Optimization Design of Centrifugal Fan Blades Based on Bézier Curve Method

Abstract

1. Introduction

2. The Experiment and Numerical Methodology of the Fan

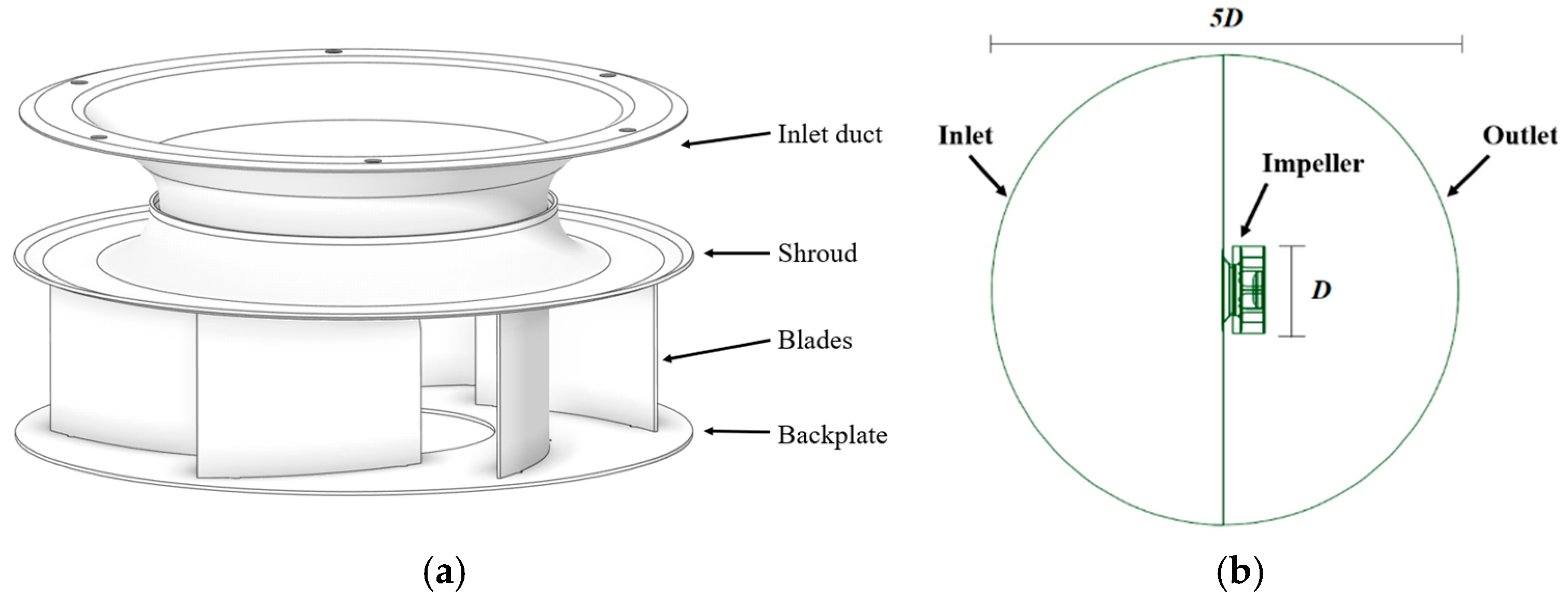

2.1. The Model of the Voluteless Centrifugal Fan

2.2. Boundary Condition and Mesh Validation

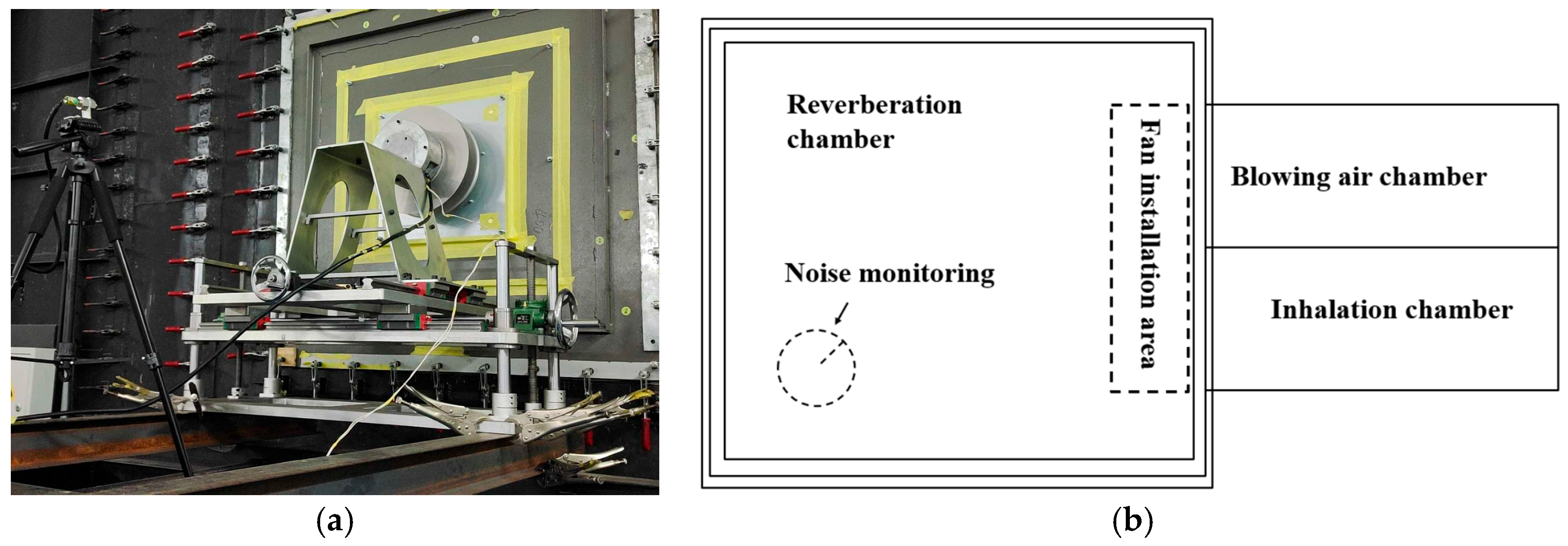

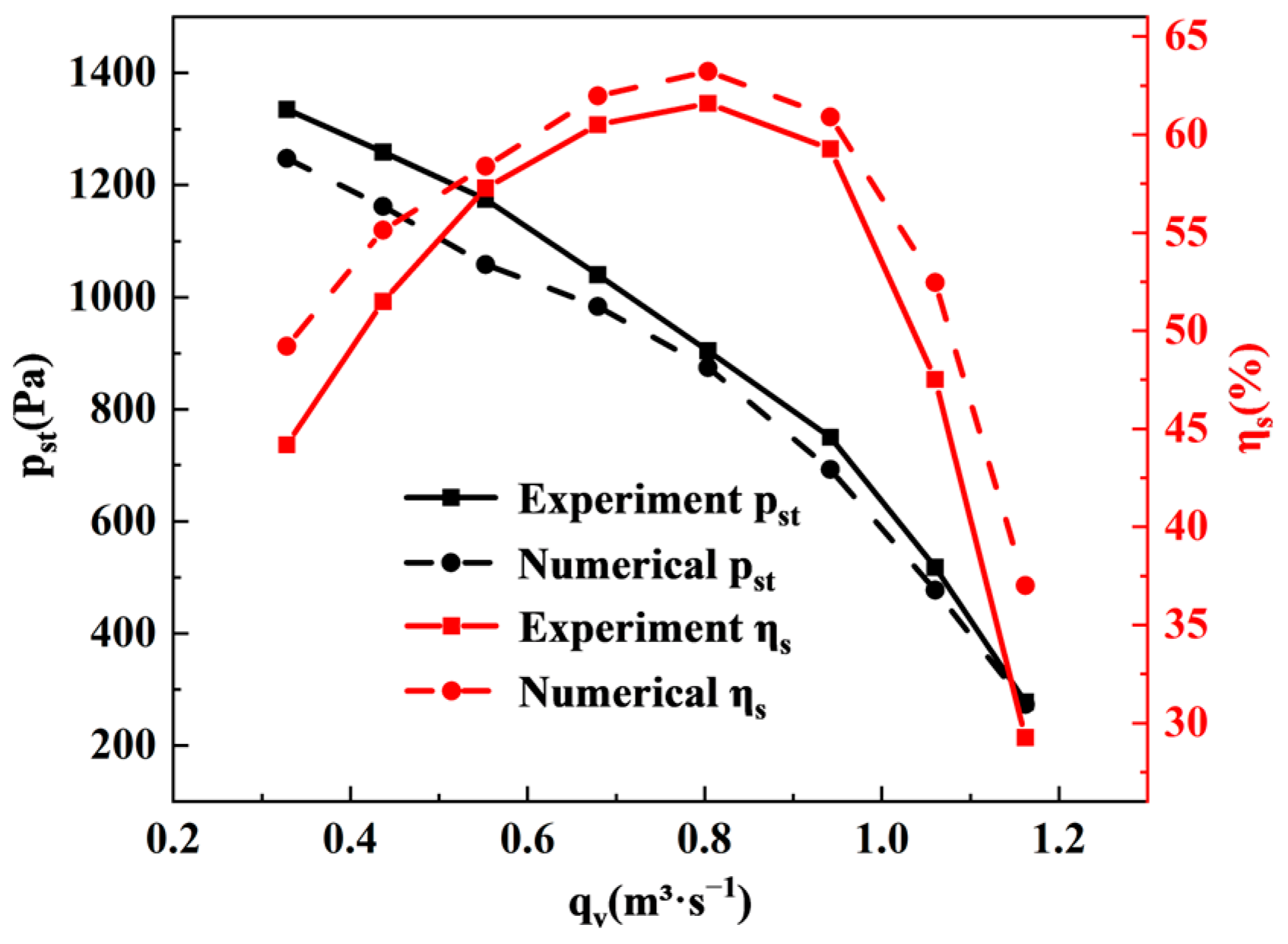

2.3. External Characteristic Performance Experiment and Numerical Validation

3. Multi-Objective Optimization Task

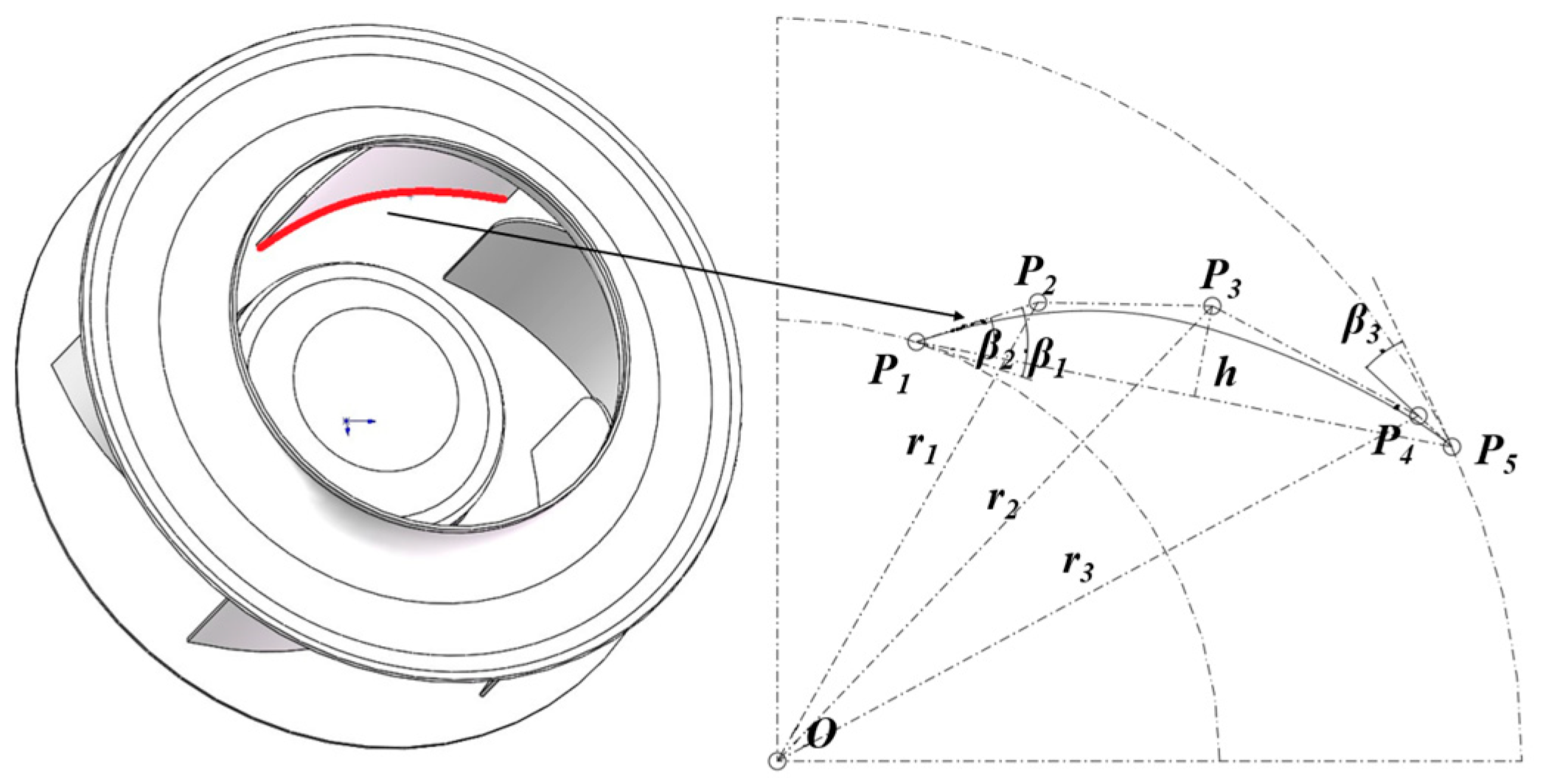

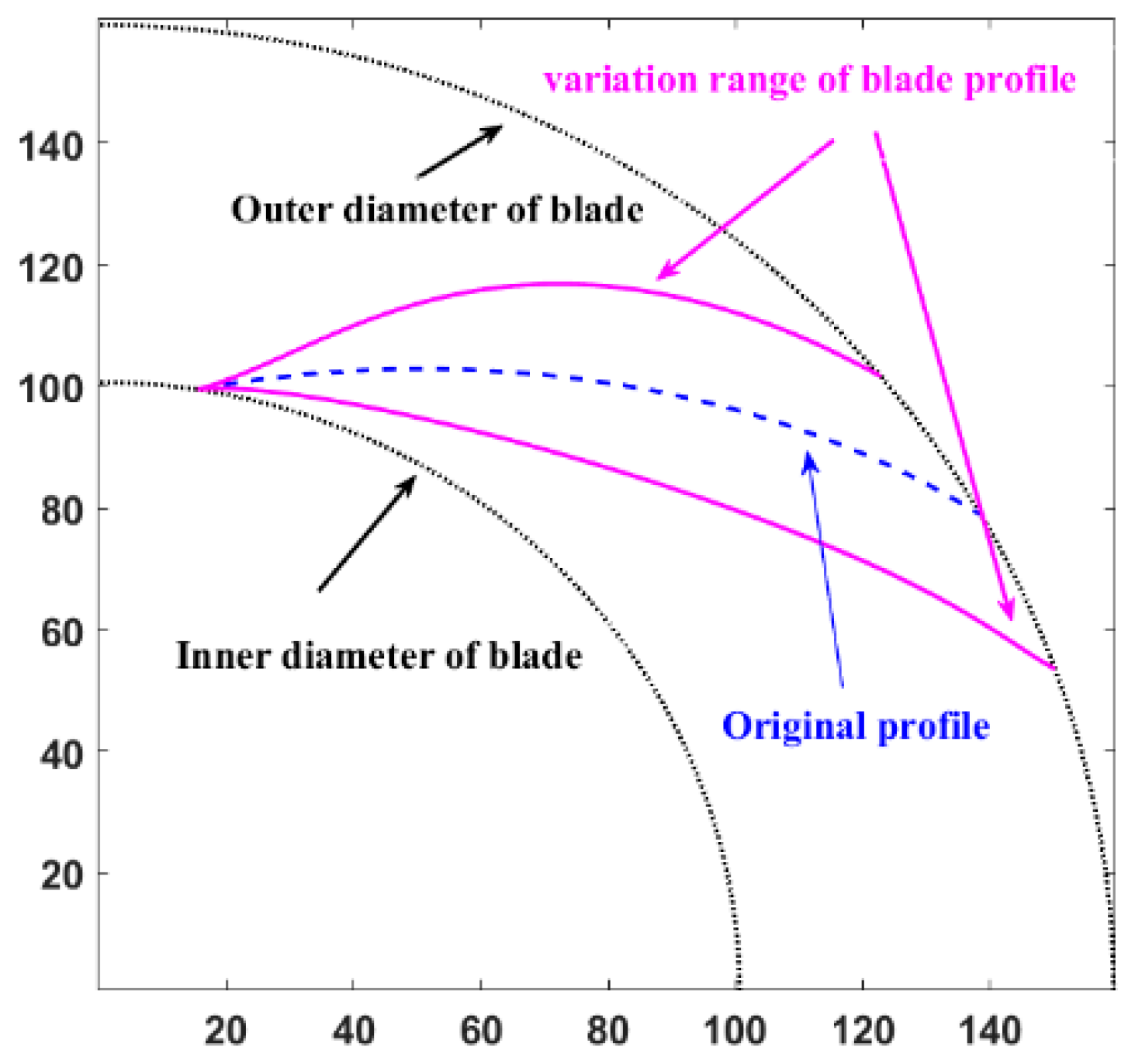

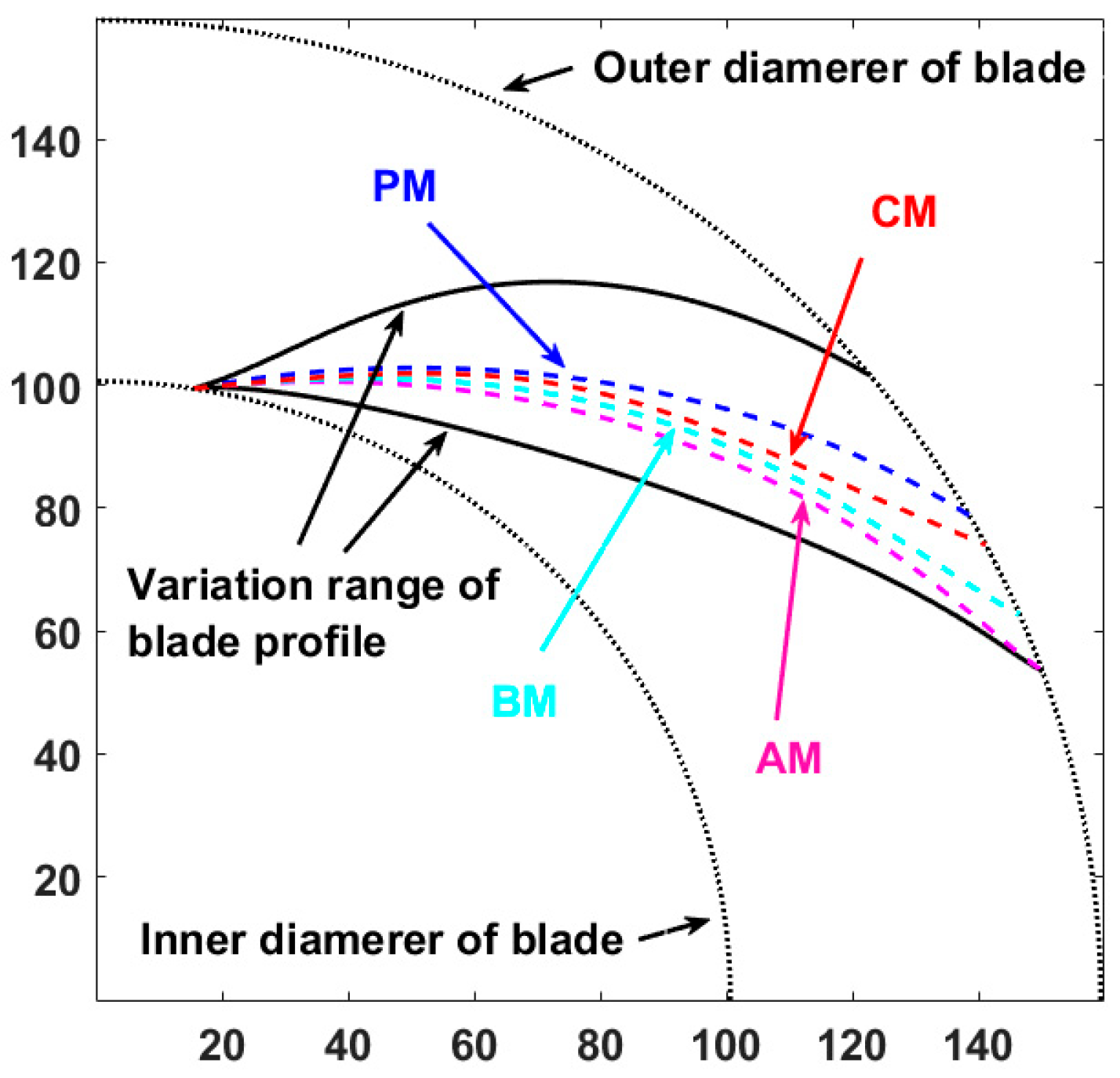

3.1. Blade Profile Parameter Design with Bézier Curve Method

