1. Introduction

Due to the good performance and riding quality, along with easy maintenance and repair, asphalt pavement has increased year by year in China [

1]. However, the temperature sensitivity of asphalt materials is high and the mechanical properties of asphalt pavement will degrade under large temperature difference [

2]. Northeast China belongs to the seasonal frozen region and the average temperature in winter can reach −20 °C and above 20 °C in summer. In order to improve the performance of asphalt pavement, reduce the damage of pavement, and extend the service life of pavement, nanomodification and fiber modification technologies have been applied in asphalt mixture.

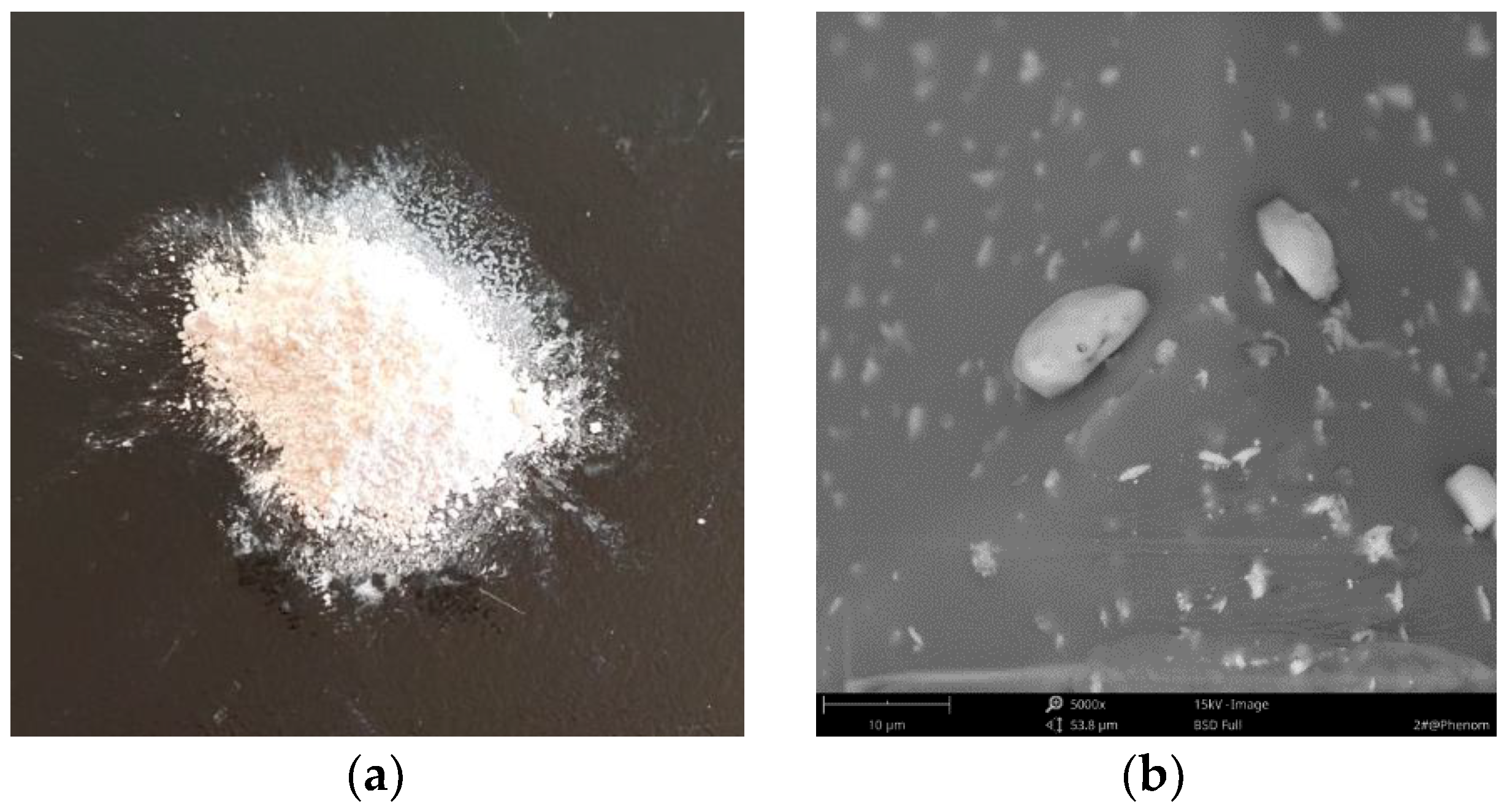

Nanotechnology is a new technology that has gradually emerged in recent years. Nanomaterials have been gradually applied as asphalt mixture modifiers due to their special properties not found in macroscopic materials. Ameri et al. evaluated moisture susceptibility of hot mix asphalt (HMA) with and without Zycosoil as a nano-organosilane anti-stripping additive and hydrated lime in the form of slurry. The results found that use of Zycosoil additive will increase adhesion bond between the aggregates and asphalt binders, and in turn influences the moisture resistance of the mixture to moisture damage [

3]. Hamedi studied the effects of using nano-CaCO

3 as an antistrip additive on moisture susceptibility of asphalt mixtures have been assessed using the surface free energy (SFE) method and modified Lottman test. Adding nanomaterials lead to the decrease of the acid component of SFE and increase of basic component of SFE for the asphalt binder that lead to an increase of adhesion between the asphalt binder and sensitive aggregate against moisture damage [

4]. Nano-TiO

2 is a commonly used nanomodified material. Shafabakhsh et al. found that nano-TiO

2 could effectively improve the viscosity, anti-rutting, and anti-fatigue properties of asphalt mixture [

5]. Sadeghnejad et al. used nanomaterials to modify SMA and the test results showed that nano-TiO

2 could improve the anti-rutting ability and splitting strength ratio and prolong the service life of an asphalt mixture [

6]. Nazari et al. evaluated the microstructure and chemical properties of nanocomposite modified asphalt by X-ray and scanning electron microscopy. It was found that the addition of nanomaterials improved the fatigue resistance of asphalt mixture [

7].

