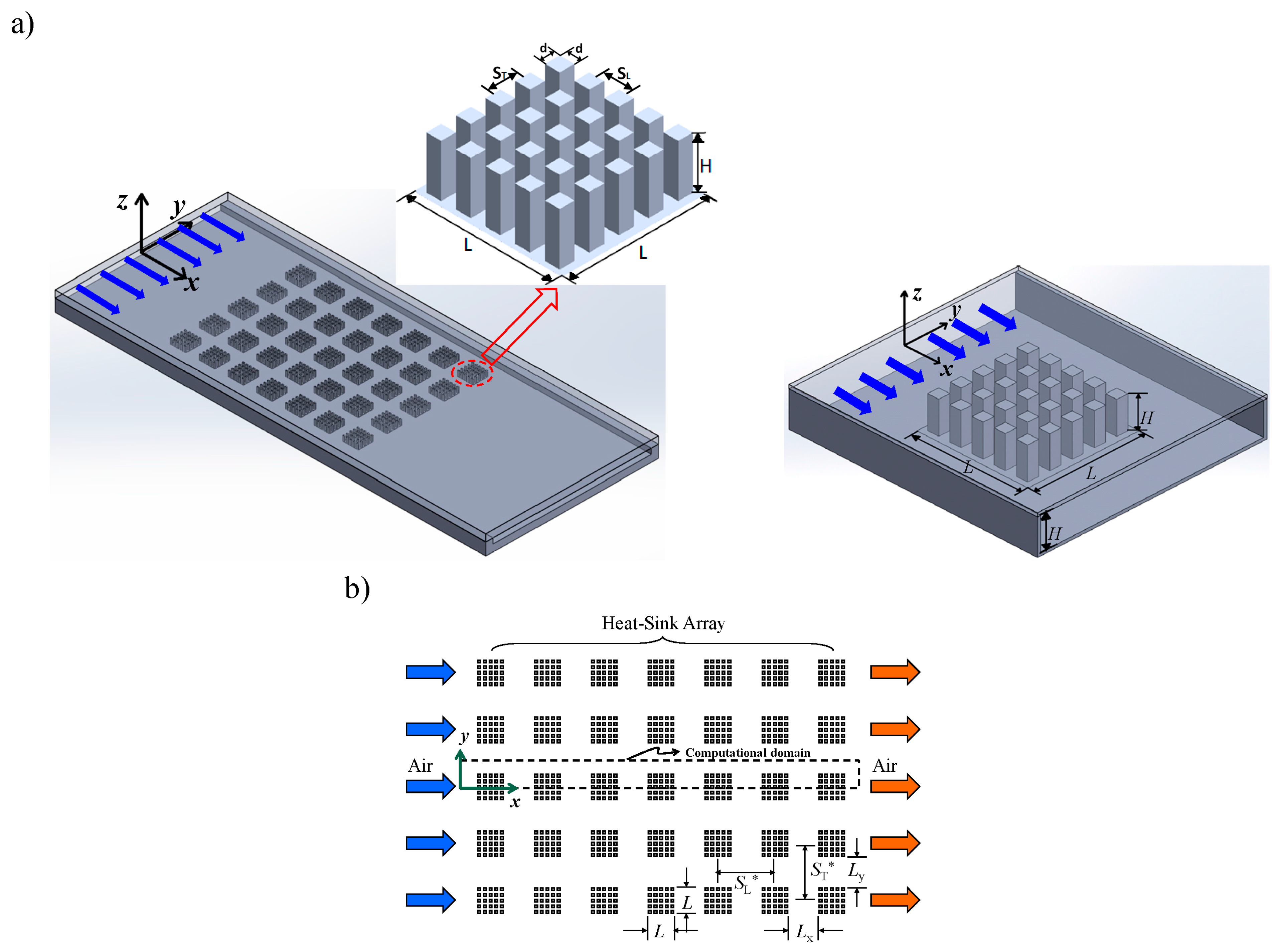

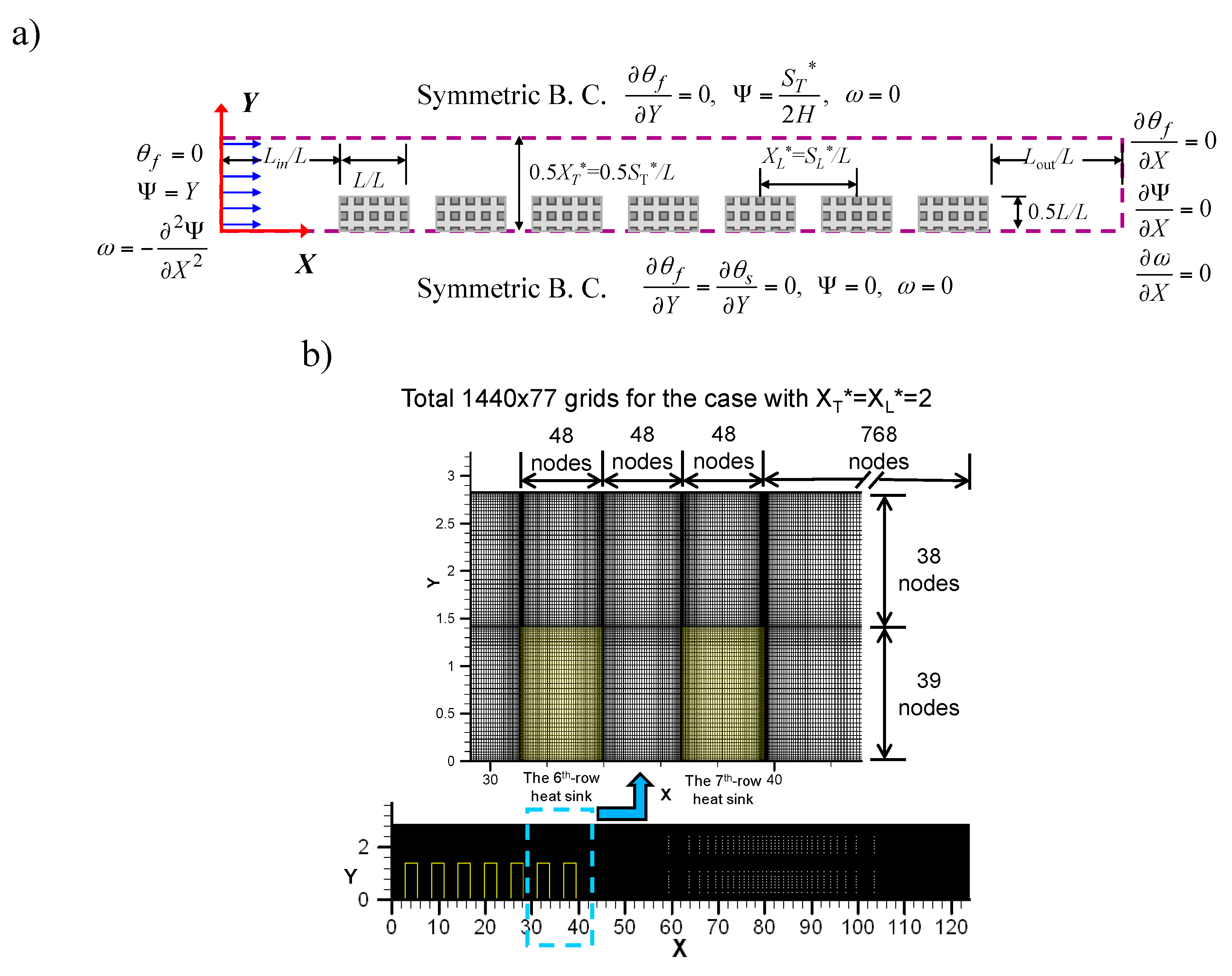

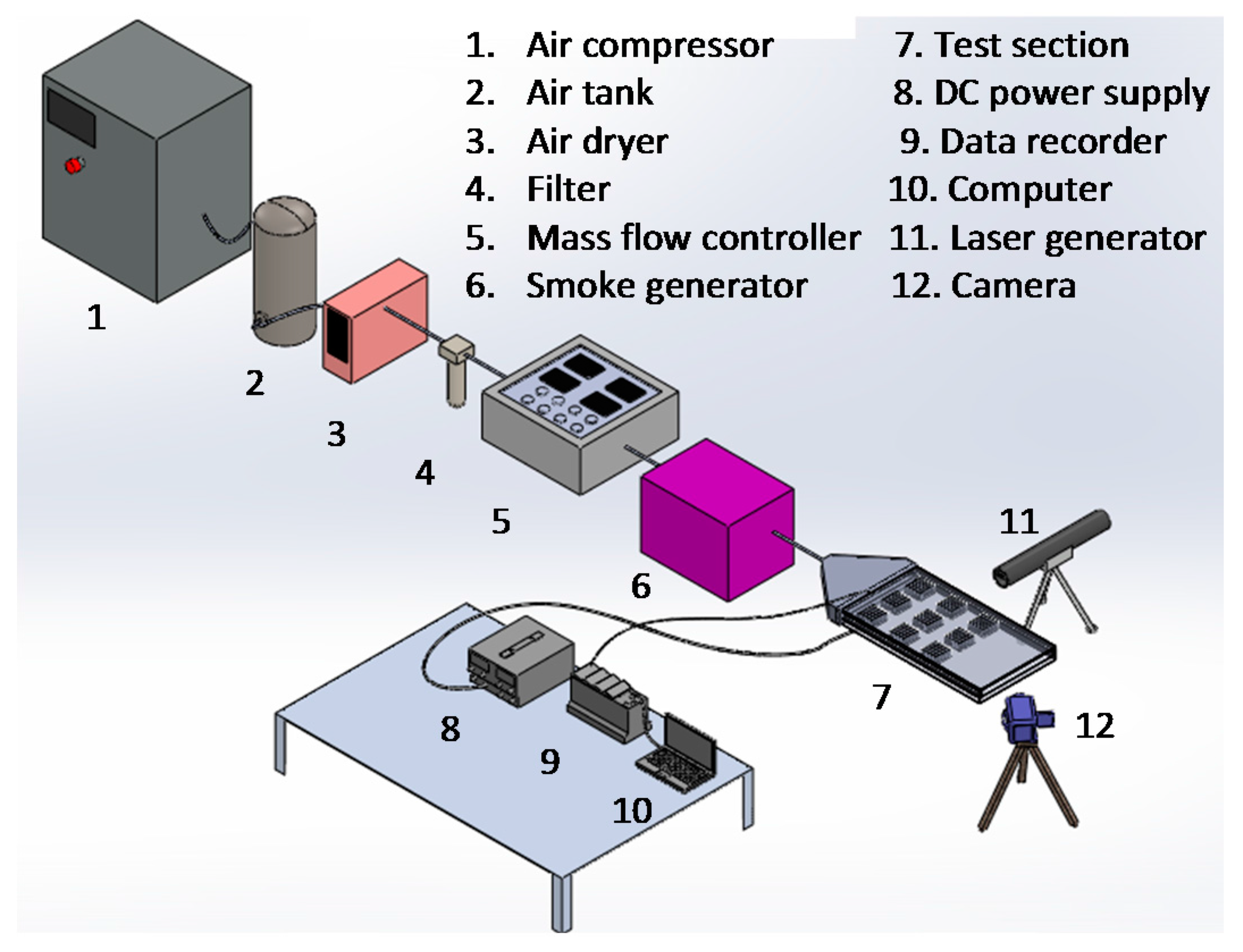

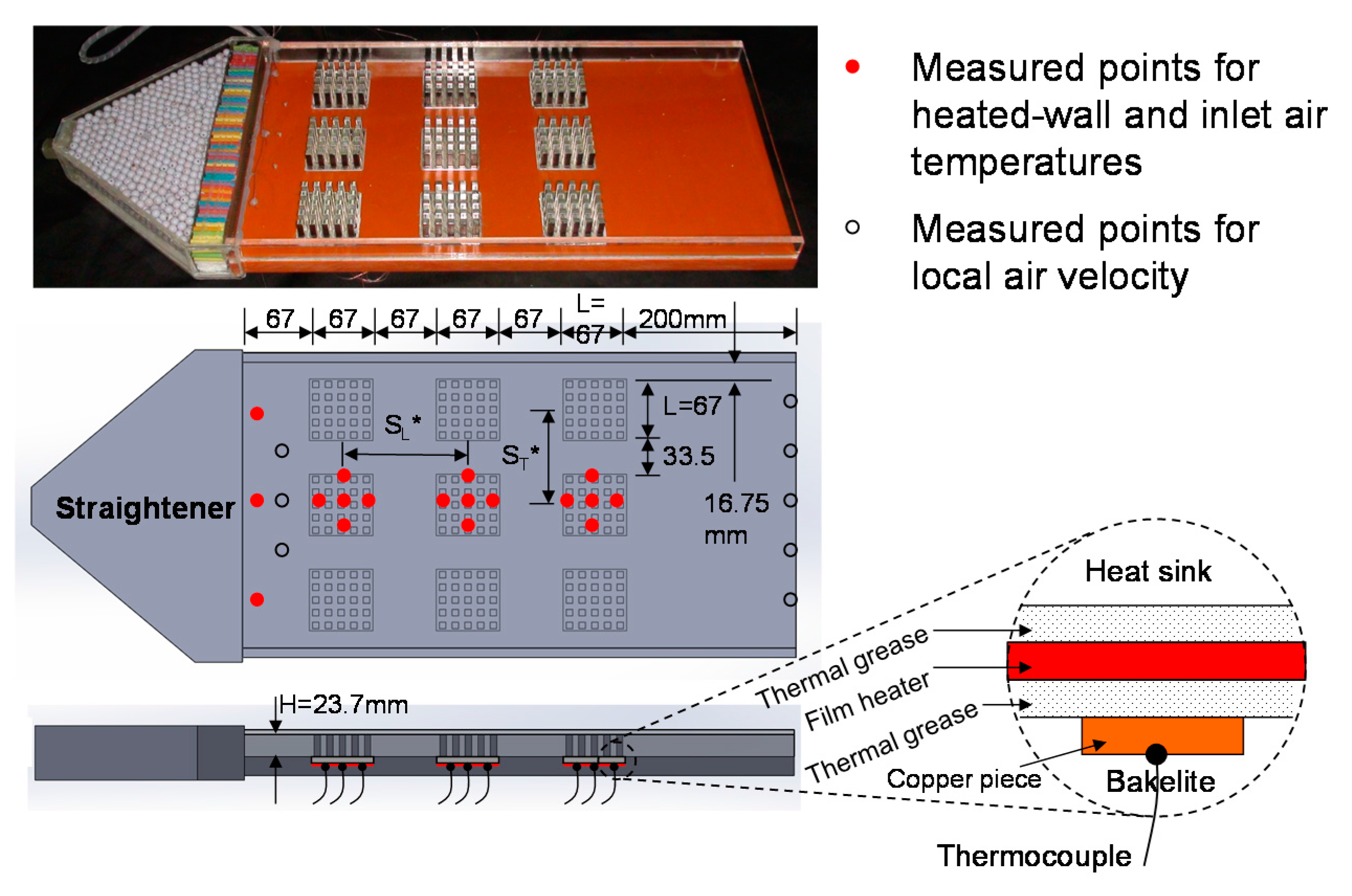

4.1. Flow Behaviors

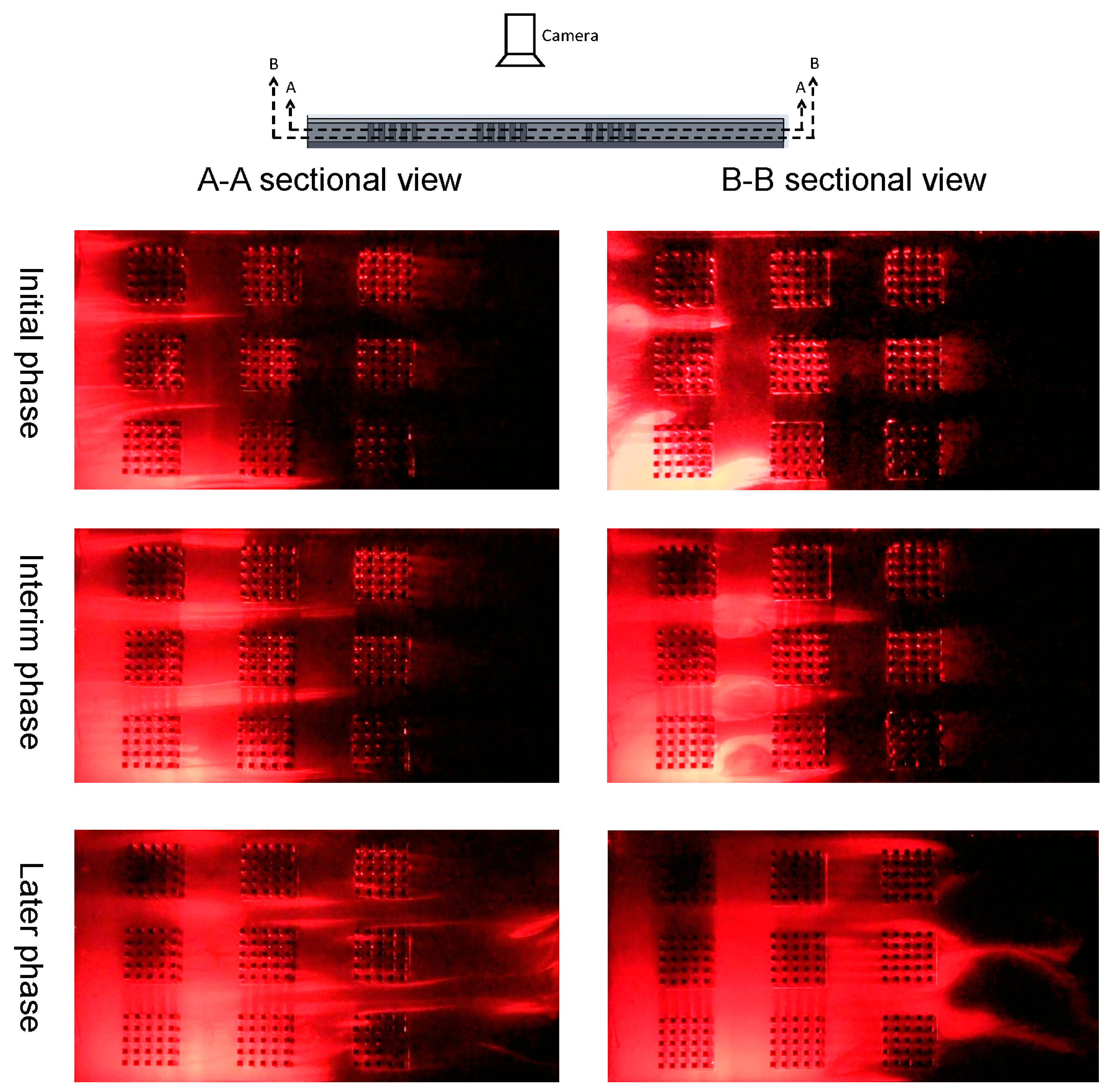

Figure 6 shows the flow visualizations of 3 × 3 pin-fin heat-sink array in a rectangular channel in the A-A and B-B sectional views of laser sheet (top-view surface tangential to inside of heat-sink array). From the visualizations of initial, interim and later phases, it can be found that the smoke flows mainly through each longitudinal passage between in-line heat sinks; minority plume goes through the heat sinks. The flow visualizations of various top views give the similar flow behaviors. Of course, the real flow pattern in the present rectangular channel with 3 × 3 pin-fin heat-sink array cannot be two-dimensional completely due to the end-wall effect. However, by comparing with the variations of fluid flow in the

