Benefits and Limitations of Lean Tools in the Building Design Process: A Functional and Comparative Analysis

Abstract

1. Introduction

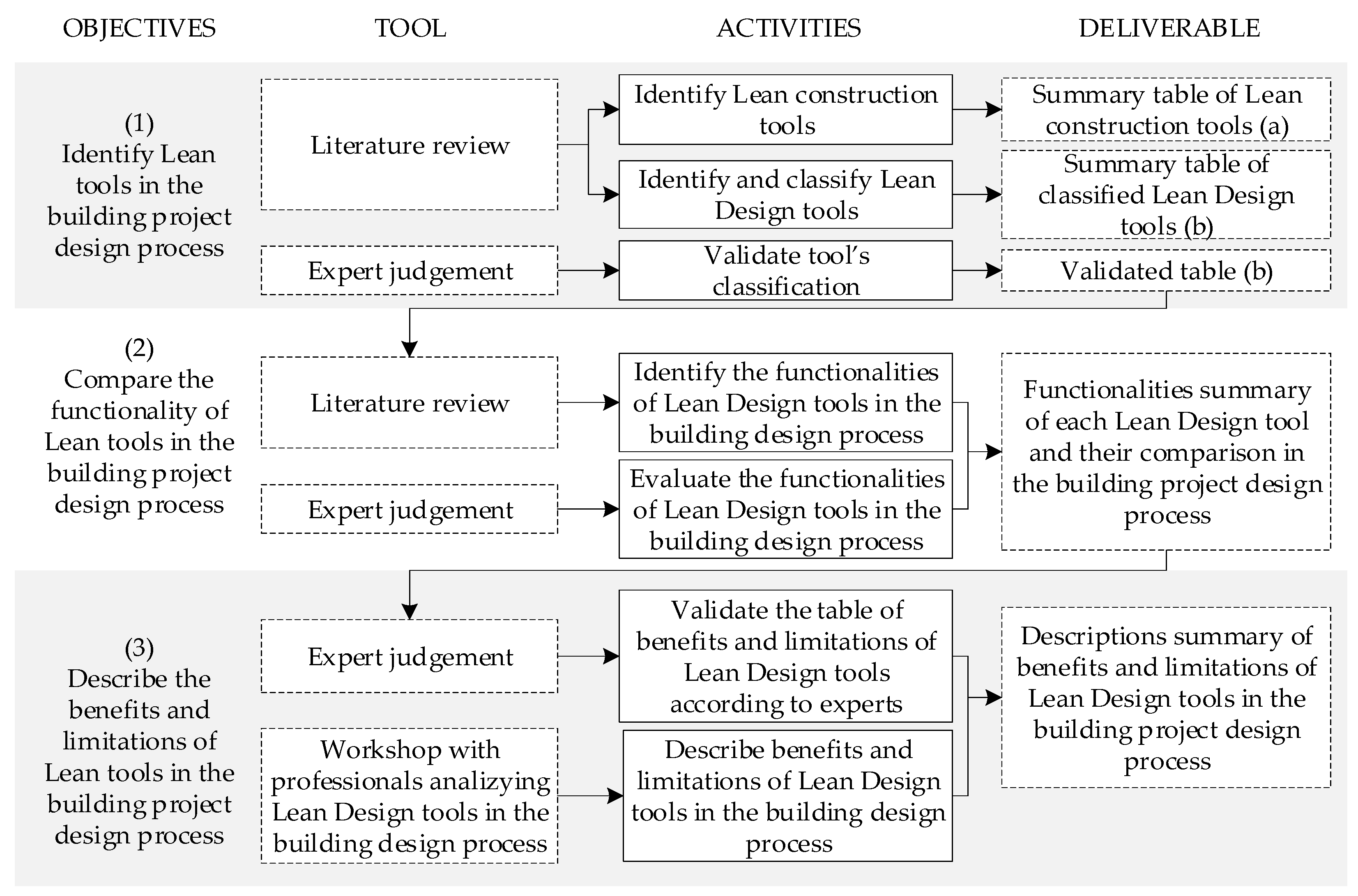

2. Research Method

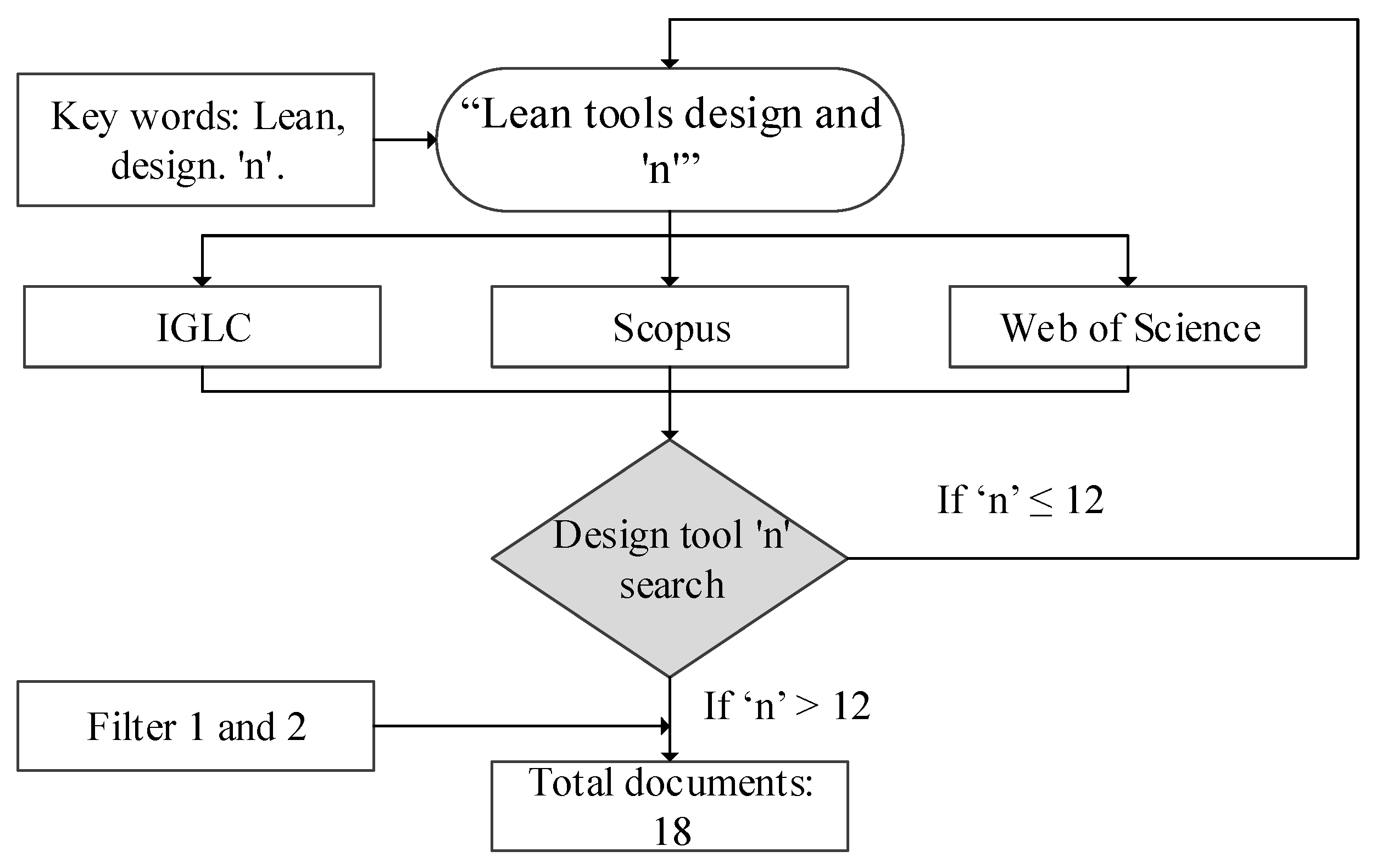

2.1. Identifying Lean Tools in the Building Project Design Process

- Which tools/methodologies do you know (have heard of, read about, applied, or know have been applied)? If you know of another, please specify.

