Innovative Stackable Multijet-Printed Templates for Precise Veneer Preparation: A Dental Technique

Abstract

1. Introduction

2. Materials and Methods

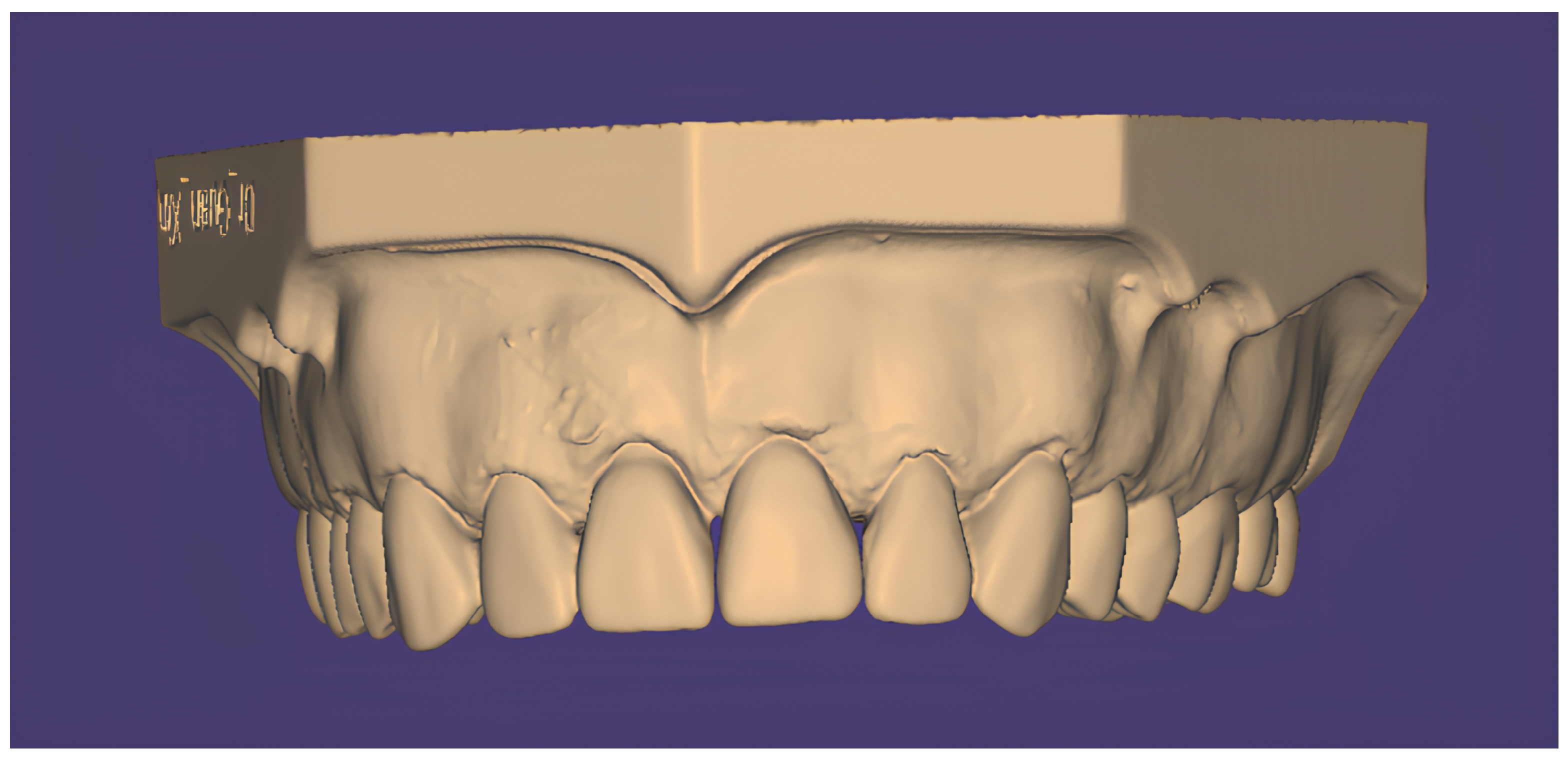

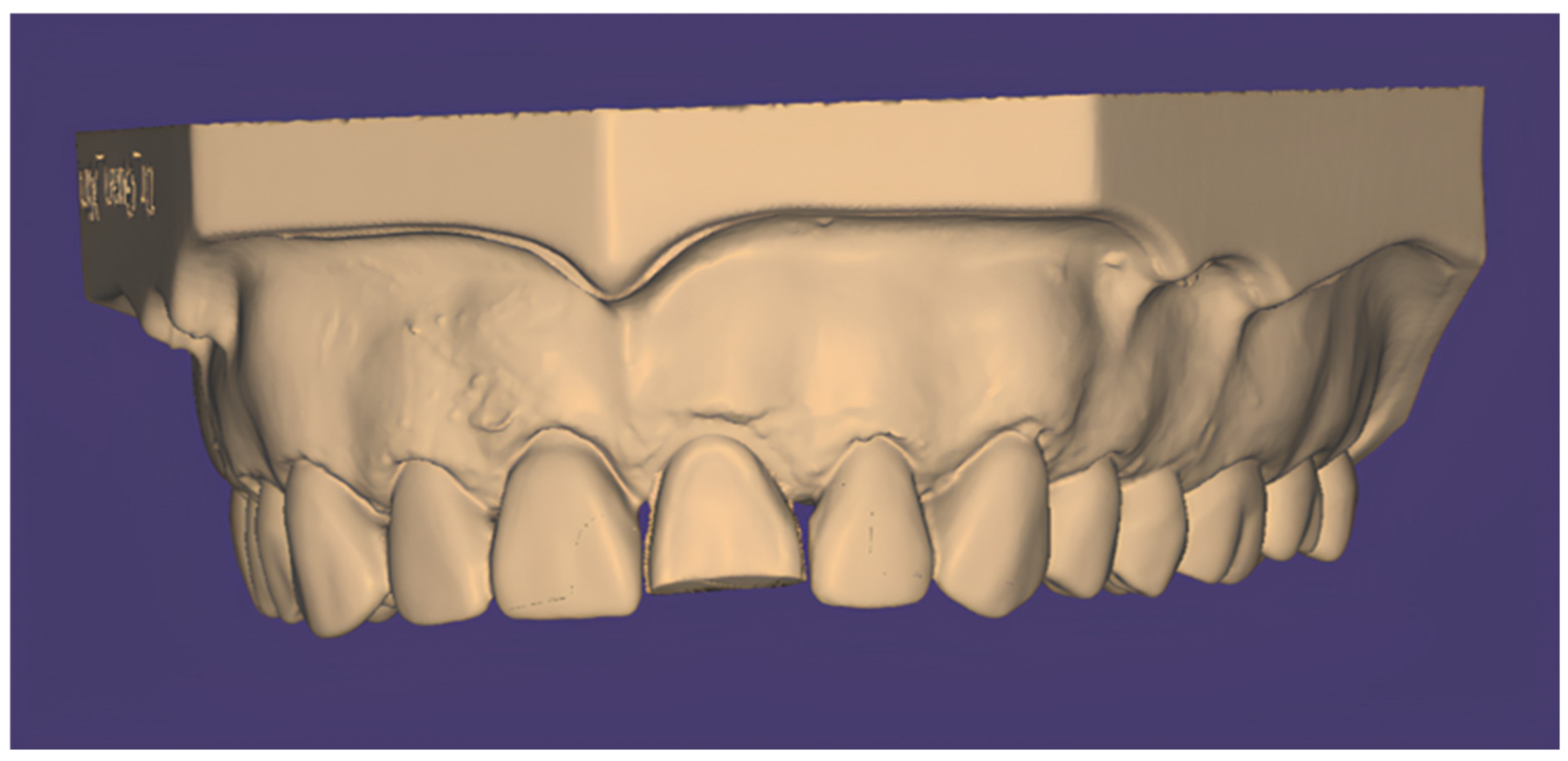

