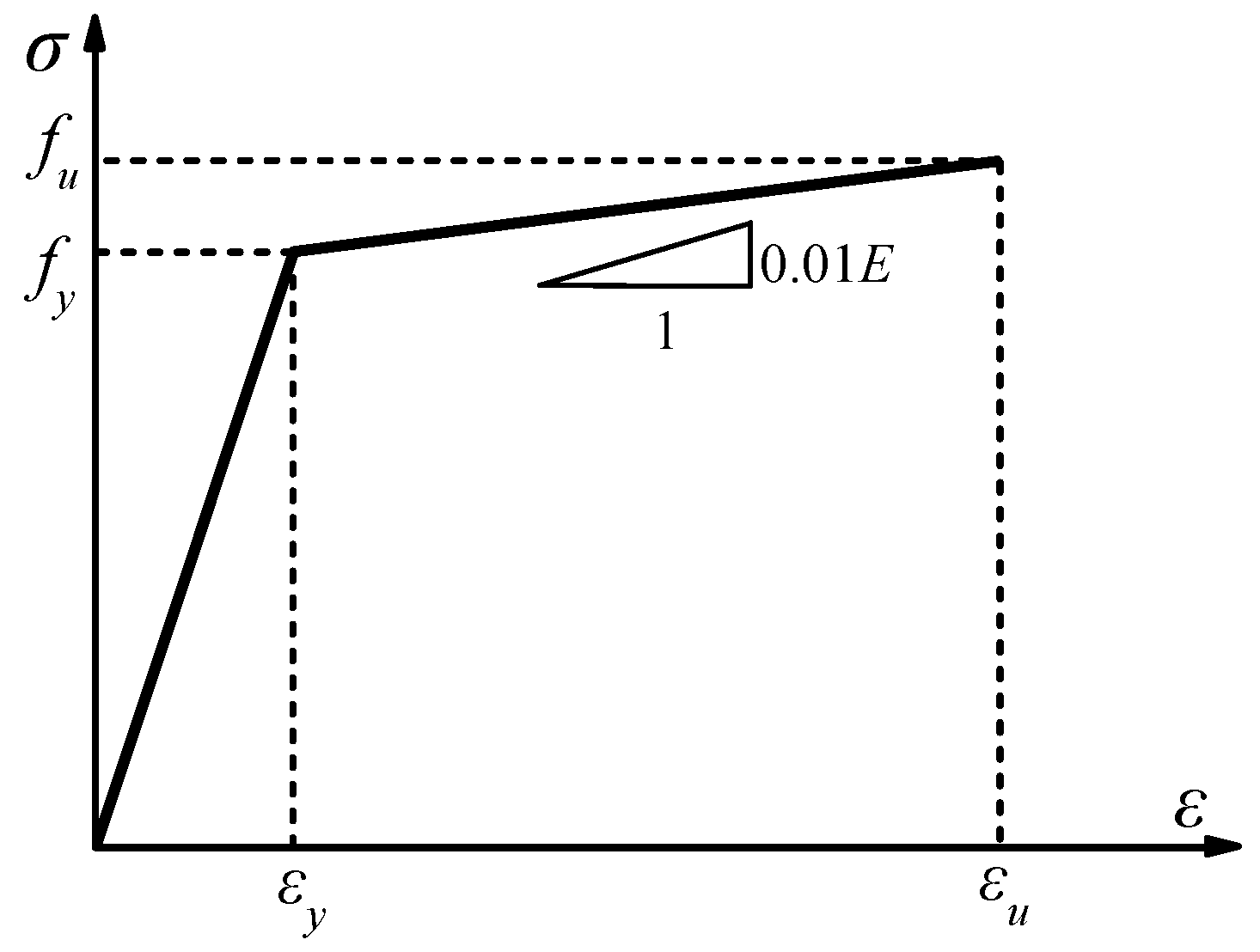

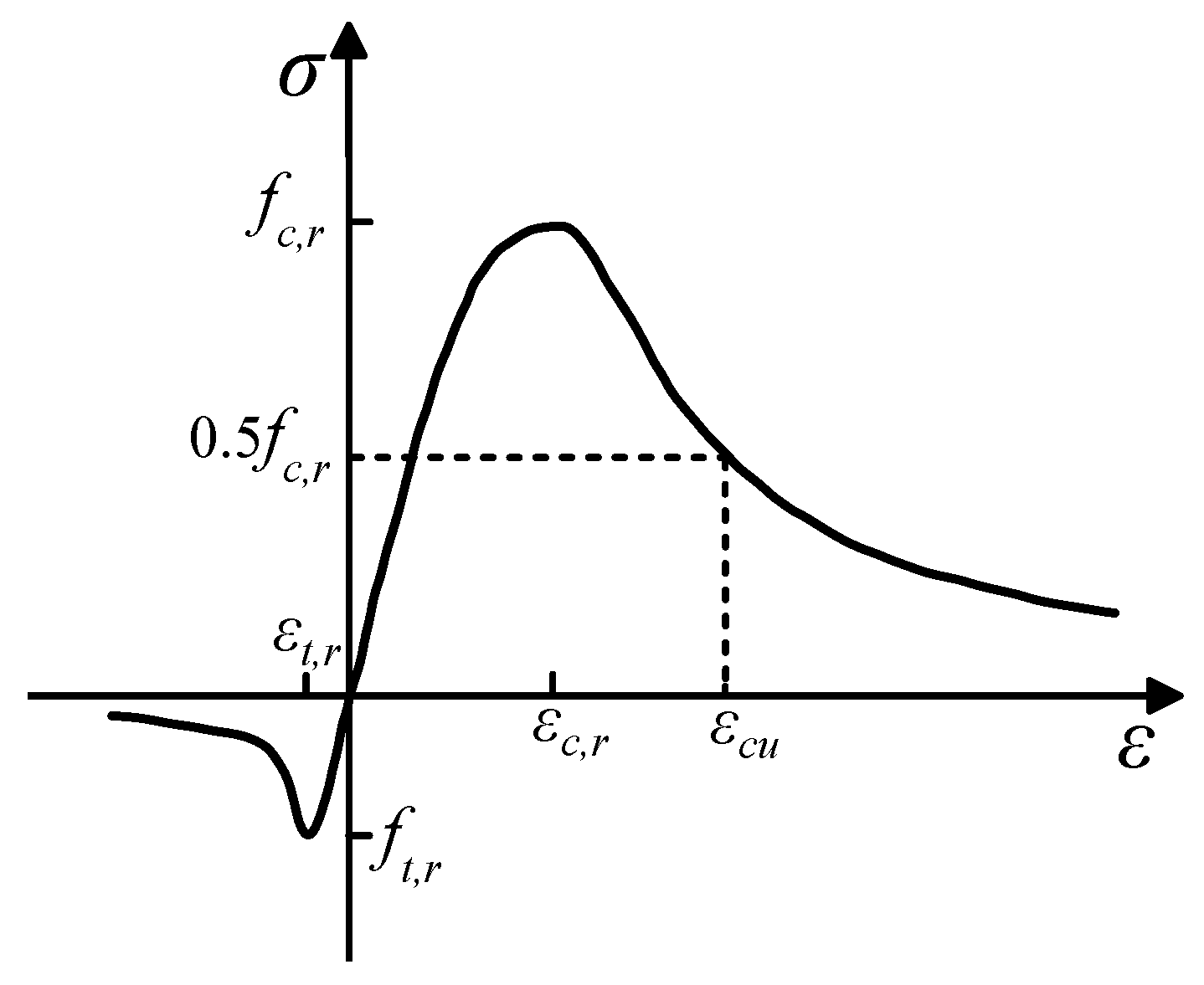

4.2. Material Modelling

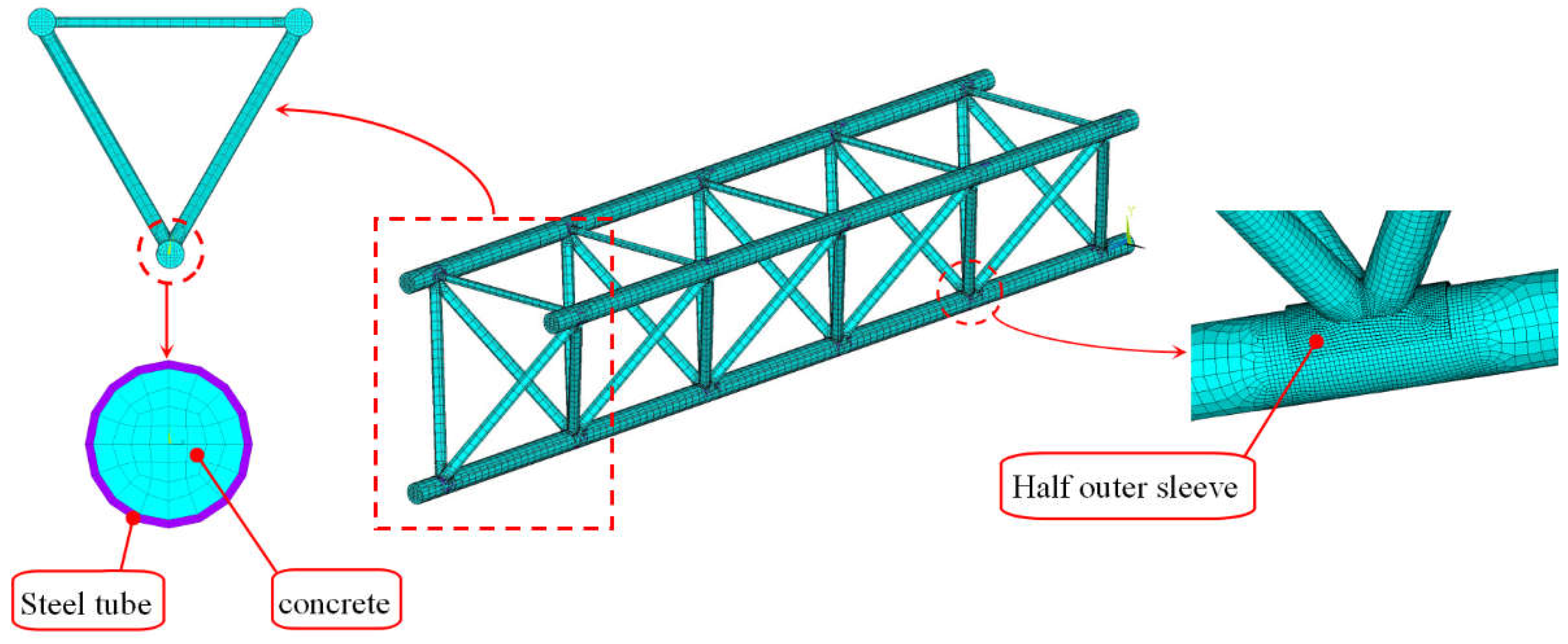

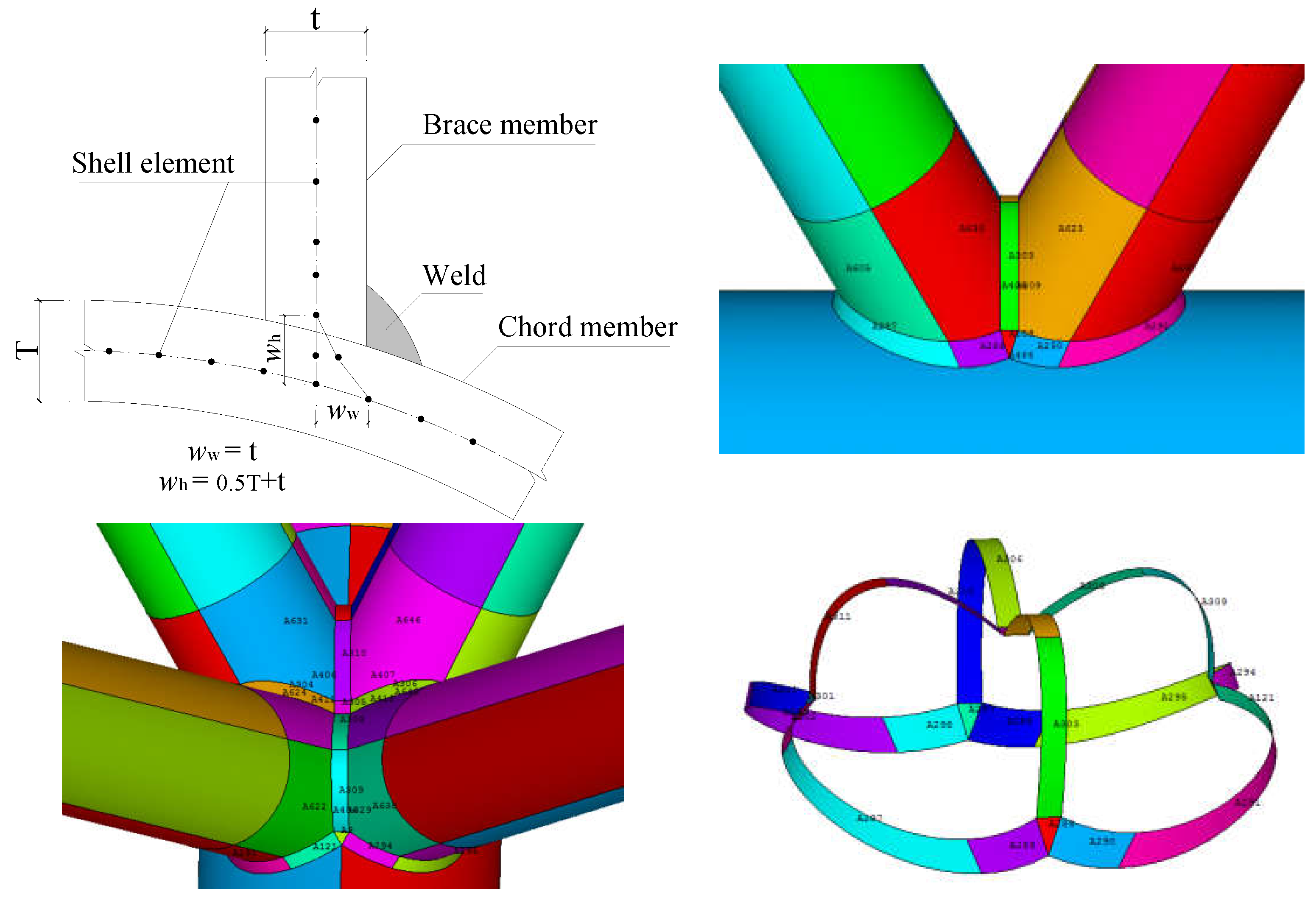

4.3. Finite Element Type and Mesh Size

4.4. Weld Modeling and Steel Tube–Concrete Infill Interface Model

4.5. Loading and Boundary Conditions

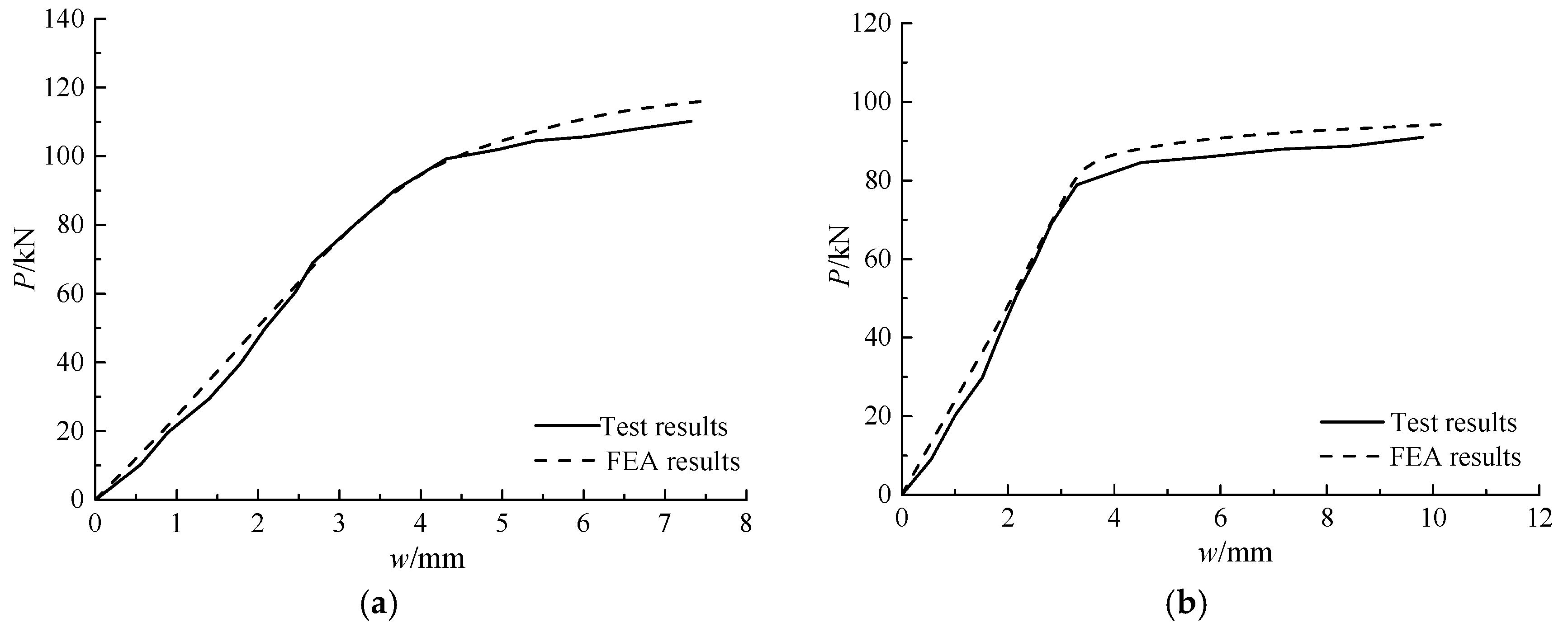

4.6. Verification of Finite Element Models

5. Conclusions and Future Work

- (1)

- The typical failure modes for three empty tubular trusses—T-HW, T-HN, and TS-AS—are basically the same, which resulted from the surface plasticity of the bottom chord member, the weld fracture around tubular joints at the bottom chord member, and bending deformation occurring at the bottom chord. It should be noted that the concave deformation at the end joints of TS-AS were slighter than the concave deformation of T-HW and T-HN, while its concave deformation areas at the end joints were more extensive than for T-HW and T-HN.

- (2)

