Reliability-Based and Cost-Oriented Product Optimization Integrating Fuzzy Reasoning Petri Nets, Interval Expert Evaluation and Cultural-Based DMOPSO Using Crowding Distance Sorting

Abstract

:Featured Application

Abstract

1. Introduction

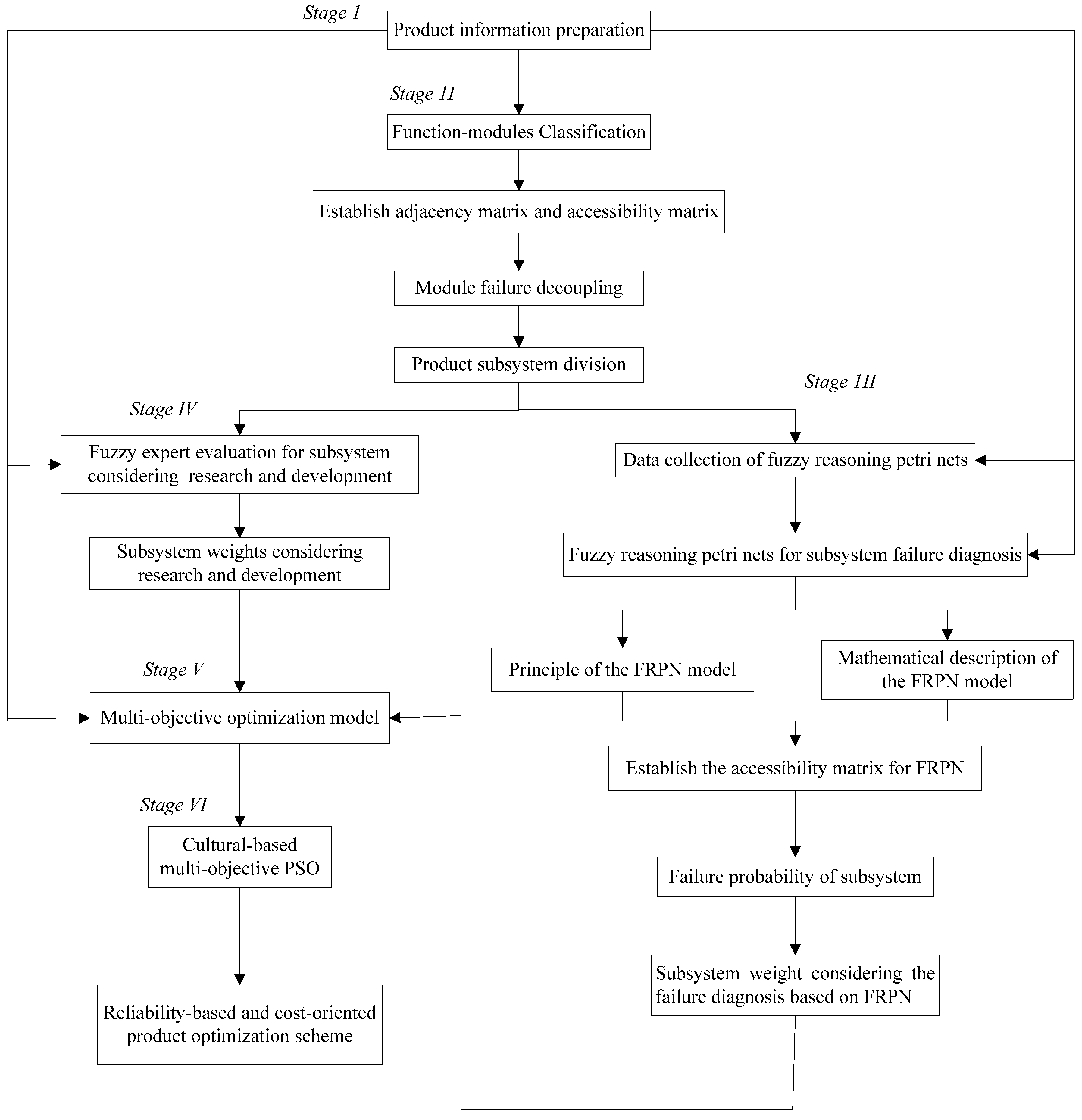

2. Framework of Proposed Method

3. Detailed Operators

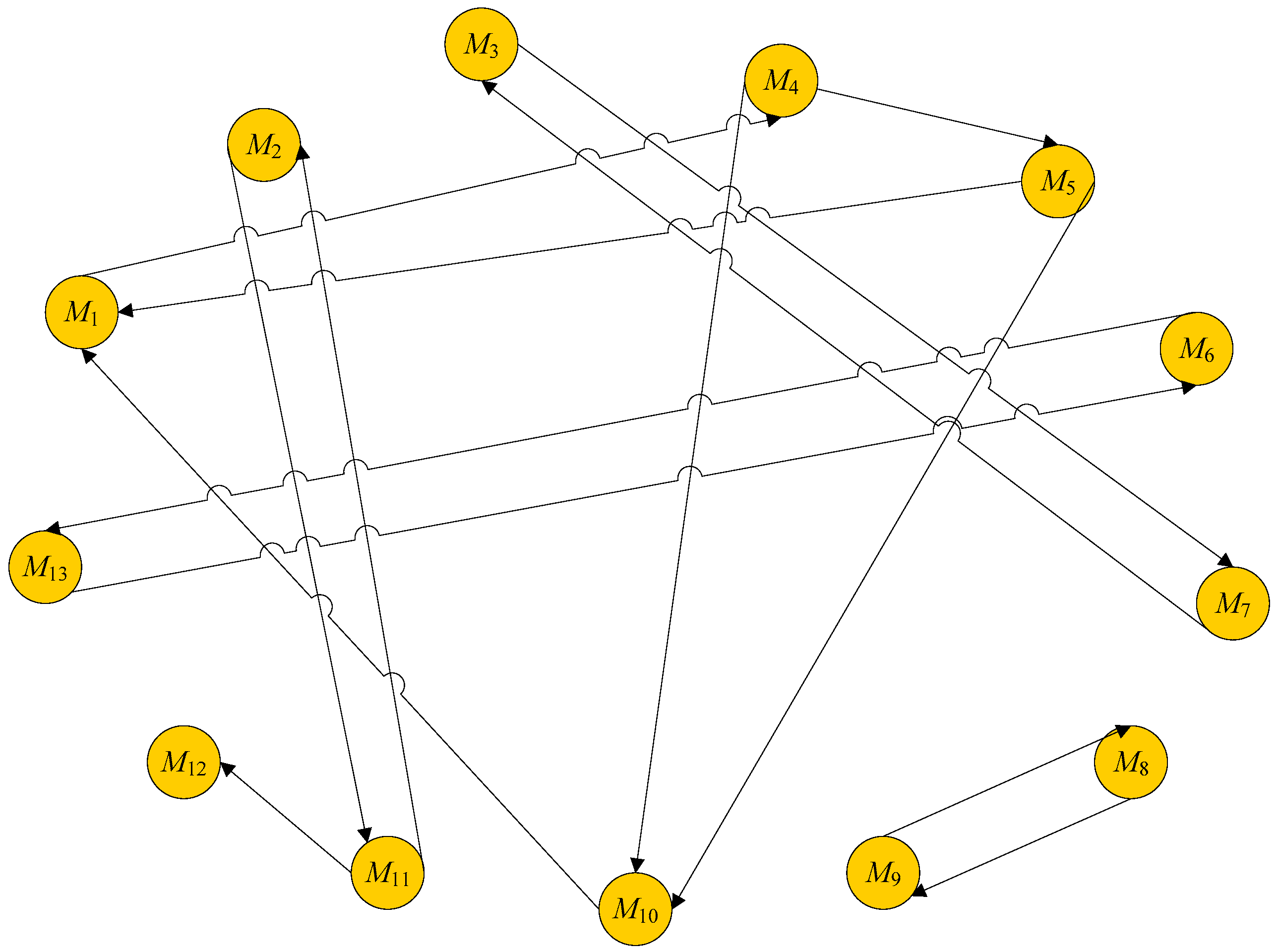

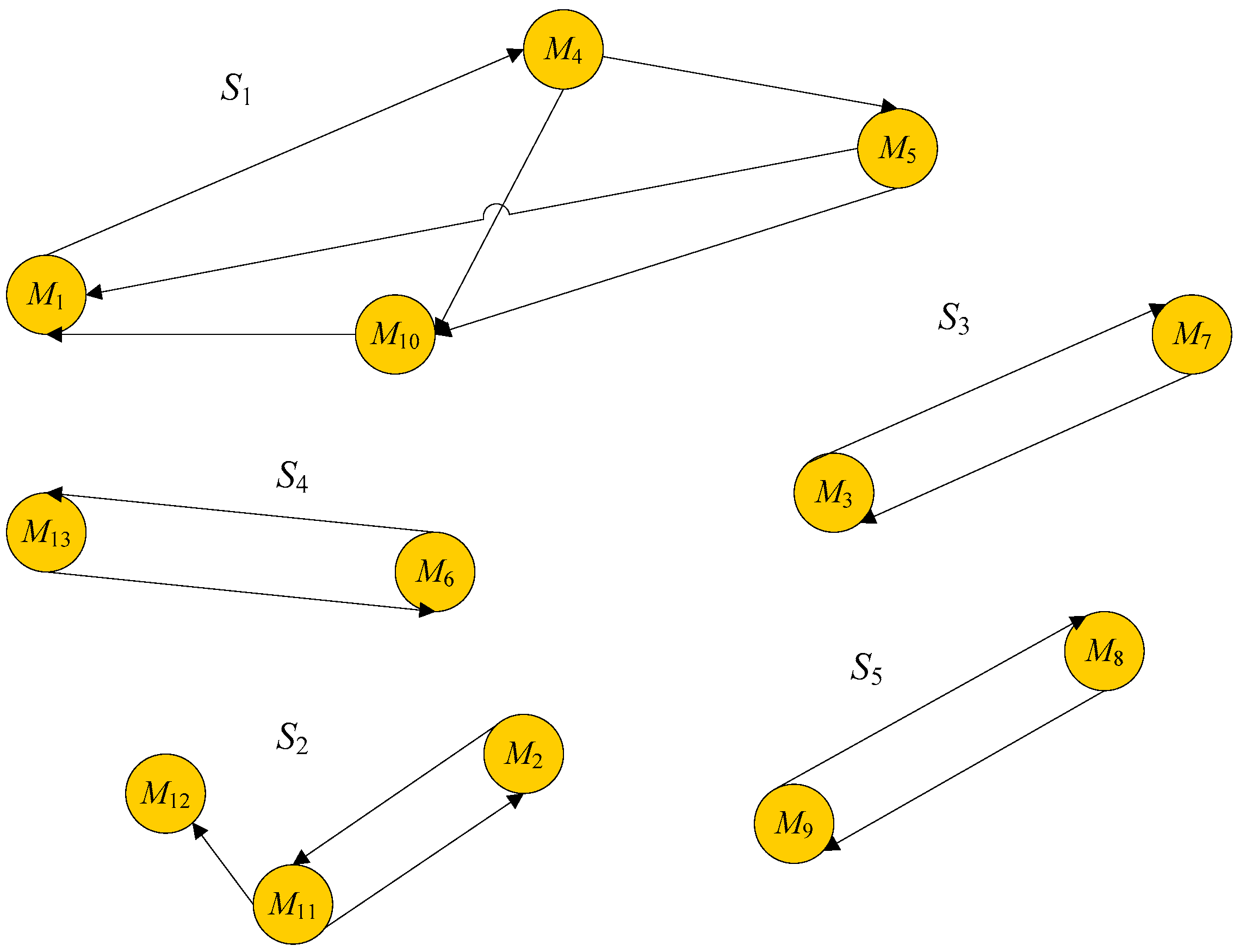

3.1. Subsystem Division Based on Failure Decoupling

- Build the adjacency matrix based on the directed graph and its transposed matrix .

- Analyze the yth column of the adjacency matrix A and AT (k = 1, 2, …, n). If the element axy of A is 1 and the ary of AT is 1, set the all the axr of A to be 1 with the adoption of permutation and combination. Establish its derivative matrix represented as M.

- Obtain the transposed matrix of M, denoted as MT.

