Abstract

The aim of the study was to develop a new generation of potato-based snack granules enriched with fresh blueberries and evaluate the extrusion-cooking process along with selected physical properties. Blueberries were added in varying amounts (10%, 20%, and 30%) as an ingredient for the semi-finished product. The analysis focused on the impact of moisture content, screw speed, and blueberry concentration on extrusion efficiency and product properties. The results showed significant effects of blueberry addition on extrusion-cooking efficiency (14.40 to 37.12 kg/h) and energy consumption (0.003 to 0.021 kWh/kg). Durability, bulk density, water absorption index (WAI) and water solubility index (WSI) were evaluated with values ranging from 95.46 to 97.61%, 345.07 to 547.37 kg/m3, 2.90 to 3.88 g/g and 8.23 to 18.52%. The incorporation of blueberries also eliminated the need for drying, reducing water consumption and energy demand. Additionally, the antioxidant potential of the blueberry-enriched samples was assessed, indicating improved health benefits (DPPH from 22.71 to 94.22%). Based on the results, the incorporation of up to 30% blueberries is recommended for optimal physical properties and enhanced antioxidant activity.

1. Introduction

Blueberry (Vaccinium corymbosum L.), a fruit from the Ericaceae family, is becoming increasingly popular due to health benefits and pleasant taste. It is a rich source of bioactive compounds, such as vitamins, anthocyanins, phenolic compounds and essential minerals [1,2,3]. The most important vitamins found in blueberries include vitamin C, E and K, while anthocyanins, flavonoids and phenolic acids are the main phenolic compounds [4,5]. Studies on commercial blueberry samples have shown that the vitamin C content in fresh fruit ranges from 3.4 to 9.5 mg per 100 g, anthocyanin content from 25 to 495 mg/100 g and quercetin from 24 mg/100 g. The total phenolic content ranges from 48 to 304 mg/100 g [6,7]. Regular consumption of blueberries is associated with a number of health benefits, including a reduced risk of cardiovascular diseases, anti-inflammatory effects and protection against neurodegenerative disorders. Anthocyanins in blueberries exhibit strong antioxidant properties, neutralizing free radicals and protecting cells from oxidative damage [8,9,10]. These compounds also demonstrate anticancer activity, as confirmed by numerous in vitro and in vivo studies. Fruit processing methods, including those applied to blueberries, can lead to significant losses of nutrients [11]. Traditional thermal treatments such as boiling, baking and pasteurization have been shown to reduce anthocyanin and vitamin content. Boiling blueberries in water causes leaching of antioxidant compounds and the extent of loss increases with longer thermal processing times [12,13,14].

One of the fruit processing methods with high potential is extrusion-cooking technology. Extrusion-cooking involves the mechanical processing of food materials under the influence of high pressure, shear forces and controlled temperature [15,16,17,18]. The ability to precisely adjust the temperature during the extrusion-cooking process helps to minimize the degradation of heat-sensitive nutrients and bioactive compounds. As a result, it is possible to produce food with high health-promoting value and improved sensory qualities [19,20]. Extrusion-cooking is widely used in the production of both functional foods and various snack products [21,22]. Blueberries can serve as a valuable functional addition to such products. This additive has recently become popular for its health-promoting properties resulted from high content of bioactive compounds such as anthocyanins, phenolic acids and flavonoids. To date, some types of functional food enriched with the fruit was evaluated. Blueberries are added in form of powder, juice, extract, dried fruit etc. Despite significant pro-health activity of the additive, relatively few products with documented by scientists’ activity are available on the market. Most of papers are based on quality/quantity analysis and biological activities of selected form of blueberry additive. Example of analysis of functional food product are studies based on exploration the enrichment of extruded snacks made from rice and buckwheat flour with blueberry powder, evaluating their sensory and antioxidant properties. These studies have shown that increasing the amount of blueberry in the formulation leads to a rise in antioxidant activity and an improvement in nutritional profile. Significant decreasing of fat content and starch was also recorded [23]. Interesting studies based on preparation of blueberry juice powders as potential functional food ingredients were also presented [24]. Scientists explicitly indicate that the freeze-dried juice powders can be used as rich source of pro-health secondary plant metabolites as well as for stabilization new assortment of functional food. The resulting powders exhibited favorable properties, including low water activity (below 0.5), high solubility (exceeding 90%), and efficient retention of bioactive compounds—recovering over 70% of total phenolics and more than 60% of total monomeric anthocyanins. Their antioxidant capacity reached up to 4 mg gallic acid equivalents per gram of dry matter. Many papers based on functional foods enriched with berries are available. Example can be studies presented by Lucas et al. [25] who focused on determination physicochemical properties and constituents of extrudates enriched with acai. Results revealed that the natural additive significantly improved pro-health and nutritional values including anthocyanins (from 0 to 20.1 mg/100g), carotenoids (from 1.6 to 6.2 µg/g), protein content by 6.3% as well as mineral content up to 32.2%. It is worth to mention that our previous studies based on another barriers, namely Aronia melanocarpa confirmed significant influence of the fruits on pro-health properties of new assortment of functional food [26]. In this case, the potato-based snack pellets enriched with 10% and 30% of fresh chokeberry revealed significant increase in antioxidant activity (from 20% to 90% of free radical scavenging), increase in crude protein and crude ash.

The aim of this study was to determine the optimal extrusion-cooking conditions, including screw speed, moisture content and the amount of fresh blueberry to produce snack pellets with high health-promoting value and desirable sensory quality. At the same time, the research focused on reducing water usage and minimizing the loss of bioactive compounds, aligning with the principles of sustainable development.

2. Materials and Methods

2.1. Materials

The extrusion-cooking process of snack pellets enriched with fresh blueberries was thoroughly developed and tested in the laboratories of the Department of Process Engineering at the University of Life Sciences in Lublin in 2021. The main goal of the study was to create innovative snack products with high health-promoting potential, physical quality and environmental value by incorporating fresh blueberries as a functional ingredient.

The preparation of the snack pellets followed specifically developed formulations, with fresh blueberries (Calypso, harvest data and location: first week of August, Rossosz, Poland) sourced from local producer (Parafiniuk Sp. z o.o., Rossosz, Poland) as the primary ingredient. The blueberry cultivar was selected based on sensory attributes, including flavor, fruit size and firmness, as well as the timing of harvest to ensure optimal maturity. Other components used in the production process included high-quality potato starch (from Przedsiębiorstwo Przemysłu Ziemniaczanego Bronisław S.A., Bronisław, Poland), potato flakes (Zakłady Przemysłu Ziemniaczanego w Lublinie, Lublin, Poland), rapeseed oil (Zakłady Tłuszczowe “Kruszwica”, Kruszwica, Poland), beet sugar (Krajowa Spółka Cukrowa S.A., Toruń, Poland) and salt (CIECH Soda Polska S.A., Innowrocław, Poland). The use of fresh blueberries aimed to enrich the snacks with bioactive compounds such as vitamin C, anthocyanins, and phenolic compounds, all known for their strong antioxidant and anticancer properties. For comparison, a control sample without the addition of fresh blueberries was also prepared. This allowed for the assessment of the actual impact of the fruit addition on the final product’s structure, physical and functional properties.

2.2. Preparation of Mixtures and Extrusion-Cooking Process

At the beginning of the experiment, raw material mixtures were prepared based on the formulations developed for this study. The addition of fresh blueberries was carried out at three levels: 0%, 10%, and 30% of the total weight of all ingredients used (Table 1). These levels were selected based on preliminary research and a review of relevant literature, as they were considered sufficient to achieve the desired health benefits without significantly affecting the sensory and textural properties of the final products [26]. The inclusion of fresh fruit at levels exceeding 30% may result in processing challenges, including extrusion-cooking instability, fluctuations in pressure and temperature and a decline in the quality of the extrudates. The fresh blueberries, sourced from local suppliers, were blended using a Germin CY-329 blender (Germin Berlinger, Jarosław, Poland). Each batch (4.5 kg) was prepared separately, maintaining the appropriate ratios depending on the selected fruit content. To ensure uniform distribution of all ingredients and consistent moisture, the mixtures were sieved. Afterward, the prepared samples were stored under refrigeration for 24 h, allowing for moisture stabilization and homogeneous blending of components.

