Study on the Rheological Properties of High Calcium Desulfurization Ash–Slag-Based Paste Backfill Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

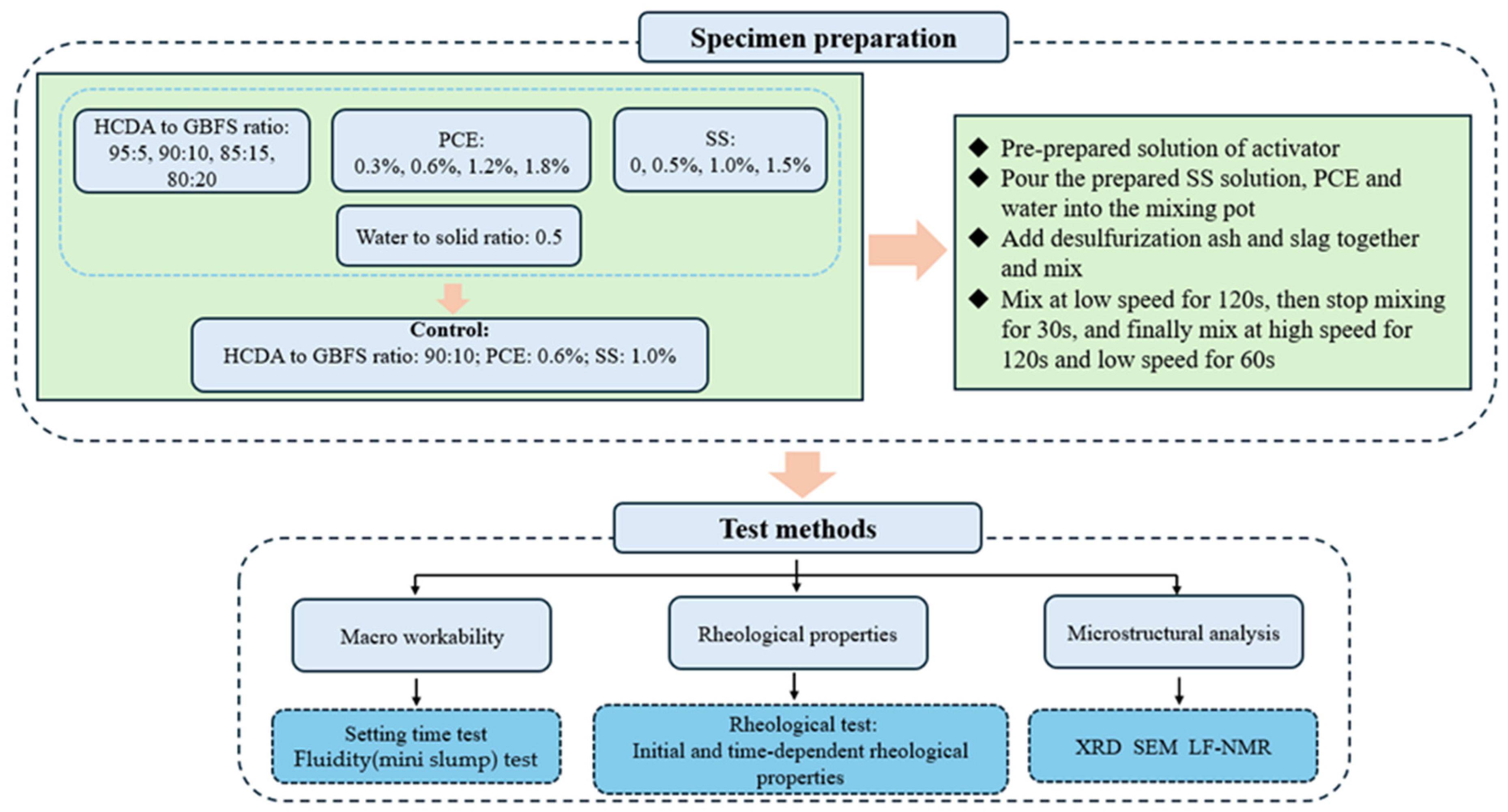

2.2. Specimen Preparation and Mixing Procedure

2.3. Test Methods

2.3.1. Setting Time Test

2.3.2. Rheological Test

2.3.3. Fluidity Test (Mini Slump)

2.3.4. Microstructure Experiment

- XRD measurement

- 2.

- Scanning electronic microscopy(SEM) measurement

- 3.