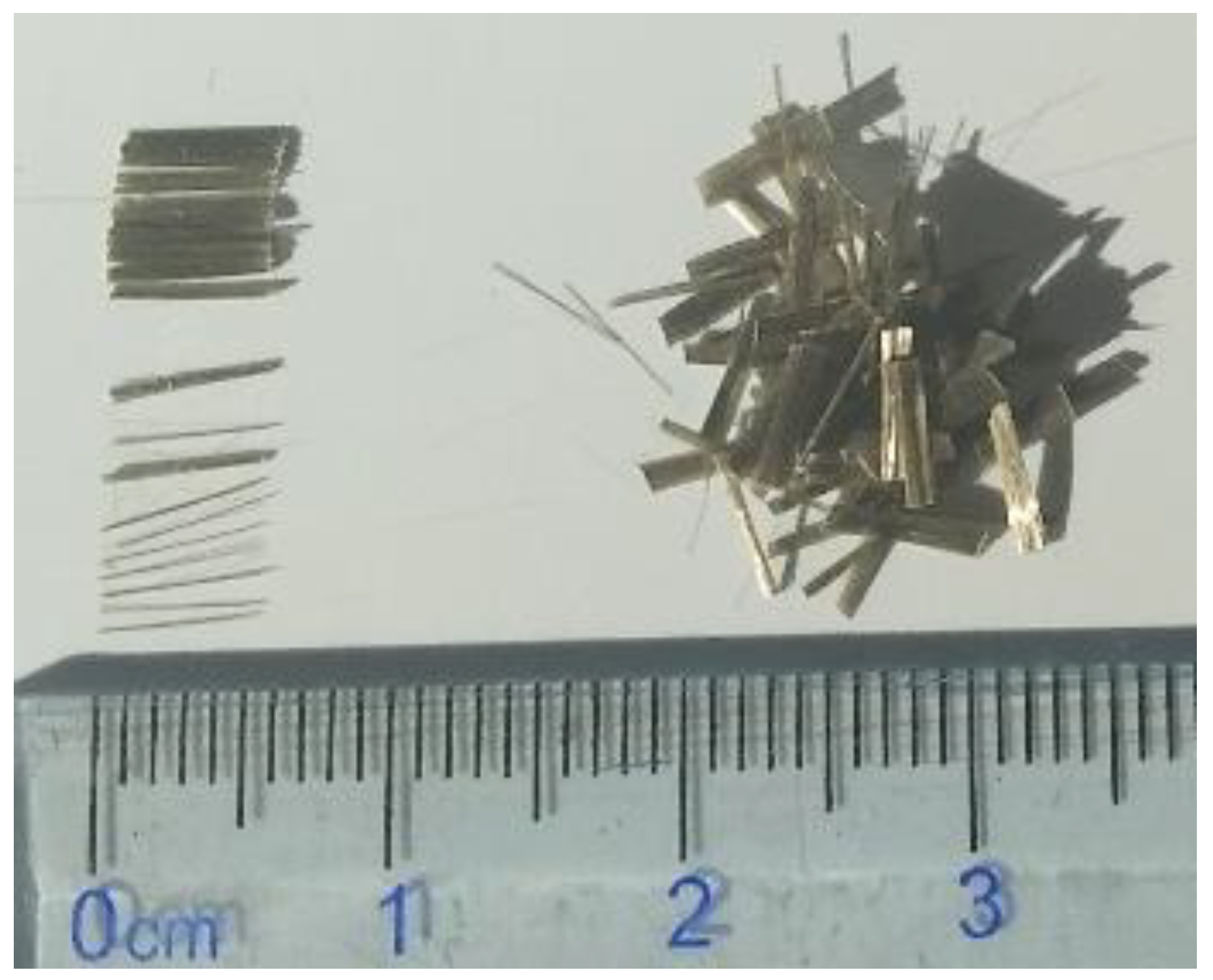

There are many kinds of fiber modifiers used in asphalt mixtures in recent years, such as polyester fiber, lignin fiber, carbon fiber, glass fiber, basalt fiber, etc. Different fiber modifiers have their own advantages and disadvantages. The low-temperature crack resistance of asphalt mixture is the main problem in the frozen region of northeast China. Compared with other fibers, basalt fiber is a mineral fiber that is abundant and easy to obtain in northeast China. Also, it will not cause environmental pollution. Basalt fiber has some advantages in terms of modifying road performance of asphalt mixtures. Zheng studied the pavement performances of basalt fiber, lignin fiber, and polyester fiber modified asphalt mixtures and found that the performance of the basalt fiber modified asphalt mixture was superior to that of the others [

8,

9]. Morova et al. studied the usability of basalt fibers in order to bear the stresses occurring at the surface layer of pavement and the optimum value of the fiber ratio leading to the optimum stability value was determined [

10]. Chen found that basalt fiber, at the optimal fiber content, could improve the water stability and high-temperature stability of the asphalt mixture more effectively than lignin fiber and polyester fiber [

11]. Qin studied the asphalt adsorption property, shear performance, crack resistance, and high-temperature rheological properties of asphalt modified by basalt fiber, lignin fiber, and polyester fiber. The microstructure and strengthening mechanism of basalt fiber was also studied by scanning electron microscopy. The results showed the basalt fiber can obviously improve the crack resistance of asphalt mastic than other fibers [

12]. Gao et al. found that basalt fiber could significantly improve the tensile strength of asphalt mixture [

13]. Chang et al. studied the low-temperature performance of asphalt mixture under salt freeze‒thaw cycles with low-temperature bending experiments. The results showed that the concentration of the salt solution and freeze‒thaw temperature had significant influence on the low-temperature performance of mixture. Basalt fiber improved the low-temperature performance of mixture under salt freeze‒thaw cycles [

14]. Davar et al. evaluated the fatigue life of basalt fiber and diatomite composite modified asphalt with four-point bending beam experiment, and the experimental results showed that basalt fiber improved the low-temperature performance of asphalt mixture [

15]. Zheng et al. studied the performance of basalt modified asphalt mixture under the coupling effect of chloride erosion and freeze‒thaw cycles. It was found that basalt fiber greatly improved the low-temperature bending and fatigue performances of asphalt mixture [

16]. In addition, basalt fiber could improve the resistance and pavement performance of asphalt road under complex environment. Zhang et al. studied the performance improvement of asphalt mixtures modified with different modifiers at different salt concentrations and different environments. The test results showed that basalt fiber had the best improvement on mechanical properties of asphalt mixtures under salty and humid environment [

17,

18]. Celauro et al. studied the performances of basalt fiber modified asphalt mixture as the surface layer of bus lane pavement, and found that basalt fiber modified asphalt had good performance in resisting permanent deformation and increasing road friction [

19]. The raw material cost of basalt fiber modified asphalt pavement has increased by 15–20%, but the service life of the pavement can increase by 30–40% [

20,

21]. From what has been discussed above, basalt fiber is suitable to be used as a modified material for asphalt pavement in northeast China.

The asphalt concrete pavement in northeast China faces the freeze–thaw cycles conditions. The freeze‒thaw cycles had a great threat to the durability of asphalt pavement. Many researchers analyzed the mechanism of freeze‒thaw damage of asphalt mixture, in general, the water permeated and remained in the pores of the pavement, when the external temperature decreased, the pore water froze and volume expanded, which resulted in the generation of frost heave. When the temperature increased, ice melted into water and began the next freeze‒thaw cycle. With repeated freeze‒thaw cycle, the internal pore morphology and bituminous viscosity of the mixture were significantly changed and the performances of the mixture were significantly reduced [

22,

23,

24,

25]. In order to more vividly reflect the mechanism of freeze‒thaw damage of asphalt mixture, research focused on the performance changes of asphalt mixture under freeze‒thaw cycles through macroscopic test or mesoscopic analysis. Xu et al. studied the micro-thermodynamic behavior of asphalt mixtures under a freeze‒thaw cycle with information entropy theory, X-ray tomography and image processing technology [