Table 1.

Percentage content of individual components in blends.

After this stage, the moisture content of the samples was determined. Based on the results of previous studies and current technological knowledge, each mixture was then adjusted to three target moisture levels: 32% and 36%. The selection of these moisture levels was aimed at ensuring a stable extrusion process and obtaining snack pellets with high sensory quality and desirable texture. After that, the samples were kept in a fridge for 24 h. This helped to even out the moisture and let all the ingredients blend together properly.

Before the extrusion-cooking process, the water content of each mixture was checked using a MA50R moisture analyzer (Radwag, Radom, Poland), which measures with high accuracy (up to 0.001%). Based on the results, the samples were moistened as needed to reach one of the planned levels: 32% and 36%. This variation was intended to evaluate how moisture content affects the extrusion-cooking process and the quality of the final product. To ensure the even distribution of fresh blueberries throughout the mixtures and to unify the moisture level, each batch was also sieved through a 0.5 mm mesh screen.

The extrusion-cooking process of snack pellets enriched with fresh blueberries was carried out using a single-screw extruder-cooker EXP-45-32 (Zamak Mercator, Skawina, Poland), equipped with a plasticizing system with a screw length-to-diameter (L/D) ratio of 20. To examine the effect of screw speed on the quality of the final products, the process was conducted at two screw speeds: 60 rpm and 100 rpm. The process settings were based on previous research experience and the properties of the raw material mixtures. The temperature range in the heating zones of the extruder-cooker was set from 44 °C to 68 °C to help preserve as many bioactive compounds as possible from the fresh blueberries (Table 2).

Table 2.

Temperature in different extruder-cooker sections.

In summary, each of the prepared batches (4.5 kg) with different percentages of blueberry addition (0, 10 and 30%) was moistened to the planned levels (32 and 36%) and used to obtain extrudates at two different extruder-cooker screw speed (60 and 100 rpm).

After passing through the plasticizing section, the dough was shaped into flat strips using a ring die with dimensions of 25 mm × 0.6 mm and then were cut into a ring shape with a diameter of approximately 2 mm and a thickness of 1.5 mm. The formed extrudates were dried in a laboratory shelf dryer at 40 °C for 12 h to reached a final moisture content approximately 9%. This moisture level ensured microbiological stability and the desired texture of the products. After drying, the samples were placed in resealable plastic bags to protect them from air and moisture until further analysis.

2.3. Efficiency of the Extrusion-Cooking Process

To evaluate the efficiency of the extrusion-cooking process, a quantitative analysis of the product exiting the forming die was carried out. The measurement involved weighing the extruded material at regular 30-s intervals, while all processing parameters, including feed rate and device settings, remained constant throughout the test. Each measurement was performed three times to reduce the impact of random issues and increase the accuracy and reliability of the results. A high-precision electronic stopwatch (Allright Classic ST01, Poznań, Poland) was used to measure time intervals, while the weight of the samples was measured using a digital scale (model DS-788, Yakudo, Tokyo, Japan). Time intervals for each measurement were recorded using the stopwatch, ensuring precise monitoring of sample handling during the experiment. Based on the collected data, the average mass of the product was calculated and used as an indicator of process efficiency. This value was considered representative for each specific set of process conditions. The applied methodology was according to Matysiak et al. [27], who developed a similar system for evaluating extrusion-cooking efficiency in mixtures based on potato flour. Adapting this method for extrudates with fresh blueberries allowed for a reliable comparison of the effects of different processing settings on production efficiency. The calculations were made based on the following formula:

where Q means extrusion-cooking process efficiency (kg/h), m is a mass of extrudate exiting through the die (kg), t denotes time (h).

2.4. Energy Consumption of the Extrusion-Cooking Process

During the extrusion-cooking process, active power consumption was monitored using a built-in wattmeter, which is an integral part of the extruder’s equipment. The device recorded data related to the motor’s operation, including voltage, current and load in real time, providing a basis for further energy calculations. Based on the motor’s technical specifications and the operating parameters recorded during the trial, the mechanical energy demand per unit mass of processed material was calculated. This value defined as Specific Mechanical Energy (SME), is an important indicator of the energy efficiency of the extrusion-cooking process. The calculations followed the procedure proposed by Matysiak et al. [27], which takes into account both the power consumed by the motor and the process throughput. A mathematical formula was used to convert the recorded data into SME values, allowing for the estimation of the amount of mechanical energy delivered to the raw material during process:

where means SME is the specific mechanical energy (kWh/kg), n is screw speed per minute (rpm), nm is the maximum extruder-cooker rotational speed (rpm), O denotes the engine load (%), P is nominal electrical power as specified on the control panel (kW) and Q means the extrusion-cooking process efficiency (kg/h).

2.5. Bulk Density of Snack Pellets

Bulk density of the obtained snack pellets was determined by Combrzyński et al. [28], calculating the ratio of the sample’s mass to volume. The weight of each sample was measured using a digital scale (model DS-788, Yakudo, Tokyo, Japan) with an accuracy of 0.001 kg, while the volume was determined using a cylindrical container with 1 L of capacity. Each sample was measured three times, which ensured high measurement accuracy, estimated at 0.01 kg/m³. The final bulk density value for each sample was calculated as the arithmetic mean of the three measurements, which influenced to reduce the effect of random issues and improve the reliability of the results. The bulk density value was calculated according to the equation proposed by:

where BD means bulk density (kg/m3), m denotes sample mass (kg) and V container volume (m3).

2.6. Durability of Extrudates

The durability of snack pellets was evaluated by measuring their resistance to rotational forces in a closed test chamber. The assessment was carried out using a Pfost-type device, which generates a specific level of kinetic energy necessary to induce mechanical stress within the sample. This method enables a more precise evaluation of the material’s resistance to breakage and helps identify potential structural weaknesses in the pellets. The resulting durability values can be used to compare the quality of different snack types or to optimize the production process, supporting the delivery of high-quality final products and improving their stability during transport and storage. The tests were conducted according to the procedure described by Wójtowicz et al. [29], ensuring both repeatability and compliance with established standards. Each sample was tested three times and the arithmetic mean of the results was calculated to provide a more accurate representation of the pellets’ mechanical durability:

where D is the Durability (%), mpt weight of the sample after the test in the chamber (g), mi is initial sample mass (g).

2.7. Water Absorption Index of Snack Pellets

The Water Absorption Index (WAI) was determined according to the procedure described by Bouasla et al. [30], which allows for evaluating the water-binding capacity of the tested extrudates. For the analysis, 0.7 g of ground sample was accurately mixed with 7 mL of distilled water. The mixture was stirred continuously for 20 min to ensure even hydration of the particles. After mixing, the resulting suspension was centrifuged for 10 min at 15,000 rpm using a Digicen 21 centrifuge (Labsystem, Kraków, Poland). Once separated, the supernatant was carefully removed and the remaining gel was weighed using a precision laboratory scale WPS 210/C (Radwag, Radom, Poland) with an accuracy of 0.001 g. The measurement was performed three times for each sample and the final WAI value was calculated as the average of the obtained results. The calculations were carried out using an appropriate formula that expresses the product’s ability to retain water after contact with a liquid:

where WAI is the Water Absorption Index expressed in g/g, mg is the mass of the gel after centrifugation (g), ms is the mass of the dry sample used in the analysis (g).

