Assessment of Sustainability and Risk Indicators in an Urban Logistics Network Analysis Considering a Business Continuity Plan

Abstract

1. Introduction

2. Literature Review

3. Problem Statement and Proposed Integrated Methodology

3.1. Problem Statement

3.2. Proposed Integrated Procedure Under Uncertainty

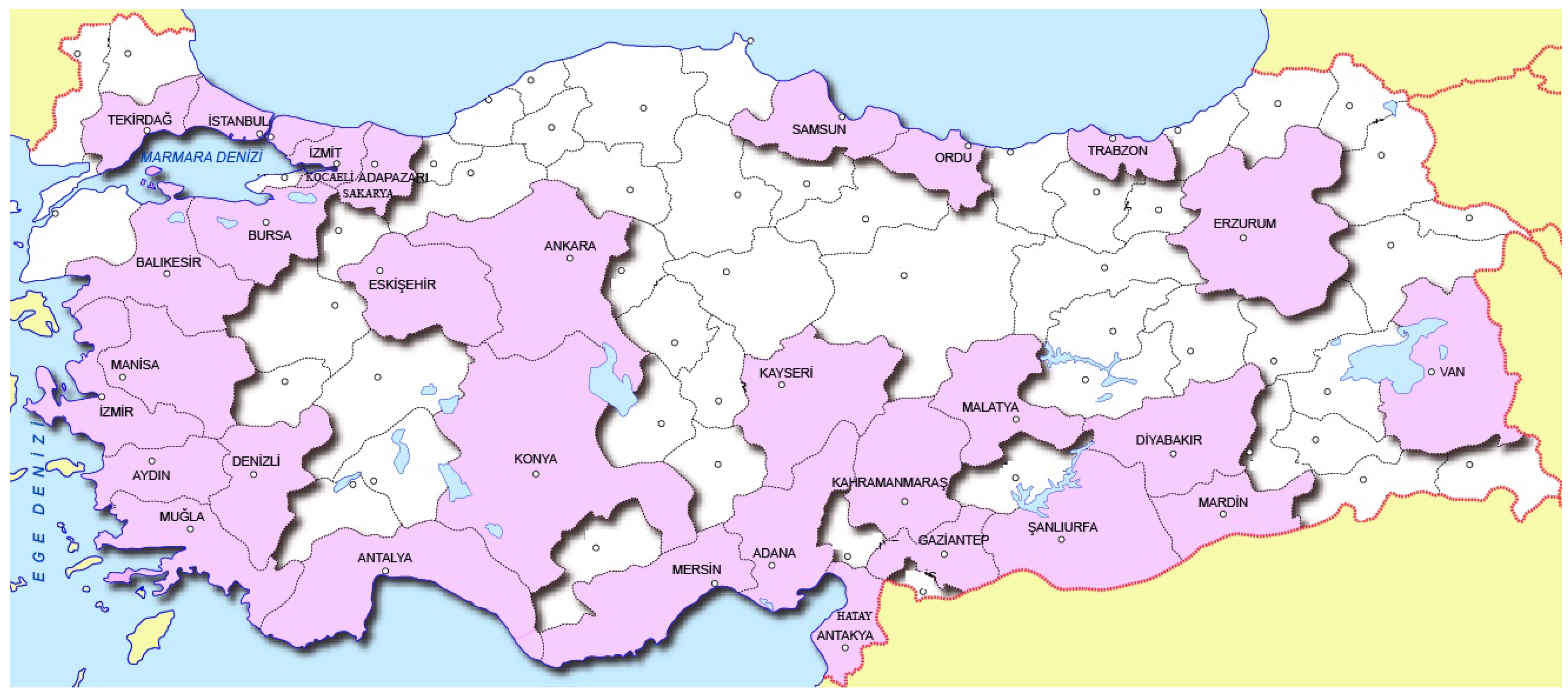

4. Application of the Proposed Methodology Under Uncertainty

4.1. Criteria and Alternatives

4.2. Prioritizing the Main Criteria and Sub-Criteria

4.3. Ranking Cities

4.4. Comparison of the Cities

5. Managerial and Policy Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1.0000 | 1.0000 | 1.0000 | 2.5946 | 1.0000 | 2.8845 | 2.5946 | 1.8882 | 1.7007 | 2.5946 |

| C2 | 1.0000 | 1.0000 | 1.0000 | 1.1117 | 1.0000 | 3.0435 | 2.5946 | 1.8882 | 2.0992 | 2.8845 |

| C3 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 2.3338 | 2.8845 | 2.3338 | 2.0992 | 1.0000 | 2.5946 |

| C4 | 0.3854 | 0.8995 | 1.0000 | 1.0000 | 1.9922 | 1.3741 | 2.5946 | 0.1648 | 1.0000 | 2.8845 |

| C5 | 1.0000 | 1.0000 | 0.4285 | 0.5019 | 1.0000 | 1.0000 | 1.0000 | 2.8845 | 2.8845 | 2.8845 |

| C6 | 0.3467 | 0.3286 | 0.3467 | 0.7277 | 1.0000 | 1.0000 | 0.3466 | 0.3466 | 2.8845 | 1.6984 |

| C7 | 0.3854 | 0.3854 | 0.4285 | 0.3854 | 1.0000 | 2.8854 | 1.0000 | 1.0000 | 1.0000 | 2.8845 |

| C8 | 0.5296 | 0.5296 | 0.4764 | 6.0672 | 0.3467 | 2.8854 | 1.0000 | 1.0000 | 1.0000 | 2.8845 |

| C9 | 0.5880 | 0.4764 | 1.0000 | 1.0000 | 0.3467 | 0.3467 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| C10 | 0.3854 | 0.3467 | 0.3854 | 0.3467 | 0.3467 | 0.5888 | 0.3467 | 0.3467 | 1.0000 | 1.0000 |

| C1.1 | C1.2 | C1.3 | C1.4 | C1.5 | C1.6 | C1.7 | C1.8 | C1.9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1.1 | 1.0000 | 1.3741 | 1.3741 | 0.2379 | 0.2649 | 0.2795 | 0.2950 | 0.2510 | 0.2379 |