- Process the matrix M and the matrix MT according to the above iterative criterion. Stop the iteration until the elements in M do not change as the number of iterations increases.

- Replace all the elements in the leading diagonal of M by 1 to get the reachability matrix .

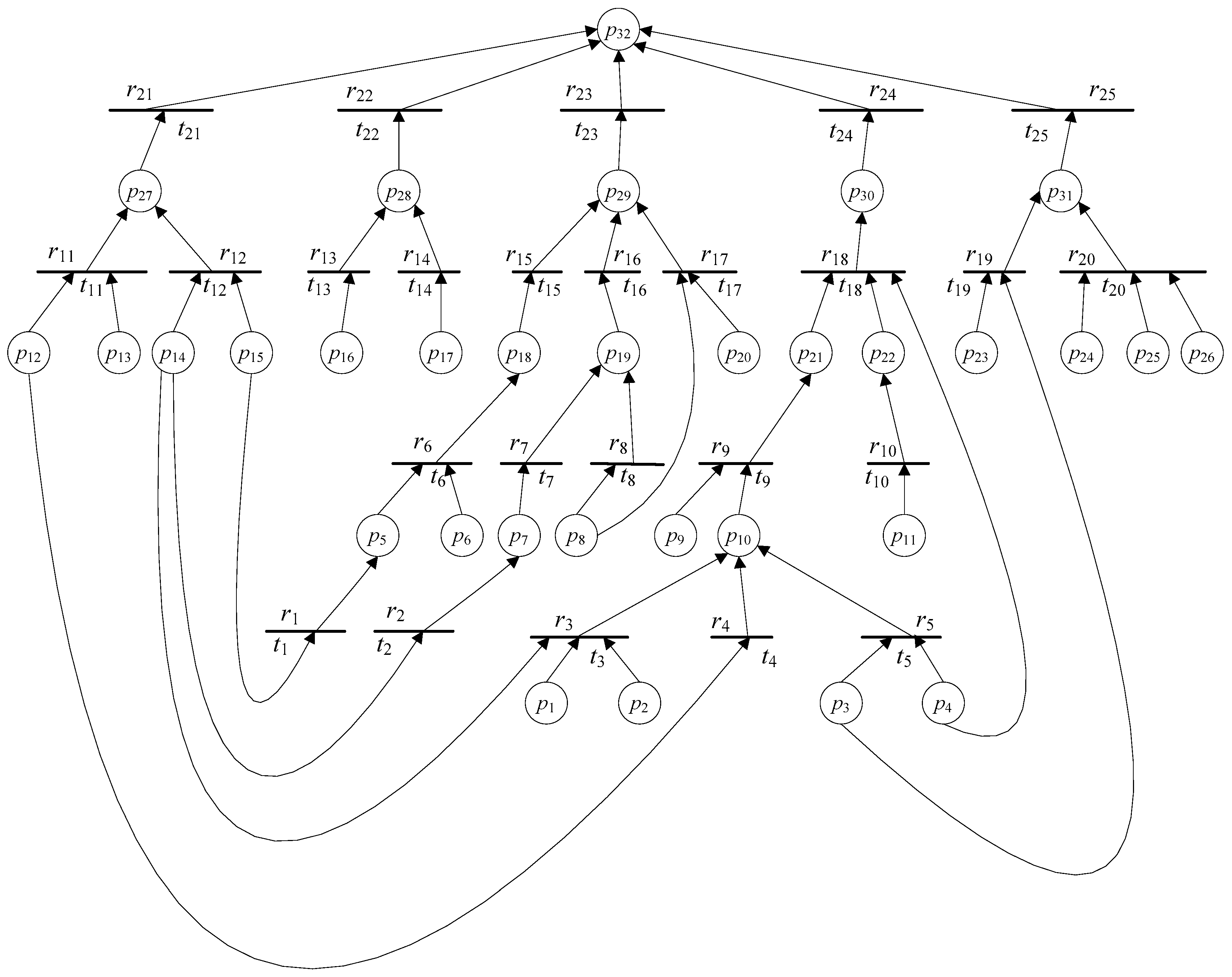

3.2. Subsystem Weight Considering the Failure Diagnosis Based on FRPN

3.2.1. Fuzzy Production Rules

3.2.2. Definition of Fuzzy Petri Nets

- P = {p1, p2, …, pn} is the finite set of the fuzzy places, and they represent a series of fuzzy propositions;

- Trans = {r1, r2, …, rn} is the finite set of the transitions, and they represent the implementation of fuzzy rules;

- I is the directed arcs matrix from propositions to rules. I (pi, rj) = 1 if there is a directed arc form the proposition pi to the rule rj; otherwise, I (pi, rj) = 0. i = 1, 2, …, n; j = 1,2, …, m.