2.8. The Water Solubility Index of Snack Pellets

The Water Solubility Index (WSI) was determined according to the method described by Kupryaniuk et al. [31], as a continuation of the WAI measurement procedure. After centrifugation and separation of the supernatant, the liquid phase was evaporated under laboratory conditions. The drying process was carried out in a chamber dryer SLW 53 STD (Pol-Eko Aparatura S.J., Wodzisław Śląski, Poland) at a constant temperature of 110 °C, until complete water removal. The residue left after evaporation—representing the water-soluble solid fraction—was weighed using a precision laboratory micro balance WPS 210/C (Radwag, Radom, Poland), with a measurement accuracy of 0.001 g. Each sample was measured three times, ensuring reliable results. The final WSI value was calculated as the average of the three measurements, using a formula that expresses the percentage of water-soluble substances relative to the original sample mass:

where WSI—Water Solubility Index (%), mv—mass of the container before drying (g), mdv—mass of the container after drying, including dry residue (g), ms mass of the dry sample used for the analysis (g).

2.9. Preparation of Extracts

The extraction process was carried out using an ultrasonic bath (Bandelin Electronic GmbH & Co. KG, Berlin, Germany) operating at 60 °C, with an ultrasound frequency of 33 kHz and a power output of 320 W. To prepare the extracts, 4 g of ground extrudates were mixed with 80 mL of methanol (99.8%) and sonicated for 40 min. After sonication, the mixture was filtered, and the residue was subjected to a second extraction using another 80 mL of methanol under the same conditions. The two methanolic extracts were then combined, evaporated to dryness, and reconstituted in 10 mL of methanol. These final extracts were analyzed for their antioxidant activity (free radical scavenging capacity), total phenolic content, and total free phenolic acids.

2.10. Evaluation of Free Radical Scavenging Activity—DPPH Method

The free radical scavenging activity of the prepared extracts was assessed using the DPPH (2,2-diphenyl-1-picrylhydrazyl) assay. This analysis followed a modified version of the method described by Burda and Oleszek [32], utilizing a Genesys 20 UV-VIS spectrophotometer (Thermo Scientific, Waltham, MA, USA). Measurements were conducted at a wavelength of 517 nm, recorded every 5 min over a 30-min period, with pure methanol used for calibration. Each sample was tested in triplicate. The antioxidant activity was calculated using the following equation:

where: A0—absorbance of sample (DPPH) without tested extract; A1—absorbance of sample (DPPH) with tested extract.

2.11. Content of Phenolic Acids

Phenolic acid profiling in wheat grain samples was conducted using a Waters ACQUITY UPLC system (Waters Corp., Milford, MA, USA) equipped with a photodiode array (PDA) detector and a triple-quadrupole mass spectrometer (Waters Corp.). Extracts, prepared at a concentration of 50 mg/mL, were separated on a Waters ACQUITY UPLC®® HSS C18 column (100 × 2.1 mm, 1.8 µm particle size) maintained at 30 °C. The mobile phase consisted of solvent A (0.1% formic acid in Milli-Q water) and solvent B (acetonitrile with 0.1% formic acid). Separation was achieved through a combination of isocratic and gradient elution at a flow rate of 0.50 mL/min under the following gradient program: 0–0.5 min, 8% B; 0.5–8 min, 8–20% B; 8–8.10 min, 20–95% B; 8.10–10 min, 95% B; 10–10.10 min, 95–8% B; 10.10–12 min, 8% B. The injection volume was 2.5 μL using full loop mode. Detection of phenolic acids was carried out in negative ion mode with selected reaction monitoring (SRM). The mass spectrometry conditions followed those outlined by Czaban et al. [33]. Phenolic acid concentrations were determined using calibration curves (Table 3).

Table 3.

Parameters of the calibration curve for nine different phenolic acids.

2.12. Total Content of Polyphenolic Compounds (TPC) with Use of Folin-Ciocalteu Method

The total phenolic content was determined using a modified version of the Folin–Ciocalteu (FC) method. Specifically, 200 μL of each extract was combined with 1.8 mL of distilled water. Following this, 200 μL of the FC reagent was added to the mixture, which was then stirred and allowed to stand for 5 min. Subsequently, 2 mL of 7% sodium carbonate (Na2CO3) solution was added, and the mixture was incubated at 40 °C for 60 min. Absorbance was measured at 760 nm using a Genesys 20 UV-VIS spectrophotometer (Thermo Scientific, Waltham, MA, USA). The phenolic content was quantified and expressed as micrograms of gallic acid equivalents (GAE) per gram of dry matter (d.m.).

2.13. Statistical Analysis

All the statistical analyses were done using Statistica 13.3 software (StatSoft Inc., Tulsa, OK, USA). The obtained data were analyzed with one-way (ANOVA) analysis of variance followed by the post hoc test with the Fisher’s LSD (least significant difference) at the significance level of α = 0.05 to assimilate mean values. To verify the assumptions of normality of the variables and homogeneity of variances, the Shapiro–Wilk and Levene tests were conducted.

3. Results and Discussion

3.1. Impact of Ingredients and Processing Conditions on Extrusion-Cooking Process

The analysis showed that the efficiency of the extrusion-cooking process was significantly influenced by three main technological factors: screw speed, moisture content of the mixture and the level of fresh blueberry addition (Table 4). The interactions between these factors affected both the processing capacity of the system and the material flow efficiency through the extruder-cooker barrel. One of the most noticeable trends was the increase in efficiency with higher screw speed. For each tested combination of moisture level and blueberry content, extrusion-cooking at 100 rpm resulted in clearly higher efficiency compared to 60 rpm. This effect can be attributed to more efficient material transport through the barrel and more dynamic die filling. The increase in screw speed plays a crucial role in enhancing the overall efficiency of the extruder, as it promotes better flow and reduces the resistance of the material, thereby improving it. For example, in the case of a mixture without blueberries and 36% moisture, increasing the screw speed from 60 to 100 rpm raised the throughput from 21.84 to 36.16 kg/h, representing an increase of over 60%. Another important factor was the addition of fresh blueberries, which tended to reduce process efficiency, especially at higher addition levels. This was likely due to the presence of bioactive components—such as fiber, pectin, and additional moisture from the fruit—which increased the viscosity and flow resistance of the mixture. As a result, at 30% blueberry content, with 36% moisture and 60 rpm, the throughput dropped to 14.40 kg/h, the lowest value recorded among all tested combinations. In comparison, under the same conditions without blueberries, the throughput was 21.68 kg/h, confirming the negative impact of a raw material high in moisture and fiber. The effect of moisture content on extrusion-cooking efficiency was less consistent and depended on other factors. At lower blueberry levels (0–10%), a higher moisture content (36%) improved throughput, likely due to reduced internal friction and better dough formation. However, at 30% blueberry addition, this effect disappeared or reversed—excess moisture combined with high fruit content led to overloading of the feed system and material flow difficulties, significantly reducing the mass efficiency.

Table 4.

Results of extrusion-cooking efficiency and energy consumption of snack pellets.

The results obtained in the present study showed that increasing the screw speed from 60 to 100 rpm led to a significant improvement in productivity (e.g., from 21.6 to 36.0 kg/h for a blend without blueberries). This confirms the general relationship between increased material transport and increased extruder productivity. Similar trends regarding the influence of processing parameters on extrusion-cooking efficiency were reported by Bouasla et al. [34], who analyzed the production of gluten-free extrudates based on rice and legumes. The authors demonstrated that both screw speed and raw material composition significantly affected process performance—highest efficiency was achieved at higher screw speeds and moderate moisture content. The results have shown that an increase in the screw speed from 60 to 100 rpm led to a significant increase in process efficiency (from 10.56 to 16.8 kg/h). At the same time, Bouasla et al. observed that plant-based additives rich in fiber may lead to higher flow resistance, thereby reducing process efficiency. This observation is consistent with the current findings, where increasing the fresh blueberry content to 30% resulted in a notable decline in efficiency, particularly at higher moisture content.

In summary, the highest throughput (37.12 kg/h) was achieved with a mixture containing 10% blueberry, 32% moisture, and a screw speed of 100 rpm. This suggests the presence of an optimal fruit addition level, which under favorable conditions may enhance rather than hinder process efficiency. Conversely, the lowest efficiency (14.40 kg/h) was recorded for the mixture with the highest moisture (36%) and blueberry content (30%), processed at the lowest screw speed (60 rpm).

