1. Introduction

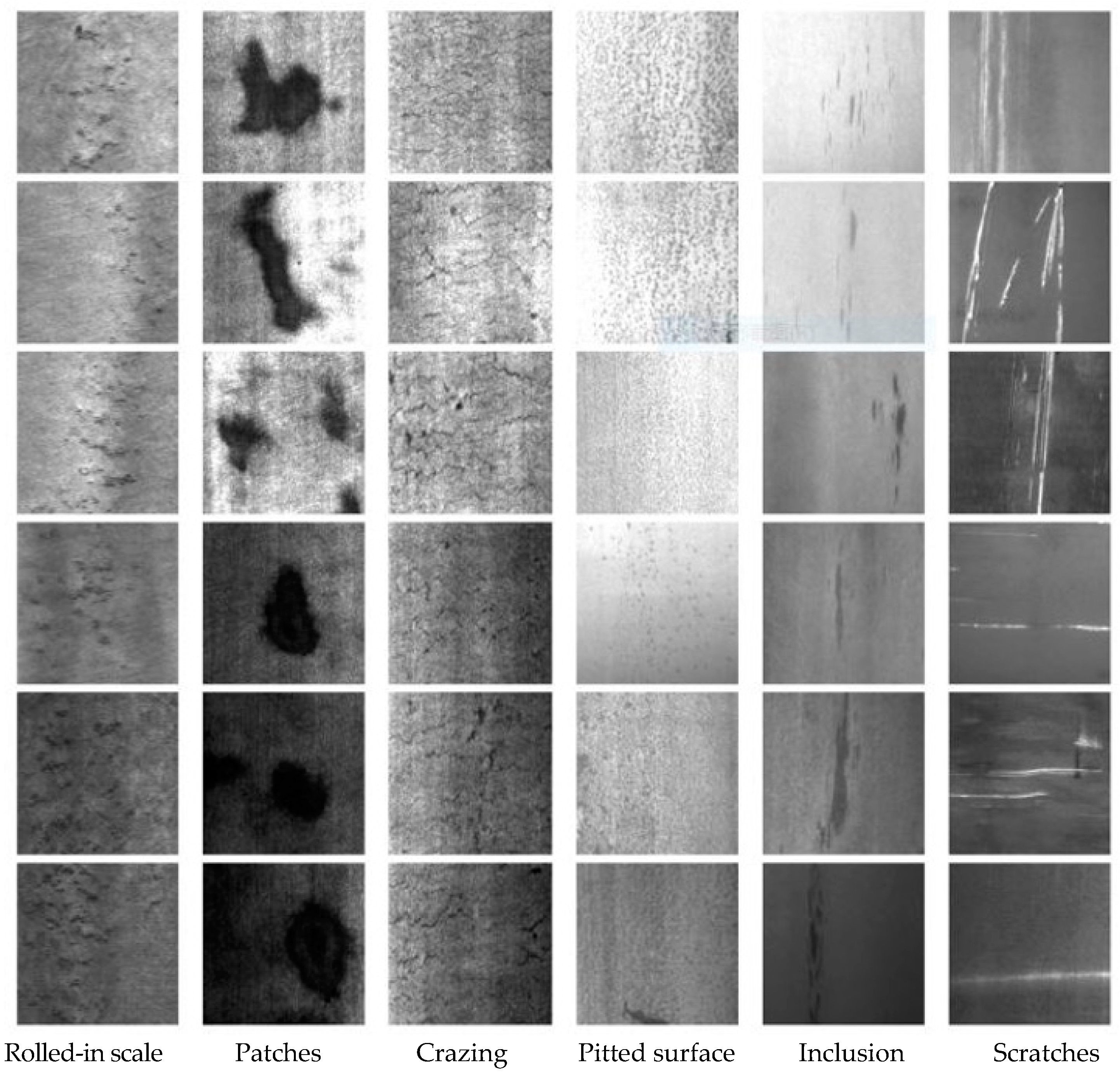

China’s iron and steel industry has made tremendous contributions to the development of its national economy. In recent years, the rapid rise in the output of steel products has been accompanied by a large number of defects, which could bring significant economic losses to enterprises, and ultimately affect their brand image. Therefore, it is necessary to study detection methods, particularly since artificial detection methods no longer meet the enterprise requirements regarding time, cost, and precision.

Visual detection technology based on image processing has been widely used in various fields, such as medicine [

1], the iron and steel industry [

2,

3], art [

4], the textile industry [

5], and the automobile industry [

6] for its unique advantages of intuition, accuracy, and convenience. Early detection methods for steel defects are classified as contact detection and non-contact detection [

7]. The former receives information through direct contact with the sample surface by the sensing element of a contact-detection device. The latter is based on the technology of photoelectricity, and electromagnetism to obtain the parameter information of the sample surface without contacting it.

Contact-detection methods include magnetic particle testing (MPT) and liquid penetration testing (LPT). Although intuitive images can be quickly obtained via these methods, to do so is not practicable. Non-contact methods include ultrasonic scanning, electromagnetic testing, etc., in which ultrasound or electromagnetic signals are converted to optical signals. Results are not intuitive, but need to be judged by professionals.

Visual detection based on image sensors stands out from the range of non-contact detection technologies, because it is an effective combination of the high speed achieved with contact detection methods and the independence of non-contact detection methods. The key feature is that it can be implemented by using only a universal computer and a dedicated image processor. Indeed, the number of publications related to defect detection has grown rapidly over the past decade, which is a trend that may be due to the rapid advance of computing capacity, the enhancement of sensor performance, and the great improvement of image processing technology.

