A Review in Fault Diagnosis and Health Assessment for Railway Traction Drives

Abstract

1. Introduction

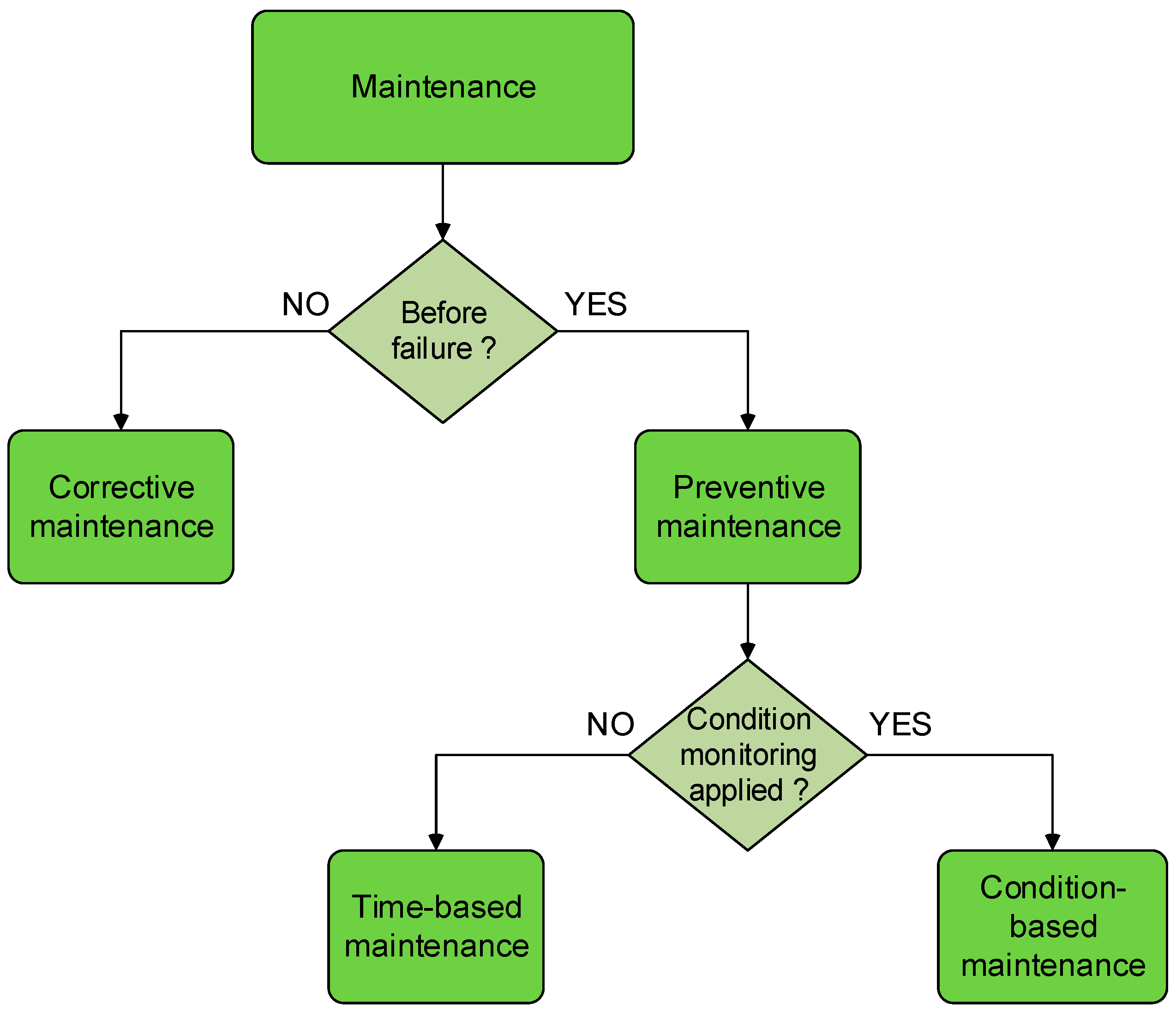

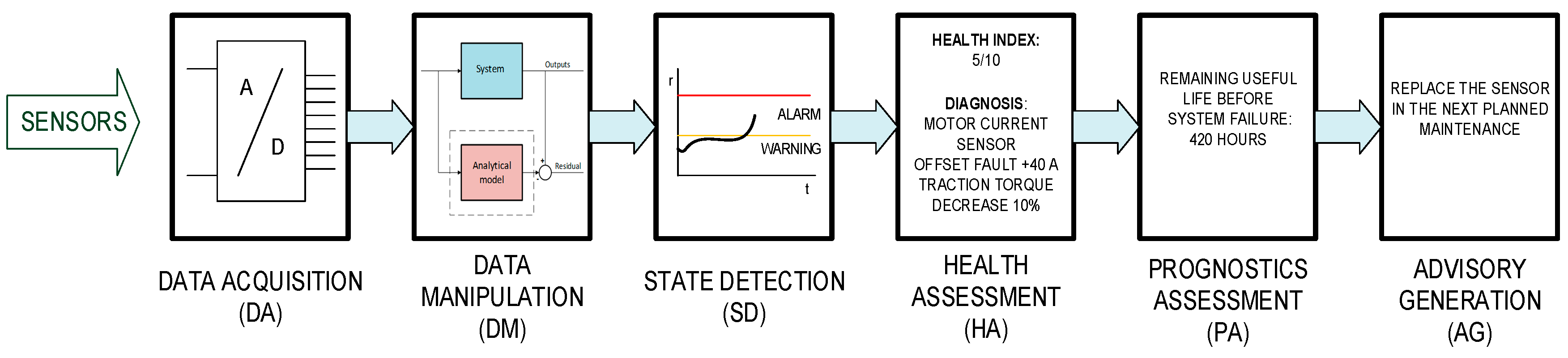

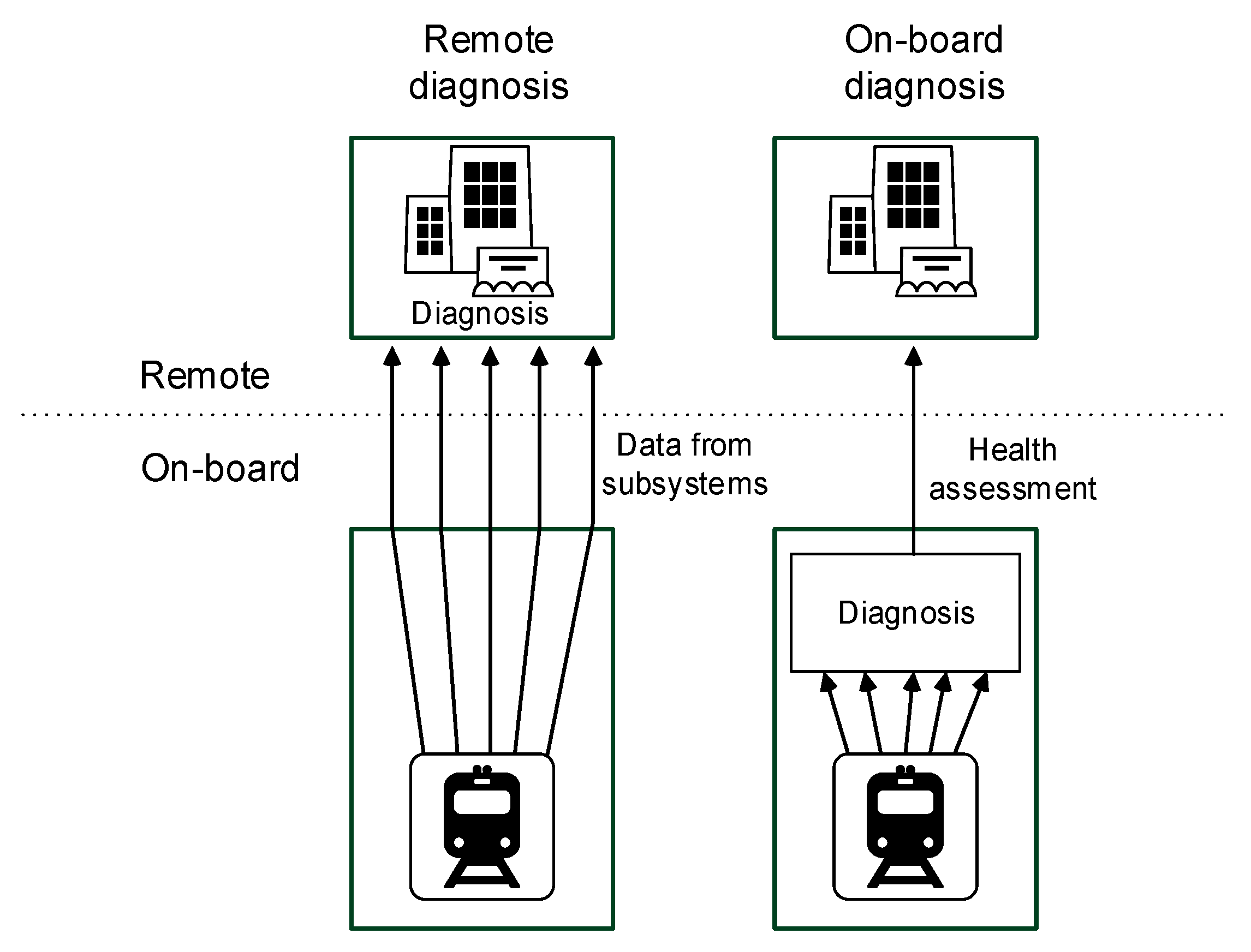

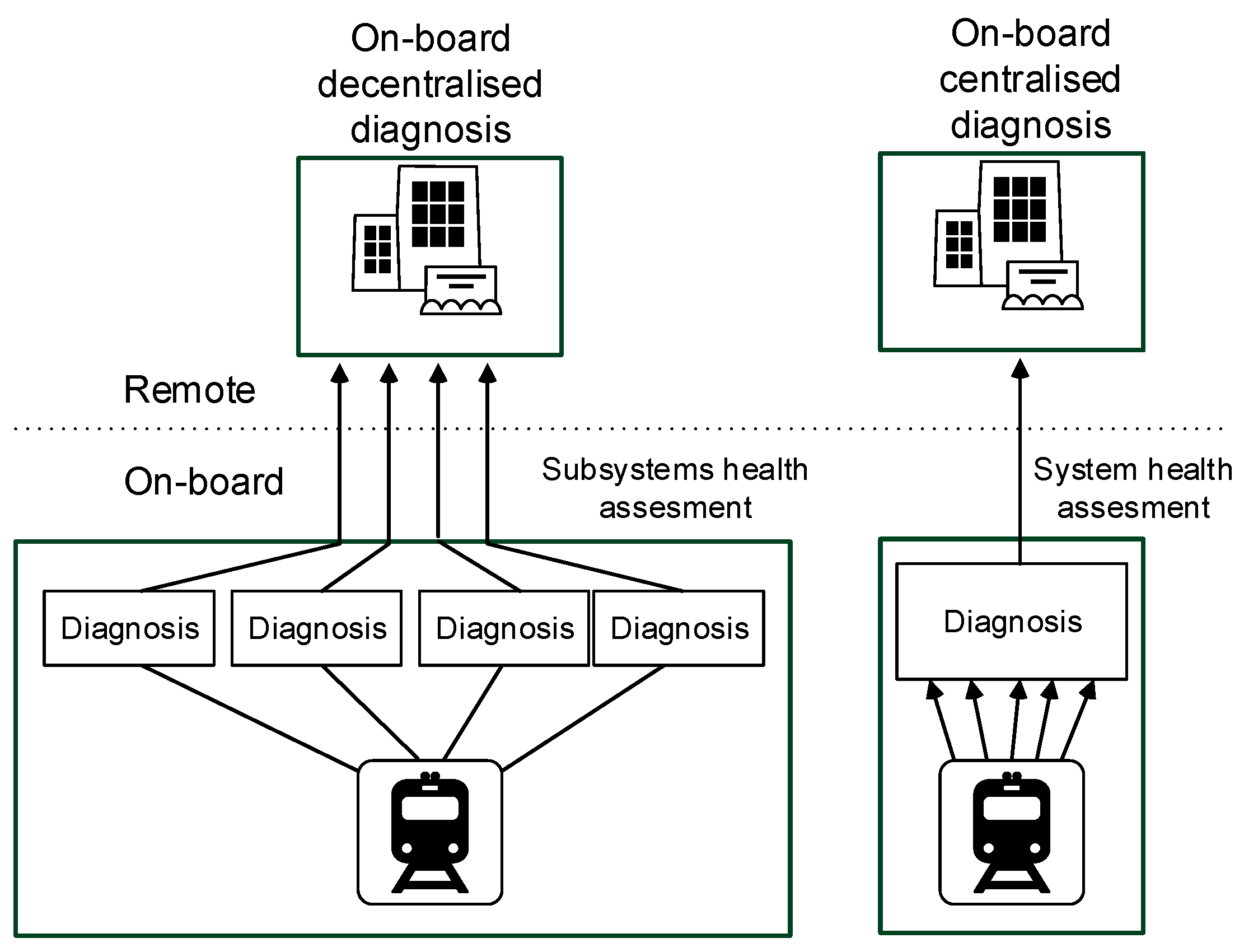

2. Condition-Based Maintenance in Railway Systems

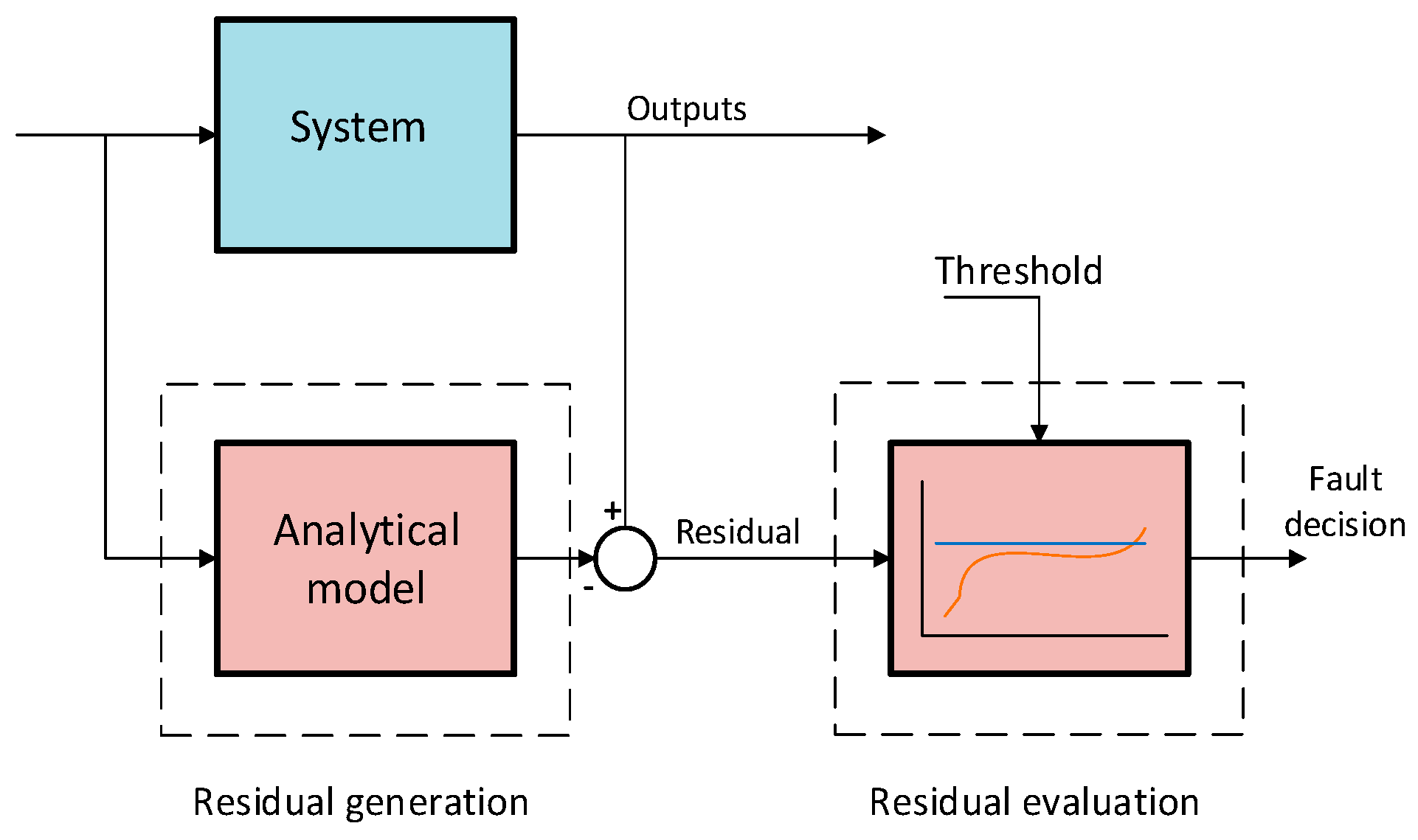

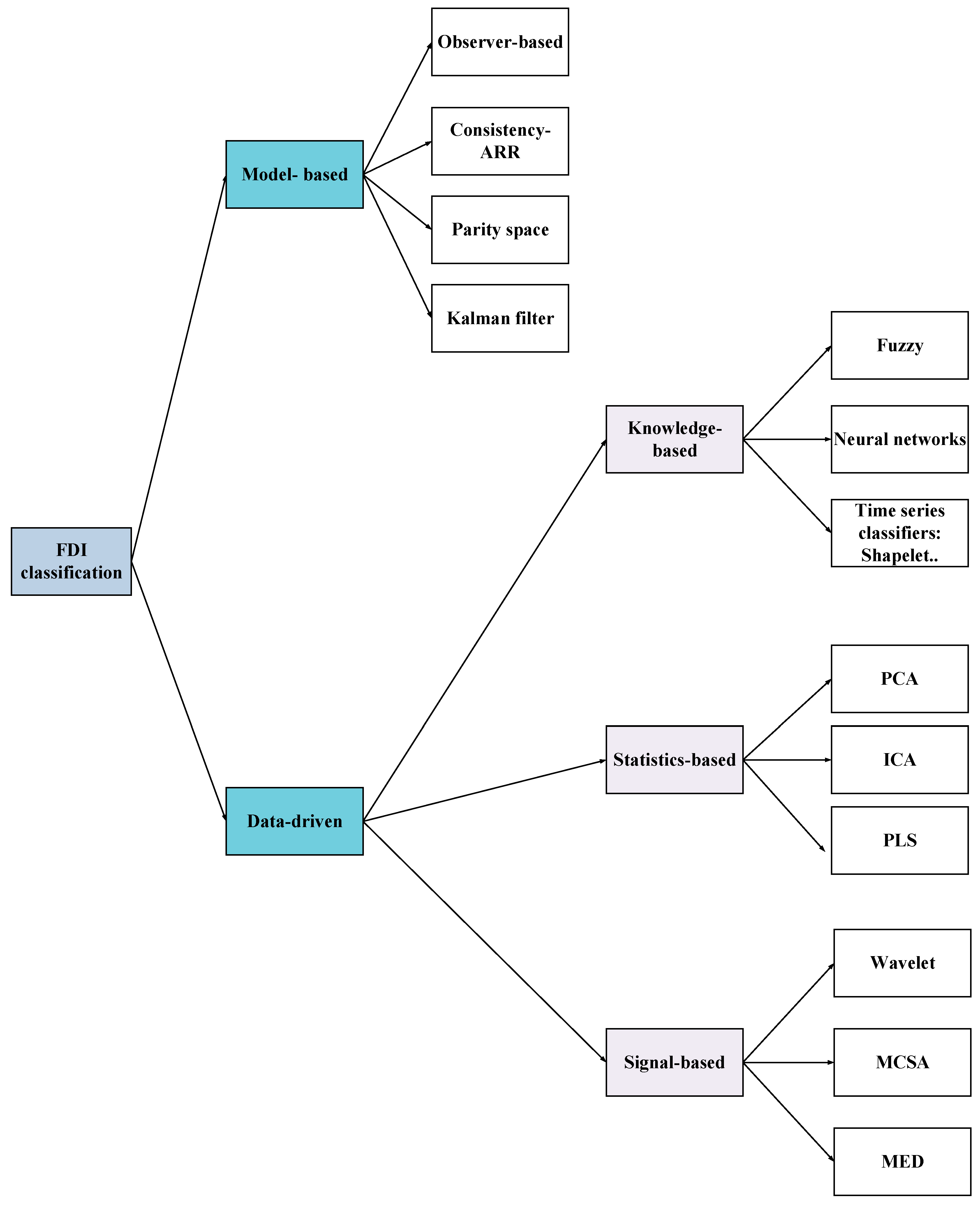

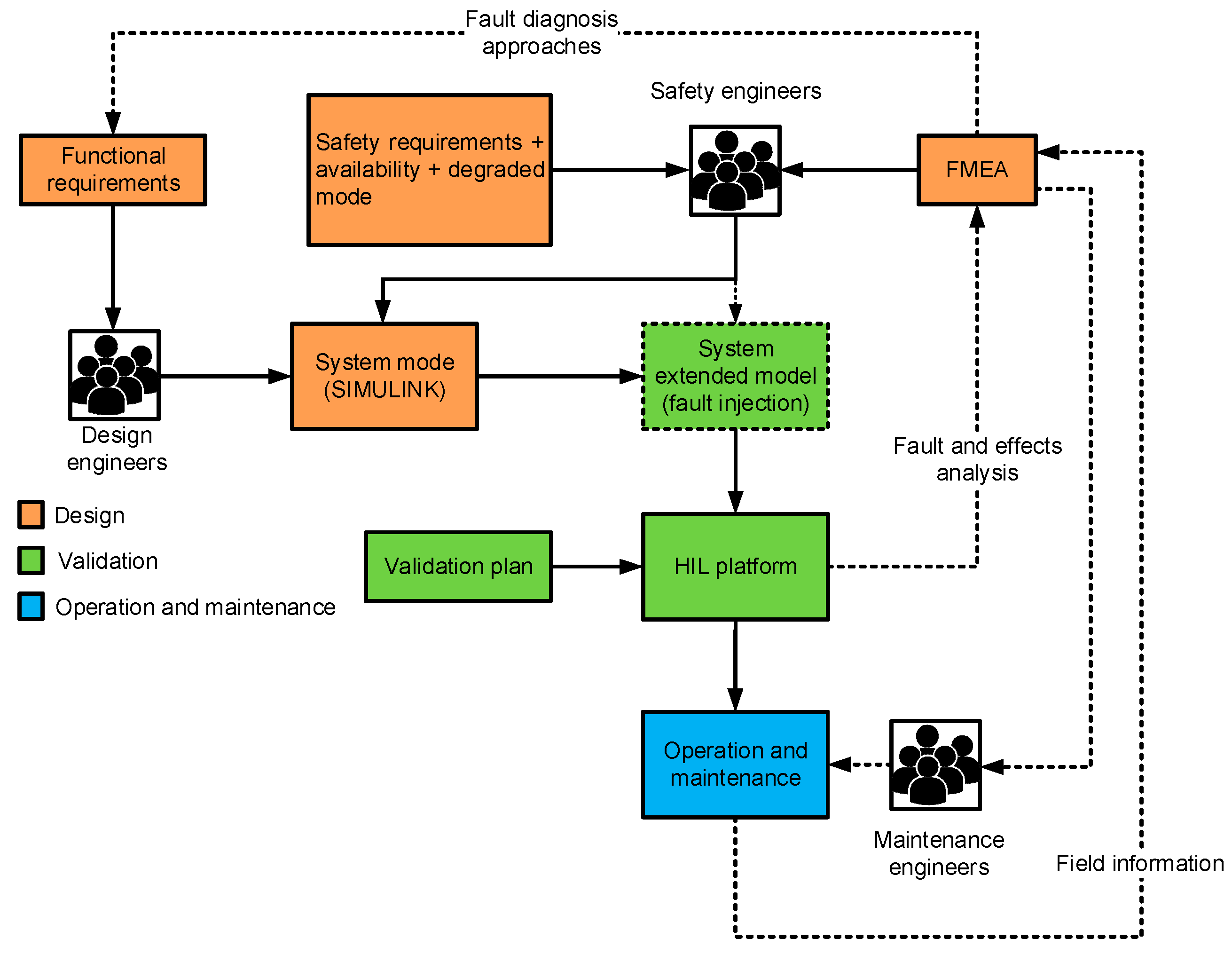

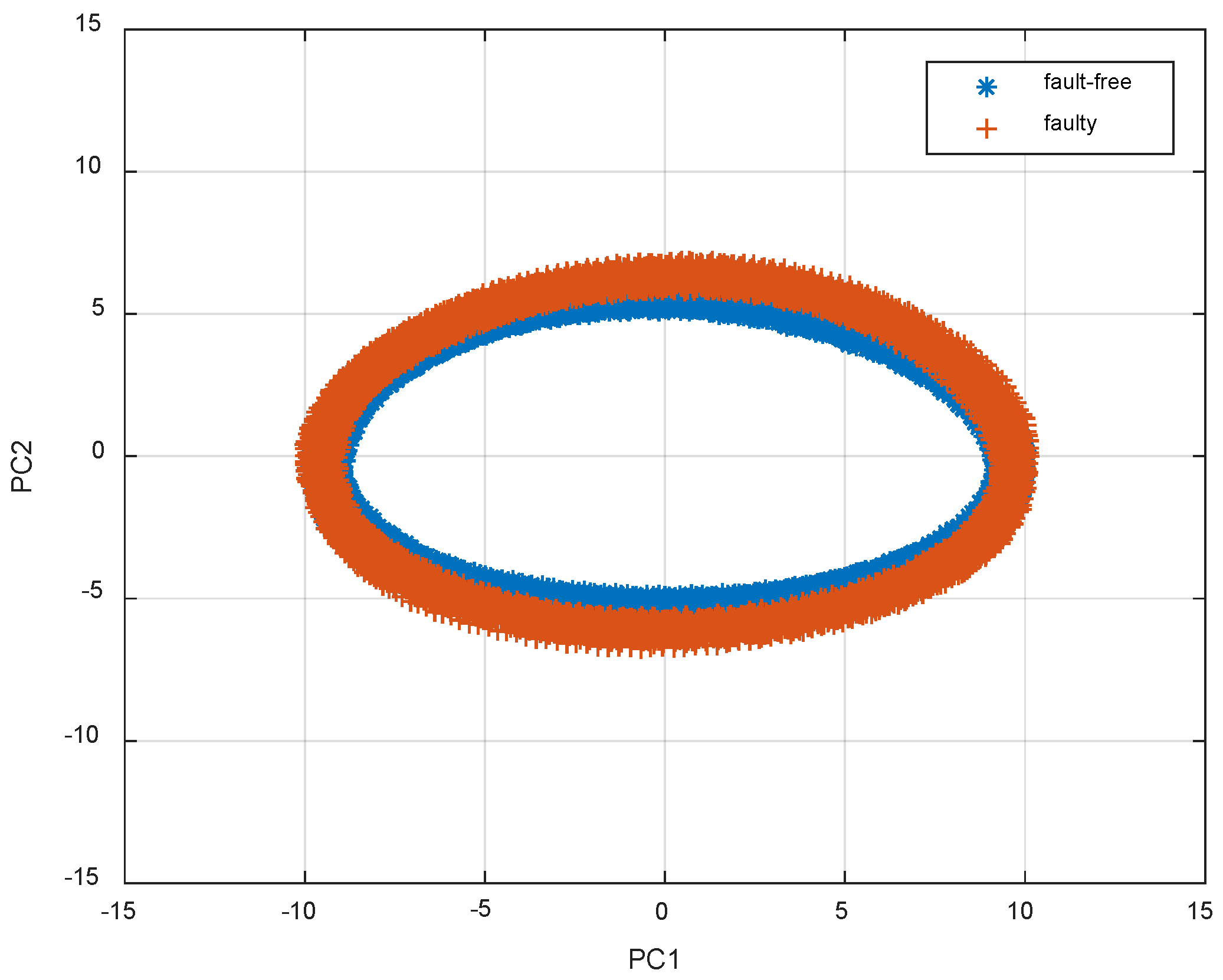

3. Fault Diagnosis in Railway Systems

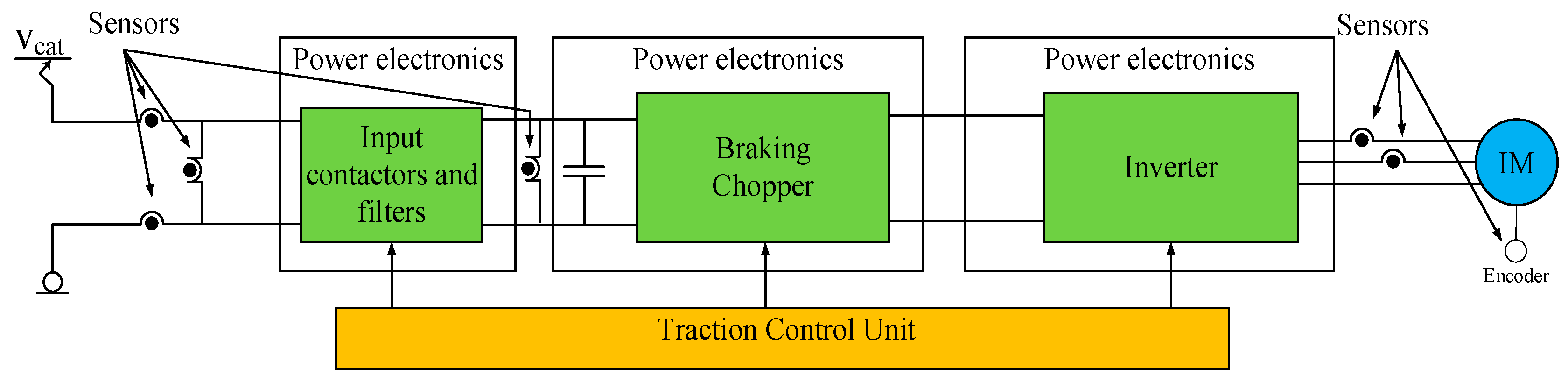

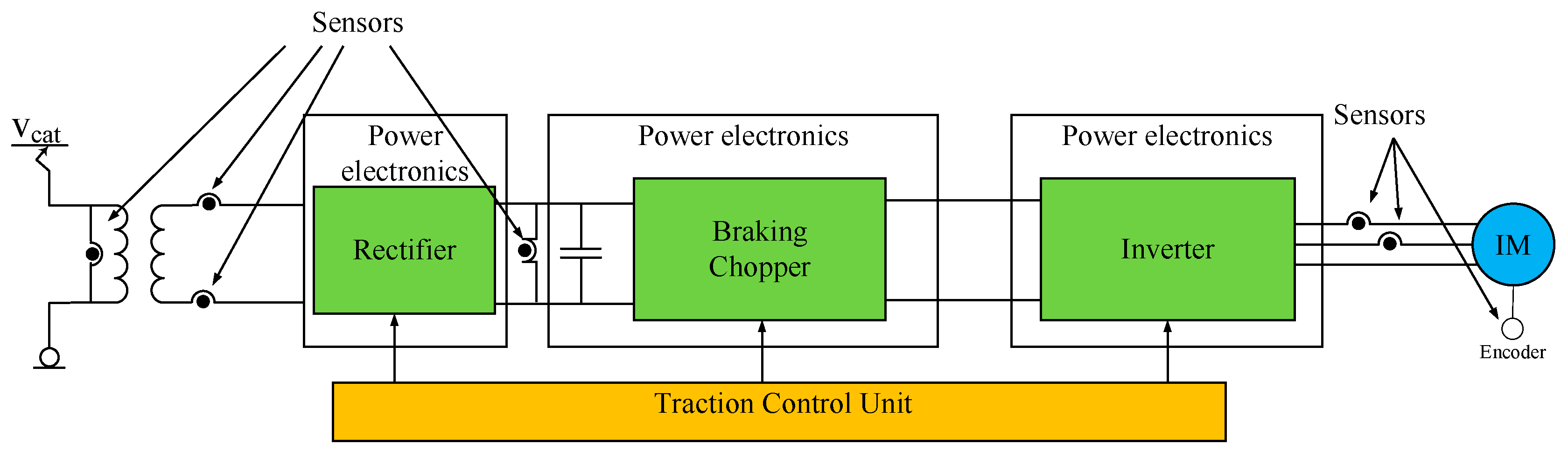

4. Fault Diagnosis in Railway Traction Drives

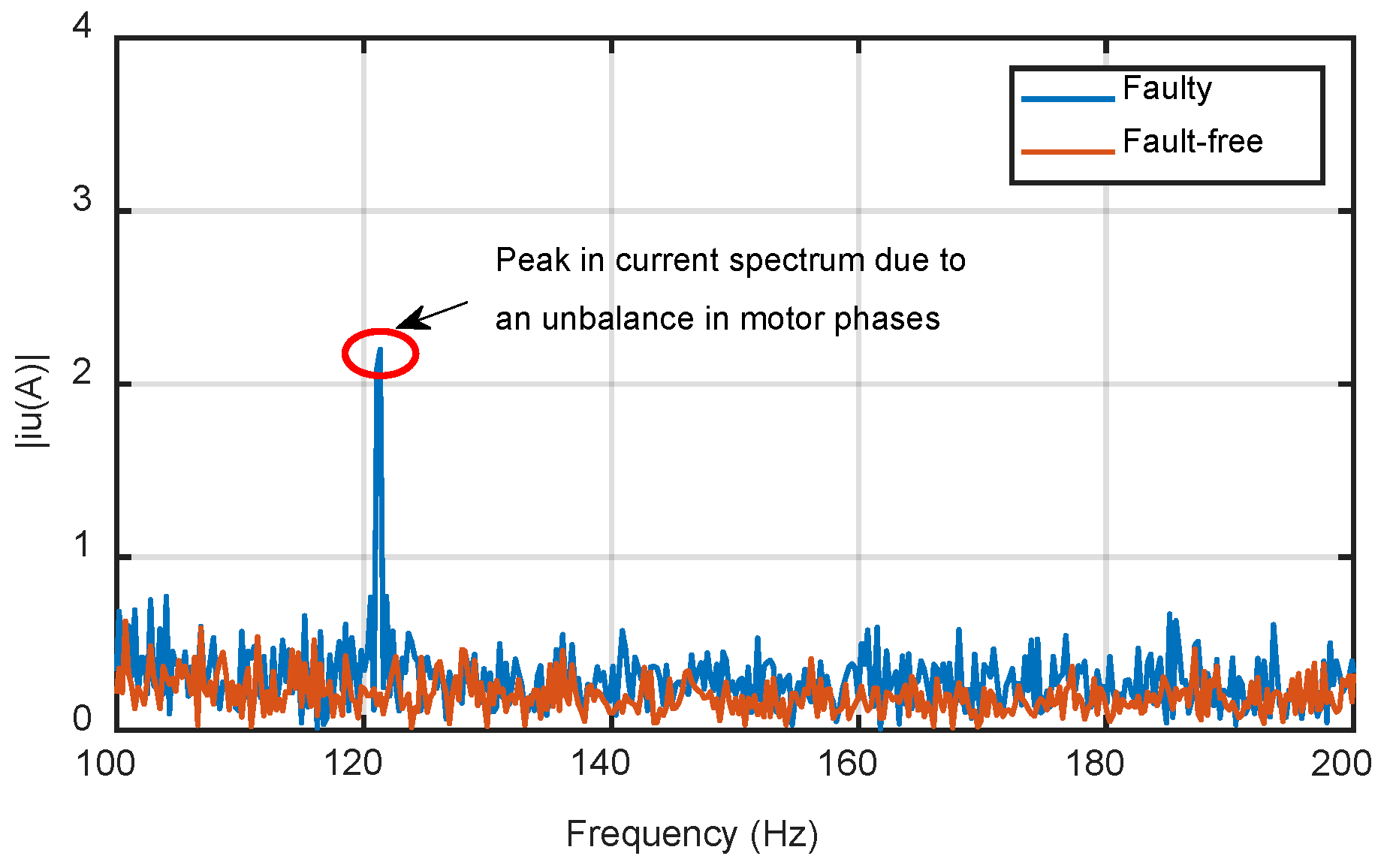

4.1. Fault Diagnosis in Electric Machines

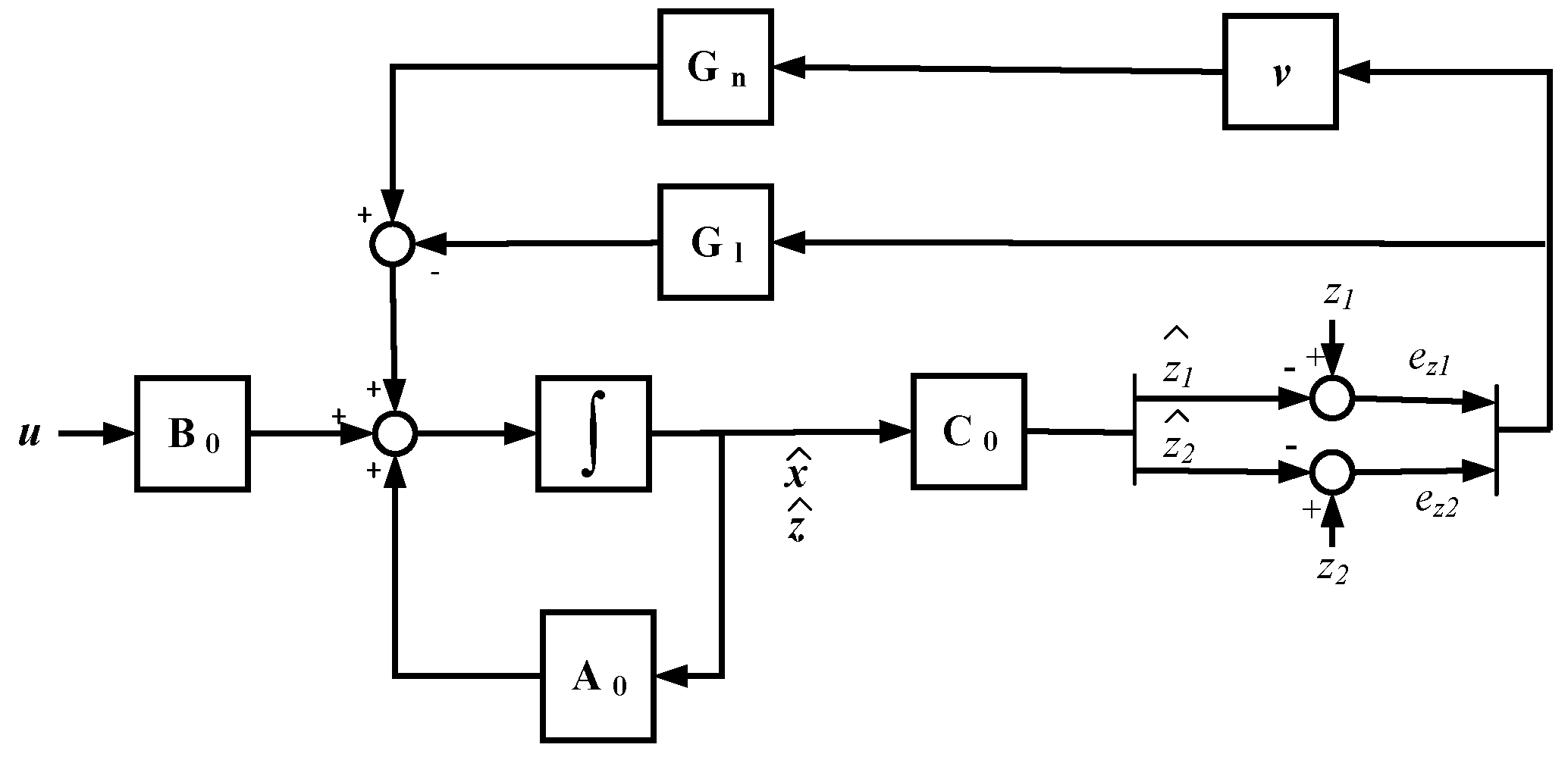

4.2. Fault Diagnosis in Sensors

4.3. Fault Diagnosis in Power Electronics