- LF-NMR experiment

3. Results and Discussion

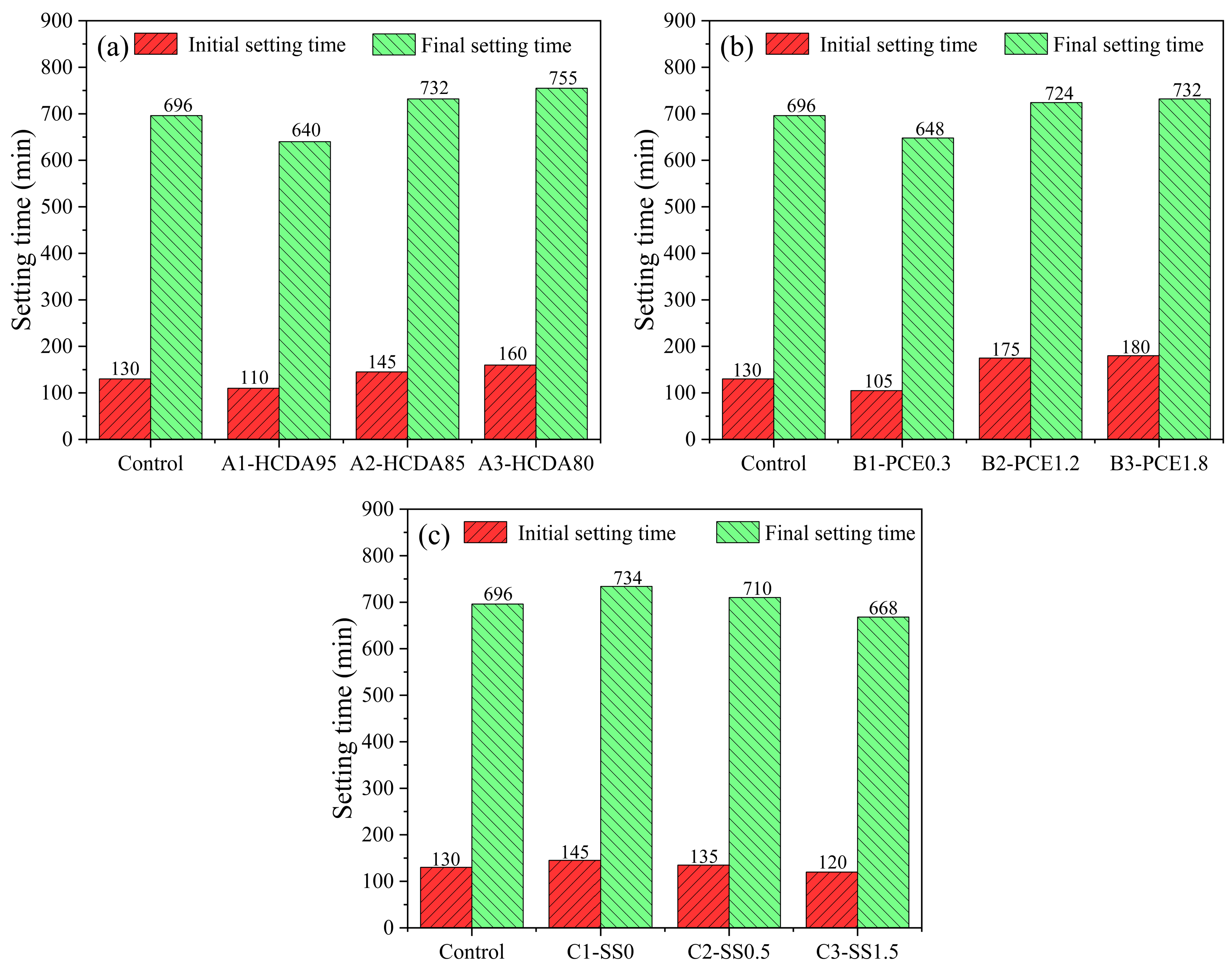

3.1. Setting Time

3.2. Rheological Property Analysis

3.2.1. Rheology Model Fitting and Initial Rheological Parameters

3.2.2. Time-Dependent Rheological Parameters