| C1.2 | 0.7277 | 1.0000 | 1.0000 | 0.3466 | 0.2025 | 0.3466 | 0.3284 | 0.3284 | 0.3112 |

| C1.3 | 0.7277 | 1.0000 | 1.0000 | 0.2025 | 1.2360 | 0.3466 | 0.3466 | 0.3466 | 0.2136 |

| C1.4 | 4.2035 | 2.8855 | 4.9390 | 1.0000 | 1.0000 | 1.8882 | 2.6680 | 2.3338 | 1.1117 |

| C1.5 | 3.7751 | 4.9390 | 0.8091 | 1.0000 | 1.0000 | 2.3338 | 2.3338 | 1.1117 | 2.8845 |

| C1.6 | 3.5775 | 2.8855 | 2.8855 | 0.5296 | 0.4285 | 1.0000 | 1.0000 | 0.2025 | 0.3466 |

| C1.7 | 3.3903 | 3.0448 | 2.8855 | 0.3748 | 0.4285 | 1.0000 | 1.0000 | 1.0000 | 0.3466 |

| C1.8 | 3.9836 | 3.0448 | 2.8855 | 0.4285 | 0.8995 | 4.9390 | 1.0000 | 1.0000 | 2.8845 |

| C1.9 | 4.2035 | 3.2129 | 4.6806 | 0.8995 | 0.3467 | 2.8855 | 2.8855 | 0.3467 | 1.0000 |

| C2.1 | C2.2 | C2.3 | C2.4 | C2.5 | |

|---|---|---|---|---|---|

| C2.1 | 1.0000 | 0.7277 | 0.4763 | 0.8090 | 1.0000 |

| C2.2 | 1.3742 | 1.0000 | 0.4763 | 1.0000 | 0.5287 |

| C2.3 | 2.0997 | 2.0997 | 1.0000 | 1.3740 | 1.3741 |

| C2.4 | 1.2361 | 1.0000 | 0.7278 | 1.0000 | 0.8995 |

| C2.5 | 1.0000 | 1.8914 | 0.7277 | 1.1118 | 1.0000 |

| C3.1 | C3.2 | C3.3 | C3.4 | C3.5 | |

|---|---|---|---|---|---|

| C3.1 | 1.0000 | 1.8907 | 0.5423 | 3.2156 | 3.2156 |

| C3.2 | 0.5289 | 1.0000 | 0.4500 | 1.5277 | 2.2149 |

| C3.3 | 1.8438 | 2.2224 | 1.0000 | 1.9922 | 1.9922 |

| C3.4 | 0.3110 | 0.6546 | 0.5019 | 1.0000 | 0.2791 |

| C3.5 | 0.3110 | 0.4515 | 0.5019 | 3.5830 | 1.0000 |

| C4.1 | C4.2 | C4.3 | C4.4 | C4.5 | |

|---|---|---|---|---|---|

| C4.1 | 1.0000 | 1.6984 | 1.1117 | 1.5277 | 3.0476 |

| C4.2 | 0.5888 | 1.0000 | 1.0000 | 0.2950 | 1.5277 |

| C4.3 | 0.8995 | 1.0000 | 1.0000 | 0.2950 | 1.8882 |

| C4.4 | 0.6546 | 3.3903 | 3.3903 | 1.0000 | 1.0000 |

| C4.5 | 0.3281 | 0.6546 | 0.5296 | 1.0000 | 1.0000 |

| C5.1 | C5.2 | C5.3 | C5.4 | |

|---|---|---|---|---|

| C5.1 | 1.0000 | 1.1117 | 1.1117 | 0.3988 |

| C5.2 | 0.8995 | 1.0000 | 1.0000 | 1.3760 |

| C5.3 | 0.8995 | 1.0000 | 1.0000 | 1.0000 |

| C5.4 | 2.5077 | 0.7268 | 1.0000 | 1.0000 |

| C6.1 | C6.2 | C6.3 | C6.4 | |

|---|---|---|---|---|

| C6.1 | 1.0000 | 1.0000 | 2.3338 | 4.4975 |

| C6.2 | 1.0000 | 1.0000 | 2.5946 | 3.8289 |

| C6.3 | 0.4285 | 0.3854 | 1.0000 | 2.8845 |

| C6.4 | 0.2223 | 0.2612 | 0.3467 | 1.0000 |

| C7.1 | C7.2 | C7.3 | C7.4 | C7.5 | C7.6 | C7.7 | C7.8 | |

|---|---|---|---|---|---|---|---|---|

| C7.1 | 1.0000 | 1.0000 | 0.8524 | 1.0000 | 0.2795 | 0.3284 | 0.2025 | 0.3466 |

| C7.2 | 1.0000 | 1.0000 | 1.0000 | 0.3466 | 0.2649 | 0.2379 | 0.2795 | 0.2950 |

| C7.3 | 1.1732 | 1.0000 | 1.0000 | 0.3466 | 0.3466 | 0.3112 | 0.2950 | 0.4500 |

| C7.4 | 1.0000 | 2.8855 | 2.8855 | 1.0000 | 0.2025 | 0.3284 | 0.3466 | 0.8524 |

| C7.5 | 3.5775 | 3.7751 | 2.8855 | 4.9390 | 1.0000 | 0.3466 | 0.3466 | 0.3466 |

| C7.6 | 3.0448 | 4.2035 | 3.2129 | 3.0448 | 2.8855 | 1.0000 | 1.0000 | 1.0000 |

| C7.7 | 4.9390 | 3.5775 | 3.3903 | 2.8855 | 2.8855 | 1.0000 | 1.0000 | 1.0000 |

| C7.8 | 2.8855 | 3.3903 | 2.2224 | 1.1732 | 2.8855 | 1.0000 | 1.0000 | 1.0000 |

| C8.1 | C8.2 | C8.3 | C8.4 | C8.5 | C8.6 | C8.7 | C8.8 | |

|---|---|---|---|---|---|---|---|---|

| C8.1 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.8882 | 2.3338 | 1.0000 |

| C8.2 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| C8.3 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.5277 |

| C8.4 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 0.5579 | 1.0000 | 1.0000 | 1.6095 |

| C8.5 | 1.0000 | 1.0000 | 1.0000 | 1.7925 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| C8.6 | 0.5296 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 2.8845 | 2.3338 |

| C8.7 | 0.4285 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 0.3467 | 1.0000 | 1.0000 |

| C8.8 | 1.0000 | 1.0000 | 0.6546 | 0.6213 | 1.0000 | 0.4285 | 1.0000 | 1.0000 |

| C9.1 | C9.2 | C9.3 | C9.4 | C9.5 | C9.6 | C9.7 | C9.8 | |

|---|---|---|---|---|---|---|---|---|

| C9.1 | 1.0000 | 1.4498 | 2.7376 | 2.5946 | 1.6984 | 1.6984 | 2.2498 | 1.3741 |

| C9.2 | 0.6897 | 1.0000 | 2.3338 | 2.3338 | 1.1117 | 2.5946 | 1.3741 | 1.1318 |

| C9.3 | 0.3653 | 0.4285 | 1.0000 | 1.0000 | 0.3859 | 2.2498 | 1.1117 | 0.4214 |

| C9.4 | 0.3854 | 0.4285 | 1.0000 | 1.0000 | 0.1745 | 1.0000 | 1.0000 | 2.0992 |

| C9.5 | 0.5888 | 0.8995 | 2.5913 | 5.7318 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| C9.6 | 0.5888 | 0.3854 | 0.4445 | 1.0000 | 1.0000 | 1.0000 | 2.8845 | 2.8845 |