- The TS-FC specimen did not fail until reaching the maximum load the test setup could produce, and there was no visible change in appearance. Furthermore, the load carrying capacity and integral rigidity of specimen TS-FC are larger than for specimen TS-AS, which illustrated that the reinforcing method of filling concrete into the top and bottom chord members can improve the mechanical behavior and integral stiffness of trusses better than adding a half outer sleeve on each joint.

- (3)

- Compared with the load carrying capacity of specimen T-HW, the load carrying capacity of specimen T-HN decreased by 18%, and the load carrying capacity of specimen TS-AS increased by 36%, whereas the load carrying capacity of specimen TS-FC increased by more than 60%. The deflections of the specimens TS-AS, T-HN, and T-HW are in descending order, meaning that specimen TS-AS has the best deformability, while specimen T-HN has better deformability than specimen T-HW.

- (4)

- The axial strains of the top chord members in compression are much smaller than the yield strain of the steel material, whereas the axial strains of the bottom chord members in tension are smaller than the yield strain of steel materials, and the axial strains of diagonal brace members are close to the yield strain of the steel materials. In addition, the strains at the crown positions on joints of the T-HW and T-HN specimens vary greatly, which means there is a case of stress concentration, whereas the strains at the same position of specimens TS-AS and TS-FC vary uniformly. It is shown that the reinforcing methods of adding a half outer sleeve on each joint and filling concrete into the top and bottom chord members could help to improve the force condition of joints of warren CHS tubular trusses.

- (5)

- The midspan vertical deflections under different load levels, the failure modes, and the load carrying capacity obtained from the finite element analysis of each specimen were compared with the corresponding test results. Good agreement between the experimental and finite element analysis results was achieved and the finite element models were accurate and reliable to be the basis of parametric analysis.

Author Contributions

Funding

Conflicts of Interest

References

- Tiainen, T.; Mela, K.; Jokinen, T.; Heinisuo, M. The effect of steel grade on weight and cost of warren-type welded tubular trusses. Proc. Inst. Civ. Eng. Struct. Build. 2017, 170, 855–873. [Google Scholar] [CrossRef]

- Gillman, A.; Fuchi, K.; Buskohl, P.R. Truss-based nonlinear mechanical analysis for origami structures exhibiting bifurcation and limit point instabilities. Int. J. Solids Struct. 2018, 147, 80–93. [Google Scholar] [CrossRef]

- Jiang, T.; Wu, Q.; Wang, L.; Huo, L.; Song, G. Monitoring of Bolt Looseness-induced Damage in Steel Truss Arch Structure using Piezoceramic Transducers. IEEE Sens. J. 2018, 18, 6677–6685. [Google Scholar] [CrossRef]

- Song, G.; Vlattas, J.; Johnson, S.E.; Agrawal, B.N. Active vibration control of a space truss using a lead zirconate titanate stack actuator. Proc. Inst. Mechan. Eng. Part G J. Aerosp. Eng. 2001, 215, 355–361. [Google Scholar] [CrossRef]