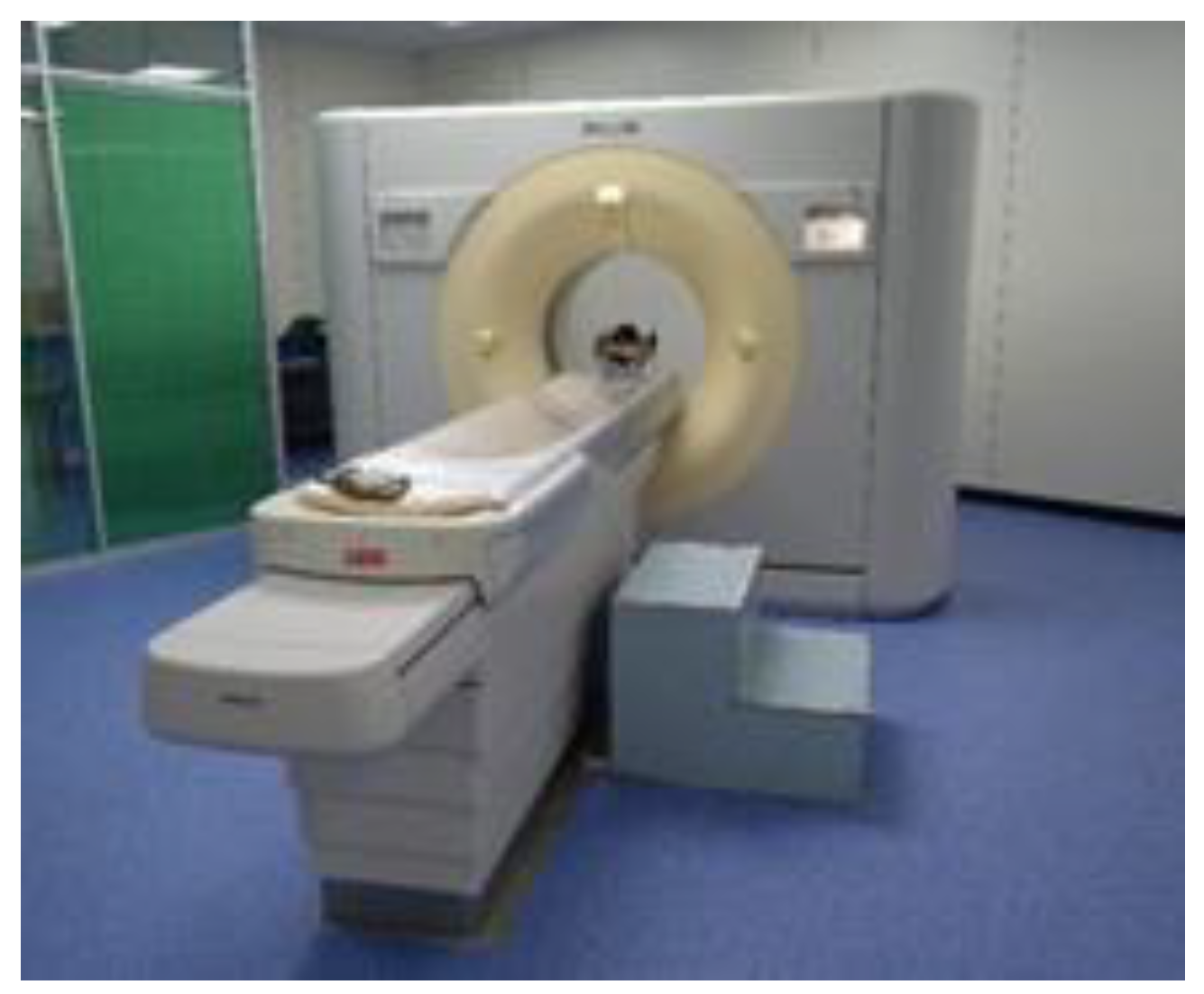

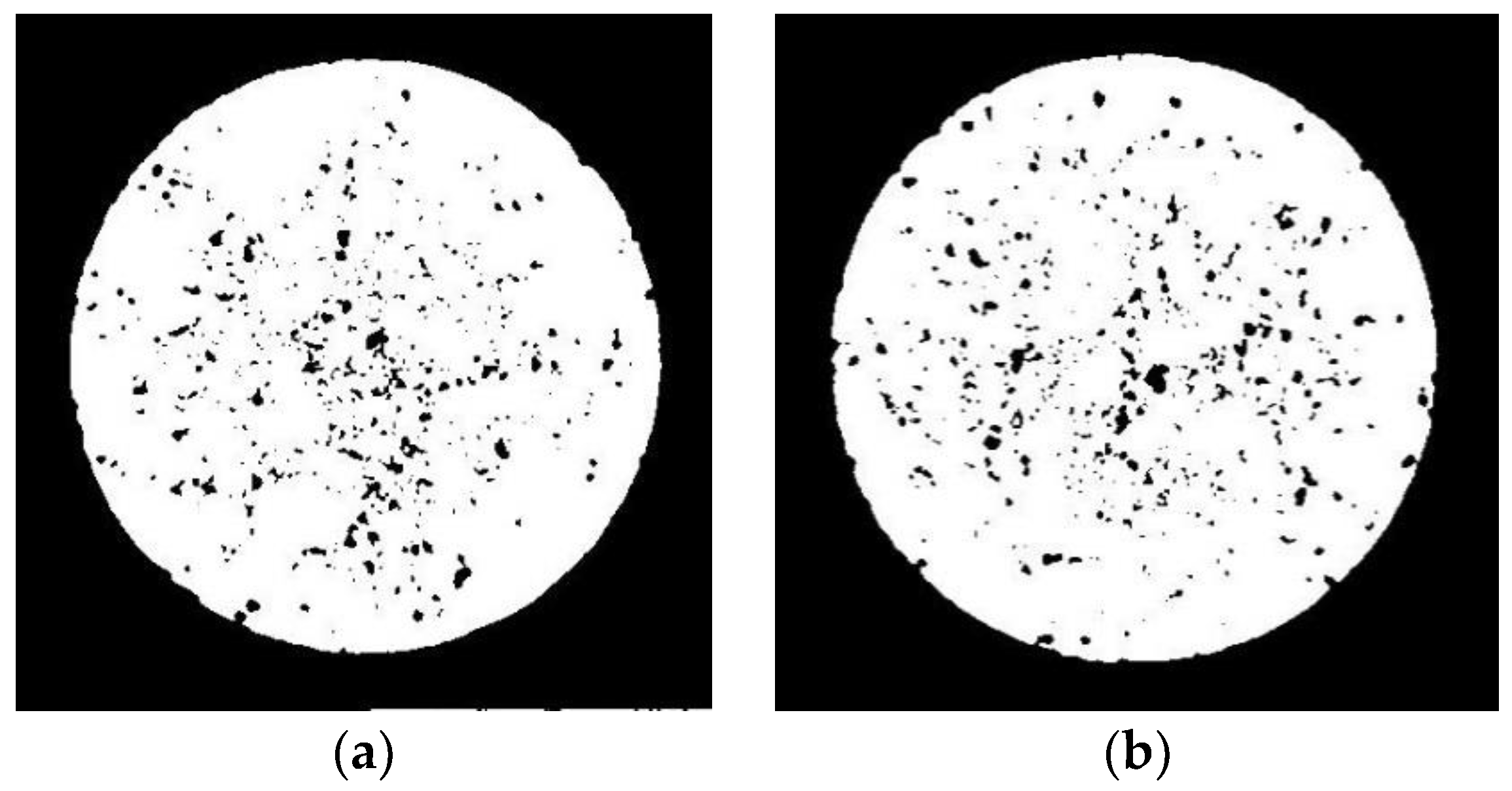

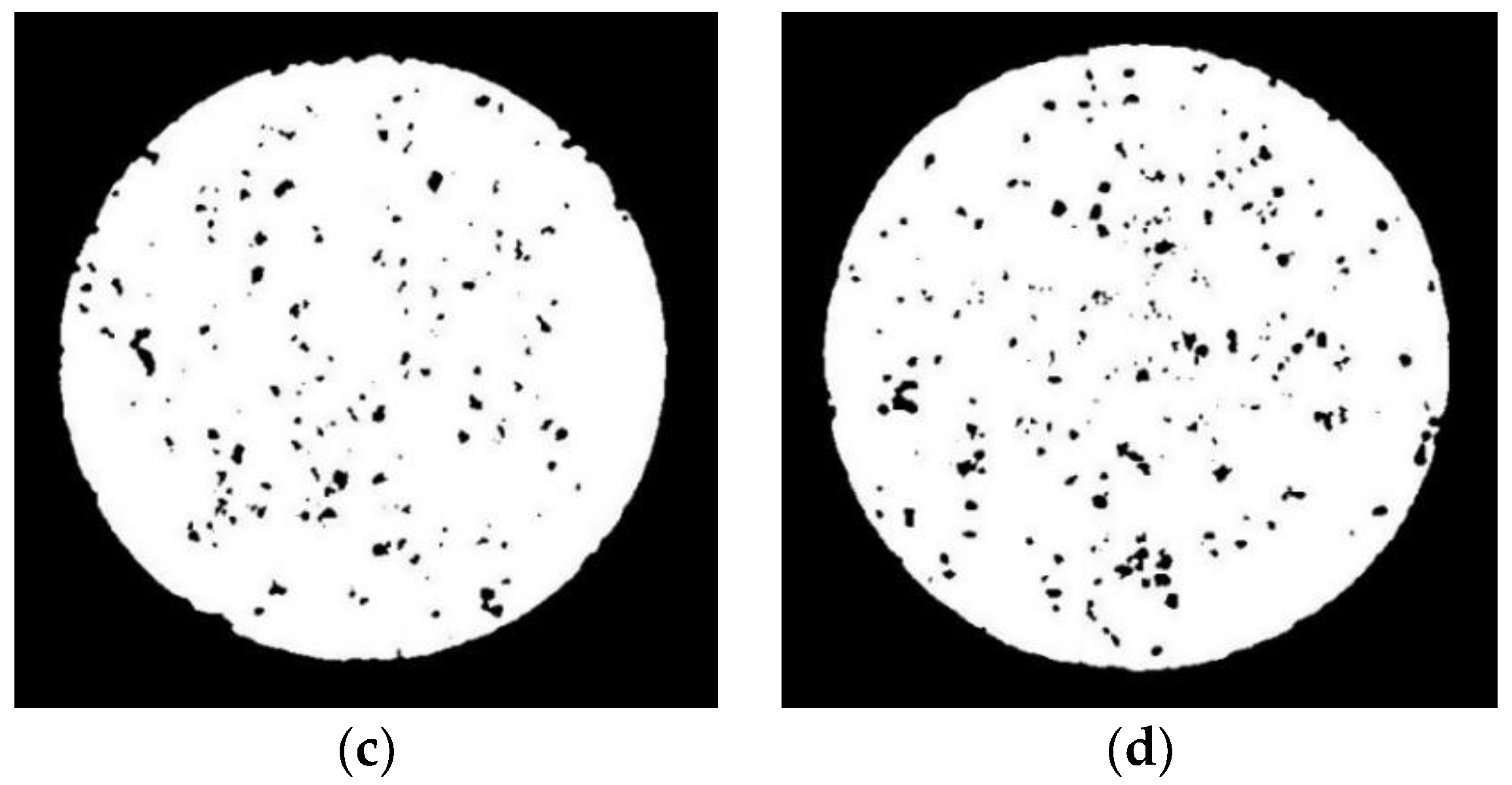

26]. Nian performed the freeze‒thaw aging test and carried out Fourier transform infrared spectroscopy quantitative to analyze the compositions and rheological properties of asphalt mixture in cold regions [

27]. Xu et al. studied the internal evolution and analyzed the pore distribution changes and permeability of asphalt mixture during a freeze‒thaw cycle with X-ray tomography [

28,

29]. Wang et al. analyzed the pore structure of semi-rigid base materials under freeze‒thaw cycles with X-ray tomography [

30]. Ma et al. established the performance decay model of asphalt pavement in cold regions. The results showed that the freeze‒thaw cycles had a significant impact on pavement reliability. The more unstable the conditions of the freeze‒thaw cycle, the greater the impact on pavement capacity [

31]. Sol-Sánchez analyzed the evolution of the strength and bearing capacity of asphalt mixtures exposed to long-term moisture over several freeze‒thaw cycles and a varying number of days of thermal aging. It found that the air void content has a significant influence on the long-term evolution of the mixture properties under moisture, which is a reversible process, unlike the other two climate agents studied [