| C9.7 | 0.4445 | 0.7277 | 0.8995 | 1.0000 | 1.0000 | 0.3467 | 1.0000 | 1.0000 |

| C9.8 | 0.7277 | 0.8836 | 2.3728 | 0.4764 | 1.0000 | 0.3467 | 1.0000 | 1.0000 |

| C10.1 | C10.2 | C10.3 | C10.4 | C10.5 | C10.6 | C10.7 | C10.8 | C10.9 | C10.10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| C10.1 | 1.0000 | 0.2506 | 0.3853 | 0.3103 | 0.3853 | 0.3466 | 0.4763 | 0.4284 | 0.47627 | 0.4284 |

| C10.2 | 3.9896 | 1.0000 | 1.0000 | 0.5295 | 0.2787 | 0.8995 | 0.8090 | 0.6545 | 1.0000 | 0.8994 |

| C10.3 | 2.5953 | 1.0000 | 1.0000 | 0.8995 | 1.1117 | 1.0000 | 1.0000 | 0.8995 | 0.65451 | 0.7277 |

| C10.4 | 3.2228 | 1.8886 | 1.1118 | 1.0000 | 1.2360 | 1.0000 | 1.0000 | 1.0000 | 0.52951 | 1.0000 |

| C10.5 | 2.5953 | 3.5885 | 0.8995 | 0.8091 | 1.0000 | 0.3466 | 0.3466 | 1.0000 | 1.0000 | 1.2360 |

| C10.6 | 2.8855 | 1.1118 | 1.0000 | 1.0000 | 2.8855 | 1.0000 | 0.2025 | 0.2025 | 1.0000 | 0.7277 |

| C10.7 | 2.0997 | 1.2361 | 1.0000 | 1.0000 | 2.8855 | 4.9390 | 1.0000 | 0.3853 | 0.42838 | 1.0000 |

| C10.8 | 2.3344 | 1.5279 | 1.1118 | 1.0000 | 1.0000 | 4.9390 | 2.5953 | 1.0000 | 0.38531 | 1.0000 |

| C10.9 | 2.0997 | 1.0000 | 1.5279 | 1.8886 | 1.0000 | 1.0000 | 2.3344 | 2.5953 | 1.0000 | 0.5295 |

| C10.10 | 2.3344 | 1.1118 | 1.3742 | 1.0000 | 0.8091 | 1.3742 | 1.0000 | 1.0000 | 1.88855 | 1.0000 |

References

- Gomes, N. Ford Pegs Cost of UAW Labor Deal at $8.8 Billion, Cuts Full-Year Profit View. 2023. Available online: https://www.reuters.com/business/autos-transportation/ford-forecasts-lower-2023-adjusted-ebit-2023-11-30/ (accessed on 7 March 2024).

- Ivanov, D. Cash flow dynamics in the supply chain during and after disruptions. Transp. Res. Part E Logist. Transp. Rev. 2024, 185, 103526. [Google Scholar] [CrossRef]

- Reuters. Suez Disruption: A New Inflation Risk on the Horizon. 2023. Available online: https://www.reuters.com/world/middle-east/suez-disruption-new-inflation-risk-horizon-2023-12-19/ (accessed on 7 March 2024).

- United Nations Trade & Development. Unprecedented Shipping Disruptions Raise Risk to Global Trade, UNCTAD Warns. 2024. Available online: https://unctad.org/news/unprecedented-shipping-disruptions-raise-risk-global-trade-unctad-warns (accessed on 7 March 2024).

- Barmuta, K.; Rusakova, N.; Malkhasyan, A. Improving the method of analyzing risks of the company’s logistics processes. Transp. Res. Procedia 2022, 63, 737–745. [Google Scholar] [CrossRef]

- OECD. Enterprises by Business Size. 2021. Available online: https://data.oecd.org/entrepreneur/enterprises-by-business-size.htm (accessed on 10 March 2024).

- Kato, M.; Charoenrat, T. Business continuity management of small and medium size enterprises: Evidence from Thailand. Int. J. Disaster Risk Reduct. 2018, 27, 577–587. [Google Scholar] [CrossRef]

- Özdemir, A.; Erdem, M.; Kosunalp, S.; Iliev, T. Evaluation of sustainable and intelligent transportation processes considering environmental, social, and risk assessment pillars employing an integrated intuitionistic fuzzy-embedded decision-making methodology. Sustainability 2025, 17, 2945. [Google Scholar] [CrossRef]

- Awang Ali, Q.S.; Hanafiah, M.H.; Mogindol, S.H. Systematic literature review of Business Continuity Management (BCM) practices: Integrating organisational resilience and performance in Small and medium enterprises (SMEs) BCM framework. Int. J. Disaster Risk Reduct. 2023, 99, 104135. [Google Scholar] [CrossRef]

- Kalogiannidis, S.; Kalfas, D.; Papaevangelou, O.; Giannarakis, G.; Chatzitheodoridis, F. The role of artificial intelligence technology in predictive risk assessment for business continuity: A case study of Greece. Risks 2024, 12, 19. [Google Scholar] [CrossRef]

- Sambo, F.; Bankole, F.O. A normative process model for ICT business-continuity plan for disaster management in small, medium and large enterprise. Int. J. Electr. Comput. Eng. 2016, 6, 2425–2431. [Google Scholar]

- Sadeghi, R.J.K.; Azadegan, A.; Ojha, D.; Ogden, J.A. Benefiting from supplier business continuity: The role of supplier monitoring and buyer power. Ind. Mark. Manag. 2022, 106, 432–443. [Google Scholar] [CrossRef]

- European Energy Agency. Transport and Mobility. 2024. Available online: https://www.eea.europa.eu/en/topics/in-depth/transport-and-mobility/ (accessed on 3 March 2024).

- United States Environmental Protection Agency. Carbon Pollution from Transportation. 2024. Available online: https://www.epa.gov/transportation-air-pollution-and-climate-change/carbon-pollution-transportation/ (accessed on 3 March 2024).

- Schwaab, J.A.; Thielmann, S. Chapter 1: The challenge: Sustainable road transport. In Policy Guidelines for Road Transport Pricing; United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2002. [Google Scholar]

- United Nations Climate Change (UNCC). The Paris Agreement. 2020. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 3 March 2024).

- Amol, A.P.; Aditya, K.; Nikit, A.; David, W.; Deepak, R. Why Regional and Long-Haul Trucks Are Primed for Electrification Now. 2021. Available online: https://etapublications.lbl.gov/publications/why-regional-and-long-haul-trucks-are/ (accessed on 1 February 2024).

- Carey, N.; Baertlein, L. Startups with Electric Vans Race to Fill Demand for Zero-Emissions Delivery. 2023. Available online: https://www.reuters.com/business/autos-transportation/startups-with-electric-vans-race-fill-demand-zero-emissions-delivery-2023-09-18/ (accessed on 1 February 2024).

- United Nations. The 17 Goals. 2023. Available online: https://sdgs.un.org/goals (accessed on 3 March 2024).

