Evolution Law and Control on Deviatoric Stress in Surrounding Rock of Internal Hole-Making and Pressure Relief in Two Sides of Deep Coal Roadway: A Case Study

Abstract

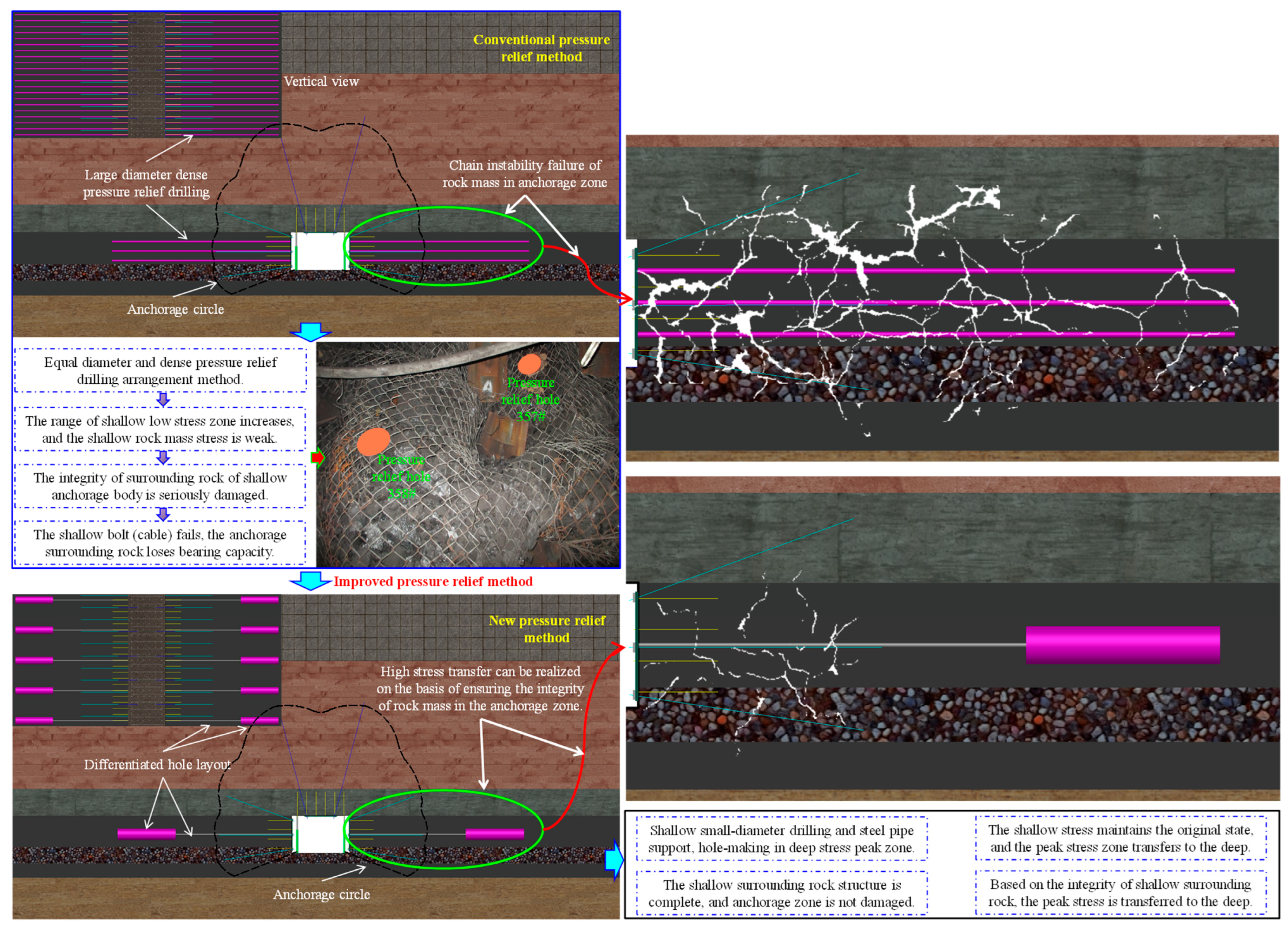

1. Introduction

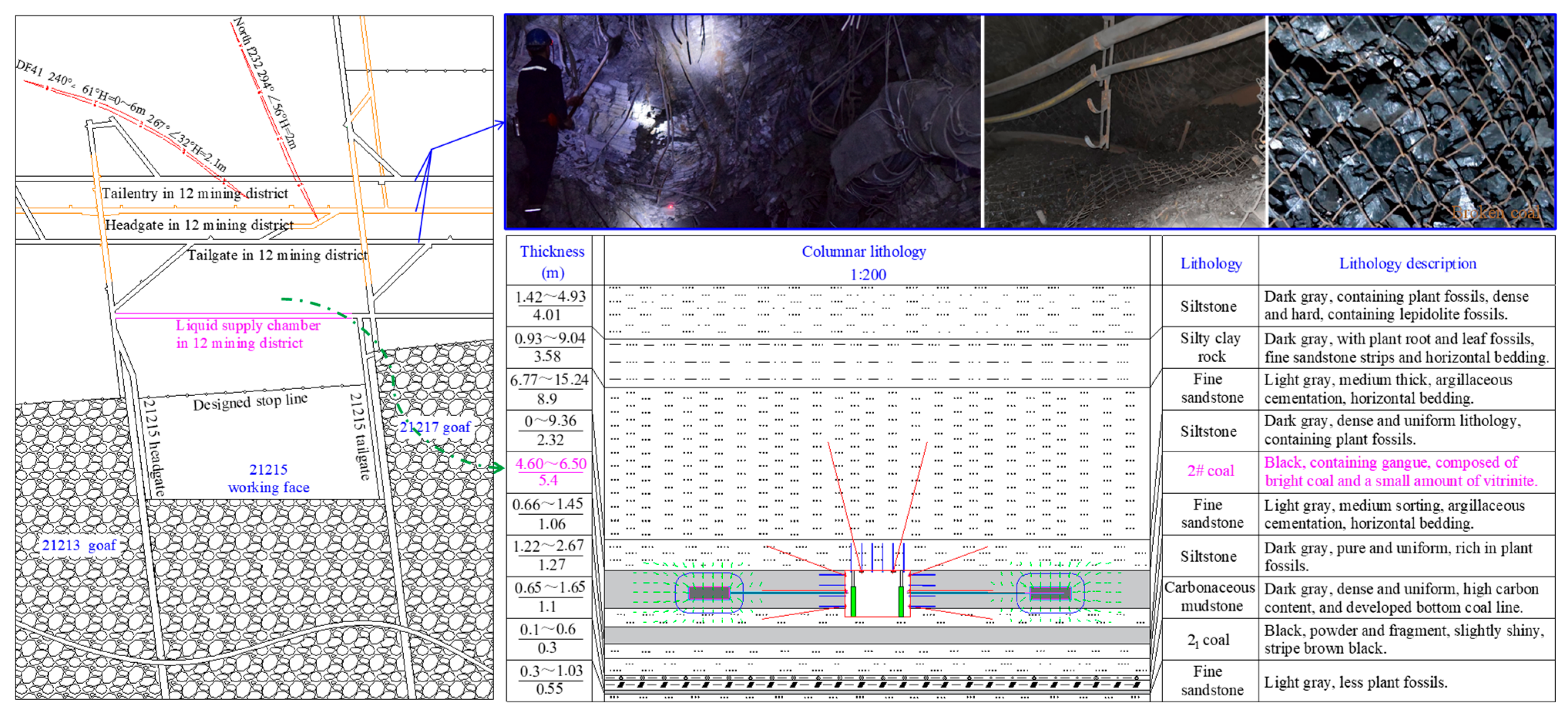

2. Study Area and Geological Conditions

2.1. Engineering Geological Overview

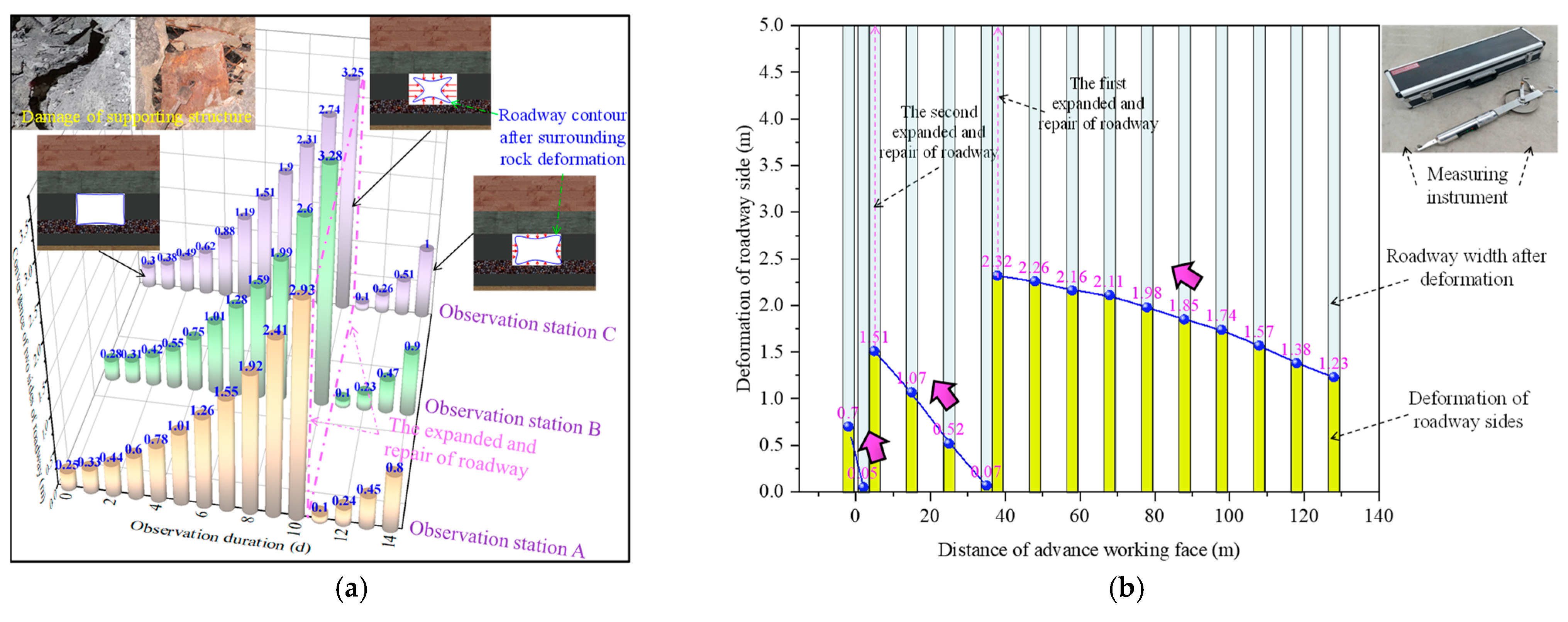