- Wardenier, J.; Packer, J.A.; Zhao, X.L.; Vegte, G.J.V.D. Hollow Sections in Structural Applications; CIDECT: Geneva, Switzerland, 2010. [Google Scholar]

- Yang, W.W.; Wang, X.L.; Wang, D.D. Design of long-span and wave-shaped steel canopy structure of ningxia helan mountain stadium. Adv. Mater. Res. 2011, 243–249, 72–78. [Google Scholar] [CrossRef]

- Kaveh, A.; Khayatazad, M. Ray optimization for size and shape optimization of truss structures. Comput. Struct. 2013, 117, 82–94. [Google Scholar] [CrossRef]

- Fenton, M.; McNally, C.; Byrne, J.; Hemberg, E.; McDermott, J.; O’Neill, M. Automatic innovative truss design using grammatical evolution. Autom. Constr. 2014, 39, 59–69. [Google Scholar] [CrossRef]

- Khademi, F. Load Rating of Railway Bridges by Analysis and Testing; Dissertations & Theses—Gradworks; Illinois Institute of Technology: Chicago, IL, USA, 2015. [Google Scholar]

- Khademi, F. Enhancing Load Rating of Railway Truss Bridges through a Hybrid Structural Analysis and Instrumentation Procedure. Ph.D. Thesis, Illinois Institute of Technology, Chicago, ON, USA, 2017. [Google Scholar]

- Wardenier, J.; Kurobane, Y.; Packer, J.A.; Vegte, G.J.V.D.; Zhao, X.L. Design Guide for CIRCULAR Hollow Section (CHS) Joints under Predominantly Static Loading; CIDECT (Ed.) and Verlag TÜV Rheinland: Cologne, Germany, 2008. [Google Scholar]

- Zhao, X.; Liu, J.; Xu, X.; Sivakumaran, K.S.; Chen, Y. Hysteretic behaviour of overlapped tubular k-joints under cyclic loading. J. Constr. Steel Res. 2018, 145, 397–413. [Google Scholar] [CrossRef]

- Chinese Code. GB/50017-2017 Standard for Design of Steel Structures; Standards Press of China: Beijing, China, 2017. [Google Scholar]

- Wang, X.L.; Yang, W.W.; Zou, L. Finite Element Analysis for Unstiffened Overlapped CHS K-Joints Welded in Different Ways. Adv. Mater. Res. 2011, 163–167, 299–306. [Google Scholar]

- Wang, X.L.; Chen, P.; Yang, W.W. Finite Element Analysis for Unstiffened Overlapped CHS KK-Joints Welded in Different Ways. Adv. Mater. Res. 2011, 446–449, 533–536. [Google Scholar] [CrossRef]

- Yang, W.; Wang, X. Numerical analysis of hysteretic behavior of unstiffened overlapped CHS K-Joints in steel pipe structures by finite element method. J. Harbin Eng. Univ. 2012, 12, 9. [Google Scholar]

- Yang, W.; Wang, X. Experimental research on seismic behavior of unstiffened overlapped CHS K-Joints. J. Build. Struct. 2013, 34, 85–92. [Google Scholar]

- Xue, J.Q.; Briseghella, B.; Chen, B.C. Effects of debonding on circular CFST stub columns. J. Constr. Steel Res. 2012, 69, 64–76. [Google Scholar] [CrossRef]

- Han, L.H.; Zheng, L.Q.; He, S.H.; Tao, Z. Tests on curved concrete filled steel tubular members subjected to axial compression. J. Constr. Steel Res. 2011, 67, 965–976. [Google Scholar] [CrossRef]

- Ding, F.X.; Luo, L.; Wang, L.; Cheng, S.; Yu, Z.W. Pseudo-static tests of terminal stirrup-confined concrete-filled rectangular steel tubular columns. J. Constr. Steel Res. 2018, 144, 135–152. [Google Scholar] [CrossRef]

- Qian, X.D.; Choo, Y.S.; Liew, J.Y.R.; Wardenier, J. Static Strength of Thick-Walled CHS X-Joints Subjected to Brace Moment Loadings. J. Struct. Eng. 2007, 133, 1278–1287. [Google Scholar] [CrossRef]

- Du, G.; Zhang, J.; Zhang, J.; Song, G. Experimental Study on Stress Monitoring of Sand-Filled Steel Tube during Impact Using Piezoceramic Smart Aggregates. Sensors 2017, 17, 1930. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Li, Z.; Song, G. A PVDF-Based Sensor for Internal Stress Monitoring of a Concrete-Filled Steel Tubular (CFST) Column Subject to Impact Loads. Sensors 2018, 18, 1682. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Xu, B.; Li, B.; Song, G.; Teng, J. Monitoring for Large Cross-Section CFSTs of a Super High-Rise Building with Piezoceramic Actuators and Sensors. Adv. Mater. Res. 2011, 163–167, 2553–2559. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, T.; Song, G.; Gu, H. Active interface debonding detection of a concrete-filled steel tube with piezoelectric technologies using wavelet packet analysis. Mech. Syst. Signal Process. 2013, 36, 7–17. [Google Scholar] [CrossRef]

- Liang, Y.; Li, D.; Parvasi, S.M.; Kong, Q.; Lim, I.; Song, G. Bond-slip detection of concrete-encased composite structure using electro-mechanical impedance technique. Smart Mater. Struct. 2016, 25, 095003. [Google Scholar] [CrossRef]