x and

y directions, the change of fluid flow in the

z direction is small and can be ignored. In other words, the present 2D simulations actually express the mean results of different cross sections along the

z-axis.

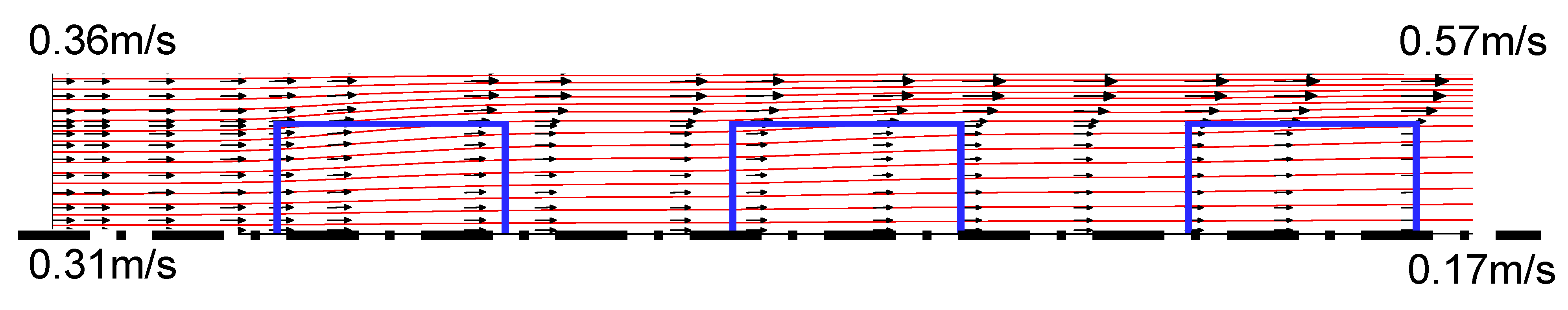

Figure 7 depicts the measured values of air velocity at the inlet and outlet of the center column of 3 × 3 heat-sink array. It generally agrees to the numerical simulation.

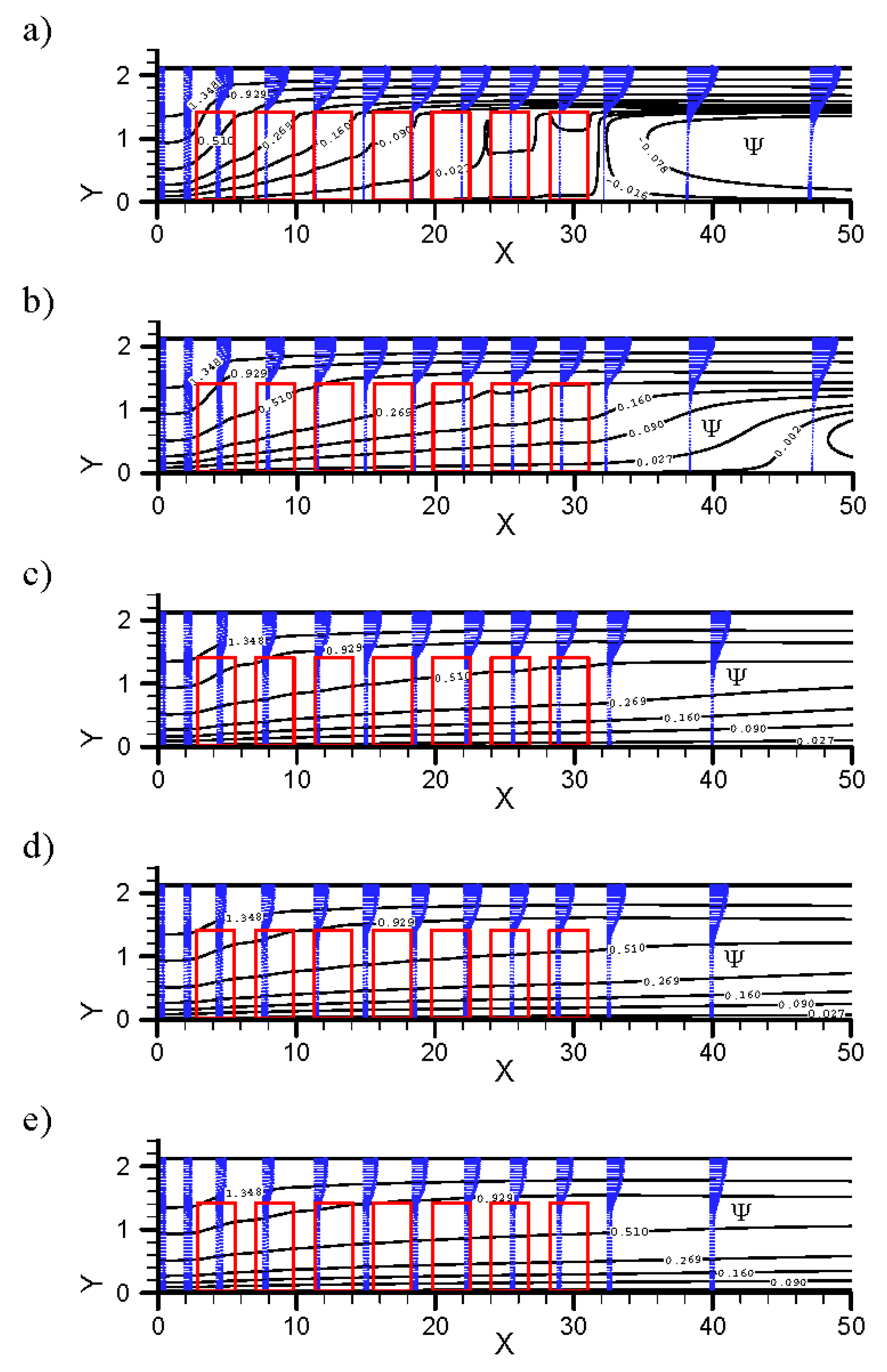

Figure 8 shows the simulation result of streamline and velocity vector of heat-sink array in different models with Reynolds number

Re = 500 and relative distances between heat sinks

XT*(=

ST*/

L) =

XL*(=

SL*/

L) = 1.5. It is observed that when the uniform air flows into the heat sink array, a part of air flows through the side-bypass gap between transverse adjacent heat sinks, the other part of air flows into the heat sink. In addition, due to the flow resistance, the air flow through the heat sink leaks from the side of heat sink to the side-bypass gap continuously. Therefore, the by-pass gap in more downstream location contains faster air flow; this phenomenon is more obvious in the heat sink array with bigger flow resistance. For example, the heat sink with smaller porosity or larger number of pin fins has this feature. For the heat sink array with bigger flow resistance, there are vortices formed earlier behind the last row of heat-sink array. Generally speaking, the heat-sink array with bigger flow resistance has more bypass air flow, which is adverse to heat transfer. The heat transfer of the downstream heat sink is thus worsened.

Figure 6.

Flow visualization images. (Re = 52; 15 liter/min).

Figure 6.

Flow visualization images. (Re = 52; 15 liter/min).

Figure 7.