2.2. Characteristics of Pressure Behavior of Surrounding Rock in Test Chamber

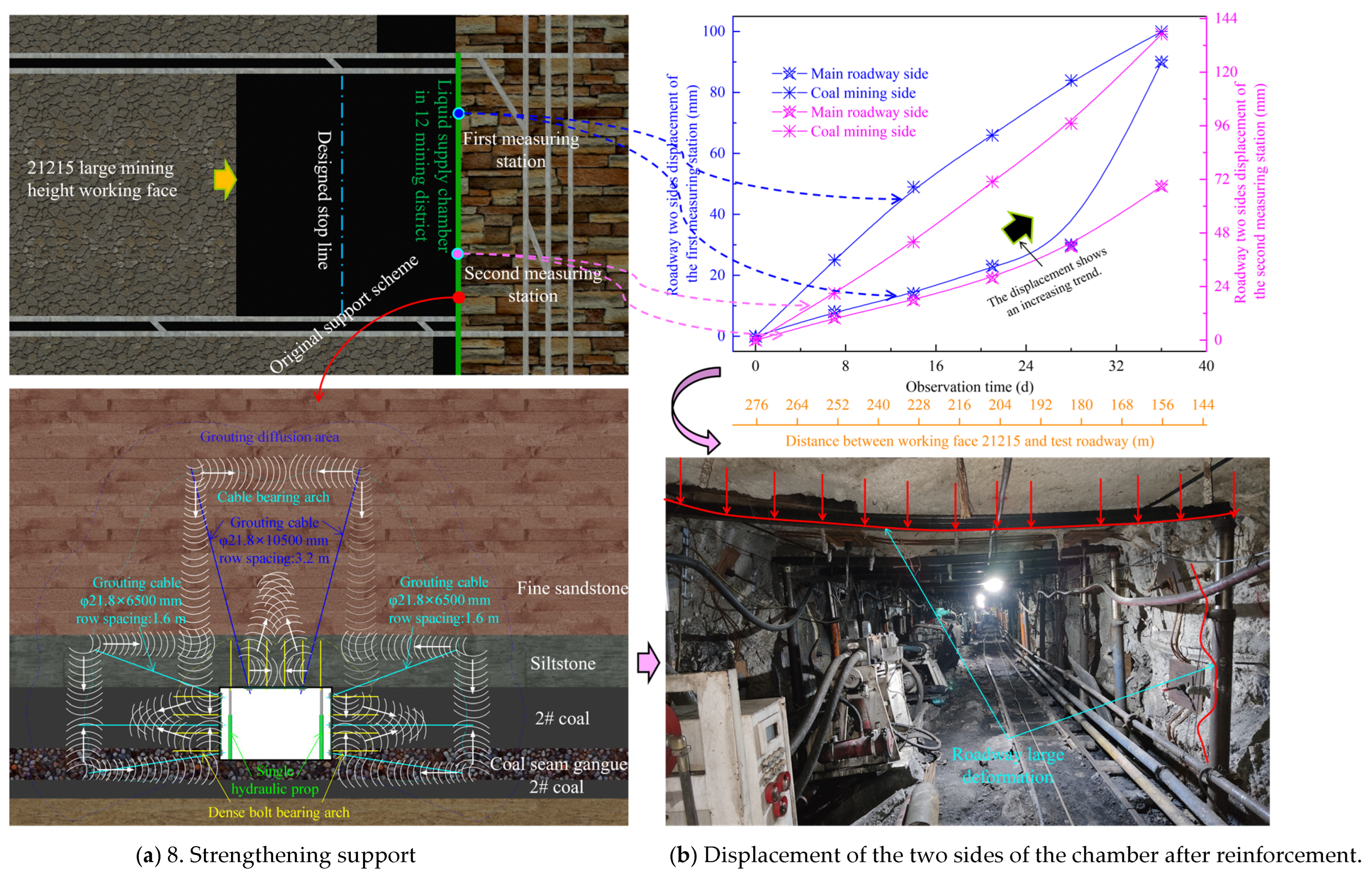

2.3. Problems in the Test Chamber After Adopting the Strengthening Support and Grouting Modification Technology

3. Methodology: Numerical Simulation Setup

3.1. Numerical Solution Model

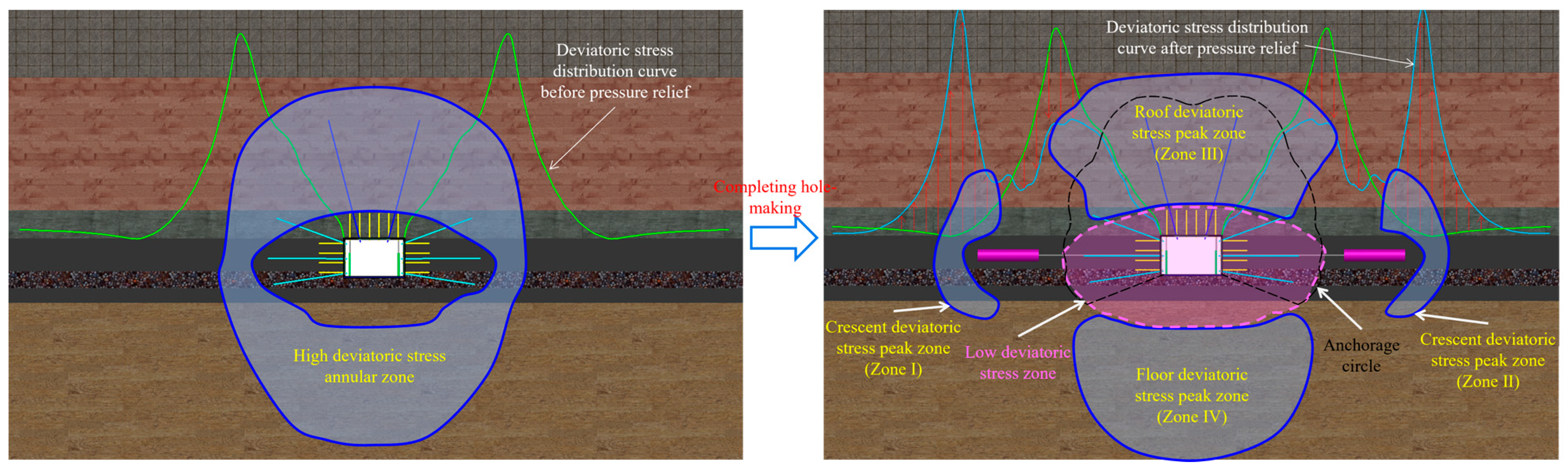