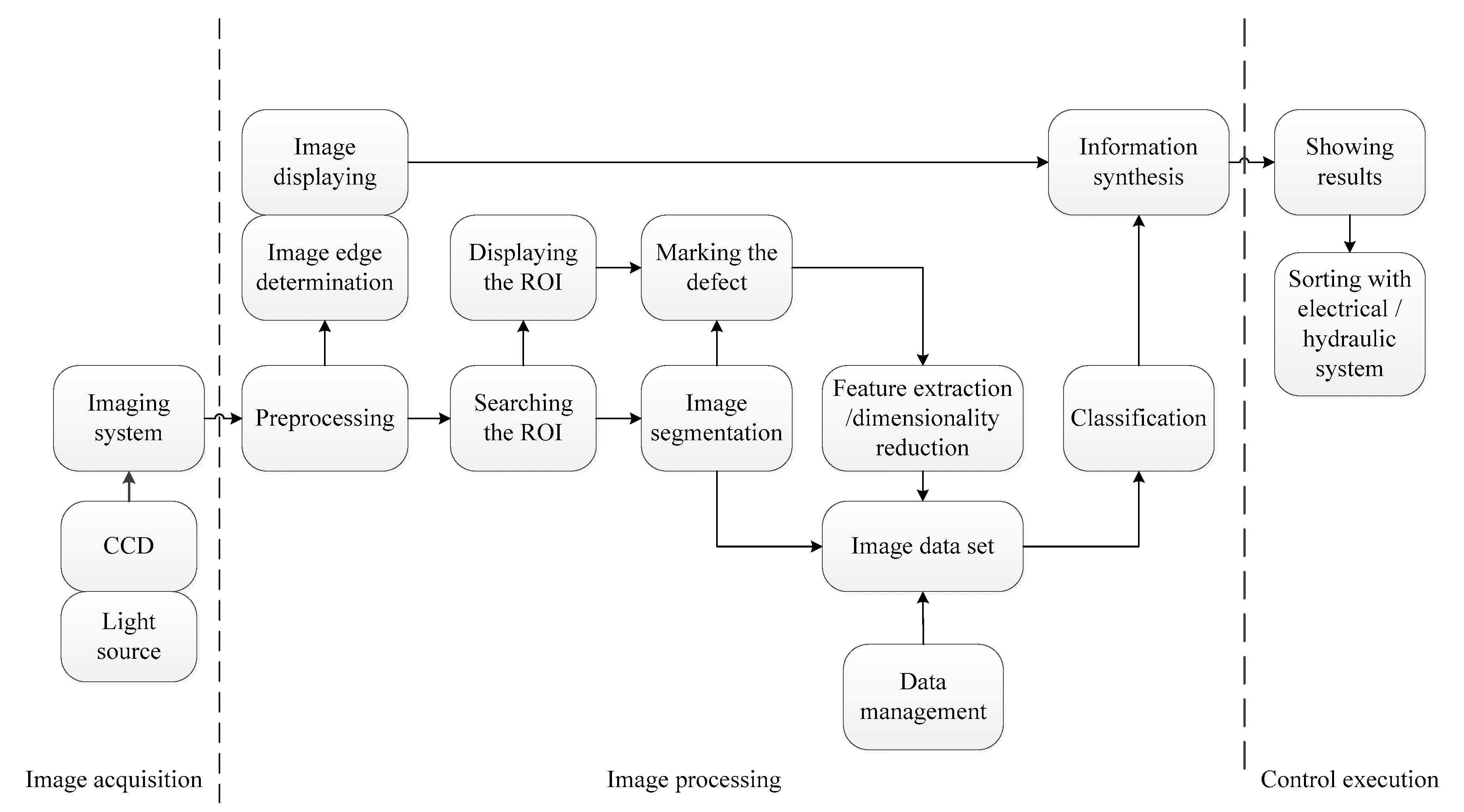

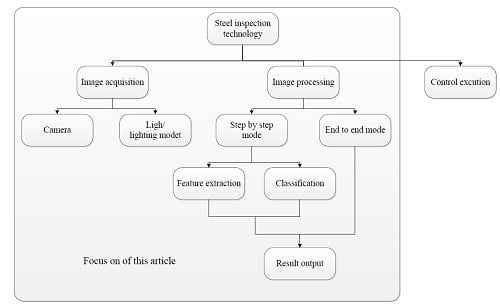

The basic components of a typical visual system are an image acquisition unit, an image processing unit, and a control execution unit (

Figure 1). The image acquisition unit is the component of the system hardware, and its main task is to obtain high-quality images, since low-quality images lead to algorithm burden. Excellent visual software can quickly and accurately detect the target features in the image and minimize dependence on the system hardware. The sorting mechanism can adopt an electromechanical system or hydraulic system, but the dynamic characteristics (i.e., rapidity and stability) of the system are important. This paper focus on image acquisition and image processing units.

With the maturity of the basic theory of image analysis, the development of the detection field has advanced by leaps and bounds, and several reviews of defect detection have been undertaken. Commercially available inspection equipment and visual inspection systems, as well as practical applications of visual inspection, are summarized in Chin [

8], Newman, [

9]. Amongst recent literature reviews, a large number of methods and techniques for the free surface detection of parts are studied in Li [

10]. Development trends of visual inspection are presented in article Shirvaikar [

11], which mainly focuses on the introduction of visual detection systems relating to hardware and software, but detailed algorithm comparisons are not provided. Reviews of visual detection in the manufacture of textiles Hanbay [

12], food, and agriculture Jfs [

13] have also contributed to the development of detection technology. However, because the reflective properties of steel products (55–65%) [

14] differ between foods and fabrics, these testing methods are for reference only. Notably, a comprehensive review of defect detection in steel surfaces has been conducted Neogi [

15], and is a valuable article for researchers in the field. However, the chronological distribution of the references in Neogi [

15] suggests that it is somewhat dated, with 13.82% of references from before 2000, 65.5% from 2001–2010, and 20.68% from after 2010. In contrast, the chronological distribution of references in the present paper—10.41% from prior to 2000, 37.5% from 2000–2010, and 52.08% from after 2010—indicates that it is more up-to-date with the latest technological developments. Thus, it is intended that the present study provide a supplement to Neogi [

15].

In

Section 2, the types of steel products and common defects are presented, so as to understand the complexity and diversity of visual detection. In

Section 3, the hardware composition of inspection systems is explained. Detection and classification methods are reviewed according to different theories in

Section 4 and

Section 5. In

Section 6, a literature analysis is conducted, which includes not only an analysis of detection technology, but also an analysis of the scale of the detection market. Conclusions and further prospects are provided in

Section 7.

3. The Hardware Composition of the Inspection System

3.1. Camera

An industrial camera is at the core of the system hardware. The frame rate (the rate at which the camera collects and transmits images) and resolution are two important parameters of the camera. The frame rate must be greater than the detection speed; 10 fps is usually sufficient to meet industrial requirements. The required resolution depends on the size of the features relative to the overall image. For example, suppose the surface scratch of an object is detected, the size of the object to be photographed is

a × b mm, and the detection accuracy is 0.01 mm. Then, the minimum resolution formula of the camera can be determined as:

Industrial cameras are divided into two types according to the differences of the image sensors: charge coupled devices (CCD) and complementary metal oxide semiconductor devices (CMOS) Koller [

51]. The differences are as follows.

- (1)

Different imaging processes: A CCD utilizes a small number of output nodes to output data uniformly, thereby ensuring good signal consistency. By contrast, each pixel in a CMOS chip has its own signal amplifier, with charge conversion done separately, so output signal consistency is poorer and more greatly affected by signal noise than with a CCD. However, a significant advantage of CMOS is low power consumption.

- (2)

Different integration: The CCD manufacturing process is complex, and the output of a CCD consists only of an analog electrical signal, which requires a decoder, analog converter, and image signal processor. As a result, a CCD has low integration. A CMOS, on the other hand, can collect signals with an analog-to-digital converter on a chip with high integration and low cost. With the advancement of CMOS imaging technology, CMOS will have greater applications in the future.

- (3)

Different image output speed: A CCD adopts photosensitive outputs sequentially, relatively slowly. With a CMOS, each charge element has its own switch controller, and the readout speed is very fast. Most high-speed cameras with a frame rate greater than 500 fps use CMOS.

- (4)

Different noise levels: CCD technology is mature, and the imaging quality is superior to that of CMOS. CMOS has a higher degree of integration, a closer spacing distance, and more interference.

As part of so-called Industry 4.0, factories around the world are developing automation and intelligence, in which smart sensors play an important role. The smart camera Lee [

52] has the functions of processor, memory, communication interface, operating system, etc., which can process a large amount of data in advance and assist subsequent automatic detection and judgment. Nguyen et al. [

53] noted an ultra-high-speed silicon image sensor. The test chip of this image sensor realizes a temporal resolution of 10 ns. For a silicon image sensor, the limit is 11.1 fps. Considering the theoretical derivation, this high-speed image sensor can reach a frame rate near the theoretical limit.

3.2. Light Selection

Lighting devices will vary because of different operating environments. For hot rolled steel, the strip itself is a luminous heating element. In order to reduce the interference of internal light sources, the intensity of the light source should be much higher than that of the steel strip. Thus, the light source can only have high-power, long-distance characteristics, so that it can provide high-intensity light at a long distance. For the cold rolling environment, although the relative distance between the light source and the steel strip is short, a more continuous light is needed to attenuate unstable infrared light, in order to ensure the highest sensitivity of the lens to the visible light spectrum. Overall, high strength, life span, design freedom, heat radiation, and response speed should be considered during lighting arrangement.