Measured values of air velocity at the center column of 3 × 3 heat-sink array. (Re = 500).

Figure 7.

Measured values of air velocity at the center column of 3 × 3 heat-sink array. (Re = 500).

Figure 8.

Streamlines and velocity vectors for various test samples with XT* = XL* = 1.5 (the scales of X-axis and Y-axis are different): (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

Figure 8.

Streamlines and velocity vectors for various test samples with XT* = XL* = 1.5 (the scales of X-axis and Y-axis are different): (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

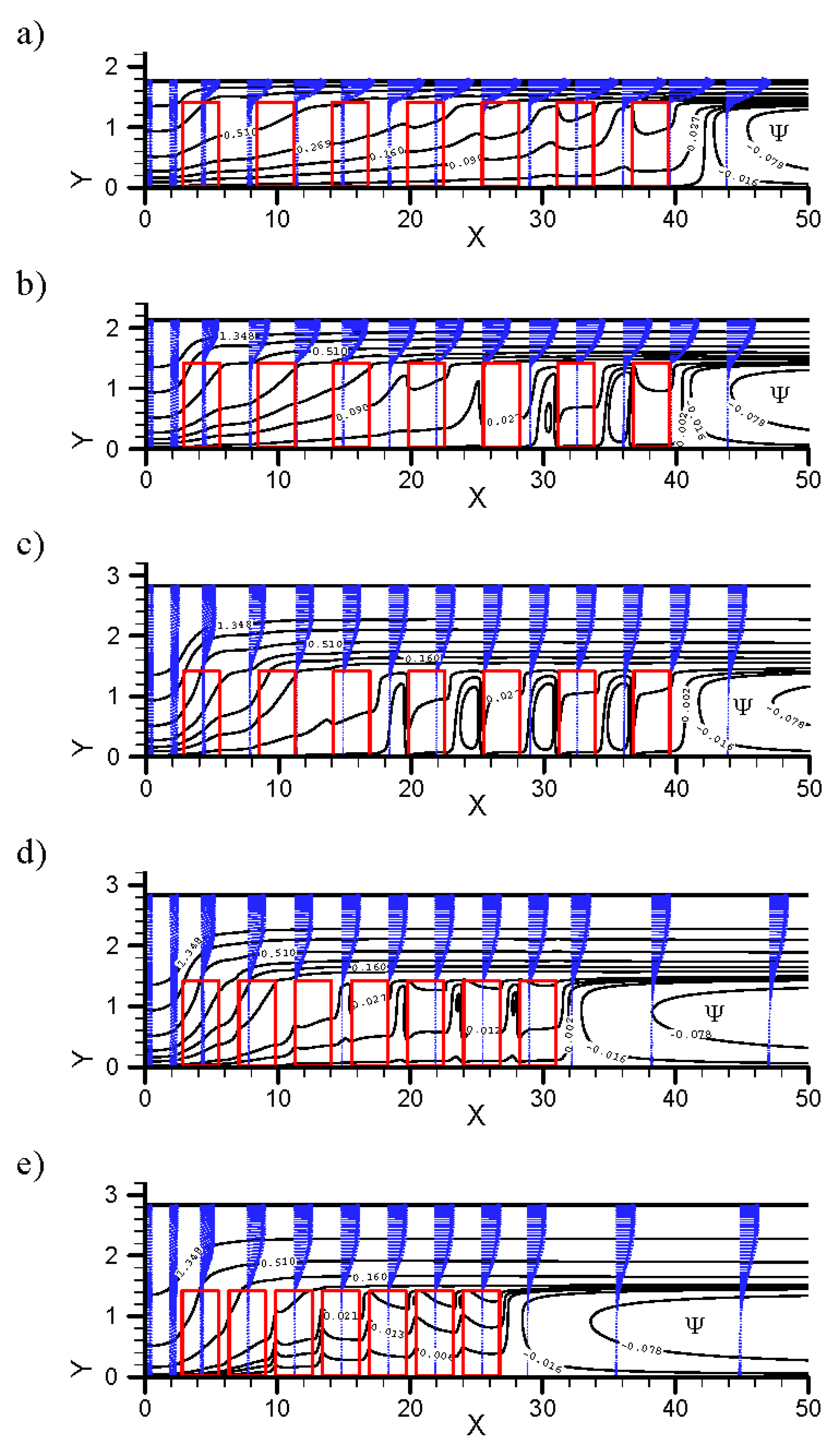

Figure 9 shows the influence of variation in the

XT* and

XL* values on the streamline and velocity vector taking Sample 1 heat sink array as an example. According to

Figure 9a–c, when the

XL* value is fixed at 2, a larger

XT* represents larger relative transverse distance between heat sinks,

i.e., larger lateral by-pass gap. In other words, a majority of air flow will pass through this gap, so that the air flow entering the heat sink decreases greatly (see

Figure 9c). A recirculating flow is even formed between adjacent front and back rows of heat sinks in the downstream region, which is very adverse to heat transfer. According to

Figure 9c–e, in the arrangement of

XT* value fixed at 2 but different

XL* values, the air velocity in the lateral by-pass gap is almost the same. This suggests that although the relative longitudinal distance between adjacent front and back rows of heat sinks is changed, the bypass air flow passing by the heat sink is not influenced (

i.e., total air flow amount through heat sinks has not changed).

Figure 9.

Streamlines and velocity vectors for test Sample 1 with various values of XT* and XL* (the scales of X-axis and Y-axis are different): (a) XT* = 1.25; XL* = 2; (b) XT* = 1.5; XL* = 2; (c) XT* = 2; XL* = 2; (d) XT* = 2; XL* = 1.5; and (e) XT* = 2; XL* = 1.25.

Figure 9.

Streamlines and velocity vectors for test Sample 1 with various values of XT* and XL* (the scales of X-axis and Y-axis are different): (a) XT* = 1.25; XL* = 2; (b) XT* = 1.5; XL* = 2; (c) XT* = 2; XL* = 2; (d) XT* = 2; XL* = 1.5; and (e) XT* = 2; XL* = 1.25.

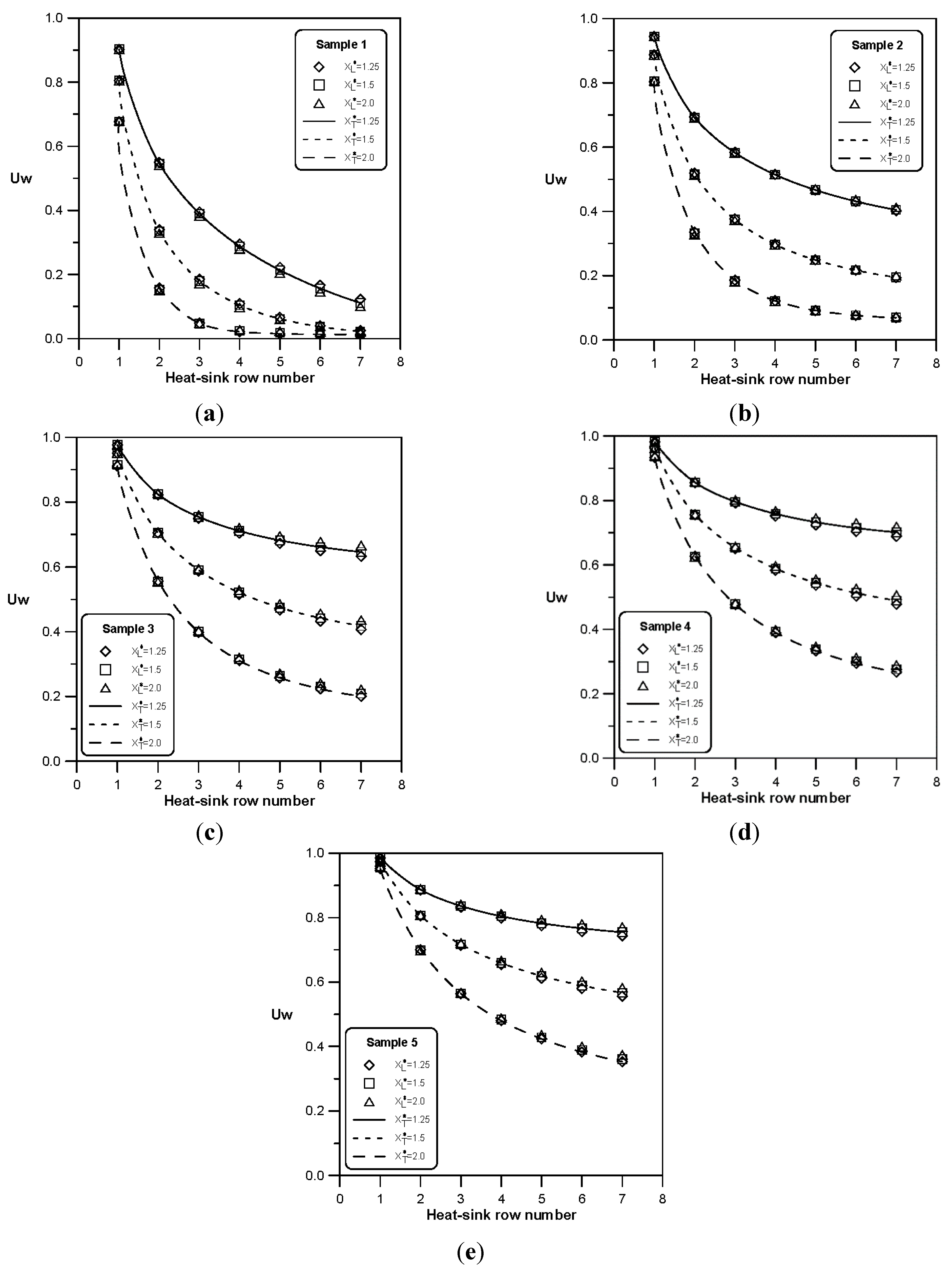

Figure 10 shows the average dimensionless velocity of air flow into windward side (

