1. Introduction

Nowadays, adding a paving asphalt layer on cracked cement concrete pavement is a widespread construction measure. Due to defects in the cement concrete layer, the bearing capacity of the structure decreases over time. As the pavement temperature increases, the effects of the interface bonding on the overlay response amplify [

1], and reflection cracks are more prone to occur in the overlay subjected to temperature change and loading; however, study has shown that glass fiber reinforced modified asphalt could strengthen the bonding and mitigate cracking of the overlay [

2]. In order to delay the development of reflection cracks, the stress-absorption layer has been adopted domestically, and some experiments have been carried out to validate the effects of anti-crack performance. The stress-absorption layer, set between the cement concrete layer and the asphalt layer, can delay the occurrence of a reflection crack, because the deformation and the ability of elastic recovery of the layer reduces the stress concentration [

3]. The stress-absorption layer is good at fatigue resistance, because the layer dissipates the concentrated stress and prevents the emergence of fatigue cracks in it, and consequently, it slows down the speed of propagation of the reflection crack, and thus attains the objectives of preventing and controlling the cracks. Nowadays, the theories and methods of fatigue fracture mechanics have been used to study the cracks of asphalt pavement. The nonlinear X-SBFEM (which is the extended proportional boundary finite element method) is capable of modeling the nonlinear fracture propagation process while taking into account the effects of cohesive interactions [

4], because the main reason for the failure of the asphalt pavement is fatigue failure under the persistent actions of traffic load and temperature load. Therefore, research of the fatigue crack propagation law of the asphalt pavement is important. The fatigue failure of asphalt pavement can be divided into two stages: The fatigue-initiation stage and the fatigue fracture stage. Some experience has been accumulated in the study of the fatigue initiation stage, and the results have been used so far. The study of the fatigue fracture stage showed that the fractured area increased significantly as the interface bonding strength decreased. On the contrary, the fractured area decreased slightly as the interface stiffness decreased [

5].

In the past, model I cracks were researched mainly through fatigue fracture tests for asphalt-overlay composite pavement. In fact, I-II composite cracks have existed extensively in pavement structures, but few experiments have been conducted [

6,

7,

8,

9,

10,

11]. The propagation behavior of composite cracks was previously simulated through the uniaxial compression experiment using a notched beam, but the cyclic loading was not applied, and the type of crack and the trend of the crack propagation were also lacking [

12]. Test simulations of the propagation process of load reflective cracking and temperature reflective cracking have been carried out to evaluate the cracking resistance of the stress-absorption layer, and it has been proven that paving of the stress-absorption layer is a good method to delay reflection cracks; however, only the influence of loading and temperature on the stress-absorption layer was tested, the material of the stress-absorption layer and the crack were not included [

13]. The effects of the thickness of the stress-absorption layer on the speed of the propagation of the reflection crack have also been investigated, but the mechanism of the stress-absorption layer was not quite clear [

14,

15,

16,

17]. With the increase of the thickness of the stress-absorption layer, the speed of the propagation of the reflection crack would decrease, but the flexural and tensile effects of the overlay would increase, and also the cost [

18,

19,

20]. It has been verified by engineering that the optimal thickness of the interlayer is 20–40 mm [

9,

10,

21]. Laboratory investigations of three types of stress-absorption layer have been carried out by fatigue experiments. The results showed that the fatigue property of the rubber asphalt stress absorption layer (RASAL) was the best, and the service life of the pavement could be improved significantly by the material; however, the crack resistance of the stress-absorption layer is not very clear [

22]. The abovementioned research shows that the stress absorption-layer is good at crack resistance. However, the analyses of the effects of the stress-absorption layer on the crack propagation process and the propagation trend of different crack types were not enough. It is important to study the influence of anti-crack additives, different crack modes, and test configurations on the crack propagation process and the propagation trend. Much research has been done on this. The mixed mode I/III fracture toughness of asphalt concrete materials was determined using the Edge Notched Disc Bend specimen [

23]. Mixed mode I/II fracture toughness of five modified asphalt mixtures containing poly phosphoric acid (PPA), Styrene Butadiene Styrene (SBS), anti-stripping agent, crumb rubber (CR), and F-T paraffin wax (Sasobit), and an unmodified one (with no additive), were investigated experimentally using a large number of cracked semi-circular bend (SCB) specimens [

24]. Two circular shape test specimens were designed and examined for the experimental determination of mode I fracture toughness in different modified hot mix asphalt materials [

25]. The effects of carbon nanotubes as a binder modifier on the fatigue and fracture performance of asphalt mixtures were investigated [

26]. Asphalt characteristic effects on its mixed mode I/II low temperature fracture toughness have also been investigated experimentally [

27].