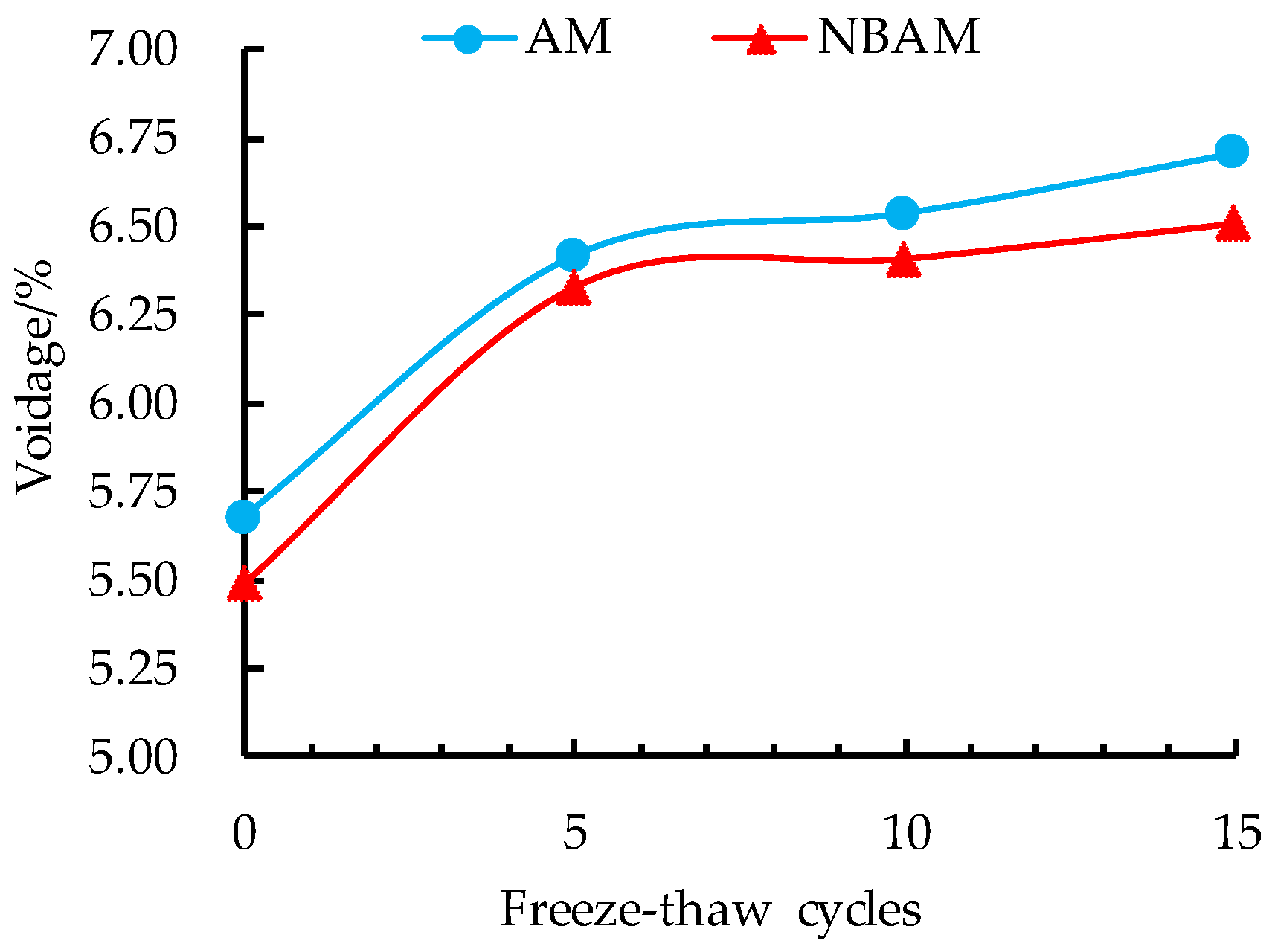

32]. Badeli et al. studied the changes of complex modulus of asphalt mixtures under rapid freeze‒thaw cycles with different compaction and dry humidity in cold regions. They established rheological model to predict the service life and fatigue crack of asphalt mixture under freeze‒thaw cycles. It was found that the freeze‒thaw cycles had a more significant effect on the stiffness of the mixture [

33,

34,

35]. Gong et al. studied the effect of freeze‒thaw cycles on mortar with the rheological test of curved beam [

36]. Linares used three representation functions to determine relaxation moduli of asphalt mixtures subject to the action of freeze‒thaw cycles. It concludes that Prony series function appeared to have better prediction than other two functions in fitting raw creep compliance data of asphalt mixtures at 0, 100, 200, 250, and 300 freeze‒thaw cycles as well as showing promising results in predicting the relaxation modulus of asphalt mixtures subjected to freeze‒thaw cycles [

37]. Lachance-Tremblay et al. used the 2S2P1D rheological model to simulate the material behavior and evaluate the evolution of linear viscoelastic properties. Repeated freeze‒thaw damaged the sample and glass asphalt mixture was damaged faster than the reference mixture. However, both mixtures reached equivalent damage after 10 freeze‒thaw cycles [

38]. In order to improve the freeze‒thaw resistance asphalt pavement, the addition of modified materials was the main methods in existing researches. Huang et al. studied the moisture resistance of asphalt mixture modified with slaked lime under freeze‒thaw cycles [

39]. Wei et al. studied the influence of diatomite and styrene‒butadience‒styrence (SBS) on the freeze‒thaw resistance of waste rubber modified asphalt mixture. They established the mathematical model and accurately predicted the porosity and indirect tensile strength during freeze‒thaw cycles [

40]. Modarres et al. studied the effect of Cement kiln dust (CKD) as a filler material on the low-temperature characteristics of hot mix asphalt (HMA). According to the obtained results, mixes containing CKD filler demonstrated better resistance against freeze‒thaw cycles compared to the control mixture containing limestone (LS). Moreover, mixes containing CKD exhibited a higher fatigue life compared to the control mix and for all mixes the fatigue life decreased by decreasing the temperature [

41]. Yan et al. studied the effects of freeze‒thaw cycles on the Marshall stability, flow value, and split tensile strength of stone mastic asphalt (SMA) mixtures with different lime content [

42]. Xu et al. studied the effect of freeze‒thaw cycles on split tensile strength and porosity of rubber modified asphalt mixture [

43]. Teguedi et al. analyzed the local volume change of asphalt mixture with different reclaimed asphalt pavement (RAP) contents under freeze‒thaw cycles with grid method and digital image processing technology [

44].