- Have you read about the application of this tool in the design phase of building projects?

- Do you know of any cases where this tool has been applied in the design of building projects?

- Have you applied this tool in the design phase of building projects?

- On a scale of 1 to 7, how much would you recommend using this tool in the design phase of building projects? (1 = not recommended, 4 = neutral, 7 = highly recommended)?

2.2. Identifying Lean Design Tool Functionalities

2.3. Benefits and Limitations of Lean Tools in the Building Design Process

3. Results and Discussion

3.1. Lean Construction Tools

3.1.1. Lean Tools Applied to Design

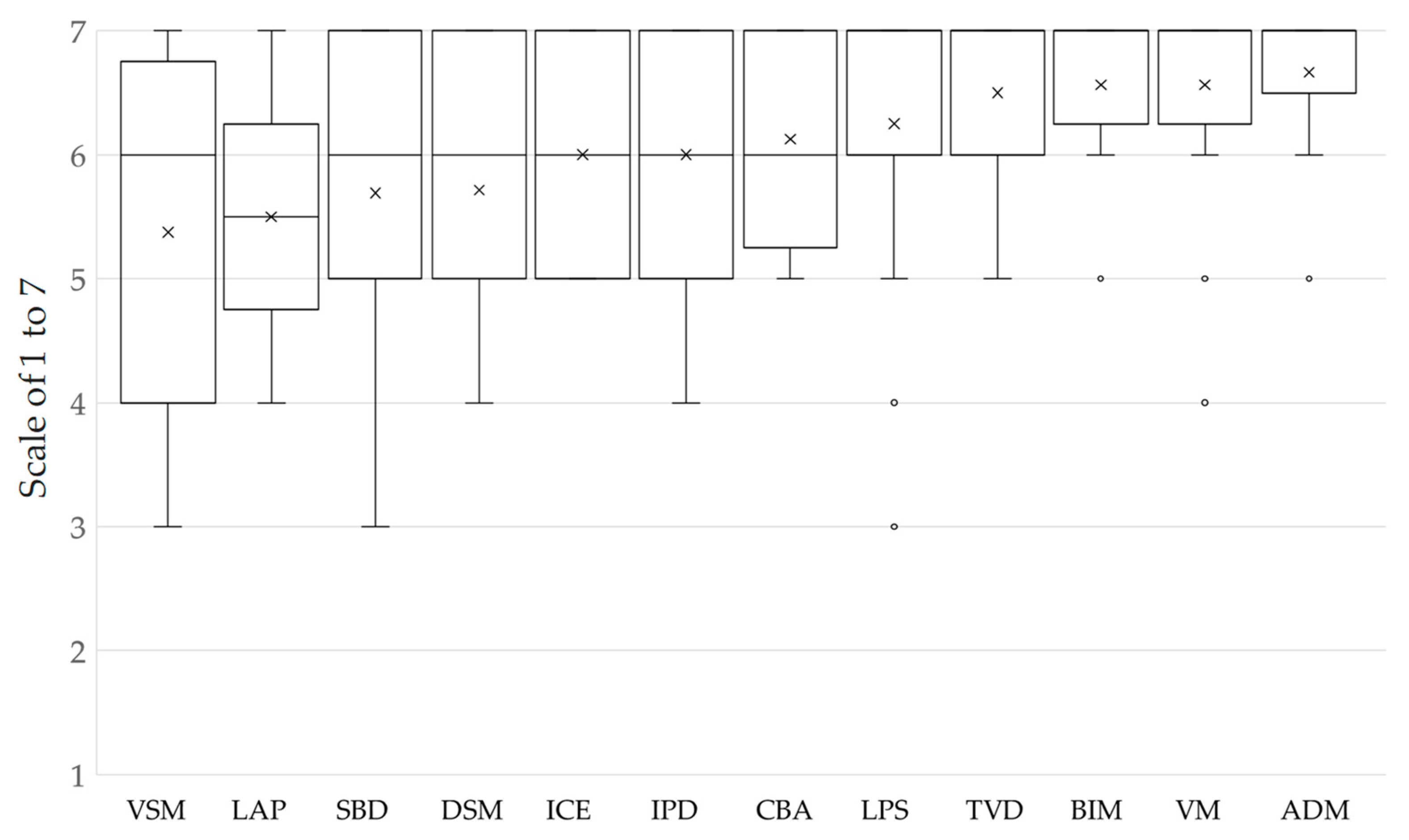

3.1.2. Validation of Lean Tools in the Building Design Process

Validation of the Proposed Lean Tools in the Building Design Process

Recommendation Rating of Each Lean Design Tool

Lean Design Tool Proposal

3.2. Lean Design and Its Functionalities

3.2.1. Definition of Each Functionality

3.2.2. Functionalities According to Management Principles

3.2.3. Functionality of Lean Tools in the Building Design Process

3.3. Benefits and Limitations of Lean Tools in Design

3.3.1. Benefits and Limitations of Agile Design Management

3.3.2. Benefits and Limitations of Last Planner System

3.3.3. Benefits and Limitations of BIM

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koskela, L.; Ballard, G. Towards Lean Design Management. In Proceedings of the 5th Annual Conference of the International Group for Lean Construction, Gold Coast, Australia, 16–17 July 1997; pp. 1–13. [Google Scholar]

- Bibby, L. Improving Design Management Techniques in Construction. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2003. [Google Scholar]

- El Reifi, M.H.; Emmitt, S.; Ruikar, K. Developing a Conceptual Lean Briefing Process Model for Lean Design Management. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction 2013, Fortaleza, Brazil, 29 July–2 August 2013. [Google Scholar]

- Aslam, M.; Baffoe-Twum, E.; Saleem, F. Design Changes in Construction Projects—Causes and Impact on the Cost. Civ. Eng. J. 2019, 5, 1647–1655. [Google Scholar] [CrossRef]

- Mpofu, B.; Ochieng, E.G.; Moobela, C.; Pretorius, A. Profiling Causative Factors Leading to Construction Project Delays in the United Arab Emirates. Eng. Constr. Archit. Manag. 2017, 24, 346–376. [Google Scholar] [CrossRef]

- Oakland, J.; Marosszeky, M. Total Quality in the Construction Supply Chain; Routledge: London, UK, 2006. [Google Scholar]

- Latham, M. Constructing the Team: Final Report: Joint Review of Procurement and Contractual Arrangements in the United Kingdom Construction Industry; HMSO: Edinburgh, UK, 1994; ISBN 011752994X. [Google Scholar]

- Larsson, J. Johan Larsson Managing Radical Innovation in the Swedish Infrastructure Sector. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 2016. [Google Scholar]