The results of the analysis showed that SME (Specific Mechanical Energy) was notably affected by the process parameters, including screw speed, blueberry content, and the moisture level in the mixture (Table 4). A significantly decreasing trend in SME was observed with increasing screw speed and higher content of fresh blueberry addition in the raw material composition. The highest SME values were observed for samples without blueberry addition, processed at the lower screw speed of 60 rpm—measuring 0.038 kWh/kg (at 32% moisture) and 0.034 kWh/kg (at 36%). However, when the screw speed increased to 100 rpm, the mechanical energy consumption decreased noticeably. For the same samples (without blueberry), SME dropped to 0.016 kWh/kg (32%) and 0.022 kWh/kg (36%). The decrease in SME with the increase in rotational speed for the control sample may result from the decrease in the viscosity of the processed mass due to the higher thermomechanical interactions at higher rotational speeds [35]. The whole process affects the easier liquefaction of the suspension and the easier flow of the material through the plasticizing system, which ultimately affects the lower energy consumption of the device.

The addition of fresh blueberries had a significant effect on reducing SME, especially at the 10% addition level. The specific mechanical energy values in this group were among the lowest recorded across all tested samples. The minimum SME was noted at 0.003 kWh/kg (100 rpm, 36% moisture). This low energy consumption may be attributed to the presence of natural fruit juices, which likely increase the plasticity of the mixture and facilitate material flow through the extruder-cooker, thereby reducing flow resistance during processing. This effect is likely due to the shorter residence time of the material in the plasticizing section at higher speed, which leads to less intense mechanical processing. At the highest blueberry addition level (30%), SME values began to increase again, particularly at higher screw speed. For example, at 100 rpm and 32% moisture, SME reached 0.021 kWh/kg, a value comparable to control sample. This suggests that an excess of fruit may lead to inconsistencies in the structure of the processed mass, resulting in higher friction within the extruder-cooker and thus increased mechanical energy demand. Moisture content of the mixture also influenced SME values, although the effect was less consistent. For the control sample, increasing moisture from 32% to 36% at 60 rpm led to a decrease in SME, which can be explained by improved slippage and reduced internal friction. However, in mixtures with 30% blueberry, the trend was reversed—SME increased with higher moisture levels. This may indicate that the optimal hydration level was exceeded, leading to deterioration in the rheological properties of the raw material and greater mechanical resistance during processing. The lowest specific mechanical energy consumption (SME) was recorded for the mixture with 10% blueberry, at 36% moisture and a screw speed of 100 rpm, reaching 0.003 kWh/kg. In contrast, the highest SME was observed for the mixture without blueberry, at 32% moisture and 60 rpm, with a value of 0.038 kWh/kg. This indicates a more than threefold difference between the extreme cases, highlighting the strong influence of both formulation and process parameters on energy efficiency during extrusion-cooking process.

The authors also found that increasing the moisture content of the mix, especially when combined with fresh blueberries, resulted in a decrease in SME. The water from the fruit further improved hydration, reduced flow resistance and lowered the mechanical energy needed for processing. A similar effect was observed in the study by Kantrong et al. [36] where the impact of extrusion-cooking process parameters on the physical properties of rice and mushroom-based snacks was analyzed. The authors showed that at the highest raw material moisture content (18%), the SME value decreased. Feed moisture content in this research was from 12 to 18%.

SME results were in the range of 198.69–416.11 kJ/kg. This was explained by better slippage of the mixture inside the extruder and lower mechanical resistance. Singh et al. [37] also observed a decrease in SME with increasing moisture content and temperature during the extrusion of lentil protein isolate in the form of textured vegetable protein. The specific mechanical energy (SME) values ranged from 126.0 to 66.9 Wh/kg. The authors explained this effect by the reduced viscosity of the mixture and better slippage of the material inside the extruder-cooker barrel. As a result, mechanical resistance decreased, leading to lower energy requirements during processing. Feed moisture content in this research was from 30 to 40%.

3.2. Impact of Ingredients and Processing Conditions on Selected Physical Properties

Bulk density is an important functional parameter of extruded products, affecting on texture and packaging efficiency [38]. It is directly related to the degree of expansion, internal structure and porosity of the extrudate. The conducted analysis showed a clear influence of blueberry addition, moisture content and screw speed on the bulk density of the final product (Table 5).

Table 5.

Results of selected physical properties of snack pellets enriched with blueberry processed at variable conditions (n = 3 ± SD).

In the case of control samples, the bulk density remained at a moderate level, ranging from 384.6 to 425.2 kg/m³. A minor decrease in density was observed when moisture content increased from 32% to 36% at 60 rpm, which may be the result of more intense material swelling and greater expansion under conditions favorable for starch gelatinization. For example, at 60 rpm, bulk density decreased from 420.7 to 384.6 kg/m³. The addition of 10% blueberry resulted in more varied bulk density values, which either decreased or increased depending on other processing conditions. The lowest density in this group was recorded at 60 rpm and 32% moisture (345.1 kg/m³), indicating a better expansion effect and a lighter extrudate structure. However, at 100 rpm and 36% moisture, the bulk density increased to 449.5 kg/m³, suggesting that under more intense processing conditions, the presence of sugars and fiber from the fruit may limit expansion and lead to a denser product structure. The most notable effect on increased bulk density was observed with the use of 30% blueberry addition. In every combination of processing parameters, significantly higher bulk density values were obtained, ranging from 494.4 to 547.4 kg/m³—the highest range among all tested samples. The high blueberry content likely hindered the formation of a porous structure, by limiting air bubble development, increasing the viscosity of the mixture and the action of hydrophilic components (such as fiber and pectin), which reduce expansion of the extrudate as it exits the die. Additionally, both increasing the moisture content and the screw speed under conditions with 30% blueberry addition led to a further increase in bulk density—from 494.4 kg/m³ (60 rpm, 32% moisture) to 547.4 kg/m³ (100 rpm, 36% moisture). This suggests that under these conditions, the structure of the extrudate becomes more compact and less expanded.

Lisiecka et al. [39] reported analogous findings, where an increase in fresh beetroot content led to a decrease in bulk density of pellets. The highest bulk density of the pellet was recorded for the control sample at a screw speed of 100 rpm, while the lowest was observed for the pellet containing 20% of fresh beetroot processed at 60 rpm (466.5 kg/m³ and 239.0 kg/m³, respectively). The authors explained this by structure loosening caused by the presence of dietary fiber. In the present study, however, an opposite trend was observed. The addition of fresh blueberry, especially at 30%, resulted in a rise in bulk density. This was likely due to limited expansion caused by the presence of pectin and natural sugars in the fruit. In both studies, screw speed had a significant impact—higher speeds promoted an increase in density, which may be related to the formation of a more compact structure under intensified processing conditions. Mitrus et al. [40] also reported comparable relationships between formulation, processing parameters and bulk density of snack pellets. They found that the highest bulk density values occurred in control samples without vegetable addition, processed at higher screw speed and lower moisture levels. In their study, pellets with 20% fresh broccoli showed the lowest density (256 kg/m³), while the control mixtures, extruded at 100 rpm and 32% moisture, reached up to 379 kg/m³. These findings partially align with the results of the present study—here, screw speed also had a positive effect on increasing density. However, unlike broccoli, the addition of blueberry led to an increase in BD, likely due to reduced expansion caused by the presence of sugars and pectin in the fruit.

Durability is an important indicator of the mechanical quality of extruded products, reflecting their resistance to abrasion, breakage and damage under dynamic forces. This parameter depends on the internal structure of the extrudate, as well as on the raw material composition and processing conditions.