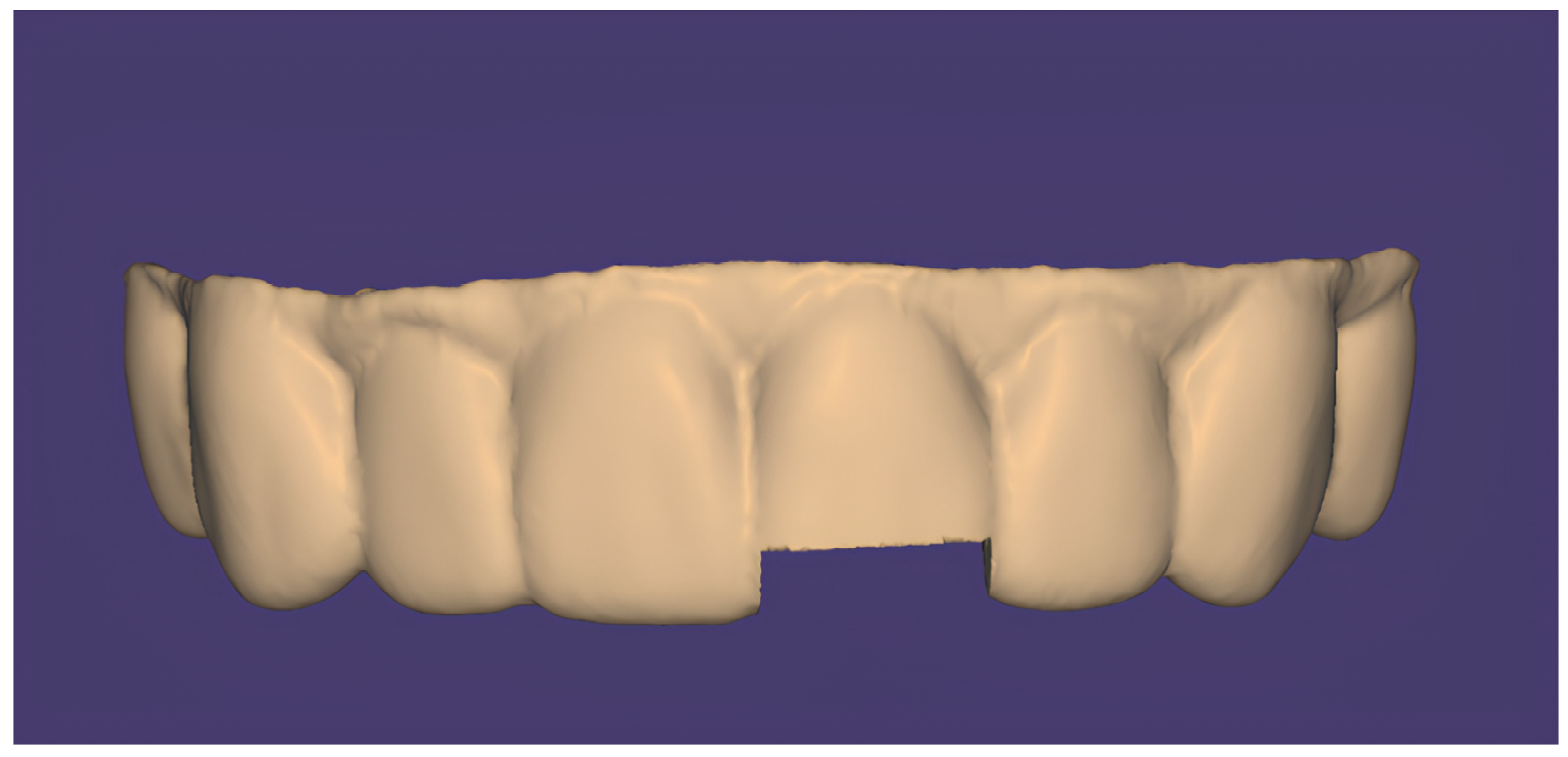

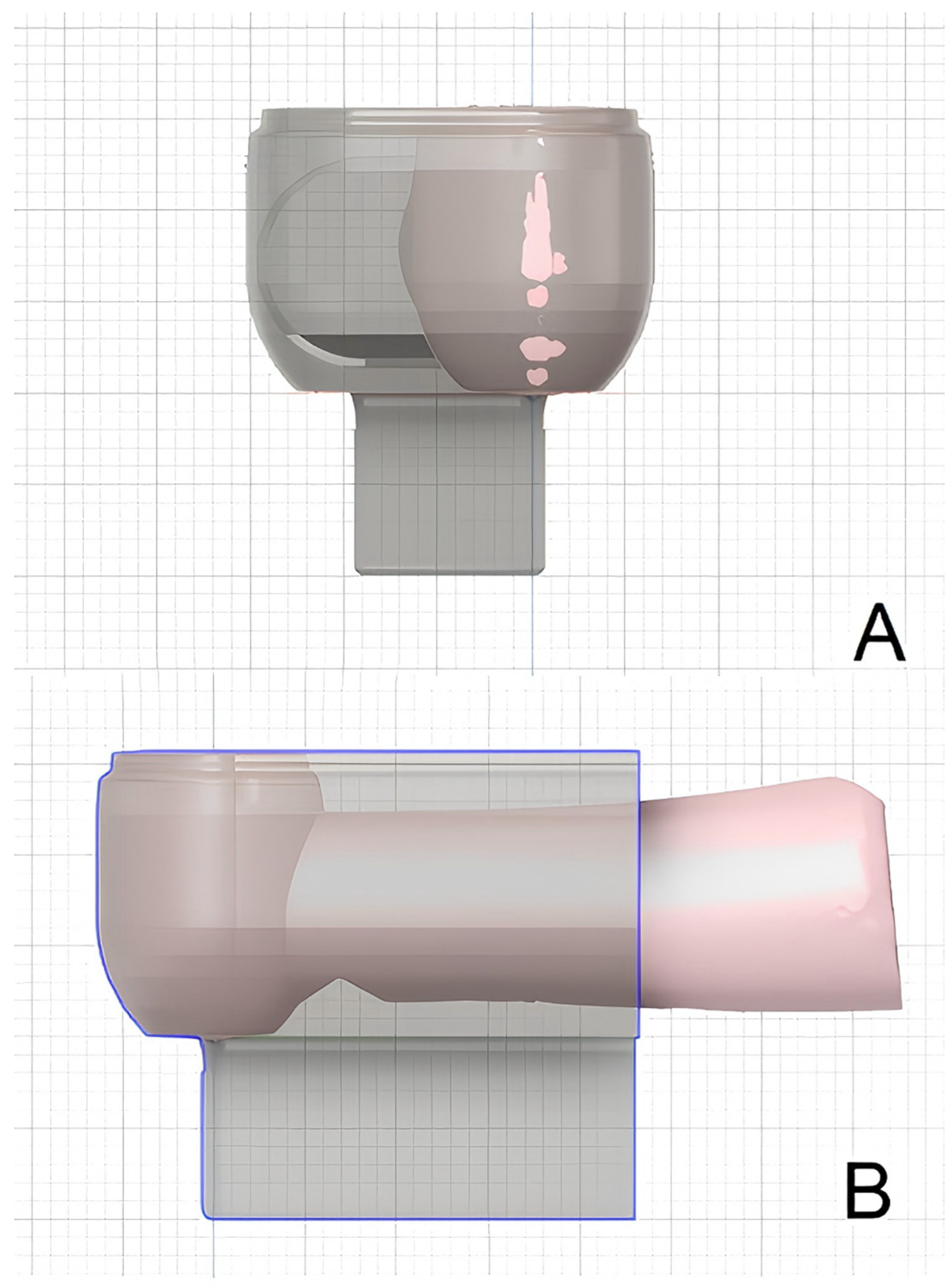

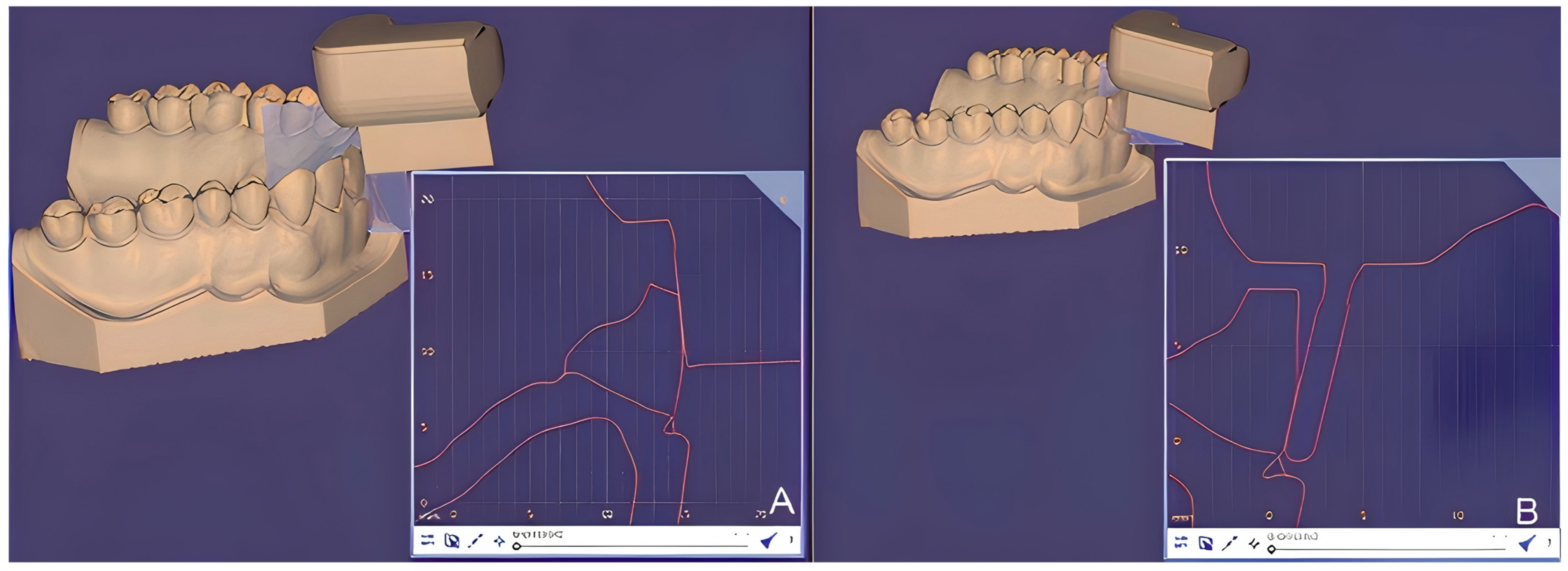

2.1. Tooth Reduction Template Design for Incisal Reduction

2.2. Tooth Reduction Template Design for Labial Reduction