- Egan, J. The Report of the Construction Task Force Rethinking Construction; Department of the Environment, Transport and the Regions: London, UK, 1998. [Google Scholar]

- Baiden, B.; Price, A.; Dainty, A. Looking beyond Processes: Human Factors in Team Integration. In Proceedings of the 19th Annual ARCOM Conference, Brighton, UK, 3–5 September 2003; Volume 1. [Google Scholar]

- Dainty, A.R.J.; Moore, D.R. The Performance of Integrated D&b Teams in Unexpected Change Event. Glasg. Caled. Univ. Assoc. Res. Constr. Manag. 2000, 1, 281–290. [Google Scholar]

- Mossman, A. What Is Lean Construction: Another Look. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–22 July 2018; pp. 1240–1250. [Google Scholar]

- Bertelsen, S. Lean Construction: Where Are We and How to Proceed? Lean Constr. J. 2004, 1, 46–69. [Google Scholar] [CrossRef]

- Freire, J.; Alarcón, L.F. Achieving Lean Design Process: Improvement Methodology. J. Constr. Eng. Manag. 2002, 128, 248–256. [Google Scholar] [CrossRef]

- O’brien, W.J.; Fischer, M.A.; Akinci, B.H.; O’brien, A. Importance of Site Conditions and Capacity Allocation for Construction Cost and Performance: A Case Study. In Proceedings of the 5th Annual Conference of the International Group for Lean Construction, Gold Coast, Australia, 16–17 July 1997. [Google Scholar]

- Gambatese, J.A.; Asce, M.; Pestana, C.; Lee, H.W. Alignment between Lean Principles and Practices and Worker Safety Behavior. J. Constr. Eng. Manag. 2016, 143, 04016083. [Google Scholar] [CrossRef]

- Formoso, C.T.; Tzotzopoulos, P.; Jobim, M.S.S.; Liedtke, R. Developing a protocol for Managing the Design process in the Building Industry. In Proceedings of the 6th Annual Conference of the International Group for Lean Construction, Guaruja, Brazil, 13–15 August 1998. [Google Scholar]

- El Reifi, M.H.; Emmitt, S. Perceptions of Lean Design Management. Archit. Eng. Des. Manag. 2013, 9, 195–208. [Google Scholar] [CrossRef]

- Kestle, L.; Potangaroa, R.; Storey, B. Integration of Lean Design and Design Management and Its Influence on the Development of a Multidisciplinary Design Management Model for Remote Site Projects. Archit. Eng. Des. Manag. 2011, 7, 139–153. [Google Scholar] [CrossRef]

- Tauriainen, M.; Marttinen, P.; Dave, B.; Koskela, L. The Effects of BIM and Lean Construction on Design Management Practices. Procedia Eng. 2016, 164, 567–574. [Google Scholar] [CrossRef]

- Franco, J.V.; Picchi, F.A. Lean Design in Building Projects: Guiding Principles and Exploratory Collection of Good Practices. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016. [Google Scholar]

- Mongeon, P.; Paul-Hus, A. The Journal Coverage of Web of Science and Scopus: A Comparative Analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Castañeda, K.; Sánchez, O.; Herrera, R.F.; Mejía, G. Highway Planning Trends: A Bibliometric Analysis. Sustainability 2022, 14, 5544. [Google Scholar] [CrossRef]

- Aslam, M.; Gao, Z.; Smith, G. Optimizing Construction Design Process Using the Lean Based Approach. Lean Constr. J. 2020, 2020, 176–204. [Google Scholar]

- Goepel, K.D. Group Consensus Cluster Analysis Using Shannon Alpha and Beta Entropy. Submitt. Publ. 2022, 14. [Google Scholar] [CrossRef]

- RIBA. Sinclair Dale RIBA Plan of Work 2020 Overview RIBA Plan of Work; Royal Institute of British Architects: London, UK, 2020. [Google Scholar]

- Ansah, R.H.; Sorooshian, S. Lean Construction: An Effective Approach for Project Management. ARPN J. Eng. Appl. Sci. 2016, 11, 1607–1612. [Google Scholar]

- Abdul-Rahman, H.; Wang, C.; Lim, I.Y.W. Waste Processing Framework for Non-Value-Adding Activities Using Lean Construction. J. Front. Constr. 2012, 1, 8–13. [Google Scholar]

- Sawhney, R.; Subburaman, K.; Sonntag, C.; Rao, P.R.V.; Capizzi, C. A Modified FMEA Approach to Enhance Reliability of Lean Systems. Int. J. Qual. Reliab. Manag. 2010, 27, 832–855. [Google Scholar] [CrossRef]

- Bahrami, M.; Bazzaz, D.H.; Sajjadi, S.M. Innovation and Improvements in Project Implementation and Management; Using FMEA Technique. Procedia Soc. Behav. Sci. 2012, 41, 418–425. [Google Scholar] [CrossRef]

- Carbone, T.A.; Tippett, D.D. Project Risk Management Using the Project Risk FMEA. Eng. Manag. J. 2004, 16, 28–35. [Google Scholar] [CrossRef]

- Alireza, A.; Sorooshian, S. Lean Manufacturing Tools; UMP Publisher: Kuantan, Malaysia, 2014. [Google Scholar]

- Aziz, R.F.; Hafez, S.M. Applying Lean Thinking in Construction and Performance Improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar] [CrossRef]

- Ballard, G. The Last Planner System of Production Control. Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2000. [Google Scholar]

- Muhammad, W.M.N.W.; Ismail, Z.; Hashim, A.E. Exploring Lean Construction Components for Malaysian Construction Industry. In Proceedings of the Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; pp. 947–951. [Google Scholar]

- Salem, O.; Solomon, J.; Genaidy, A.; Luegring, M. Site Implementation and Assessment of Lean Construction Techniques. Lean Constr. J. 2005, 2, 1–21. [Google Scholar] [CrossRef]

- Lean Production Lean Production: Online Resource for Lean-Based Information and Tools 2025. Available online: https://www.leanproduction.com/top-25-lean-tools/ (accessed on 15 March 2025).

- Tsao, C.C.Y.; Tommelein, I.D.; Swanlund, E.S.; Howell, G.A. Work Structuring to Achieve Integrated Product–Process Design. J. Constr. Eng. Manag. 2004, 130, 780–789. [Google Scholar] [CrossRef]

- Lean Construction Institute. An Introduction to Lean Architecture & Engineering. Available online: https://leanconstruction.org/lean-topics/lean-in-design-architecture-and-engineering/ (accessed on 1 March 2025).

- Tezel, A.; Koskela, L.; Aziz, Z. Lean Thinking in the Highways Construction Sector: Motivation, Implementation and Barriers. Prod. Plan. Control 2018, 29, 247–269. [Google Scholar] [CrossRef]

- Gosling, J.; Pero, M.; Schoenwitz, M.; Towill, D.; Cigolini, R. Defining and Categorizing Modules in Building Projects: An International Perspective. J. Constr. Eng. Manag. 2016, 142, 4016062. [Google Scholar] [CrossRef]

- Lean Construction Institute. An Introduction to Integrated Project Delivery. Available online: https://leanconstruction.org/lean-topics/integrated-project-delivery-ipd/ (accessed on 14 February 2025).