3.2. Deviatoric Stress Is Used as the Basis for Pressure Relief Effect Evaluation

3.3. Evaluation Index of Pressure Relief Effect and Classification of Pressure Relief Degree

3.4. Determination of Key Parameters of Internal Hole-Making

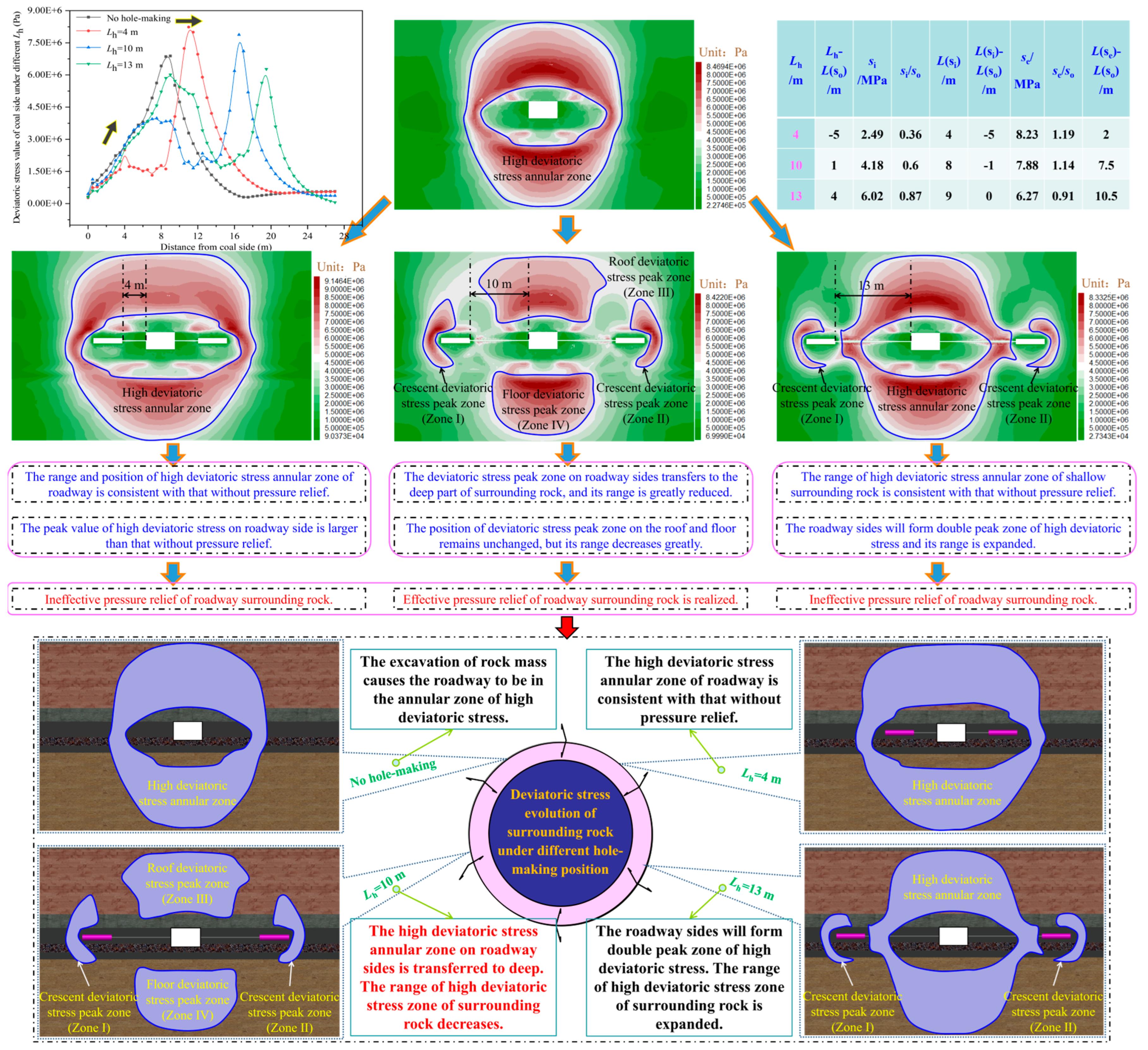

3.4.1. Determination of Internal Hole-Making Position (Depth)

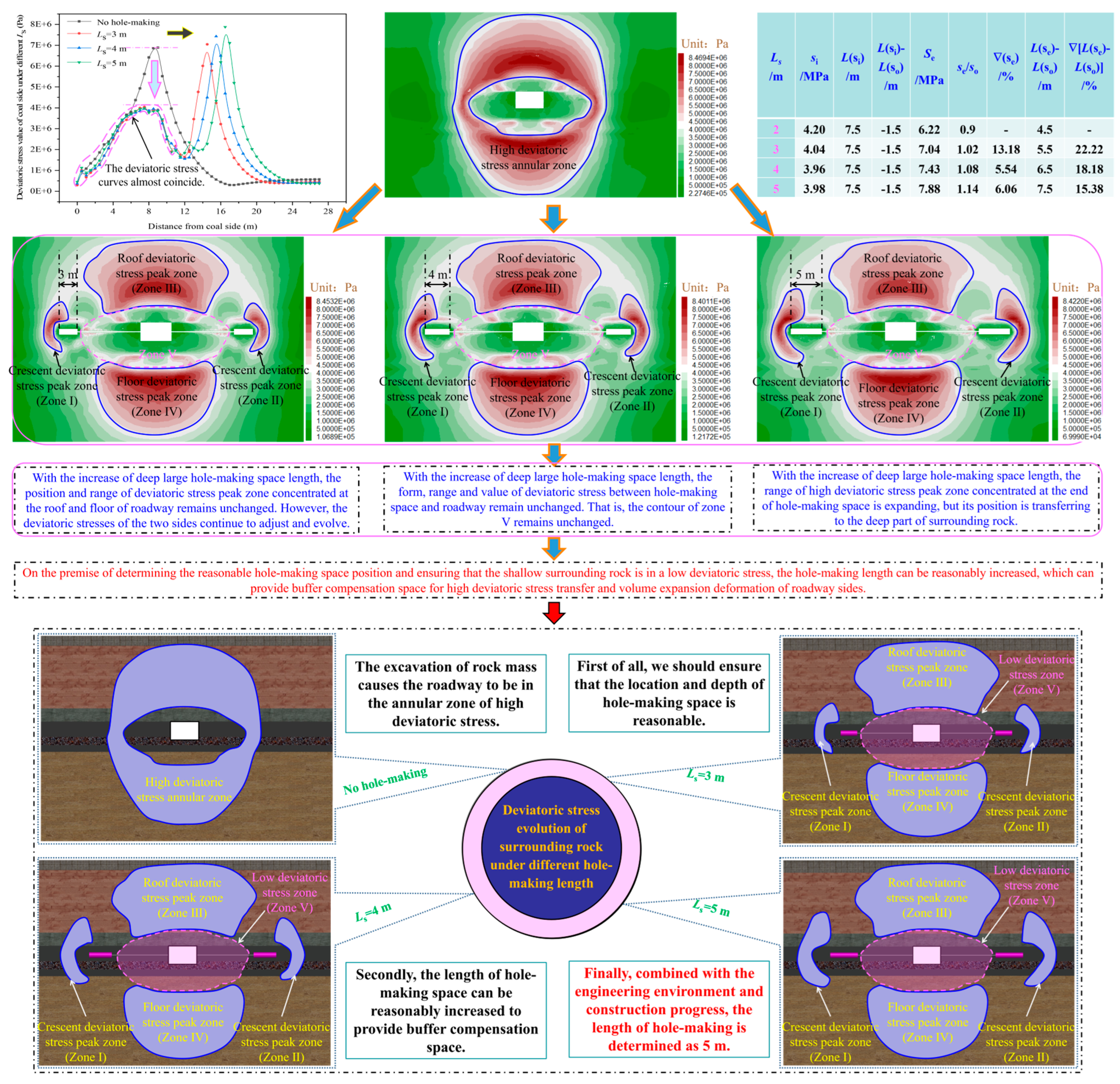

3.4.2. Determination of Internal Hole-Making Length

