Model Performance Improvement by Accumulated Application of Machine Data in Machine Learning Model for TBM Advance Rate Prediction

Abstract

1. Introduction

2. Dataset

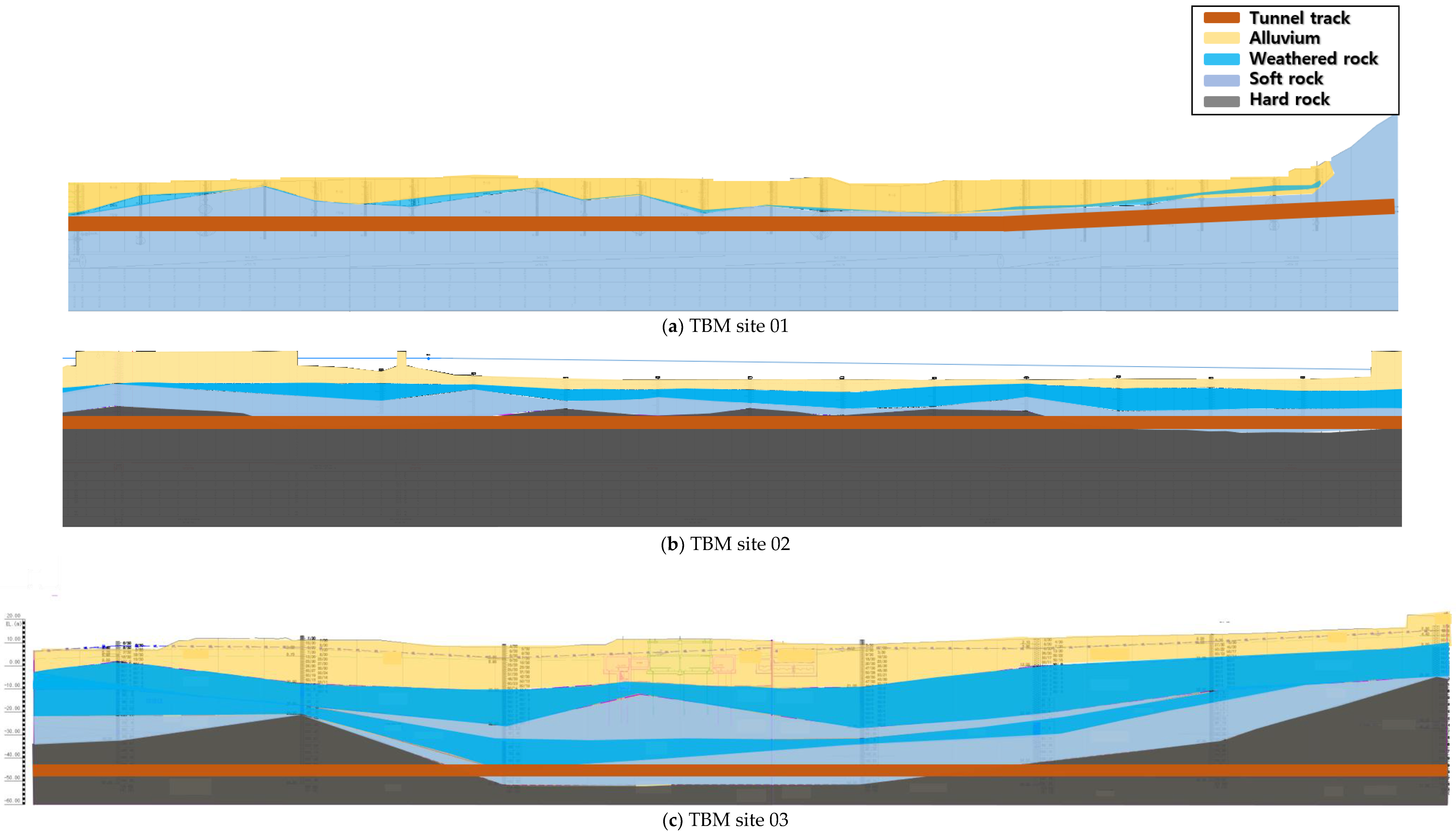

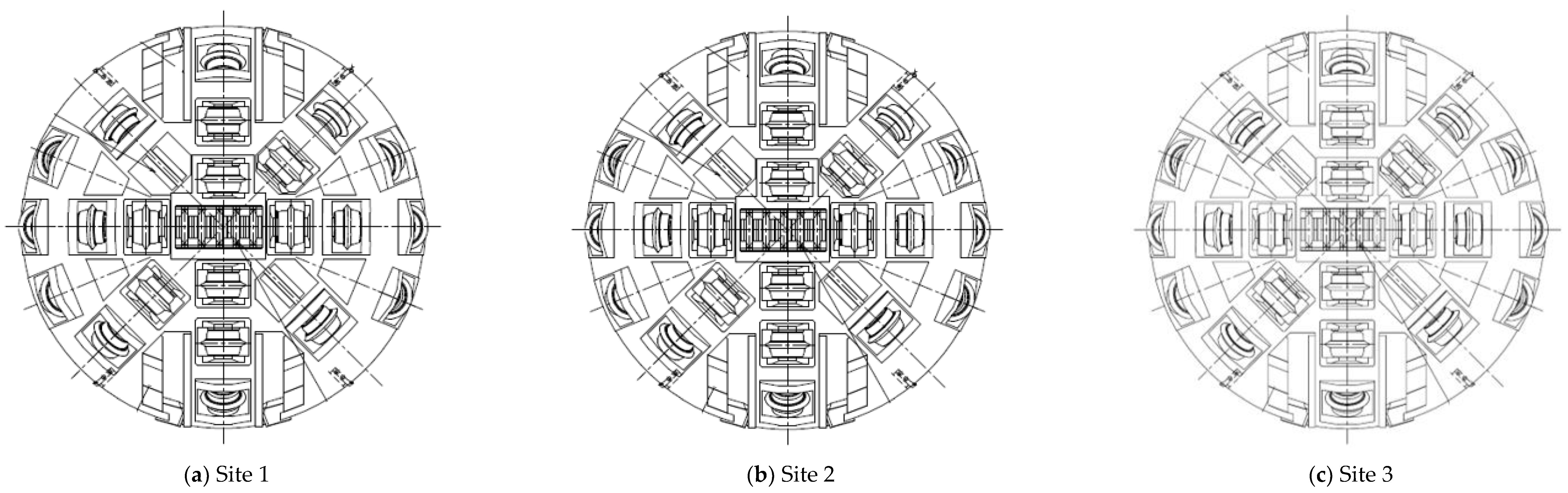

2.1. Project Description

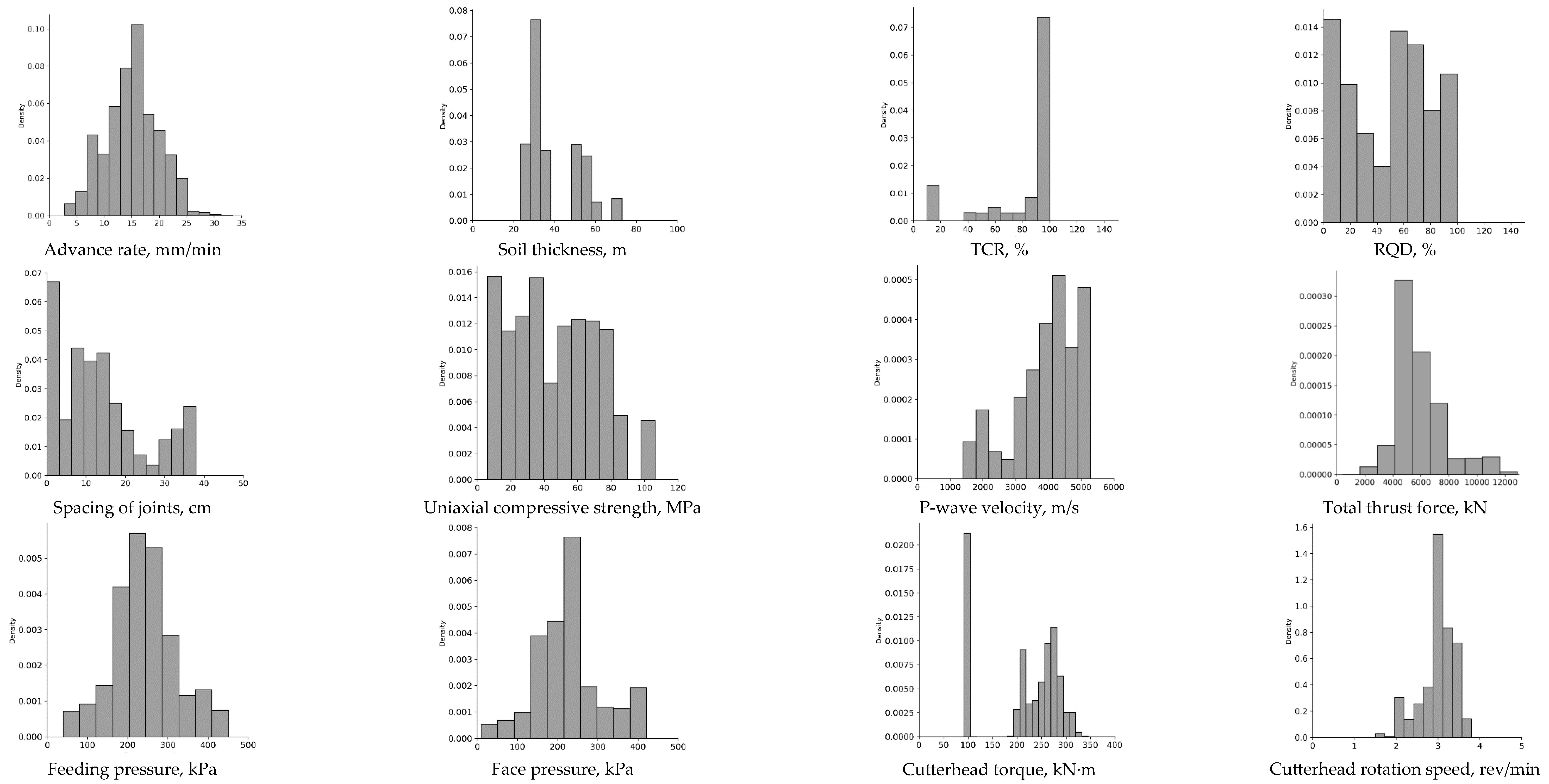

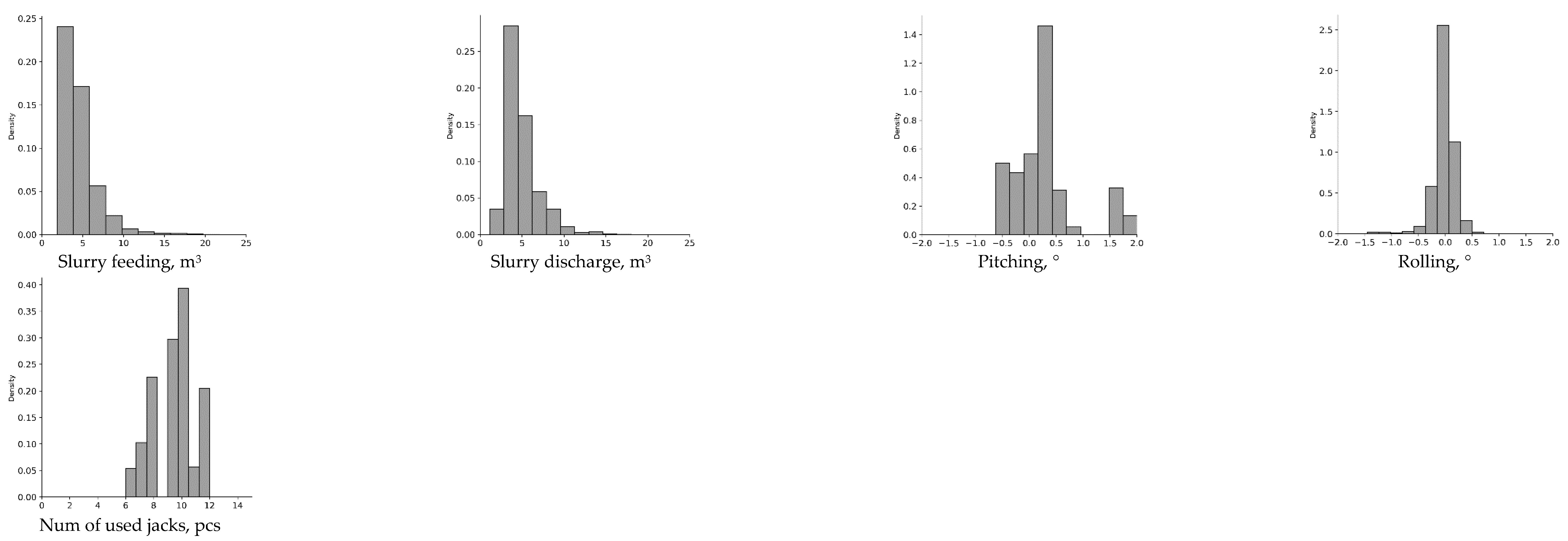

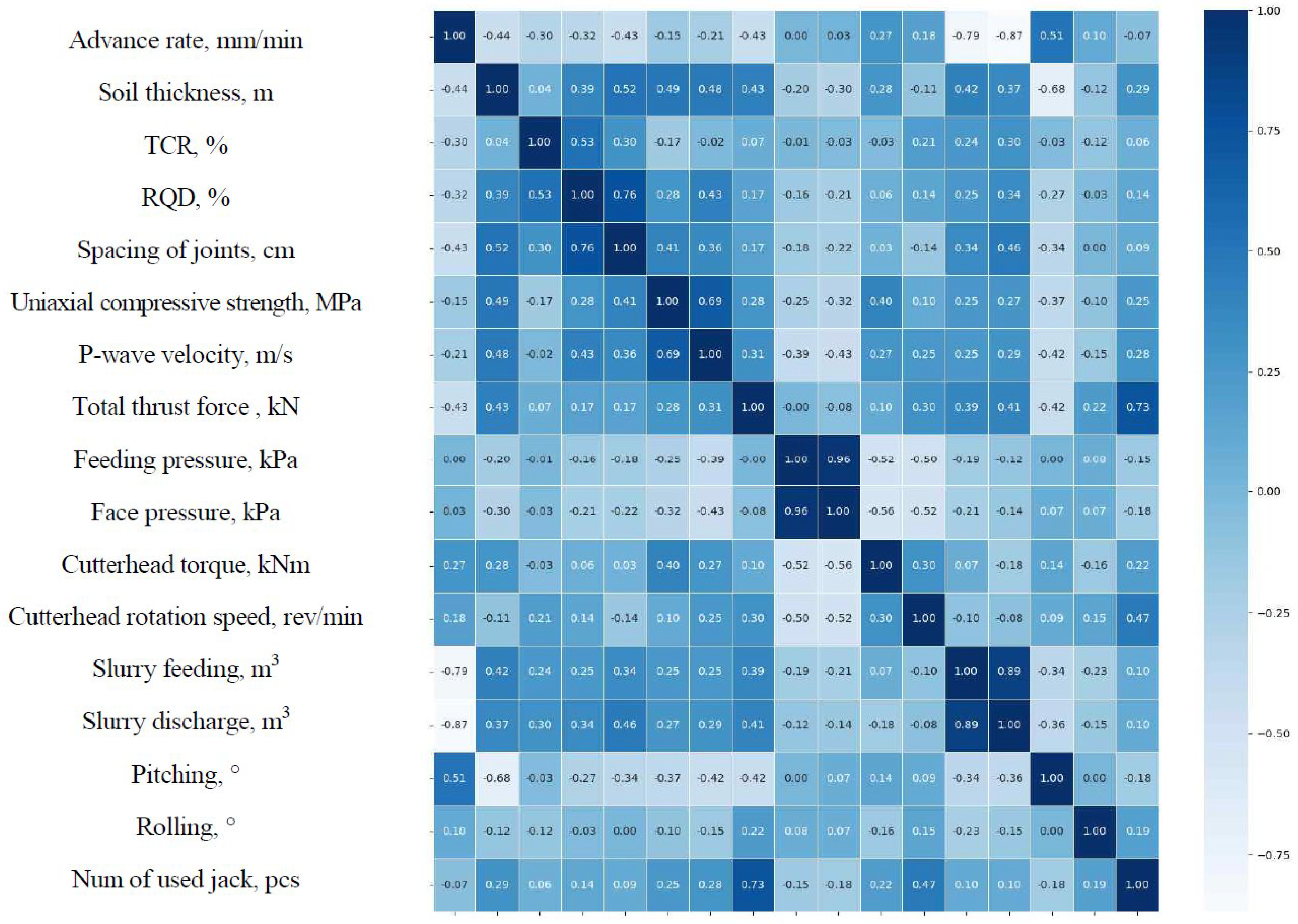

2.2. Feature Selection

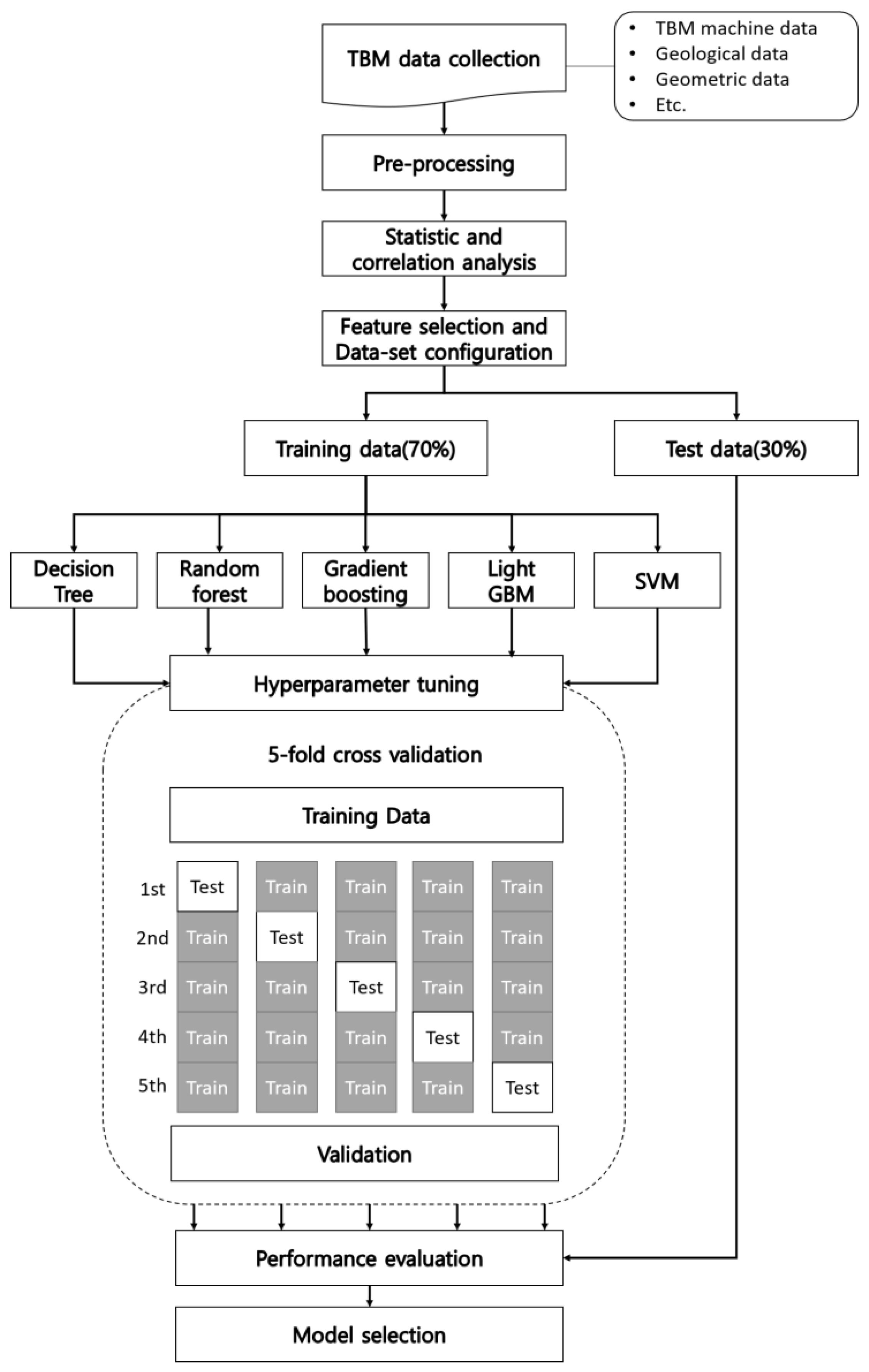

3. Preliminary Model for Prediction of Advance Rate

3.1. Performance Evaluation Method and Hyperparameters

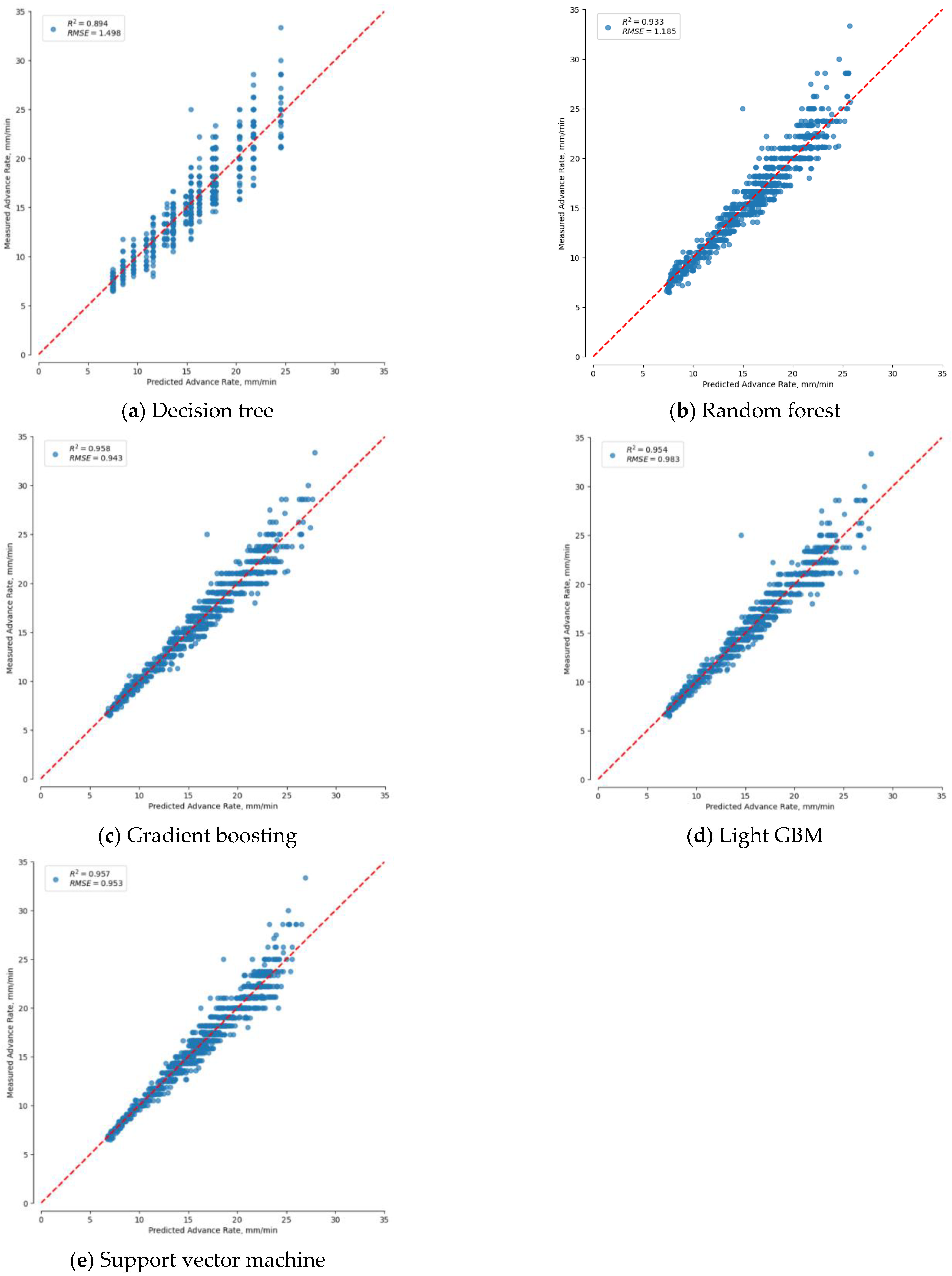

3.2. Selection of Preliminary Model

4. Prediction Results of Advance Rate in TBM Site 3

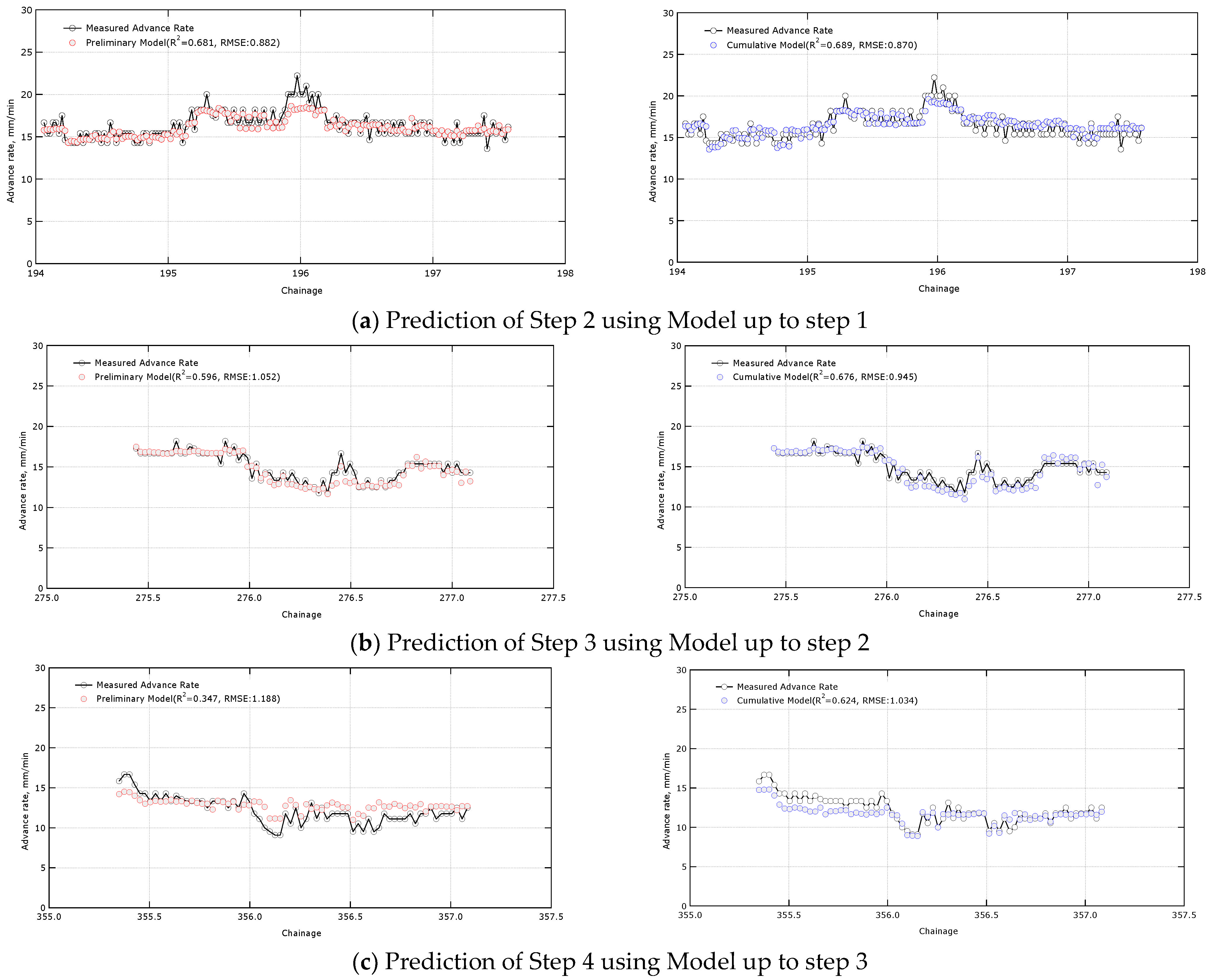

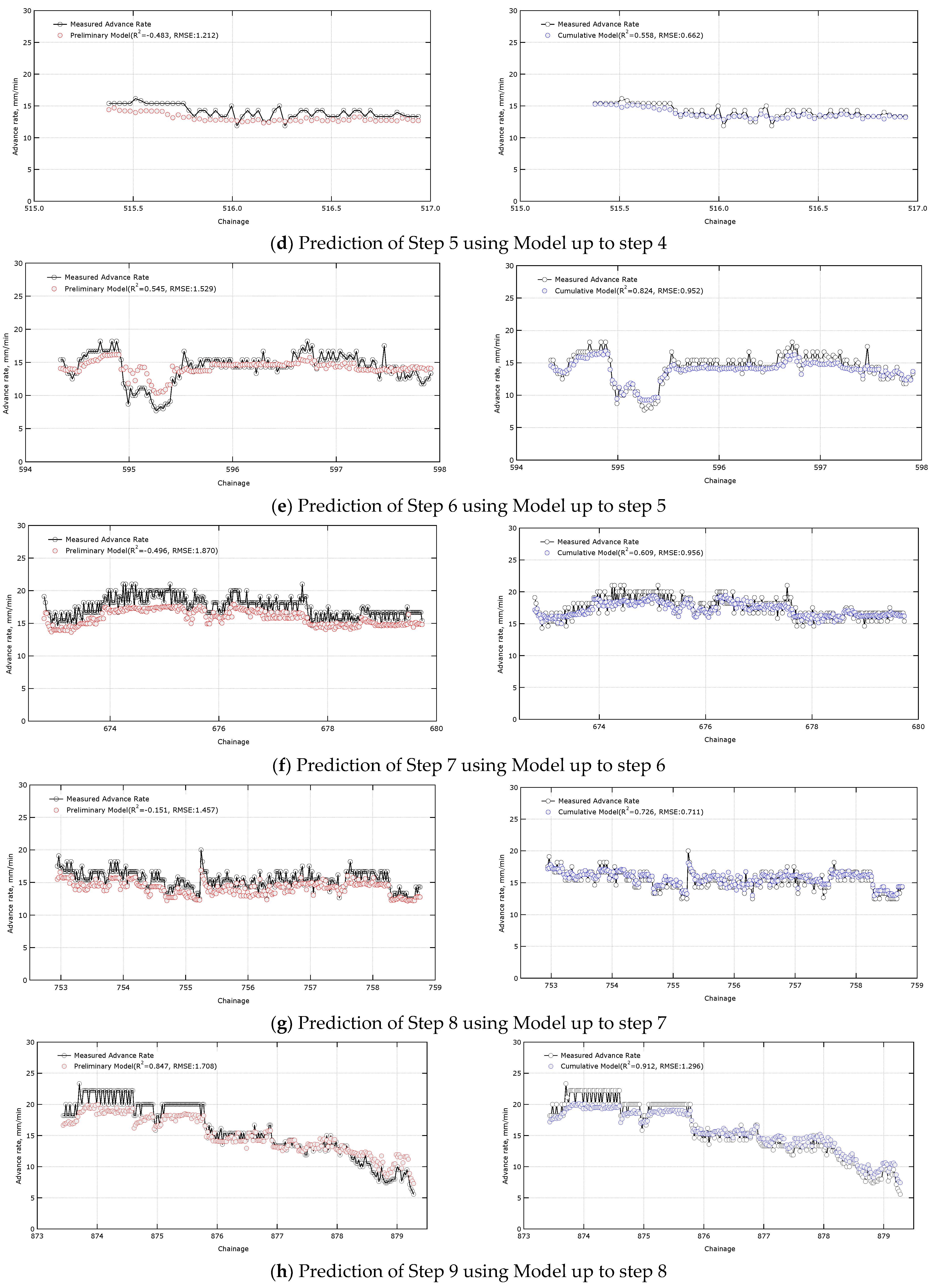

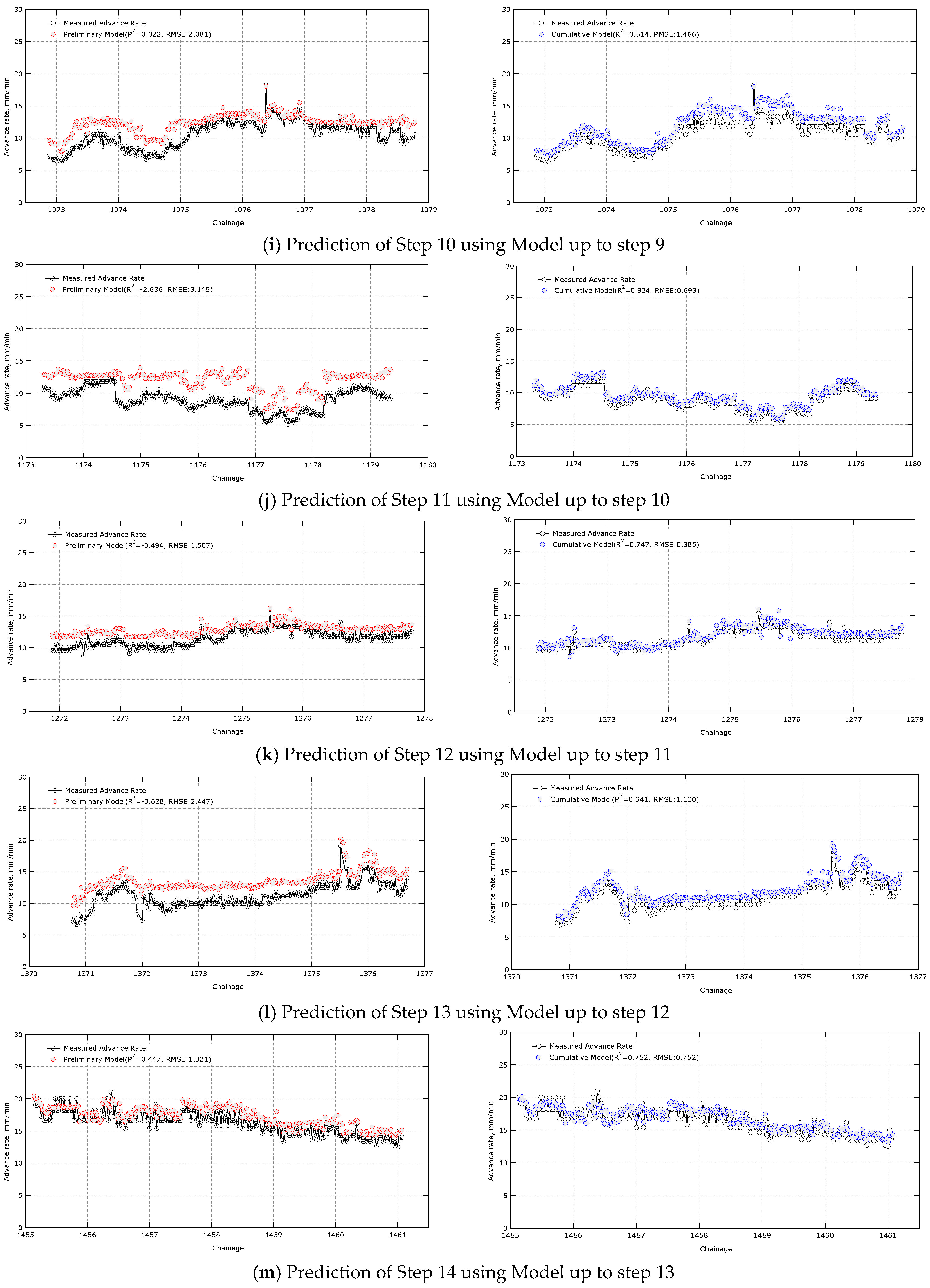

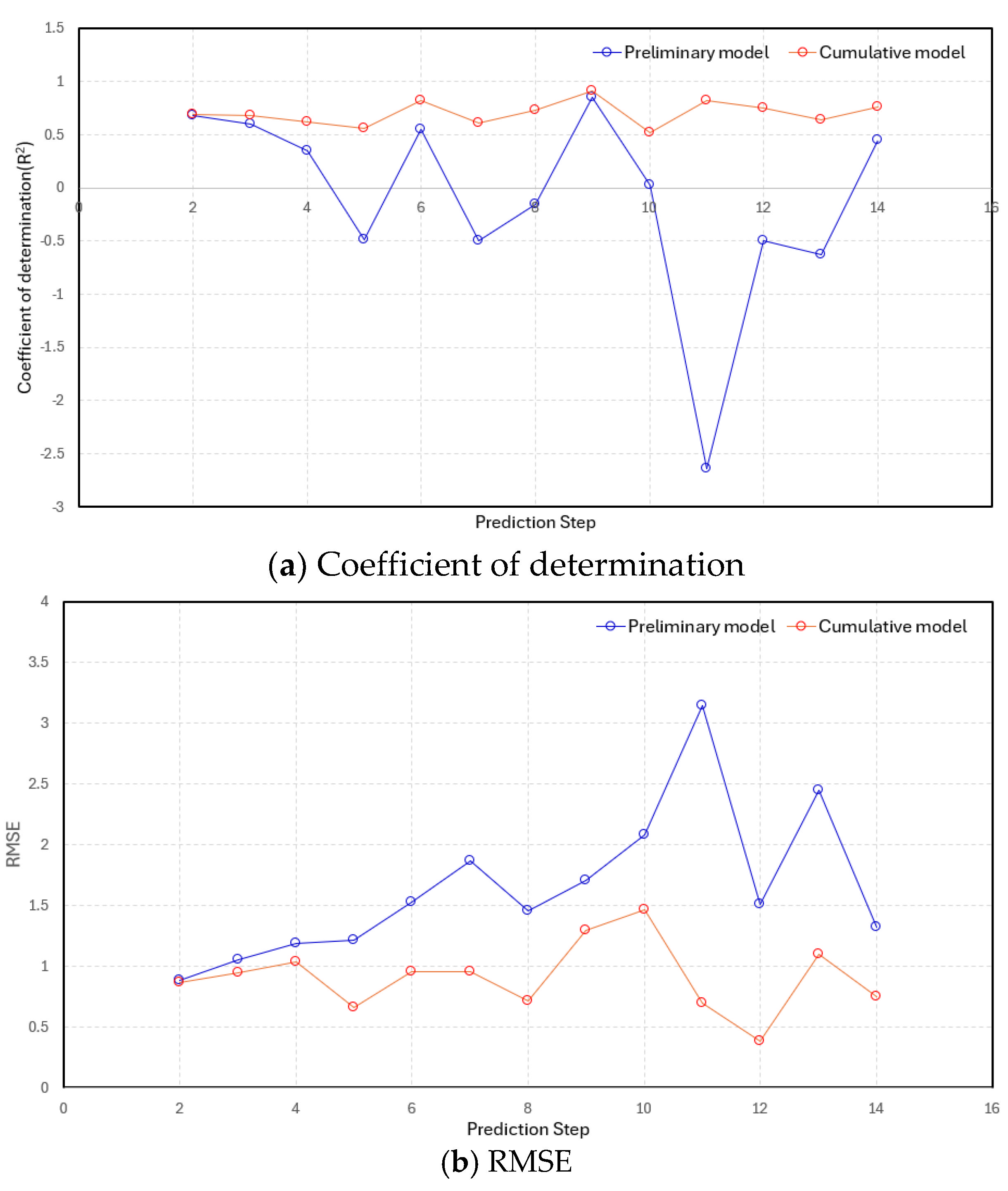

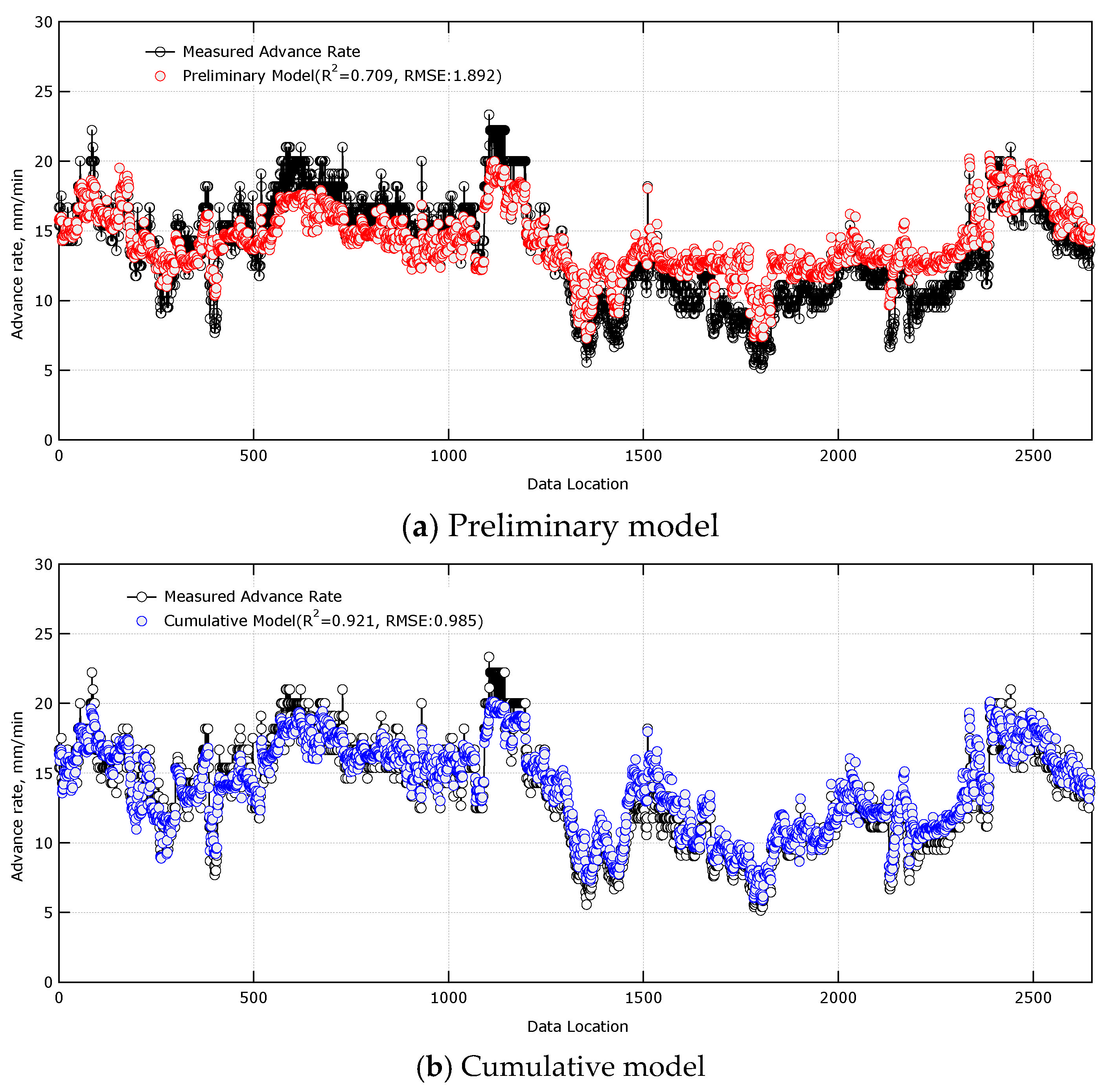

4.1. Preliminary Model vs. Cumulative Model

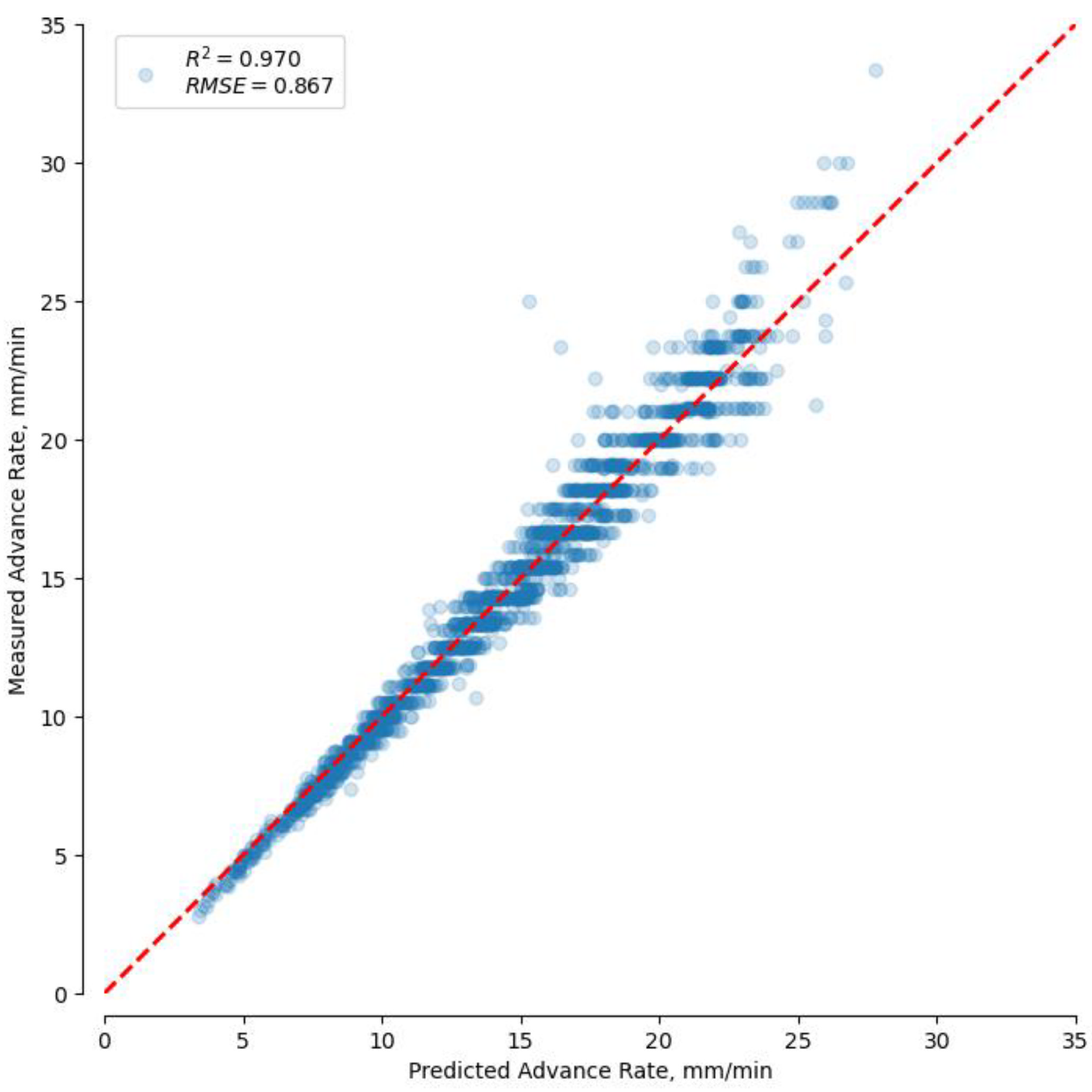

4.2. Prediction Results for Total Data of TBM Site 3

5. Conclusions