In the present study, all tested samples showed relatively high durability level, although some subtle differences were observed depending on the technological parameters applied (Table 5). In the case of control samples, durability remained consistently high—between 97.61% and 98.10%—regardless of screw speed and moisture level, indicating a stable mechanical structure of the material processed under controlled conditions. The addition of 10% fresh blueberry caused a minor decrease in durability level, particularly at lower moisture content and screw speed, with values dropping to 96.69%. This may be attributed to a mild weakening of the extrudate structure, likely caused by the presence of fruit particles and potential disruption of starch network formation during extrusion-cooking process. The lowest durability values were observed in mixtures containing 30% blueberry, processed at both 60 and 100 rpm with 32% moisture, reaching 95.46%. Although this still represents a high level of mechanical resistance, it indicates a gradual weakening of structural integrity with increasing amounts of fruit-based components. An increase of mixture moisture to 36% in each tested group (0%, 10% and 30% blueberry) contributed to a partial compensation of structural weakening, with durability value increasing to the range of 96.69–97.61%. This improvement may result from better surface formation and reduced brittleness at the point of extrudate discharge. At the same time, higher screw speed did not show a significant impact on this parameter, suggesting that within the tested range, the mechanical conditions were not sufficiently distinct to noticeably influence the mechanical resistance of the final products.

In presented study, the effect of the addition of fresh blueberries on shelf life was observed (the minimum value of shelf life was 94.36%, and the maximum value reached 97.00%), while changes in other process parameters did not significantly affect this result. Similar findings were obtained in the study by Mitrus et al. [40], who found that the addition of fresh broccoli reduced the durability of pellets, with the lowest value (99.06%) observed for the sample with 30% broccoli. The highest durability (99.88%) was recorded for the control pellets. Similar observations have also been made by Soja et al. [41], who found that the addition of pomace to extrudates reduced durability, particularly at higher screw speed. In their study, control extrudates had the highest durability coefficient (99.85%), while the addition of 10% pomace resulted in values ranging from 99.67% to 99.88, regardless of the type of ingredient. In the present study, it was also observed that the addition of fresh fruits, such as blueberries, reduced the durability of extrudates, with values ranging from 94.36% to 97.00%. In line with the observations of Soja et al. higher screw speed led to a decrease in durability, and samples without additives had the highest durability coefficient, suggesting that the presence of plant-based ingredients affects the kinetic strength of extrudates.

The Water Absorption Index (WAI) indicates the extent of modification of starch and other hydrophilic ingredients during the extrusion-cooking process. This parameter depends mainly on the intensity of heat and mechanical treatment, as well as on the composition of the raw material, particularly the content of dietary fiber and gelling agents. In this study, the WAI value responded noticeably to all three tested process variables: screw speed, moisture content of the mixture and the level of fresh blueberry addition (Table 5). The highest WAI values were recorded for control sample processed at 100 rpm and 36% moisture, where the index reached 4.07. Such high values are likely related to intense starch gelatinization, which occurs under greater mechanical energy input and in the presence of a sufficient amount of water that promotes swelling of starch structures. These findings illustrate that the combination of high moisture content and intensive mixing contributes to increased water absorption capacity, particularly in systems free from interfering components.

A decrease in WAI with increasing levels of fresh blueberry, particularly at the 30% level, was observed in the current study. The presence of fiber and pectin may have disrupted starch swelling, reducing its water-binding capacity. The highest WAI values were recorded for control samples, processed at higher moisture content and screw speed. Similar results were reported in a study by Dushkova et al. [42] involving goji berry addition, where an increase in mixture moisture and fruit content led to a decrease in WAI. The maximum WAI value of 8.05 g/g was obtained at the lowest moisture content (13%) and the smallest addition of goji (1%), whereas the minimum WAI value of 6.05 g/g was recorded at the highest moisture content (19%) and the highest level of goji addition (5%). This was explained by starch dextrinization and the presence of lipids, which can limit starch gelatinization. Similar results were presented by Drożdż et al. [43], who reported a gradual decrease in WAI in extruded products with the addition of fruit pomace—from 6.5 g/g in the control sample to 4.6 g/g in samples with the highest fruit content. The authors explained this effect by the reduced gelatinization of starch in the presence of fiber fractions and other components from the fruits. An analogous trend was observed in the present study—an increase in fresh blueberry content led to a systematic decrease in WAI, which may be related to the disruption of starch swelling by pectin and fiber present in the fruit. In both cases, fruit-based plant additives affected the reduction of water absorption capacity in the extrudates.

In contrast, the addition of fresh blueberries to the mixtures led to a general decrease in WAI values, especially at the highest addition level. Under these conditions, the index dropped to as low as 2.90 (at 100 rpm and 36% moisture). This reduction can be explained by the presence of dietary fiber and simple sugars in the fruit, which may limit starch expansion and gelatinization, acting as a barrier to water absorption. Additionally, organic acids naturally present in blueberries may alter the reaction environment, further affecting the material’s ability to retain water. At the lowest blueberry addition level (10%), WAI values were similar to those of the control samples and did not show a significant reduction. For example, at 60 rpm and 36% moisture, the WAI was 3.88, suggesting that a small amount of fruit does not noticeably interfere with the swelling process and may even positively influence the water-holding structure of the extrudate under certain conditions.

In summary, the highest water absorption capacity was observed in samples without blueberry addition, processed at higher moisture levels and increased screw speeds. The decrease in WAI values with increasing blueberry content may indicate a limiting effect on starch expansion and porous structure formation, which from a technological perspective could significantly influence the rehydration properties of the final product.

The Water Solubility Index (WSI) reflects the degree of degradation of soluble components, primarily starch and soluble fiber fractions, resulting from the combined effects of temperature, mechanical shear and moisture during the extrusion-cooking process. This parameter is particularly sensitive to the intensity of thermomechanical treatment and the presence of water-soluble compounds in the raw material (Table 5).

In the control sample, an increase moisture content from 32% to 36% caused a significant rise in WSI, observed at both low and high screw speed. At 60 rpm, WSI increased from 8.23% to 17.22%, and at 100 rpm, from 7.53% to 18.35%. This indicates that higher moisture supports stronger thermohydrolysis and starch fragmentation, leading to a greater amount of water-soluble components in the product. The addition of fresh blueberries to the mixtures resulted in notable changes in WSI values, although the direction of these changes depended on other processing parameters. At low moisture content, blueberry addition led to an increase in WSI. For instance, at 60 rpm with 30% blueberry, WSI reached 12.72%, compared to 8.23% in the control sample. This suggests that the presence of simple sugars and low-molecular-weight fiber fractions in blueberries may have contributed to a higher proportion of water-soluble components, especially under less intense plasticization conditions. In contrast, under conditions of higher moisture content and low screw speed the effect was reversed—the addition of blueberries reduced WSI compared to the control samples. For example, with 10% blueberry, WSI dropped to 8.23%, which may result from increased water retention by fiber and less efficient breakdown of starch fractions in a more viscous environment. A high fruit content may also have altered the thermal profile within the extruder-cooker, potentially limiting complete gelatinization and fragmentation of starch molecules. The highest WSI values were observed under conditions of high moisture content and high screw speed regardless of blueberry addition—for example, 18.52% was recorded for samples with 30% blueberry. This suggests that under such intensive processing conditions, the degradation of structural components was strong enough to override the protective effects of fiber or simple sugars.

In the present study authors observed an increase in WSI with higher temperature and screw speed, and a decrease in WSI as the mix moisture was reduced. In Kowalski et al. [44] research the WSI values for all extrudates ranged from 14.5% to 15.87%, indicating a clear effect of temperature and screw speed on starch solubility. Similar results were reported by Dushkova et al. [42] who observed that WSI increased with higher temperature and screw speed. The study revealed a maximum WSI value of 25.61% at a feed moisture content of 13% and a 5% addition of goji, while the minimum WSI value of 17.13% was observed at a moisture content of 19% and a 1% addition of goji. Both studies found that a decrease in feed moisture resulted in a decrease in WSI. These results confirm the relationship between extrusion cooking parameters and WSI, although differences in raw material composition and process conditions may lead to some variation in the final values.