- Ernstrom, J.W.; Associated General Contractors of America. The Contractors’ Guide to BIM; Associated General Contractors of America: Arlington, VA, USA, 2006. [Google Scholar]

- Miron, L.I.G.; Kaushik, A.; Koskela, L. Target Value Design: The Challenge of Value Generation. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 29–31 July 2015; pp. 815–825. [Google Scholar]

- Salazar, L.A.; Ballard, G.; Arroyo, P.; Alarcón, L.F. Indicators for Observing Elements of Linguistic Action Perspective in Last Planner® System. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 402–411. [Google Scholar]

- Arroyo, P.; Tommelein, I.D.; Ballard, G. Comparing AHP and CBA as Decision Methods to Resolve the Choosing Problem in Detailed Design. J. Constr. Eng. Manag. 2015, 141, 4014063. [Google Scholar] [CrossRef]

- Parrish, K.; Tommelein, I.D. Making Design Decisions Using Choosing by Advantages. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction (IGLC), Taipei, China, 15–17 July 2009; pp. 501–510. [Google Scholar]

- Hanahoe, J.; Taggart, M.; Willis, C. Not Seeing the Wood for the Trees—A Gemba Walk Through a Timber Framed Housing Development. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2019; pp. 1209–1218. [Google Scholar]

- Lean Construction Institute an Introduction to A3 Problem Solving. 2025. Available online: https://leanconstruction.org/lean-topics/a3/ (accessed on 4 February 2025).

- Su, Y.; Lucko, G. Comparison and Renaissance of Classic Line-of-Balance and Linear Schedule Concepts for Construction Industry. Organ. Technol. Manag. Constr. Int. J. 2015, 7, 1315–1329. [Google Scholar] [CrossRef]

- de Sousa Leal Martins Moura, R.; Monteiro, J.M.F.; Heineck, L.F.M. Line of Balance—Is It a Synthesis of Lean Production Principles as Applied to Site Programming of Works? In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction (IGLC), Oslo, Norway, 25–27 June 2014; pp. 703–714. [Google Scholar]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers, and Contractors; Wiley: Hoboken, NJ, USA, 2008; ISBN 9780470185285. [Google Scholar]

- Achell, J.F.P.; Pérez, I.R. Lean Construction y La Planificación Colaborativa: Metodología Del Last Planner® System; Consejo General de la Arquitectura Técnica de España: Madrid, Spain, 2019; ISBN 978-84-09-10609-7. [Google Scholar]

- Ogunbiyi, O.E. Implementation of the Lean Approach in Sustainable Construction: A Conceptual Framework. Ph.D. Thesis, University of Central Lancashire, Preston, UK, 2014. [Google Scholar]

- Dakhli, Z.; Lafhaj, Z.; Bernard, M. Application of Lean to the Bidding Phase in Building Construction: A French Contractor’s Experience. Int. J. Lean Six Sigma 2017, 8, 153–180. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A.; En-Nadi, A. A Comparative Study between Lean Construction and the Traditional Production System. Int. J. Eng. Res. Afr. 2017, 29, 118–132. [Google Scholar] [CrossRef]

- Orihuela, P.; Orihuela, J.; Pacheco, S. Communication Protocol for Implementation of Target Value Design (TVD) in Building Projects. Procedia Eng. 2015, 123, 361–369. [Google Scholar] [CrossRef][Green Version]

- Meijon Morêda Neto, H.; Bastos Costa, D.; Coelho Ravazzano, T. Recommendations for Target Value Design Implementation for Real Estate Development in Brazil. Archit. Eng. Des. Manag. 2019, 15, 48–65. [Google Scholar] [CrossRef]

- Silveira, S.S.; Alves, T. da C.L. Target Value Design Inspired Practices to Deliver Sustainable Buildings. Buildings 2018, 8, 116. [Google Scholar] [CrossRef]

- Oliva, C.A.; Denis Granja, A. An Investigation into Collaborative Practices in Social Housing Projects as a Precondition for Target Value Design Adoption. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013. [Google Scholar]

- Do, D.; Ballard, G.; Tommelein, I.D. An Analysis of Potential Misalignment of Commercial Incentives in Integrated Project Delivery and Target Value Design. In Proceedings of the 23rd Conference of the International Group for Lean Construction, Perth, Australia, 28–31 July 2015. [Google Scholar]

- Chuquín, F.; Chuquín, C.; Saire, R. Lean Design in Hydraulic Infrastructure—River Defenses and Dikes—A Case Study from Peru. In Proceedings of the IGLC2021—29th Annual Conference of the International Group for Lean Construction—Lean Construction in Crisis Times: Responding to the Post-Pandemic AEC Industry Challenges, Lima, Peru, 14–17 July 2021; Department of Engineering, Civil Engineering Division, Pontificia Universidad Catolica del Peru: Lima, Peru, 2021; pp. 585–594. [Google Scholar]

- Arroyo, P.; Ballard, G.; Tommelein, I.D. Choosing by Advantages and rhetoric in Building Design: Relationship and potential Synergies. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014. [Google Scholar]

- Demir, S.T.; Theis, P. Agile Design Management. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction (IGLC), Boston, MA, USA, 18 July 2016; p. 13. [Google Scholar]

- Lappalainen, E.; Uusitalo, P.; Seppänen, O.; Peltokorpi, A. Design Process Stability: Observations of Batch Size, Throughput Time and Reliability in Design. In Proceedings of the IGLC 2021—29th Annual Conference of the International Group for Lean Construction—Lean Construction in Crisis Times: Responding to the Post-Pandemic AEC Industry Challenges, Lima, Peru, 14–17 July 2021; pp. 605–612. [Google Scholar]

- Rosas, E. Integrating the Design Structure Matrix and the Last Planner Syste into Building Design. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013. [Google Scholar]

- Mota, B.; Biotto, C.; Choudhury, A.; Abley, S.; Kagioglou, M. Lean Design Management in a Major Infrastructure Project in UK. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 3–5 July 2019; pp. 37–48. [Google Scholar]

- Khan, S.; Tzortzopoulos, P. Effects of the Interactions Between LPS and BIM on Workflow in Two Building Design Projects. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014. [Google Scholar]

- Salazar, L.A.; Pardo, D.; Guzmán, S. Results of Key Indicators from Linguistic Action Perspective in Pandemic: Case Study. In Proceedings of the IGLC 2021—29th Annual Conference of the International Group for Lean Construction—Lean Construction in Crisis Times: Responding to the Post-Pandemic AEC Industry Challenges, Lima, Peru, 14–17 July 2021; pp. 363–372. [Google Scholar]

- Pedó, B.; Brandalise, F.M.P.; Viana, D.D.; Tzortzopoulos, P.; Formoso, C.T.; Whitelock-Wainwright, A. Digital Visual Management Tools in Design Management. In Proceedings of the IGLC28—28th Annual Conference of the International Group for Lean Construction 2020, Berkeley, CA, USA, 6–10 July 2020; The International Group for Lean Construction: Berkeley, CA, USA, 2020; pp. 901–912. [Google Scholar]

- Pedo, B.; Koskela, L.; Tzortzopoulos, P.; Tezel, A.; Robinson, S. Visual Management (VM) Supporting Collaborative Practices in Infrastructure Engineering Design. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: Depok, Indonesia, 2022; Volume 1101. [Google Scholar]

- Aka, A.; Emuze, F.; Das, D. Mapping Waste in the Structural Design Process in South African Projects. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017. [Google Scholar]

- Leite, K.P.; De, J.; Neto, P.B. Product Development and Design Management Value Stream in Housing Design. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 419–428. [Google Scholar]