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahmad, R.; Kamaruddin, S. An overview of time-based and condition-based maintenance in industrial application. Comput. Ind. Eng. 2012, 63, 135–149. [Google Scholar] [CrossRef]

- ISO. ISO 13374-1:2003 Condition Monitoring and Diagnostics of Machines—Data Processing, Communication and Presentation—Part 1: General Guidelines; ISO: Geneva, Switzerland, 2003. [Google Scholar]

- Gouriveau, R.; Medjaher, K.; Zerhouni, N. From Prognostics and Health Systems Management to Predictive Maintenance 1; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; ISBN 9781119371052. [Google Scholar]

- Djeziri, M.A.; Benmoussa, S.; Sanchez, R. Hybrid method for remaining useful life prediction in wind turbine systems. Renew. Energy 2018, 116, 173–187. [Google Scholar] [CrossRef]

- Yin, S.; Ding, S.X.; Xie, X.; Luo, H. A Review on Basic Data-Driven Approaches for Industrial Process Monitoring. IEEE Trans. Ind. Electron. 2014, 61, 6418–6428. [Google Scholar] [CrossRef]

- Khorasgani, H.; Jung, D.; Biswas, G. Structural Approach for Distributed Fault Detection and Isolation. IFAC-PapersOnLine 2015, 48, 72–77. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques—Part I: Fault Diagnosis With Model-Based and Signal-Based Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Ding, S. Model-Based Fault Diagnosis Techniques; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-76303-1. [Google Scholar]

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control 2016, 42, 63–81. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, S.; Kim, Y.; Eng, C. A Survey of Fault Detection, Isolation, and Reconfiguration Methods. IEEE Trans. Control Syst. Technol. 2010, 18, 636–653. [Google Scholar] [CrossRef]