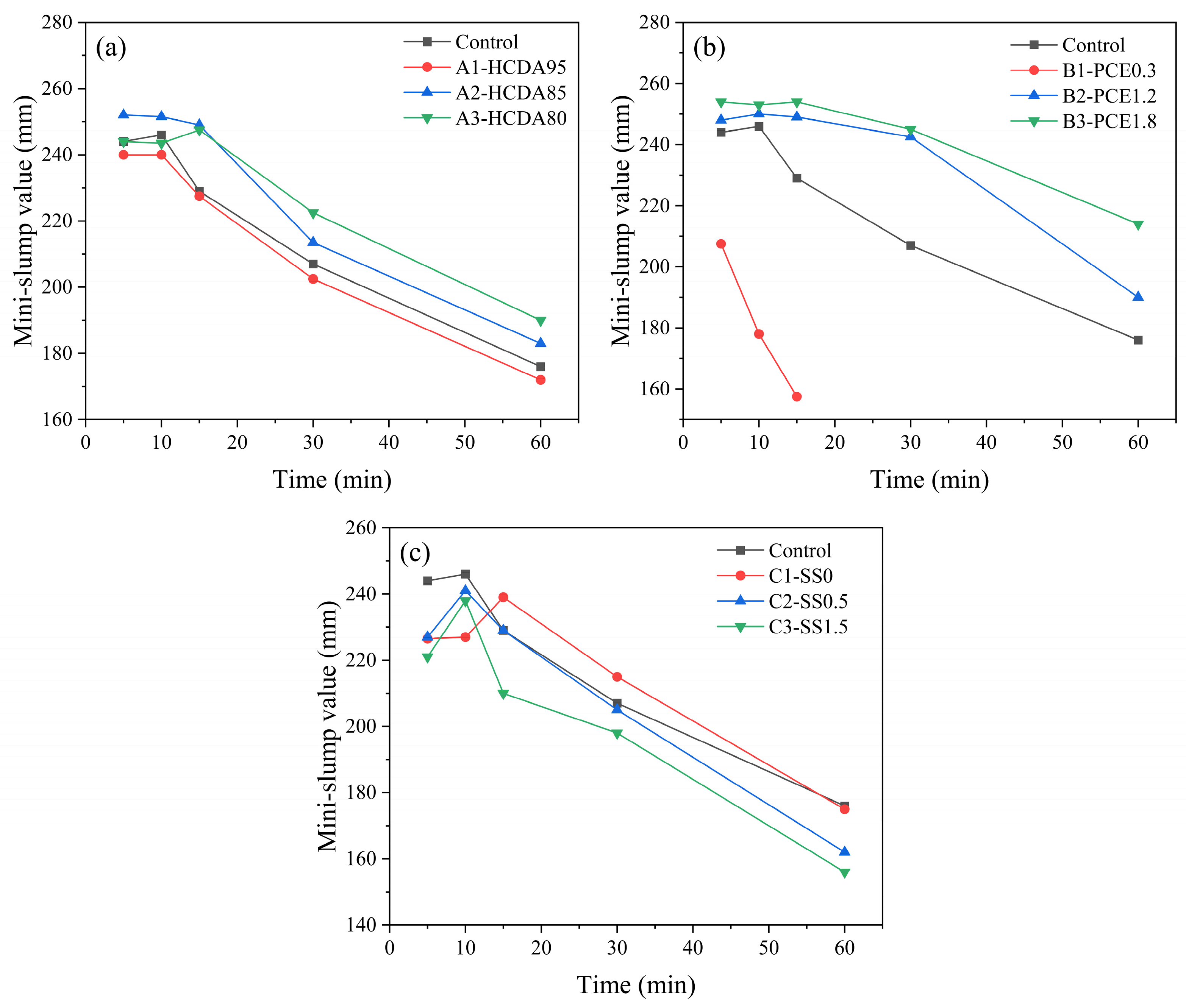

3.3. Mini-Slump

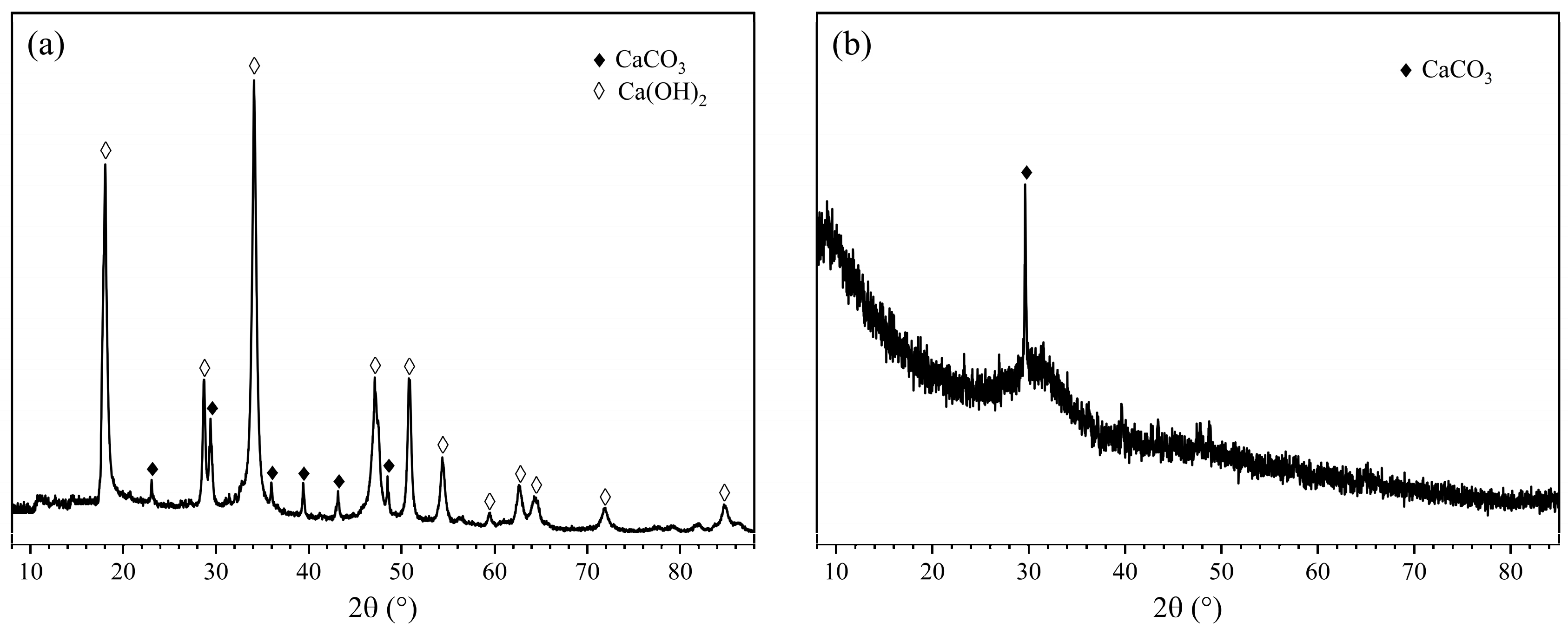

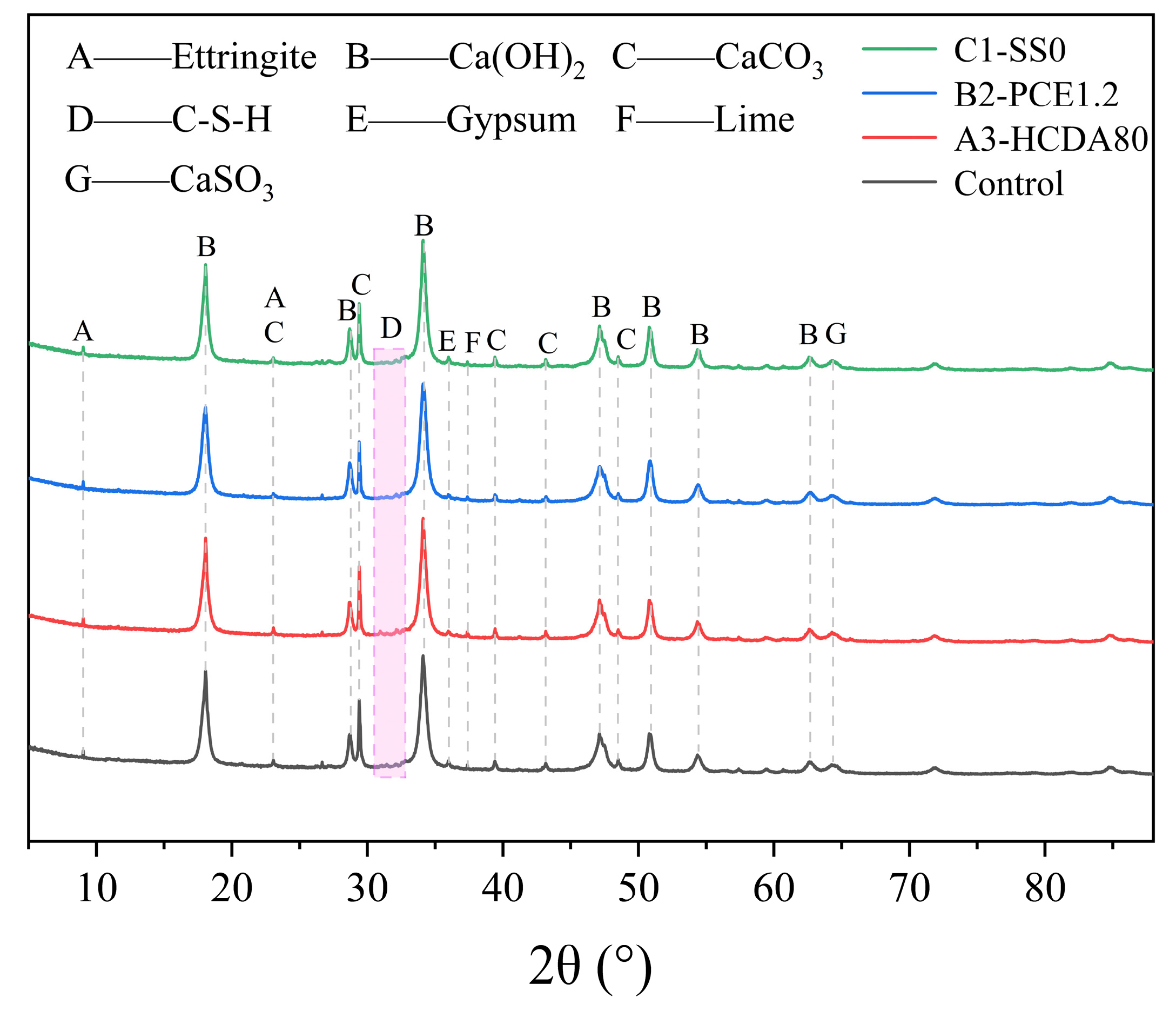

3.4. XRD Analysis

3.5. SEM Analysis

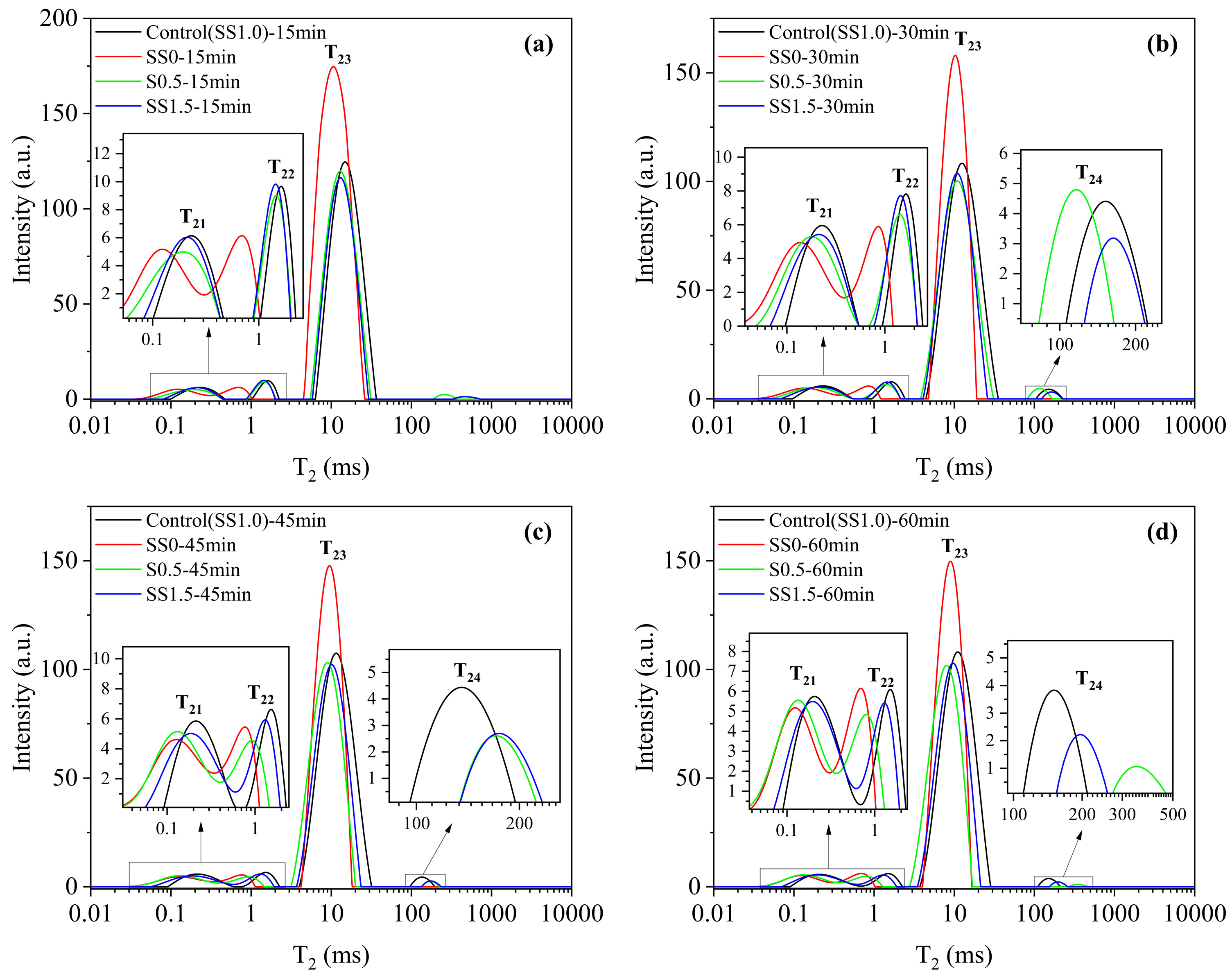

3.6. LF-NMR Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mao, Y.; Wu, H.; Wang, W.; Jia, M.; Che, X. Pretreatment of municipal solid waste incineration fly ash and preparation of solid waste source sulphoaluminate cementitious material. J. Hazard. Mater. 2020, 385, 121580. [Google Scholar] [CrossRef]