Uw) of each row of heat sink array in the in-line arrangement formed of different heat sinks when

Re = 500. As the flow resistance of passages between pin fins of heat sink is higher than the lateral by-pass gap between heat sinks, the air flow leaks into the by-pass gap continuously after it enters the first row of heat sink array. The leakage flow of upstream heat sink is higher than downstream heat sink. The heat sink with higher flow resistance (

i.e., heat sink with lower porosity or larger number of pin fins) has less air inflow and more leakage flow. The simulation results also indicate that the influence of current relative longitudinal distance (

XL*) between heat sinks on the air flow entering the heat sink and the leakage flow can be neglected. However, when the relative transverse distance (

XT*) between heat sinks is large, the air flow entering the heat sink is low, and the leakage flow is high, thus reducing the forced convection heat transfer capability of heat sink array.

Figure 10.

Dimensionless velocities of fluid flow through windward sides of various heat sinks: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

Figure 10.

Dimensionless velocities of fluid flow through windward sides of various heat sinks: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

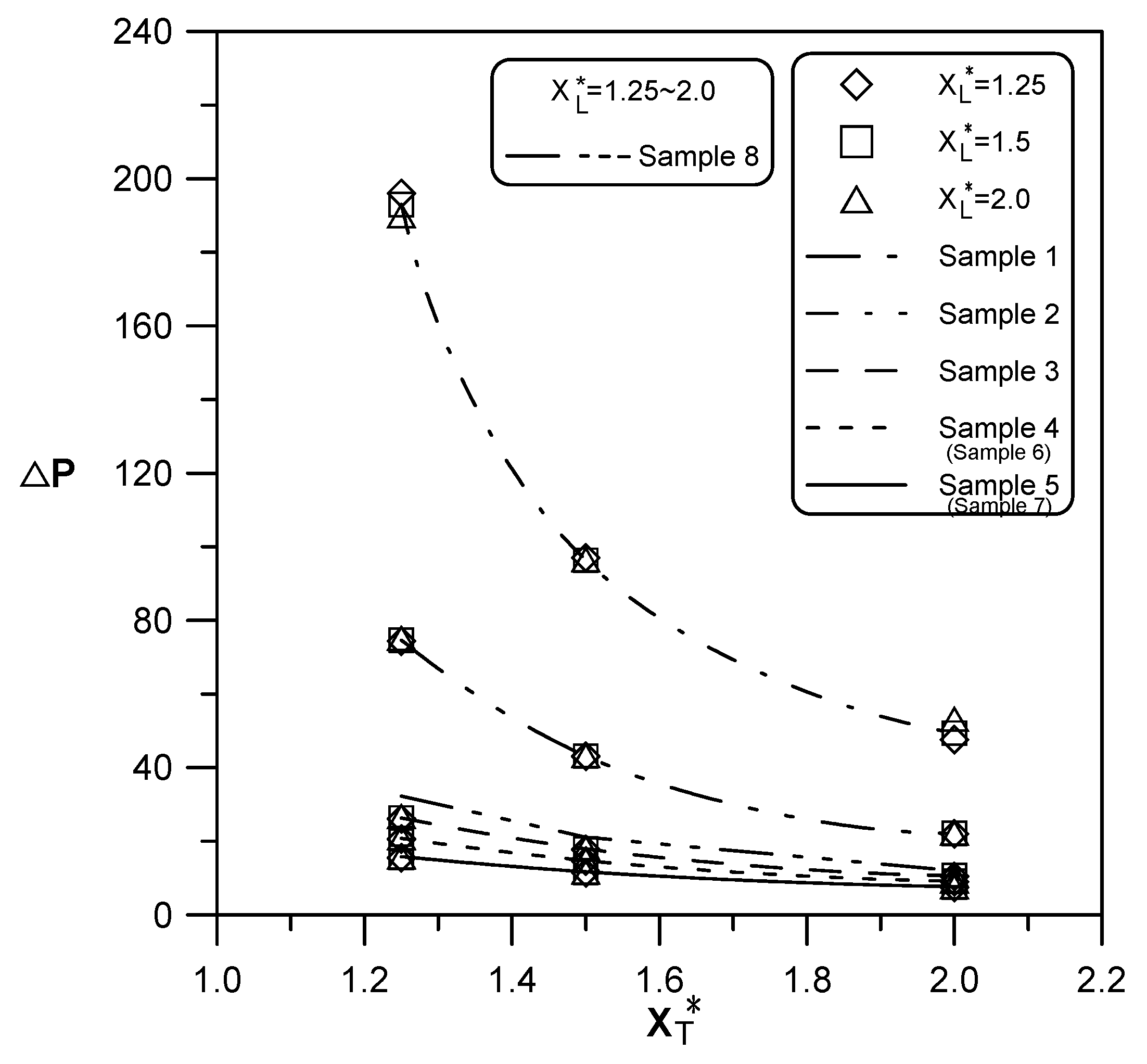

Figure 11 shows the dimensionless pressure drop when the air flow at

Re = 500 passes through different heat sink arrays with different

XT* and

XL* values. The result indicates that changing

XL* did not affect the dimensionless pressure drop, but increasing

XT* would reduce dimensionless pressure drop significantly. Because an increasing

XT* increases the air flow passing by the heat sink and reduces the air flow through the heat sink, the overall dimensionless pressure drop decreases. In addition, the array composed of heat sinks with higher flow resistance (

i.e., heat sink with lower porosity or larger number of pin fins) has a larger dimensionless pressure drop.

Figure 11.

Dimensionless pressure drops for different heat-sink arrays with various XT* and XL*.

Figure 11.

Dimensionless pressure drops for different heat-sink arrays with various XT* and XL*.