- O is the directed arcs matrix from rules to propositions. O (pi, rj) = 1 if there is a directed arc form the rule rj to the proposition pi; otherwise, O (pi, rj) = 0. i = 1, 2, …, n; j = 1, 2, …, m.

- U is the true degree matrix of propositions, u = (u1, u2, …, un)T, and ui is within (0, 1) (i = 1, 2, …, n).

- C = diag {c1, c2, …, cm} is the confidence matrix of fuzzy production rules, and cj is the confidence of the fuzzy production rule rj (j = 1, 2, …, n).

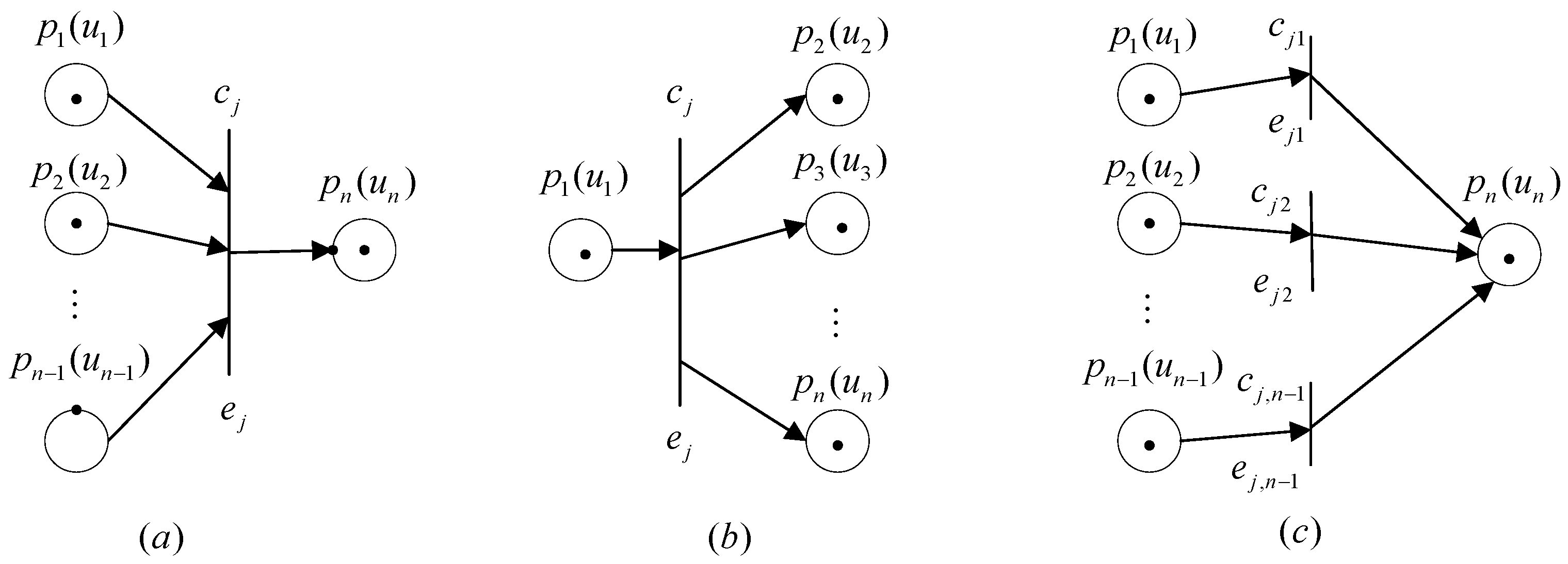

3.2.3. Fuzzy Production Rules with FRPN

3.2.4. Compound Fuzzy Production Rules with FRPN

- Type 1:

- Type 2:

- Type 3:

- Type 4:

3.2.5. Fuzzy Reasoning Algorithm of FRPN

3.3. Subsystem Weight Considering Development Cost Based on Interval Expert Evaluation

3.4. Mathematical Model of Reliability-Based and Cost-Oriented Optimization

3.5. Adoption of Cultural-Based DMOPSO Using Crowding Distance Sorting

4. Numerical Example

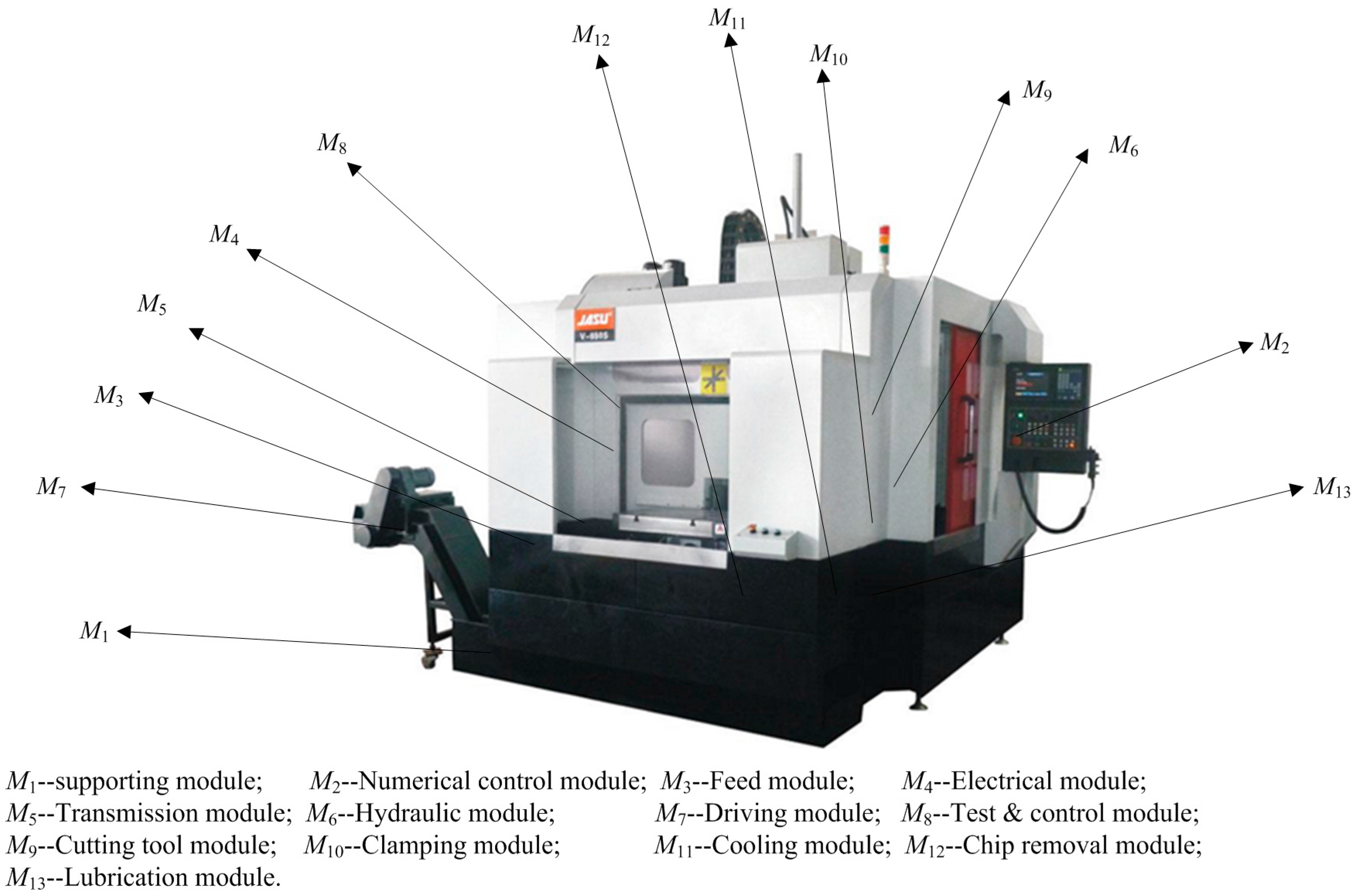

4.1. Subsystem Division Based on Failure Decoupling of CNC Machine Tool

4.2. Failure Diagnosis Based on FRPN of CNC Machine Tool

4.3. Interval Expert Evaluation for CNC Machine Tool

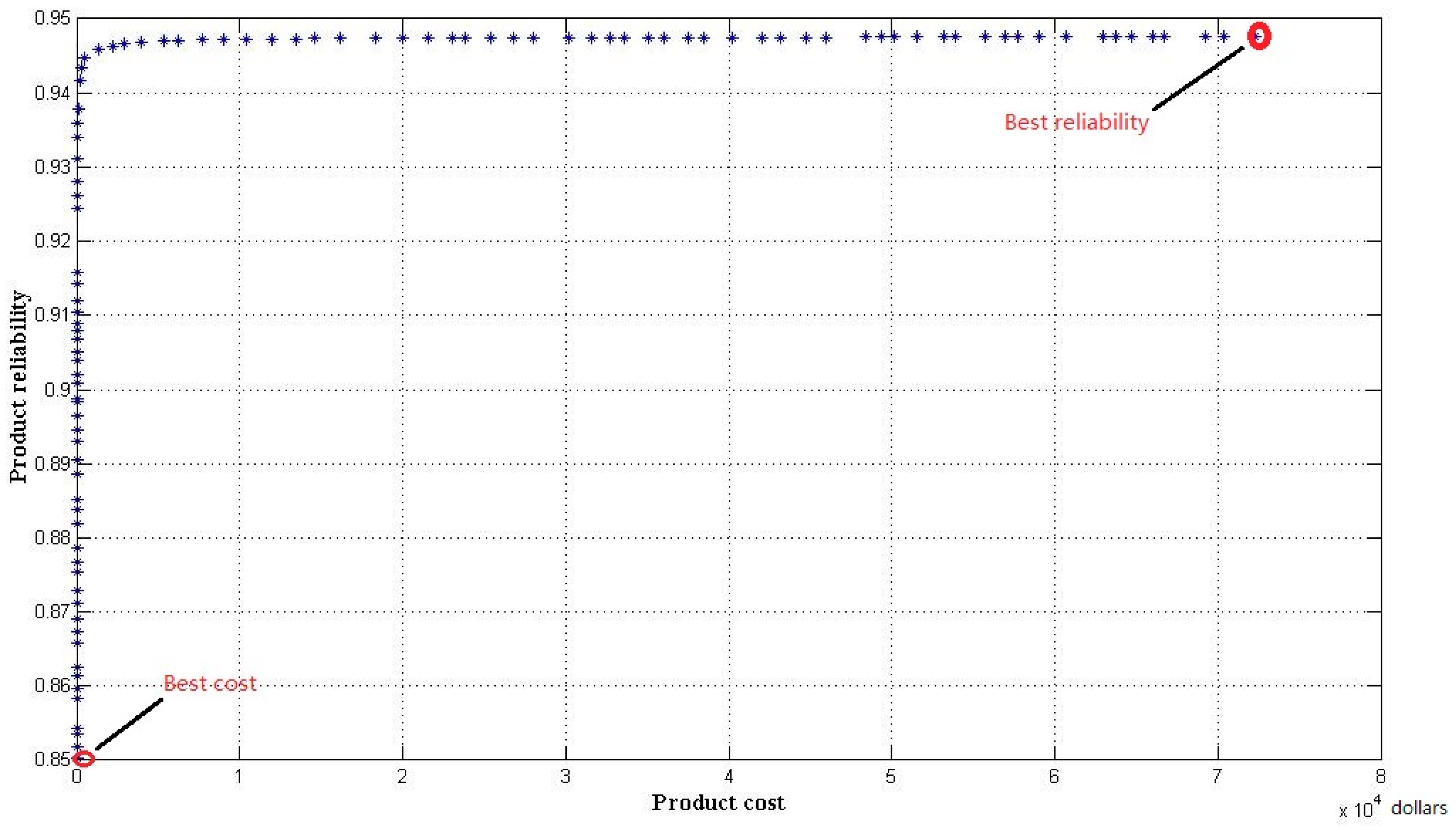

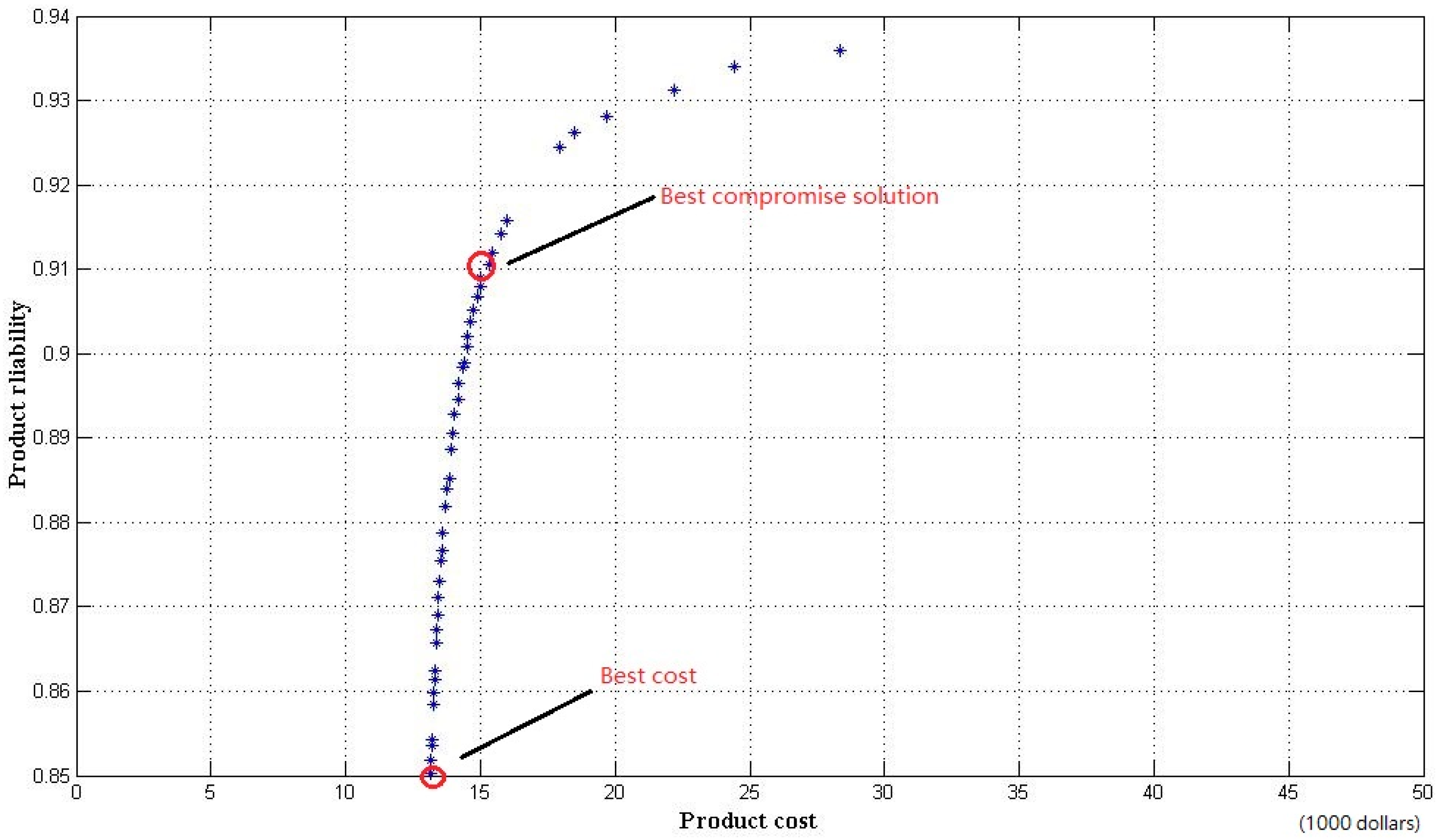

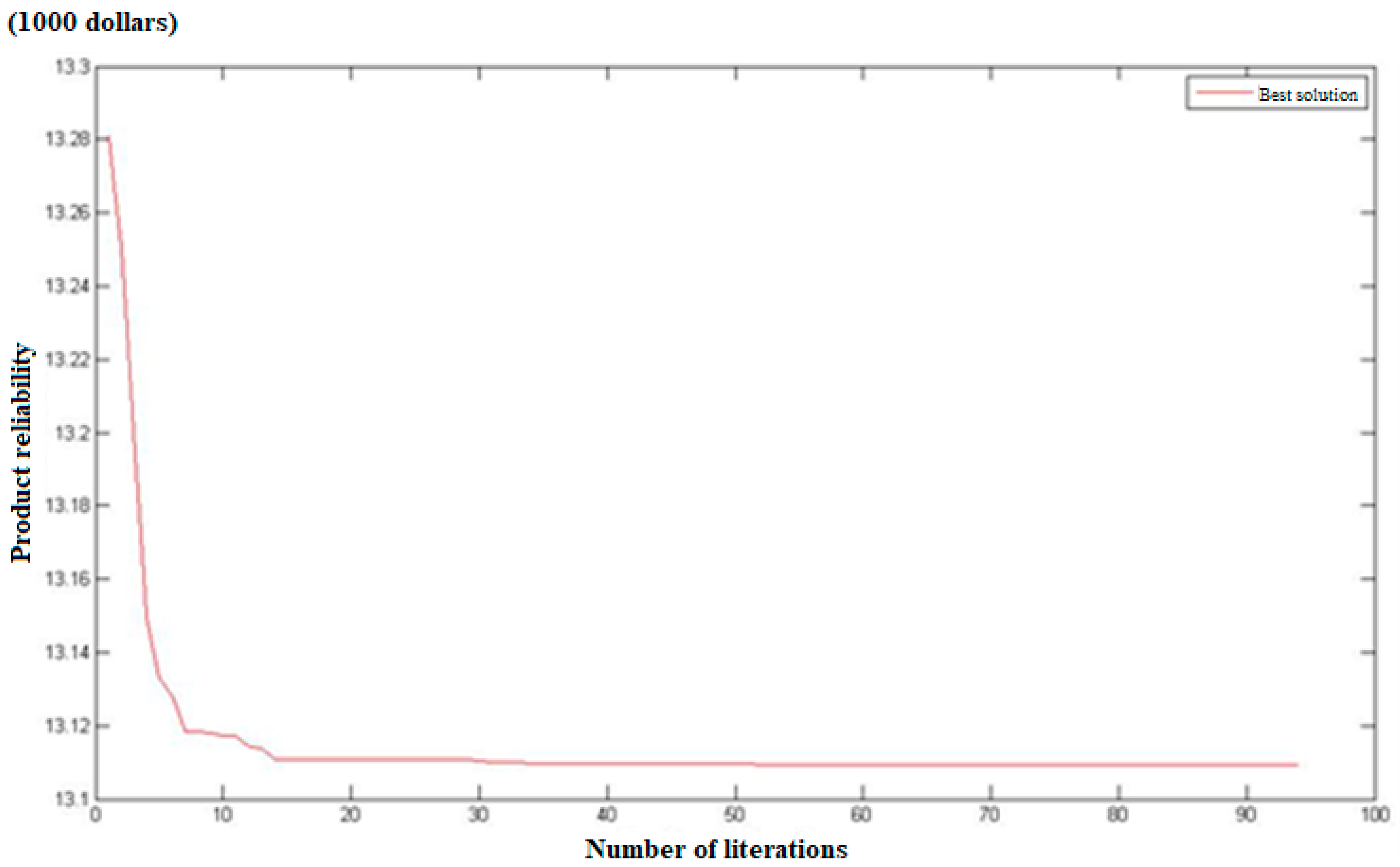

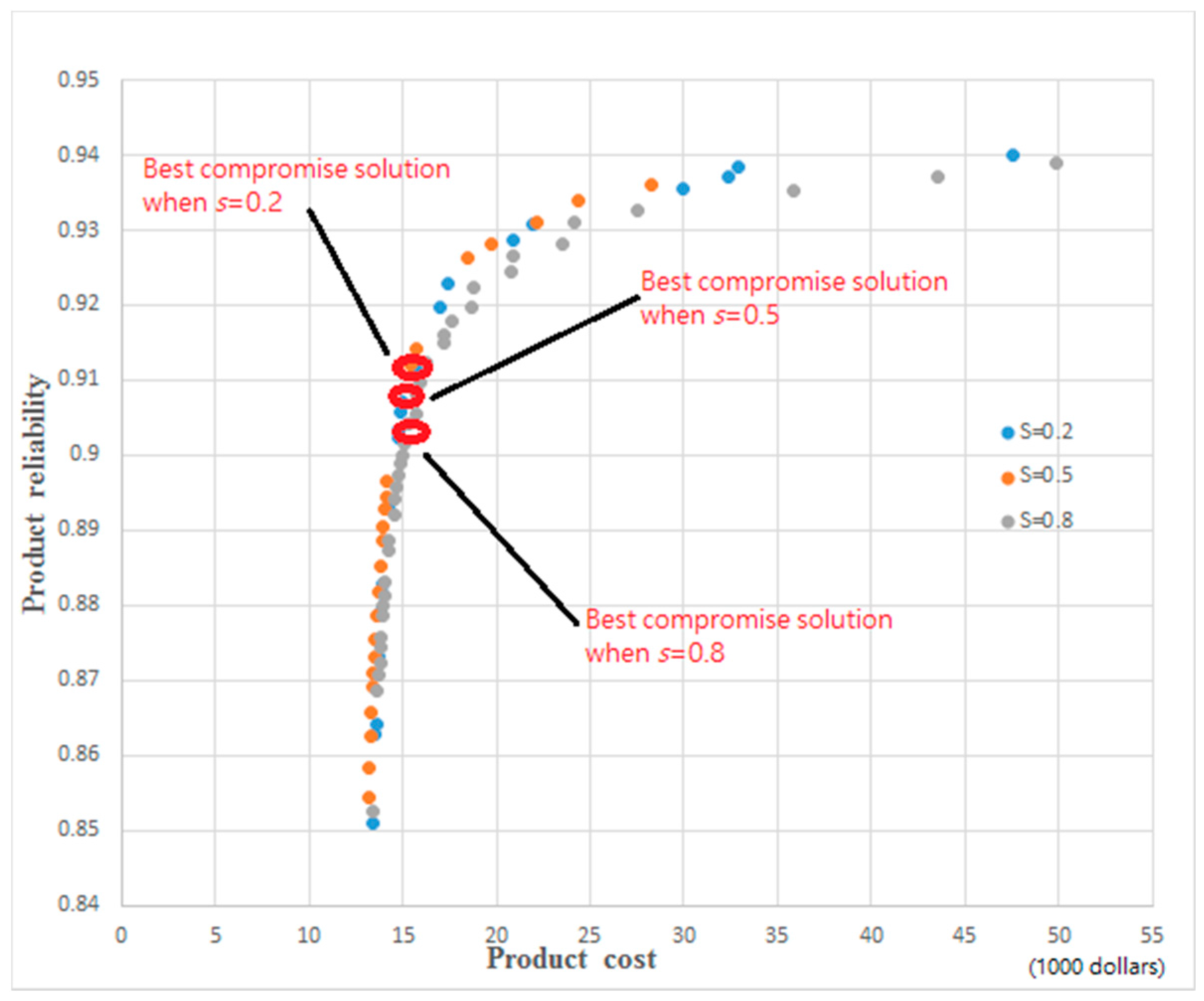

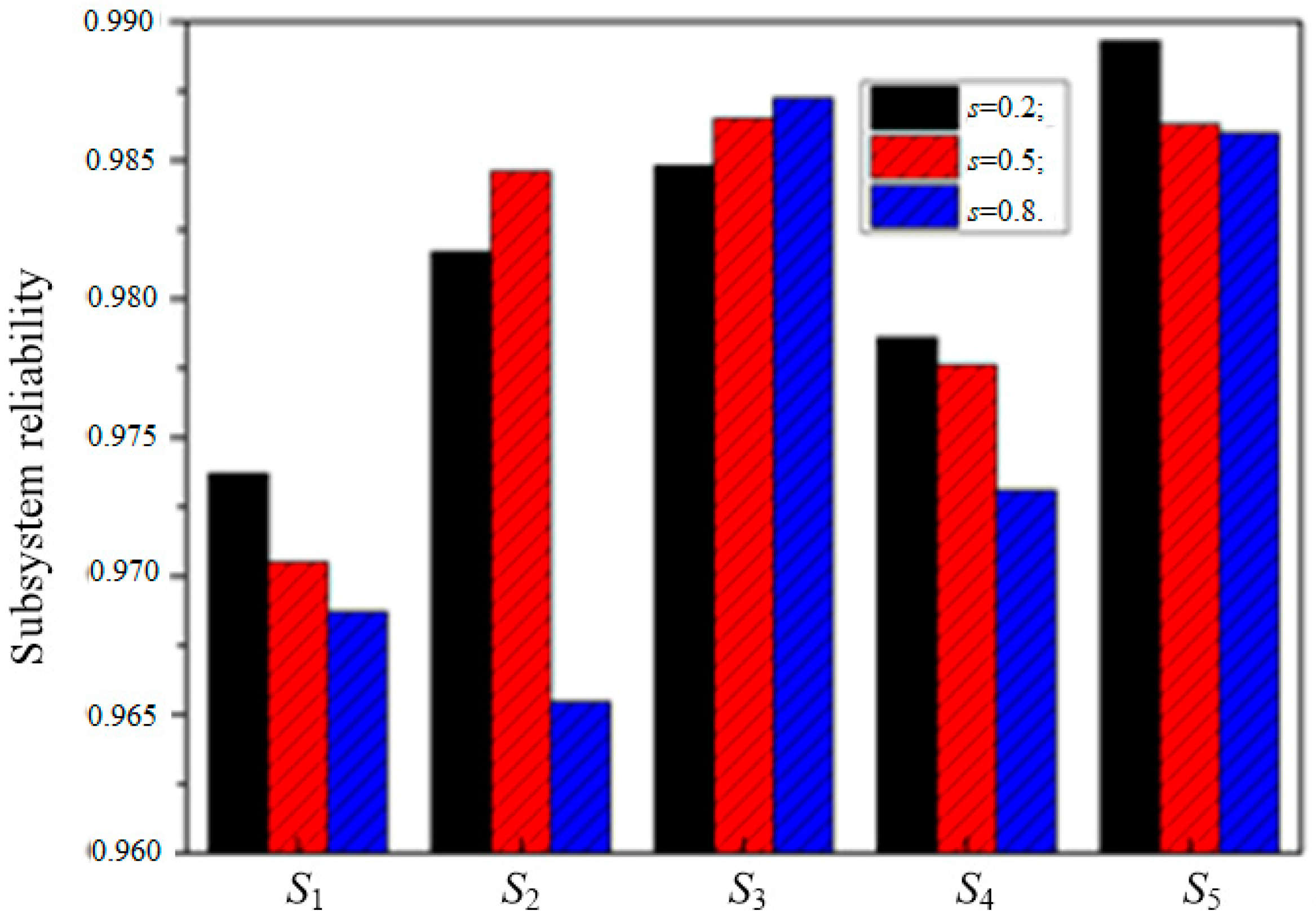

4.4. Reliability-Based and Cost-Oriented Optimization and the Solution

5. Comparison and Sensitive Analysis

5.1. Comparison

5.2. Sensitivity Analysis

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, H.; Kim, P. Reliability–redundancy allocation problem considering optimal redundancy strategy using parallel genetic algorithm. Reliab. Eng. Syst. Safe. 2017, 159, 153–160. [Google Scholar] [CrossRef]