- Bui, T.-D. Assessing sustainable supply chain transparency practices in Taiwan semiconductor industry: A hierarchical interdependence approach. Int. J. Prod. Econ. 2024, 272, 109245. [Google Scholar] [CrossRef]

- United Nations Office for Disaster Risk Reduction. SDGs with Targets related to Disaster Risk. 2023. Available online: https://www.preventionweb.net/sustainable-development-and-drr/sdgs-targets-related-disaster-risk (accessed on 10 February 2024).

- United Nations Principles for Responsible Investment. Micro Risks: A Risk Framework. 2017. Available online: https://www.unpri.org/sustainable-development-goals/the-sdgs-as-a-risk-framework/308.article (accessed on 10 February 2024).

- Sahin, E.; Iban, M.C.; Bilgilioglu, S.S. Remote sensing-enabled urban growth simulation overlaid with AHP-GIS-based urban land suitability for potential development in Mersin metropolitan area, Türkiye. Appl. Sci. 2024, 14, 3484. [Google Scholar] [CrossRef]

- Ghadge, A.; Wurtmann, H.; Seuring, S. Managing climate change risks in global supply chains: A review and research agenda. Int. J. Prod. Res. 2020, 58, 44–64. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Saad, G.H. Managing Disruption Risks in Supply Chains. Prod. Oper. Manag. 2005, 14, 53–68. [Google Scholar] [CrossRef]

- Wu, T.; Blackhurst, J.; Chidambaram, V. A model for inbound supply risk analysis. Comput. Ind. 2006, 57, 350–365. [Google Scholar] [CrossRef]

- Torabi, S.A.; Giahi, R.; Sahebjamnia, N. An enhanced risk assessment framework for business continuity management systems. Saf. Sci. 2016, 89, 201–218. [Google Scholar] [CrossRef]

- Harclerode, M.A.; Macbeth, T.W.; Miller, M.E.; Gurr, C.J.; Myers, T.S. Early decision framework for integrating sustainable risk management for complex remediation sites: Drivers, barriers, and performance metrics. J. Environ. Manag. 2016, 184, 57–66. [Google Scholar] [CrossRef]

- Liu, W.; Wang, S.; Dong, D.; Wang, J. Evaluation of the intelligent logistics eco-index: Evidence from China. J. Clean. Prod. 2020, 274, 123127. [Google Scholar] [CrossRef]

- Liu, W.; Wei, W.; Yan, X.; Dong, D.; Chen, Z. Sustainability risk management in a smart logistics ecological chain: An evaluation framework based on social network analysis. J. Clean. Prod. 2020, 276, 124189. [Google Scholar] [CrossRef]

- Kodym, O.; Kubáč, L.; Kavka, L. Risks associated with Logistics 4.0 and their minimization using Blockchain. Open Eng. 2020, 10, 74–85. [Google Scholar] [CrossRef]

- Gupta, A.; Singh, R.K. Study of sustainability issues in an Indian logistics service provider: SAP-LAP approach. Qual. Res. Organ. Manag. 2021, 16, 530–549. [Google Scholar] [CrossRef]

- De Oliveira, U.R.; Aparecida Neto, L.; Abreu, P.A.F.; Fernandes, V.A. Risk management applied to the reverse logistics of solid waste. J. Clean. Prod. 2021, 296, 126517. [Google Scholar] [CrossRef]

- ISO 31000; Risk Management—Guidelines. ISO: Geneva, Switzerland, 2018.

- Majumdar, A.; Sinha, S.K.; Shaw, M.; Mathiyazhagan, K. Analysing the vulnerability of green clothing supply chains in South and Southeast Asia using fuzzy analytic hierarchy process. Int. J. Prod. Res. 2021, 59, 752–771. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Khan, M.I. Assessment of risk in the management of Halal supply chain using fuzzy BWM method. Supply Chain Forum Int. J. 2021, 22, 57–73. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Dwivedi, A.; Khan, N.S.; Paul, S.K.; Khan, S.A.; Ahmed, S.; Sultana, R. Analysis of risk factors in sustainable supply chain management in an emerging economy of leather industry. J. Clean. Prod. 2021, 283, 124641. [Google Scholar] [CrossRef]

- Goswami, M.; Daultani, Y.; De, A. Decision modeling and analysis in new product development considering supply chain uncertainties: A multi-functional expert based approach. Expert Syst. Appl. 2021, 166, 114016. [Google Scholar] [CrossRef]

- Sakib, N.; Hossain, N.U.I.; Nur, F.; Talluri, S.; Jaradat, R.; Lawrence, J.M. An assessment of probabilistic disaster in the oil and gas supply chain leveraging Bayesian belief network. Int. J. Prod. Econ. 2021, 235, 108107. [Google Scholar] [CrossRef]

- Rama, M.; Andrade, E.; Moreira, M.T.; Feijoo, G.; González-García, S. Defining a procedure to identify key sustainability indicators in Spanish urban systems: Development and application. Sustain. Cities Soc. 2021, 70, 102919. [Google Scholar] [CrossRef]

- Liu, B.; Yang, Z.; Xue, B.; Zhao, D.; Sun, X.; Wang, W. Formalizing an integrated metric system measuring performance of urban sustainability: Evidence from China. Sustain. Cities Soc. 2022, 79, 103702. [Google Scholar] [CrossRef]

- Kusakci, S.; Yilmaz, M.K.; Kusakci, A.O.; Sowe, S.; Nantembelele, F.A. Towards sustainable cities: A sustainability assessment study for metropolitan cities in Turkey via a hybridized IT2F-AHP and COPRAS approach. Sustain. Cities Soc. 2022, 78, 103655. [Google Scholar] [CrossRef]

- Yousefi, S.; Tosarkani, B.M. The adoption of new technologies for sustainable risk management in logistics planning: A sequential dynamic approach. Comput. Ind. Eng. 2022, 173, 108627. [Google Scholar] [CrossRef]

- Gupta, S.; Chatterjee, P.; Rastogi, R.; Gonzalez, E.D.R.S. A Delphi fuzzy analytic hierarchy process framework for criteria classification and prioritization in food supply chains under uncertainty. Decis. Anal. J. 2023, 7, 100217. [Google Scholar] [CrossRef]

- Gurbuz, M.C.; Yurt, O.; Ozdemir, S.; Sena, V.; Yu, W. Global supply chains risks and COVID-19: Supply chain structure as a mitigating strategy for small and medium-sized enterprises. J. Bus. Res. 2023, 155, 113407. [Google Scholar] [CrossRef] [PubMed]

- Tavana, M.; Khalili Nasr, A.; Ahmadabadi, A.B.; Amiri, A.S.; Mina, H. An interval multi-criteria decision-making model for evaluating blockchain-IoT technology in supply chain networks. Internet Things 2023, 22, 100786. [Google Scholar] [CrossRef]

- Vergara, J.I.T.; Martínez, J.A.S.; Salais-Fierro, T.E. Performance measurement of a Resilient-Sustainable Supply Chain through fuzzy multi-criteria techniques. Comput. Ind. Eng. 2023, 177, 109059. [Google Scholar] [CrossRef]

- Song, H.; Chang, R.; Cheng, H.; Liu, P.; Yan, D. The impact of manufacturing digital supply chain on supply chain disruption risks under uncertain environment—Based on dynamic capability perspective. Adv. Eng. Inform. 2024, 60, 102385. [Google Scholar] [CrossRef]

- Saputro, T.E.; Rosiani, T.Y.; Mubin, A.; Dewi, S.K.; Baroto, T. Green supplier selection under supply risks using novel integrated fuzzy multi-criteria decision making techniques. J. Clean. Prod. 2024, 449, 141788. [Google Scholar] [CrossRef]

- Turkey Information Technologies and Communications Authority. Annual Provincial Statistics. 2024. Available online: https://www.btk.gov.tr/yillik-il-istatistikleri (accessed on 5 April 2024).

