Superior Mechanical Behavior and Fretting Wear Resistance of 3D-Printed Inconel 625 Superalloy

Abstract

1. Introduction

2. Experiments

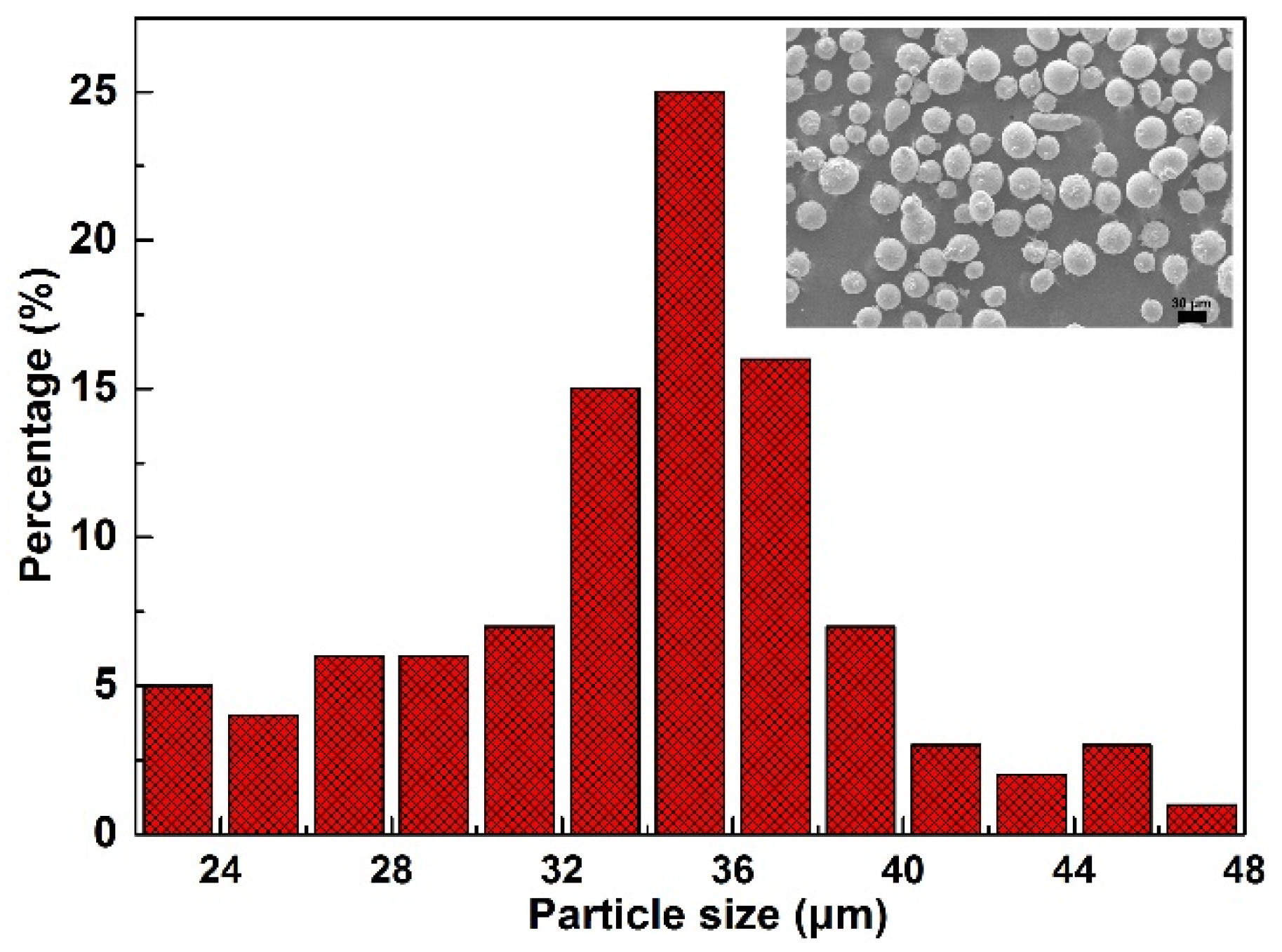

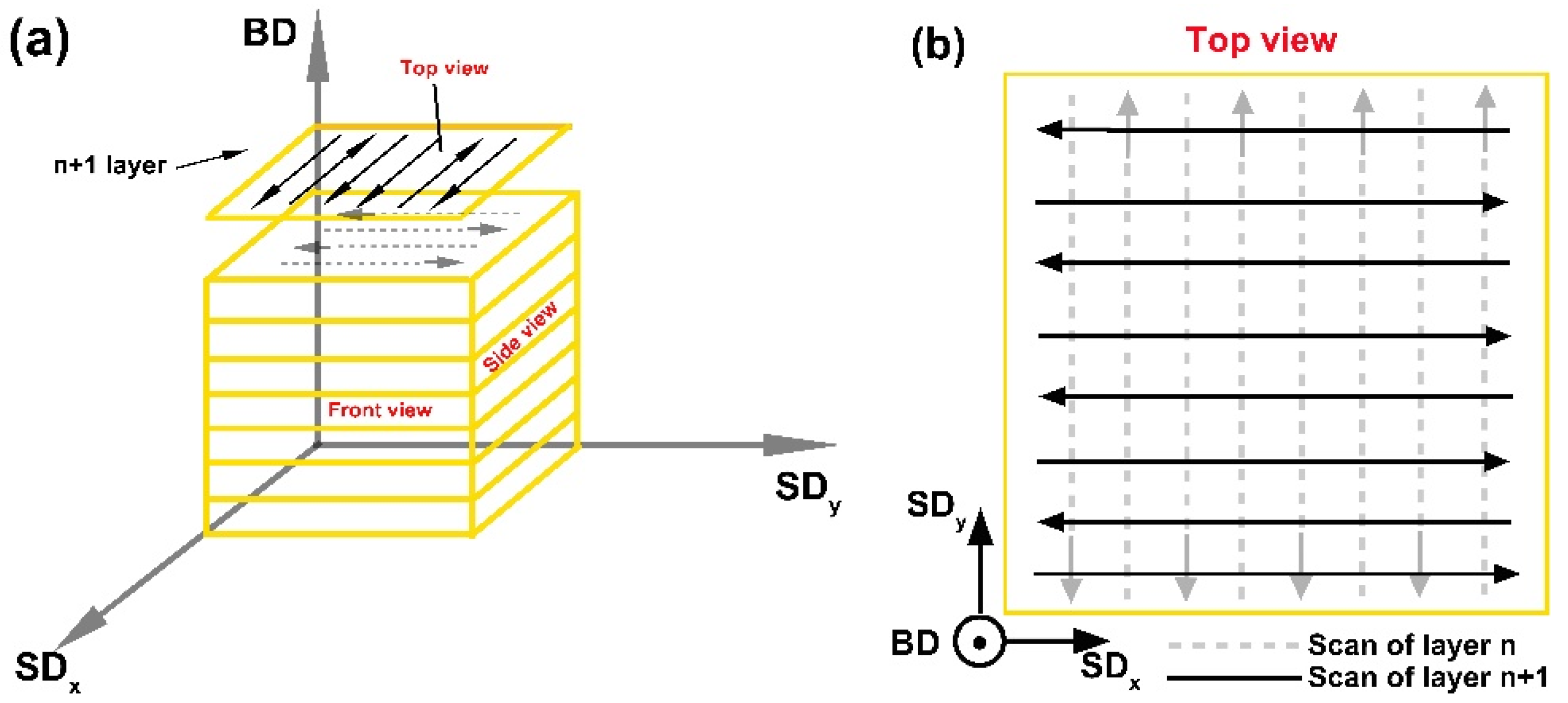

2.1. Material Preparation

2.2. Mechanical and Tribological Tests

2.3. Microstructural Characterization

3. Results and Discussion