- Feng, Q.; Kong, Q.; Tan, J.; Song, G. Grouting compactness monitoring of concrete-filled steel tube arch bridge model using piezoceramic-based transducers. Smart Struct. Syst. 2017, 20, 175–180. [Google Scholar]

- Zhang, J.; Li, Y.; Zheng, Y.; Wang, Z. Seismic Damage Investigation of Spatial Frames with Steel Beams Connected to L-Shaped Concrete-Filled Steel Tubular (CFST) Columns. Appl. Sci. 2018, 8, 1713. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Guan, W.; Du, G. Damage Detection of Concrete-Filled Square Steel Tube (CFSST) Column Joints under Cyclic Loading Using Piezoceramic Transducers. Sensors 2018, 18, 3266. [Google Scholar] [CrossRef] [PubMed]

- Gho, W.M.; Yang, Y.; Gao, F. Failure mechanisms of tubular CHS joints with complete overlap of braces. Thin-Walled Struct. 2006, 44, 655–666. [Google Scholar] [CrossRef]

- Choo, Y.S.; Qian, X.D.; Wardenier, J. Effects of boundary conditions and chord stresses on static strength of thick-walled CHS K-Joints. J. Constr. Steel Res. 2006, 62, 316–328. [Google Scholar] [CrossRef]

- Shao, Y.; He, S.; Zhang, H.; Wang, Q. Hysteretic behavior of tubular T-joints after exposure to elevated temperature. Ocean Eng. 2017, 129, 57–67. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Y.-Y. Hysteretic behaviour of tubular joints under cyclic loading. J. Constr. Steel Res. 2007, 63, 1384–1395. [Google Scholar] [CrossRef]

- Suo, Y.; Yang, W.; Chen, P. Study on Hysteresis Model of Welding Material in Unstiffened Welded Joints of Steel Tubular Truss Structure. Appl. Sci. 2018, 8, 1701. [Google Scholar] [CrossRef]

- Liu, K.; Liu, B.; Wang, Z.; Wang, G.; Guedes Soares, C. An experimental and numerical study on the behaviour of tubular components and T-joints subjected to transverse impact loading. Int. J. Impact Eng. 2018, 120, 16–30. [Google Scholar] [CrossRef]

- Qu, H.; Hu, Y.; Huo, J.; Liu, Y.; Jiang, Y. Experimental study on tubular K-joints under impact loadings. J. Constr. Steel Res. 2015, 112, 22–29. [Google Scholar] [CrossRef]

- Li, T.; Lie, S.T.; Shao, Y.B. Fatigue and fracture strength of a multi-planar circular hollow section TT-joint. J. Constr. Steel Res. 2017, 129, 101–110. [Google Scholar] [CrossRef]

- Lee, C.K.; Chiew, S.P.; Lie, S.T.; Sopha, T. Comparison of fatigue performances of gapped and partially overlapped CHS -joints. Eng. Struct. 2011, 33, 44–52. [Google Scholar] [CrossRef]

- Azari Dodaran, N.; Ahmadi, H.; Lotfollahi-Yaghin, M.A. Static strength of axially loaded tubular KT-joints at elevated temperatures: Study of geometrical effects and parametric formulation. Mar. Struct. 2018, 61, 282–308. [Google Scholar] [CrossRef]

- He, S.-B.; Shao, Y.-B.; Zhang, H.-Y.; Yang, D.-P.; Long, F.-L. Experimental study on circular hollow section (CHS) tubular K-joints at elevated temperature. Eng. Fail. Anal. 2013, 34, 204–216. [Google Scholar] [CrossRef]

- Lan, X.; Huang, Y.; Chan, T.-M.; Young, B. Static strength of stainless steel K- and N-joints at elevated temperatures. Thin-Walled Struct. 2018, 122, 501–509. [Google Scholar] [CrossRef]

- Packer, J.A. Concrete-Filled HSS Connections. J. Struct. Eng. 1995, 121, 458–467. [Google Scholar] [CrossRef]

- Sakai, Y.; Hosaka, T.; Isoe, A.; Ichikawa, A.; Mitsuki, K. Experiments on concrete filled and reinforced tubular K-joints of truss girder. J. Constr. Steel Res. 2004, 60, 683–699. [Google Scholar] [CrossRef]

- Huang, W.; Fenu, L.; Chen, B.; Briseghella, B. Experimental study on K-joints of concrete-filled steel tubular truss structures. J. Constr. Steel Res. 2015, 107, 182–193. [Google Scholar] [CrossRef]

- Feng, R.; Young, B. Tests of concrete-filled stainless steel tubular T-joints. J. Constr. Steel Res. 2008, 64, 1283–1293. [Google Scholar] [CrossRef]

- Feng, R.; Chen, Y.; Wei, J.; He, K.; Fu, L. Behaviour of grouted stainless steel tubular X-joints with CHS chord under axial compression. Thin-Walled Struct. 2018, 124, 323–342. [Google Scholar] [CrossRef]

- Yin, Y.; Han, Q.H.; Bai, L.J.; Yang, H.D.; Wang, S.P. Experimental Study on hysteretic behaviour of tubular N-joints. J. Constr. Steel Res. 2009, 65, 326–334. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, R.; Xiong, L. Experimental and numerical investigations on double-skin CHS tubular X-joints under axial compression. Thin-Walled Struct. 2016, 106, 268–283. [Google Scholar] [CrossRef]