- Wang, H.; Chai, T.-Y.; Ding, J.-L.; Brown, M. Data Driven Fault Diagnosis and Fault Tolerant Control: Some Advances and Possible New Directions. Acta Autom. Sin. 2009, 35, 739–747. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Djeziri, M.A.; Bouamama, B.O.; Merzouki, R. Bond Graph Modelling of Engineering Systems; Borutzky, W., Ed.; Springer: New York, NY, USA, 2011; ISBN 978-1-4419-9367-0. [Google Scholar]

- Triki-Lahiani, A.; Bennani-Ben Abdelghani, A.; Slama-Belkhodja, I. Fault detection and monitoring systems for photovoltaic installations: A review. Renew. Sustain. Energy Rev. 2018, 82, 2680–2692. [Google Scholar] [CrossRef]

- Yang, Z.; Chai, Y. A survey of fault diagnosis for onshore grid-connected converter in wind energy conversion systems. Renew. Sustain. Energy Rev. 2016, 66, 345–359. [Google Scholar] [CrossRef]

- Marzat, J.; Piet-Lahanier, H.; Damongeot, F.; Walter, E. Model-based fault diagnosis for aerospace systems: A survey. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2012, 226, 1329–1360. [Google Scholar] [CrossRef]

- Li, C.; Luo, S.; Cole, C.; Spiryagin, M. An overview: Modern techniques for railway vehicle on-board health monitoring systems. Veh. Syst. Dyn. 2017, 55, 1045–1070. [Google Scholar] [CrossRef]

- Feng, D.; Lin, S.; He, Z.; Sun, X. A technical framework of PHM and active maintenance for modern high-speed railway traction power supply systems. Int. J. Rail Transp. 2017, 5, 145–169. [Google Scholar] [CrossRef]

- Kia, S.H.; Henao, H.; Capolino, G.-A. Mechanical health assessment of a railway traction system. In Proceedings of the MELECON 2008—The 14th IEEE Mediterranean Electrotechnical Conference, Ajaccio, France, 5–8 May 2008; pp. 453–458. [Google Scholar]

- Sa, J.; Choi, Y.; Chung, Y.; Kim, H.-Y.; Park, D.; Yoon, S. Replacement Condition Detection of Railway Point Machines Using an Electric Current Sensor. Sensors 2017, 17, 263. [Google Scholar] [CrossRef]