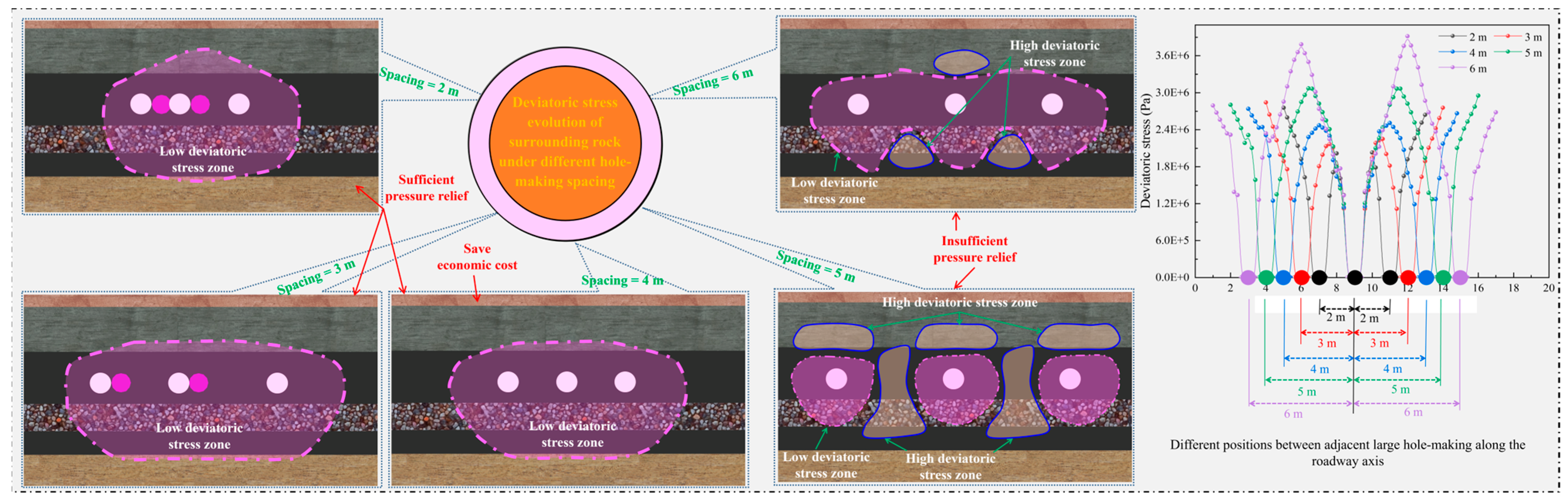

3.4.3. Determination of Internal Hole-Making Spacing

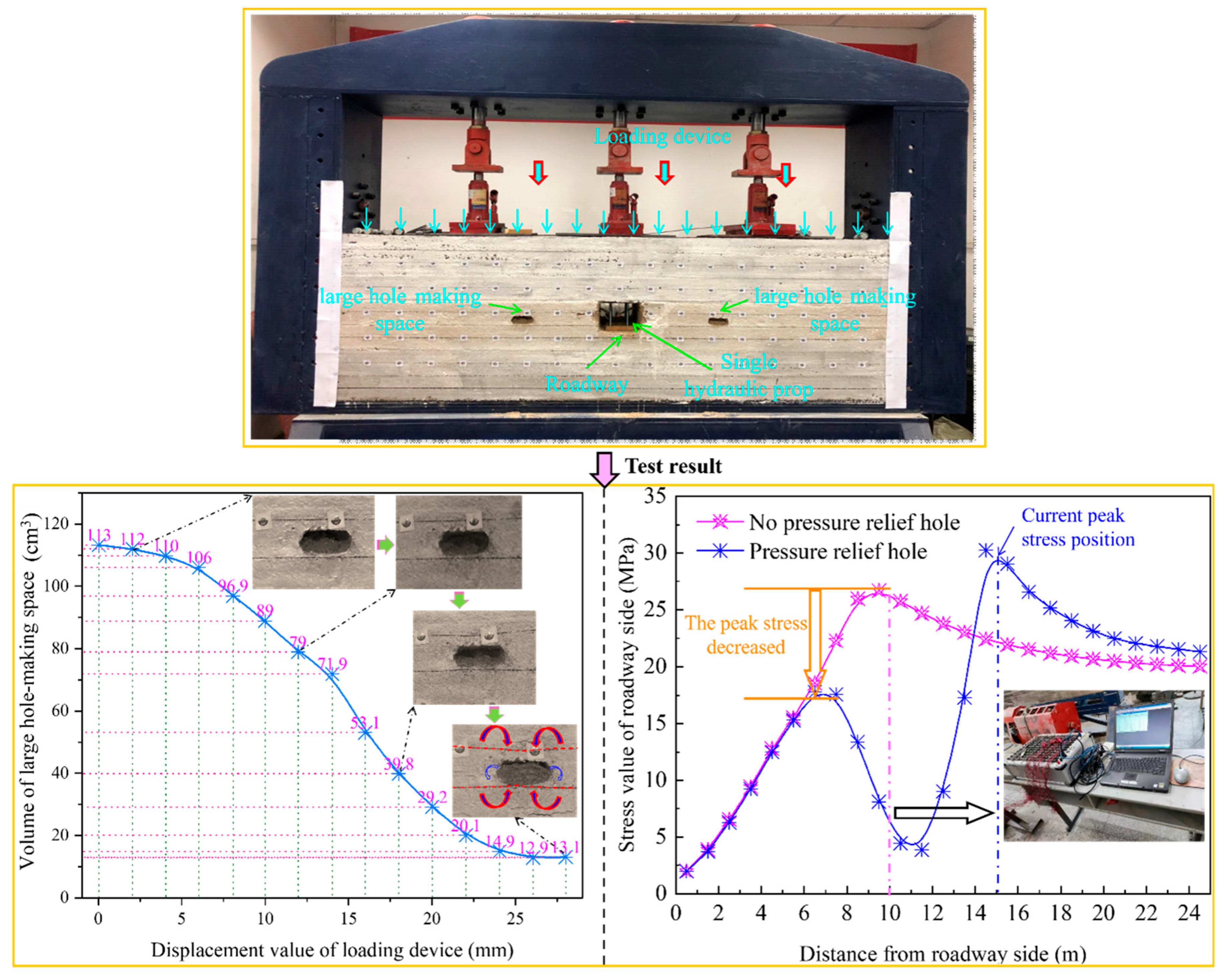

4. Physical Similarity Simulation

4.1. Similar Simulation Test Process and Parameter Design

4.2. Similarity Simulation Test Results and Analysis

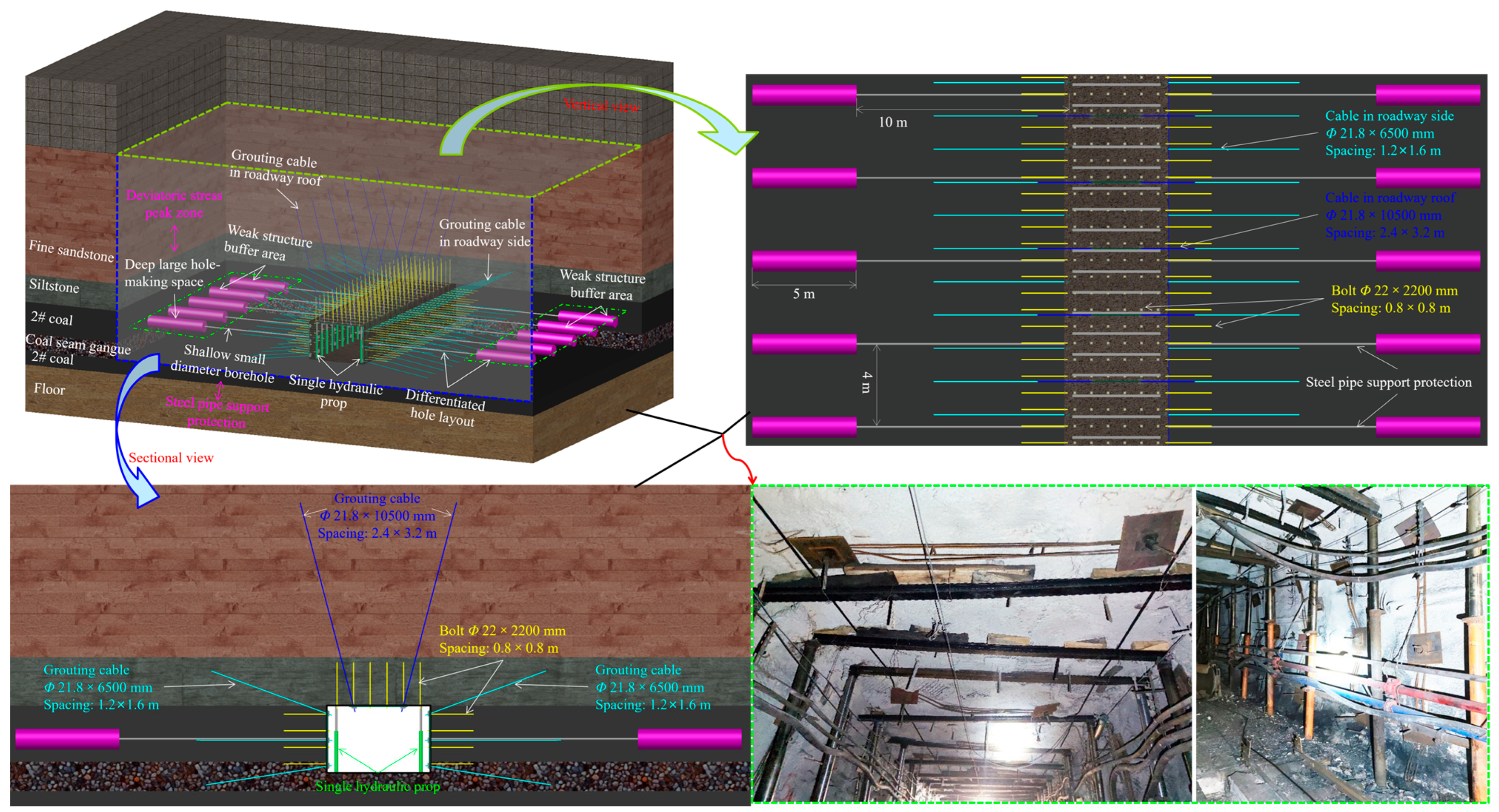

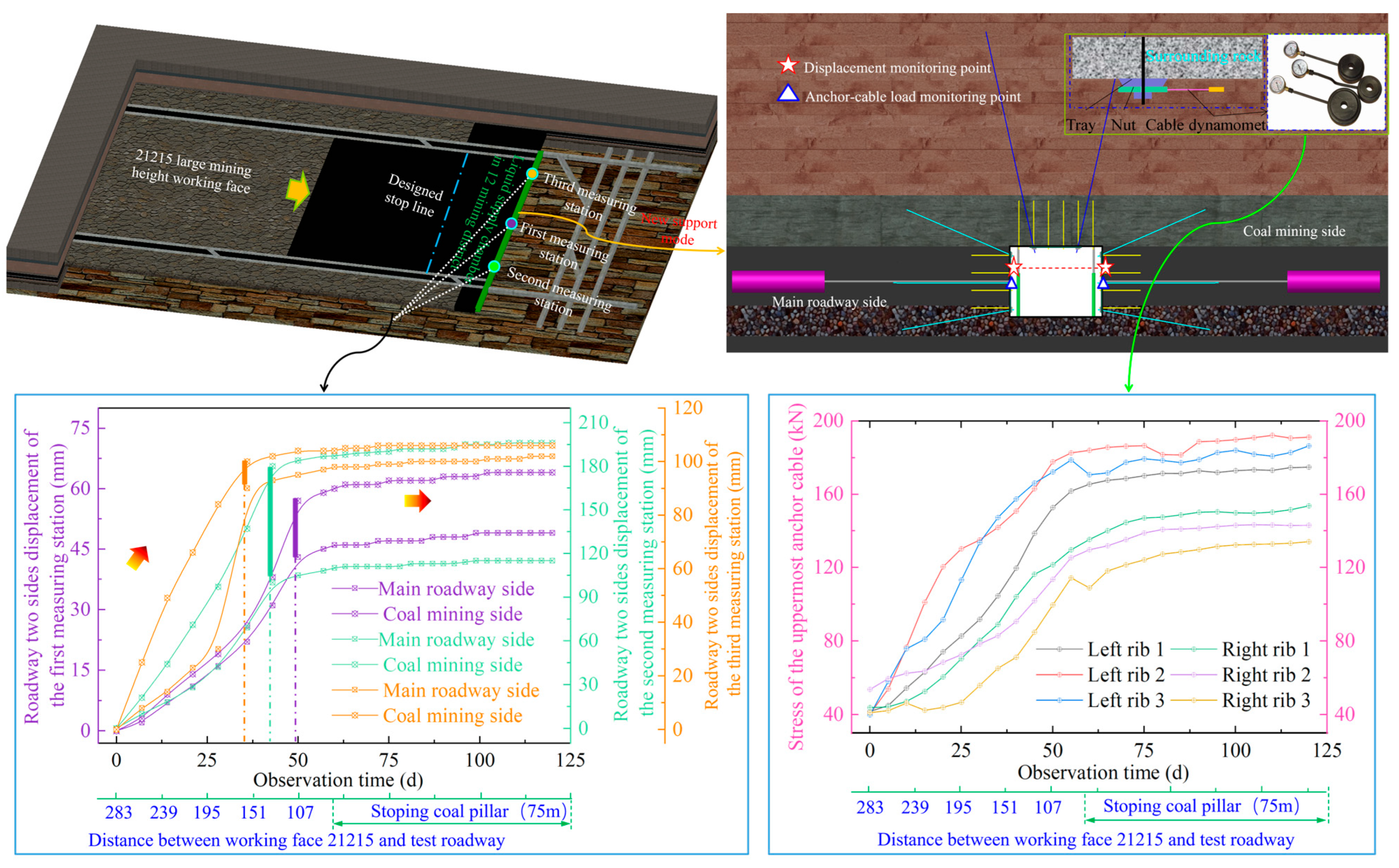