- Machine learning regression models are suitable for predicting continuous numerical values and are effective for tunneling data, which is time-series continuous data. In the preliminary model selection, five supervised learning-based regression algorithms were used to predict the advance rate of a TBM. Among the machine learning techniques, the gradient boosting model showed the best performance, with a coefficient of determination (0.958) and root mean square error (0.943).

- Tunneling data from TBM Site 3 were trained step-by-step, and the performance of the preliminary model was compared with the results of cumulative model obtained at each step. The steps were divided into 14 steps based on construction locations with available geotechnical information. Using data from each step, the performance of the preliminary model (static) and the cumulative model (dynamic model utilizing accumulated data) were evaluated. This performance review aimed to assess not only predictive ability but also generalization capabilities.

- The preliminary model’s predicted values showed a tendency toward unstable and significantly degraded prediction performance as excavation progressed, with increasing discrepancies from actual field values. In particular, there were many instances where the R2 value was negative, indicating a loss of reliability as a predictive model. In contrast, the cumulative model consistently learned data from the beginning of the prediction process, demonstrating stable and improved predictive accuracy over time. This proves the importance of the ability to dynamically adapt to changes in actual field conditions. Therefore, it can be concluded that a dynamic model, continuously updated with real-time data, is far more effective than a static model that relies solely on historical data when predicting TBM advance rate.

- The above results demonstrate the effectiveness of the cumulative model. Building a cumulative model for a wider range of ground conditions could improve the model’s generalization performance. Finally, this study excluded a significant amount of machine data in order to utilize ground data. Ground investigations, aside from those typically performed during the design phase, are rarely performed during TBM construction. Therefore, a data processing method capable of broadly utilizing machine data is needed in AI models for TBM performance