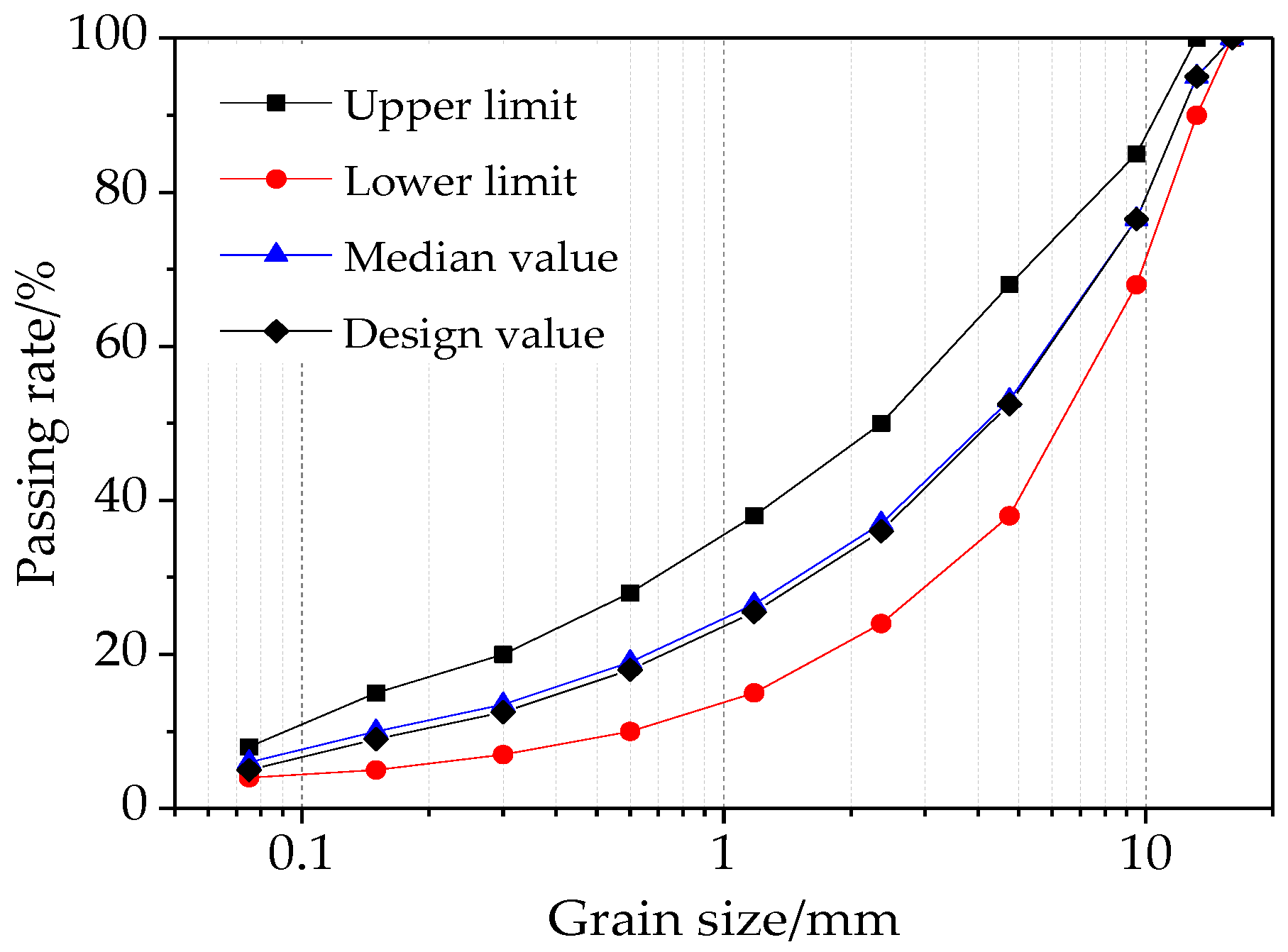

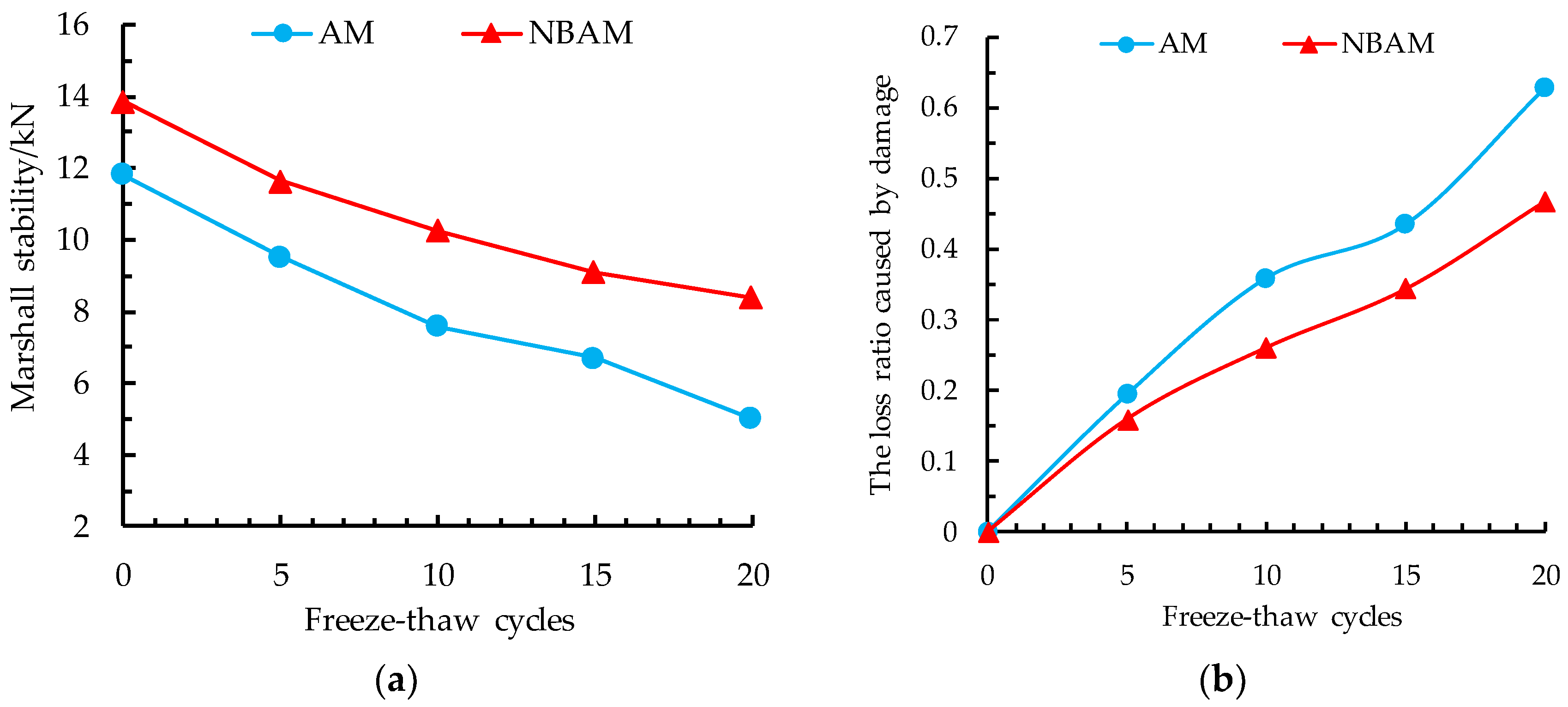

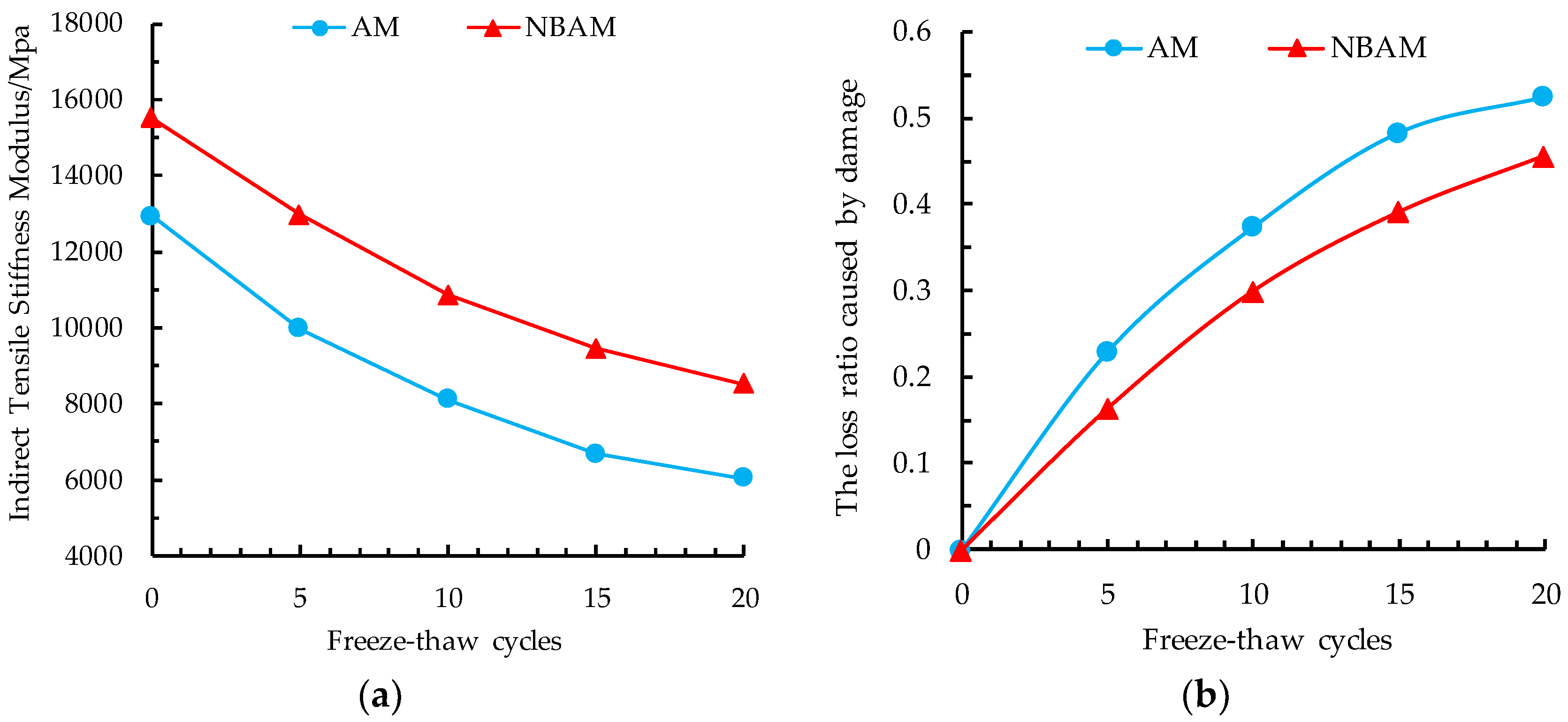

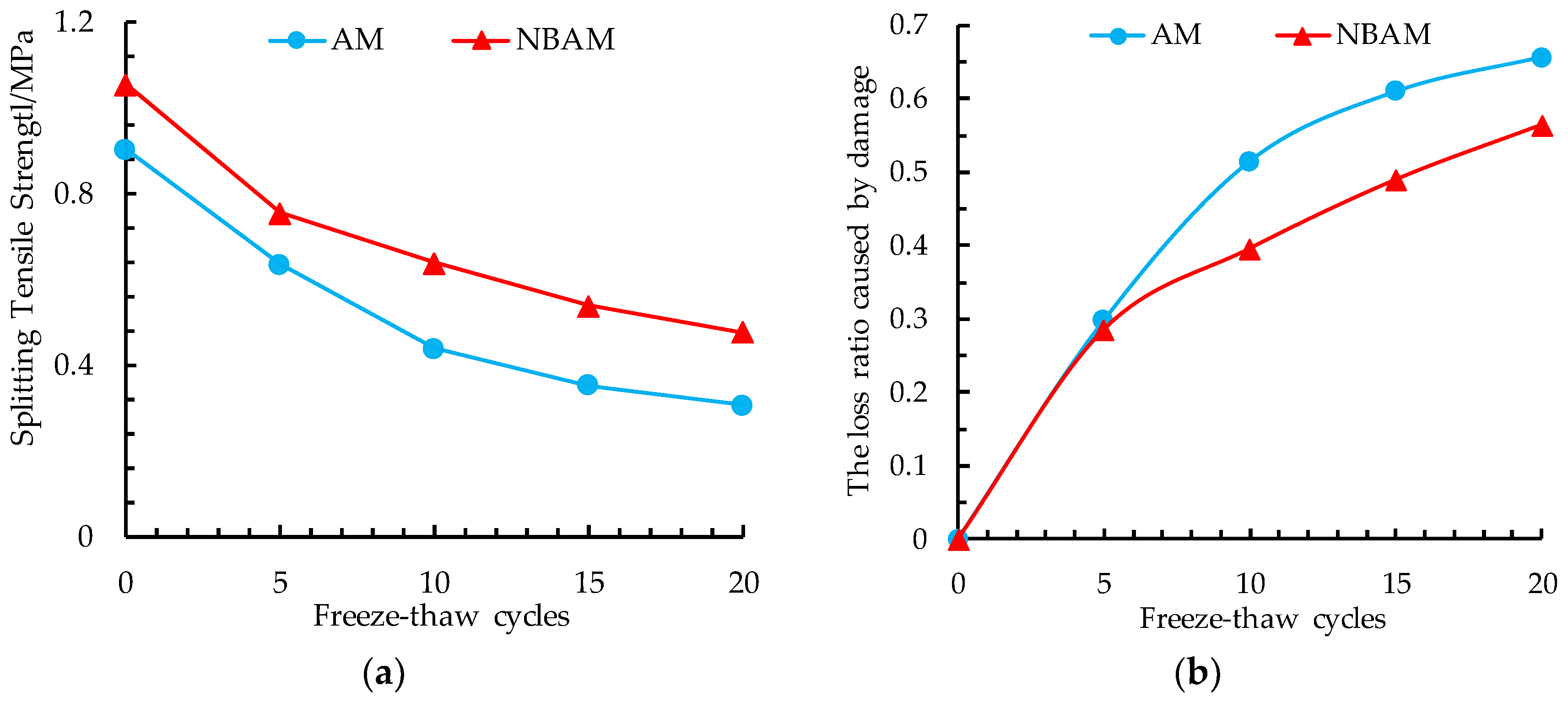

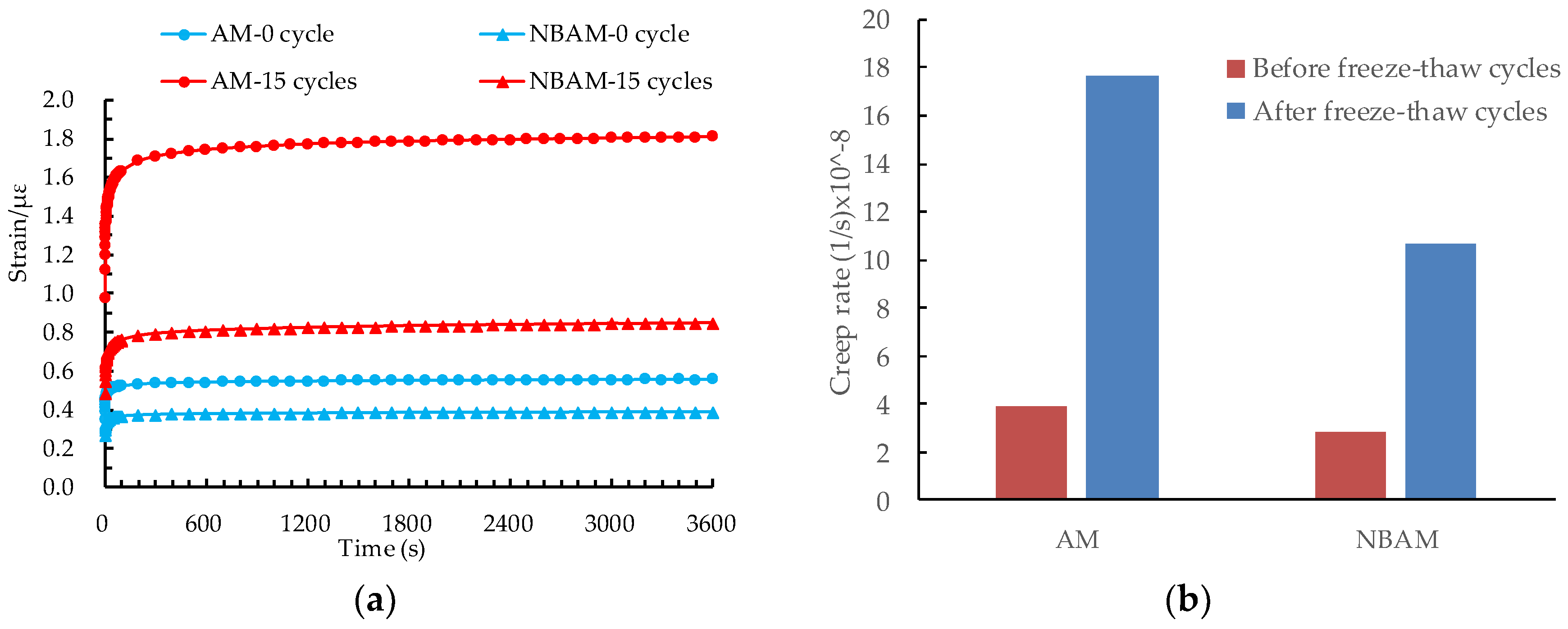

In this paper, in order to evaluate whether the freeze‒thaw performance of nano-TiO2/CaCO3 and basalt fiber composite modified asphalt mixture meets the climate requirements of seasonal frozen area, various physical and mechanical properties under freeze‒thaw cycles were studied. Two kinds of asphalt mixtures, matrix asphalt mixture (AM) and nano-TiO2/CaCO3 and basalt fiber composite modified asphalt mixture (NBAM), were prepared with the best oil‒stone ratio. The freeze‒thaw cycles test was carried out. The degradation and damage mechanism of physical and mechanical properties for different asphalt mixtures were analyzed. The improvements on mechanical properties of nano-TiO2/CaCO3 and basalt fiber composite modified asphalt mixture after freeze‒thaw cycle were studied.

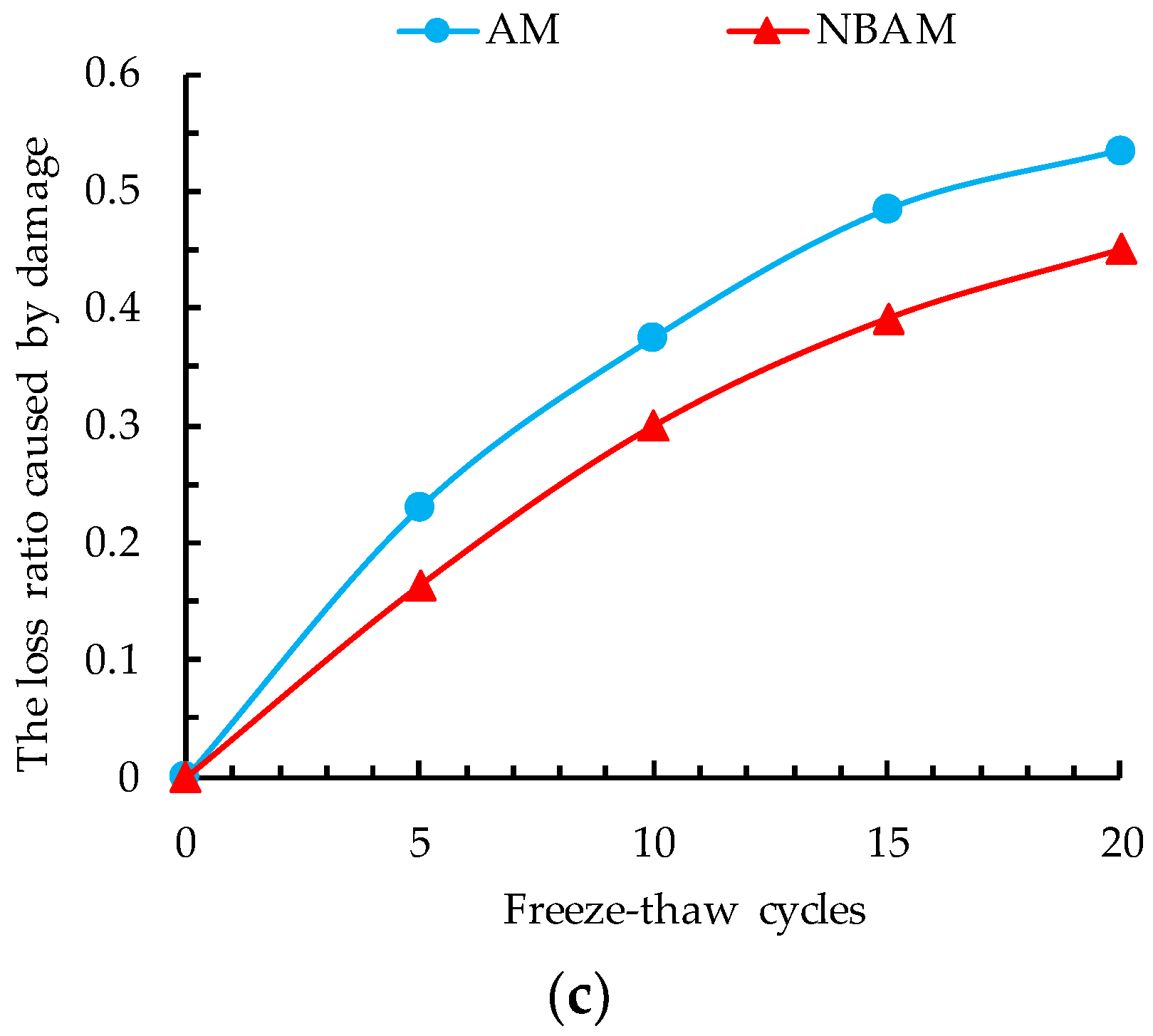

4. Analysis of Damage Model of Asphalt Mixture Based on Grey Theory