- Feng, J.; Xu, J.; Liao, W.; Liu, Y. Review on the Traction System Sensor Technology of a Rail Transit Train. Sensors 2017, 17, 1356. [Google Scholar] [CrossRef]

- Yu, X.; Jiang, J. A survey of fault-tolerant controllers based on safety-related issues. Annu. Rev. Control 2015, 39, 46–57. [Google Scholar] [CrossRef]

- Capolino, G.-A.; Antonino-Daviu, J.A.; Riera-Guasp, M. Modern Diagnostics Techniques for Electrical Machines, Power Electronics, and Drives. IEEE Trans. Ind. Electron. 2015, 62, 1738–1745. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, Y.; Wang, B.; Huang, X.; Xu, D.G. Current Sensor Fault Diagnosis and Tolerant Control for VSI-Based Induction Motor Drives. IEEE Trans. Power Electron. 2017, PP, 1. [Google Scholar] [CrossRef]

- Najafabadi, T.A.; Salmasi, F.R.; Jabehdar-Maralani, P. Detection and isolation of speed-, DC-link voltage-, and current-sensor faults based on an adaptive observer in induction-motor drives. IEEE Trans. Ind. Electron. 2011, 58, 1662–1672. [Google Scholar] [CrossRef]

- Bourogaoui, M.; Sethom, H.B.A.; Belkhodja, I.S. Speed/position sensor fault tolerant control in adjustable speed drives—A review. ISA Trans. 2016, 64, 269–284. [Google Scholar] [CrossRef] [PubMed]

- Poon, J.; Jain, P.; Konstantakopoulos, I.C.; Spanos, C.; Panda, S.K.; Sanders, S.R. Model-Based Fault Detection and Identification for Switching Power Converters. IEEE Trans. Power Electron. 2017, 32, 1419–1430. [Google Scholar] [CrossRef]

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O. State of the Art and Trends in the Monitoring, Detection and Diagnosis of Failures in Electric Induction Motors. Energies 2017, 10, 1056. [Google Scholar] [CrossRef]

- Liu, Y.; Bazzi, A.M. A review and comparison of fault detection and diagnosis methods for squirrel-cage induction motors: State of the art. ISA Trans. 2017, 70, 400–409. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Capolino, G.-A. Advances in Electrical Machine, Power Electronic, and Drive Condition Monitoring and Fault Detection: State of the Art. IEEE Trans. Ind. Electron. 2015, 62, 1746–1759. [Google Scholar] [CrossRef]

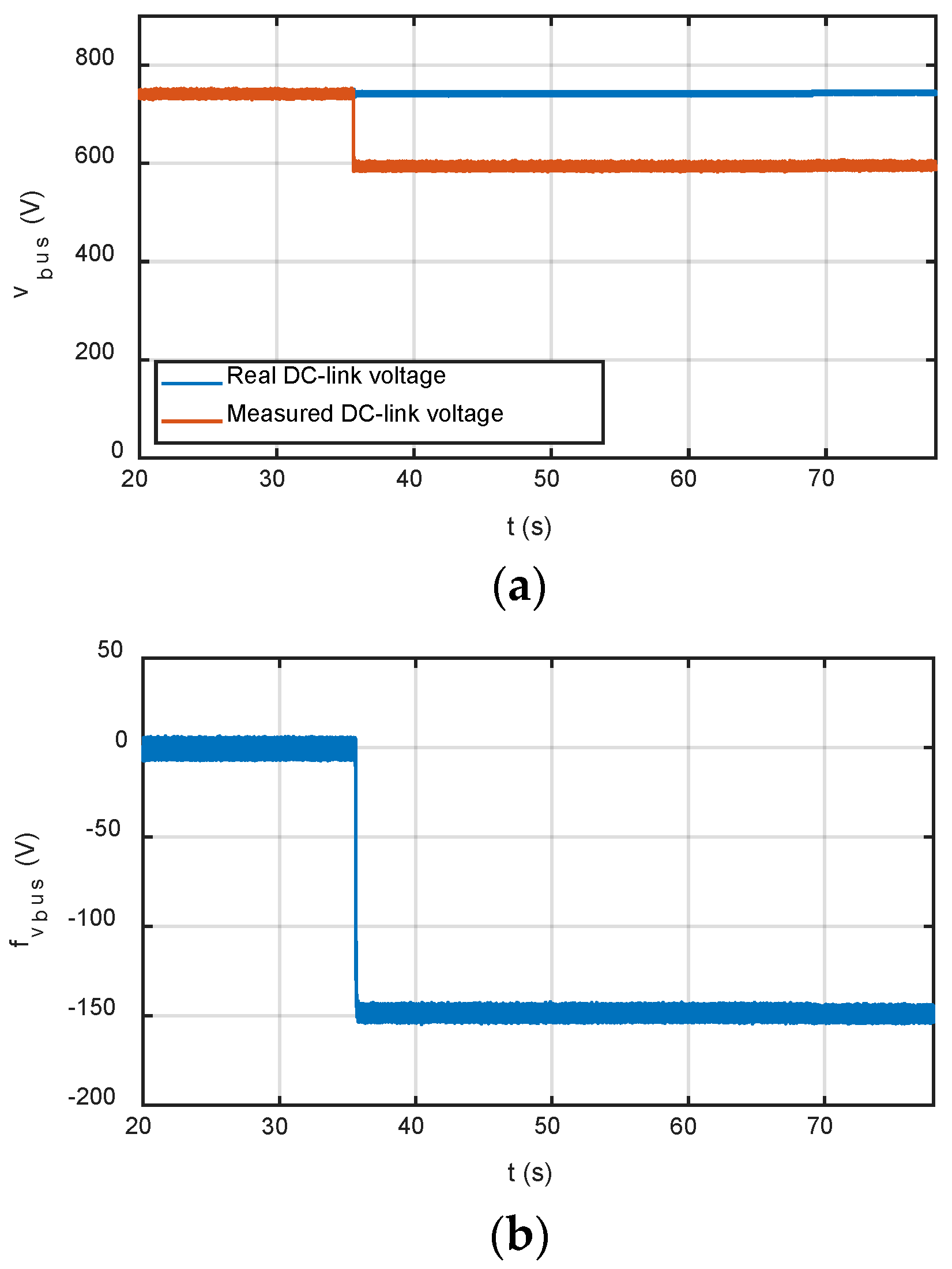

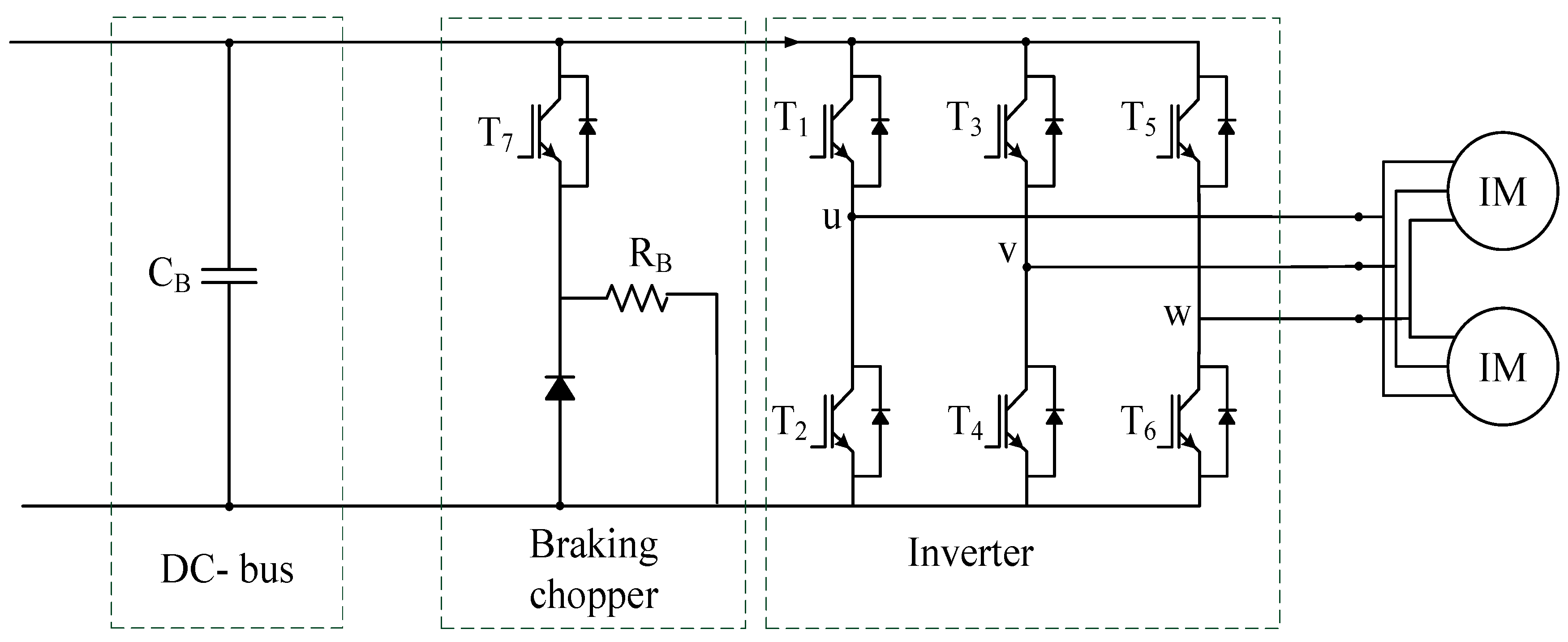

- Garramiola, F.; del Olmo, J.; Poza, J.; Madina, P.; Almandoz, G. Integral Sensor Fault Detection and Isolation for Railway Traction Drive. Sensors 2018, 18, 1543. [Google Scholar] [CrossRef] [PubMed]