prediction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rostami, J.; Ozdemir, L. A new model for performance prediction of hard rock TBMs. In Proceedings of the Rapid Excavation Tunnel Conference, Boston, MA, USA, 13–17 June 1993; pp. 793–809. [Google Scholar]

- Gong, Q.M.; Zhao, J. Influence of rock brittleness on TBM penetration rate in Singapore granite. Tunn. Undergr. Space Technol. 2007, 22, 317–324. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Li, C.; Nguyen, H.; Yagiz, S. Optimization of SVM with metaheuristics for TBM rate prediction. Eng. Appl. Artif. Intell. 2021, 97, 104015. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Tahir, M.M. SML techniques for TBM penetration rate. Appl. Sci. 2019, 9, 3715. [Google Scholar] [CrossRef]

- Kilic, K.; Ikeda, H.; Adachi, T.; Kawamura, Y. Soft ground micro-TBM jack speed and torque prediction using ML. Sci. Rep. 2024, 14, 11243. [Google Scholar] [CrossRef] [PubMed]

- Katuwal, T.B.; Panthi, K.K. TBM penetration rate prediction in Himalayan geology using machine learning. Rock Mech. Rock Eng. 2025, 1–33. [Google Scholar] [CrossRef]

- Mahdevari, S.; Shahriar, K.; Yagiz, S.; Shirazi, M.A. A support vector regression model for predicting TBM penetration rates. Int. J. Rock Mech. Min. Sci. 2014, 72, 214–229. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, Q.; Liu, Q.; Liu, X.; Liu, B.; Wang, J.; Yin, X. Real-time prediction of TBM cutterhead torque using BiLSTM. J. Rock Mech. Geotech. Eng. 2022, 14, 798–812. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J.; Han, S.; Li, B. Big data-based performance analysis of tunnel boring machine tunneling using deep learning. Buildings 2022, 12, 1567. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Z.; Wang, S.; Huang, X.; Lei, Q. Hybrid deep learning model for TBM advance rate prediction. J. Rock Mech. Geotech. Eng. 2024, 16, 65–80. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Li, L.; Fang, X.; Wang, J. Real-time prediction of hard-rock TBM advance rate using TCN. Front. Struct. Civ. Eng. 2022, 16, 401–413. [Google Scholar] [CrossRef]

- Wang, H.; Liu, L.; Song, X.; Zhang, C.; Tao, D. AL-iGAN: Active learning framework for geology reconstruction. Comput. Geotech. 2022, 147, 104676. [Google Scholar]