One study showed that for top-down cracking when the pavement was under repeated loading, shear damage occurred first in the asphalt layer, and then the damage extended horizontally, resulting in a shear-damaged layer. The damaged layer then led to a higher tensile strain in the upper mixture, which caused tension cracks, that finally propagated upwards to the pavement surface [

28]. In this study, laboratory investigations of the anti-crack performance of the high viscous asphalt sand stress absorption layer (HVASAL) and the RASAL, and the propagation mechanism of different types of cracks, were carried out by force-controlled fatigue crack propagation tests, for which three types of overlay structure with three types of pre-crack were designed. The tests were conducted at room temperature and at the same loading rate, with the cyclic loading applied at the middle of the specimen. The three types of pre-crack were the middle crack, the side crack, and the 45° inclined crack. The fatigue crack propagation, fatigue life, crack propagation rate, and crack propagation mechanism of the three types of overlay structure were compared and analyzed. The crack propagation process of the three types of overlay with the same type of crack, and the three types of crack with the same type of overlay, were compared and analyzed as well. Considering the dispersion of the data of the crack propagations, a random probability model (

model) based on the reliability theory was established to describe the propagation of the fatigue cracks. Using the least-square method, the relationships between the crack length

a and the fatigue number

N of the three types of crack were obtained by fitting the polynomials. The crack growth rates during the stable growth period of the three structures, and then the anti-crack performance of the structures, were compared. The curves of the three types of crack were analyzed. The variations of the intercept

and the slope

n with the reliability

p were discussed.

2. Materials and Methods

The size of the composite structure specimen was 300 × 90 × 100 mm

3. The concrete composite had two or three layers: The No SAL type had a 50 mm AC-13 (a type of asphalt concrete) surface (layer I), and a 50 mm cement concrete layer (layer II); the HVASAL type had a 30 mm AC-13 surface (layer I), a 20 mm HVASAL (layer II), and a 50 mm cement concrete layer (layer III); the RASAL type had a 30 mm AC-13 surface (layer I), a 20 mm RASAL (layer II), and a 50 mm cement concrete layer (layer III). Three types of penetrating crack were designed (i.e., the middle crack, the side crack, and the 45° inclined crack), and the width of the cracks was 5 mm [

29], as shown in

Figure 1 and

Figure 2.

A 70# asphalt (marking in accordance with the Chinese standard of the Technical Specifications for Construction of Highway Asphalt Pavements (JTG F40—2017) with a penetration of 70 was used as the asphalt binder for preparation of the specimens, and its specifications provided by the manufacturer are listed in

Table 1. Limestone was used as the aggregate. The ratio of binder to aggregate was 8.1% by weight. The continuous aggregate gradation, having the nominal maximum size of 9.5 mm, is listed in

Table 2. An additional 1% activated rubber crumb and 0.7% TCA additive (percentage of the mass of asphalt mixture) was added during the blending process.

- (1)

To set the pre-crack, a board was placed in the test mold, and then the cement concrete was poured into the mold and flattened.

- (2)

The mixed asphalt mixture was poured into the cement concrete rutting boards and compaction was performed.

- (3)

The composite board was cut into specimens.

The prepared specimens with the middle crack are shown in

Figure 3.

To accurately evaluate the crack resistance of HVASAL and RASAL, and investigate the propagation mechanism of the three types of crack, three-point bending failure tests and three-point bending fatigue performance tests were designed. Three-point bending failure tests were conducted to obtain the needed parameters for the three-point bending fatigue tests. Because of the thinness of the structure layer and the stress-absorption layer studied, the force control mode is closer to the actual stress state of the asphalt mixture in the pavement, so it can better explain the fatigue characteristics of the high viscosity asphalt [

11]. Hence, the force-controlled loading mode was adopted for the three-point bending fatigue tests. For both the failure and the fatigue tests, the test temperature was set at 15 °C, the loading mode was the intermediate loading, the distance between the two ends was 250 mm, and the pressure head rate of the test machine was 2 mm/min, as shown in

Figure 4. The ultimate load of the specimen was obtained by the three-point bending failure test. Forty percent of the ultimate load was used as the load for the three-point bending fatigue test.