4.2. Thermal Characteristics

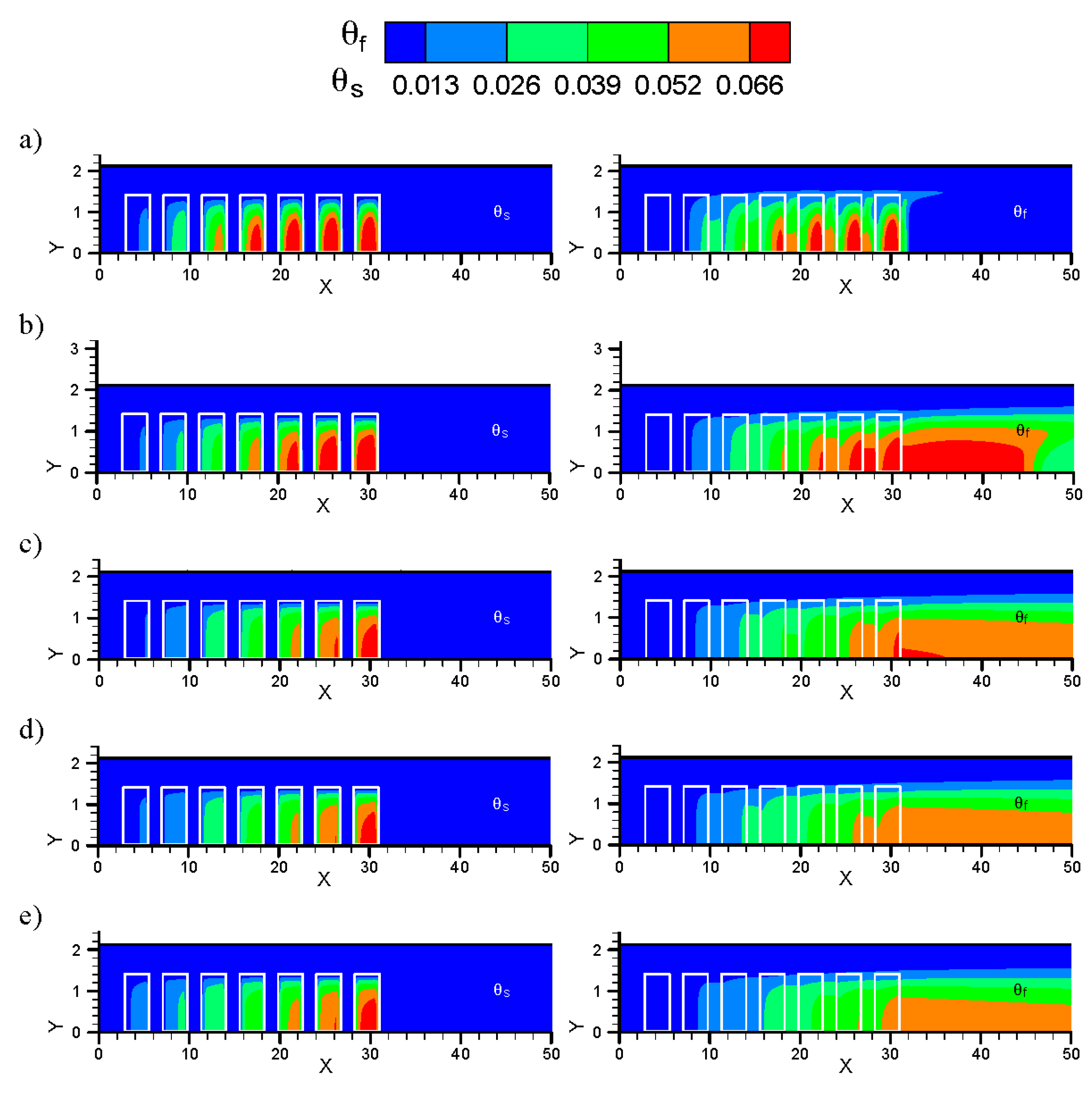

Figure 12 shows the dimensionless temperature contours of different heat sink arrays when Reynolds number

Re = 500 and

XT* =

XL* = 1.5. First, the dimensionless fluid temperature and dimensionless solid temperature in the heat sink area are compared, there is significant difference, the dimensionless solid temperature is higher than the dimensionless fluid temperature, meaning in the present numerical simulation, the solid and fluid have not yet reached local thermal equilibrium. Therefore, the two-equation model meets the thermophysics in the current test system better than one-equation model. Secondly, the dimensionless solid temperature distributions of different heat sink arrays are compared (as shown in

Figure 12a–c). It is observed that among the heat sink arrays with the same number of pin fins (Sample 1, Sample 2 and Sample 3), the heat sink array with higher porosity has lower overall dimensionless solid temperature, suggesting that the heat is transferred to the fluid effectively. This is because in the present cooling system, the heat considering fin efficiency radiates in each unit volume of heat sink, and then it is transmitted to the fluid by convection heat transfer. Therefore, it is basically conjugate heat transfer of thermal conduction and convection. When the porosity of heat sink is low, the upward thermal conduction capability of pin fins is better and the fin efficiency is good, thus contributing to overall heat transfer (Equation (13)). However, as shown in

Figure 8, the heat sink array with lower porosity generates higher flow resistance, so that less fluid flows into the heat sink, thereby reducing the convection heat transfer of heat sink. Therefore, the heat sink Sample 1 with the smallest porosity accumulates heat in the pin-fins, so that it has the highest overall dimensionless solid temperature. The heat sink Sample 3 with the largest porosity has more cold inflow, and the dimensionless solid temperature is lower. In addition, the heat sink arrays with the same porosity (Sample 3, Sample 4 and Sample 5) are compared, as shown in

Figure 12c–e. The overall dimensionless solid temperature of the Sample 3 heat sink array with more pin fins is lower than that of the Sample 4 and Sample 5 heat sink arrays with fewer pin fins, especially in the first row and the second row of heat sink array. In other words, Sample 3 with more pin fins has more heat carried away, so it is unlikely to accumulate heat. However, according to the conjugate heat transfer principle stated in

Figure 12a–c, as Sample 3, Sample 4 and Sample 5 have the same porosity, they have the same upward thermal conduction capability of pin fins. However, according to

Figure 10, the Sample 5 heat sink array with fewer pin fins has lower flow resistance, and it is supposed to have higher air inflow. The reason that the dimensionless solid temperature of heat sink is slightly higher than that of Sample 3 is explained below. First, the heat exchange area in unit volume of Sample 3 with more pin fins is far larger than that of Sample 4 and Sample 5 (see

Table 1). This makes up the air inflow during convection heat transfer. Secondly, as shown in Equations (7) and (8), Kim

et al. [

24] indicated that the heat sink with smaller pin-fin diameter has larger convection heat transfer coefficient. Therefore, the dimensionless solid temperature of Sample 3 heat sink array with smaller pin-fin diameter is slightly lower than that of Sample 5.

Figure 12.

Dimensionless temperature contours for various test samples with XT* = XL* = 1.5 (the scales of X-axis and Y-axis are different): (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

Figure 12.

Dimensionless temperature contours for various test samples with XT* = XL* = 1.5 (the scales of X-axis and Y-axis are different): (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

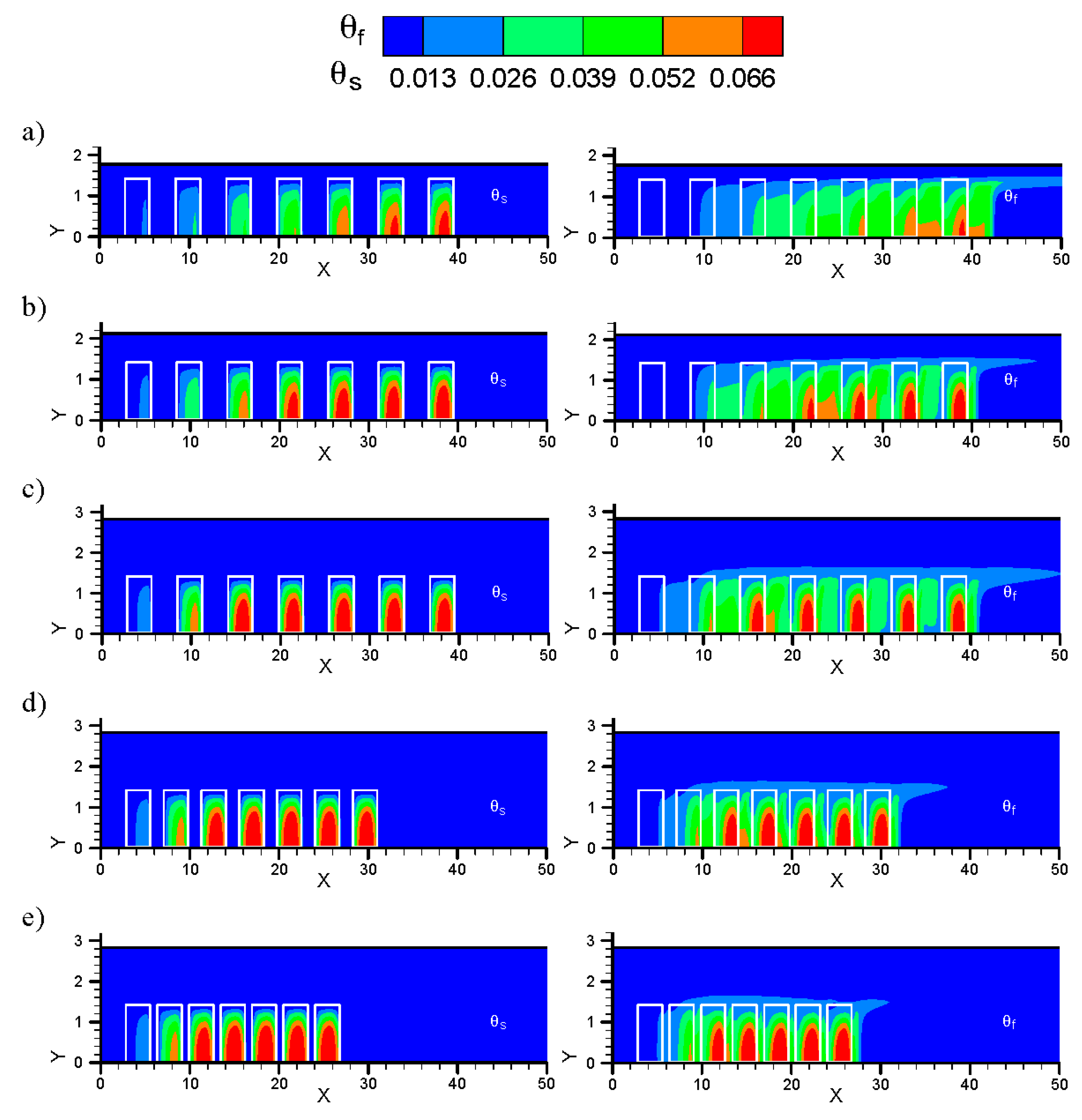

Figure 13 shows the influence of

XT* and

XL* on the dimensionless temperature contours taking Sample 1 heat sink array as an example when Reynolds number

Re = 500. At fixed

XL* = 2 and variable

XT* = 1.25, 1.5 and 2, the dimensionless solid temperature of heat sink increases with

XT*. As the increase of

XT* amplifies the bypass effect of air flow, the air flow entering the heat sink decreases, and the heat removed decreases, so the solid part of heat sink accumulates heat and has higher temperature. Relatively, when the

XT* is larger, as the air flowing into the heat sink is lower, the fluid has larger temperature rise though the pin fins transfer less heat to the fluid. This result is reflected in the dimensionless fluid temperature contours. At fixed

XT* = 2 and variable

XL* = 1.25, 1.5 and 2, the dimensionless solid temperature and dimensionless fluid temperature in the same position of various heat sinks have not varied with

XL*, meaning

XL* is not a sensitive parameter to the overall temperature distribution.