3.3. Impact of Ingredients and Processing Conditions on Phenolic Content and Antioxidant Activity

3.3.1. Free Radical Scavenging Activity—DPPH Method

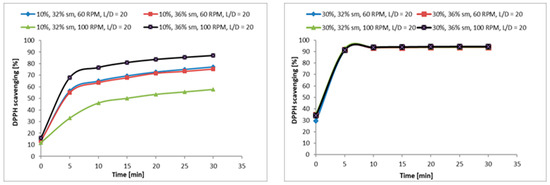

The spectrophotometric method allowed to determine ability of prepared extracts to scavenge free radicals. The obtained results explicitly indicate on high antioxidant activity of the analyzed samples. The parameter increased with increasing additive content (87% of free radical scavenging for 10% of additive content; 94.22% for 30% of additive content after 30 min. of reaction). Important is fact that the high free radical scavenging was observed within 5 min from reaction initiation and plateau was reached immediately. The feature is significant for determination power of antioxidants. Extracts from functional food enriched with 10% of blueberry is active against free radicals nevertheless the activity is weaker in comparison to samples with higher content of the fruit (Figure 1). In all cases, the increase in antioxidant activity was significant in comparison to potato base for which free radical scavenging was equal 22.71% at the end of reaction.

Figure 1.

DPPH scavenging activity of extracts obtained from functional food products enriched with 10% and 30% of blueberry.

Equally important influence on biological activity of analyzed samples had production parameters used for preparation of functional food products. The parameters, namely moisture (sm) and screw rotation speed (rpm) influenced on products with both (10% and 30%) content of fruit but more significant was observed for samples with lower amount of blueberry (Figure 2). In this case, the difference in activity for the better and the weaker parameters was above 29%. Samples with higher levels of additive did not show such a large difference in activity which did not exceed 1%.

Figure 2.

The influence of production parameters (moisture—sm, screw speed rotation—RPM) on free radical scavenging ability of functional food samples enriched with 10% and 30% of whortleberry.

3.3.2. Content of Polyphenols Based on Folin-Ciocalteu Method

In order to determine total content of polyphenolic compounds (TPC), Folin-Ciocalteu method was used. The study results revealed explicit correlation between content of blueberry and TPC (Table 6).

Table 6.

Total phenolic content determined for functional food samples enriched with 0%, 10% and 30% of blueberry based on Folin-Ciocalteu method (n = 3, mean ± SD).

Higher content of polyphenols leaded to higher antioxidant activity of samples. The TPC results confirmed the assumption due to the fact that higher content of fruit caused better free radical scavenging. Comparing TPC for potato base and food product enriched with whortleberry, the positive impact of fruits on secondary plant metabolites is evident. The studies revealed that 10%, 20% and 30% of additive content cause increase in TPC value: 43.2; 83.6 and 117 μg GAE /g dry weight, respectively, which is a significant increase in the content of active antioxidants. Similarly to DPPH assay, production parameters have impact on TPC value. In this case, the most promising turned out to be 36% sm and 100 rpm.

An analysis of the influence of the polyphenol content of berries on antioxidant properties was also carried out by the Zhang et al. [45]. They studied the following berries: raspberry, blackberry, blueberry, mulberry and black chokeberry analyzing their antioxidant activities and polyphenol compositions (juice and pomace). The results explicitly indicted that pomace from red raspberry is the most potent antioxidant agent. The high antioxidant activity is explained by high content of polyphenols (137 to 222 mg/g). The fruits compared were characterized by varying amounts of polyphenols, but the authors unanimously point out that they are an extremely valuable as a food additive. Similar analysis was provided by Li et al. [46] who focused on polyphenol content and their influence on antioxidant activity of mulberry, an another plant belonging to berries group. The TPC value ranged from 4.12 to 35.50 mg GAE/g. The content is significantly lower that the value obtained for other barriers fruits such as aforementioned red raspberry. Nevertheless, the content of polyphenols allowed to obtain high antioxidant activity and free radical scavenging ability (238.3 µmol TE/g for DPPH and 560.1 µmol TE/g for FRAP).

3.3.3. Content of Phenolic Acids—UPLC Analysis

The determination of content of phenolic acids was performed for sample revealing the highest antioxidant activity in DPPH assay. The assay was performed with the use of Waters ACQUITY UPLC Chromatogram. The study results were obtained for functional food product obtained with the following production parameters: 36% sm, 100 rpm, L/D = 20. Results are presented in Table 7.

Table 7.

Content of phenolic acids [μg/g] obtained using UPLC analysis.

It is commonly known that oxidative stress is one of crucial factors leading to various disorders including cardiovascular, cancer or neurodegeneration. In order to avoid to high level of free radicals, organism developed various systems counteracting the negative impact of the reactive molecules [47]. Nevertheless, the external source of antioxidants and free radical scavengers is essential for maintenance balance in organism. The most important source of natural antioxidants are fruits and vegetables rich in secondary plant metabolites revealing high ability to scavenging free radicals. An example of the valuable fruit is blueberry riches in phytochemicals presented in Durazzo’s et al. work [48]. The fruit is studied towards its pro-health properties from a long time. Considering the various activities, it was decided to use the fruit as additive to functional food products. Anthocyanins, phenolic acids (caffeic, chlorogenic, p-coumaric and ferulic acids), flavonols (mainly quercetin derivatives) and proanthocyanidins have received the most attention among the phytochemicals found in blueberries [49]. The following phenolic acids were found in the samples: protocatechuic, p-OH-benzoic, vanillic, caffeic, syryngic, p-coumaric, ferulic, synapic and salicylic acids, according to the chromatographic analysis carried out by the authors.

The study confirmed a high health-promoting activity based on free radical scavenging and high polyphenol content. The authors observed an increase in the total polyphenol content and antioxidant properties of the product with increasing fruit content. The most suitable for consumption are products enriched with 30% of blueberry which revealed above 90% ability to scavenge free radicals within few minutes. Additionally, the high content of polyphenols influences on the antioxidant activity but also support the fight against other negative factors leading to various disorders. Considering the fact that potato base did not reveal ability to scavenge free radicals (approx. 22%), the enrichment of the food products with fruits significantly improves their pro-health properties along with supplementation of valuable secondary plant metabolites. Significant feature of analyzed functional food samples is also lack of negative influence of production parameters (moisture and screw rotation speed) on antioxidant activity of samples with various content of fruits. The results allow us to assume that these parameters will not have a destructive effect on the health-promoting properties of the tested products. According to Carranza-Gomez et al. [50], blueberry fruits have a tremendous effect on the human body, largely due to their antioxidant properties, which are due to the presence of polyphenolic compounds, which, as shown by the research results, remained active after the extrusion-cooking process. Therefore, these products are a good source of natural antioxidants, capable of preventing certain diseases and improving the quality of health and life.

4. Conclusions

The study demonstrated that the most significant factor contributing to increased extrusion efficiency was higher screw speed, although the addition of fresh blueberry, particularly at 30%, clearly reduced the efficiency. Higher screw speed and a lower amount of blueberry (especially at 10%) significantly reduced specific mechanical energy (SME), but excessive fruit content (30%) led to a rise in energy consumption. The highest water absorption index (WAI) was observed in the control sample, processed at higher moisture and screw speed, while the addition of blueberries limited starch swelling and expansion, resulting in lower WAI values. Similarly, the water solubility index (WSI) increased with higher moisture and screw speed, but the presence of blueberries had a mixed effect, increasing solubility under low-moisture conditions and reducing it at higher moisture levels. All extrudates exhibited high mechanical resistance (above 94%), though a minor decrease in resistance was observed with an increasing amount of blueberries, especially under lower moisture conditions. The addition of fresh blueberries, particularly at 30%, caused a noticeable increase in bulk density, linked to reduced expansion and a less porous internal structure. Despite these changes, all tested functional food samples exhibited high antioxidant activity with the most valuable products being those containing 30% of the blueberry additive. The high free radical scavenging activity was closely associated with the high total polyphenol content (TPC), which varied with the content of the additive. UPLC analysis revealed several significant phenolic acids that are largely responsible for the health-promoting properties of the analyzed samples.