4. Discussion and Conclusions

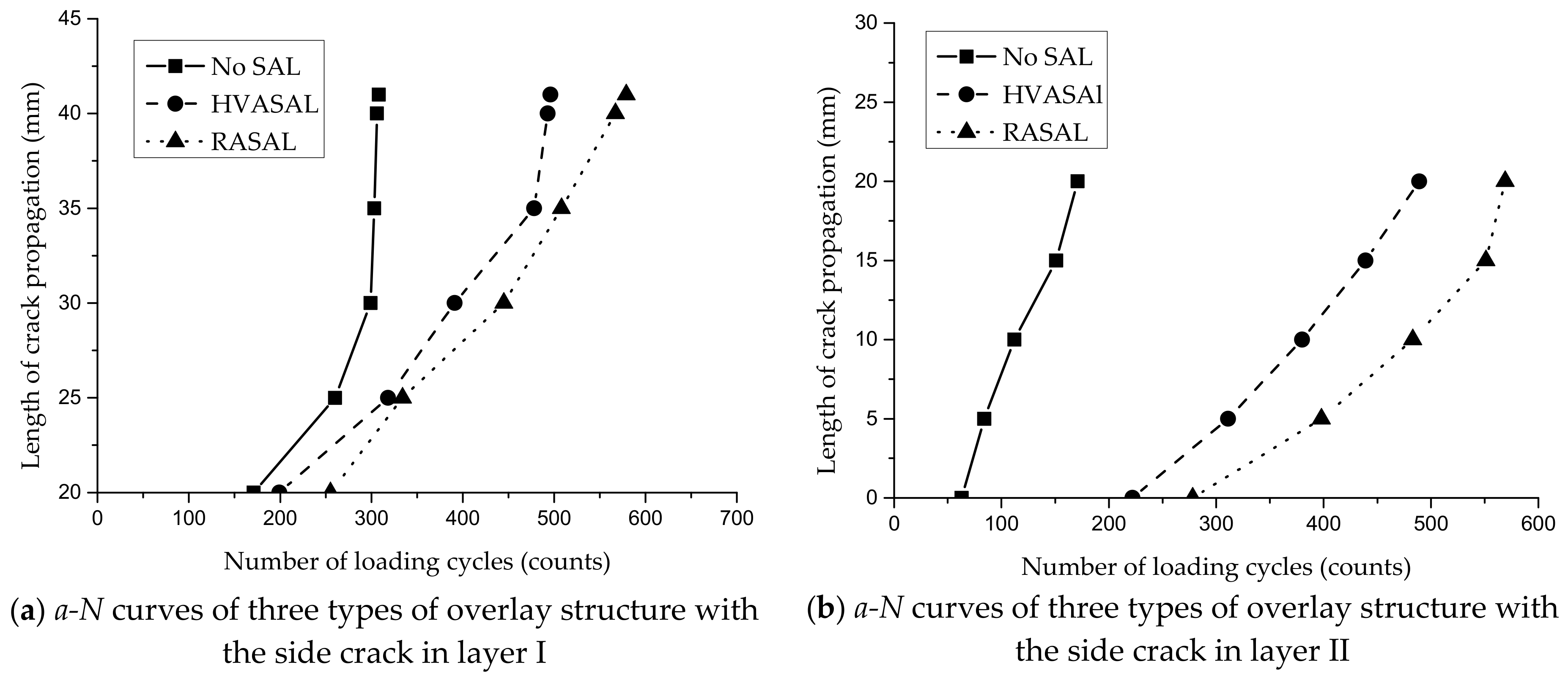

(1) Fatigue crack propagation experiments with the cyclic loadings acting in the middle of the specimens were carried out for three types of the old cement concrete asphalt overlay. The results show that for the fatigue numbers of the pre-crack of the three types of crack, the HVASAL type is 2.34 times, 3.15 times, and 2.84 times than that of the No SAL type; and the RASAL type is 3.25 times, 4.05 times, and 3.27 times that of the No SAL type. The results show that for the final fatigue lives of the three types of crack, the HVASAL type is 1.79 times, 1.61 times, and 1.55 times that of the No SAL type; and the RASAL type is 2.01 times, 1.87 times, and 1.72 times that of the No SAL type. After the stress-absorption layers were added, the fatigue lives of the structures increased significantly. The anti-crack performance of the RASAL is better than that of the HVASAL.