- Gou, B.; Ge, X.; Wang, S.; Feng, X.; Kuo, J.B.; Habetler, T.G. An Open-Switch Fault Diagnosis Method for Single-Phase PWM Rectifier Using a Model-Based Approach in High-Speed Railway Electrical Traction Drive System. IEEE Trans. Power Electron. 2016, 31, 3816–3826. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, B.; Yan, X.-G.; Mao, Z. Incipient Voltage Sensor Fault Isolation for Rectifier in Railway Electrical Traction Systems. IEEE Trans. Ind. Electron. 2017, PP, 1. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Alaswad, S.; Xiang, Y. A review on condition-based maintenance optimization models for stochastically deteriorating system. Reliab. Eng. Syst. Saf. 2017, 157, 54–63. [Google Scholar] [CrossRef]

- Olde Keizer, M.C.A.; Flapper, S.D.P.; Teunter, R.H. Condition-based maintenance policies for systems with multiple dependent components: A review. Eur. J. Oper. Res. 2017, 261, 405–420. [Google Scholar] [CrossRef]

- Shin, J.-H.; Jun, H.-B. On condition based maintenance policy. J. Comput. Des. Eng. 2015, 2, 119–127. [Google Scholar] [CrossRef]

- de Jonge, B.; Teunter, R.; Tinga, T. The influence of practical factors on the benefits of condition-based maintenance over time-based maintenance. Reliab. Eng. Syst. Saf. 2017, 158, 21–30. [Google Scholar] [CrossRef]

- Guillén, A.J.; Crespo, A.; Gómez, J.F.; Sanz, M.D. A framework for effective management of condition based maintenance programs in the context of industrial development of E-Maintenance strategies. Comput. Ind. 2016, 82, 170–185. [Google Scholar] [CrossRef]

- Del Olmo, J.; Poza, J.; Garramiola, F.; Nieva, T.; Aldasoro, L. Model driven Hardware-in-the-Loop Fault analysis of railway traction systems. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics (ECMSM), San Sebastian, Spain, 24–26 May 2017; pp. 1–6. [Google Scholar]

- Le Mortellec, A. Proposition d’une Architecture de Surveillance “Active” à base d’agents Intelligents Pour l’aide à la Maintenance de Systèmes Mobiles Application au Domaine Ferroviaire; Université de Valenciennes et du Hainaut-Cambresis: Famars, France, 2014. [Google Scholar]

- Ai, B.; Guan, K.; Rupp, M.; Kurner, T.; Cheng, X.; Yin, X.-F.; Wang, Q.; Ma, G.-Y.; Li, Y.; Xiong, L.; et al. Future railway services-oriented mobile communications network. IEEE Commun. Mag. 2015, 53, 78–85. [Google Scholar] [CrossRef]

- Jiang, X.; Li, G. Research on Fault Prognostics and Health Management of the on-Board Equipment of CTCS-3 Train Control System. Int. J. Secur. Appl. 2016, 10, 175–186. [Google Scholar] [CrossRef]

- Ciocoiu, L.; Siemieniuch, C.E.; Hubbard, E.-M. From preventative to predictive maintenance: The organisational challenge. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 231, 1174–1185. [Google Scholar] [CrossRef]

- Yokoyama, A. Innovative Changes for Maintenance of Railway by Using ICT–To Achieve “Smart Maintenance”. Procedia CIRP 2015, 38, 24–29. [Google Scholar] [CrossRef]

- Shift2Rail. Available online: https://shift2rail.org/ (accessed on 29 November 2018).

- Yang, C.; Yang, C.; Peng, T.; Yang, X.; Weihua, G. A Fault-Injection Strategy for Traction Drive Control Systems. IEEE Trans. Ind. Electron. 2017, PP, 1. [Google Scholar] [CrossRef]

- del Olmo, J.; Garramiola, F.; Poza, J.; Almandoz, G. Model-Based Fault Analysis for Railway Traction Systems. In Modern Railway Engineering; Hessami, A., Ed.; InTech: Rijeka, Croatia, 2018; ISBN 978-953-51-3860-0. [Google Scholar]

- Yang, X.; Yang, C.; Peng, T.; Chen, Z.; Liu, B.; Gui, W. Hardware-in-the-Loop Fault Injection for Traction Control System. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 696–706. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Castedo, L. Towards the Internet of Smart Trains: A Review on Industrial IoT-Connected Railways. Sensors 2017, 17, 1457. [Google Scholar] [CrossRef] [PubMed]

- Atamuradov, V.; Medjaher, K.; Dersin, P.; Lamoureux, B.; Zerhouni, N. Prognostics and Health Management for Maintenance Practitioners -Review, Implementation and Tools Evaluation. Int. J. Progn. Heal. Manag. 2017, 2153–2648. [Google Scholar]

- Karakose, M.; Yaman, O.; Murat, K.; Akin, E. A New Approach for Condition Monitoring and Detection of Rail Components and Rail Track in Railway. Int. J. Comput. Intell. Syst. 2018, 11, 830–845. [Google Scholar] [CrossRef]

- Wu, Y.; Qin, Y.; Wang, Z.; Jia, L. A UAV-Based Visual Inspection Method for Rail Surface Defects. Appl. Sci. 2018, 8, 1028. [Google Scholar] [CrossRef]

- Wei, J.; Liu, C.; Ren, T.; Liu, H.; Zhou, W. Online Condition Monitoring of a Rail Fastening System on High-Speed Railways Based on Wavelet Packet Analysis. Sensors 2017, 17, 318. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.X.; Yan, R. Wavelets; Springer: Boston, MA, USA, 2011; ISBN 978-1-4419-1544-3. [Google Scholar]

- Gómez, M.; Corral, E.; Castejón, C.; García-Prada, J. Effective Crack Detection in Railway Axles Using Vibration Signals and WPT Energy. Sensors 2018, 18, 1603. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhou, N.; Zhang, W.; Wang, Z. Application of an improved minimum entropy deconvolution method for railway rolling element bearing fault diagnosis. J. Sound Vib. 2018, 425, 53–69. [Google Scholar] [CrossRef]

- Espinosa, F.; García, J.J.; Hernández, A.; Mazo, M.; Ureña, J.; Jiménez, J.A.; Fernández, I.; Pérez, C.; García, J.C. Advanced monitoring of rail breakage in double-track railway lines by means of PCA techniques. Appl. Soft Comput. 2018, 63, 1–13. [Google Scholar] [CrossRef]

- Chen, Z. Data-Driven Fault Detection for Industrial Processes; Springer: Wiesbaden, Germany, 2017; ISBN 978-3-658-16755-4. [Google Scholar]

- Dai, C.; Huang, K.; Hu, K.; Liu, Z. Fault diagnosis approach of traction transformers in high-speed railway combining kernel principal component analysis with random forest. IET Electr. Syst. Transp. 2016, 6, 202–206. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, K. A Model-Based Diagnosis System for a Traction Power Supply System. IEEE Trans. Ind. Inform. 2017, 13, 2834–2843. [Google Scholar] [CrossRef]

- Mao, Z.; Zhan, Y.; Tao, G.; Jiang, B.; Yan, X.-G. Sensor Fault Detection for Rail Vehicle Suspension Systems With Disturbances and Stochastic Noises. IEEE Trans. Veh. Technol. 2017, 66, 4691–4705. [Google Scholar] [CrossRef]

- Bruzzese, C.; Honorati, O.; Santini, E. Rotor bars breakage in railway traction squirrel cage induction motors and diagnosis by MCSA technique Part I: Accurate fault simulations and spectral analyses. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Vienna, Austria, 7–9 September 2005; pp. 1–6. [Google Scholar]

- Cruz, S.M.A.; Stefani, A.; Filippetti, F.; Cardoso, A.J.M. A New Model-Based Technique for the Diagnosis of Rotor Faults in RFOC Induction Motor Drives. IEEE Trans. Ind. Electron. 2008, 55, 4218–4228. [Google Scholar] [CrossRef]