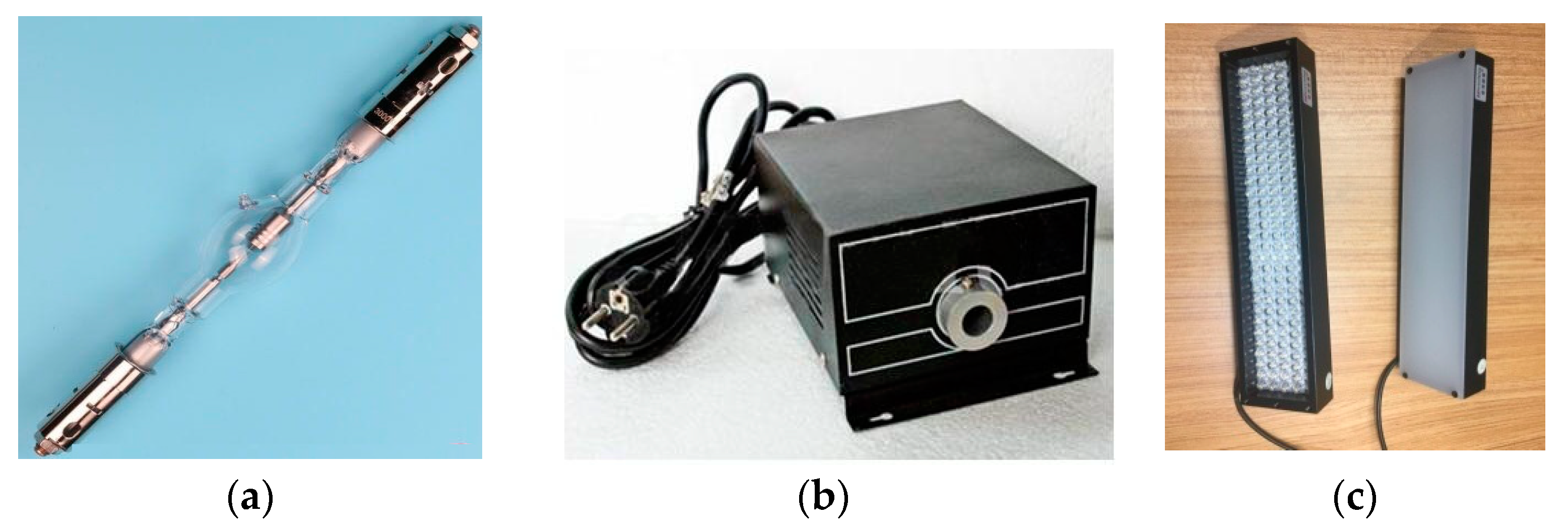

At present, some classical light sources are optical fiber, LED (light-emitting diode) lights, and stroboscopic xenon lamps. Among the latter, the strobe xenon lamp is mainly used in the area array CCD detection system as shown in

Figure 4a, since it can effectively deal with adverse environmental conditions, such as fog Luo [

22].

An example of an optical fiber light source is the halogen lamp (

Figure 4b), which is used in conjunction with a color filter adapter. The output of light through the cylinder prism can avoid overflow and increase light intensity by 10% Wu [

54], which can result in an ideal performance if high-power halogen lamps are used in industrial sites. However, halogen lamps are not suitable for hot-rolled steel in poor environments, and are mainly used in the testing environments of cold-rolled steel and finished products because of their high price and susceptibility to damage.

LED lamps (

Figure 4c) are a spontaneous radiation source. Spontaneous radiation is a process in which an excited atom spontaneously transitions from a high-energy state to a low-energy state, emitting a photon at the same time. LED lamps have the advantages of non-related light, no optical resonator, long lifespan, and easy maintenance. However, the weaknesses of the lamps are their narrow spectral range and that the wavelength is affected by the materials. The lifespan of LED lamps will also shorten as the ambient temperature increases, so they are not suitable for high-temperature applications. In addition, LEDs cannot be directly connected in parallel. Therefore, a method of a single-channel serial multi-channel parallel connection method is used to form an array LED, which then forms a light source through the prism. Owing to its low cost and long lifespan, LED light sources are usually equipped with cooling devices for hot-rolled inspection.

3.3. Lighting Method Selection

In addition to the influence of the light source and CCD sensor on detection effects, the lighting mode has a greater impact on the detection effect of steel products. Usually, lighting can be divided into light and dark lighting.

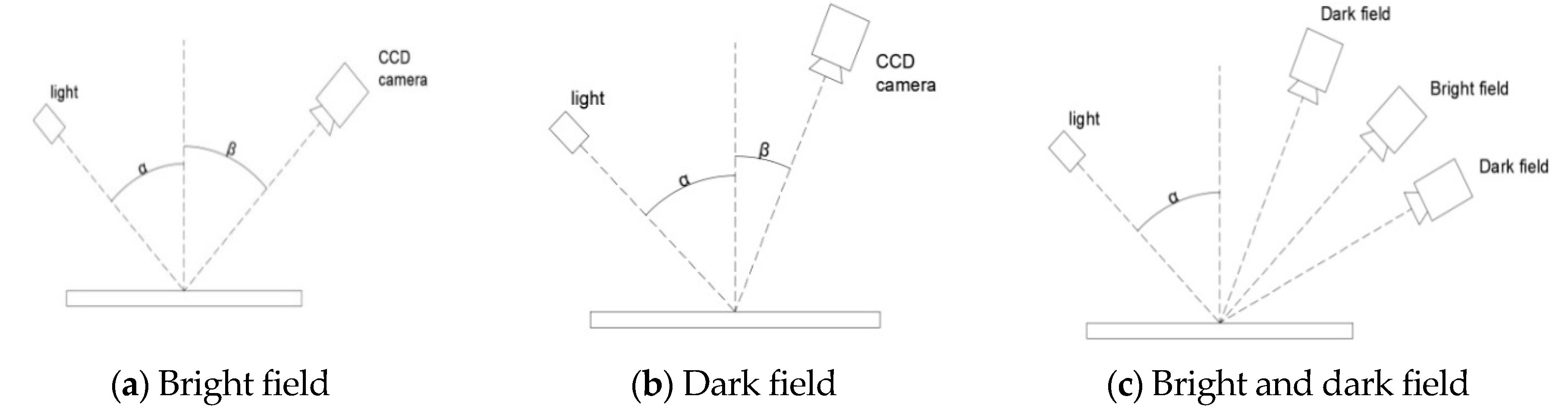

The bright field lighting method is shown in

Figure 5a. In this mode, the light source and the CCD are on the same side of the strip. The light emitted by the light source enters the camera after being reflected by the detection target. The reflection angle β is equal to the incident angle α, and the line between the CCD sensor and the image of the light source must be on the same line as the reflected light.

The reflected light is evenly distributed on each area of the CCD sensor when there is no defect on the surface. However, reflected light at the defect position will change when a defect exists, and the illuminance entering the CCD sensor will be weakened. Therefore, the reflection of light in the defect area is altered for three-dimensional defects, and the illuminance of the defect position into the CCD sensor is less than the background light entering the CCD sensor; that is to say, the defect image is darker than the background image. As for two-dimensional defects, the reflection of the defect does not change, but two-dimensional defects are usually of different shades. The light in the darker region absorbs more light; therefore, the gray value of the defect image is higher than the background image when the defect color is lighter than the surface color of the strip. Conversely, the grayscale value of the defect image is lower than the background image when the color of defects is darker than the color of non-detects.