- Abouei, A.M.; Sima, M.; Zeinal, H.A.; Coit, D.W. A novel strategy for redundant components in reliability–redundancy allocation problems. IIE Trans. 2016, 48, 1043–1057. [Google Scholar] [CrossRef]

- Conti, S.; Faraci, G.; La, C.A.; Nicolosi, R.; Rizzo, S.; Schembra, G. Effect of Islanding and Telecontrolled Switches on Distribution System Reliability Considering Load and Green-Energy Fluctuations. Appl. Sci. 2016, 6, 138. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Cheng, Q.; Qi, Y.; Cai, L. An approach of comprehensive error modeling and accuracy allocation for the improvement of reliability and optimization of cost of a multi-axis NC machine tool. Int. J. Adv. Manuf. Technol. 2016, 89, 561–579. [Google Scholar] [CrossRef]

- Khorshidi, H.A.; Gunawan, I.; Ibrahim, M.Y. A value-driven approach for optimizing reliability-redundancy allocation problem in multi-state weighted k-out-of-n system. J. Manuf. Syst. 2016, 40, 54–62. [Google Scholar] [CrossRef]

- Di, B.G.; Forcina, A.; Silvestri, A. Critical flow method: A new reliability allocation approach for a thermonuclear system. Qual. Reliab. Eng. Int. 2016, 32, 1677–1691. [Google Scholar]