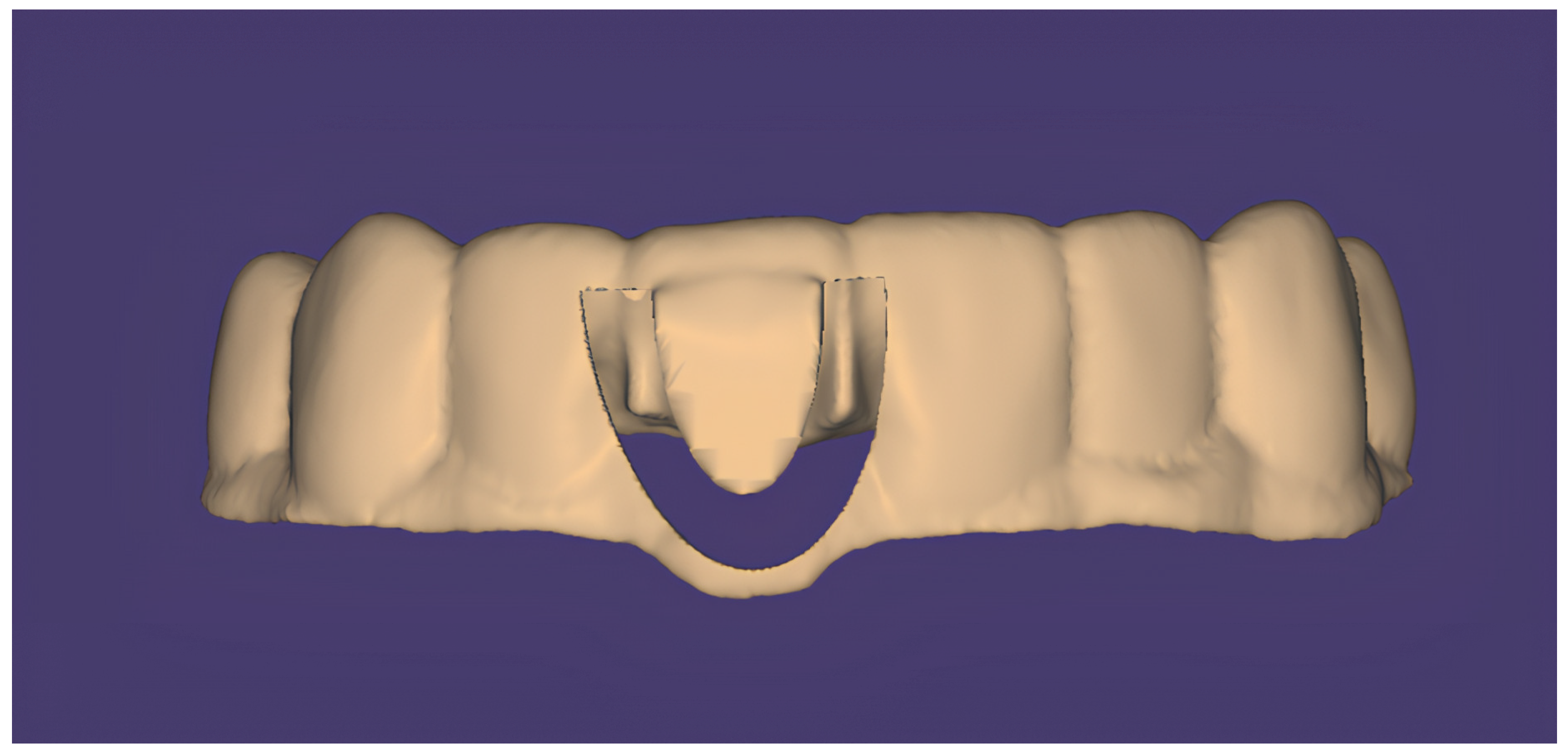

2.3. Tooth Reduction Template Design for Cervical Margin Reduction

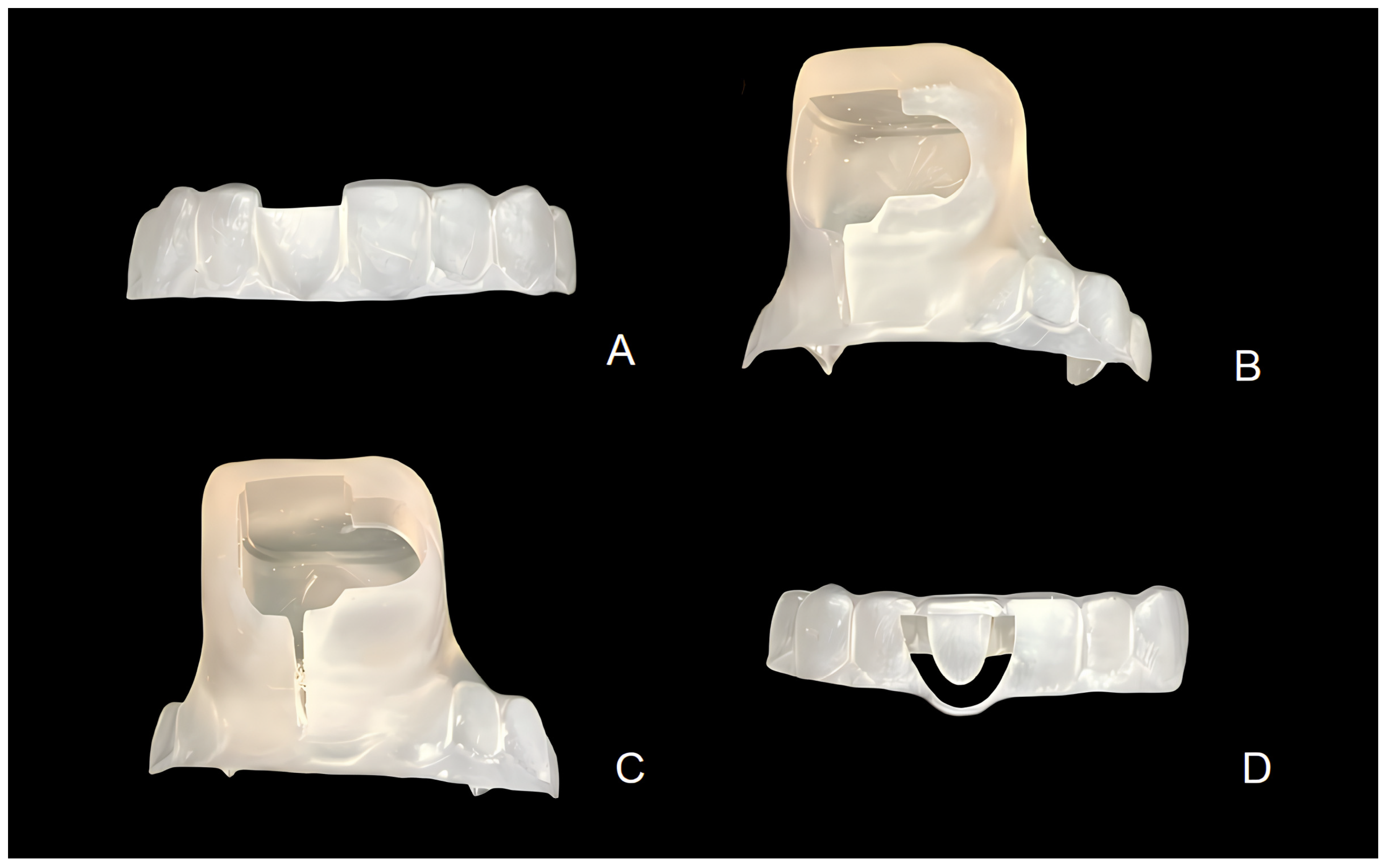

2.4. Tooth Reduction Template Fabrication