Therefore, the use of bright field lighting can not only detect two-dimensional (2D) defects, it can also detect three-dimensional (3D) defects. However, it is worth noting that the results will be significantly affected if a large fluctuation of the steel strip leads to exceeding the range of the reflection angle. Overall, the bright field method is more appropriate for detecting a type of defect that reflects and absorbs light, especially dark targets with a bright background, such as scales, oxide skins, pits, water marks, etc.

In the dark field lighting method (

Figure 5b), the light source and the CCD sensor are also on the same side of the strip. In this case, the reflection angle β is not equal to the incident angle α, and the line between the CCD sensor and the image of the light source is not on the same line as the reflected light; therefore, it is difficult for light to enter the CCD sensor. Only when three-dimensional defects exist on the strip surface will the defect change the reflective nature of the light into a diffuse reflection. Then, the camera is able to collect some diffuse light, and the light from the defect position will be stronger than from areas without a defect. In addition, the light source itself has a collection effect of high-intensity light. Even if the incident angle is changed, it has little effect on the illumination of reflected light on CCD sensors. As a result, the CCD can still effectively detect a surface defect when the surface of the strip steel generates vibration. On the whole, the dark field lighting method is more suitable for the type of defects that can emit diffuse reflected light on the surface of a bright steel plate, and, in particular, bright targets with dark backgrounds, such as skins, pits, and indentations. There is a certain degree of tolerance to the vibration of the detection point.

The bright and dark double field lighting mode (

Figure 5c) addresses the problems of detection of two-dimensional defects in dark field lighting and vibration at the detection point. However, this method has a high requirement for a high-intensity concentrated light effect of the light source; that is to say, the part of the dark field detection that is included will not be ideal if the concentrated light effect is not strong.

Overall, the appropriate light source and lighting mode allow us to capture the features of the object more accurately and improve the contrast between the object and the background. In this way, high-quality images can be obtained, and good detection results can be achieved.

6. Analysis

The following is an analysis of visual detection from the perspective of scientific literature to the perspective of market size.