- Govindan, K.; Jafarian, A.; Azbari, M.E.; Choi, T.M. Optimal bi-objective redundancy allocation for systems reliability and risk management. IEEE Trans. Cybern. 2016, 46, 1735–1748. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Zheng, S.; Liao, H.; Feng, J. A multi-attribute reliability allocation method considering uncertain preferences. Qual. Reliab. Eng. Int. 2016, 32, 2233–2244. [Google Scholar] [CrossRef]

- Cheng, J.; Tang, M.; Liu, Z.; Tan, J. Direct reliability-based design optimization of uncertain structures with interval parameters. J. Zhejiang Univ. Sci. A 2016, 17, 841–854. [Google Scholar] [CrossRef]

- Deng, S.; Yue, D.; Fu, X.; Zhou, A. Security Risk Assessment of Cyber Physical Power System Based on Rough Set and Gene Expression Programming. Acta Autom. Sin. 2015, 2, 431–439. [Google Scholar]

- Chang, K.H. A more general reliability allocation method using the hesitant fuzzy linguistic term set and minimal variance OWGA weights. Appl. Soft Comput. 2017, 56, 589–596. [Google Scholar] [CrossRef]

- Chatterjee, S.; Singh, J.B.; Roy, A. A structure-based software reliability allocation using fuzzy analytic hierarchy process. Int. J. Syst. Sci. 2015, 46, 513–526. [Google Scholar] [CrossRef]

- Tao, Y.R.; Cao, L.; Huang, Z.H.H. A novel evidence-based fuzzy reliability analysis method for structures. Struct. Multidiscip. Optim. 2016, 55, 1237–1249. [Google Scholar] [CrossRef]