- Turkey Ministry of Justice. Turkish General Directorate of Criminal Records and Statistics. 2024; Justice Statistics Publication Archive. Available online: https://adlisicil.adalet.gov.tr/Home/SayfaDetay/adalet-istatistikleri-yayin-arsivi (accessed on 5 April 2024).

- Turkish Statistical Institute (TURKSTAT). 2024. Available online: https://tuik.gov.tr/Home/Index (accessed on 2 April 2024).

- United Nations Global Compact. A Safe and Healthy Working Environment. 2023. Available online: https://unglobalcompact.org/take-action/safety-andhealth (accessed on 2 April 2024).

- WHO. Road Traffic Injuries. 2023. Available online: https://www.who.int/news-room/fact-sheets/detail/road-traffic-injuries (accessed on 2 April 2024).

- Yue, X.; Mu, D.; Wang, C.; Ren, H.; Peng, R.; Du, J. Critical risks in global supply networks: A static structure and dynamic propagation perspective. Reliab. Eng. Syst. Saf. 2024, 242, 109728. [Google Scholar] [CrossRef]

- Russo, N.; Mamede, H.S.; Reis, L.; Martins, J.; Branco, F. Exploring a multidisciplinary assessment of organisational maturity in business continuity: A perspective and future research outlook. Appl. Sci. 2023, 13, 11846. [Google Scholar] [CrossRef]

- Schachenhofer, L.; Kummer, Y.; Hirsch, P. An analysis of underused urban infrastructures: Usage opportunities and implementation barriers for sustainable logistics. Appl. Sci. 2023, 13, 7557. [Google Scholar] [CrossRef]

- Stević, Ž.; Ersoy, N.; Başar, E.E.; Baydaş, M. Addressing the global logistics performance index rankings with methodological insights and an innovative decision support framework. Appl. Sci. 2024, 14, 10334. [Google Scholar] [CrossRef]

- Erdem, M.; Özdemir, A. Evaluation of cyber security risk pillars for a digital, innovative, and sustainable model utilizing a novel fuzzy hybrid optimization. Comput. Secur. 2025, 153, 104394. [Google Scholar] [CrossRef]

- Cografyaharita. Türkiye Map. 2024. Available online: http://cografyaharita.com/turkiye-dilsiz-haritalari.html (accessed on 1 May 2024).

- Erdem, M.; Özdemir, A. Sustainability and risk assessment of data center locations under a fuzzy environment. J. Clean. Prod. 2024, 450, 141982. [Google Scholar] [CrossRef]

| Linguistic Scale | Fuzzy Number Scale |

|---|---|

| Definitely less important linguistic term (DLILT) | (0.100, 0.111, 0.125) |

| Very strongly less important linguistic term (VSLILT) | (0.125, 0.143, 0.166) |

| Strongly less important linguistic term (SLILT) | (0.166, 0.200, 0.250) |

| Marginally less important linguistic term (MLILT) | (0.250, 0.333, 0.500) |

| Equal important linguistic term (EILT) | (1.000, 1.000, 1.000) |

| Marginally more important linguistic term (MMILT) | (2.000, 3.000, 4.000) |

| Strongly more important linguistic term (SMILT) | (4.000, 5.000, 6.000) |

| Very strongly more important linguistic term (VSMILT) | (6.000, 7.000, 8.000) |

| Definitely more important linguistic term (DMILT) | (8.000, 9.000, 10.000) |

| C1 | Economic | Explanation |

| C1.1 | Economic effect of CO2 emission | It measures the economic effect of carbon dioxide released. |

| C1.2 | Energy consumption | It measures the amount of energy consumed. |

| C1.3 | Domestic material consumption | It measures the amount of materials used in production. |

| C1.4 | Investment | It measures the amount of gross fixed capital formation. |

| C1.5 | Volatility of price and cost | It expresses how widely prices and costs fluctuate. |

| C1.6 | Disposal costs of hazardous wastes | The amount of money accrued for the removal or disposal of waste or materials remaining at the end of a production process. |

| C1.7 | Maintenance costs | It refers to the total costs encountered by a business while operating. |

| C1.8 | Fiscal changes | It refers to the use of expenditures and tax policies by the government to direct the total demand for the sector, employment, inflation and economic growth. |

| C1.9 | Number of Enterprises | It measures the number of enterprises operating in the sector. |

| C2 | Safety | |

| C2.1 | Inadequate personal protective equipment | It counts the number of uses of inadequate protective equipment during control. |

| C2.2 | Dangerous working condition | It refers to the number of cases of unsafe working conditions encountered in the workplace during controls. |

| C2.3 | Mortality caused by traffic injury | It refers to the number of deaths resulting from traffic injuries. |

| C2.4 | Explosions, fires, chemical accidents | It refers to the number of chemical accidents that occur in the workplace. |

| C2.5 | Machine, equipment or facility failure | It refers to the number of machine, equipment or facility failures. |

| C3 | Hazards risk | |

| C3.1 | Earthquake | The term describes the exposure to earthquakes in both absolute and relative terms. |

| C3.2 | Flood | The term describes the exposure to floods in both absolute and relative terms. |

| C3.3 | Epidemic | The term describes the exposure to epidemic in both absolute and relative terms. |

| C3.4 | Landslide | The term describes the exposure to landslides in both absolute and relative terms. |

| C3.5 | Forest fire | The term describes the exposure to forest fires in both absolute and relative terms. |

| C4 | Legal risk | |

| C4.1 | Judicial Independence | It assesses how independent the judiciary system is from government, individuals, or companies. |

| C4.2 | Legal Framework Efficiency | It refers to the effectiveness of legal and judicial systems in resolving disputes. |

| C4.3 | The Protection of the Intellectual Property | It indicates the level of protection afforded to intellectual property rights. |

| C4.4 | Land Administration Quality | It describes the quality of land management. |

| C4.5 | Uprooted Refugees | It measures the impact of uprooted refugees on a city. |

| C5 | Energy | |

| C5.1 | Renewable energy consumption | The indicator refers to energy consumption from all renewable sources. |