6.1. Literature Analysis

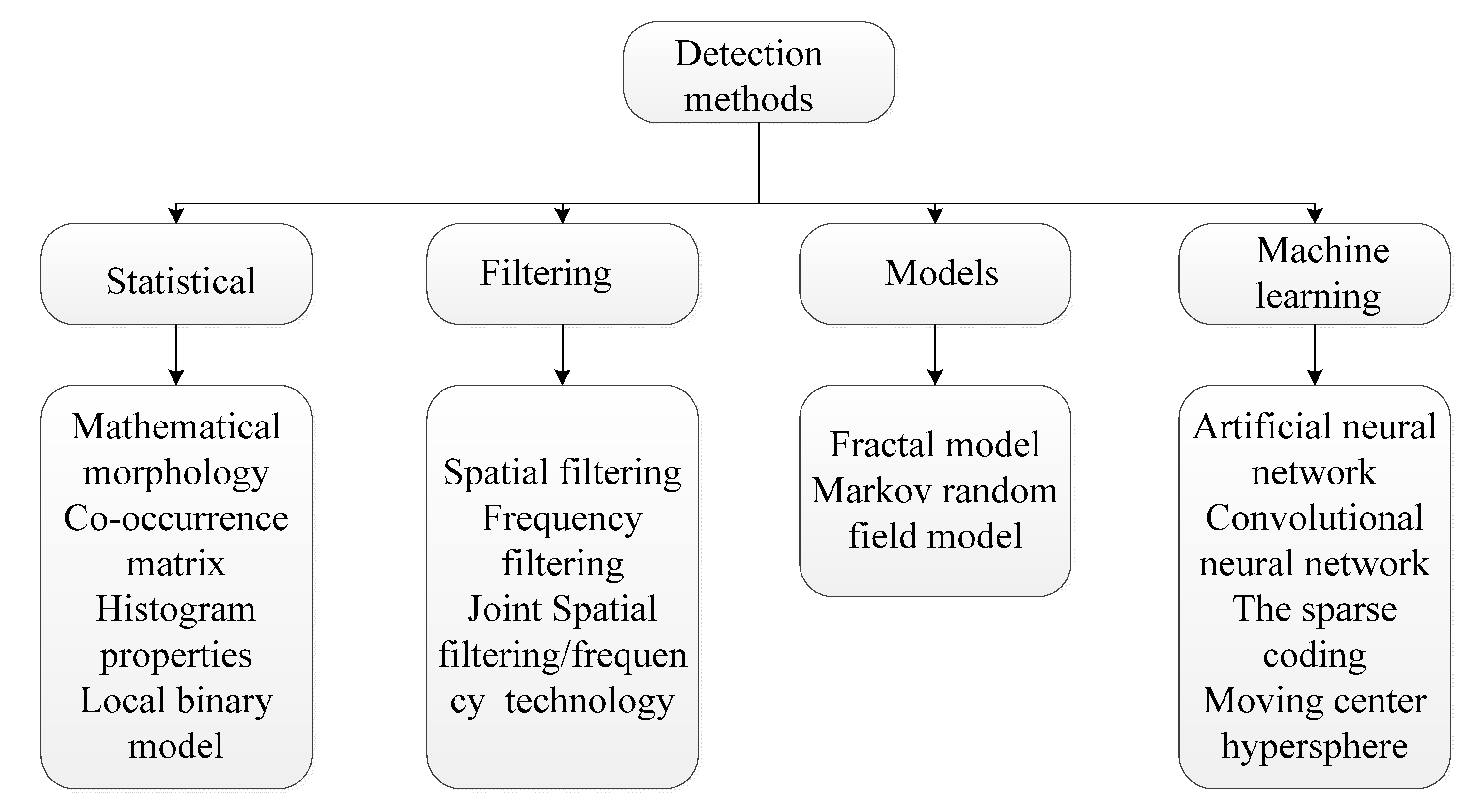

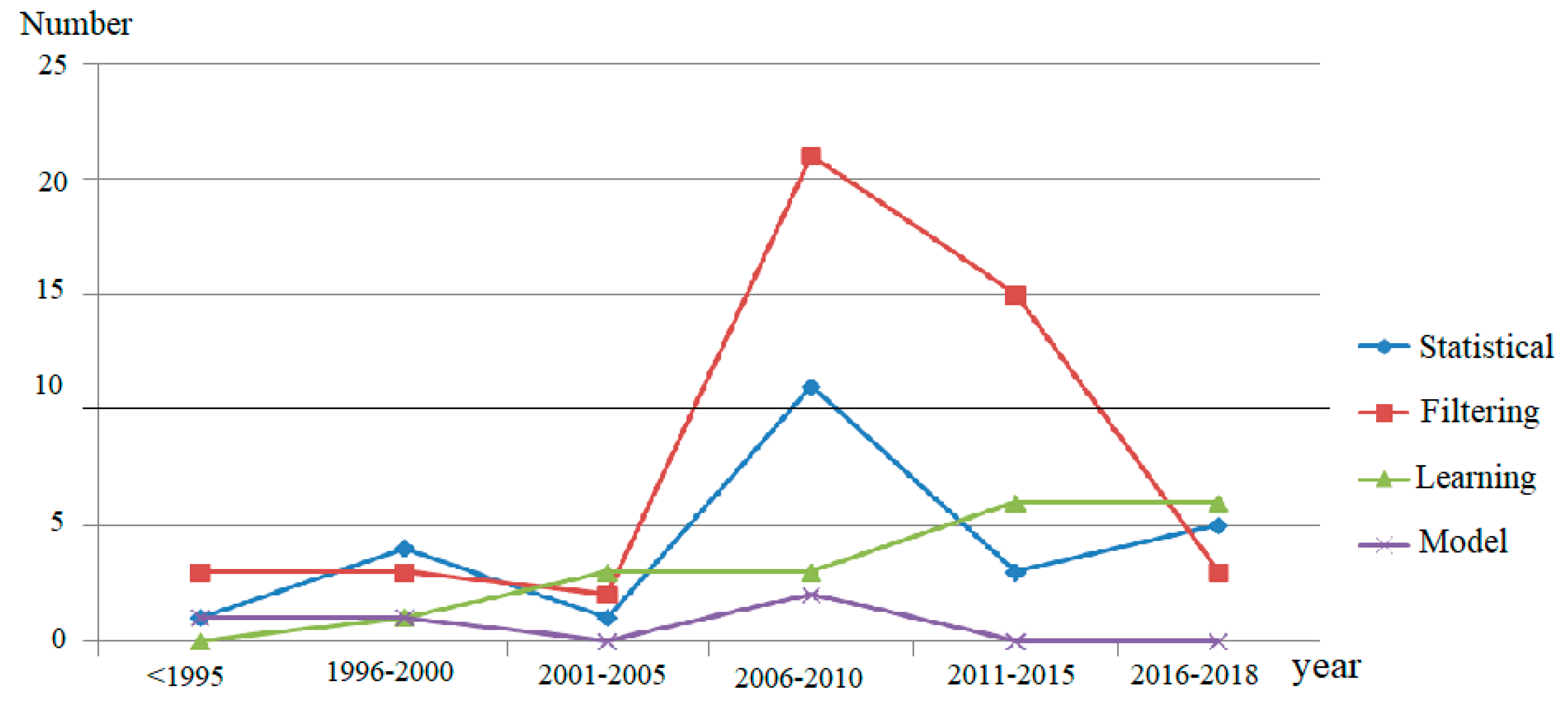

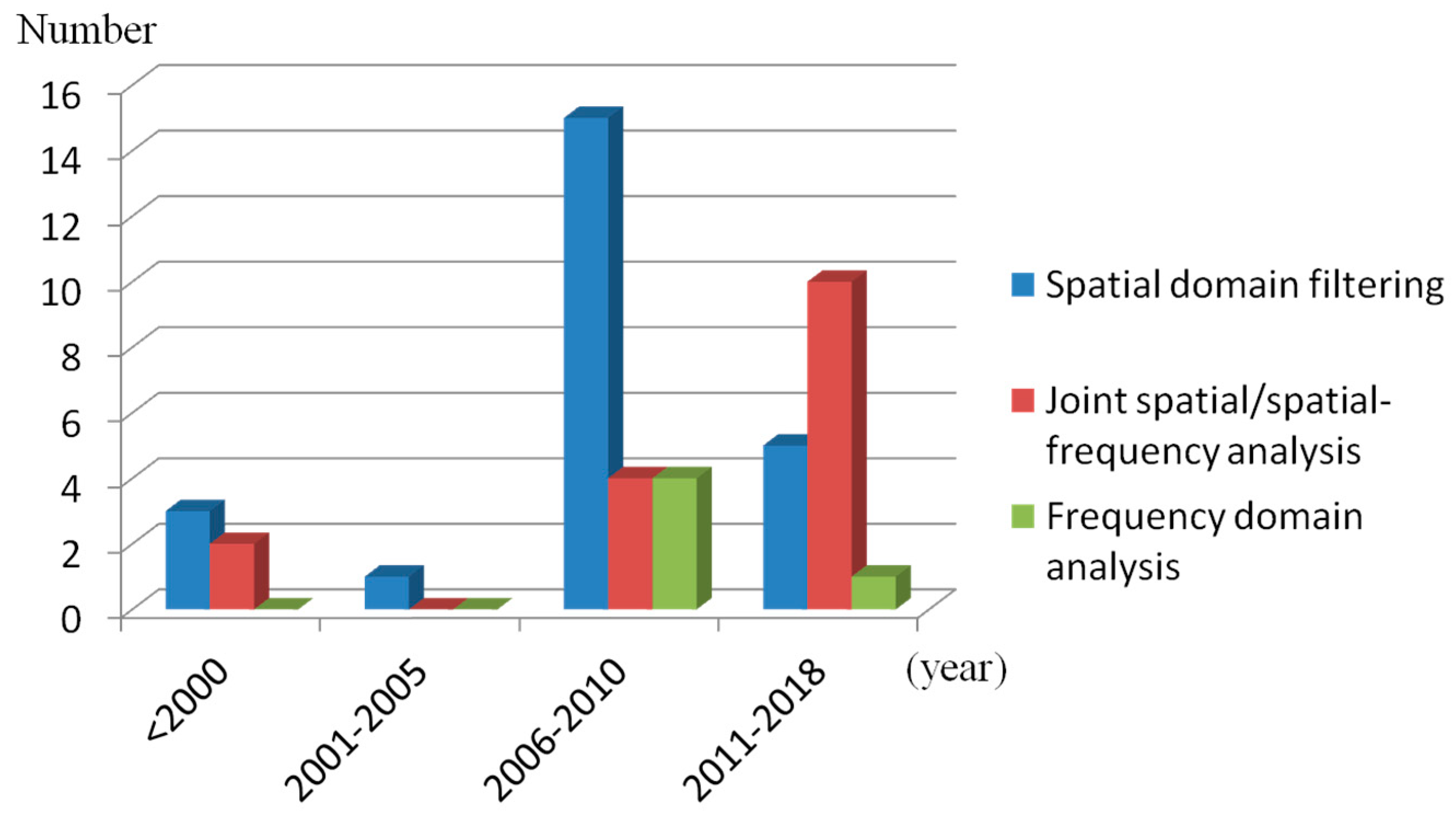

From the review of detection methods, we can see that a large number of publications over the past 30 years have been related to statistics and filtering methods, as shown in

Figure 9.

From the point of development trends, both statistical methods and filtering methods have shown a significant downward trend since 2010, while the discussion of learning-based methods has steadily improved. This has much to do with the upsurge of deep learning in recent years. Model-based detection methods have always been out of the mainstream.

A detailed analysis of filtering methods is provided in

Figure 10, because these methods have attracted much attention. From the 36 papers collected (relating to space filtering and frequency domains), it can be seen that although the best method of defect detection cannot be determined, it is clear that the joint spatial/frequency analysis methods (i.e., Gabor transform, wavelet transform, and MGA) have increased since 2010, which shows that these methods have been increasingly recognized by a majority of researchers.