5. Field Application and Discussion

5.1. Engineering Application

5.2. Discussion and Limitations

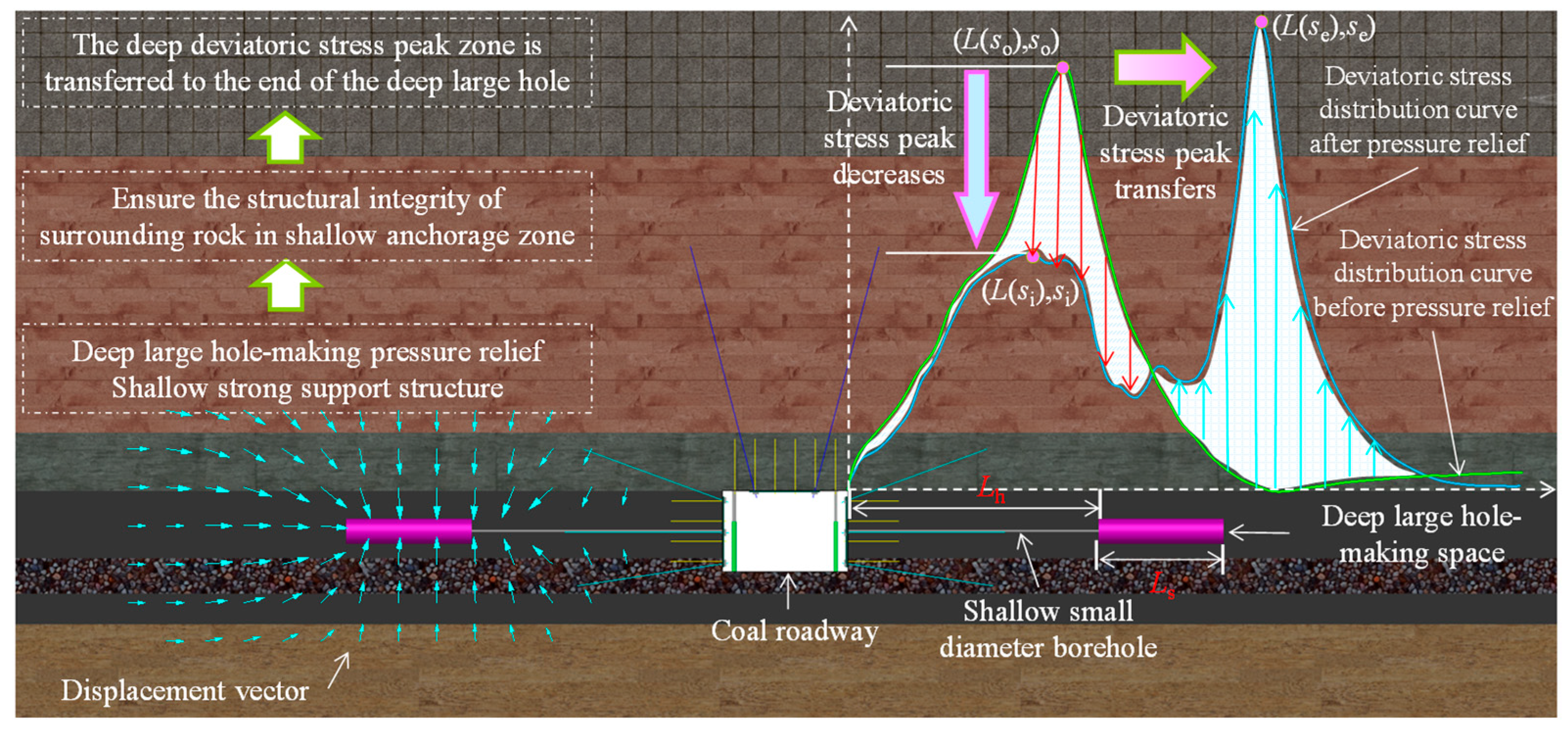

5.2.1. Validation of Cooperative Control Mechanism

5.2.2. Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, B.Y.; Wang, L.G.; Lu, Y.L.; Gu, S.T.; Sun, X.K. Failure mechanism analysis and support design for deep composite soft rock roadway: A case study of the Yangcheng coal mine in China. Shock. Vib. 2015, 2015, 452479. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, X.F.; Fan, G.W.; Zhang, D.S.; Cui, J.B. Pillar size optimization design of isolated island panel gob-side entry driving in deep inclined coal seam-case study of Pingmei No. 6 coal seam. J. Geophys. Eng. 2018, 15, 816–828. [Google Scholar] [CrossRef]