3.1. Micro-Hardness and Relative Density

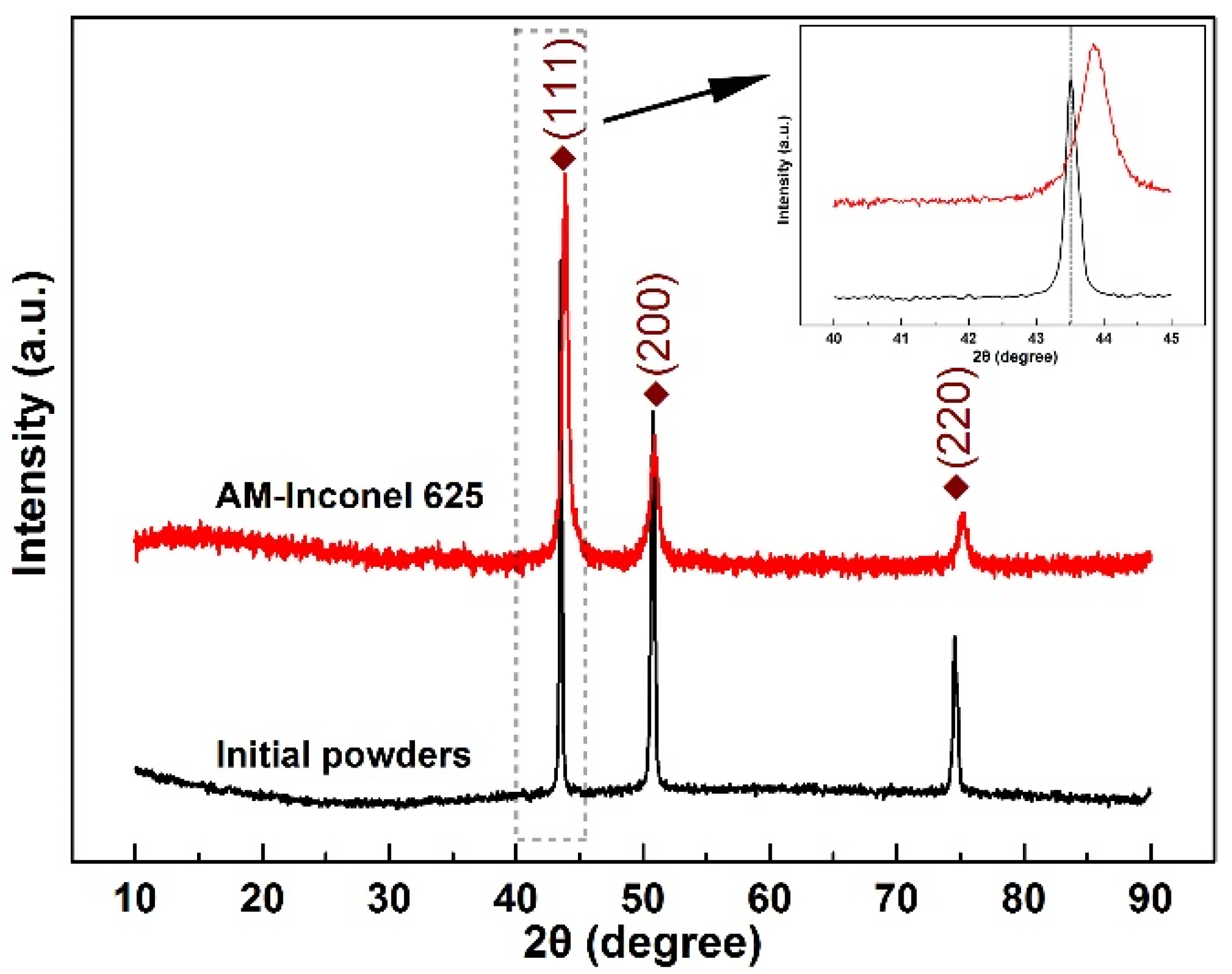

3.2. XRD Analyses

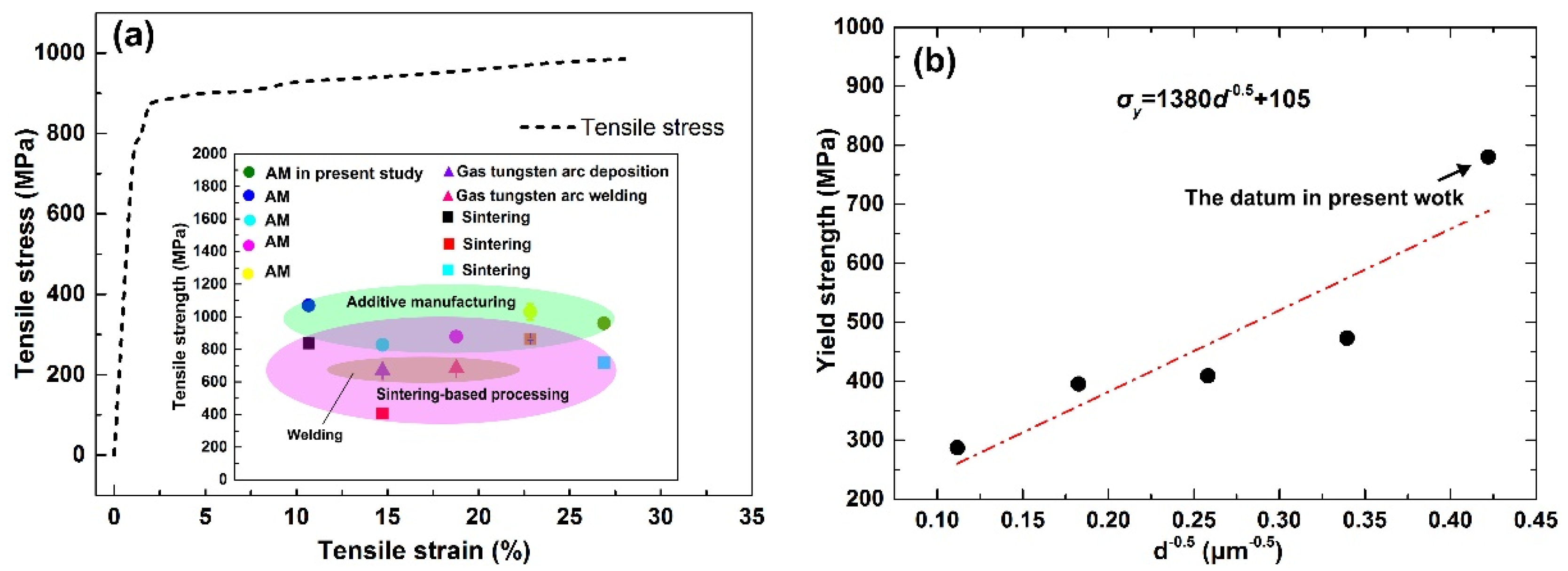

3.3. Tensile Tests

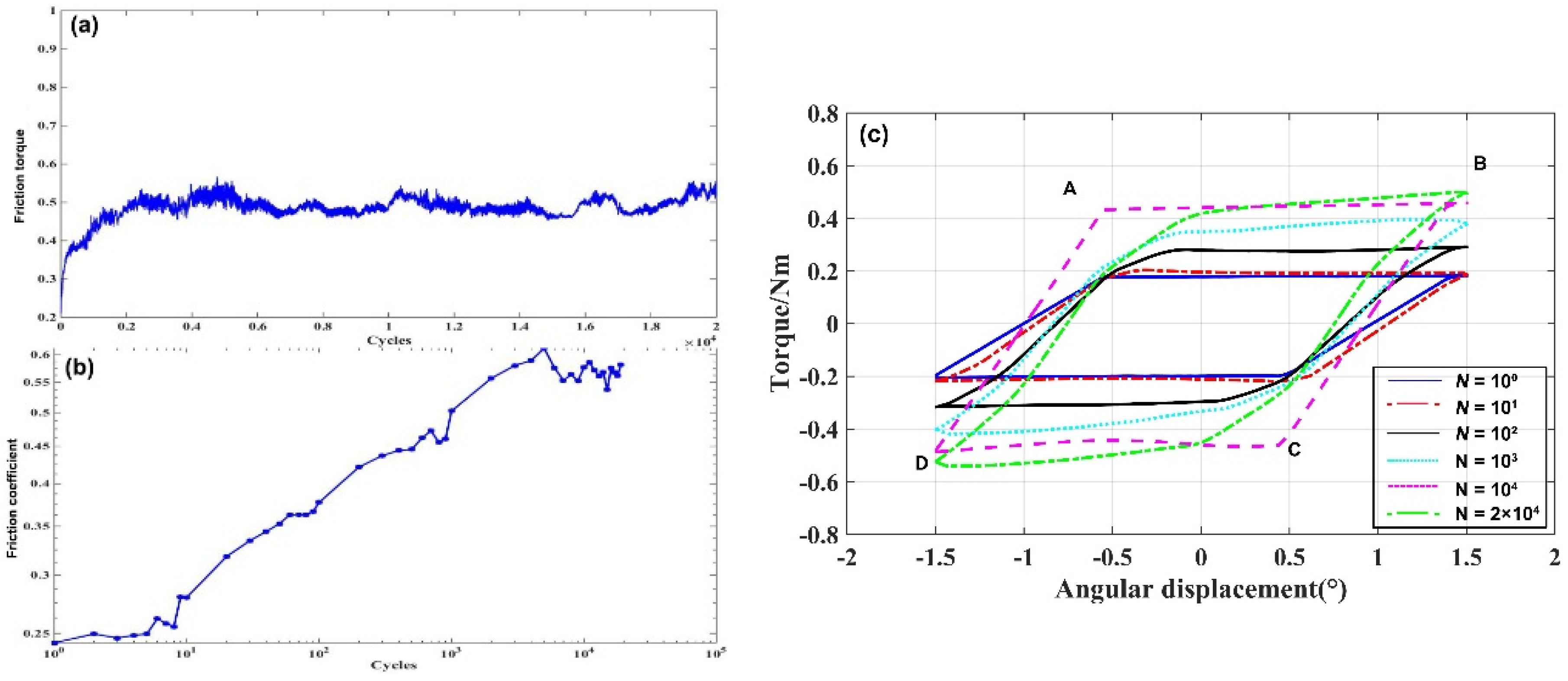

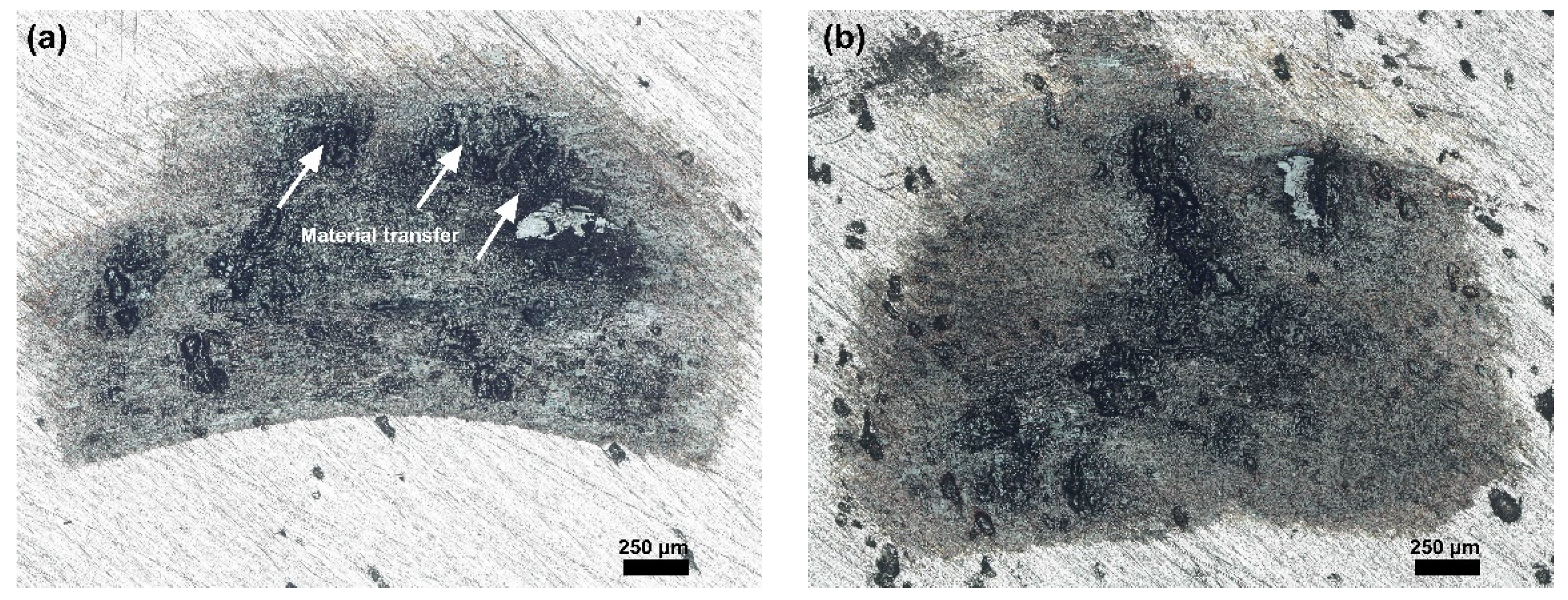

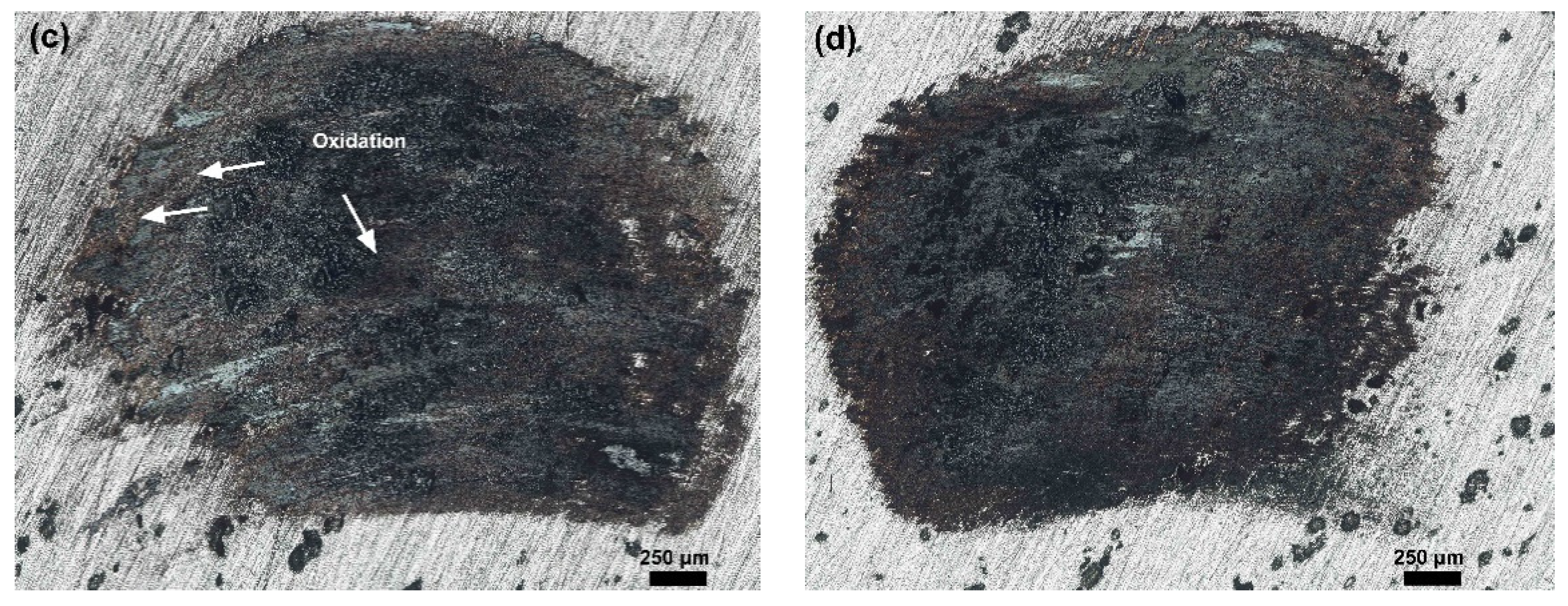

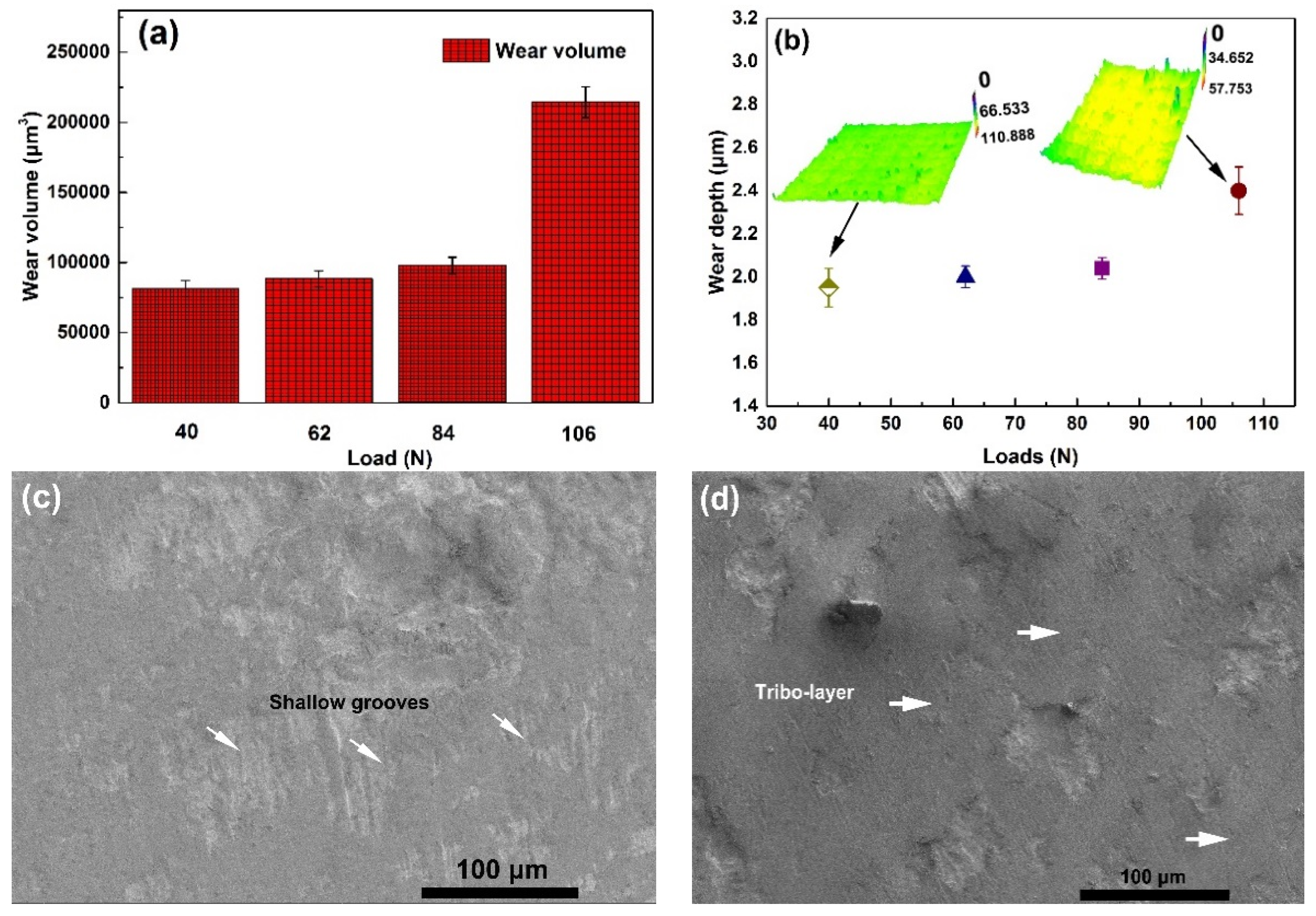