- Pons, I.; Rubio, J. Colección Guías Prácticas de Lean Construction: Las 10 Claves Del Éxito Para Su Implantación; Colegio Oficial de la Arquitectura Técnica de Málaga: Málaga, Spain, 2021. [Google Scholar]

- American Institute of Architects and AIA California, & Council. Integrated Project Delivery: A Guide; American Institute of Architects and AIA California, & Council: Los Angeles, CA, USA, 2007; ISBN 09265805. [Google Scholar]

- Ballard, G.; Howell, G.; Tommelein, I.; Zabelle, T. The Last Planner Production Workbook-Improving Reliability in Planning and Workflow; Lean Construction Institute: Berkeley, CA, USA, 2007. [Google Scholar]

- Aslam, M.; Gao, Z.; Smith, G. Framework for Selection of Lean Construction Tools Based on Lean Objectives and Functionalities. Int. J. Constr. Manag. 2022, 22, 1559–1570. [Google Scholar] [CrossRef]

- Kapur, R. Managerial Functions within the Organization. Res. Gate 2018, 11, 2020. [Google Scholar]

- Arroyo, P.; Long, D. Collaborative Design Decisions. In Proceedings of the IGLC 2018—Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 18–22 July 2018; The International Group for Lean Construction: Chennai, India, 2018; Volume 1, pp. 463–472. [Google Scholar]

- Ballard, G. Toward Construction JIT. Lean Constr. 1995, 291, 300. [Google Scholar]

- Alves, T.d.C.L.; Lichtig, W.; Rybkowski, Z.K. Implementing Target Value Design: Tools and Techniques to Manage the Process. Health Environ. Res. Des. J. 2017, 10, 18–29. [Google Scholar] [CrossRef]

- Tribelsky, E.; Sacks, R. The Relationship Between Information Flow and Project Success in Multi-Disciplinary Civil Engineering Design. In Proceedings of the IGLC, Haifa, Israel, 14–16 July 2010. [Google Scholar]

- Giménez, Z.; Mourgues, C.; Alarcón, L.F.; Mesa, H. Proposal of a Model for Measuring Value in the Design Process. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 3–5 July 2019; pp. 49–62. [Google Scholar]

- Khalife, S.; Hamzeh, F. A Framework for Understanding the Dynamic Nature of Value in Design and Construction. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 3–5 July 2019; pp. 617–628. [Google Scholar]

- Barth, K.B.; Formoso, C.T.; Sterzi, M.P. Performance Measurement in Lean Production Systems: An Exploration on Requirements and Taxonomies. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 3–5 July 2019; pp. 629–641. [Google Scholar]

- EL Mounla, K.; Beladjine, D.; Beddiar, K.; Mazari, B. Lean-BIM Approach for Improving the Performance of a Construction Project in the Design Phase. Buildings 2023, 13, 654. [Google Scholar] [CrossRef]

- Mckay, J.; Marshall, P.; Grainger, N.; Hirschheim, R. Change Implementers’ Resistance: Considering Power and Resistance in IT Implementation Projects. In Proceedings of the ACIS 2012: Proceedings of the 23rd Australasian Conference on Information Systems, Geelong, Australia, 3–5 December 2012. [Google Scholar]

- Kirkman, B.L.; Jones, R.G.; Shapiro, D.L. Why Do Employees Resist Teams? Examining the “Resistance Barrier” to Work Team Effectiveness. Int. J. Confl. Manag. 2000, 11, 74–92. [Google Scholar] [CrossRef]

- Demski, S. Resistance to Change: Why Your TQM Efforts May Fail. J. Manag. Eng. 1993, 9, 426–432. [Google Scholar] [CrossRef]

- Heigermoser, D.; García de Soto, B.; Abbott, E.L.S.; Chua, D.K.H. BIM-Based Last Planner System Tool for Improving Construction Project Management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- AlSehaimi, A.O.; Tzortzopoulos Fazenda, P.; Koskela, L. Improving Construction Management Practice with the Last Planner System: A Case Study. Eng. Constr. Archit. Manag. 2014, 21, 51–64. [Google Scholar] [CrossRef]

- Sbiti, M.; Beladjine, D.; Beddiar, K.; Mazari, B. Leveraging Quantity Surveying Data and BIM to Automate Mechanical and Electrical (M & E) Construction Planning. Appl. Sci. 2022, 12, 4546. [Google Scholar] [CrossRef]

| Id | Academic Degree | Professional Title | Research Line | Years of Experience | Role | Country of Residence |

|---|---|---|---|---|---|---|

| 1 | Ph.D. | Civil Engineer | Construction Management | >25 | Professor/Consultant | Ecuador |

| 2 | Ph.D. | Civil Engineer | Situation Awareness in Construction | >25 | Consultant | Finland |

| 3 | Master’s | Civil Engineer | Lean-BIM | >25 | Manager | Germany |

| 4 | Ph.D. | Civil Engineer | Lean Construction | >25 | Professor | UK |

| 5 | Ph.D. | Architect | Target Value Delivery—Lean Design | >20 | Professor/Consultant | Chile |

| 6 | Ph.D. | Civil Engineer | Construction Management and Technology | >20 | Professor | Brazil |

| 7 | Ph.D. | Civil Engineer | Lean Construction | >15 | Professor | South Africa |

| 8 | Ph.D. | Civil Engineer | Construction Management | >10 | Professor | Colombia |

| 9 | Ph.D. | Construction Engineer | Last Planner System | >10 | Professor | Chile |

| 10 | Ph.D. | Civil Engineer | Lean-BIM in Design | >10 | Professor/Consultant | Chile |

| 11 | Ph.D. | Architect | Lean Construction | >10 | Professor | Brazil |

| 12 | Ph.D. | Civil Engineer | Construction Technology | >10 | Senior | Nigeria |

| 13 | Ph.D. | Civil Engineer | Lean-IPD | >10 | Manager | Germany |

| 14 | Ph.D. | Civil Engineer | Lean Construction | >10 | Manager | USA |

| 15 | Ph.D. | Civil Engineer | Lean-BIM-Roads | >5 | Professor | Chile |

| 16 | Bachelor’s | Civil Engineer | Construction Management | >5 | Consultant | Peru |

| Id | Academic Degree | Professional Title | Research Line | Years of Experience | Role | Country of Residence |

|---|---|---|---|---|---|---|

| 1 | Ph.D. | Civil Engineer | Construction Management | >40 | Consultant | Chile |

| 2 | Bachelor’s | Architect | Design-Construction | >40 | Professor | Peru |

| 3 | Bachelor’s | Civil Engineer | Construction | >30 | - | Finland |

| 4 | Ph.D. | Architect | TVD | >25 | Consultant/Professor | Chile |

| 5 | Master’s | Civil Engineer | Lean Construction | >25 | Consultant/Professor | Peru |

| 6 | Ph.D. | Professor | Operational Management in Construction | >20 | Professor | Finland |

| 7 | Ph.D. | Architect | Lean Construction | >20 | Professor | UK |

| 8 | Ph.D. | Civil Engineer | Virtual Design and Construction | >20 | Professor | Chile |

| 9 | Master’s | Civil Engineer | Lean | >15 | Consultant | UK |

| 10 | Master’s | Civil Engineer | BIM-Lean | >15 | Professor/Consultant | Peru |