- Hou, C.; Han, L.-H.; Mu, T.-M. Behaviour of CFDST chord to CHS brace composite K-joints: Experiments. J. Constr. Steel Res. 2017, 135, 97–109. [Google Scholar] [CrossRef]

- Xu, F.; Chen, J.; Jin, W.L. Experimental investigation of SCF distribution for thin-walled concrete-filled CHS joints under axial tension loading. Thin-Walled Struct. 2015, 93, 149–157. [Google Scholar] [CrossRef]

- Qian, X.; Jitpairod, K.; Marshall, P.; Swaddiwudhipong, S.; Ou, Z.; Zhang, Y.; Pradana, M.R. Fatigue and residual strength of concrete-filled tubular X-joints with full capacity welds. J. Constr. Steel Res. 2014, 100, 21–35. [Google Scholar] [CrossRef]

- Tong, L.W.; Xu, G.W.; Yang, D.L.; Mashiri, F.R.; Zhao, X.L. Fatigue behavior and design of welded tubular T-joints with CHS brace and concrete-filled chord. Thin-Walled Struct. 2017, 120, 180–190. [Google Scholar] [CrossRef]

- Wu, Q.; Yoshimura, M.; Takahashi, K.; Nakamura, S.; Nakamura, T. Nonlinear seismic properties of the Second Saikai Bridge: A concrete filled tubular (CFT) arch bridge. Eng. Struct. 2006, 28, 163–182. [Google Scholar] [CrossRef]

- Chen, B.C.; Wang, T.L. Overview of Concrete Filled Steel Tube Arch Bridges in China. Pract. Period. Struct. Des. Constr. 2009, 14, 70–80. [Google Scholar] [CrossRef]

- Han, L.H. Some Recent Developments of Concrete Filled Steel Tubular (CFST) Structures in China. In Proceedings of the International Conference on Steel & Composite Structures, Sydney, Australia, 21–23 July 2010; pp. 41–52. [Google Scholar]

- Xu, W.; Han, L.-H.; Tao, Z. Flexural behaviour of curved concrete filled steel tubular trusses. J. Constr. Steel Res. 2014, 93, 119–134. [Google Scholar] [CrossRef]

- Zhou, W.; Chen, Y.; Wang, K.; Han, S.; Palacios Galarza, F. Experimental research on circular concrete filled stainless steel tubular truss. Thin-Walled Struct. 2017, 117, 224–238. [Google Scholar] [CrossRef]

- Mujagic, J.R.U.; Easterling, W.S.; Murray, T.M. Design and behavior of light composite steel–concrete trusses with drilled standoff screw shear connections. J. Constr. Steel Res. 2010, 66, 1483–1491. [Google Scholar] [CrossRef]

- Tullini, N.; Minghini, F. Nonlinear analysis of composite beams with concrete-encased steel truss. J. Constr. Steel Res. 2013, 91, 1–13. [Google Scholar] [CrossRef]

- Huang, W.; Fenu, L.; Chen, B.; Briseghella, B. Experimental study on joint resistance and failure modes of concrete filled steel tubular (CFST) truss girders. J. Constr. Steel Res. 2018, 141, 241–250. [Google Scholar] [CrossRef]

- Chinese Code. Jgj81-2002 Technical Specification for Welding of Steel Structure of Building; Standards Press of China: Beijing, China, 2003. [Google Scholar]

- Chinese Code. Gb/T 228-2002 Metallic Materials-Tensile Testing at Ambient Temperature; Standards Press of China: Beijing, China, 2002. [Google Scholar]

- Chinese Code. Gb/T50081-2002 Test Method of Mechanical Properties on Ordinary Concrete; Standards Press of China: Beijing, China, 2003. [Google Scholar]

- ANSYS-Inc. ANSYS Structural Analysis Guide. 2004. Available online: http://www.ansys.stuba.sk/html/guide_55/g-str/GSTRToc.htm (accessed on 1 November 2018).

- Shao, Y.-B.; Li, T.; Lie Seng, T.; Chiew, S.-P. Hysteretic behaviour of square tubular T-joints with chord reinforcement under axial cyclic loading. J. Constr. Steel Res. 2011, 67, 140–149. [Google Scholar] [CrossRef]

- Chinese Code. Gb/50010-2010 Design of Concrete Structures; Standards Press of China: Beijing, China, 2010. [Google Scholar]

- Vegte, G.J.V.D. The Static Strength of Uniplanar and Multiplanar Tubular T- and X-Joints; Delft University Press: Delft, The Netherlands, 1995. [Google Scholar]

- Corigliano, P.; Crupi, V.; Guglielmino, E.; Fricke, W. FE analysis of cruciform welded joints considering different mechanical properties for base material, heat affected zone and weld metal. Frattura ed Integrità Strutturale 2014, 8, 304–310. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V.; Fricke, W.; Friedrich, N.; Guglielmino, E. Experimental and numerical analysis of fillet-welded joints under low-cycle fatigue loading by means of full-field techniques. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1327–1338. [Google Scholar] [CrossRef]

- Zhao, J.; Bao, T.; Chen, S.; Kundu, T. Smart Aggregate-Piezoceramic Patch Combination for Health Monitoring of Concrete Structures. J. Sens. 2016, 2016, 1–7. [Google Scholar] [CrossRef]