3.4. Tribological Tests

4. Conclusions

- Mechanical test results reveal that the AM-processed Inconel 625 have high hardness value (335 HV), superior tensile strength (952 ± 18 MPa) and yield strength (793 MPa), as well as excellent wear-resistance.

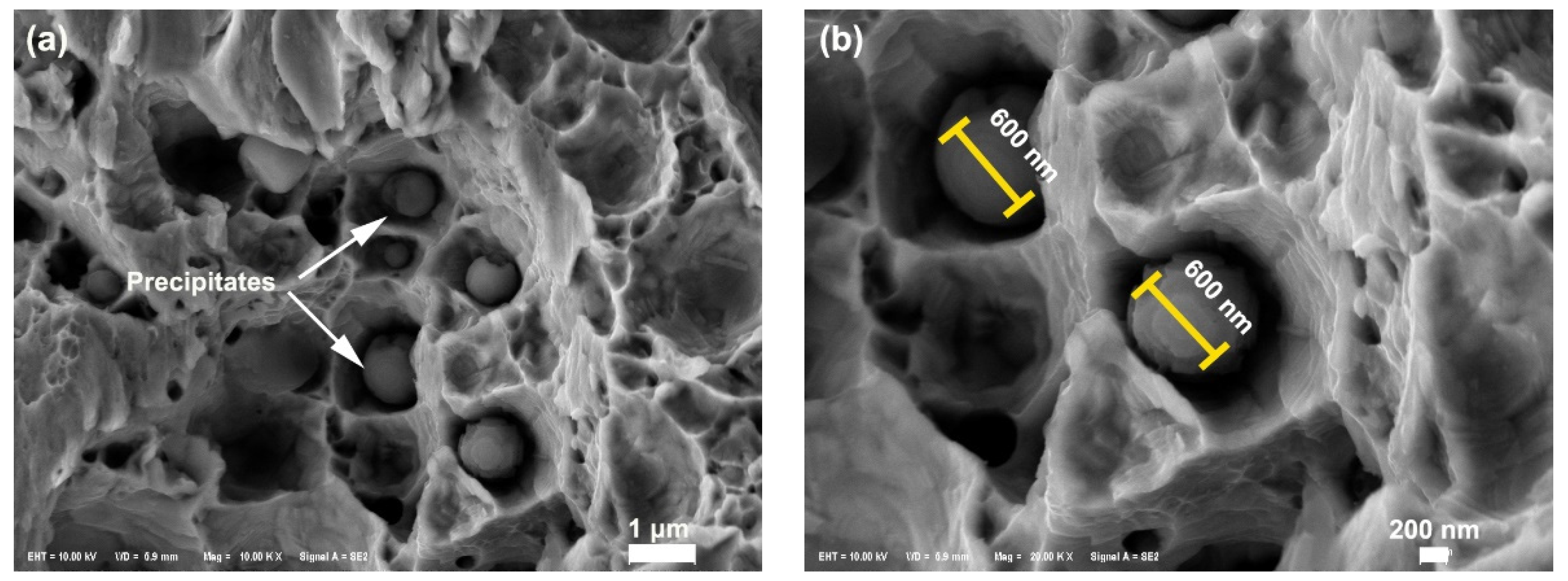

- Contributions of precipitates and GB strengthening can be quantitatively calculated for the AM-Inconel 625 alloy. The precipitates and GB contribute 27.9 and 66.7 MPa, respectively, to the overall strength.

- The wear depth of traditional nickel-based materials usually varies 40–140 μm per 200 cycles depending on the operating conditions. However, the AM-processed Inconel 625 alloy demonstrates the good wear-resistance, which controls wear depth of the fretting surface within 2.4 μm after 2 × 104 cycles.

- The wear characteristics of AM-processed Inconel 625 depend significantly on the continuous tribo-layers. XPS analysis shows that the observed stable and coherent tribo-layer is characterized by a mixture of Fe2O3, Fe3O4, Cr2O3 and Mn2O3.