The existed methods for damage prediction model of asphalt mixture after the freeze‒thaw cycles mainly included: BP neural network method, support vector machine method, probability statistics and grey theory. The gray theory GM (1, N) model was a widely used prediction model [

51,

52,

53]. It required less useful information and had higher prediction accuracy. In this study, the interaction between various properties of asphalt mixture and freeze‒thaw damage was considered. The equal-pitch gray prediction model GM (1, 3) was used to predict the freeze‒thaw damage of asphalt mixture.

The establishment of the GM (1, N) model is described in the literature [

51], and the final results are shown in Equations (5) and (6):

In this study, GM (1, 3) prediction model was established with matlab program according to the reference [

51]. The freeze‒thaw data were fitted respectively, the stability, splitting tensile strength damage and stiffness modulus damage of asphalt mixture after freeze‒thaw damage were taken as

sequence,

sequence and

sequence. The asphalt mixture specimens were tested and the prediction model was established after 0, 5, 10, 15 freeze‒thaw cycles. The prediction was conducted based on 20 times GM (1, 3) model. Because the grey theory model conducted iterative prediction based on the previous data, this study selected the 15th measured data for derivation. The 20th prediction results were compared with actual data and the prediction accuracy was analyzed. Prediction damage and error are shown in

Table 7.

Table 7 indicated that the relative errors between the calculated results and experimental results were less than 15%. Comparing the predicted results of GM (1, 3) model for each performance index, it can be concluded that the predicted results of splitting tensile strength were the best and its absolute values were all small. The prediction result of indirect tensile modulus was better, while the prediction result of stability had a certain error. However, all were less than 15%. Therefore, the established GM (1, 3) gray prediction model could better predict the stability, indirect tensile stiffness modulus and splitting tensile strength of asphalt mixture under freeze‒thaw cycles.

The prediction curves of the loss ratio caused by freeze‒thaw damage of stability, splitting tensile strength and stiffness modulus of four asphalt mixtures with GM (1, 3) model are shown in

Figure 13.