- Xie, Z.Z.; Zhang, N.; Yuan, Y.X.; Xu, G.; Wei, Q. Study on safety control of composite roof in deep roadway based on energy balance theory. Sustainability 2019, 11, 3688. [Google Scholar] [CrossRef]

- Zhang, J.F.; Jiang, F.X.; Yang, J.B.; Bai, W.S.; Zhang, L. Rockburst mechanism in soft coal seam within deep coal mines. Int. J. Min. Sci. Technol. 2017, 27, 551–556. [Google Scholar] [CrossRef]

- Li, S.C.; Wang, Q.; Wang, H.T.; Jiang, B.; Wang, D.C.; Zhang, B.; Li, Y.; Ruan, G.Q. Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. Tunn. Undergr. Space Technol. 2015, 47, 52–63. [Google Scholar] [CrossRef]

- Hu, Y.B.; Li, W.P.; Wang, Q.Q.; Liu, S.L.; Wang, Z.K. Study on failure depth of coal seam floor in deep mining. Environ. Earth Sci. 2019, 78, 697. [Google Scholar] [CrossRef]

- Jing, H.W.; Wu, J.Y.; Yin, Q.; Wang, K. Deformation and failure characteristics of anchorage structure of surrounding rock in deep roadway. Int. J. Min. Sci. Technol. 2020, 30, 593–604. [Google Scholar] [CrossRef]

- Xie, Z.Z.; Zhang, N.; Feng, X.W.; Liang, D.X.; Wei, Q.; Weng, M.Y. Investigation on the evolution and control of surrounding rock fracture under different supporting conditions in deep roadway during excavation period. Int. J. Rock Mech. Min. Sci. 2019, 123, 104122. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Xu, Y.; Kulatilake, P.; Huang, X. Physical model test and numerical analysis on the behavior of stratified rock masses during underground excavation. Int. J. Rock Mech. Min. Sci. 2012, 49, 134–147. [Google Scholar] [CrossRef]

- Cai, M.F. Key theories and technologies for surrounding rock stability and ground control in deep mining. J. Min. Strata Control Eng. 2020, 2, 5–13. [Google Scholar]

- Wang, W.J.; Yuan, C.; Yu, W.J.; Wu, H.; Peng, W.Q.; Peng, G.; Liu, X.S.; Dong, E.Y. Stability control method of surrounding rock in deep roadway with large deformation. J. China Coal Soc. 2016, 41, 2921–2931. [Google Scholar]

- Bai, Q.S.; Tu, S.H.; Wang, F.T.; Zhang, C. Field and numerical investigations of gateroad system failure induced by hard roofs in a longwall top coal caving face. Int. J. Coal Geol. 2017, 173, 176–199. [Google Scholar] [CrossRef]

- Xie, S.R.; Pan, H.; Chen, D.D.; Zeng, J.C.; Song, H.Z.; Cheng, Q.; Xiao, H.B.; Yan, Z.Q.; Li, Y.H. Stability analysis of integral load-bearing structure of surrounding rock of gob-side entry retention with flexible concrete formwork. Tunn. Undergr. Space Technol. 2020, 103, 103492. [Google Scholar] [CrossRef]

- Yu, W.J.; Li, K. Deformation mechanism and control technology of surrounding rock in the deep-buried large-span chamber. Geofluids 2020, 2020, 8881319. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Deng, M.; Bai, J.B.; Yan, S.; Yu, X.Y. Stability control of gob-side entry retained under the gob with close distance coal seams. Int. J. Min. Sci. Technol. 2021, 31, 321–332. [Google Scholar] [CrossRef]

- Guo, D.M.; Kang, X.C.; Lu, Z.Y.; Chen, Q.Y.; Zhang, W.; Zhao, Z.F.; Cao, Y.P. Flexural floor heave mechanism and floor corner piles control technology in soft rock roadway. J. Min. Sci. Technol. 2021, 6, 536–547. [Google Scholar]

- Li, W.T.; Wang, Q.; Li, S.C.; Wang, D.C.; Huang, F.C.; Zuo, J.Z.; Zhang, S.G.; Wang, H.T. Deformation and failure mechanism analysis and control of deep roadway with intercalated coal seam in roof. J. China Coal Soc. 2014, 39, 47–56. [Google Scholar]

- Wang, Q.; Pan, R.; Li, S.C.; He, M.C.; Ren, Y.X.; Wang, L.; Ding, G.L.; Sun, H.B.; Jiang, B. Gob side entry failure mechanism and control of bolt-grouting in three soft coal seam. J. China Coal Soc. 2016, 41, 1111–1119. [Google Scholar]

- Chen, D.D.; Jia, Q.B.; Zhang, Z.F.; Xie, S.R.; Wang, Y.Y.; Wang, Z.Q.; Li, Z.J.; Tian, C.Y.; Xie, F.X. Study on the Failure Mechanism and a New Monitoring Method of Borehole Stress Gauge Monitoring Coal Seam Mining Stress. Rock Mech. Rock Eng. 2025. [Google Scholar] [CrossRef]

- Wang, J.; Liu, P.; Liu, S.; Ma, L.; Liu, Y.P.; Chen, X. Study on collaborative pressure relief control technology for surrounding rock stability of dynamic pressure roadway in coal mine. J. Min. Sci. Technol. 2021, 6, 323–332. [Google Scholar]

- Zhou, L.S.; Huang, Y.B.; Shao, Z.H.; Ma, F.L.; Zhang, P.; Wang, Y. Research on surrounding rock rheological effect and control method of large section chamber group in deep well. Geotech. Geol. Eng. 2021, 39, 5041–5061. [Google Scholar] [CrossRef]

- Yu, W.J.; Li, K.; Liu, Z.; An, B.F.; Wang, P.; Wu, H. Mechanical characteristics and deformation control of surrounding rock in weakly cemented siltstone. Environ. Earth Sci. 2021, 80, 337. [Google Scholar] [CrossRef]

- Xie, S.R.; Wang, E.; Chen, D.D.; Sun, Y.H.; Cheng, Q.; Ji, C.W.; Yan, Z.Q.; Xiao, H.B. Failure analysis and control mechanism of gob-side entry retention with a 1.7-m flexible-formwork concrete wall: A case study. Eng. Fail. Anal. 2020, 117, 104816. [Google Scholar] [CrossRef]