Author Contributions

Funding

Conflicts of Interest

References

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Chlebus, E.; Kuźnicka, B.; Kurzynowski, T.; Dybała, B. Microstructure and mechanical behaviour of Ti–6Al–7Nb alloy produced by selective laser melting. Mater. Charact. 2011, 62, 488–495. [Google Scholar] [CrossRef]

- Wang, F. Mechanical property study on rapid additive layer manufacture Hastelloy® X alloy by selective laser melting technology. Int. J. Adv. Manuf. Tech. 2012, 58, 545–551. [Google Scholar] [CrossRef]

- Paul, C.P.; Ganesh, P.; Mishra, S.K.; Bhargava, P.; Negi, J.; Nath, A.K. Investigating laser rapid manufacturing for Inconel-625 components. Opt. Laser Technol. 2007, 39, 800–805. [Google Scholar] [CrossRef]

- Shankar, V.; Rao, K.B.S.; Mannan, S.L. Microstructure and mechanical properties of Inconel 625 superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Thivillon, L.; Bertrand, P.; Smurov, I. Strategy of manufacturing components with designed internal structure by selective laser melting of metallic powder. Appl. Surf. Sci. 2007, 254, 980–983. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.S.; Shi, Y.S.; Zhu, Z.C.; Zhang, D.Q. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Iwabuchi, A. Fretting wear of inconel 625 at high temperature and in high vacuum. Wear 1985, 106, 163–175. [Google Scholar] [CrossRef]

- Hong, C.; Gu, D.; Dai, D.; Alkhayat, M.; Urban, W.; Yuan, P.; Cao, S.; Gasser, A.; Weisheit, A.; Kelbassa, I. Laser additive manufacturing of ultrafine TiC particle reinforced Inconel 625 based composite parts: Tailored microstructures and enhanced performance. Mater. Sci. Eng. A 2015, 635, 118–128. [Google Scholar] [CrossRef]

- Lotfi, M.; Jahanbakhsh, M.; Farid, A.A. Wear estimation of ceramic and coated carbide tools in turning of Inconel 625: 3D FE analysis. Tribol. Int. 2016, 99, 107–116. [Google Scholar] [CrossRef]

- Sames, W.; List, F.; Pannala, S.; Dehoff, R.; Babu, S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 1–46. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Epitaxy and Microstructure Evolution in Metal Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 527–530. [Google Scholar] [CrossRef]

- Ramsperger, M.; Mújica Roncery, L.; Lopez-Galilea, I.; Singer, R.F.; Theisen, W.; Körner, C. Solution Heat Treatment of the Single Crystal Nickel-Base Superalloy CMSX-4 Fabricated by Selective Electron Beam Melting. Adv. Eng. Mater. 2015, 17, 1486–1493. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W. Microstructure characteristics and formation mechanisms of in situ WC cemented carbide based hardmetals prepared by Selective Laser Melting. Mater. Sci. Eng. A 2010, 527, 7585–7592. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Fernández, A.; Celaya, A.; Lamikiz, A.; López de Lacalle, L.N. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Laser Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

- Martínez Krahmer, D.; Polvorosa, R.; López de Lacalle, L.N.; Alonso-Pinillos, U.; Abate1, G.; Riu, F. Alternatives for Specimen Manufacturing in Tensile Testing of Steel Plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Liu, X.; Zhou, L. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol. Int. 2019, 129, 75–81. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Zhang, P.; Wang, J.; Liu, X.; Zhou, L. Wear-triggered self-healing behavior on the surface of nanocrystalline nickel aluminum bronze/Ti3SiC2 composites. Appl. Surf. Sci. 2018, 436, 1038–1049. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Chen, Y.; Liu, X.; Zhou, L.; Lin, D. Gas-atomized copper-based particles encapsulated in graphene oxide for high wear-resistant composites. Compos. Part B 2019, 157, 131–139. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Liu, X.; Zhai, W.; Zhang, P.; Zhang, G. Fretting wear properties of plasma-sprayed Ti3SiC2 coatings with oxidative crack-healing feature. Tribol. Int. 2018, 118, 196–207. [Google Scholar] [CrossRef]

- Mostafaei, A.; Toman, J.; Stevens, E.L.; Hughes, E.T.; Krimer, Y.L.; Chmielus, M. Microstructural evolution and mechanical properties of differently heat-treated binder jet printed samples from gas- and water-atomized alloy 625 powders. Acta Mater. 2016, 122, 280–289. [Google Scholar] [CrossRef]

- Tian, Y.; Gontcharov, A.; Gauvin, R.; Lowden, P.; Brochu, M. Effect of heat treatment on microstructure evolution and mechanical properties of Inconel 625 with 0.4 wt % boron modification fabricated by gas tungsten arc deposition. Mater. Sci. Eng. A 2016, 684, 275–283. [Google Scholar] [CrossRef]

- Wang, J.F.; Sun, Q.J.; Wang, H.; Liu, J.P.; Feng, J.C. Effect of location on microstructure and mechanical properties of additive layer manufactured Inconel 625 using gas tungsten arc welding. Mater. Sci. Eng. A 2016, 676, 395–405. [Google Scholar] [CrossRef]

- Wang, P.; Li, T.; Lim, Y.F.; Tan, C.K.I.; Chi, D. Sintering and mechanical properties of mechanically milled Inconel 625 superalloy and its composite reinforced by carbon nanotube. Met. Powder Rep. 2016. [Google Scholar] [CrossRef]

- Li, G.; Huang, J.; Wu, Y. An investigation on microstructure and properties of dissimilar welded Inconel 625 and SUS 304 using high-power CO2 laser. Int. J. Adv. Manuf. Technol. 2015, 76, 1203–1214. [Google Scholar] [CrossRef]

- Jalal, M.; Ramezanianpour, A.A.; Pool, M.K. Split tensile strength of binary blended self compacting concrete containing low volume fly ash and TiO2 nanoparticles. Compos. Part B 2013, 55, 324–337. [Google Scholar] [CrossRef]

- Gupta, R.K.; Anil Kumar, V.; Gururaja, U.V.; Shivaram, B.R.N.V.; Maruti Prasad, Y.; Ramkumar, P.; Chakravarthi, K.V.A.; Sarkar, P. Processing and Characterization of Inconel 625 Nickel Base Superalloy. Mater. Sci. Forum 2015, 38, 830–831. [Google Scholar] [CrossRef]