- Wu, C.; Li, J.; Lu, Y.; Zhu, D. The influence of industrial solid waste in conjunction with lepidolite tailings on the mechanical properties and microstructure of cemented backfill materials. Constr. Build. Mater. 2024, 419, 135422. [Google Scholar] [CrossRef]

- Hu, Y.; Hu, R.; Zhang, B.; Han, B. Research on mechanical properties and mix proportion design of solid waste-based cemented paste backfill. Case Stud. Constr. Mater. 2024, 21, e03618. [Google Scholar] [CrossRef]

- Navarrete, I.; Vargas, F.; Martinez, P.; Paul, A.; Lopez, M. Flue gas desulfurization (FGD) fly ash as a sustainable, safe alternative for cement-based materials. J. Clean. Prod. 2021, 283, 124646. [Google Scholar] [CrossRef]

- de Castro, R.d.P.V.; de Medeiros, J.L.; Araújo, O.d.Q.F.; de Andrade Cruz, M.; Ribeiro, G.T.; de Oliveira, V.R. Fluidized bed treatment of residues of semi-dry flue gas desulfurization units of coal-fired power plants for conversion of sulfites to sulfates. Energy Convers. Manag. 2017, 143, 173–187. [Google Scholar] [CrossRef]

- Li, X.; Han, J.; Liu, Y.; Dou, Z.; Zhang, T. Summary of research progress on industrial flue gas desulfurization technology. Sep. Purif. Technol. 2022, 281, 119849. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Fontes, M.P.F.; Ribeiro, J.C.L.; Vieira, C.M.F.; Pacheco, A.A.; Azevedo, A.R.G.D. Technical and environmental assessment of the incorporation of iron ore tailings in construction clay bricks. Constr. Build. Mater. 2019, 227, 116669. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, K.; He, X.; Wei, Z.; Zhang, J. Study on proportioning experiment and performance of solid waste for underground backfilling. Mater. Today Commun. 2022, 32, 103863. [Google Scholar] [CrossRef]

- Koukouzas, N.; Ketikidis, C.; Itskos, G.; Spiliotis, X.; Karayannis, V.; Papapolymerou, G. Synthesis of CFB-Coal Fly Ash Clay Bricks and Their Characterisation. Waste Biomass Valorization 2011, 2, 87–94. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Zhang, Z.; Wang, Y.; Xue, Y.; Hao, X.; Lu, Y. Circulating Fluidized Bed Fly Ash Mixed Functional Cementitious Materials: Shrinkage Compensation of f-CaO, Autoclaved Hydration Characteristics and Environmental Performance. Materials 2021, 14, 6004. [Google Scholar] [CrossRef]

- Jia, G.; Wang, Y.; Yang, F. A Review on the Application of Circulating Fluidized Bed Fly Ash in Building Materials. Adv. Mater. Sci. Eng. 2022, 2022, 1–19. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T. Effects of High CaO Fly Ash and Sulfate Activator as a Finer Binder for Cementless Grouting Material. Materials 2019, 12, 3664. [Google Scholar] [CrossRef]

- Ren, K.; Ma, S.; Feng, Y.; Xu, N.; Bai, S. Study on the composite gravel preparation and the synergistic absorption of CO2 by fly ash of CFB boiler. Fuel 2023, 342, 127843. [Google Scholar] [CrossRef]

- Li, X.; Chen, Q.; Ma, B.; Huang, J.; Jian, S.; Wu, B. Utilization of modified CFBC desulfurization ash as an admixture in blended cements: Physico-mechanical and hydration characteristics. Fuel 2012, 102, 674–680. [Google Scholar] [CrossRef]

- Yang, L.; Jing, M.; Lu, L.; Zhu, X.; Zhao, P.; Chen, M.; Li, L.; Liu, J. Effects of modified materials prepared from wastes on the performance of flue gas desulfurization gypsum-based composite wall materials. Constr. Build. Mater. 2020, 257, 119519. [Google Scholar] [CrossRef]

- Wang, C.-Q.; Cheng, L.-X.; Wang, Z.-Y.; Qi, C.-J.; Huang, D.-M.; Wei, S. Preparation and properties of high blending phosphogypsum-desulfurization ash-waste soil based functional prefabricated autoclaved aerated concrete slabs. Constr. Build. Mater. 2024, 423, 135879. [Google Scholar] [CrossRef]

- Li, K.; Zhou, Z.; Cao, W.; Zhang, Y. Effect of dry desulfurization ash as a filler on asphalt pavement performance. Constr. Build. Mater. 2024, 412, 134692. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Li, Z.; Ren, Y.; Wang, Y.; Zhang, W. Preparation, characterization and application of red mud, fly ash and desulfurized gypsum based eco-friendly road base materials. J. Clean. Prod. 2021, 284, 124777. [Google Scholar] [CrossRef]

- Wei, Z.; Liu, Q.; Sun, Z.; Huang, X.; Gan, M.; Ji, Z.; Chen, X.; Fan, X. Co-disposal of semi-dry desulfurization residue and red mud into high performance alkali activated material. Constr. Build. Mater. 2022, 350, 128776. [Google Scholar] [CrossRef]

- Feng, X.; Wang, C.; Ding, S. Performance of desulfurization ash for the preparation of grouting fire prevention material. Environ. Sci. Pollut. Res. 2019, 26, 19228–19240. [Google Scholar] [CrossRef]

- Kovler, K. Setting and Hardening of Gypsum-Portland Cement-Silica Fume Blends, Part 2: Early Strength, DTA, XRD, and SEM Observations. Cem. Concr. Res. 1998, 28, 523–531. [Google Scholar] [CrossRef]

- Rathnayake, M.; Julnipitawong, P.; Tangtermsirikul, S.; Toochinda, P. Utilization of coal fly ash and bottom ash as solid sorbents for sulfur dioxide reduction from coal fired power plant: Life cycle assessment and applications. J. Clean. Prod. 2018, 202, 934–945. [Google Scholar] [CrossRef]