| 11 | Ph.D. | Civil Engineer | Lean in Construction | >10 | Manager | USA |

| 12 | Ph.D. | Architect | Target Value Delivery—Lean Construction—BIM | >10 | Professor | Brazil |

| 13 | Ph.D. | Civil Engineer | Lean Construction | >10 | Professor | South Africa |

| 14 | Ph.D. | Architect | Lean Management in Design | >10 | Professor/Consultant | Brazil |

| 15 | Doctor | Civil Engineer | Lean-BIM-Roads | >5 | Professor | Chile |

| 16 | Master’s | Civil Engineer | BIM-Lean-GIS | >5 | - | Colombia |

| 17 | Ph.D. | Civil Engineer | Technology and Management in AIC Industry | >5 | Professor | Chile |

| 18 | Ph.D. (c) | Civil Engineer | Design and Planning of Road Infrastructure Projects | >5 | Professor | Chile |

| 19 | Master’s | Civil Engineer | BIM-Lean-GIS | >5 | Consultant | Colombia |

| Id | Profession | Position | Years of Experience |

|---|---|---|---|

| 1 | Architect | Architect | >30 |

| 2 | Civil Engineer | Structural Engineer | >30 |

| 3 | Architect | Architect | >20 |

| 4 | Industrial Maintenance Technician | BIM Manager | >20 |

| 5 | Civil Engineer | Structural Engineer | >18 |

| 6 | Architect | Architect | >16 |

| 7 | Civil Engineer | General Manager of Real Estate | >10 |

| 8 | Civil Engineer | Structural Engineer | >6 |

| 9 | Civil Engineer | Structural Engineer | >2 |

| 10 | Civil Engineer | Structural Engineer | >2 |

| 11 | Civil Engineer | Structural Engineer | >2 |

| 12 | Civil Engineer | Specialty Engineer (MEP) | >2 |

| 13 | Civil Engineer | Specialty Engineer (MEP) | >2 |

| 14 | Civil Engineer | Project Coordinator | >2 |

| 15 | Civil Engineer | Project Control Engineer | >2 |

| Tool | Description | Refs. |

|---|---|---|

| 5S | Sort, Set in Order, Shine, Standardize, Sustain. A process for eliminating workplace waste using visual controls. | [1,2,3] |

| Concurrent Engineering | Parallel execution of multidisciplinary tasks to optimize engineering cycles for efficiency, quality, and functionality. | [1,4] |

| Check Sheet | A structured form is used to collect and analyze data on problem patterns, events, and causes. | [1] |

| Construction Process Analysis | Updated process and flow diagrams using symbols to identify problems and improve analysis. | [1,5] |

| Six Sigma | A methodology for improving quality by eliminating defects and reducing variability in processes. | [1,2] |

| Pareto Analysis | A bar chart analyzing the frequency of causes or problems in processes, highlighting their importance. | [28] |

| Failure Mode and Effects Analysis (FMEA) | A step-by-step approach to identifying, eliminating, and prioritizing failures in products or services. | [29,30,31] |

| Continuous Flow | Operating continuously and progressively, generating or processing through sequential steps. | [32,33] |

| FIFO line (First In, First Out) | A method to manage work requests based on flow order, from first to last. | [32] |

| Jidoka/Automation | Partial automation of the manufacturing process, allows operators to perform other tasks while machines run. | [32] |

| Kanban (Pull System) | An information control process regulating resource flow, ensuring timely parts and supply requests. | [28,32] |

| Kaizen | An approach focused on improving quality and efficiency by eliminating waste. | [32] |

| The Last Planner | The methodology ensures predictable workflow and reliable project outcomes by identifying obstacles in advance. | [34] |

| Poka-Yoke (Error Proofing) | A mechanism designed to detect and prevent errors in processes, aiming for zero defects. | [28,32] |

| First Run Studies | Executing tests to determine the best means, strategies, and sequencing for a process. | [35,36] |

| Bottleneck Analysis | Identifying process bottlenecks that limit productivity and improving their performance. | [28,37] |

| Visual Management | A technique to enhance efficiency and clarity in processes through visual signals. | [32,33,35] |

| Synchronize/Line Balancing | Leveling workload across all processes in a value stream to eliminate excess capacity and bottlenecks. | [32] |

| Work Structuring | Designing and operating processes based on supply chain, resource allocation, and assembly for quality results. | [35,38] |

| 5 Whys | A problem-solving tool that repeatedly asks ‘why’ to find the root cause of a problem. | [35,38] |

| Fail-Safe for Quality | A method to detect defects and risks, similar to Poka-Yoke but focused on safety measures. | [35,36] |

| Daily Huddle Meetings | Daily team meetings promote communication, engagement, and problem-solving. | [35,36] |

| SMART Goals | Specific, measurable, achievable, relevant, and time-bound goals. | [37] |

| PDCA (Plan, Do, Check, Act) | An iterative approach: Plan, Do, Check, Act for continuous process improvement. | [37] |

| Work Standardization | Documented procedures capturing best practices, constantly updated. | [28,32] |

| Statistical Process Control | A quality control tool monitors and controls process outputs for optimal performance. | [32] |

| Just in Time (JIT) | A method reducing production flow times, supplier response, and waste. | |

| Team Preparation | Training process on waste reduction, continuous flow, and work standardization. | [32] |

| Muda Walk | Technique to identify waste by observing operations and highlighting improvement areas. | [28] |

| Value Stream Mapping | A technique to analyze, document, and visually improve process flow. | [28,37] |

| Root Cause Analysis | A problem-solving method that focuses on identifying and solving root causes instead of symptoms. | [37] |

| Set Based Design | A design methodology keeps options flexible as long as possible. | [39] |

| Prefabrication/Modular | Prefabricating building components in a controlled environment before on-site assembly. | [40,41] |

| Integrated Project Delivery | A methodology bringing key stakeholders together for project collaboration. | [42] |

| Building Information Modeling (BIM) | Software for intelligent building simulation and data-driven decision-making. | [43] |

| Theory of Constraints | A theory improving workflow by reducing constraints and ensuring steady material flow. | [36] |

| Target Value Design | A system reversing design practices where costs dictate design instead of vice versa. | [44] |

| Linguistic Action Perspective | Applying Speech Act Theory to project management, recognizing conversations as actions. | [45] |

| Choosing by Advantages | A structured decision-making system focusing on advantages to determine the best choice. | [46,47] |

| Gemba Walk | A Lean manufacturing practice emphasizing direct workplace observation. | [48] |

| A3 Report | A concise visual report for problem-solving, strategy development, and reporting. | [49] |

| Location-Based Scheduling | A scheduling method designing a continuous, uninterrupted production flow. | [50] |

| Flow line | A diagram illustrating production unit delivery over time, focusing on delivery rates. | [51] |

| Takt-time Planning | A unit of time defining production pace to meet demand while balancing workflow. | [52] |

| Integrated Concurrent Session | An integration event gathering stakeholders to accelerate design problem resolution. | [52] |

| Big Room | A project approach streamlining communication, improving decision-making, and reducing silos. | [53] |

| Total Productive Maintenance | A maintenance tool focusing on proactive and preventive equipment care. | [40,41] |

| Ishikawa Diagram | A tool for identifying and analyzing the root cause of a problem. | [54,55,56] |