2.5. Veneer Preparation Guided via Stackable Templates

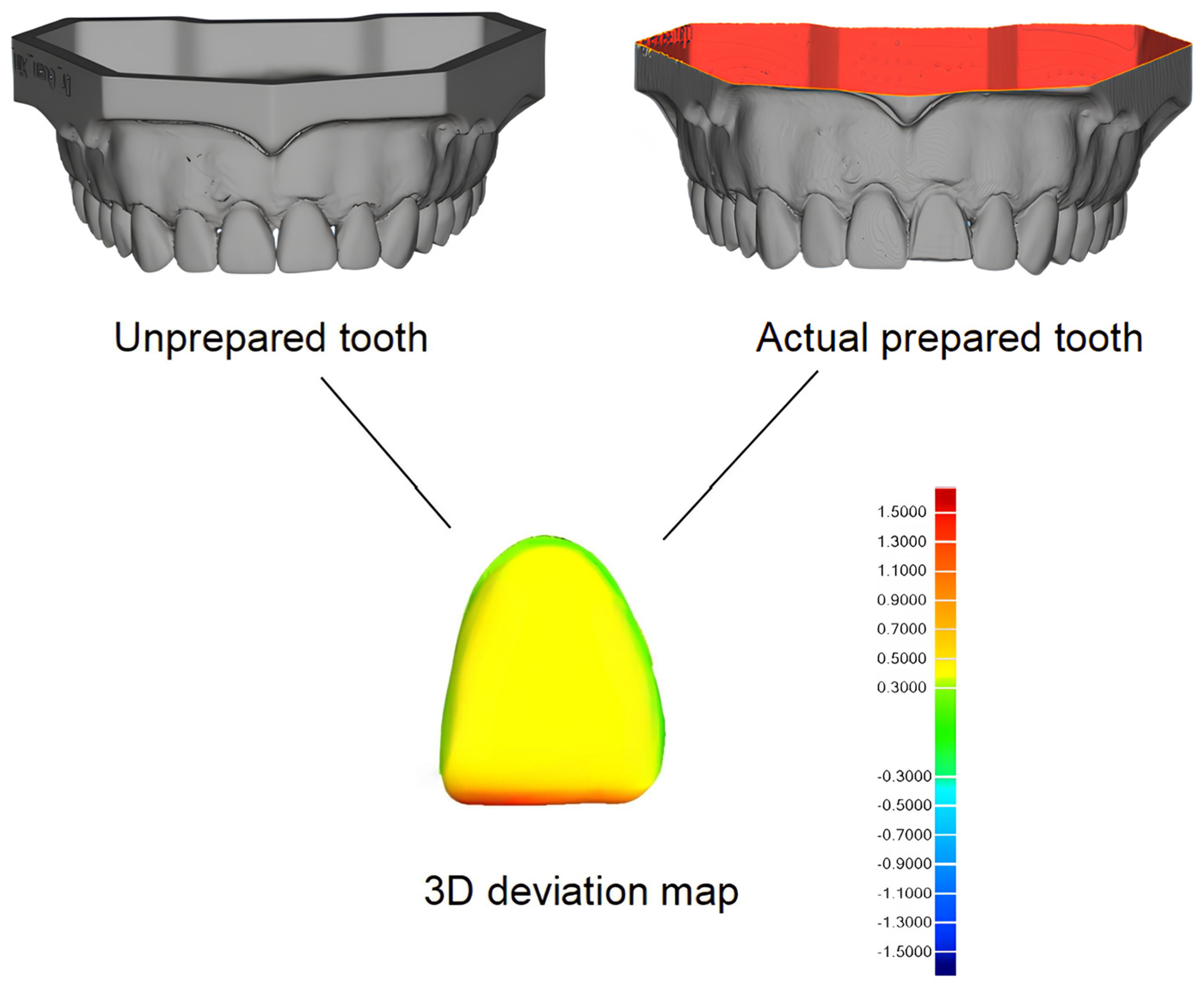

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dumfahrt, H.; Schäffer, H. Porcelain laminate veneers. A retrospective evaluation after 1 to 10 years of service: Part II—Clinical results. Int. J. Prosthodont. 2000, 13, 9–18. [Google Scholar] [PubMed]

- Friedman, M.J. Masters of esthetic dentistry: Porcelain veneer restorations: A clinician’s opinion about a disturbing trend. J. Esthet. Restor. Dent. 2001, 13, 318. [Google Scholar] [CrossRef] [PubMed]

- Strassler, H.E. Minimally invasive porcelain veneers: Indications for a conservative esthetic dentistry treatment modality. Gen. Dent. 2007, 55, 686–694. [Google Scholar] [PubMed]

- Peumans, M.; De Munck, J.; Fieuws, S.; Lambrechts, P.; Vanherle, G.; Van Meerbeek, B. A prospective ten-year clinical trial of porcelain veneers. J. Adhes. Dent. 2004, 6, 65–76. [Google Scholar]