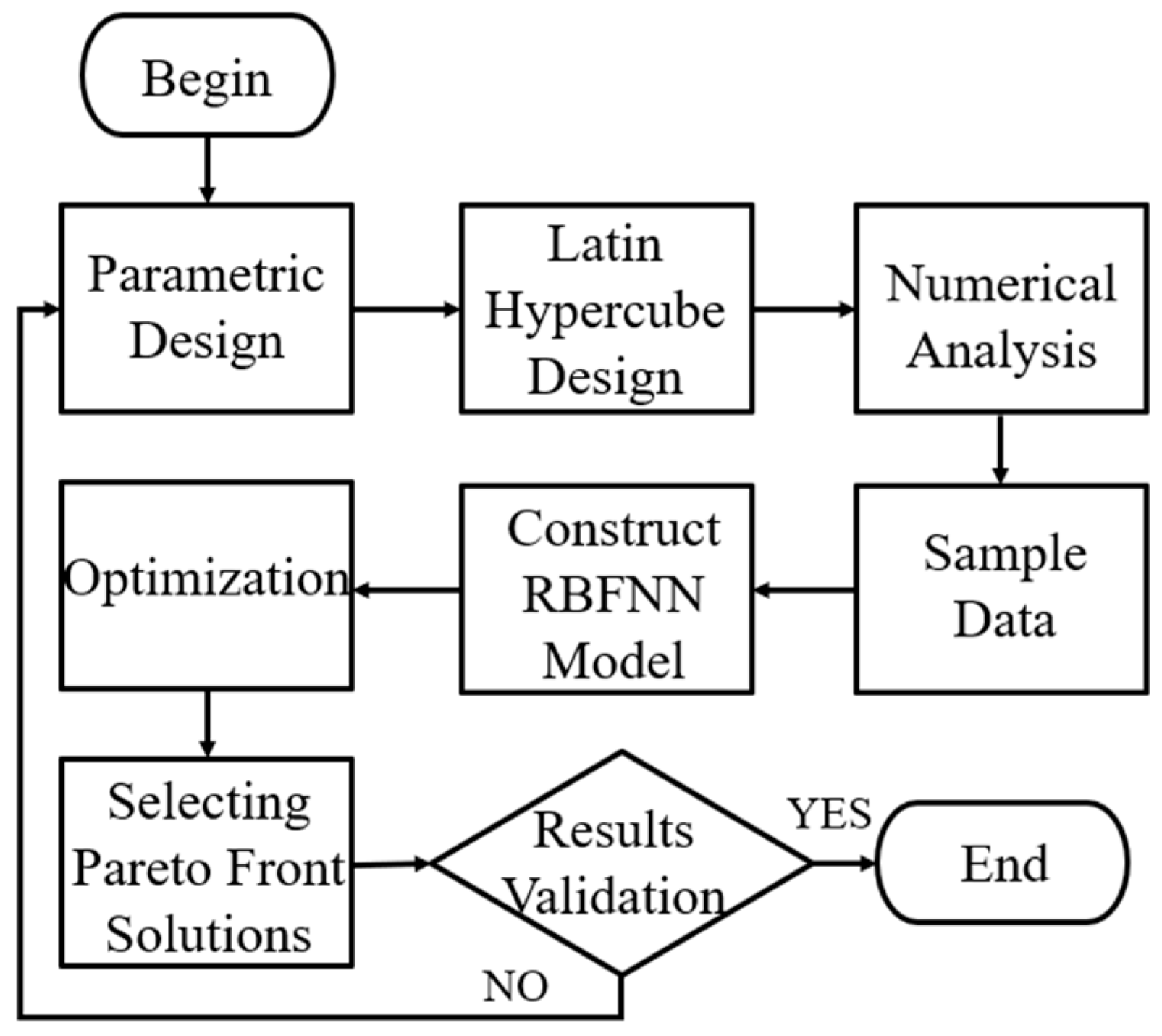

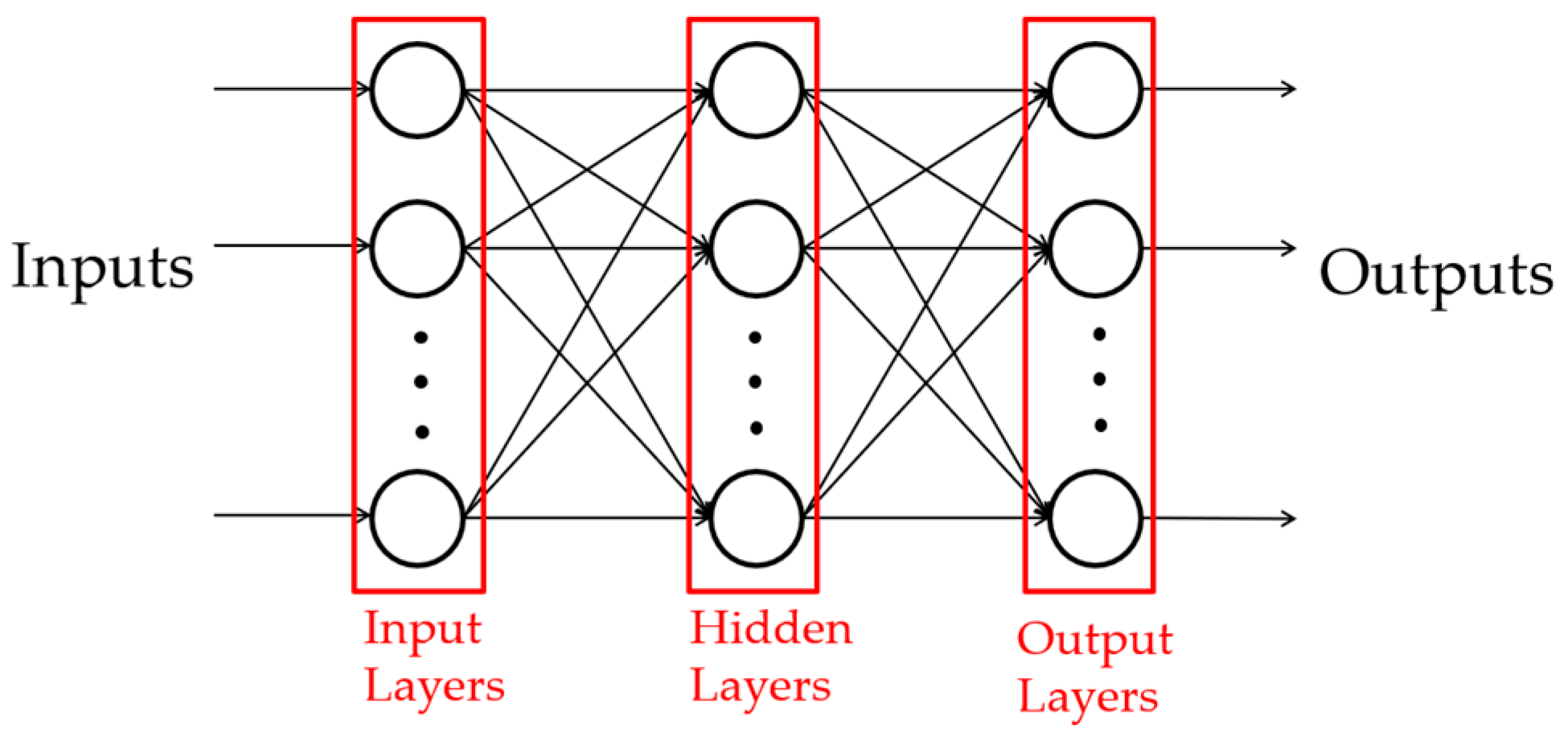

3.2. Design Parameter Selection and Surrogate Model Construction

3.3. Optimization Schemes

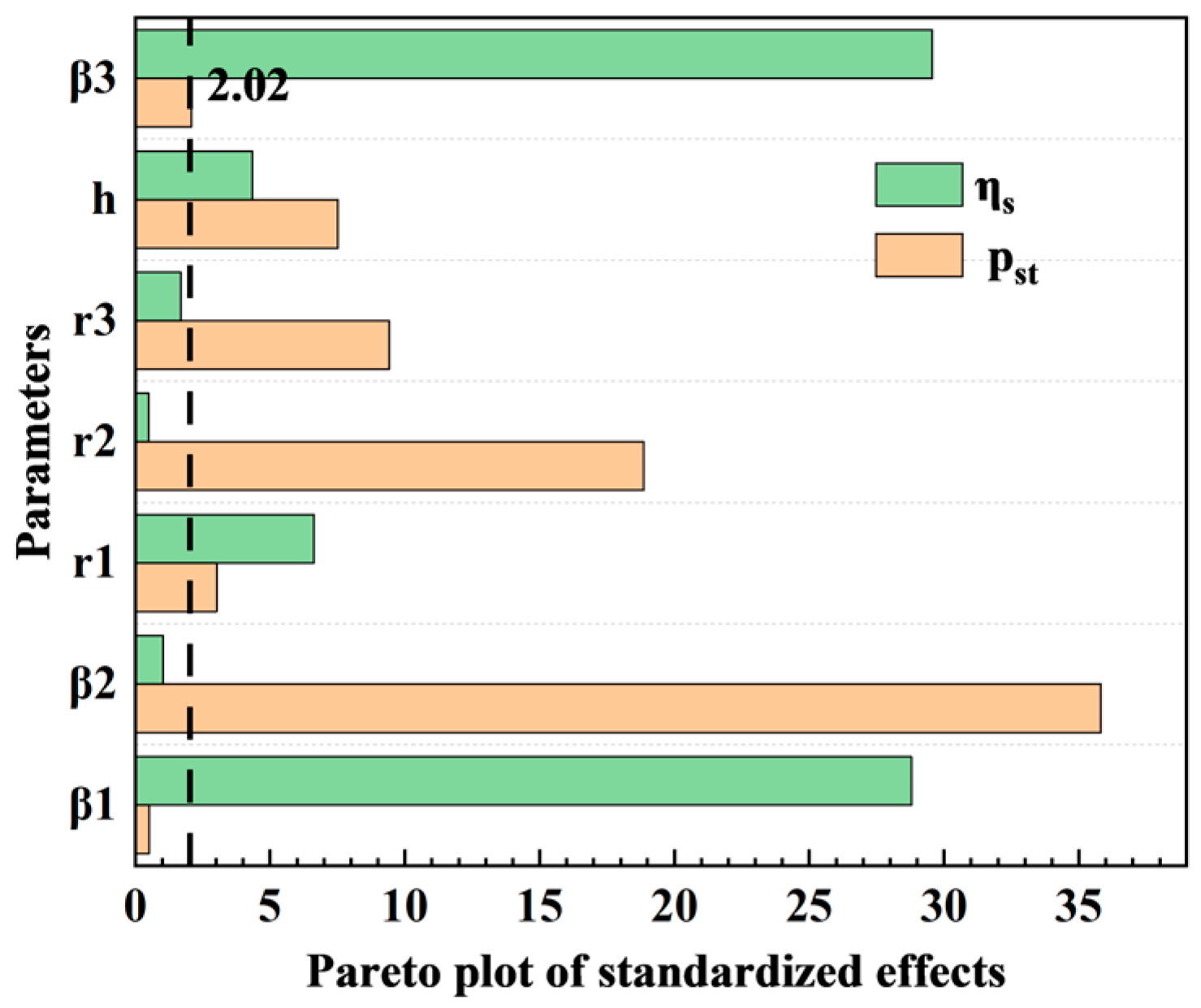

3.4. Significance Test of Parameter

4. Result and Discussion

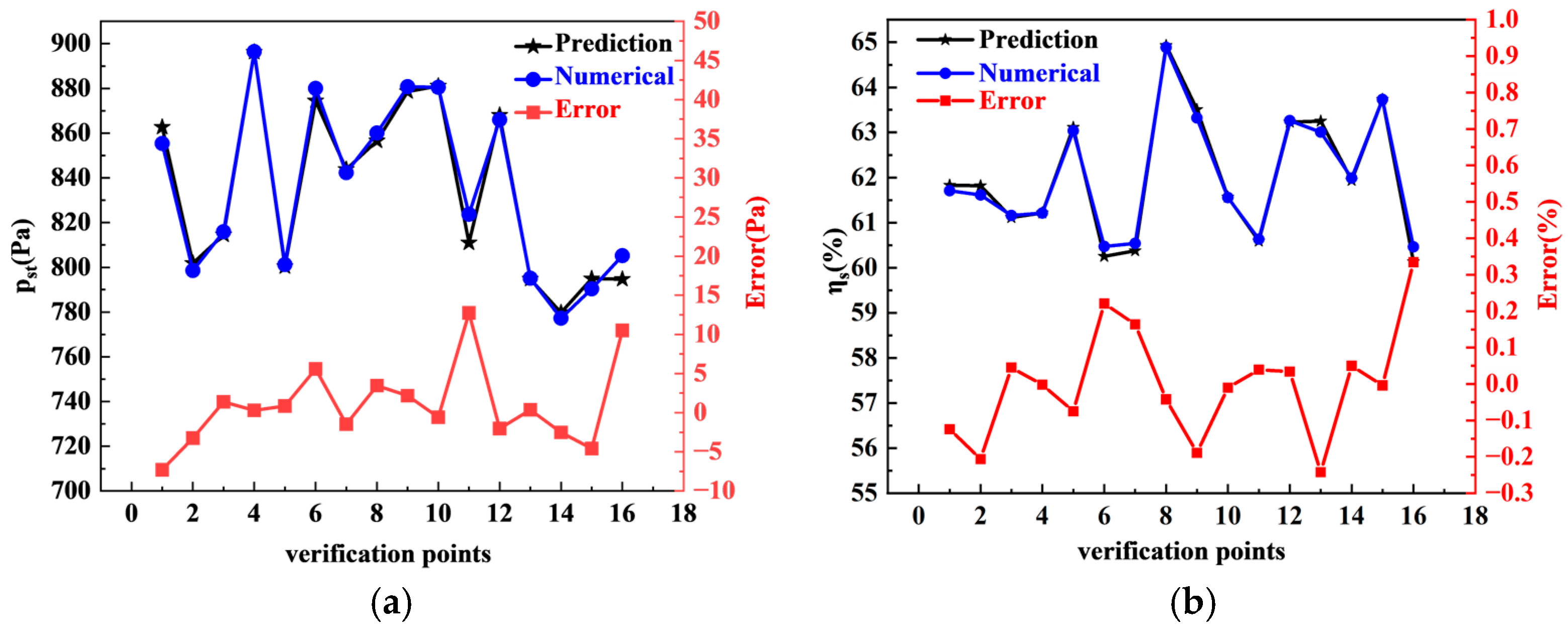

4.1. Selection and Validation of Optimization Results

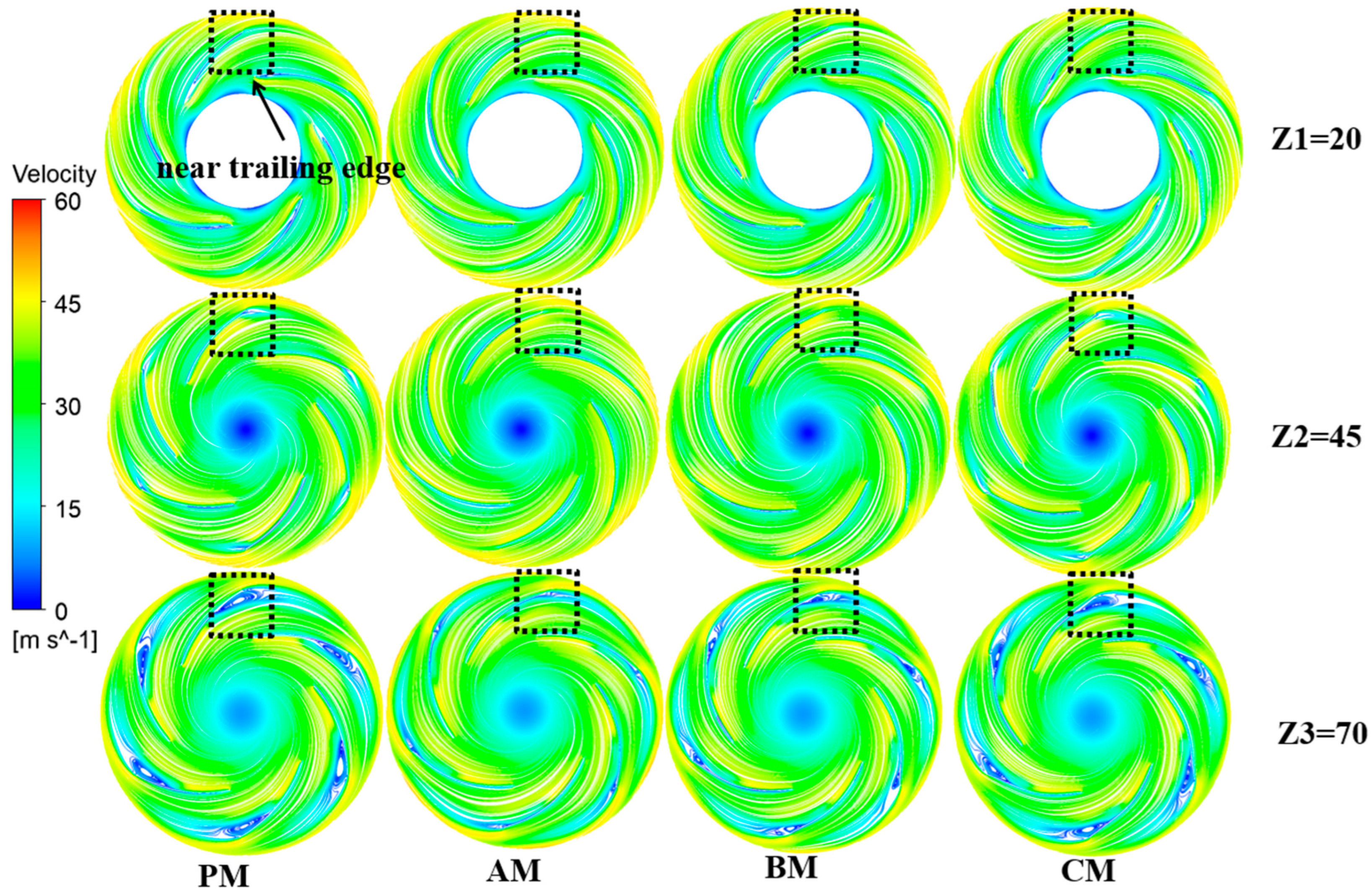

4.2. Flow-Field Analysis

5. Conclusions

- The fourth-order Bézier curve method achieved a fitting accuracy of 99.6% when reproducing the original blade shape, which met the required precision for blade profile fitting.