- Blanco, F.; Garcia, M.P.; Ayala, J.; Mayoral, G.; Garcia, M.A. The effect of mechanically and chemically activated fly ashes on mortar properties. Fuel 2006, 85, 2018–2026. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Jiao, F.; Qin, W.; Yang, C. Production and resource utilization of flue gas desulfurized gypsum in China—A review. Environ. Pollut. 2021, 288, 117799. [Google Scholar] [CrossRef]

- Ma, Y.; Nie, Q.; Xiao, R.; Hu, W.; Han, B.; Polaczyk, P.A.; Huang, B. Experimental investigation of utilizing waste flue gas desulfurized gypsum as backfill materials. Constr. Build. Mater. 2020, 245, 118393. [Google Scholar] [CrossRef]

- Ren, J.; Liu, B.; Guo, J.; Liu, J.; Xing, F.; Zhu, H.; Zhao, L.; Mi, T. Bio-treatment of municipal solid waste incineration fly ash: A sustainable path for recyclability. J. Clean. Prod. 2024, 434, 139869. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Wu, A.; Shi, D.; Yang, S.; Ruan, Z.; Song, X.; Zhang, M. Early mechanical strength, hydration mechanism and leaching behavior of alkali-activated slag/fly ash paste filling materials. J. Build. Eng. 2024, 84, 108481. [Google Scholar] [CrossRef]

- Song, X.; Huang, Y.; Wang, S.; Yu, H.; Hao, Y. Macro-mesoscopic mechanical properties and damage progression of cemented tailings backfill under cyclic static load disturbance. Compos. Struct. 2023, 322, 117433. [Google Scholar] [CrossRef]

- Zhang, S.; Du, W.; Jin, Y.; Li, Y. Performance and hydration mechanism of fly ash coal-based solid waste backfill material affected by multiple factors. Mater. Today Commun. 2024, 41, 110639. [Google Scholar] [CrossRef]

- Wu, M.; Wang, C.; Zuo, Y.; Yang, S.; Zhang, J.; Luo, Y. Study on strength prediction and strength change of Phosphogypsum-based composite cementitious backfill based on BP neural network. Mater. Today Commun. 2024, 41, 110331. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Li, B.; Zhou, N.; Xiao, X.; Li, M.; Zhu, C. Environmental behavior of construction and demolition waste as recycled aggregates for backfilling in mines: Leaching toxicity and surface subsidence studies. J. Hazard. Mater. 2020, 389, 121870. [Google Scholar] [CrossRef] [PubMed]

- Xin, J.; Liu, L.; Xu, L.; Wang, J.; Yang, P.; Qu, H. A preliminary study of aeolian sand-cement-modified gasification slag-paste backfill: Fluidity, microstructure, and leaching risks. Sci. Total Environ. 2022, 830, 154766. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Qiu, J.; Wu, P.; Guo, Z.; Zhang, S.; Sun, X. Preparing a binder for cemented paste backfill using low-aluminum slag and hazardous oil shale residue and the heavy metals immobilization effects. Powder Technol. 2022, 399, 117167. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, H.; Tang, X.; Wang, Y.; An, H.; Liu, J. Historical trend and decarbonization pathway of China’s cement industry: A literature review. Sci. Total Environ. 2023, 891, 164580. [Google Scholar] [CrossRef]

- Clavier, K.A.; Watts, B.; Liu, Y.; Ferraro, C.C.; Townsend, T.G. Risk and performance assessment of cement made using municipal solid waste incinerator bottom ash as a cement kiln feed. Resour. Conserv. Recycl. 2019, 146, 270–279. [Google Scholar] [CrossRef]

- Liu, S.; Fall, M. Fresh and hardened properties of cemented paste backfill: Links to mixing time. Constr. Build. Mater. 2022, 324, 126688. [Google Scholar] [CrossRef]

- Haiqiang, J.; Fall, M.; Cui, L. Yield stress of cemented paste backfill in sub-zero environments: Experimental results. Miner. Eng. 2016, 92, 141–150. [Google Scholar] [CrossRef]

- Yin, S.; Yan, Z.; Chen, X.; Wang, L. Effect of fly-ash as fine aggregate on the workability and mechanical properties of cemented paste backfill. Case Stud. Constr. Mater. 2022, 16, e01039. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Pel, L.; Zhao, Y.; Zhu, Q.; Kwek, J.W.; Zhang, L.; Jiang, H.; Yang, J.; Qu, Z. A contribution to understanding the rheological measurement, yielding mechanism and structural evolution of fresh cemented paste backfill. Cem. Concr. Compos. 2023, 143, 105221. [Google Scholar] [CrossRef]

- Sagade, A.; Fall, M. Study of fresh properties of cemented paste backfill material with ternary cement blends. Constr. Build. Mater. 2024, 411, 134287. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Saa, E.G. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Space Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, X.; Zhang, X.; Qiu, J.; Jiang, H.; Zhao, Y.; Wu, P.; Zhang, Q. Effect of superplasticizer on rheology and thixotropy of superfine-tailings cemented paste backfill: Experiment and modelling. Constr. Build. Mater. 2022, 316, 125693. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, K.; Chen, Y.; Wu, H.; Li, C. Rheological performance regulation of solidified soil slurry for mine reclamation: Superplasticizer selection and structural characterization based on in-situ techniques. Constr. Build. Mater. 2024, 445, 137954. [Google Scholar] [CrossRef]

- GB/T 203—2008; Granulated Blast Furnace Slag Used for Cement Production. China National Standardization Administration Committee: Beijing, China, 2008.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of The Portland Cement. China National Standardization Administration Committee: Beijing, China, 2011.