Figure 13.

Dimensionless temperature contours for test Sample 1 with various values of XT* and XL* (the scales of X-axis and Y-axis are different): (a) XT* = 1.25; XL* = 2; (b) XT* = 1.5; XL* = 2; (c) XT* = 2; XL* = 2; (d) XT* = 2; XL* = 1.5; and (e) XT* = 2; XL* = 1.25.

Figure 13.

Dimensionless temperature contours for test Sample 1 with various values of XT* and XL* (the scales of X-axis and Y-axis are different): (a) XT* = 1.25; XL* = 2; (b) XT* = 1.5; XL* = 2; (c) XT* = 2; XL* = 2; (d) XT* = 2; XL* = 1.5; and (e) XT* = 2; XL* = 1.25.

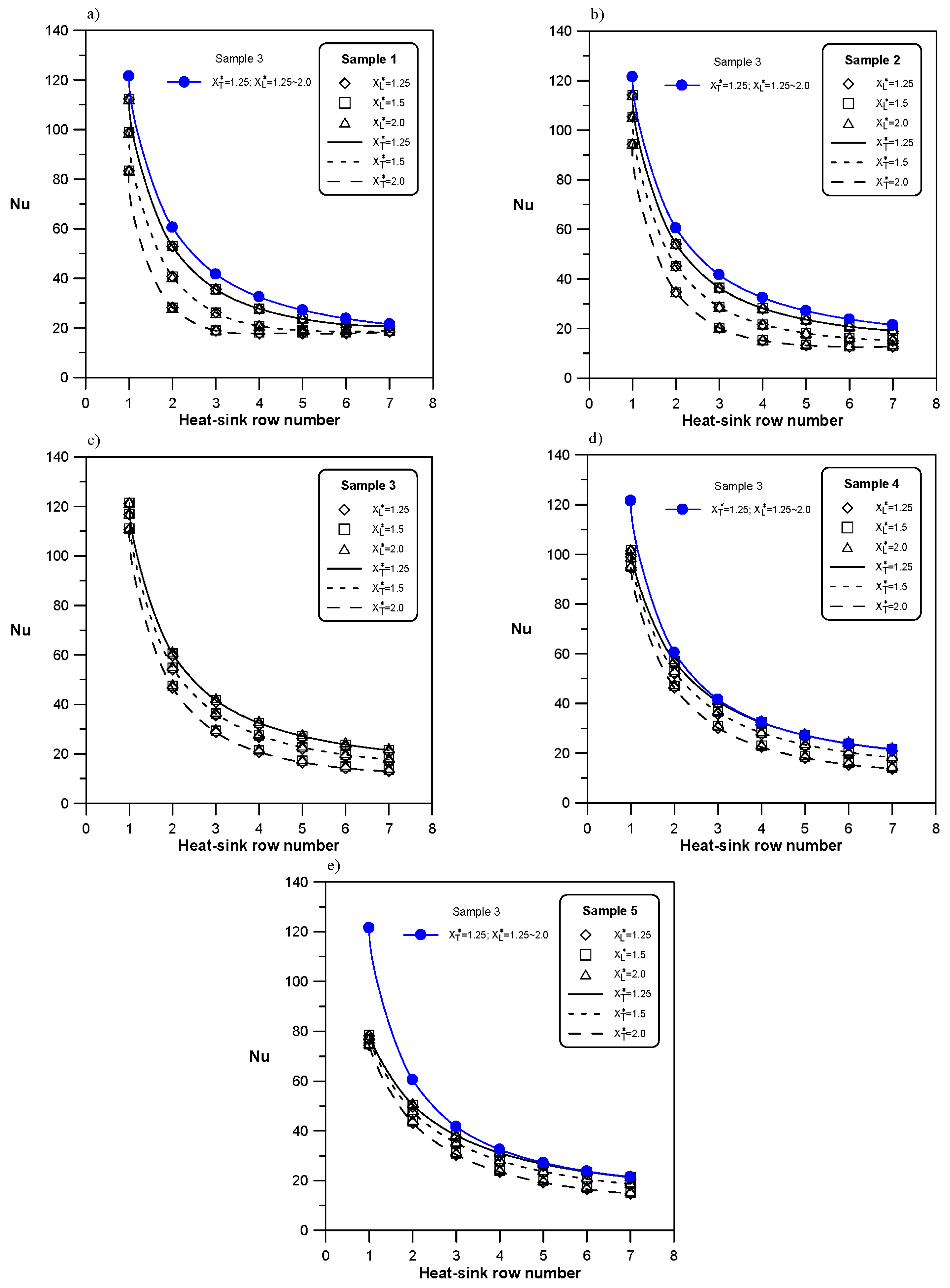

Figure 14 shows the Nusselt numbers of various rows of heat sink array at different

XT* and

XL* values of Samples 1–5 when Reynolds number

Re = 500. The number of pin fins of Sample 3 heat sink is 9 × 9, the porosity is 0.75. This heat sink array has a higher Nusselt number among all the heat sink arrays, and the Nusselt number of various heat sink arrays increases with decreasing

XT*, but not varies with

XL*. This result conforms to the dimensionless temperature contours in

Figure 12 and

Figure 13.

Figure 14.

Nusselt number distributions along the main stream direction for various heat-sink arrays: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

Figure 14.

Nusselt number distributions along the main stream direction for various heat-sink arrays: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; and (e) Sample 5.

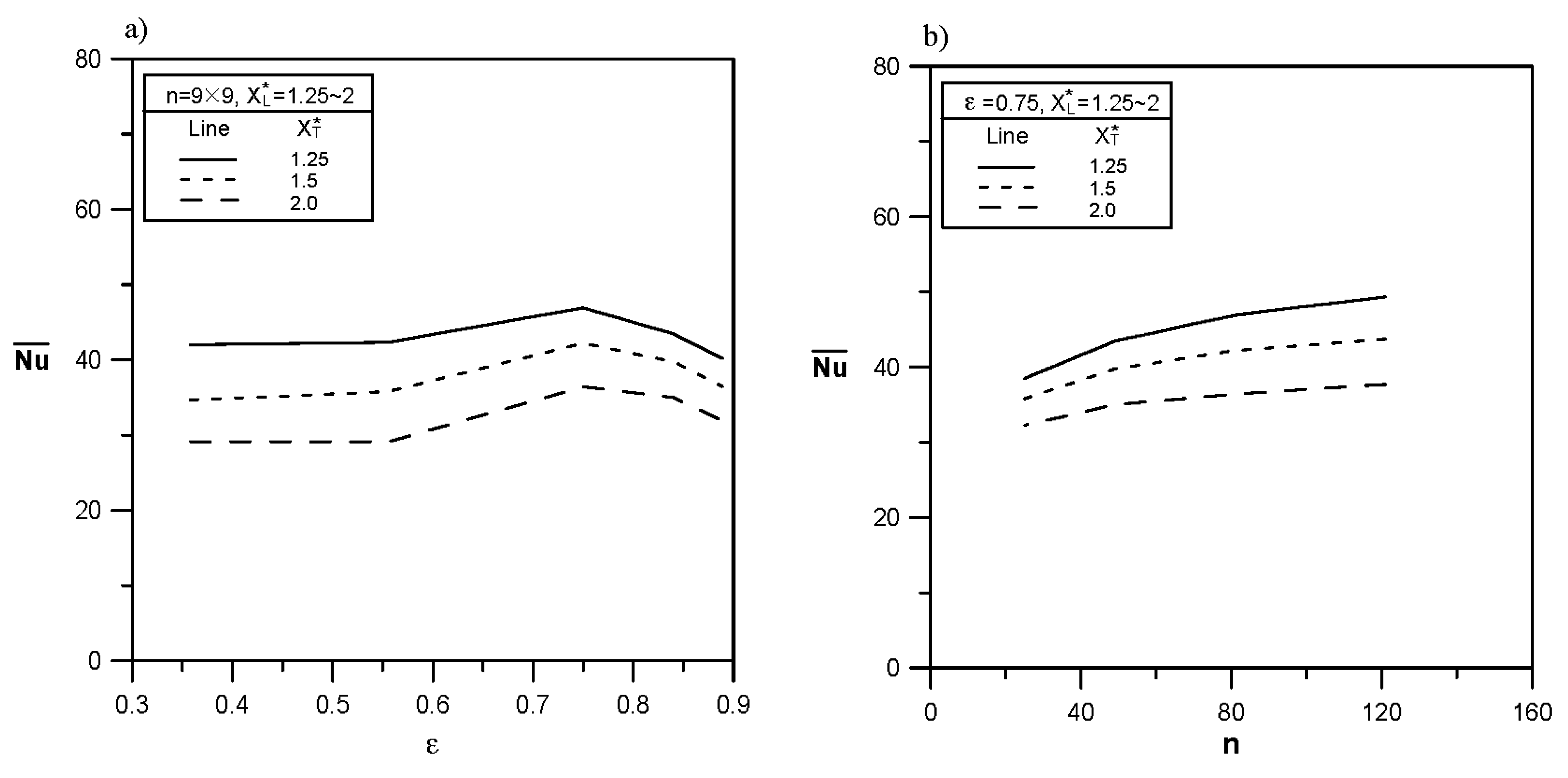

Figure 15 shows the relationship of average Nusselt number to the porosity and number of pin fins of heat sink array when Reynolds number

Re = 500. In order to clarify the influences of porosity and number of pin fins on the average Nusselt number, the heat transfer characteristics of heat sink arrays with higher porosity (Sample 6 and Sample 7, see

Table 1) and heat sink array with more pin fins (Sample 8, see

Table 1) were also simulated.