| Tool | Description | Applied Case |

|---|---|---|

| Target Value Design (TVD) | It is an approach that considers Architecture, Engineering, and Construction as a complex system with definition, design, and construction phases. This approach reverses conventional design practices by making costs guide the design instead of design determining the costs. | BD * [57,58,59], SHD * [60], HBD [61] |

| Set-based Design (SBD) | Designers generate design solutions that incorporate multiple criteria, considering the schedule and budget. These solutions are collaboratively improved until a satisfactory resolution is achieved, while progressively adapting to time and cost constraints. | HID * [62], BD [62] |

| Choosing by Advantage (CBA) | It is a proven and effective decision-making method that involves evaluating the advantages of each option and determining the best alternative. | BD [63], CRD * [47] |

| Agile Design Management | The implementation of an agile approach in design management involves the ability to embrace changes flexibly and continuously add value for both designers and clients. | DS [64], SD [65] |

| Design Structure Matrix (DSM) | It is a visual tool for modeling networks that represents system elements and their interactions, facilitating problem decomposition and integration. | (BD) [66], (ID) [67] |

| Last Planner System (LPS) | This tool increases process clarity, promotes collaboration, and facilitates communication among designers while strengthening workflow stability and reliability. | BD [66,68], SD [65], ID [67] |

| Building Information Modeling (BIM) | It refers to the development and use of software to simulate the creation and operation of a building. The result is a detailed building model enriched with intelligent and parameterized data, offering insights and analysis useful for decision-making and process improvement in construction. | (BD) [62,68], (SDB) [20] |

| Linguistic Action Perspective (LAP) | This approach implies that conversations not only precede action but are actions themselves due to the commitments that arise. Conversations for action involve four fundamental speech acts: (1) request or offer, (2) promise or acceptance, (3) declaration of completion, and (4) declaration of satisfaction. | DS * [69] |

| Visual Management (VM) | Visual management refers to a set of practices that support communication through the use of various visual elements. | ED * [70] ID, [71] |

| Integrated Project Delivery (IPD) | It is a construction project execution method where key parties unite under a single agreement. This promotes continuous collaboration, reduces waste, improves efficiency, fosters team respect, and enhances project outcomes, including the benefits obtained. | HBD [61] |

| Value Stream Mapping (VSM) | It is a highly effective tool for optimizing process flow and reducing waste. Value Stream Mapping is an approach where a team maps the value stream in repetitive processes, leading team members to analyze where value is added and where it is not. | BD [62,72], HD [73] |

| Integrated Concurrent Engineering (ICE) | It involves collaboration among various actors, such as the design team, specialized engineers, and consultants. This process consists of three elements: performance metrics, BIM + simulation, and process design. This problem-solving technique accelerates solutions by considering multiple perspectives. Design reviews occur in a room where stakeholders discuss design aspects on large screens to speed up the process. | BD [62] |

| Functionality | Definition | References |

|---|---|---|

| Global Collaborative Scheduling | Initial planning that details project milestones and phases, organized by function or area, covering the entire duration and guided by constraints and objectives. | [36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77] |

| Phase Collaborative Scheduling (Pull Planning) | A team planning technique that works backward from a target date, organizing tasks to release work requested by others, reducing waste, and focusing on value addition. | [36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77] |

| Lookahead Collaborative Scheduling | An intermediate planning process that adjusts budgets and schedules, optimizes resources and coordinates activities to effectively control project workflow. | [76,77] |

| Weekly Collaborative Scheduling | The most detailed planning phase before execution, conducted by various supervisors, promotes bidirectional communication and efficiency in projects. | [36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77] |

| Data Recording and Analysis | Involves examining collected data to extract valuable information, and identify patterns, trends, relationships, or significant conclusions from documents or records. | [77,78,79] |

| Constraint Analysis | Evaluates the necessary conditions for an activity to be executed, identifying the constraints that prevent its realization. | [74,77] |

| Visual Communication | Represents design as an information flow using images, graphics, and models to improve communication, reduce time and errors, and enhance collaboration among stakeholders. | [24,77] |

| Root Cause Problem Analysis | A problem-solving approach that seeks the root cause of a problem through repeated ‘why’ questioning to resolve its origin. | [76,77] |

| Design-Construction Coordination | Effectively integrates architectural and engineering design during construction to avoid issues, and costly changes, and ensure design feasibility in practice. | [24] |

| Progress Evaluation Against Schedule | Analysis of team progress according to the schedule, measured by evaluating the number of committed tasks completed divided by the total committed tasks and comparing it to the target progress. | [74,77] |

| Open, Transparent Communication Sharing Information with the Entire Team | Direct and honest exchange of information without blame, promoting problem-solving, cooperation, and trust in projects and organizations. | [75,77] |

| Stakeholder Involvement | Stakeholder involvement involves collaboration among clients, architects, engineers, contractors, and specialists to achieve common goals, prevent design changes, and improve the client’s technical understanding. | [24,77] |

| Optimization of Value/Cost Ratio for the Client | Identifying needs through regular dialogue, optimizing costs and schedules, avoiding scope changes, and ensuring client satisfaction. | [24,77] |

| Exploration of Alternative Solutions | The evaluation of options by a design team based on project requirements and preferences, promoting participation and considering diverse perspectives. | [75] |

| Effective Teamwork | Collaboration in a project team where members are committed to goals and values, led by the most qualified individuals, with defined roles and open communication. | [75,77] |

| Identification and Minimization of Non-Value-Added Activities | Recognizing necessary activities where some add value, and others do not, by mapping the value flow to eliminate or minimize non-value-adding activities. | [74,77] |

| Anticipation and Rapid Problem-Solving | Based on foreseeing problematic situations, identifying patterns or difficulties that may arise in the future, and, if they occur, quickly and effectively finding collaborative solutions. | [74,77] |

| Commitment Management | Ensures responsible fulfillment of agreements and tasks, ensuring efficiency and punctuality in work environments. | [74,76,77] |

| Creation of New Workflows | Designing and implementing efficient procedures or systems for performing specific tasks or processes within an organization. | [62,77] |

| Complexity Reduction | Aims to simplify tasks, processes, and complex systems to make them more straightforward and understandable. | [66,77] |

| Customer Value Focus | Focuses on creating value by eliminating superfluous activities, promoting collaboration among stakeholders, defining value, and committing to the client to establish value goals. | [24] |

| Continuous Improvement | The constant pursuit of perfection through regular application of Lean concepts, measurement, analysis, and practice adjustments to optimize efficiency and customer satisfaction. | [24,77] |

| Reliable Information Flow (Consistent and Accurate) | Timely and accurate data delivery between teams, avoiding causes of design changes, ensuring reliability, and eliminating unnecessary or incorrect information. | [24] |

| Communication Instances | Different moments or events where interaction occurs within a work team, including the exchange of information. | [62,74] |

| Reduction of Workload on Individuals | Reduction in the number of tasks or activities assigned to an individual or a work team. | [67] |

| Prevention of Project Delays | Additional time periods are incorporated after processes with variable outcomes to serve as scheduling buffers and prevent project delays. | [77,80] |

| Planning | Organizing | Directing | Control | Global |

|---|---|---|---|---|

| Global collaborative scheduling | Design-construction coordination | Open and transparent communication | Data recording and analysis | Visual communication |

| Phase collaborative scheduling (Pull planning) | Complexity reduction | Identification and minimization of losses | Constraint analysis | Optimization of value/cost ratio for the client |