| C5.2 | Renewable energy production | The indicator refers to energy production from all renewable sources. |

| C5.3 | Primary energy supply | It measures the primary energy supply. |

| C5.4 | Electricity generation | It measures in gigawatt hours and as a percentage of total energy production. |

| C6 | Environmetal impact and utilization | |

| C6.1 | Air pollution (micrograms per cubic meter) | It measures the average annual concentration of fine particles suspended in the air (PM2.5). |

| C6.2 | Air pollution, population exposure | It measures the percentage of the population exposed to PM2.5 concentrations |

| C6.3 | Total GHG emissions | It measures total greenhouse gas emissions |

| C6.4 | Biodiversity covered by protected areas | It defines areas designated for the long-term protection and maintenance of biological diversity. |

| C7 | Transportation Infrastructure | |

| C7.1 | Air transport, freight tonne-kilometres | It is the sum obtained by multiplying the weight of the load carried on each flight by its distance. |

| C7.2 | Road network | It measures the total length of the road network. |

| C7.3 | Container port traffic | It measures container flow in a standard size container in port container traffic. |

| C7.4 | Quality of air transport infrastructure | It refers to the quality of air transportation infrastructure. |

| C7.5 | Quality of port infrastructure | It refers to the quality of port infrastructure. |

| C7.6 | Quality of railroad infrastructure | It refers to the quality of railroad infrastructure. |

| C7.7 | Green number of vehicles | It refers to the number of green/electrical vehicles. |

| C7.8 | Number of energy/charge stations | It refers to the number of energy/charge stations. |

| C8 | Information Technology Infrastructure | |

| C8.1 | Secure Servers | It refers to the number of secure socket layer protocol certificates. |

| C8.2 | Information and communication technology | It defines the level of development of information and communication. |

| C8.3 | Broadband subscriptions | It measures broadband subscriptions by the total number of subscribers. |

| C8.4 | System Failure | It measures recorded outages that occur in the system or network. |

| C8.5 | Network security | It defines its protection against breaches, intrusions and other threats occurring in the network. |

| C8.6 | Data corruption | It describes errors encountered that cause undesirable changes in the original data. |

| C8.7 | IoT | It refers to the platform’s integration with new technologies such as sensors, RFID and NFC and the internet. |

| C8.8 | Software | It refers to the software malfunctions or failures. |

| C9 | Process/operation | |

| C9.1 | Lack of tech skills | It measures the technical expertise of labor force. |

| C9.2 | Machinery breakdowns | It measures machine malfunctions encountered in a certain period. |

| C9.3 | Shipping damages | It refers to the damage of the products during transportation and transportation. |

| C9.4 | Poor process output | It refers to the efficiency of processes. |

| C9.5 | Changing consumer preferences | It describes its flexibility in responding to the changing consumer. |

| C9.6 | Supplier failure | It measures the total or partial failure of suppliers or service providers or disruption in the supply of products or the provision of a particular service. |

| C9.7 | Raw materials shortage | It refers to the possible raw material shortage. |

| C9.8 | Poor supplier selection | It refers to the disruption caused by the supplier’s failure to fulfill its obligations. |

| C10 | Social | |

| C10.1 | Rural Access Index | It considers the proportion of the rural population who live within 2 km of an all-season road. |

| C10.2 | Convenient access to public transport | It takes into account people’s access to public or private transportation. |

| C10.3 | Passenger car registrations | It measures the number of new passenger cars or vehicles registered. |

| C10.4 | Population | It measures the population of the metropolitan area. |

| C10.5 | Proportion of informal employment | It measures the rate of informal employment. |

| C10.6 | Manager–employee relationships | It defines the relationship between manager and employee in the workplace. |

| C10.7 | Workplace culture | It refers to the institutionality of the organization where the workforce works. |

| C10.8 | Successful partnership among partners | It refers to a mutually beneficial partnership or collaboration. |

| C10.9 | Business ethics | It refers to moral principles, policies and values that may harm internal or external stakeholders. |

| C10.10 | Vendor or Supplier Breaches | It refers to vendor or supplier breaches in a certain period. |

| Main Criterion | Calculated Weights for Each Criterion | Sub-Criterion | Calculated Local Weights | Calculated Global Weights |