- Kaur, N.; Bhalla, S. Combined Energy Harvesting and Structural Health Monitoring Potential of Embedded Piezo-Concrete Vibration Sensors. J. Energy Eng. 2015, 141, D4014001. [Google Scholar] [CrossRef]

- Kong, Q.; Robert, R.; Silva, P.; Mo, Y. Cyclic Crack Monitoring of a Reinforced Concrete Column under Simulated Pseudo-Dynamic Loading Using Piezoceramic-Based Smart Aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Xu, K.; Deng, Q.; Cai, L.; Ho, S.; Song, G. Damage Detection of a Concrete Column Subject to Blast Loads Using Embedded Piezoceramic Transducers. Sensors 2018, 18, 1377. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Kong, Q.; Zhou, H.; Gu, H. Multiple Cracks Detection in Pipeline Using Damage Index Matrix Based on Piezoceramic Transducer-Enabled Stress Wave Propagation. Sensors 2017, 17, 1812. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Li, B.; Song, G. Active Debonding Detection for Large Rectangular CFSTs Based on Wavelet Packet Energy Spectrum with Piezoceramics. J. Struct. Eng. 2013, 139, 1435–1443. [Google Scholar] [CrossRef]

- Shi, Y.; Luo, M.; Li, W.; Song, G. Grout compactness monitoring of concrete-filled fiber-reinforced polymer tube using electromechanical impedance. Smart Mater. Struct. 2018, 27, 055008. [Google Scholar] [CrossRef]

- Yan, S.; Fu, J.; Sun, W.; Qi, B.; Liu, F. PZT-Based Detection of Compactness of Concrete in Concrete Filled Steel Tube Using Time Reversal Method. Math. Probl. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Luo, M.; Li, W.; Hei, C.; Song, G. Concrete Infill Monitoring in Concrete-Filled FRP Tubes Using a PZT-Based Ultrasonic Time-of-Flight Method. Sensors 2016, 16, 2083. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Y.; Du, G.; Song, G. Damage Detection of L-Shaped Concrete Filled Steel Tube (L-CFST) Columns under Cyclic Loading Using Embedded Piezoceramic Transducers. Sensors 2018, 18, 2171. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Luo, M.; Hei, C.; Song, G. Quantitative evaluation of compactness of concrete-filled fiber-reinforced polymer tubes using piezoceramic transducers and time difference of arrival. Smart Mater. Struct. 2017, 27, 035023. [Google Scholar] [CrossRef]

| Specimen ID | Chord | Brace | Lateral Bracing | Dimensionless Parameters | ||||

|---|---|---|---|---|---|---|---|---|

| D × T (mm) | d × t (mm) | d1 × t1 (mm) | θ | β | γ | τ | Oν | |

| T-HW | 60 × 2.5 | 33 × 2 | 22 × 2 | 60o | 0.58 | 12 | 0.8 | 39.3% |

| T-HN | 60 × 2.5 | 33 × 2 | 22 × 2 | 60o | 0.58 | 12 | 0.8 | 39.3% |

| TS-AS | 60 × 2.5 | 33 × 2 | 22 × 2 | 60o | 0.58 | 12 | 0.8 | 39.3% |

| TS-FC | 60 × 2.5 | 33 × 2 | 22 × 2 | 60o | 0.58 | 12 | 0.8 | 39.3% |

| Steel Tube | Elastic Modulus E (N/mm2) | Tensile Yield Stress fy (MPa) | Ultimate Tensile Stress fu (MPa) | fy/fu | Elongation δ (%) |

|---|---|---|---|---|---|

| Φ60 × 2.5 Φ33 × 2 Φ22 × 2 | 2.071 × 105 1.957 × 105 2.123 × 105 | 268.57 306.21 324.36 | 430.14 446.04 462.35 | 0.62 0.69 0.70 | 17.87 19.29 15.62 |

| concrete type | elastic modulus Ec (N/mm2) | concrete cube strength (MPa) | |||

| Self-compacting | 2.77 × 104 | 18.3 | |||

| Specimen | Yield Load Fy (kN) | Peak Load Fp (kN) | Comparison Fp/Fy |

|---|---|---|---|

| T-HW T-HN TS-AS TS-FC | 100 80 140 ---- | 110 90 150 ---- | 1.1 1.13 1.07 ---- |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Lin, J.; Gao, N.-n.; Yan, R. Experimental Study on the Static Behavior of Reinforced Warren Circular Hollow Section (CHS) Tubular Trusses. Appl. Sci. 2018, 8, 2237. https://doi.org/10.3390/app8112237

Yang W, Lin J, Gao N-n, Yan R. Experimental Study on the Static Behavior of Reinforced Warren Circular Hollow Section (CHS) Tubular Trusses. Applied Sciences. 2018; 8(11):2237. https://doi.org/10.3390/app8112237

Chicago/Turabian StyleYang, Wenwei, Jiankang Lin, Ni-na Gao, and Ruhao Yan. 2018. "Experimental Study on the Static Behavior of Reinforced Warren Circular Hollow Section (CHS) Tubular Trusses" Applied Sciences 8, no. 11: 2237. https://doi.org/10.3390/app8112237

APA StyleYang, W., Lin, J., Gao, N.-n., & Yan, R. (2018). Experimental Study on the Static Behavior of Reinforced Warren Circular Hollow Section (CHS) Tubular Trusses. Applied Sciences, 8(11), 2237. https://doi.org/10.3390/app8112237