- Batugin, A.; Wang, Z.Q.; Su, Z.H.; Sidikovna, S.S. Combined support mechanism of rock bolts and anchor cables for adjacent roadways in the external staggered split-level panel layout. Int. J. Coal Sci. Technol. 2021, 8, 659–673. [Google Scholar] [CrossRef]

- Chen, J.H.; Zhao, H.B.; He, F.L.; Zhang, J.W.; Tao, K.M. Studying the performance of fully encapsulated rock bolts with modified structural elements. Int. J. Coal Sci. Technol. 2021, 8, 64–76. [Google Scholar] [CrossRef]

- Xie, S.R.; Wang, E.; Chen, D.D.; Jiang, Z.S.; Li, H.; Liu, R.P. Collaborative control technology of external anchor-internal unloading of surrounding rock in deep large-section coal roadway under strong mining influence. J. China Coal Soc. 2022, 47, 1946–1957. [Google Scholar]

- Sun, Y.J.; Zuo, J.P.; Karakus, M.; Liu, L.; Zhou, H.W.; Yu, M.L. A new theoretical method to predict strata movement and surface subsidence due to inclined coal seam mining. Rock Mech. Rock Eng. 2021, 54, 2723–2740. [Google Scholar] [CrossRef]

- He, M.C.; Chen, S.Y.; Guo, Z.B.; Yang, J.; Gao, Y.B. Control of surrounding rock structure for gob-side entry retaining by cutting roof to release pressure and its engineering application. J. China Univ. Min. Technol. 2017, 46, 959–969. [Google Scholar]

- Qi, H.G. Research and practice on integrated pressure releasing technology in deep coal mine rock roadway under high stress. J. Min. Saf. Eng. 2016, 33, 1023–1029. [Google Scholar]

- Wang, M.; Wang, X.Y.; Xiao, T.Q. Borehole destressing mechanism and determination method of its key parameters in deep roadway. J. China Coal Soc. 2017, 42, 1138–1145. [Google Scholar]

- Zuo, J.P.; Shi, Y.; Liu, D.J.; Sun, Y.J.; Chen, Y. The equivalent ellipse model and simulation analysis of destressing by cutting groove in deep soft rock roadway. J. China Univ. Min. Technol. 2019, 48, 1–11. [Google Scholar]

- Zhang, S.C.; Li, Y.Y.; Shen, B.T.; Sun, X.Z.; Gao, L.Q. Effective evaluation of pressure relief drilling for reducing rock bursts and its application in underground coal mines. Int. J. Rock Mech. Min. Sci. 2019, 114, 7–16. [Google Scholar] [CrossRef]

- Li, Y.P.; Sun, D.Q.; Zhao, S.K.; Liang, K.H.; Cui, K.; Wang, H.H. Investigation of pressure relief borehole effects using in situ testing based on distributed optical fibre sensing technology. Adv. Civ. Eng. 2021, 2021, 8847500. [Google Scholar] [CrossRef]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-Hole Destress Blasting for Rockburst Control during Deep Underground Coal Mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- Chen, T.; Vennes, I.; Mitri, H.S. A Novel V-Cut Method for Explosive-Free Breakage of Biaxially Loaded Rock Using Soundless Chemical Demolition Agents. J. Rock Mech. Geotech. Eng. 2024, 16, 4866–4877. [Google Scholar] [CrossRef]

- Konicek, P.; Chen, T.; Mitri, H.S. Numerical Modeling of Destress Blasting for Strata Separation. J. Rock Mech. Geotech. Eng. 2023, 15, 2238–2249. [Google Scholar] [CrossRef]

| Rock Stratum | D/kg·m−3 | K/GPa | G/GPa | /° | /MPa | /MPa |

|---|---|---|---|---|---|---|

| Silty sand claystone | 2239 | 6.33 | 5.2 | 27 | 3.0 | 1.9 |

| Fine sandstone | 2610 | 7.03 | 5.4 | 35 | 3.3 | 2.4 |

| Siltstone | 2596 | 7.06 | 6.2 | 33 | 2.9 | 1.9 |

| 2# coal seam | 1420 | 2.5 | 1.6 | 20 | 0.9 | 0.3 |

| Carbonaceous mudstone | 2190 | 7.6 | 6.2 | 30 | 3.0 | 2.1 |

| Coarse sandstone | 2646 | 9.4 | 7.2 | 34 | 3.3 | 2.6 |

| No. | Lithology (Sand:Lime:Gypsum) | Thickness (cm) | Sand (kg) | Lime (kg) | Gypsum (kg) | Water (kg) |

|---|---|---|---|---|---|---|

| 1 | Gritstone (8:0.5:0.5) | 1.58 | 6.96 | 0.43 | 0.43 | 0.78 |

| 2 | Fine sandstone (7:0.5:0.5) | 0.55 | 2.38 | 0.17 | 0.17 | 0.27 |

| 3 | 21#coal (8:0.7:0.3) | 0.3 | 1.32 | 0.12 | 0.05 | 0.15 |

| 4 | Carbonaceous mudstone (8:0.5:0.5) | 1.1 | 4.40 | 0.28 | 0.28 | 0.50 |

| 5 | Siltstone (7:0.5:0.5) | 1.27 | 5.50 | 0.39 | 0.39 | 0.63 |

| 6 | Fine sandstone (7:0.5:0.5) | 1.06 | 4.60 | 0.33 | 0.33 | 0.53 |

| 7 | 2#coal (8:0.7:0.3) | 1.80 | 23.78 | 2.08 | 0.89 | 2.67 |

| 8 | Siltstone (7:0.5:0.5) | 2.32 | 10.06 | 0.72 | 0.72 | 1.15 |

| 9 | Fine sandstone (7:0.5:0.5) | 1.87 | 48.64 | 3.48 | 3.48 | 5.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Gong, H.; Ren, Y.; Xie, S.; Han, F. Evolution Law and Control on Deviatoric Stress in Surrounding Rock of Internal Hole-Making and Pressure Relief in Two Sides of Deep Coal Roadway: A Case Study. Appl. Sci. 2026, 16, 469. https://doi.org/10.3390/app16010469

Gong H, Ren Y, Xie S, Han F. Evolution Law and Control on Deviatoric Stress in Surrounding Rock of Internal Hole-Making and Pressure Relief in Two Sides of Deep Coal Roadway: A Case Study. Applied Sciences. 2026; 16(1):469. https://doi.org/10.3390/app16010469

Chicago/Turabian StyleGong, Haijun, Yuxin Ren, Shengrong Xie, and Feng Han. 2026. "Evolution Law and Control on Deviatoric Stress in Surrounding Rock of Internal Hole-Making and Pressure Relief in Two Sides of Deep Coal Roadway: A Case Study" Applied Sciences 16, no. 1: 469. https://doi.org/10.3390/app16010469

APA StyleGong, H., Ren, Y., Xie, S., & Han, F. (2026). Evolution Law and Control on Deviatoric Stress in Surrounding Rock of Internal Hole-Making and Pressure Relief in Two Sides of Deep Coal Roadway: A Case Study. Applied Sciences, 16(1), 469. https://doi.org/10.3390/app16010469