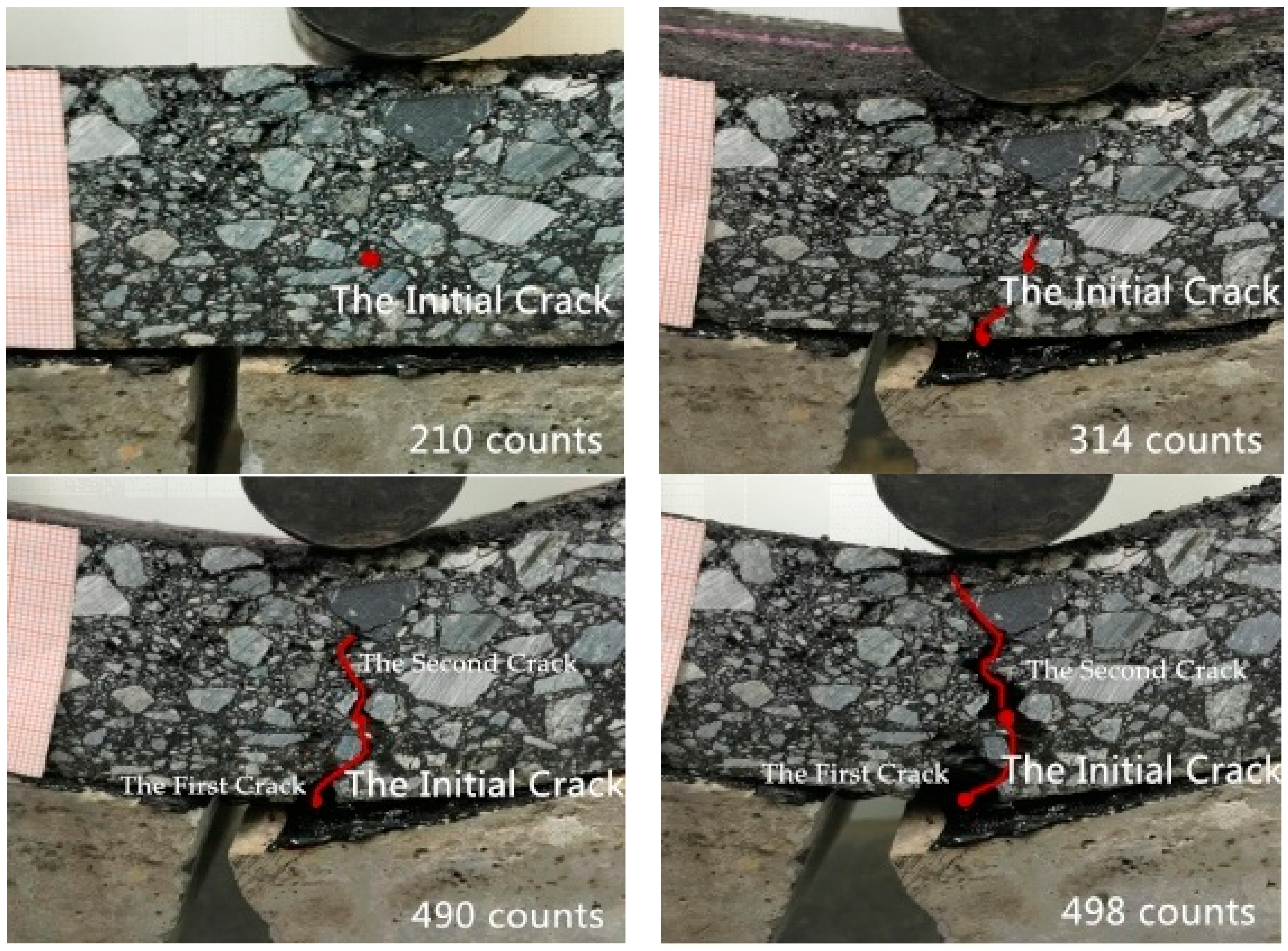

(2) The propagation processes, and the directions of the overlay cracks of the composite specimens, were analyzed and recorded. It was found that the cracks in the stress-absorption layer always initiated from the interface of layers I and II, then once there was a crack in the stress-absorption layer, the two cracks expanded at the same time. The crack propagation direction of the No SAL type structure was the same as the structure with a stress-absorption layer, but the crack expansion area was relatively concentrated. This demonstrated that the stress absorption layer could disperse the concentrated stress and reduce the peak stress caused by cracks in cement concrete, hence the reflection cracks were delayed.

(3) The three types of structure and three types of crack (the middle crack, the side crack, and the inclined crack) have different effects on the fatigue properties of the asphalt overlay on the cement concrete basement. The inclined crack has the maximum fatigue life, the side crack has the minimum life, and the middle crack has an in-between life.

(4) These three test configurations provide three different mixed mode behaviors of cracks. As middle cracks occurred, there were two initial cracking points in the structure with the stress-absorption layer, with one located at the interface between the stress-absorption layer and the surface layer, and the other located at the bottom of the stress-absorption layer; subsequently, the stress-absorption layer and asphalt overlay would fracture. When there is no stress-absorption layer, the crack occurred along the interface of the cement concrete layer, passing through the overlay to all the specimens; the crack propagated in the direction of a certain lateral deviation and then had a straight upward expansion. For the side crack, the mechanism of the initial cracking points in the structure with stress-absorption layer were the same as that of the middle crack; one propagated vertically upward in mode I, the other propagated to the span center at a 45° angle in a mixed mode I and II. When there is no stress-absorption layer, the initiation of the crack was the same as that of the middle crack; that is, it propagated to the span center in a mixed mode I and II, extended directly below the pressure head, and then the specimen was destroyed. For the inclined crack, the mechanism of the crack propagation with the stress-absorption layer is the same as the former two types. When there is no stress-absorption layer, the crack occurred at the bottom of the asphalt overlay, and then some cracks appeared in the middle of the specimen due to the loading at the right of the crack, and propagated to the pressure head until the specimen failed. The mechanism of crack initiation is the same; however, the propagation direction and mode are different due to the relative loading position and the type of cracks.