- Based on the blade profile display results, the fourth-order Bézier curve method offered more flexible control over the curvature at different chord lengths. The optimized blade curvature increased from the inlet to a peak and then decreases towards the outlet, resulting in a more pronounced profile at the inlet and a smoother profile at the outlet.

- The optimal Latin hypercube summation method was used to construct the samples, and significance analysis was conducted on the design parameters. It can be seen form the result that β2 and r2 had a greater influence on static pressure, while β1 and β3 had a greater impact on static pressure efficiency. The optimization results were consistent with the significance analysis, indicating that there were interactions among the design parameters and that the overall model was extremely significantly correlated.

- The radial basis neural network accurately and effectively captured the mapping relationship between the design parameters and the target outcomes. Compared with numerical results, the prediction error of the surrogate model did not exceed 1%, which met the accuracy requirements.

- After optimization, the fan’s static pressure at the design operating condition increased by 12.7 Pa, and the static pressure efficiency increased by 3.2%, leading to improved fan performance. The optimized fan’s high-efficiency point shifted toward the low-flow region, with notable improvements in both efficiency and static pressure under low-flow conditions. This broadened the high-efficiency operating range, making the fan better suited to various application scenarios.

- After optimization, the streamlines aligned more closely with the blade profile. The impact at the blade inlet and the separation on the suction side were improved, resulting in reduced flow loss. At the same time, the vortical structures and vortex intensity within the channel were significantly diminished, effectively suppressing complex flow phenomena.