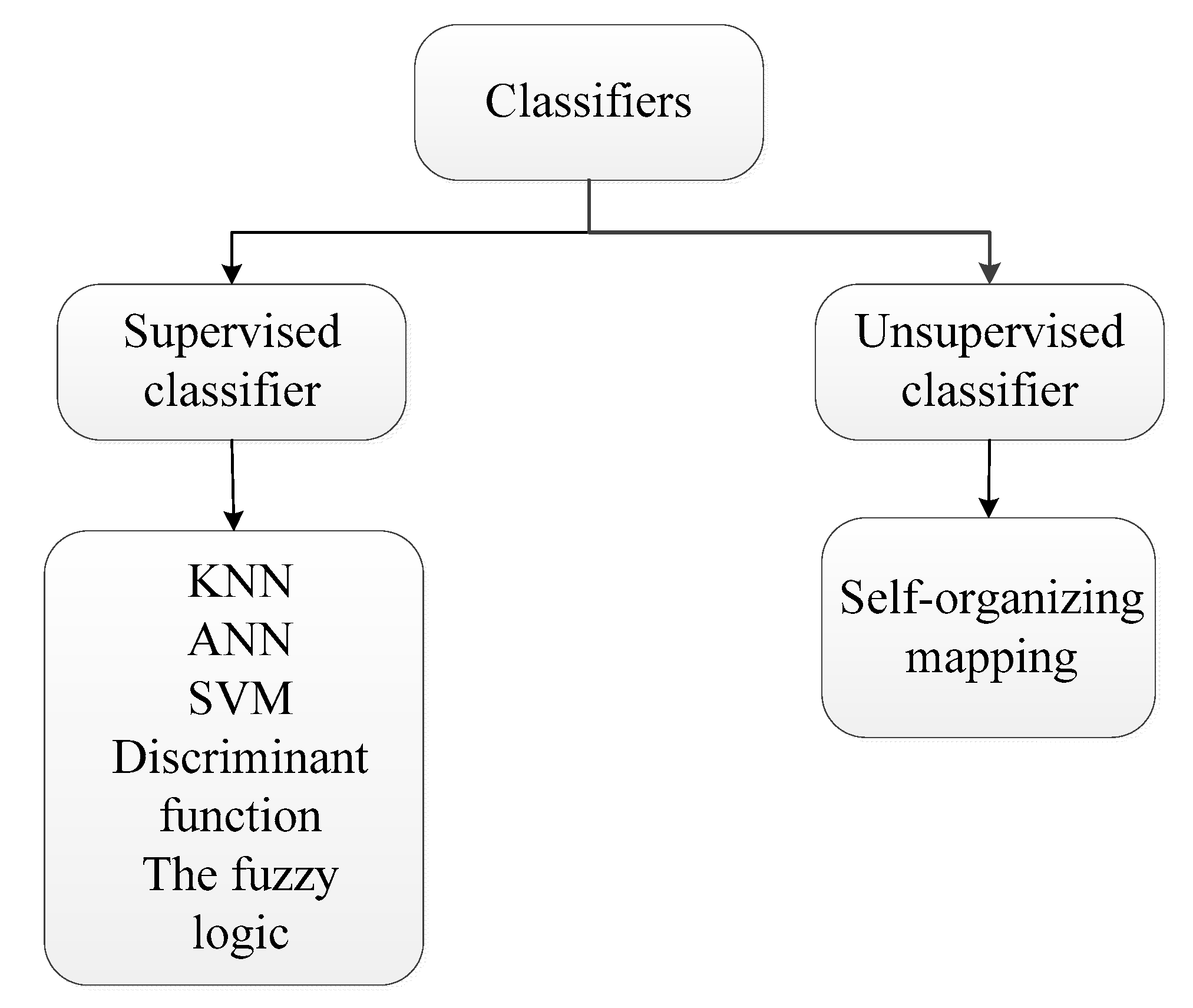

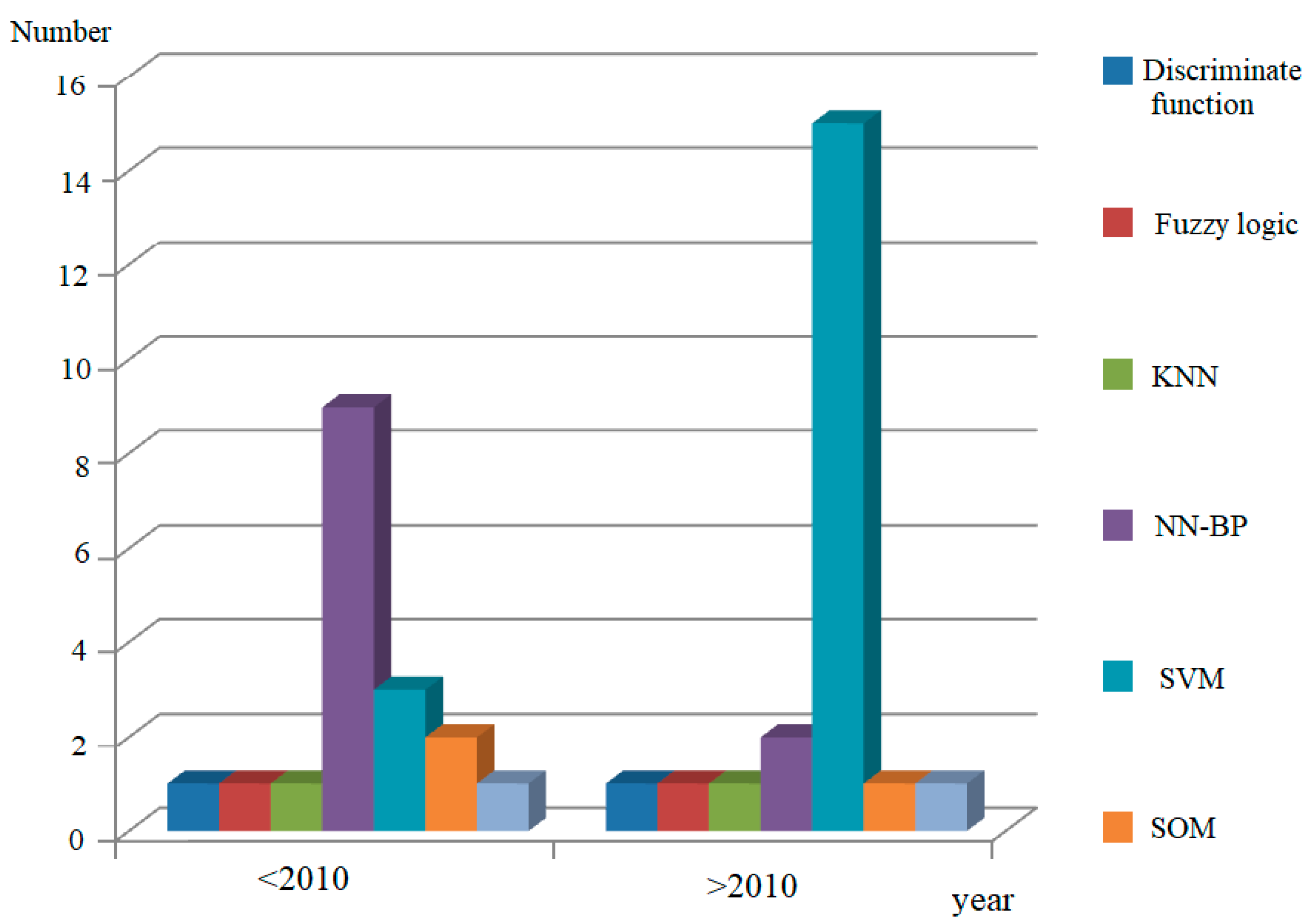

In terms of classification methods, supervised classification methods have always dominated compared to unsupervised classification methods. As the knowledge set of defect models is imperfect, the supervised classification method is preferred if prior knowledge is available, since this method can achieve superior results.