|---|---|---|---|---|

| C1 | 0.1542 | |||

| C1.1. | 0.0410 | 0.0063 | ||

| C1.2. | 0.0411 | 0.0063 | ||

| C1.3. | 0.0460 | 0.0071 | ||

| C1.4. | 0.1967 | 0.0303 | ||

| C1.5. | 0.1743 | 0.0269 | ||

| C1.6. | 0.0864 | 0.0133 | ||

| C1.7. | 0.0992 | 0.0153 | ||

| C1.8. | 0.1683 | 0.0260 | ||

| C1.9. | 0.1470 | 0.0227 | ||

| C2 | 0.1470 | |||

| C2.1. | 0.1503 | 0.0221 | ||

| C2.2. | 0.1568 | 0.0231 | ||

| C2.3. | 0.2961 | 0.0435 | ||

| C2.4. | 0.1858 | 0.0273 | ||

| C2.5. | 0.2110 | 0.0310 | ||

| C3 | 0.1447 | |||

| C3.1. | 0.2885 | 0.0417 | ||

| C3.2. | 0.1723 | 0.0249 | ||

| C3.3. | 0.3143 | 0.0455 | ||

| C3.4. | 0.0883 | 0.0128 | ||

| C3.5. | 0.1366 | 0.0198 | ||

| C4 | 0.0942 | |||

| C4.1. | 0.2899 | 0.0273 | ||

| C4.2. | 0.1440 | 0.0136 | ||

| C4.3. | 0.1635 | 0.0154 | ||

| C4.4. | 0.2811 | 0.0265 | ||

| C4.5. | 0.1215 | 0.0114 | ||

| C5 | 0.1093 | |||

| C5.1. | 0.2080 | 0.0227 | ||

| C5.2. | 0.2618 | 0.0287 | ||

| C5.3. | 0.2417 | 0.0264 | ||

| C5.4. | 0.2884 | 0.0315 | ||

| C6 | 0.0617 | |||

| C6.1. | 0.3763 | 0.0232 | ||

| C6.2. | 0.3712 | 0.0229 | ||

| C6.3. | 0.1737 | 0.0107 | ||

| C6.4. | 0.0788 | 0.0049 | ||

| C7 | 0.0791 | |||

| C7.1. | 0.0545 | 0.0043 | ||

| C7.2. | 0.0474 | 0.0037 | ||

| C7.3. | 0.0549 | 0.0043 | ||

| C7.4. | 0.0833 | 0.0066 | ||

| C7.5. | 0.1355 | 0.0107 | ||

| C7.6. | 0.2182 | 0.0173 | ||

| C7.7. | 0.2273 | 0.0180 | ||

| C7.8. | 0.1789 | 0.0142 | ||

| C8 | 0.1010 | |||

| C8.1. | 0.1489 | 0.0150 | ||

| C8.2. | 0.1237 | 0.0125 | ||

| C8.3. | 0.1304 | 0.0132 | ||

| C8.4. | 0.1220 | 0.0123 | ||

| C8.5. | 0.1331 | 0.0134 | ||

| C8.6. | 0.1450 | 0.0146 | ||

| C8.7. | 0.0975 | 0.0099 | ||

| C8.8. | 0.0994 | 0.0101 | ||

| C9 | 0.0660 | |||

| C9.1. | 0.2080 | 0.0137 | ||

| C9.2. | 0.1682 | 0.0111 | ||

| C9.3. | 0.0838 | 0.0055 | ||

| C9.4. | 0.0832 | 0.0055 | ||

| C9.5. | 0.1530 | 0.0101 | ||

| C9.6. | 0.1156 | 0.0076 | ||

| C9.7. | 0.0887 | 0.0059 | ||

| C9.8. | 0.0995 | 0.0066 | ||

| C10 | 0.0428 | |||

| C10.1. | 0.0401 | 0.0017 | ||

| C10.2. | 0.0833 | 0.0036 | ||

| C10.3. | 0.0967 | 0.0041 | ||

| C10.4. | 0.1110 | 0.0048 | ||

| C10.5. | 0.0957 | 0.0041 | ||

| C10.6. | 0.0841 | 0.0036 | ||

| C10.7. | 0.1146 | 0.0049 | ||

| C10.8. | 0.1288 | 0.0055 | ||

| C10.9. | 0.1287 | 0.0055 | ||

| C10.10. | 0.1170 | 0.0050 |

| All Criteria | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cities | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank | OPS | Rank |

| Adana | 0.276 | 13 | 0.432 | 23 | 0.867 | 21 | 0.871 | 23 | 0.145 | 26 | 0.475 | 3 | 0.804 | 1 | 0.318 | 4 | 0.094 | 12 | 0.819 | 14 | 0.203 | 7 |

| Ankara | 0.342 | 3 | 0.705 | 1 | 0.659 | 29 | 0.632 | 29 | 0.307 | 2 | 0.298 | 7 | 0.565 | 27 | 0.485 | 2 | 0.276 | 3 | 0.840 | 9 | 0.444 | 2 |

| Antalya | 0.274 | 20 | 0.467 | 3 | 0.798 | 25 | 0.821 | 25 | 0.221 | 3 | 0.183 | 16 | 0.798 | 2 | 0.246 | 6 | 0.117 | 10 | 0.553 | 23 | 0.215 | 6 |

| Aydın | 0.273 | 21 | 0.441 | 8 | 0.939 | 10 | 0.948 | 8 | 0.186 | 11 | 0.233 | 10 | 0.718 | 8 | 0.109 | 20 | 0.066 | 27 | 0.842 | 8 | 0.156 | 14 |

| Balıkesir | 0.278 | 11 | 0.433 | 22 | 0.908 | 18 | 0.934 | 13 | 0.187 | 6 | 0.459 | 4 | 0.756 | 5 | 0.163 | 11 | 0.063 | 29 | 0.828 | 10 | 0.202 | 9 |

| Bursa | 0.310 | 5 | 0.433 | 21 | 0.748 | 27 | 0.752 | 27 | 0.171 | 21 | 0.249 | 8 | 0.605 | 25 | 0.165 | 10 | 0.231 | 4 | 0.845 | 4 | 0.224 | 5 |

| Denizli | 0.269 | 27 | 0.439 | 10 | 0.924 | 14 | 0.931 | 14 | 0.186 | 12 | 0.152 | 19 | 0.695 | 14 | 0.108 | 23 | 0.087 | 16 | 0.843 | 7 | 0.156 | 13 |

| Diyarbakır | 0.270 | 24 | 0.439 | 9 | 0.937 | 11 | 0.918 | 17 | 0.182 | 16 | 0.150 | 20 | 0.710 | 10 | 0.100 | 24 | 0.071 | 26 | 0.560 | 22 | 0.089 | 26 |

| Erzurum | 0.274 | 19 | 0.435 | 16 | 0.977 | 2 | 0.984 | 2 | 0.185 | 14 | 0.049 | 26 | 0.571 | 26 | 0.110 | 18 | 0.074 | 24 | 0.374 | 27 | 0.147 | 21 |

| Eskişehir | 0.269 | 28 | 0.448 | 5 | 0.941 | 9 | 0.939 | 11 | 0.185 | 13 | 0.050 | 25 | 0.771 | 4 | 0.236 | 7 | 0.064 | 28 | 0.845 | 5 | 0.153 | 17 |

| Gaziantep | 0.306 | 6 | 0.437 | 12 | 0.916 | 16 | 0.915 | 18 | 0.116 | 30 | 0.117 | 21 | 0.671 | 21 | 0.167 | 9 | 0.180 | 7 | 0.808 | 15 | 0.126 | 23 |

| Hatay | 0.270 | 25 | 0.415 | 28 | 0.924 | 13 | 0.927 | 15 | 0.119 | 29 | 0.323 | 6 | 0.516 | 29 | 0.074 | 26 | 0.061 | 30 | 0.376 | 26 | 0.074 | 27 |

| Istanbul | 0.602 | 1 | 0.624 | 2 | 0.000 | 30 | 0.000 | 30 | 0.805 | 1 | 0.526 | 2 | 0.388 | 30 | 0.746 | 1 | 0.657 | 1 | 0.639 | 17 | 0.964 | 1 |

| Izmir | 0.315 | 4 | 0.467 | 4 | 0.661 | 28 | 0.667 | 28 | 0.198 | 4 | 0.637 | 1 | 0.674 | 20 | 0.430 | 3 | 0.226 | 6 | 0.725 | 16 | 0.306 | 3 |

| Kahramanmaraş | 0.271 | 23 | 0.431 | 24 | 0.944 | 8 | 0.946 | 9 | 0.164 | 25 | 0.246 | 9 | 0.679 | 18 | 0.096 | 25 | 0.072 | 25 | 0.365 | 28 | 0.033 | 29 |

| Kayseri | 0.268 | 29 | 0.437 | 11 | 0.890 | 19 | 0.877 | 20 | 0.170 | 22 | 0.189 | 15 | 0.635 | 24 | 0.139 | 15 | 0.078 | 22 | 0.821 | 12 | 0.162 | 10 |

| Kocaeli | 0.306 | 7 | 0.375 | 29 | 0.775 | 26 | 0.770 | 26 | 0.178 | 19 | 0.206 | 13 | 0.683 | 16 | 0.146 | 14 | 0.231 | 5 | 0.851 | 2 | 0.203 | 8 |

| Konya | 0.411 | 2 | 0.444 | 7 | 0.816 | 24 | 0.846 | 24 | 0.165 | 24 | 0.170 | 17 | 0.534 | 28 | 0.306 | 5 | 0.374 | 2 | 0.828 | 11 | 0.224 | 4 |