Author Contributions

Conceptualization, M.C., J.S., K.W.-K. and. B.B.; methodology, M.C., J.S. and K.W.-K.; software, J.S.; validation, M.C., M.K. and B.B.; formal analysis, M.C., J.S. and B.B.; investigation, M.C., J.S., T.O., K.W.-K., J.M. and B.B.; resources, M.C.; data curation, M.C.; writing—original draft preparation, M.C., J.S., K.W.-K., J.M. and B.B.; writing—review and editing, M.C., J.S. and B.B.; visualization, M.C. and J.S.; supervision, M.C.; project administration, M.C.; funding acquisition, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The National Centre for Research and Development (NCBiR), grant number LIDER/29/0158/L-10/18/NCBR/2019, entitled “Development of a Comprehensive Technology of Obtaining High-Quality Extruded Snacks Based on Minimally Processed Vegetable and Animal Raw Materials”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, L.; Lan, W.; Chen, D. Blueberry (Vaccinium spp.) Anthocyanins and Their Functions, Stability, Bioavailability, and Applications. Foods 2024, 13, 2851. [Google Scholar] [CrossRef] [PubMed]

- Krishna, P.; Pandey, G.; Thomas, R.; Parks, S. Improving Blueberry Fruit Nutritional Quality through Physiological and Genetic Interventions: A Review of Current Research and Future Directions. Antioxidants 2023, 12, 810. [Google Scholar] [CrossRef] [PubMed]

- Song, G.-Q.; Hancock, J.F. Recent Advances in Blueberry Transformation. Int. J. Fruit Sci. 2012, 12, 316–332. [Google Scholar] [CrossRef]

- Silva, S.; Costa, E.M.; Veiga, M.; Morais, R.M.; Calhau, C.; Pintado, M. Health promoting properties of blueberries: A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 181–200. [Google Scholar] [CrossRef]

- Lachowicz-Wiśniewska, S.; Pratap-Singh, A.; Ochmian, I.; Kapusta, I.; Kotowska, A.; Pluta, S. Biodiversity in nutrients and biological activities of 14 highbush blueberry (Vaccinium corymbosum L.) cultivars. Sci. Rep. 2024, 14, 22063. [Google Scholar] [CrossRef]

- Ashique, S.; Mukherjee, T.; Mohanty, S.; Garg, A.; Mishra, N.; Kaushik, M.; Bhowmick, M.; Chattaraj, B.; Mohanto, S.; Srivastava, S.; et al. Blueberries in focus: Exploring the phytochemical potentials and therapeutic applications. J. Agric. Food Res. 2024, 18, 101300. [Google Scholar] [CrossRef]

- Jurikova, T.; Skrovankova, S.; Mlcek, J.; Balla, S.; Snopek, L. Bioactive Compounds, Antioxidant Activity, and Biological Effects of European Cranberry (Vaccinium oxycoccos). Molecules 2019, 24, 24. [Google Scholar] [CrossRef]

- Cerezo, A.B.; Cătunescu, G.M.; González, M.M.-P.; Hornedo-Ortega, R.; Pop, C.R.; Rusu, C.C.; Chirilă, F.; Rotar, A.M.; Garcia-Parrilla, M.C.; Troncoso, A.M. Anthocyanins in Blueberries Grown in Hot Climate Exert Strong Antioxidant Activity and May Be Effective against Urinary Tract Bacteria. Antioxidants 2020, 9, 478. [Google Scholar] [CrossRef]

- Cassidy, A.; Bertoia, M.; Chiuve, S.; Flint, A.; Forman, J.; Rimm, E.B. Habitual intake of anthocyanins and flavanones and risk of cardiovascular disease in men. Am. J. Clin. Nutr. 2016, 104, 587–594. [Google Scholar] [CrossRef]

- Subash, S.; Essa, M.M.; Al-Adawi, S.; Memon, M.A.; Manivasagam, T.; Akbar, M. Neuroprotective effects of berry fruits on neurodegenerative diseases. Neural Regen Res. 2014, 9, 1557–1566. [Google Scholar] [CrossRef]

- Johnson, S.A.; Arjmandi, B.H. Evidence for anti-cancer properties of blueberries: A mini-review. Anti-Cancer Agents Med. Chem. 2013, 8, 1142–1148. [Google Scholar] [CrossRef] [PubMed]

- Kalt, W.; Cassidy, A.; Howard, L.R.; Krikorian, R.; Stull, A.J.; Tremblay, F.; Zamora-Ros, R. Recent Research on the Health Benefits of Blueberries and Their Anthocyanins. Adv. Nutr. 2020, 11, 224–236. [Google Scholar] [CrossRef]

- Nemzer, B.; Vargas, L.; Xia, X.; Sintara, M.; Feng, H. Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem. 2018, 262, 242–250. [Google Scholar] [CrossRef]

- Mieszczakowska-Frąc, M.; Celejewska, K.; Płocharski, W. Impact of Innovative Technologies on the Content of Vitamin C and Its Bioavailability from Processed Fruit and Vegetable Products. Antioxidants 2021, 10, 54. [Google Scholar] [CrossRef] [PubMed]

- Choton, S.; Gupta, N.; Bandral, J.D.; Anjum, N.; Choudary, A. Extrusion technology and its application in food processing: A review. Pharm. Innov. 2020, 9, 162–168. [Google Scholar] [CrossRef]

- Šárka, E.; Sluková, M.; Henke, S. Changes in Phenolics during Cooking Extrusion: A Review. Foods 2021, 10, 2100. [Google Scholar] [CrossRef]

- Mironeasa, S.; Coţovanu, I.; Mironeasa, C.; Ungureanu-Iuga, M. A Review of the Changes Produced by Extrusion Cooking on the Bioactive Compounds from Vegetal Sources. Antioxidants 2023, 12, 1453. [Google Scholar] [CrossRef]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion processing of raw food materials and by-products: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef]

- Cotacallapa-Sucapuca, M.; Vega, E.N.; Maieves, H.A.; Berrios, J.D.J.; Morales, P.; Fernández-Ruiz, V.; Cámara, M. Extrusion Process as an Alternative to Improve Pulses Products Consumption. A Review. Foods 2021, 10, 1096. [Google Scholar] [CrossRef]

- Roye, C.; Henrion, M.; Chanvrier, H.; De Roeck, K.; De Bondt, Y.; Liberloo, I.; King, R.; Courtin, C.M. Extrusion-Cooking Modifies Physicochemical and Nutrition-Related Properties of Wheat Bran. Foods 2020, 9, 738. [Google Scholar] [CrossRef]

- Combrzyński, M.; Oniszczuk, T.; Wójtowicz, A.; Biernacka, B.; Wojtunik-Kulesza, K.; Bąkowski, M.; Różyło, R.; Szponar, J.; Soja, J.; Oniszczuk, A. Nutritional Characteristics of New Generation Extruded Snack Pellets with Edible Cricket Flour Processed at Various Extrusion Conditions. Antioxidants 2023, 12, 1253. [Google Scholar] [CrossRef] [PubMed]

- Korkerd, S.; Wanlapa, S.; Puttanlek, C.; Uttapap, D.; Rungsardthong, V. Expansion and functional properties of extruded snacks enriched with nutrition sources from food processing by-products. J. Food Sci. Technol. 2016, 53, 561–570. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Gao, Y.; Wang, R.; Sun, Y.; Li, X.; Liang, J. Effects of Adding Blueberry Residue Powder and Extrusion Processing on Nutritional Components, Antioxidant Activity and Volatile Organic Compounds of Indica Rice Flour. Biology 2022, 11, 1817. [Google Scholar] [CrossRef]

- Estupiñan-Amaya, M.; Fuenmayor, C.A.; López-Córdoba, A. New Freeze-Dried Andean Blueberry Juice Powders for Potential Application as Functional Food Ingredients: Effect of Maltodextrin on Bioactive and Morphological Features. Molecules 2020, 25, 5635. [Google Scholar] [CrossRef] [PubMed]