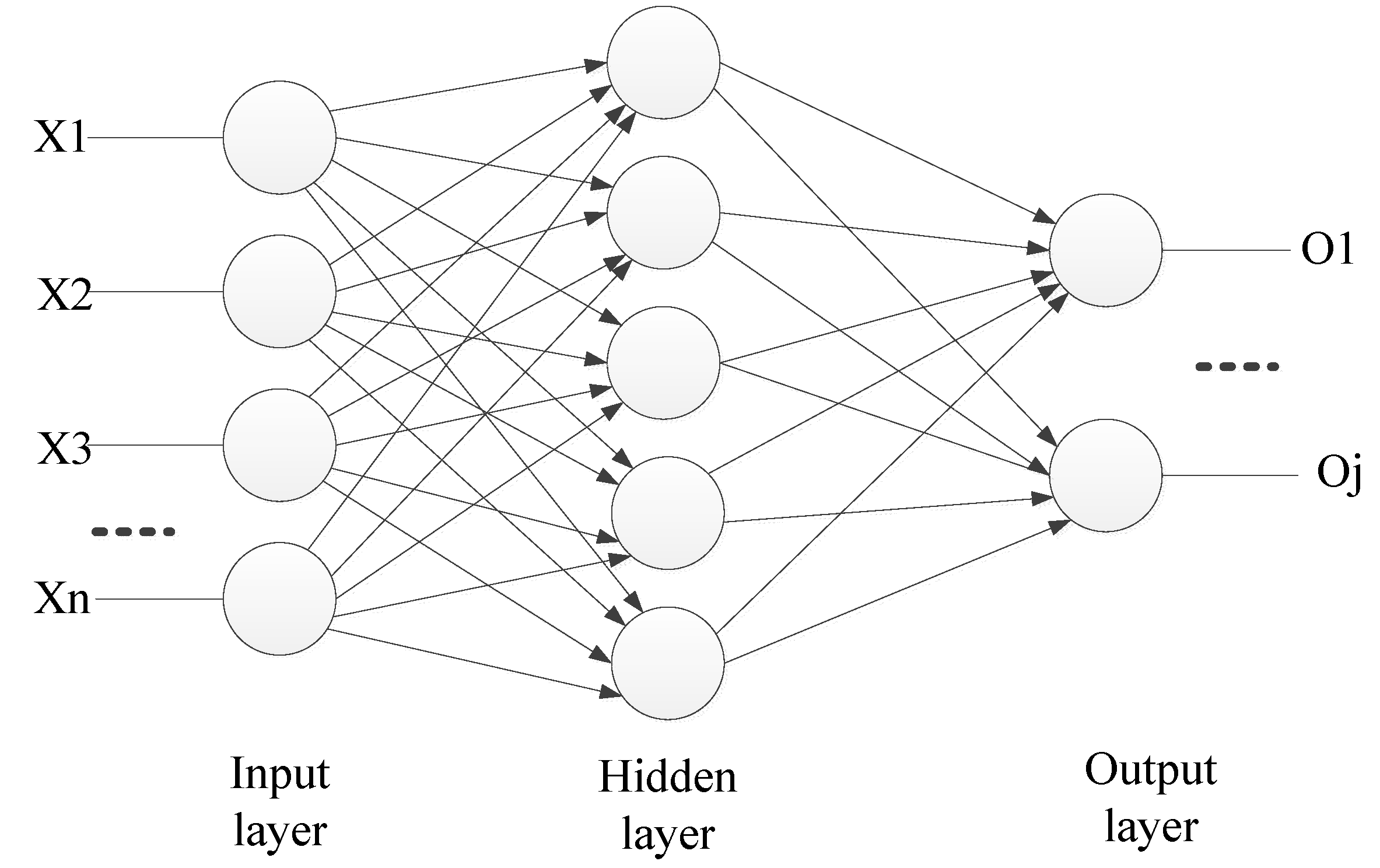

Support vector machines and neural networks based on back propagation (NN-BP) are the mainstream supervised classification methods.

It can be seen from the

Figure 11 that the NN-BP method was a classifier that was commonly discussed in the literature prior to 2010, and that the frequency of discussion of SVMs has increased sharply since 2010.

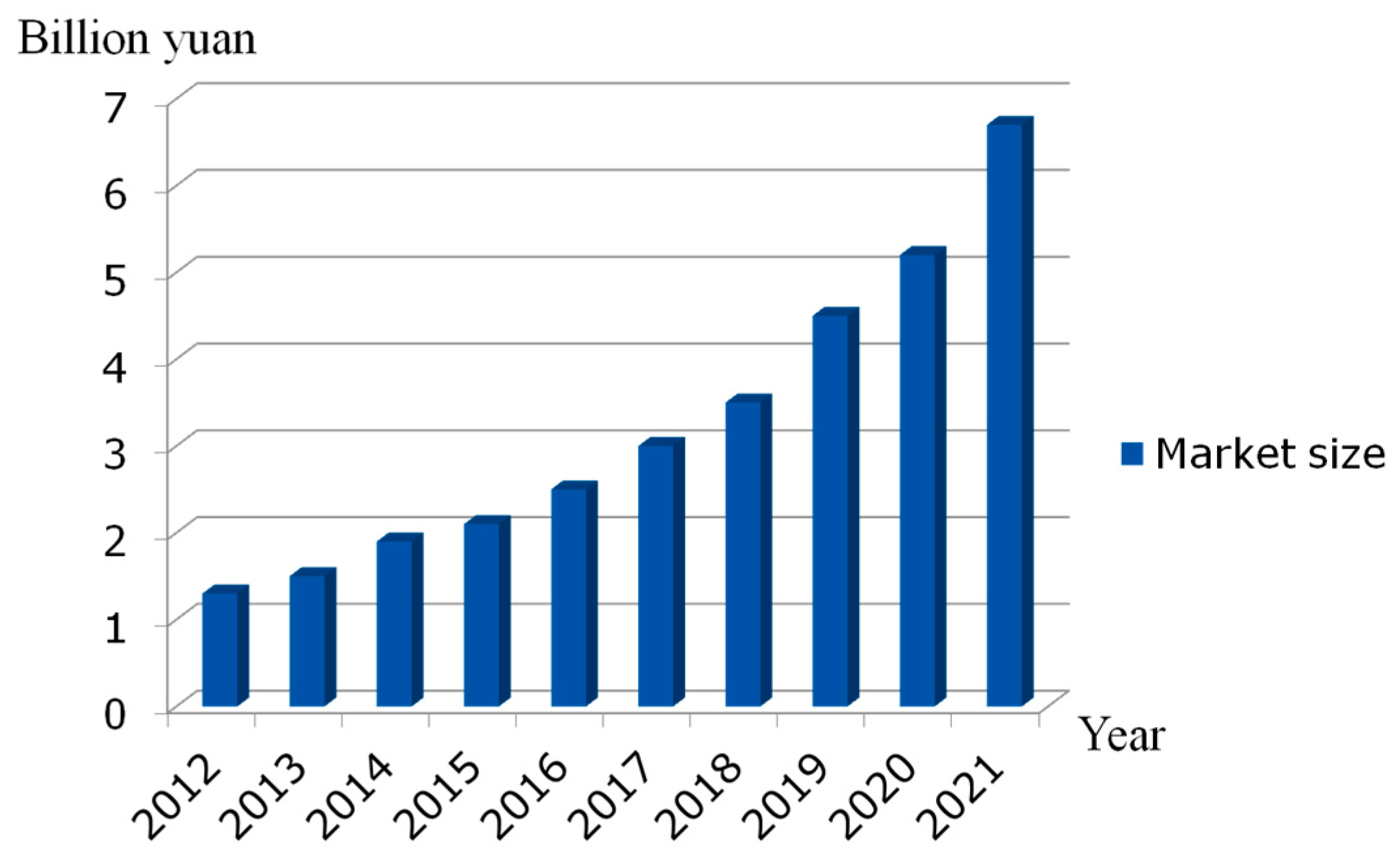

6.2. Market Size Analysis of Visual Inspection

In 2017, the size of the global machine vision market was about USD

$7.2 billion, growing 6.8% year-on-year. The market size is expected to be USD

$7.7 billion in 2018, and could break through USD

$9 billion in 2021, with an expected average annual compound growth rate of around 7.5% for 2018–2021. Germany and the United States are the world’s two largest national machine vision markets, accounting for more than 30% of the worldwide market in 2017. China’s machine vision industry has emerged since 2010, and is now in a period of rapid development. China’s market size in 2017 was CNY ¥2.9 billion (about USD

$42.64 million), accounting for 6.41% of the global market, and up 18.3% year-on-year. With the deepening of automation and the intellectualization of various industries, it is estimated that the average annual growth rate of China’s machine vision market will be around 20% in 2018–2021, which was higher than the global average growth rate, as shown in

Figure 12 [

90].