- Sancho, C.; Gomez-Parra, M.; Munoz-Condes, P.; San Andres, M.A.G.; Gonzalez-Fernandez, F.J.; Carpio, J.; Guirado, R. Advanced Maintenance of Rail Traction Motors Using a Magnetic Leakage Flux Technique. IEEE Trans. Ind. Appl. 2012, 48, 942–951. [Google Scholar] [CrossRef]

- Zoeller, C.; Vogelsberger, M.A.; Fasching, R.; Grubelnik, W.; Wolbank, T.M. Evaluation and Current-Response-Based Identification of Insulation Degradation for High Utilized Electrical Machines in Railway Application. IEEE Trans. Ind. Appl. 2017, 53, 2679–2689. [Google Scholar] [CrossRef]

- Youssef, A.B.; El Khil, S.K.; Slama-Belkhodja, I. State Observer-Based Sensor Fault Detection and Isolation, and Fault Tolerant Control of a Single-Phase PWM Rectifier for Electric Railway Traction. IEEE Trans. Power Electron. 2013, 28, 5842–5853. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, B.; Yan, X.-G.; Mao, Z. Incipient sensor fault estimation and accommodation for inverter devices in electric railway traction systems. Int. J. Adapt. Control Signal Process. 2017, 31, 785–804. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, B.; Yan, X.-G.; Mao, Z. Sliding mode observer based incipient sensor fault detection with application to high-speed railway traction device. ISA Trans. 2016, 63, 49–59. [Google Scholar] [CrossRef]

- Xia, J.; Guo, Y.; Dai, B.; Zhang, X. Sensor Fault Diagnosis and System Reconfiguration Approach for Electric Traction PWM Rectifier Based on Sliding Mode Observer. IEEE Trans. Ind. Appl. 2017, PP, 1. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; del Olmo, J.; Madina, P.; Almandoz, G. DC-Link Voltage and Catenary Current Sensors Fault Reconstruction for Railway Traction Drives. Sensors 2018, 18, 1998. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, B.; Shi, P. Incipient fault diagnosis for T–S fuzzy systems with application to high-speed railway traction devices. IET Control Theory Appl. 2016, 10, 2286–2297. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, B.; Lu, N.; Yang, H.; Zhou, Y. Multiple incipient sensor faults diagnosis with application to high-speed railway traction devices. ISA Trans. 2017, 67, 183–192. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Lu, N.; Chen, W. Real-time incipient fault detection for electrical traction systems of CRH2. Neurocomputing 2018, 306, 119–129. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Chen, W.; Yi, H. Data-driven Detection and Diagnosis of Incipient Faults in Electrical Drives of High-Speed Trains. IEEE Trans. Ind. Electron. 2018, 1. [Google Scholar] [CrossRef]

- Xie, D.; Ge, X. Open-circuit fault diagnosis for single-phase cascaded H-bridge rectifiers in electrical traction systems. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–6. [Google Scholar]

- Hu, K.; Liu, Z.; Lin, S. Wavelet Entropy-Based Traction Inverter Open Switch Fault Diagnosis in High-Speed Railways. Entropy 2016, 18, 78. [Google Scholar] [CrossRef]

- Fei, M.; Ning, L.; Huiyu, M.; Yi, P.; Haoyuan, S.; Jianyong, Z. On-line fault diagnosis model for locomotive traction inverter based on wavelet transform and support vector machine. Microelectron. Reliab. 2018, 88–90, 1274–1280. [Google Scholar] [CrossRef]

- Tian, Z.; Ge, X. An on-line fault diagnostic method based on frequency-domain analysis for IGBTs in traction PWM rectifiers. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 3403–3407. [Google Scholar]

- Perpiñà, X.; Serviere, J.F.; Jordà, X.; Fauquet, A.; Hidalgo, S.; Urresti-Ibañez, J.; Rebollo, J.; Mermet-Guyennet, M. IGBT module failure analysis in railway applications. Microelectron. Reliab. 2008, 48, 1427–1431. [Google Scholar] [CrossRef]

- Buiatti, G.M.; Martin-Ramos, J.A.; Amaral, A.M.R.; Dworakowski, P.; Cardoso, A. Condition Monitoring of Metallized Polypropylene Film Capacitors in Railway Power Trains. IEEE Trans. Instrum. Meas. 2009, 58, 3796–3805. [Google Scholar] [CrossRef]

- Torrent, M.; Perat, J.; Jiménez, J. Permanent Magnet Synchronous Motor with Different Rotor Structures for Traction Motor in High Speed Trains. Energies 2018, 11, 1549. [Google Scholar] [CrossRef]

- Bonnett, A.; Yung, C. Increased Efficiency Versus Increased Reliability. IEEE Ind. Appl. Mag. 2008, 14, 29–36. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Tassoni, C.; Capolino, G.-A. Advances in Diagnostic Techniques for Induction Machines. IEEE Trans. Ind. Electron. 2008, 55, 4109–4126. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Diagnosis of the three-phase induction motor using thermal imaging. Infrared Phys. Technol. 2017, 81, 7–16. [Google Scholar] [CrossRef]

- Maraaba, L.; Al-Hamouz, Z.; Abido, M. An Efficient Stator Inter-Turn Fault Diagnosis Tool for Induction Motors. Energies 2018, 11, 653. [Google Scholar] [CrossRef]

- Morinigo-Sotelo, D.; Romero-Troncoso, R.D.J.; Panagiotou, P.A.; Antonino-Daviu, J.A.; Gyftakis, K.N. Reliable Detection of Rotor Bars Breakage in Induction Motors via MUSIC and ZSC. IEEE Trans. Ind. Appl. 2018, 54, 1224–1234. [Google Scholar] [CrossRef]

- Balaban, E.; Saxena, A.; Bansal, P.; Goebel, K.F.; Curran, S. Modeling, Detection, and Disambiguation of Sensor Faults for Aerospace Applications. IEEE Sens. J. 2009, 9, 1907–1917. [Google Scholar] [CrossRef]

- Ronanki, D.; Singh, S.A.; Williamson, S.S. Comprehensive Topological Overview of Rolling Stock Architectures and Recent Trends in Electric Railway Traction Systems. IEEE Trans. Transp. Electrif. 2017, 3, 724–738. [Google Scholar] [CrossRef]

- Fusco, L.; Pagano, M. An approach to design a prognostic based maintenance strategy for railway power converter unit. In Proceedings of the 2015 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles (ESARS), Aachen, Germany, 3–5 March 2015; Volume 2015, pp. 1–6. [Google Scholar]

- Choi, U.M.; Blaabjerg, F.; Lee, K.B. Study and Handling Methods of Power IGBT Module Failures in Power Electronic Converter Systems. IEEE Trans. Power Electron. 2015, 30, 2517–2533. [Google Scholar] [CrossRef]

- Wang, H.; Blaabjerg, F. Reliability of Capacitors for DC-Link Applications in Power Electronic Converters—An Overview. IEEE Trans. Ind. Appl. 2014, 50, 3569–3578. [Google Scholar] [CrossRef]

| Company | Supervision System |

|---|---|

| CAF | sDiag, COSMOS |

| Bombardier | ORBIFLO, AIMS |

| Siemens | Railigent |

| Alstom | TrainTracer, HealthHub |

| FDI Approach | Reference | Electric Machine | Sensors | Power Electronics |

|---|---|---|---|---|

| MCSA | [63] | Rotor bars | ||

| VCT | [64] | Rotor bars | ||

| Flux FFT | [65] | Dirt | ||

| Current transient FFT | [66] | Insulation degradation | ||

| Observer-based | [31,33,67,68,69,70,71] | Voltage and current | ||

| ToMFIR | [72,73] | Speed and current | ||

| PCA, ICA | [74,75] | Voltage, current and speed | ||

| Model-based estimator | [32,76] | Power switches | ||

| Wavelet entropy | [77] | Power switches | ||

| Wavelet energy and SVM | [78] | Power switches | ||

| Current FFT | [79] | Power switches | ||

| Fault signatures analysis | [80] | Power switches | ||

| Least squares | [81] | Capacitor |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garramiola, F.; Poza, J.; Madina, P.; Del Olmo, J.; Almandoz, G. A Review in Fault Diagnosis and Health Assessment for Railway Traction Drives. Appl. Sci. 2018, 8, 2475. https://doi.org/10.3390/app8122475

Garramiola F, Poza J, Madina P, Del Olmo J, Almandoz G. A Review in Fault Diagnosis and Health Assessment for Railway Traction Drives. Applied Sciences. 2018; 8(12):2475. https://doi.org/10.3390/app8122475

Chicago/Turabian StyleGarramiola, Fernando, Javier Poza, Patxi Madina, Jon Del Olmo, and Gaizka Almandoz. 2018. "A Review in Fault Diagnosis and Health Assessment for Railway Traction Drives" Applied Sciences 8, no. 12: 2475. https://doi.org/10.3390/app8122475

APA StyleGarramiola, F., Poza, J., Madina, P., Del Olmo, J., & Almandoz, G. (2018). A Review in Fault Diagnosis and Health Assessment for Railway Traction Drives. Applied Sciences, 8(12), 2475. https://doi.org/10.3390/app8122475