- Yang, T.; Zhu, H.; Zhang, Z.; Gao, X.; Zhang, C.; Wu, Q. Effect of fly ash microsphere on the rheology and microstructure of alkali-activated fly ash/slag pastes. Cem. Concr. Res. 2018, 109, 198–207. [Google Scholar] [CrossRef]

- Puertas, F.; Varga, C.; Alonso, M.M. Rheology of alkali-activated slag pastes. Effect of the nature and concentration of the activating solution. Cem. Concr. Compos. 2014, 53, 279–288. [Google Scholar] [CrossRef]

- GB/T 8077-2012; Methods for Testing Uniformity of Concrete Admixture. China National Standardization Administration Committee: Beijing, China, 2012.

- Huang, T.; Yuan, Q.; Zuo, S.; Shi, C. Evolution of elastic behavior of alite paste at early hydration stages. J. Am. Ceram. Soc. 2020, 103, 6490–6504. [Google Scholar] [CrossRef]

- Huang, T.; Yuan, Q.; He, F.; Xie, Y. Understanding the mechanisms behind the time-dependent viscoelasticity of fresh C3A–gypsum paste. Cem. Concr. Res. 2020, 133, 106084. [Google Scholar] [CrossRef]

- Bligh, M.W.; d’Eurydice, M.N.; Lloyd, R.R.; Arns, C.H.; Waite, T.D. Investigation of early hydration dynamics and microstructural development in ordinary Portland cement using 1H NMR relaxometry and isothermal calorimetry. Cem. Concr. Res. 2016, 83, 131–139. [Google Scholar] [CrossRef]

- Nguyen, H.-A.; Chang, T.-P.; Chen, C.-T.; Huang, T.-Y. Engineering and creep performances of green super-sulfated cement concretes using circulating fluidized bed combustion fly ash. Constr. Build. Mater. 2022, 346, 128274. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Zhang, L.; Wan, Y.; Li, H.; Jiao, X. Rheology, mechanics, microstructure and durability of low-carbon cementitious materials based on circulating fluidized bed fly ash: A comprehensive review. Constr. Build. Mater. 2024, 411, 134688. [Google Scholar] [CrossRef]

- Li, P.P.; Yu, Q.L.; Brouwers, H.J.H. Effect of PCE-type superplasticizer on early-age behaviour of ultra-high performance concrete (UHPC). Constr. Build. Mater. 2017, 153, 740–750. [Google Scholar] [CrossRef]

- Chen, X.; Yang, X.; Wu, K.; Chen, Q.; Yang, Z.; Xu, L.; Li, H. Understanding the role of C–S–H seed/PCE nanocomposites, triethanolamine, sodium nitrate and PCE on hydration and performance at early age. Cem. Concr. Compos. 2023, 139, 105002. [Google Scholar] [CrossRef]

- Chang, J.J. A study on the setting characteristics of sodium silicate-activated slag pastes. Cem. Concr. Res. 2003, 33, 1005–1011. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, Y.; Wang, K.; Bu, Y.; Wang, C.; Ma, C.; Liu, H. Delaying the hydration of portland cement by sodium silicate: Setting time and retarding mechanism. Constr. Build. Mater. 2019, 205, 543–548. [Google Scholar] [CrossRef]

- Yang, P.; Liu, L.; Suo, Y.; Qu, H.; Xie, G.; Zhang, C.; Deng, S.; Lv, Y. Basic characteristics of magnesium-coal slag solid waste backfill material: Part I. preliminary study on flow, mechanics, hydration and leaching characteristics. J. Environ. Manag. 2023, 329, 117016. [Google Scholar] [CrossRef]

- Dai, X.; Aydin, S.; Yardimci, M.Y.; Lesage, K.; De Schutter, G. Early age reaction, rheological properties and pore solution chemistry of NaOH-activated slag mixtures. Cem. Concr. Compos. 2022, 133, 104715. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.J.; Jiao, D.W.; An, X.P. Review on Rheological Properties, Models and Measurements for Fresh Cementitious Materials. J. Chin. Ceram. Soc. 2017, 45, 700–709. [Google Scholar] [CrossRef]

- de Larrard, F.; Ferraris, C.F.; Sedran, T. Fresh concrete: A Herschel-Bulkley material. Mater. Struct. 1998, 31, 494–498. [Google Scholar] [CrossRef]

- Lopez Gonzalez, P.L.; Novais, R.M.; Labrincha, J.A.; Blanpain, B.; Pontikes, Y. Modifications of basic-oxygen-furnace slag microstructure and their effect on the rheology and the strength of alkali-activated binders. Cem. Concr. Compos. 2019, 97, 143–153. [Google Scholar] [CrossRef]

- Sun, R.; Wang, D. The property, structure, and phase evolution of a binary cementitious material derived from sintering flue gas desulphurization ash and steel slag. J. Build. Eng. 2024, 86, 108908. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, T.; Ni, W.; Li, K.; Gao, W.; Wang, K.; Zhang, Y. The mechanism of hydrating and solidifying green mine fill materials using circulating fluidized bed fly ash-slag-based agent. J. Hazard. Mater. 2021, 415, 125625. [Google Scholar] [CrossRef]

- Feneuil, B.; Pitois, O.; Roussel, N. Effect of surfactants on the yield stress of cement paste. Cem. Concr. Res. 2017, 100, 32–39. [Google Scholar] [CrossRef]

- Qian, Y.; Lesage, K.; El Cheikh, K.; De Schutter, G. Effect of polycarboxylate ether superplasticizer (PCE) on dynamic yield stress, thixotropy and flocculation state of fresh cement pastes in consideration of the critical micelle concentration (CMC). Cem. Concr. Res. 2018, 107, 75–84. [Google Scholar] [CrossRef]

- Tadros, T.F. Rheology of Dispersions: Principles and Applications; Wiley-VCH: Weinheim, Germany, 2010. [Google Scholar]

- Kashani, A.; Provis, J.L.; Qiao, G.G.; van Deventer, J.S.J. The interrelationship between surface chemistry and rheology in alkali activated slag paste. Constr. Build. Mater. 2014, 65, 583–591. [Google Scholar] [CrossRef]