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, L.; Dou, H.-S.; Wei, Y.; Chen, Y.; Cao, W.; Ying, C. Optimization of Blade Profile of a Plenum Fan. Int. J. Fluid Mach. Syst. 2016, 9, 95–106. [Google Scholar] [CrossRef]

- Ye, J.; Liu, W.; Duan, P.; Huang, X.; Shao, J.; Zhang, Y. Investigation of the Performance and Flow Behaviors of the Multi-Blade Centrifugal Fan Based on the Computer Simulation Technology. Wirel. Pers. Commun. 2018, 103, 563–574. [Google Scholar] [CrossRef]

- Ni, S.; Cao, W.; Xu, J.; Wang, Y.; Zhang, W. Effects of an Inclined Blade on the Performance of a Sirocco Fan. Appl. Sci. 2019, 9, 3154. [Google Scholar] [CrossRef]

- Kulfan, B.M. Recent Extensions and Applications of the ‘CST’ Universal Parametric Geometry Representation Method. Aeronaut. J. 2010, 114, 157–176. [Google Scholar] [CrossRef]

- Zhu, M.; Li, Z.; Li, G.; Ye, X.; Liu, Y.; Chen, Z.; Li, N. An Investigation on Optimized Performance of Voluteless Centrifugal Fans by a Class and Shape Transformation Function. Processes 2023, 11, 1751. [Google Scholar] [CrossRef]

- Zhou, S.; Yang, K.; Zhang, W.; Zhang, K.; Wang, C.; Jin, W. Optimization of Multi-Blade Centrifugal Fan Blade Design for Ventilation and Air-Conditioning System Based on Disturbance CST Function. Appl. Sci. 2021, 11, 7784. [Google Scholar] [CrossRef]