| Malatya | 0.278 | 10 | 0.434 | 20 | 0.973 | 5 | 0.982 | 3 | 0.179 | 18 | 0.022 | 30 | 0.707 | 13 | 0.109 | 22 | 0.083 | 20 | 0.597 | 21 | 0.149 | 20 |

| Manisa | 0.274 | 18 | 0.446 | 6 | 0.865 | 22 | 0.875 | 21 | 0.186 | 10 | 0.383 | 5 | 0.663 | 23 | 0.159 | 12 | 0.102 | 11 | 0.843 | 6 | 0.161 | 11 |

| Mardin | 0.277 | 12 | 0.364 | 30 | 0.997 | 1 | 0.995 | 1 | 0.169 | 23 | 0.079 | 24 | 0.714 | 9 | 0.069 | 27 | 0.087 | 15 | 0.360 | 30 | 0.059 | 28 |

| Mersin | 0.294 | 9 | 0.430 | 25 | 0.857 | 23 | 0.872 | 22 | 0.138 | 27 | 0.110 | 23 | 0.789 | 3 | 0.110 | 19 | 0.167 | 8 | 0.821 | 13 | 0.125 | 24 |

| Muğla | 0.275 | 15 | 0.436 | 15 | 0.914 | 17 | 0.939 | 12 | 0.186 | 9 | 0.218 | 11 | 0.707 | 12 | 0.153 | 13 | 0.090 | 13 | 0.604 | 19 | 0.149 | 18 |

| Ordu | 0.272 | 22 | 0.434 | 18 | 0.973 | 6 | 0.962 | 6 | 0.179 | 17 | 0.024 | 29 | 0.693 | 15 | 0.038 | 30 | 0.083 | 21 | 0.392 | 24 | 0.146 | 22 |

| Sakarya | 0.299 | 8 | 0.425 | 26 | 0.945 | 7 | 0.941 | 10 | 0.173 | 20 | 0.161 | 18 | 0.682 | 17 | 0.124 | 16 | 0.164 | 9 | 0.850 | 3 | 0.153 | 16 |

| Samsun | 0.270 | 26 | 0.435 | 17 | 0.921 | 15 | 0.926 | 16 | 0.186 | 8 | 0.217 | 12 | 0.710 | 11 | 0.110 | 17 | 0.075 | 23 | 0.619 | 18 | 0.158 | 12 |

| Şanlıurfa | 0.274 | 17 | 0.436 | 14 | 0.926 | 12 | 0.953 | 7 | 0.137 | 28 | 0.201 | 14 | 0.676 | 19 | 0.109 | 21 | 0.083 | 19 | 0.362 | 29 | 0.113 | 25 |

| Tekirdağ | 0.261 | 30 | 0.424 | 27 | 0.889 | 20 | 0.889 | 19 | 0.185 | 15 | 0.111 | 22 | 0.747 | 6 | 0.173 | 8 | 0.088 | 14 | 0.851 | 1 | 0.154 | 15 |

| Trabzon | 0.275 | 14 | 0.434 | 19 | 0.973 | 4 | 0.979 | 4 | 0.187 | 7 | 0.032 | 27 | 0.723 | 7 | 0.054 | 29 | 0.085 | 17 | 0.392 | 25 | 0.149 | 19 |

| Van | 0.275 | 16 | 0.436 | 13 | 0.974 | 3 | 0.971 | 5 | 0.197 | 5 | 0.027 | 28 | 0.667 | 22 | 0.065 | 28 | 0.084 | 18 | 0.601 | 20 | 0.018 | 30 |

| Kusakci et al. [42] | The Proposed Method | |||

|---|---|---|---|---|

| Cities | Score | Rank | OPS | Rank |

| Adana | 0.535 | 25 | 0.276 | 13 |

| Ankara | 0.721 | 4 | 0.342 | 3 |

| Antalya | 1.000 | 1 | 0.274 | 20 |

| Aydın | 0.695 | 5 | 0.273 | 21 |

| Balıkesir | 0.639 | 13 | 0.278 | 11 |

| Bursa | 0.615 | 18 | 0.310 | 5 |

| Denizli | 0.668 | 9 | 0.269 | 27 |

| Diyarbakır | 0.517 | 28 | 0.270 | 24 |

| Erzurum | 0.640 | 12 | 0.274 | 19 |

| Eskişehir | 0.802 | 3 | 0.269 | 28 |

| Gaziantep | 0.610 | 19 | 0.306 | 6 |

| Hatay | 0.580 | 22 | 0.270 | 25 |

| Istanbul | 0.590 | 20 | 0.602 | 1 |

| Izmir | 0.642 | 11 | 0.315 | 4 |

| Kahramanmaraş | 0.558 | 24 | 0.271 | 23 |

| Kayseri | 0.620 | 17 | 0.268 | 29 |

| Kocaeli | 0.690 | 6 | 0.306 | 7 |

| Konya | 0.687 | 7 | 0.411 | 2 |

| Malatya | 0.627 | 16 | 0.278 | 10 |

| Manisa | 0.634 | 14 | 0.274 | 18 |

| Mardin | 0.501 | 29 | 0.277 | 12 |

| Mersin | 0.587 | 21 | 0.294 | 9 |

| Muğla | 0.921 | 2 | 0.275 | 15 |

| Ordu | 0.534 | 26 | 0.272 | 22 |

| Sakarya | 0.647 | 10 | 0.299 | 8 |

| Samsun | 0.563 | 23 | 0.270 | 26 |

| Şanlıurfa | 0.527 | 27 | 0.274 | 17 |

| Tekirdağ | 0.686 | 8 | 0.261 | 30 |

| Trabzon | 0.631 | 15 | 0.275 | 14 |

| Van | 0.480 | 30 | 0.275 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erdem, M.; Özdemir, A.; Kosunalp, S.; Iliev, T. Assessment of Sustainability and Risk Indicators in an Urban Logistics Network Analysis Considering a Business Continuity Plan. Appl. Sci. 2025, 15, 5145. https://doi.org/10.3390/app15095145

Erdem M, Özdemir A, Kosunalp S, Iliev T. Assessment of Sustainability and Risk Indicators in an Urban Logistics Network Analysis Considering a Business Continuity Plan. Applied Sciences. 2025; 15(9):5145. https://doi.org/10.3390/app15095145

Chicago/Turabian StyleErdem, Mehmet, Akın Özdemir, Selahattin Kosunalp, and Teodor Iliev. 2025. "Assessment of Sustainability and Risk Indicators in an Urban Logistics Network Analysis Considering a Business Continuity Plan" Applied Sciences 15, no. 9: 5145. https://doi.org/10.3390/app15095145

APA StyleErdem, M., Özdemir, A., Kosunalp, S., & Iliev, T. (2025). Assessment of Sustainability and Risk Indicators in an Urban Logistics Network Analysis Considering a Business Continuity Plan. Applied Sciences, 15(9), 5145. https://doi.org/10.3390/app15095145