Figure 15a indicates that when the porosity of heat sink with 9 × 9 pin-fins increases from 0.358 to 0.556, the average Nusselt number changes slightly. When the porosity increases from 0.556 to 0.750, the average Nusselt number is increased significantly by 11.7% (for cases with

XT* = 1.25)–24.8% (for cases with

XT* = 2). However, when the porosity increases continuously from 0.750, the average Nusselt number decreases obviously. This is because the overall heat exchange area decreases with the pin diameter of pin-fin heat sink, which is adverse to convection heat transfer, and the upward thermal conduction capability of pin-fins declines, thus reducing the fin efficiency. As a result, the average Nusselt number decreases on the contrary.

Figure 11b indicates that when the porosity is fixed at 0.75, increasing the number of pin fins continuously can increase the average Nusselt number. In order to keep the fixed porosity, the pin diameter must be reduced while the number of pin fins is increased; at this point, the overall heat transfer area still increases with the number of pin fins, which is advantageous to the convection heat transfer. According to empirical Equations (7) and (8) suggested by Kim

et al. [

24], the decrease in pin diameter increases the convection heat transfer coefficient. Therefore, the average Nusselt number increases with the number of pin fins. However, at the Reynolds number

Re = 500, when the number of pin fins is large, the average Nusselt number increases with the number of pin fins slowly. The pressure drop of the heat sink array increases with the number of pin fins, thus preventing the air flow from entering the heat sink effectively for cooling.

Figure 15.

Average Nusselt numbers of pin-fin heat-sink array: (a) effect of heat-sink porosity and (b) effect of pin-fin numbers.

Figure 15.

Average Nusselt numbers of pin-fin heat-sink array: (a) effect of heat-sink porosity and (b) effect of pin-fin numbers.

4.3. Semi-Empirical Correlation

Figure 16 illustrates the energy-balance schematic diagram for the air flow heated via the heat sink in this issue. The inlet air flow has the uniform temperature (

Ti) and velocity (

ui). According to

Figure 10, the average velocity of air flow into windward side (

uw,k,

i.e., the average velocity of flow-in air flow) of each heat sink decreases along the downward stream. In other words, a part of flow-in air continuously results in leakage air at each downward heat sink to join the bypass flow. Therefore, the energy balance for the flow-in air heated via each heat sink can be expressed as follows:

where

Ti,k and

To,k are the average air temperatures at the inlet and outlet faces of the

kth heat sink, respectively;

Tb,k is the bulk mean temperature of the air through the

kth heat sink; and

Qw,k* is the heat transferred to the air flow through the

kth heat sink. Because that the leakage-flow effect, the mean velocity of air flow through the

kth heat sink is expressed as

ui(

Uw,k +

Uw,k+1)/2. Besides, the

Qw,k* is less than the total heat (

Qw,k) dissipated from the

kth heat sink since that the heat carried by the leakage air does not join to result in the

To,k.

Figure 16.

Energy-balance schematic diagram for the air flow heated via the heat sink.

Figure 16.

Energy-balance schematic diagram for the air flow heated via the heat sink.

Equations (17) and (18) are the definitions of the average Nusselt number (Nui,k and Nub,k) of the kth heat sink separately based on Ti,1 (i.e., Ti) and Tb,k. Substitute Equations (17) and (18) into Equation (15), the relationship between Nui,k and Nub,k can be written as Equation (19).

Finally, a semi-empirical correlation (see Equation (20)) can be completed to be a closed form by combined with Equations (7) and (8) suggested by Kim

et al. [

24], the present numerical data of

Uw,k plotted in

Figure 10, and the assumption of

Qw,k*/

Qw,k =

Uw,k+1/

Uw,k. For the present numerical simulation,

C1 and

C2 are 0.363 and 0.542, respectively (see Equation (7)).

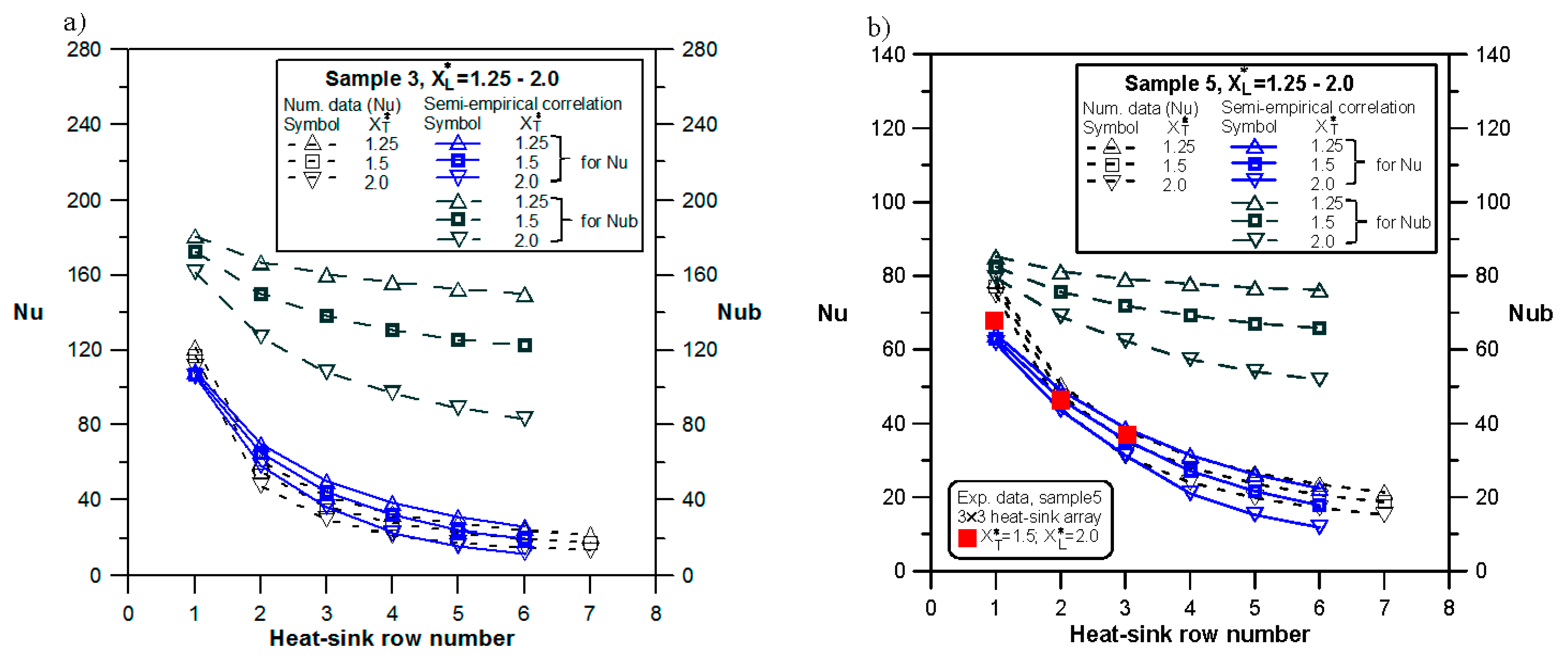

The comparison results of the present numerical Nusselt number with the semi-empirical predictions and the experimental data for Sample 3 and Sample 5 heat-sink arrays with

Re = 500 are plotted in

Figure 17. The predicted

Nu values generally agree with those numerical data. In addition, the numerical data and the predictions of Equation (20) also agree with the typical experimental results, demonstrating the correctness of the present study.

Figure 17.

Comparison results of Nusselt number with semi-empirical predictions and experimental data: (a) Sample 3 and (b) Sample 5.

Figure 17.

Comparison results of Nusselt number with semi-empirical predictions and experimental data: (a) Sample 3 and (b) Sample 5.