- Palacios, M.; Gismera, S.; Alonso, M.M.; d’Espinose de Lacaillerie, J.B.; Lothenbach, B.; Favier, A.; Brumaud, C.; Puertas, F. Early reactivity of sodium silicate-activated slag pastes and its impact on rheological properties. Cem. Concr. Res. 2021, 140, 106302. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Wu, A.; Jiang, H.; Peng, Q.; Zhang, X. Evaluation of time-dependent rheological properties of cemented paste backfill incorporating superplasticizer with special focus on thixotropy and static yield stress. J. Cent. South Univ. 2022, 29, 1239–1249. [Google Scholar] [CrossRef]

- Jiang, H.; Fall, M.; Yilmaz, E.; Li, Y.; Yang, L. Effect of mineral admixtures on flow properties of fresh cemented paste backfill: Assessment of time dependency and thixotropy. Powder Technol. 2020, 372, 258–266. [Google Scholar] [CrossRef]

- Puertas, F.; Fernández-Jiménez, A.; Blanco-Varela, M.T. Pore solution in alkali-activated slag cement pastes. Relation to the composition and structure of calcium silicate hydrate. Cem. Concr. Res. 2004, 34, 139–148. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, Z.; Hu, J.; Yu, Q.; Shi, C. Effects of anionic species of activators on the rheological properties and early gel characteristics of alkali-activated slag paste. Cem. Concr. Res. 2022, 162, 106968. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Shui, L.; Wang, Y.; Gu, M.; Wang, X.; Wang, H.; Peng, L. Effects of PCEs with various carboxylic densities and functional groups on the fluidity and hydration performances of cement paste. Constr. Build. Mater. 2019, 202, 656–668. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, B.; Tang, Y.; Zhao, G.; Pang, Z.; Shi, C. Innovative strategies for time-release PCE design and cement paste flowability control. Cem. Concr. Compos. 2024, 154, 105785. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q. Time-dependent rheological behavior of cementitious paste under continuous shear mixing. Constr. Build. Mater. 2019, 226, 591–600. [Google Scholar] [CrossRef]

- Zhou, K.; Ai, K.; Zhang, J.; Li, J. Nuclear Magnetic Rresonance Characteristics in Fresh Filling Slurry. Sci. Technol. Rev. 2013, 31, 50–53. [Google Scholar] [CrossRef]

- Ji, Y.; Sun, Z.; Yang, X.; Li, C.; Tang, X. Assessment and mechanism study of bleeding process in cement paste by 1H low-field NMR. Constr. Build. Mater. 2015, 100, 255–261. [Google Scholar] [CrossRef]

| Materials | Content of Each Ingredient (wt %) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | Fe2O3 | I | Other | |

| HCDA | 0.903 | 0.240 | 0.505 | 0.011 | 12.063 | 0.043 | 85.231 | 0.027 | 0.260 | 0.148 | 3.622 |

| GBFS | 6.123 | 13.299 | 28.852 | 0.014 | 2.689 | 0.469 | 45.810 | 0.978 | 0.654 | 0.040 | 0.440 |

| Item | HCDA to GBFS Ratio by Mass | PCE Addition (wt %) * | SS Addition (wt %) * |

|---|---|---|---|

| Control | 90:10 | 0.6% | 1.0% |

| A1-HCDA95 | 95:5 | 0.6% | 1.0% |

| A2-HCDA85 | 85:15 | ||

| A3-HCDA80 | 80:20 | ||

| B1-PCE0.3 | 90:10 | 0.3% | 1.0% |

| B2-PCE1.2 | 1.2% | ||

| B3-PCE1.8 | 1.8% | ||

| C1-SS0 | 90:10 | 0.6% | / |

| C2-SS0.5 | 0.5% | ||

| C3-SS1.5 | 1.5% |

| Item | Yield Stress (Pa) | Consistency Index (Pa·sn) | Power Law Index | R2 | Plastic Viscosity (Pa·s) |

|---|---|---|---|---|---|

| Control | 0.269 | 0.5133 | 1.1527 | 0.998 | 0.9868 |

| A1-HCDA95 | 0.684 | 0.3773 | 1.2985 | 0.996 | 1.3567 |

| A2-HCDA85 | 0.171 | 0.2983 | 1.2568 | 0.998 | 0.8966 |

| A3-HCDA80 | 0.082 | 0.2105 | 1.3344 | 0.999 | 0.8834 |

| B1-PCE0.3 | 0.320 | 0.3489 | 1.2019 | 0.999 | 0.8284 |

| B2-PCE1.2 | 0.628 | 0.6493 | 1.1738 | 0.997 | 1.3664 |

| B3-PCE1.8 | 0.349 | 0.3020 | 1.2922 | 0.999 | 1.0569 |

| C1-SS0 | 0.535 | 0.3167 | 1.3022 | 0.999 | 1.1571 |

| C2-SS0.5 | 0.571 | 0.2466 | 1.3349 | 0.999 | 1.0371 |

| C3-SS1.5 | 0.875 | 0.1691 | 1.4285 | 0.999 | 1.0645 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, W.; Chen, J.; Ma, W. Study on the Rheological Properties of High Calcium Desulfurization Ash–Slag-Based Paste Backfill Material. Appl. Sci. 2025, 15, 5105. https://doi.org/10.3390/app15095105

Ling W, Chen J, Ma W. Study on the Rheological Properties of High Calcium Desulfurization Ash–Slag-Based Paste Backfill Material. Applied Sciences. 2025; 15(9):5105. https://doi.org/10.3390/app15095105

Chicago/Turabian StyleLing, Weigao, Jun Chen, and Wenbo Ma. 2025. "Study on the Rheological Properties of High Calcium Desulfurization Ash–Slag-Based Paste Backfill Material" Applied Sciences 15, no. 9: 5105. https://doi.org/10.3390/app15095105

APA StyleLing, W., Chen, J., & Ma, W. (2025). Study on the Rheological Properties of High Calcium Desulfurization Ash–Slag-Based Paste Backfill Material. Applied Sciences, 15(9), 5105. https://doi.org/10.3390/app15095105