The world’s major machine vision manufacturers include Keenshi, Konrad, Darsa, Panasonic, and Omron. In 2016, their combined market share was about 38.0%. Typical Chinese enterprises are Daheng, New Epoch Technology, and Shenzhen JT Automation Equipment, which are less competitive compared with international well-known players, and each made up less than 1.5% of the global market in 2016.

At present, Chinese machine vision products are mainly used in semiconductor, electronic manufacturing, automobile, and other fields. The demand for machine vision in these fields accounted for nearly 60% of total demand in 2017.

7. Conclusions

In this paper, studies of software and hardware for visual detection from 90 papers are reviewed. The discussion of hardware includes coverage of cameras, light sources, and lighting modes, and a basis of selection is provided. In the software discussion, detection methods are divided into the categories of statistics, filtering, models, and machine learning according to basic theories of image processing. Classification methods are divided into supervised and unsupervised learning. The main ideas, advantages, and disadvantages of these methods are discussed, which can help users choose the most appropriate methods for different application environments.

Recommendations relating to the key technologies of visual detection, cameras, light sources, and image-processing algorithms can be summarized as follows:

The linear array camera is an inevitable choice for the selection of industrial cameras, because area-array cameras cannot achieve the resolution and frame rate required in conditions of high detection accuracy and fast motion. The frame rate of the camera must be greater than the speed of the object. Therefore, large frame rate, small pixel size line array cameras have good development prospects.

LED light sources have good color performance, a wide spectrum range (i.e., they can cover the whole range of visible light), high luminous intensity, and a long period of stability. As their manufacturing processes and technology matures, and prices fall, LED lamps will be used more widely.

It is difficult to select one kind of detection algorithm to meet the range of needs of accurate detection for multiple types of unbalanced defects; therefore, the fusion of multiple technologies is an expected trend.

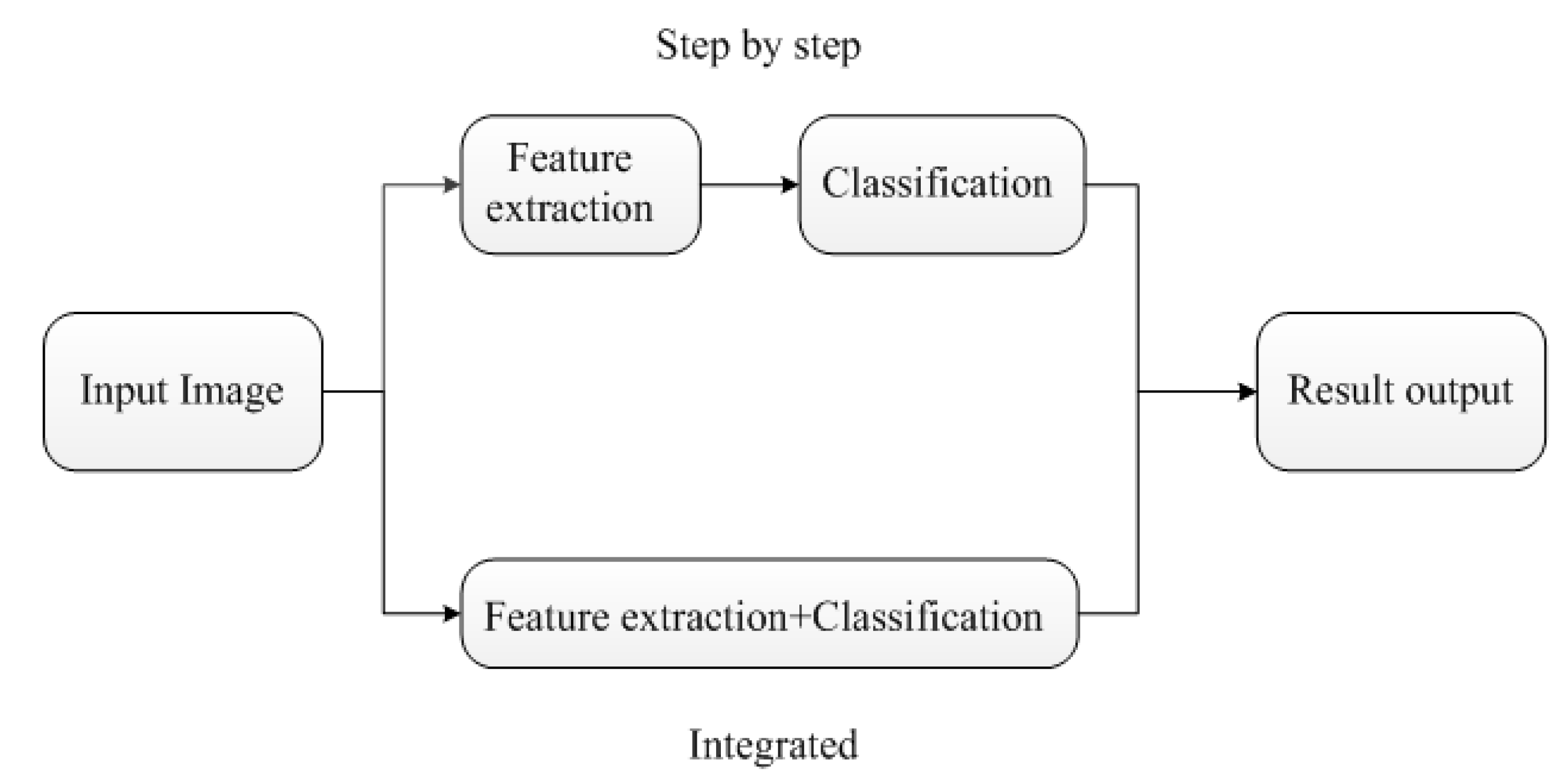

The conventional detection process starts with feature extraction, followed by classification and a result output. The feature extraction process adopts artificial design features, and is tedious and complicated. However, the end-to-end approach combines feature extraction and the classification process into one body through deep learning neural networks, and features are extracted automatically through the learning of training sets (

Figure 13), as seen in Yi [

40], Park [

82], Masci [

21]. This method is simple and achieves high detection accuracy. Moreover, it can be readily generalized. However, its biggest disadvantage is that it needs a large number of training images, with specific needs of training sets (e.g., the training set must cover sufficient defect types); otherwise, detection results are not ideal. The excellent performance of convolutional networks based on deep learning in the field of image processing makes it inevitable that it will be developed further in the future. The convolutional neural network algorithm with small and zero samples will be the focus of future research in the field of visual detection.

For industrial applications, it is important that real-time performance meets production requirements. However, detection accuracy depends on the complexity of the deep network, while the complexity of the network can restrict the production process. Therefore, it is a direction of future efforts to find a balance between algorithm complexity, detection accuracy, and time taken for detection.

A well-recognized standard data set and a good communication protocol for experimental data is required for the detection of defects on steel surfaces. Only in this way can fair, comparative analysis be realized.

In addition, our future work will pay attention to research progress on the detection of surface defects of steel products based on image processing in order to continuously enrich and update the relevant literature review.