- Lucas, B.F.; Guelpa, R.; Vaihinger, M.; Vaihinger, M.; Brunner, T.; Costa, J.A.; Denkel, C. Extruded snacks enriched with açaí berry: Physicochemical properties and bioactive constituents. Food Sci. Technol. 2022, 42, 14822. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Combrzyński, M.; Biernacka, B.; Różyło, R.; Bąkowski, M.; Wojtunik-Kulesza, K.; Mołdoch, J.; Kowalska, I. Fresh Chokeberry (Aronia melanocarpa) Fruits as Valuable Additive in Extruded Snack Pellets: Selected Nutritional and Physiochemical Properties. Plants 2023, 12, 3276. [Google Scholar] [CrossRef]

- Matysiak, A.; Wójtowicz, A.; Oniszczuk, T. Process efficiency and energy consumption during the extrusion of potato and multigram formulations. Agric. Eng. 2018, 22, 49–57. [Google Scholar] [CrossRef]

- Combrzyński, M.; Biernacka, B.; Wójtowicz, A.; Kupryaniuk, K.; Oniszczuk, T.; Mitrus, M.; Różyło, R.; Gancarz, M.; Stasiak, M.; Kasprzak-Drozd, K. Analysis of the extrusion-cooking process and selected physical properties of snack pellets with the addition of fresh kale. Int. Agroph. 2023, 37, 353–364. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Combrzyński, M.; Biernacka, B.; Oniszczuk, T.; Mitrus, M.; Różyło, R.; Gancarz, M.; Oniszczuk, A. Application of Edible Insect Flour as a Novel Ingredient in Fortified Snack Pellets: Processing Aspects and Physical Characteristics. Processes 2023, 11, 2561. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Kupryaniuk, K.; Oniszczuk, T.; Combrzyński, M.; Lisiecka, K.; Janczak, D. Influence of Modification of the Plasticizing System on the Extrusion-Cooking Process and Selected Physicochemical Properties of Rapeseed and Buckwheat Straws. Materials 2022, 15, 5039. [Google Scholar] [CrossRef]

- Burda, S.; Oleszek, W. Antioxidant and antiradical activities of flavonoids. J. Agric. Food Chem. 2001, 49, 2774–2779. [Google Scholar] [CrossRef] [PubMed]

- Czaban, J.; Sułek, A.; Pecio, Ł.; Żuchowski, J.; Podolska, G. Effect of genotype and crop management systems on phenolic acid content in winter wheat grain. J. Food Agric. Environ. 2013, 11, 1201–1206. [Google Scholar]

- Bouasla, A.; Wójtowicz, A.; Juśko, S.; Zidoune, M.N. Energy Consumption and Process Efficiency as Affected by Extrusion-Cooking Conditions and Recipe Formulation During the Production of Gluten-Free Rice-Legumes Products. Agric. Eng. 2017, 21, 39–46. [Google Scholar] [CrossRef][Green Version]

- Lewko, P.; Wójtowicz, A.; Różańska-Boczula, M. Effect of Extruder Configuration and Extrusion Cooking Processing Parameters on Selected Characteristics of Non-Starch Polysaccharide-Rich Wheat Flour as Hybrid Treatment with Xylanase Addition. Processes 2024, 12, 1159. [Google Scholar] [CrossRef]

- Kantrong, H.; Charunuch, C.; Limsangouan, N.; Pengpinit, W. Influence of process parameters on physical properties and specific mechanical energy of healthy mushroom-rice snacks and optimization of extrusion process parameters using response surface methodology. J. Food Sci. Technol. 2018, 55, 3462–3472. [Google Scholar] [CrossRef]

- Singh, R.; Guerrero, M.; Nickerson, M.T.; Koksel, F. Effects of extrusion screw speed, feed moisture content, and barrel temperature on the physical, techno-functional, and microstructural quality of texturized lentil protein. J. Food Sci. 2024, 89, 2040–2053. [Google Scholar] [CrossRef]

- Umoh, E.O.; Iwe, M.O. Influence of extrusion process conditions on bulk density, water absorption capacity and oil absorption capacity of extruded aerial yam-soybean flour mixture. Afr. J. Food Sci. 2023, 17, 111–121. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. Effect of fresh beetroot application and processing conditions on some quality features of new type of potato-based snacks. LWT-Food Sci. Technol. 2021, 141, 110919. [Google Scholar] [CrossRef]

- Mitrus, M.; Combrzyński, M.; Biernacka, B.; Wójtowicz, A.; Milanowski, M.; Kupryaniuk, K.; Gancarz, M.; Soja, J.; Różyło, R. Fresh Broccoli in Fortified Snack Pellets: Extrusion-Cooking Aspects and Physical Characteristics. Appl. Sci. 2023, 13, 8138. [Google Scholar] [CrossRef]

- Soja, J.; Combrzyński, M.; Oniszczuk, T.; Gancarz, M.; Oniszczuk, A. Extrusion-Cooking Aspects and Physical Characteristics of Snacks Pellets with Addition of Selected Plant Pomace. Appl. Sci. 2024, 14, 8754. [Google Scholar] [CrossRef]

- Dushkova, M.; Simitchiev, A.; Petrova, T.; Menkov, N.; Desseva, I.; Mihaylova, D. Physical and Functional Characteristics of Extrudates Prepared from Quinoa Enriched with Goji Berry. Appl. Sci. 2023, 13, 3503. [Google Scholar] [CrossRef]

- Drożdż, W.; Boruczkowska, H.; Boruczkowski, T.; Tomaszewska-Ciosk, E.; Zdybel, E. Use of blackcurrant and chokeberry press residue in snack products. Pol. J. Chem. Technol. 2019, 21, 13–19. [Google Scholar] [CrossRef]

- Kowalski, R.; Medina-Meza, I.G.; Thapa, B.B.; Murphy, K.M.; Ganjyal, G.M. Extrusion processing characteristics of quinoa (Chenopodium quinoa Willd.) var. Cherry Vanilla. J. Cereal Sci. 2016, 70, 91–98. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Zhang, J.; Zhang, Y.T.; Sun, J.Y.; Prieto, M.A.; Simal-Gandara, J.; Putnik, P.; Li, N.Y.; Liu, C. The link between the phenolic composition and the antioxidant activity in different small berries: A metabolomic approach. LWT 2023, 182, 114853. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Y.; Xiang, J.; Wang, C.; Johnson, J.B.; Beta, T. Diverse polyphenol components contribute to antioxidant activity and hypoglycemic potential of mulberry varieties. LWT 2023, 173, 114308. [Google Scholar] [CrossRef]

- MatÉs, J.M.; Pérez-Gómez, C.; De Castro, I.N. Antioxidant enzymes and human diseases. Clin. Biochem. 1999, 32, 595–603. [Google Scholar] [CrossRef]

- Durazzo, A.; Lucarini, M.; Souto, E.B.; Cicala, C.; Caiazzo, E.; Izzo, A.A.; Novellino, E.; Santini, A. Polyphenols: A concise overview on the chemistry, occurrence, and human health. Phytother. Res. 2019, 33, 2221–2243. [Google Scholar] [CrossRef]

- Colak, N.; Primetta, A.K.; Riihinen, K.R.; Jaakola, L.; Grúz, J.; Strnad, M.; Torun, H.; Ayaz, F.A. Phenolic compounds and antioxidant capacity in different-colored and non-pigmented berries of bilberry (Vaccinium myrtillus L.). Food Biosci. 2017, 20, 67–68. [Google Scholar] [CrossRef]

- Carranza-Gomez, M.; Valle-Guadarrama, S.; Domínguez-Puerto, R.; Sandoval-Castilla, O.; Guerra-Ramírez, D. Bioactive Compounds and Pigmenting Potential of Vaccinium corymbosum Extracts Separated with Aqueous Biphasic Systems Aided by Centrifugation. Processes 2025, 13, 1072. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).