- Mishra, S.; Vanli, O.A.; Alduse, B.P.; Jung, S. Hurricane loss estimation in wood-frame buildings using Bayesian model updating: Assessing uncertainty in fragility and reliability analyses. Eng. Struct. 2017, 135, 81–94. [Google Scholar] [CrossRef]

- Ren, H.P.; Chen, H.H.; Fei, W.; Li, D.F. A MAGDM method considering the amount and reliability information of interval-valued intuitionistic fuzzy sets. Int. J. Fuzzy Syst. 2016, 19, 715–725. [Google Scholar] [CrossRef]

- Zwirglmaier, K.; Straub, D.; Groth, K.M. Capturing cognitive causal paths in human reliability analysis with Bayesian network models. Reliab. Eng. Syst. Saf. 2017, 158, 117–129. [Google Scholar] [CrossRef]

- Feng, Y.; Hong, Z.; Cheng, J.; Jia, L.; Tan, J. Low carbon-oriented optimal reliability design with interval product failure analysis and grey correlation analysis. Sustainability 2017, 9, 369. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, P.; Zhu, Y.; Zhang, Y. A comprehensive reliability allocation method for series systems based on failure mode and effects analysis transformed functions. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016, 230, 2239–2248. [Google Scholar] [CrossRef]

- Kang, S.; Kim, E.; Shim, J.; Cho, S.; Chang, W.; Kim, J. Mining the relationship between production and customer service data for failure analysis of industrial products. Comput. Ind. Eng. 2017, 106, 137–146. [Google Scholar] [CrossRef]

- Liu, J.; Zio, E. System dynamic reliability assessment and failure prognostics. Reliab. Eng. Syst. Saf. 2017, 160, 21–36. [Google Scholar] [CrossRef]

- Song, L.; Fei, C.W.; Wen, J.; Bai, G.C. Multi-objective reliability-based design optimization approach of complex structure with multi-failure modes. Aerosp. Sci. Technol. 2017, 64, 52–62. [Google Scholar] [CrossRef]

- Kim, K.O.; Yang, Y.; Zuo, M.J. A new reliability allocation weight for reducing the occurrence of severe failure effects. Reliab. Eng. Syst. Saf. 2013, 117, 81–88. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, C.; Zhou, M.C.; Zeng, Q.; Yla-Jaaski, A. Automatic Composition of Semantic Web Services Based on Fuzzy Predicate Petri Nets. IEEE Trans. Autom. Sci. Eng. 2015, 12, 680–689. [Google Scholar] [CrossRef]

- Gao, M.M.; Zhou, M.C.; Tang, Y. Intelligent Decision Making in Disassembly Process Based on Fuzzy Reasoning Petri Nets. IEEE Trans. Syst. Man Cybern. 2004, 34, 2029–2034. [Google Scholar] [CrossRef]

- Wang, Y.S.; Lei, H.; Han, X. The stochastic Petri net based reliability analysis for software partition integrated modular avionics. IEEE Aerosp. Electron. Syst. Mag. 2015, 30, 30–37. [Google Scholar]

- Tang, Y.; Zhou, M.C.; Gao, M. Fuzzy-Petri-Net Based Disassembly Planning Considering Human Factors. IEEE Trans. Syst. Man Cybern. 2006, 36, 718–726. [Google Scholar] [CrossRef]

- Zhang, X.J.; Yao, S.Z. Fuzzy stochastic Petri nets and analysis of the reliability of multi-state systems. IET Softw. 2015, 9, 83–93. [Google Scholar] [CrossRef]

- Wu, X.; Wu, X. Mission reliability modeling and evaluation of multi-mission phased mission system based on an extended object-oriented Petri net. Eksploatacja I Niezawodnosc 2017, 19, 244–253. [Google Scholar] [CrossRef]

- Wu, J.; Yan, S.Z.; Xie, L.Y.; Gao, P. Reliability apportionment approach for spacecraft solar array using fuzzy reasoning Petri net and fuzzy comprehensive evaluation. Acta Astronaut. 2012, 76, 136–144. [Google Scholar] [CrossRef]

- Wilson, K.J.; Quigley, J. Allocation of tasks for reliability growth using multi-attribute utility. Eur. J. Oper. Res. 2016, 255, 259–271. [Google Scholar] [CrossRef]

- Li, Z.; Tian, G.; Cheng, G.; Liu, H.; Cheng, Z. An integrated cultural particle swarm algorithm for multi-objective reliability-based design optimization. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2013, 228, 1185–1196. [Google Scholar] [CrossRef]

- Abido, M.A.; Bakhashwain, J.M. Optimal VAR dispatch using a multiobjective evolutionary algorithm. Int. J. Electr. Power 2005, 27, 13–20. [Google Scholar] [CrossRef]

- Wu, J.N.; Yan, S.Z.; Xie, L.Y. Reliability analysis method of a solar array by using fault tree analysis and fuzzy reasoning Petri net. Acta Astronaut. 2011, 69, 960–968. [Google Scholar] [CrossRef]

- Gao, M.M.; Zhou, M.C.; Huang, X.G.; Wu, Z.M. Fuzzy reasoning Petri nets. IEEE Trans. Syst. Man Cybern. A Syst. Hum. 2003, 3, 314–324. [Google Scholar]

- Liu, H.-C.; You, J.-X.; Li, Z.W.; Tian, G. Fuzzy Petri nets for knowledge representation and reasoning: A literature review. Eng. Appl. Artif. Intell. 2017, 60, 45–56. [Google Scholar] [CrossRef]

- Hai, S.X.; Gong, Z.T.; Li, H.X. Generalized differentiability for n-dimensional fuzzy-number-valued functions and fuzzy optimization. Inf. Sci. 2016, 374, 151–163. [Google Scholar] [CrossRef]

- Nieto, P.J.G.; García-Gonzalo, E.; Lasheras, F.S.; Juez, F.J.D. Hybrid PSO–SVM-based method for forecasting of the remaining useful life for aircraft engines and evaluation of its reliability. Reliab. Eng. Syst. Saf. 2015, 138, 219–231. [Google Scholar] [CrossRef]

- Yi, P.; Wei, K.; Kong, X.; Zhu, Z. Cumulative PSO-Kriging model for slope reliability analysis. Probab. Eng. Mech. 2015, 39, 39–45. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Z.; Song, Y.; Wei, Z. A multi-objective particle swarm optimizer with distance ranking and its applications to air compressor design optimization. Trans. Meas. Control 2012, 34, 526–556. [Google Scholar] [CrossRef]

- Liu, H.; Miao, E.M.; Wei, X.Y.; Zhuang, X.D. Robust modeling method for thermal error of CNC machine tools based on ridge regression algorithm. Int. J. Mach. Tools Manuf. 2017, 113, 35–48. [Google Scholar] [CrossRef]

| Number of the CNC Machine Tool | Module Failure | Number of the CNC Machine Tool | Module Failure |

|---|---|---|---|

| 1 | Overmuch wear of the belt | 9 | There is a taper in the head of the machine tool |

| Runaway speed | Water is unable to flow into the cooling pump | ||

| Much noise of the hydraulic motor | The lathe dose not run after programming | ||

| Noise of the main axis is abnormal | The rotation of the main shaft is unstable | ||

| The tool holder cannot rotate | Bad lubrication | ||

| 2 | Water leakage | 10 | Loss of coordinate data after power failure |

| Loose of the protective cover | No input signal | ||

| Hydraulic chuck does not work | The knife holder cannot change the knife | ||

| The crumbs cannot be ruled out | Bad cooling of the air-conditioning | ||

| The monitor screen is not bright | A short journey of the claw | ||

| 3 | Cooling water pump tripping | 11 | Z-axis stop suddenly |

| Oil filling pipe burst | No Lubricating oil on the guide way | ||

| The main spindle does not work | Low accuracy of the hydraulic chuck | ||

| No electricity can flow into the machine tool | X-axis stop suddenly | ||

| The tool holder is not located accurately | The artifact has a convex plane | ||

| 4 | The lathe has no input signal | 12 | There is motor noise when the X-axis moves |

| The tool vibrates when the workpiece is processed | The bed saddle does not move with the input of location instruction | ||