| Lookahead collaborative scheduling | Stakeholder involvement | Anticipation and rapid problem-solving | Root cause analysis of problems | Focus on value for the client |

| Weekly collaborative scheduling | Effective teamwork | Consistent and accurate information flow | Progress evaluation against the schedule | Continuous improvement |

| Exploration of alternative solutions | Commitment management | Reduction of team workload | - | Prevention of project delays |

| Creation of new workflows | Communication instances | - | - | - |

| Functionality | Tools |

|---|---|

| Global collaborative scheduling | TVD [59], ADM [64], LPS [67,77] [*], BIM [*], VM [*] |

| Phase collaborative scheduling (Pull planning) | LPS [77] [*], BIM [*], LAP [*], VM [*], JIT [77] |

| Lookahead collaborative scheduling | LPS [77] [*], BIM [*], LAP [*], VM [*] |

| Weekly collaborative scheduling | ADM [*], LPS [71,77] [*], LAP [*], VM [*] |

| Exploration of alternative solutions | TVD [*], SBD [62,77] [*], CBA [63] [*] |

| Creation of new workflows | BIM [*], DSM [70], IPD [*], VSM [62], ICE [*], A3 Report [*] |

| Design-construction coordination | TVD [60,77] [*], SBD [77], ADM [*], LPS [67], BIM [62] [*], DSM [*], VM [*], IPD [61,77], |

| Complexity reduction | SBD [77], ADM [64] [*], LPS [68], BIM [68,77] [*], DSM [66] [*], VM [70] [*], IPD [77], VSM [62,77], ICE [*], A3 Report [*] |

| Stakeholder involvement | TVD [57,59,77] [*], SBD [62,77], CBA [47], ADM [64], LPS [67,77] [*], BIM [62] [*], LAP [*], VM [70], IPD [77] [*], VSM [62,73,77], ICE [*], JIT [77] |

| Effective teamwork | TVD [57,59] [*], SBD [77], CBA [63] [*], ADM [64] [*], LPS [67,68] [*], BIM [*], DSM [66], LAP [*], VM [70], IPD [61] [*], VSM [62], ICE [62], JIT [77] |

| Commitment management | SBD [62], ADM [*], LPS [67] [*], LAP [45,69] [*], VM [70], IPD [*], |

| Communication instances | TVD [*], SBD [62], CBA [63], ADM [64] [*], LPS [67] [*], BIM [62] [*], LAP [69] [*], VM [70] [*], IPD [*], VSM [62], ICE [62], A3 Report [*] |

| Open and transparent communication | SBD [77], CBA [63], ADM [64] [*], LPS [67] [*], BIM [77] [*], DSM [67], LAP [*], VM [*], IPD [61,77] [*], VSM [62,74,77], ICE [62] [*], A3 report [*], JIT [77] |

| Identification and minimization of losses | LPS [20] [*], BIM [62] [*], VM [70], VSM [62,74,77] [*], 5S [*], 5why [*], JIT [*] |

| Anticipation and rapid problem-solving | ADM [*], BIM [*], VM [77], IPD [*], ICE [*] |

| Consistent and accurate information flow | LPS [24], BIM [62] [*], DSM [66] [*] |

| Reduction of team workload | ADM [67], LPS [*], BIM [68], LAP [45,69], VSM [*], ICE [*], |

| Data recording and analysis | TVD [60,77], ADM [*], LPS [77] [*], BIM [20] [*], VM [70], VSM [74,77], A3 Report [79,81] |

| Constraint analysis | ADM [*], LPS [68,77] [*], BIM [*], |

| Root cause analysis of problems | LPS [68], A3 Report [*], 5 why [76] [*] |

| Progress evaluation against the schedule | LPS [67] [*], LAP [45,69] |

| Visual communication | LPS [66], BIM [20,62] [*], DSM [66], VM [70] [*], VSM [62], ICE [62], A3 Report [81] [*],5S [77] |

| Optimization of value/cost ratio for the client | TVD [57,77] [*], SBD [62] [*], BIM [77], IPD [61] [*] |

| Focus on value for the client | TVD [57,58] [*], SBD [62] [*], CBA [63], BIM [20], IPD [61,77] [*], ICE [*] |

| Continuous improvement | TVD [59], SBD [77], ADM [*], LPS [77] [*], BIM [*], LAP [*], VM [77], IPD [77], VSM [62] [*], A3 Report [*],5S [*],5 Why [*] |

| Prevention of project delays | ADM [*], LPS [77] [*], DSM [*], LAP [*] |

| Building Design Tools | Functionalities According to Literature (%) | Functionalities According to Experts (%) | Difference Between Literature and Experts (%) |

|---|---|---|---|

| Last Planner System (LPS) | 65% | 62% | 4% |

| Building Information Modeling (BIM) | 50% | 62% | −12% |

| Agile Design Management (ADM) | 27% | 46% | −19% |

| Linguistic Action Perspective (LAP) | 15% | 42% | −27% |

| Visual Management (VM) | 42% | 38% | 4% |

| Integrated Project Delivery (IPD) | 31% | 38% | −8% |

| A3 Report | 12% | 35% | −23% |

| Integrated Concurrent Engineering (ICE) | 15% | 31% | −15% |

| Target Value Design (TVD) | 31% | 27% | 4% |

| Design Structure Matrix (DSM) | 19% | 19% | 0% |

| 5 Why | 15% | 15% | 0% |

| Value Stream Mapping (VSM) | 46% | 12% | 35% |

| Set-Based Design (SBD) | 42% | 12% | 31% |

| Choosing by Advantage (CBA) | 23% | 12% | 12% |

| 5S | 4% | 8% | −4% |

| Just In Time (JIT) | 4% | 4% | 0% |

| Combinations | Covered Functionalities |

|---|---|

| LPS-BIM | 88% |

| ADM-BIM | 88% |

| BIM-LAP | 81% |

| BIM-IPD | 81% |

| LPS-A3 Report | 81% |

| BIM-VM | 77% |

| LPS-VM | 77% |

| ADM-LPS | 73% |

| Tools | Benefits | Disadvantages and/or Limitations |

|---|---|---|

| Agile Design Management |

|

|

| Last Planner System (LPS) |

|

|

| Building Information Models (BIM) |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luna, A.; Herrera, R.F.; Castañeda, K.; Atencio, E.; Biotto, C. Benefits and Limitations of Lean Tools in the Building Design Process: A Functional and Comparative Analysis. Appl. Sci. 2025, 15, 5137. https://doi.org/10.3390/app15095137

Luna A, Herrera RF, Castañeda K, Atencio E, Biotto C. Benefits and Limitations of Lean Tools in the Building Design Process: A Functional and Comparative Analysis. Applied Sciences. 2025; 15(9):5137. https://doi.org/10.3390/app15095137

Chicago/Turabian StyleLuna, Adriana, Rodrigo F. Herrera, Karen Castañeda, Edison Atencio, and Clarissa Biotto. 2025. "Benefits and Limitations of Lean Tools in the Building Design Process: A Functional and Comparative Analysis" Applied Sciences 15, no. 9: 5137. https://doi.org/10.3390/app15095137

APA StyleLuna, A., Herrera, R. F., Castañeda, K., Atencio, E., & Biotto, C. (2025). Benefits and Limitations of Lean Tools in the Building Design Process: A Functional and Comparative Analysis. Applied Sciences, 15(9), 5137. https://doi.org/10.3390/app15095137