- Ma, D.; Stoica, A.D.; Wang, Z.; Beese, A.M. Crystallographic texture in an additively manufactured nickel-base superalloy. Mater. Sci. Eng. A 2017, 684, 47–53. [Google Scholar] [CrossRef]

- Ashtiani, H.R.R.; Zarandooz, R. Microstructural and mechanical properties of resistance spot weld of Inconel 625 supper alloy. Int. J. Adv. Manuf. Technol. 2016, 84, 607–619. [Google Scholar] [CrossRef]

- Hehr, A.; Dapino, M.J. Interfacial shear strength estimates of NiTi–Al matrix composites fabricated via ultrasonic additive manufacturing. Compos. Part B 2015, 77, 199–208. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef]

- Lloyd, D.J. Precipitation Hardening. Metall. Mater. Trans. A 1985, 16, 2131–2165. [Google Scholar]

- Courtney, T.H. Mechanical Behavior of Materials; Waveland Press: Long Grove, IL, USA, 2005. [Google Scholar]

- Crudden, D.J.; Mottura, A.; Warnken, N.; Raeisinia, B.; Reed, R.C. Modelling of the influence of alloy composition on flow stress in high-strength nickel-based superalloys. Acta Mater. 2014, 75, 356–370. [Google Scholar] [CrossRef]

- Thompson, A.A. Yielding in nickel as a function of grain or cell size. Acta Metall. 1975, 23, 1337–1342. [Google Scholar] [CrossRef]

- Chen, X.H.; Lu, L.; Lu, K. Grain size dependence of tensile properties in ultrafine-grained Cu with nanoscale twins. Scr. Mater. 2011, 64, 311–314. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Basu, B.; Vitchev, R.G.; Vleugels, J.; Celis, J.P.; Biest, O.V.D. Influence of humidity on the fretting wear of self-mated tetragonal zirconia ceramics. Acta Mater. 2000, 48, 2461–2471. [Google Scholar] [CrossRef]

- Wang, J.; Luo, X.H.; Sun, Y.H. Torsional Fretting Wear Properties of Thermal Oxidation-Treated Ti3SiC2 Coatings. Coatings 2018, 8, 324. [Google Scholar] [CrossRef]

- Tewari, A.; Basu, B.; Bordia, R.K. Model for fretting wear of brittle ceramics. Acta Mater. 2009, 57, 2080–2087. [Google Scholar] [CrossRef]

- Swaminathan, V.; Gilbert, J.L. Fretting corrosion of CoCrMo and Ti6Al4V interfaces. Biomaterials 2012, 33, 5487–5503. [Google Scholar] [CrossRef] [PubMed]

- Sikdar, K.; Shekhar, S.; Balani, K. Fretting wear of Mg–Li–Al based alloys. Wear 2014, 318, 177–187. [Google Scholar] [CrossRef]

- Lan, P.; Meyer, J.L.; Vaezian, B.; Polycarpou, A.A. Advanced polymeric coatings for tilting pad bearings with application in the oil and gas industry. Wear 2016, 354, 10–20. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, X.; Lu, W.; Zhai, W.; Zhou, M.; Wang, J. Fretting wear behavior of CuNiAl against 42CrMo4 under different lubrication conditions. Tribol. Int. 2018, 117, 59–67. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.; Liu, X.; Zhai, W.; Zhou, M.; Jiang, X. A comparative study on torsional fretting and torsional sliding wear of CuNiAl under different lubricated conditions. Tribol. Int. 2018, 117, 78–86. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.; Liu, X.; Zhai, W.; Zhou, M.; Zeng, W. Torsional fretting and torsional sliding wear behaviors of CuNiAl against 42CrMo4 under dry condition. Tribol. Int. 2018, 118, 11–19. [Google Scholar] [CrossRef]

- Lu, W.; Zhai, W.; Zhang, P.; Zhou, M.; Liu, X.; Zhou, L. Effect of different levels of free water in oil on the fretting wear of nickel-aluminum bronze based composites. Wear 2017, 390–391, 376–384. [Google Scholar] [CrossRef]

- Zhai, W.; Lu, W.; Zhang, P.; Zhou, M.; Liu, X.; Zhou, L. Microstructure, mechanical and tribological properties of nickel-aluminium bronze alloys developed via gas-atomization and spark plasma sintering. Mater. Sci. Eng. A 2017, 707, 325–336. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.; Liu, X.; Zhou, M.; Zhai, W.; Zhang, G.; Zeng, W.; Jiang, X. Torsional fretting wear behavior of CuNiAl against 42CrMo4 under flat on flat contact. Wear 2017, 380, 6–14. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.; Liu, X.; Zhou, M.; Zhai, W.; Zhang, G.; Zeng, W.; Jiang, X.; Lu, W.; Zhang, P.; et al. Influence of surface topography on torsional fretting wear under flat-on-flat contact. Tribol. Int. 2017, 109, 367–372. [Google Scholar]

- Zhai, W.; Shi, X.; Yang, K.; Huang, Y.; Zhou, L.; Lu, W. Mechanical and tribological behaviors of the tribo-layer of the nanocrystalline sturcture during sliding contact: Experiments and model assessment. Compos. Part B 2017, 108, 354–363. [Google Scholar] [CrossRef]

- Zhai, W.; Shi, X.; Yang, K.; Zhou, L.; Lu, W. Tribological Behaviors of Ni3Al Intermetallics with MoO3 Multilayer Ribbon Crystal Prepared by Spark Plasma Sintering. Acta Metall. Sin Engl. 2017, 30, 576–584. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, G.; Liu, X.; Jiang, X. Prediction of surface topography at the end of sliding running-in wear based on areal surface parameters. Tribol. Trans. 2014, 57, 553–560. [Google Scholar] [CrossRef]

- Yang, K.; Ma, H.; Li, X.; He, Q. The Analysis in In Situ Preparation, Mechanics and Tribology of TiAl-SnAgCu/Graphene Composites. Adv. Eng. Mater. 2018, 800719, 1–8. [Google Scholar] [CrossRef]

- Ng, K.L.; Sun, Q.P.; Tomozawa, M.; Miyazak, S. Wear behavior of NITI thin film at micro-scale. Int. J. Mod. Phys. B 2012, 24, 85–93. [Google Scholar] [CrossRef]

- Shi, W.; Luo, X.; Zhang, Z.; Liu, Y.; Lu, W. Influence of external load on the frictional characteristics of rotary model using a molecular dynamics approach. Comput. Mater. Sci. 2016, 122, 201–209. [Google Scholar] [CrossRef]