| The noise of the main motor is abnormal | The fuse is burned out frequently | ||

| The air conditioner does not work | X-axis Slide down after power off | ||

| The oil pipe ruptures | The servo alarm sounds the alarm | ||

| 5 | Automatic power off of the CNC machine tools | 13 | The oil pipe ruptures |

| Black lines appear on the monitor | The hydraulic chuck pressure cannot be raised | ||

| The tool will rotate automatically with the electricity | The rotation of the main shaft is unstable | ||

| The knife dish shakes | The processed threads are not qualified | ||

| The CNC machine tools do not move with the hand-cranking | The Stretch Speed of the stage is too slow | ||

| 6 | The hydraulic chuck does not work | 14 | The machined artifacts have a taper |

| Water leakage of the machine tools | The threading are not standard | ||

| The main transformer was burnt | Crumbs cannot be ruled out quickly | ||

| The voltage of the system drops sharply after changing the knife | The oil pipe ruptures | ||

| The speed display is not accurate | There is no brake when the main shaft stops turning | ||

| 7 | Protective glass crushing | 15 | The program does not run after the change of the knife |

| The knife cannot stop turning | A blank screen of the computer’s display settings | ||

| The finished arc is not qualified | The size of the sample workpiece is inconsistent | ||

| The hydraulic system cannot start | The turning operation of Z-axis is not standard | ||

| A blank screen of the computer’s display settings | The blade cannot be accurately positioned | ||

| 8 | X-axis can not move to the zero point | 16 | No electric current can flow into the CNC machine tools |

| Overmuch wear of the belt | The workpiece processed have crow’s feet | ||

| Cutting vibration | The revolving speed of the X-axis is unstable | ||

| The main shaft does not run after the system is motivated | Cutting vibration | ||

| The workpiece processed have crow’s feet | Knives cannot be replaced at will |

| Failure Denoted by | Failure Denoted by | ||||

|---|---|---|---|---|---|

| Crush of the protective cover | 0.46 | The rotation of the main shaft is unstable | 0.69 | ||

| Large vibration amplitude with transmission | 0.51 | The hydraulic pressure chuck sounds the alarm | - | ||

| The tool holder is not located accurately | 0.62 | The hydraulic tool holder is not flexible | - | ||

| Crumbs cannot be ruled out quickly | 0.65 | Knives cannot be replaced at will | 0.90 | ||

| Bad lubrication | - | Too much noise of the main motor | - | ||

| The external voltage is unstable | 0.68 | The sleeve does not stretch scale automatically | - | ||

| NC hardware damage | - | The hydraulic chuck is automatically opened when the processing is stopped | 0.68 | ||

| The feed speed is stable | 0.82 | There is no electric current can flow into the servo module | 0.76 | ||

| Lack of driving force | 0.61 | Bad cooling of the air-conditioning | 0.80 | ||

| Low detection sensitivity | - | The bed saddle does not move with the input of location instruction | 0.55 | ||

| Low accuracy of the closed-loop feedback | 0.58 | Failure of the S1 | - | ||

| Tool wear overmuch | 0.70 | Failure of the S2 | - | ||

| Liquid coolant leakage | 0.74 | Failure of the S3 | - | ||

| The pressure of the hydraulic chuck cannot be raised | 0.63 | Failure of the S4 | - | ||

| A blank screen of the computer’s display settings | 0.82 | Failure of the S5 | - | ||

| X-axis can not move to the zero point | 0.75 | The CNC machine tool can not work | - |

| t1 | If p15, then p5 | 0.85 | t14 | If p17, then p28 | 0.85 |

| t2 | If p14, then p7 | 0.89 | t15 | If p18, then p29 | 0.82 |

| t3 | If p14 and p1 and p2, then p10 | 0.88 | t16 | If p19, then p29 | 0.87 |

| t4 | If p12, then p10 | 0.80 | t17 | If p8 and p20, then p29 | 0.90 |

| t5 | If p3 and p4, then p10 | 0.90 | t18 | If p21 and p22 and p4, then p30 | 0.91 |

| t6 | If p5 and p6, then p18 | 0.92 | t19 | If p23 and p3, then p31 | 0.84 |

| t7 | If p7, then p19 | 0.86 | t20 | If p24 and p25 and p26, then p31 | 0.87 |

| t8 | If p8 and p9, then p19 | 0.82 | t21 | If p27, then p32 | ? |

| t9 | If p10, then p21 | 0.91 | t22 | If p28, then p32 | ? |

| t10 | If p11, then p22 | 0.90 | t23 | If p29, then p32 | ? |

| t11 | If p12 and p13, then p27 | 0.84 | t24 | If p30, then p32 | ? |

| t12 | If p14 and p15, then p27 | 0.86 | t25 | If p31, then p32 | ? |

| t13 | If p16, then p28 | 0.93 | |||

| Subsystem/Factor | K | S | Cr | T | M | E |

|---|---|---|---|---|---|---|

| S1 | [2.5, 4.3] | [3.5, 5.3] | [2.1, 4.2] | [5.0, 6.8] | [6.2, 7.6] | [4.9, 7.0] |

| S2 | [4.3, 5.6] | [5.8, 7.7] | [4.8, 6.7] | [3.9, 5.5] | [5.6, 8.0] | [3.9, 5.8] |

| S3 | [6.0, 7.6] | [5.9, 7.4] | [5.3, 6.8] | [2.9, 4.5] | [4.7, 6.6] | [4.1, 5.5] |

| S4 | [5.9, 7.3] | [4.9, 6.6] | [3.8, 5.6] | [4.0, 5.9] | [6.3, 7.6] | [3.9, 6.2] |

| S5 | [5.8, 7.0] | [7.0, 8.8] | [6.2, 7.7] | [4.1, 6.2] | [4.9, 6.5] | [7.3, 8.9] |

| Si | fi | Ri,min | Ri,max | Bi (1000 dollars) | |

|---|---|---|---|---|---|

| S1 | 0.7881 | 0.9100 | 0.9800 | 0.2781 | 6.4000 |

| S2 | 0.7384 | 0.9300 | 0.9950 | 0.1668 | 6.5900 |

| S3 | 0.7616 | 0.9300 | 0.9950 | 0.1854 | 8.5360 |

| S4 | 0.8085 | 0.9200 | 0.9850 | 0.2356 | 4.3300 |

| S5 | 0.8234 | 0.9300 | 0.9940 | 0.1541 | 5.6910 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Z.; Feng, Y.; Li, Z.; Tian, G.; Tan, J. Reliability-Based and Cost-Oriented Product Optimization Integrating Fuzzy Reasoning Petri Nets, Interval Expert Evaluation and Cultural-Based DMOPSO Using Crowding Distance Sorting. Appl. Sci. 2017, 7, 791. https://doi.org/10.3390/app7080791

Hong Z, Feng Y, Li Z, Tian G, Tan J. Reliability-Based and Cost-Oriented Product Optimization Integrating Fuzzy Reasoning Petri Nets, Interval Expert Evaluation and Cultural-Based DMOPSO Using Crowding Distance Sorting. Applied Sciences. 2017; 7(8):791. https://doi.org/10.3390/app7080791

Chicago/Turabian StyleHong, Zhaoxi, Yixiong Feng, Zhongkai Li, Guangdong Tian, and Jianrong Tan. 2017. "Reliability-Based and Cost-Oriented Product Optimization Integrating Fuzzy Reasoning Petri Nets, Interval Expert Evaluation and Cultural-Based DMOPSO Using Crowding Distance Sorting" Applied Sciences 7, no. 8: 791. https://doi.org/10.3390/app7080791

APA StyleHong, Z., Feng, Y., Li, Z., Tian, G., & Tan, J. (2017). Reliability-Based and Cost-Oriented Product Optimization Integrating Fuzzy Reasoning Petri Nets, Interval Expert Evaluation and Cultural-Based DMOPSO Using Crowding Distance Sorting. Applied Sciences, 7(8), 791. https://doi.org/10.3390/app7080791