- Wei, Y.; Ying, C.; Xu, J.; Cao, W.; Wang, Z.; Zhu, Z. Effects of Single-Arc Blade Profile Length on the Performance of a Forward Multiblade Fan. Processes 2019, 7, 629. [Google Scholar] [CrossRef]

- Lee, K.J.; Park, I.W.; Bang, K.S.; Kim, Y.M.; Ahn, Y.C. Optimal Design of a Plenum Fan with Three-Dimensional Blades. Appl. Sci. 2020, 10, 3460. [Google Scholar] [CrossRef]

- Lei, J.; Cui, Q.; Qin, G. Performance Improvement of Multi-Blade Centrifugal Fan Based on Impeller Outlet Flow Control. Phys. Fluids 2024, 36, 095181. [Google Scholar] [CrossRef]

- Ferrari, C.; Beccati, N.; Pedrielli, F. CFD Methodology for an Underhood Analysis towards the Optimum Fan Position in a Compact Off-Road Machine. Energies 2023, 16, 4369. [Google Scholar] [CrossRef]

- Shao, W.; Feng, J.; Zhang, F.; Wang, S.; Li, Y.; Lv, J. Aerodynamic Performance Optimization of Centrifugal Fan Blade for Air System of Self-Propelled Cotton-Picking Machine. Agriculture 2023, 13, 1579. [Google Scholar] [CrossRef]

- Li, Z.; Luo, P.; Zhu, M.; Chen, Z. Surrogate Model on the Extension Operation Range of an Isolated Centrifugal Fan. J. Appl. Fluid Mech. 2024, 17, 900–911. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Yang, H.; Zhu, Z.; Wei, Y. Blade Shape Optimization and Internal-Flow Characteristics of the Backward Non-Volute Centrifugal Fan. Proc. Inst. Mech. Eng. Part J. Power Energy 2022, 236, 673–688. [Google Scholar] [CrossRef]

- Kim, S.J.; Sung, H.J.; Wallin, S.; Johansson, A.V. Design of the Centrifugal Fan of a Belt-Driven Starter Generator with Reduced Flow Noise. Int. J. Heat Fluid Flow 2019, 76, 72–84. [Google Scholar] [CrossRef]

- Acarer, S.; Uyulan, Ç.; Karadeniz, Z.H. Optimization of Radial Inflow Wind Turbines for Urban Wind Energy Harvesting. Energy 2020, 202, 117772. [Google Scholar] [CrossRef]

- Ferrari, C.; Pinelli, M.; Spina, P.R.; Bolognin, P.; Borghi, L. In Fluid Dynamic Design and Optimization of Two Stage Centrifugal Fan for Industrial Burners. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; 2011; pp. 483–490. [Google Scholar]

- Rengma, T.S.; Gupta, M.K.; Subbarao, P.M.V. A Novel Method of Optimizing the Savonius Hydrokinetic Turbine Blades Using Bezier Curve. Renew. Energy 2023, 216, 119091. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Z.; Liu, J.; Liu, M.; Zhou, Y. Optimization Design of Centrifugal Impeller Based on Bezier Surface and FFD Space Grid Parameterization. PLoS ONE 2024, 19, e0310792. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.; Li, L.; Wang, B.; Wang, H.; Yu, J.; Liang, L.; Xie, C.; Tang, Y. Optimization of Submersible LNG Centrifugal Pump Blades Design Based on Support Vector Regression and the Non-Dominated Sorting Genetic Algorithm II. Energy 2024, 313, 133812. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Design flow rate/kg·s−1 | 0.964 |

| Design rotational speed/r·min−1 | 3100 |

| Number of blades | 6 |

| Outer diameter of impeller/mm | 360 |

| Inner diameter of impeller/mm | 213 |

| Blade inlet angle/° | 20 |

| Blade outlet angle/° | 30.9 |

| Thickness of blades/mm | 2 |

| Width of the impeller/mm | 94 |

| Parameters | Expression | Original Value | Variety Range |

|---|---|---|---|

| β1 | 20° | 15°~25° | |

| β2 | 30.9° | 20°~40° | |

| r1 | 117.8 mm | 110 mm~135 mm | |

| r2 | 141.36 mm | 125 mm~150 mm | |

| r3 | 155.74 mm | 149 mm~157 mm | |

| h | 18.97 mm | 13 mm~25 mm | |

| β3 | 20.67° | 15°~25° |

| p Value | ||

|---|---|---|

| Item | pst | ηs |

| Model | <0.0001 | <0.0001 |

| β1 | 0.6416 | <0.0001 |

| β2 | <0.0001 | 0.2351 |

| r1 | 0.0043 | <0.0001 |

| r2 | <0.0001 | 0.8135 |

| r3 | <0.0001 | 0.1189 |

| h | <0.0001 | <0.0001 |

| β3 | 0.0389 | <0.0001 |

| Case | pst (N)/Pa | pst (R)/Pa | ηs (N)/% | ηs (R)/% |

|---|---|---|---|---|

| Prototype (PM) | 870.30 | 63.01 | ||

| A model (AM) | 882.98 | 881.20 | 66.25 | 66.28 |

| B model (BM) | 916.61 | 913.44 | 65.31 | 65.14 |

| C model (CM) | 929.72 | 936.91 | 63.43 | 63.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liang, K.; He, T.; He, H.; Zheng, D.; Li, M.; Gong, D.; Jiang, L. Optimization Design of Centrifugal Fan Blades Based on Bézier Curve Method. Appl. Sci. 2025, 15, 5052. https://doi.org/10.3390/app15095052

Wang J, Liang K, He T, He H, Zheng D, Li M, Gong D, Jiang L. Optimization Design of Centrifugal Fan Blades Based on Bézier Curve Method. Applied Sciences. 2025; 15(9):5052. https://doi.org/10.3390/app15095052

Chicago/Turabian StyleWang, Jiaju, Kunfeng Liang, Tao He, Haijiang He, Dayuan Zheng, Min Li, Dewu Gong, and Lihua Jiang. 2025. "Optimization Design of Centrifugal Fan Blades Based on Bézier Curve Method" Applied Sciences 15, no. 9: 5052. https://doi.org/10.3390/app15095052

APA StyleWang, J., Liang, K., He, T., He, H., Zheng, D., Li, M., Gong, D., & Jiang, L. (2025). Optimization Design of Centrifugal Fan Blades Based on Bézier Curve Method. Applied Sciences, 15(9), 5052. https://doi.org/10.3390/app15095052