- Yang, W.; Chen, Z.; Zhao, H.; Li, J.; Chen, S.; Shi, C. Physical feature shared online transfer learning framework for cross-engineering rock mass quality perception during TBM excavation. Tunn. Undergr. Space Technol. 2026, 168, 107111. [Google Scholar] [CrossRef]

- Yang, W.; Chen, Z.; Zhao, H.; Chen, S.; Shi, C. Feature fusion method for rock mass classification prediction and interpretable analysis based on TBM operating and cutter wear data. Tunn. Undergr. Space Technol. 2025, 157, 106351. [Google Scholar] [CrossRef]

- Latif, K.; Sharafat, A.; Seo, J. Digital twin-driven framework for TBM performance prediction, visualization, and monitoring through machine learning. Appl. Sci. 2023, 13, 11435. [Google Scholar] [CrossRef]

- Loy-Benitez, J.; Lee, H.K.; Song, M.K.; Lee, J.K.; Lee, S.S. Real-time unsupervised monitoring of earth pressure balance shield-induced sinkholes in mixed-face ground conditions via convolutional variational autoencoders. Tunn. Undergr. Space Technol. 2024, 152, 105908. [Google Scholar] [CrossRef]

- Gao, X.; Song, X.; Shi, M.; Zhang, C.; Zhang, H. Real-time forecast models for TBM load parameters based on machine learning methods. arXiv 2021, arXiv:2104.06353. [Google Scholar] [CrossRef]