(5) The probability model quantifies the relationship between the crack propagation rate and ∆K. Two important parameters C and n, in Paris formula based on reliability, are consistent with the variation of the crack type in crack propagation. The effects of the three types of crack on the fatigue properties of the asphalt overlay are different. The reliability values of fatigue fracture by different crack types can be studied further to improve existing reliability theories, while solving practical problems.

(6) The p-da/dN probabilistic model can be used to study the effects of different cracks on C and n. Two important parameters of the Paris formula and the variation of crack type in crack propagation were obtained. Under different reliability, the parameter n is the largest in the No SAL type. The larger the slope is, the faster the crack growth, the worse the crack resistance, and the shorter the fatigue life. Therefore, the structure with the stress-absorption layer can effectively reduce the crack propagation rate, and effectively extend the service life of pavement.

(7) Asphalt mixture has an obvious brittle or quasi-brittle behavior at low temperature, so the fatigue crack propagation can be analyzed based on fracture mechanics. The critical fatigue crack propagation of the specimen with the middle crack occurs at the center of the bottom of the specimen, and the critical fatigue crack propagation of the specimens with the side crack and inclined crack occurs in the direction of maximum circumferential normal stress. There exist three stages of fatigue crack propagation (i.e., the crack initiation stage, the stable crack propagation stage, and the unstable fracture stage) in brittle or quasi-brittle materials, like the asphalt mixture at low temperature. After the cracking initiation, the toughness of the material increases with a stable crack growth until the unstable fracture happens. The increase of the toughness of material during the stable crack propagation is due to the cohesive force on the fictitious crack zone. The initial cracking point and the critical fracture point can be distinguished from a complete process of crack propagation, which can be described by the double-K criterion.