- Lan, P.; Zhang, Y.; Dai, W.; Polycarpou, A. A phenomenological elevated temperature friction model for viscoelastic polymer coatings based on nanoindentation. Tribol. Int. 2018, 119, 299–307. [Google Scholar] [CrossRef]

- Lan, P.; Polychronopoulou, K.; Zhang, Y.; Polycarpou, A.A. Three-body abrasive wear by (silica) sand of advanced polymeric coatings for tilting pad bearings. Wear 2017, 382, 40–50. [Google Scholar] [CrossRef]

- Lan, P.; Gheisari, R.; Meyer, J.; Polycarpou, A. Tribological performance of aromatic thermosetting polyester (ATSP) coatings under cryogenic conditions. Wear 2018, 398, 47–55. [Google Scholar] [CrossRef]

- Lan, P.; Meyer, J.L.; Economy, J.; Polycarpou, A.A. Unlubricated tribological performance of aromatic thermosetting polyester (ATSP) coatings under different temperature conditions. Tribol. Lett. 2016, 61, 10. [Google Scholar]

- Zhang, G.; Liu, X.; Lu, W. A parameter prediction model of running-in based on surface topography. Proc. Inst. Mech. Eng. Part C 2013, 227, 1047–1055. [Google Scholar] [CrossRef]

- Zhang, H.; Brown, L.; Blunt, L.; Jiang, X.; Barrans, S. The contribution of the micropores in bone cement surface to generation of femoral stem wear in total hip replacement. Tribol. Int. 2011, 44, 1476–1482. [Google Scholar] [CrossRef]

- Zhang, H.; Brown, L.T.; Blunt, L.A.; Jiang, X.; Barrans, S.M. Understanding initiation and propagation of fretting wear on the femoral stem in total hip replacement. Wear 2009, 266, 566–569. [Google Scholar] [CrossRef]

- Lan, P.; Polycarpou, A. High temperature and high pressure tribological experiments of advanced polymeric coatings in the presence of drilling mud for oil & gas applications. Tribol. Int. 2018, 120, 218–225. [Google Scholar]

- Shakoor, R.A.; Waware, U.S.; Ali, K.; Kahraman, R.; Popelka, A.; Yusuf, M.M.; Hasan, A. Novel Electrodeposited Ni-B/Y2O3 Composite Coatings with Improved Properties. Coatings 2017, 7, 161. [Google Scholar] [CrossRef]

- Tan, B.J.; Klabunde, K.J.; Sherwood, P.M.A. X-ray photoelectron spectroscopy studies of solvated metal atom dispersed catalysts. Monometallic iron and bimetallic iron-cobalt particles on alumina. Chem. Mater. 2002, 2, 186–191. [Google Scholar] [CrossRef]

- Brion, D. Etude par spectroscopie de photoelectrons de la degradation superficielle de FeS2, CuFeS2, ZnS et PbS a l’air et dans l’eau. Appl. Surf. Sci. 1980, 5, 133–152. [Google Scholar] [CrossRef]

- Kar, P.K.; Singh, G. Evaluation of Nitrilotrimethylene Phosphonic Acid and Nitrilotriacetic Acid as Corrosion Inhibitors of Mild Steel in Sea Water. ISRN Mater. Sci. 2011, 2011, 167487. [Google Scholar] [CrossRef]

- Grohmann, I.; Kemnitz, E.; Lippitz, A.; Unger, W.E.S. Curve fitting of Cr 2p photoelectron spectra of Cr2O3 and CrF3. Surf. Int. Anal. 2004, 23, 887–891. [Google Scholar] [CrossRef]

- Allen, G.C.; Harris, S.J.; Jutson, J.A.; Dyke, J.M. A study of a number of mixed transition metal oxide spinels using X-ray photoelectron spectroscopy. Appl. Surf. Sci. 1989, 37, 111–134. [Google Scholar] [CrossRef]

- Kato, H.; Komai, K. Tribofilm formation and mild wear by tribo-sintering of nanometer-sized oxide particles on rubbing steel surfaces. Wear 2007, 262, 36–41. [Google Scholar] [CrossRef]

| Chemical Composition (wt. %) | |||||||

|---|---|---|---|---|---|---|---|

| Elements Mass Ratio | Ni | Cr | Fe | Nb | Mo | Mn | Si |

| Bal. | 20.5 | 3.4 | 3.6 | 8.9 | 0.4 | 0.5 | |

| Specimen | Method | Micro-Hardness (HV) | Relative Density | Ref. |

|---|---|---|---|---|

| As-prepared | AM | 335 | 99.7% | Present work |

| Inconel 625 | Sintering + ageing | 327 | 99.2% | [16] |

| Inconel 625 | AM | 343 | - | [7] |

| Inconel 625 | Gas tungsten arc deposition | 328 | - | [17] |

| Inconel 625 | Gas tungsten arc welding | 270 | - | [18] |

| Inconel 625 | Sintering | 275 | 91.8 | [19] |

| Milled Inconel 625 | Sintering | 320 | 84 | [19] |

| Inconel 625 | Welding | 252 | - | [20] |

| Normal Load (N) | Friction Coefficient | Dissipation Energy (J) |

|---|---|---|

| 40 | 0.39 | 47.44 × 10-4 |

| 62 | 0.42 | 62.50 × 10-4 |

| 84 | 0.46 | 92.74 × 10-4 |

| 106 | 0.50 | 127.20 × 10-4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Zhou, M. Superior Mechanical Behavior and Fretting Wear Resistance of 3D-Printed Inconel 625 Superalloy. Appl. Sci. 2018, 8, 2439. https://doi.org/10.3390/app8122439

Gao Y, Zhou M. Superior Mechanical Behavior and Fretting Wear Resistance of 3D-Printed Inconel 625 Superalloy. Applied Sciences. 2018; 8(12):2439. https://doi.org/10.3390/app8122439

Chicago/Turabian StyleGao, Yong, and Mingzhuo Zhou. 2018. "Superior Mechanical Behavior and Fretting Wear Resistance of 3D-Printed Inconel 625 Superalloy" Applied Sciences 8, no. 12: 2439. https://doi.org/10.3390/app8122439

APA StyleGao, Y., & Zhou, M. (2018). Superior Mechanical Behavior and Fretting Wear Resistance of 3D-Printed Inconel 625 Superalloy. Applied Sciences, 8(12), 2439. https://doi.org/10.3390/app8122439