- Liu, F.; Yang, M.; Ke, J. Prediction method of TBM tunnel surrounding rock classification based on LSTM-SVM. Adv. Mech. Eng. 2024, 16, 16878132241255209. [Google Scholar] [CrossRef]

- Zhang, M.; Ji, A.; Zhou, C.; Ding, Y.; Wang, L. Real-time prediction of TBM penetration rates using a transformer-based ensemble deep learning model. Autom. Constr. 2024, 168, 105793. [Google Scholar] [CrossRef]

- Fu, X.; Ponnarasu, S.; Zhang, L.; Tiong, R.L.K. Online multi-objective optimization for real-time TBM attitude control with spatio-temporal deep learning model. Autom. Constr. 2024, 158, 105220. [Google Scholar] [CrossRef]

- Shen, X.; Chen, X.; Fu, Y.; Cao, C.; Yuan, D.; Li, X.; Xiao, Y. Prediction and analysis of slurry shield TBM disc cutter wear and its application in cutter change time. Wear 2022, 498, 204314. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, P.; Wu, H.; Wang, Z.; Zhong, Z. Prediction of shield tunneling-induced ground settlement using machine learning techniques. Front. Struct. Civ. Eng. 2019, 13, 1363–1378. [Google Scholar] [CrossRef]

| Items | Preliminary Model | Cumulative Model | |

|---|---|---|---|

| Site 1 | Site 2 | Site 3 | |

| Outside diameter (mm) | 3590 | 3500 | 3590 |

| Inside diameter (mm) | 3530 | 3436 | 3530 |

| Max. shield jack thrust force (kN) | 12,000 (1000 × 12 shield jacks) | 12,000 (1000 × 12 shield jacks) | 12,000 (1000 × 12 shield jacks) |

| Max. cutterhead torque (kN·m) | 1410 | 1410 | 1410 |

| Max. RPM (r/min) | 4.6 | 4.6 | 4.6 |

| Cutter (EA) | 22 (roller) + 5 (center) | 22 (roller) + 5 (center) | 22 (roller) + 5 (center) |

| Segment ring length (m) | 1.2 | 1.2 | 1.2 |

| Factors | Min | Q1 (25%) | Q2 (50%) | Q3 (75%) | Max | Average | Standard Deviation | |

|---|---|---|---|---|---|---|---|---|

| Advance rate, mm/min | Site 1 | 6.13 | 10.00 | 13.33 | 15.39 | 21.00 | 12.82 | 3.13 |

| Site 2 | 6.67 | 15.83 | 19.00 | 21.11 | 33.33 | 18.45 | 4.14 | |

| Site 3 | 2.78 | 9.52 | 13.33 | 15.83 | 22.22 | 12.84 | 4.18 | |

| Total | 2.78 | 11.77 | 15.38 | 18.18 | 33.33 | 15.03 | 4.78 | |

| Soil thickness, m | Site 1 | 31.41 | 32.42 | 33.40 | 34.42 | 53.52 | 33.46 | 2.32 |

| Site 2 | 23.38 | 27.45 | 28.54 | 29.48 | 32.77 | 28.15 | 2.14 | |

| Site 3 | 51.38 | 51.84 | 54.67 | 57.74 | 73.07 | 56.79 | 6.74 | |

| Total | 23.38 | 28.77 | 32.72 | 51.84 | 73.07 | 39.31 | 13.43 | |

| TCR, % | Site 1 | 18.00 | 76.00 | 94.00 | 97.00 | 100.00 | 80.48 | 26.05 |

| Site 2 | 13.00 | 70.00 | 93.00 | 100.00 | 100.00 | 79.33 | 28.78 | |

| Site 3 | 10.00 | 97.00 | 98.00 | 100.00 | 100.00 | 85.49 | 29.00 | |

| Total | 10.00 | 76.00 | 97.00 | 100.00 | 100.00 | 81.73 | 28.28 | |

| RQD, % | Site 1 | 0.00 | 10.00 | 50.00 | 67.00 | 100.00 | 44.37 | 33.65 |

| Site 2 | 0.00 | 19.00 | 30.00 | 62.00 | 87.00 | 36.85 | 27.17 | |

| Site 3 | 0.00 | 52.00 | 71.00 | 92.00 | 100.00 | 65.96 | 27.06 | |

| Total | 0.00 | 19.00 | 55.00 | 74.00 | 100.00 | 48.76 | 31.67 | |

| Spacing of joints, cm | Site 1 | 0.00 | 7.00 | 13.00 | 17.00 | 35.00 | 14.54 | 11.11 |

| Site 2 | 2.00 | 3.00 | 6.00 | 12.00 | 19.00 | 7.75 | 5.60 | |

| Site 3 | 0.00 | 12.00 | 20.00 | 30.00 | 38.00 | 20.45 | 11.09 | |

| Total | 0.00 | 6.00 | 12.00 | 17.00 | 38.00 | 13.89 | 10.81 | |

| Uniaxial compressive strength, MPa | Site 1 | 6.28 | 10.78 | 33.76 | 56.36 | 67.13 | 31.93 | 21.96 |

| Site 2 | 7.90 | 25.30 | 37.10 | 55.10 | 101.90 | 41.45 | 24.26 | |

| Site 3 | 28.40 | 43.30 | 72.90 | 77.45 | 106.36 | 63.20 | 21.04 | |

| Total | 6.28 | 25.30 | 43.30 | 68.70 | 106.36 | 46.28 | 25.92 | |

| P-wave velocity, m/s | Site 1 | 1986.00 | 2986.00 | 3618.00 | 3997.00 | 4860.00 | 3440.66 | 766.14 |

| Site 2 | 1429.00 | 3068.00 | 4118.00 | 4487.00 | 5123.00 | 3725.24 | 1057.33 | |

| Site 3 | 1400.00 | 4181.00 | 4827.00 | 5175.00 | 5287.00 | 4581.47 | 766.39 | |

| Total | 1400.00 | 3375.00 | 4132.00 | 4624.00 | 5287.00 | 3939.66 | 1009.76 | |

| Total thrust force, kN | Site 1 | 3406.70 | 4458.55 | 5115.20 | 5918.25 | 7648.70 | 5326.44 | 1065.55 |

| Site 2 | 406.00 | 4516.00 | 4981.00 | 5516.00 | 7700.00 | 5070.21 | 794.44 | |

| Site 3 | 2021.00 | 5590.90 | 6923.80 | 8794.90 | 12,896.90 | 7239.20 | 2282.88 | |

| Total | 406.00 | 4674.00 | 5443.40 | 6717.10 | 12,896.90 | 5876.08 | 1813.62 | |

| Feeding pressure, kPa | Site 1 | 98.07 | 284.39 | 313.81 | 362.85 | 421.69 | 313.37 | 61.36 |

| Site 2 | 98.07 | 176.52 | 225.55 | 245.17 | 274.59 | 210.43 | 37.79 | |

| Site 3 | 39.23 | 166.71 | 205.94 | 274.59 | 451.11 | 219.22 | 90.94 | |

| Total | 39.23 | 186.33 | 235.36 | 284.39 | 451.11 | 241.09 | 79.47 | |

| Face pressure, kPa | Site 1 | 147.10 | 274.59 | 304.01 | 362.85 | 421.69 | 308.12 | 63.38 |

| Site 2 | 88.26 | 166.71 | 215.75 | 235.36 | 264.78 | 202.70 | 37.75 | |

| Site 3 | 9.81 | 147.10 | 186.33 | 235.36 | 421.69 | 190.67 | 87.35 | |

| Total | 9.81 | 176.52 | 225.55 | 264.78 | 421.69 | 226.95 | 81.72 | |

| Cutterhead torque, kN·m | Site 1 | 92.00 | 95.00 | 97.00 | 98.00 | 105.00 | 96.79 | 2.58 |

| Site 2 | 192.30 | 244.80 | 265.90 | 276.50 | 345.30 | 258.52 | 30.26 | |

| Site 3 | 185.00 | 222.00 | 253.00 | 281.00 | 323.00 | 254.03 | 33.49 | |

| Total | 92.00 | 101.00 | 242.00 | 273.00 | 345.30 | 213.52 | 75.86 | |

| Cutterhead rotation speed, rev/min | Site 1 | 2.00 | 2.30 | 2.80 | 2.90 | 3.00 | 2.64 | 0.37 |

| Site 2 | 2.50 | 3.10 | 3.20 | 3.30 | 3.80 | 3.20 | 0.21 | |

| Site 3 | 1.50 | 3.00 | 3.10 | 3.50 | 3.61 | 3.07 | 0.48 | |

| Total | 1.50 | 2.80 | 3.10 | 3.20 | 3.80 | 3.00 | 0.43 | |

| Slurry feeding, m3 | Site 1 | 2.29 | 3.20 | 3.85 | 5.00 | 9.39 | 4.24 | 1.39 |

| Site 2 | 1.87 | 2.84 | 3.28 | 4.32 | 10.70 | 3.81 | 1.45 | |

| Site 3 | 2.74 | 3.85 | 4.60 | 6.47 | 21.71 | 5.54 | 2.69 | |

| Total | 1.87 | 3.15 | 3.93 | 5.03 | 21.71 | 4.51 | 2.09 | |

| Slurry discharge, m3 | Site 1 | 2.57 | 4.37 | 5.22 | 6.32 | 11.86 | 5.50 | 1.75 |

| Site 2 | 1.16 | 3.00 | 3.34 | 4.10 | 10.91 | 3.79 | 1.30 | |

| Site 3 | 2.98 | 4.14 | 4.83 | 6.54 | 18.02 | 5.65 | 2.38 | |

| Total | 1.16 | 3.39 | 4.40 | 5.56 | 18.02 | 4.88 | 2.04 | |

| Pitching, ° | Site 1 | 0.05 | 0.19 | 0.21 | 0.22 | 0.25 | 0.20 | 0.04 |

| Site 2 | −0.07 | 0.36 | 0.46 | 1.64 | 2.01 | 0.81 | 0.62 | |

| Site 3 | −0.63 | −0.44 | −0.27 | −0.08 | 0.32 | −0.25 | 0.23 | |

| Total | −0.63 | −0.09 | 0.21 | 0.40 | 2.01 | 0.29 | 0.61 | |

| Rolling, ° | Site 1 | −0.21 | −0.04 | 0.02 | 0.07 | 0.28 | 0.02 | 0.08 |

| Site 2 | −0.52 | −0.12 | −0.03 | 0.04 | 0.72 | −0.04 | 0.16 | |

| Site 3 | −1.45 | −0.12 | 0.02 | 0.14 | 0.64 | −0.03 | 0.30 | |

| Total | −1.45 | −0.09 | 0.00 | 0.08 | 0.72 | −0.02 | 0.21 | |

| Num of used Jack, pcs | Site 1 | 6.00 | 8.00 | 9.00 | 10.00 | 12.00 | 8.58 | 1.30 |

| Site 2 | 6.00 | 8.00 | 9.00 | 10.00 | 12.00 | 9.12 | 1.19 | |

| Site 3 | 6.00 | 9.00 | 10.00 | 12.00 | 12.00 | 10.37 | 1.70 | |

| Total | 6.00 | 8.00 | 9.00 | 10.00 | 12.00 | 9.40 | 1.59 | |

| Definition of the Terms | Formulas for Measuring Performance |

|---|---|

| MSE: Mean Squared Error | |

| RMSE: Root Mean Squared Error | |

| R-squared: Coefficient of determination |

| Model | Hyperparameter | |

| Tree-based methods | Decision tree, dt | max depth: 4 |

| Ensemble learning method | Random forest, rf | max depth: 5 max features: 7 n_estimators: 200 |

| Gradient boosting, gb | learning rate: 0.0195 max depth: 5 max features: 7 n_estimators: 650 | |

| Light GBM, lgb | learning rate: 0.01 max depth: 5 n_estimators: 800 colsample_bytree: 0.8 subsample: 0.8 | |

| Support vector machine | SVR | C: 10 gamma: 1.09 epsilon: 0.25 |

| Model | Train Dataset | Test Dataset | |||

|---|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | ||

| Tree-based methods | Decision tree, dt | 0.899 | 1.411 | 0.894 | 1.498 |

| Ensemble learning method | Random forest, rf | 0.938 | 1.100 | 0.933 | 1.185 |

| Gradient boosting, gb | 0.958 | 0.618 | 0.958 | 0.943 | |

| Light GBM, lgb | 0.957 | 0.772 | 0.954 | 0.983 | |

| Support vector machine | SVR | 0.954 | 0.913 | 0.957 | 0.953 |

| Step | Chainage (m) |

|---|---|

| 1 | 93.6~97.3 |

| 2 | 194.0~197.6 |

| 3 | 275.4~277.1 |

| 4 | 355.3~357.1 |

| 5 | 515.0~517.0 |

| 6 | 594.0~598.0 |

| 7 | 673.4~680.0 |

| 8 | 752.5~759.0 |

| 9 | 873.4~879.5 |

| 10 | 1072.5~1078.5 |

| 11 | 1173~1179.5 |

| 12 | 1271.5~1278 |

| 13 | 1370~1377 |

| 14 | 1455~1461.5 |

| Step | Chainage (m) | ML Model | Hyperparameter | R2 | RMSE |

|---|---|---|---|---|---|

| 1 | 93.6~97.3 | Gradient boosting, gb | learning rate: 0.0195 max depth: 5 max features: 6 n_estimators: 800 | 0.968 | 0.889 |

| 2 | 194.0~197.6 | Gradient boosting, gb | learning rate: 0.08 max depth: 5 max features: 6 n_estimators: 100 | 0.964 | 0.909 |

| 3 | 275.4~277.1 | Gradient boosting, gb | learning rate: 0.02 max depth: 6 max features: 7 n_estimators: 300 | 0.963 | 0.940 |

| 4 | 355.3~357.1 | Gradient boosting, gb | learning rate: 0.03 max depth: 6 max features: 7 n_estimators: 350 | 0.962 | 0.923 |

| 5 | 515.0~517.0 | Gradient boosting, gb | learning rate: 0.02 max depth: 5 max features: 6 n_estimators: 700 | 0.964 | 0.892 |

| 6 | 594.0~598.0 | Gradient boosting, gb | learning rate: 0.035 max depth: 5 max features: 7 n_estimators: 950 | 0.961 | 0.933 |

| 7 | 673.4~680.0 | Gradient boosting, gb | learning rate: 0.02 max depth: 6 max features: 6 n_estimators: 355 | 0.960 | 0.944 |

| 8 | 752.5~759.0 | Gradient boosting, gb | learning rate: 0.019 max depth: 5 max features: 7 n_estimators: 700 | 0.962 | 0.914 |

| 9 | 873.4~879.5 | Gradient boosting, gb | learning rate: 0.021 max depth: 6 max features: 6 n_estimators: 400 | 0.967 | 0.896 |

| 10 | 1072.5~1078.5 | Gradient boosting, gb | learning rate: 0.0195 max depth: 5 max features: 7 n_estimators: 800 | 0.969 | 0.885 |

| 11 | 1173~1179.5 | Gradient boosting, gb | learning rate: 0.02 max depth: 6 max features: 6 n_estimators: 450 | 0.970 | 0.878 |

| 12 | 1271.5~1278 | Gradient boosting, gb | learning rate: 0.124 max depth: 6 max features: 6 n_estimators: 200 | 0.969 | 0.874 |

| 13 | 1370~1377 | Gradient boosting, gb | learning rate: 0.0125 max depth: 6 max features: 6 n_estimators: 310 | 0.970 | 0.867 |

| Prediction Step | Preliminary Model | Cumulative Model | ||

|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | |

| 2 | 0.681 | 0.882 | 0.689 | 0.870 |

| 3 | 0.596 | 1.052 | 0.676 | 0.945 |

| 4 | 0.347 | 1.188 | 0.624 | 1.034 |

| 5 | −0.483 | 1.212 | 0.558 | 0.662 |

| 6 | 0.545 | 1.529 | 0.824 | 0.952 |

| 7 | −0.496 | 1.870 | 0.609 | 0.956 |

| 8 | −0.151 | 1.457 | 0.726 | 0.711 |

| 9 | 0.847 | 1.708 | 0.912 | 1.296 |

| 10 | 0.022 | 2.081 | 0.514 | 1.466 |

| 11 | −2.636 | 3.145 | 0.824 | 0.693 |

| 12 | −0.494 | 1.507 | 0.747 | 0.385 |

| 13 | −0.628 | 2.447 | 0.641 | 1.100 |

| 14 | 0.447 | 1.321 | 0.762 | 0.752 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Choi, S.-W.; Kang, T.-H.; Chang, S.-H. Model Performance Improvement by Accumulated Application of Machine Data in Machine Learning Model for TBM Advance Rate Prediction. Appl. Sci. 2026, 16, 295. https://doi.org/10.3390/app16010295

Choi S-W, Kang T-H, Chang S-H. Model Performance Improvement by Accumulated Application of Machine Data in Machine Learning Model for TBM Advance Rate Prediction. Applied Sciences. 2026; 16(1):295. https://doi.org/10.3390/app16010295

Chicago/Turabian StyleChoi, Soon-Wook, Tae-Ho Kang, and Soo-Ho Chang. 2026. "Model Performance Improvement by Accumulated Application of Machine Data in Machine Learning Model for TBM Advance Rate Prediction" Applied Sciences 16, no. 1: 295. https://doi.org/10.3390/app16010295

APA StyleChoi, S.-W., Kang, T.-H., & Chang, S.-H. (2026). Model Performance Improvement by Accumulated Application of Machine Data in Machine Learning Model for TBM Advance Rate Prediction. Applied Sciences, 16(1), 295. https://doi.org/10.3390/app16010295