- Piemjai, M.; Arksornnukit, M. Compressive fracture resistance of porcelain laminates bonded to enamel or dentin with four adhesive systems. J. Prosthodont. 2007, 16, 457–464. [Google Scholar] [CrossRef] [PubMed]

- Cherukara, G.P.; Davis, G.R.; Seymour, K.G.; Zou, L.; Samarawickrama, D.Y. Dentin exposure in tooth preparations for porcelain veneers: A pilot study. J. Prosthet. Dent. 2005, 94, 414–420. [Google Scholar] [CrossRef]

- Gürel, G. Predictable, precise, and repeatable tooth preparation for porcelain laminate veneers. Pract. Proced. Aesthet. Dent. 2003, 15, 17–24. [Google Scholar]

- Sisler, Z.S. Preparation Guides: 10 Steps to Maximize Success for Veneer Preparation. J. Cosmet. Dent. 2020, 35, 26–33. [Google Scholar]

- Guzman Perez, G.; Jurado, C.A.; Azpiazu Flores, F.; Afrashtehfar, K.I.; Tsujimoto, A. Minimally Invasive Laminate Veneer Therapy for Maxillary Central Incisors. Medicina 2023, 59, 603. [Google Scholar] [CrossRef]

- Liu, C.; Guo, J.; Gao, J.; Yu, H. Computer-Assisted Tooth Preparation Template and Pre-Designed Restoration: A Digital Workflow. Int. J. Comput. Dent. 2020, 23, 351–362. [Google Scholar]

- Guan, X.; Beh, Y.H.; Tew, I.M. Computer-Assisted Porcelain Laminate Veneer Preparation: A Scoping Review of Stereolithographic Template Design and Fabrication Workflows. Dent. J. 2024, 12, 302. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.L.; Bai, H.F.; Zhao, Y.J.; Wang, Y.; Ye, H.Q.; Sun, Y.C. 3D Evaluation of Accuracy of Tooth Preparation for Laminate Veneers Assisted by Rigid Constraint Guides Printed by Selective Laser Melting. Chin. J. Dent. Res. 2020, 23, 183–189. [Google Scholar]

- Robles, M.; Jurado, C.A.; Azpiazu-Flores, F.X.; Villalobos-Tinoco, J.; Afrashtehfar, K.I.; Fischer, N.G. An innovative 3D printed tooth reduction guide for precise dental ceramic veneers. J. Funct. Biomater. 2023, 14, 216. [Google Scholar] [CrossRef] [PubMed]

- Figueira, J.; Guaqueta, N.; Ramirez, D.I.; Kois, J. Veneer tooth preparation utilizing a novel digital designed workflow: A case report. J. Esthet. Restor. Dent. 2023, 35, 803–809. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; He, J.; Fan, L.; Lu, J.; Xie, C.; Yu, H. Accuracy of reduction depths of tooth preparation for porcelain laminate veneers assisted by different tooth preparation guides: An in vitro study. J. Prosthodont. 2022, 31, 593–600. [Google Scholar] [CrossRef]

- Chai, S.Y.; Bennani, V.; Aarts, J.M.; Lyons, K. Incisal preparation design for ceramic veneers: A critical review. J. Am. Dent. Assoc. 2018, 149, 25–37. [Google Scholar] [CrossRef]

- Alothman, Y.; Bamasoud, M.S. The success of dental veneers according to preparation design and material type. Open Access Maced. J. Med. Sci. 2018, 6, 2402. [Google Scholar] [CrossRef]

- Luo, T.; Zhang, J.; Fan, L.; Huang, Y.; Yu, J.; Yu, H. A digital workflow with the virtual enamel evaluation and stereolithographic template for accurate tooth preparation to conservatively manage a case of complex exogenous dental erosion. J. Esthet. Restor. Dent. 2022, 34, 733–740. [Google Scholar] [CrossRef]

- Gao, J.; Li, J.; Liu, C.; Fan, L.; Yu, J.; Yu, H. A stereolithographic template for computer-assisted teeth preparation in dental esthetic ceramic veneer treatment. J. Esthet. Restor. Dent. 2020, 32, 763–769. [Google Scholar] [CrossRef]

- Silva, B.P.D.; Stanley, K.; Gardee, J. Laminate veneers: Preplanning and treatment using digital guided tooth preparation. J. Esthet. Restor. Dent. 2020, 32, 150–160. [Google Scholar] [CrossRef]

- Etemad-Shahidi, Y.; Qallandar, O.B.; Evenden, J.; Alifui-Segbaya, F.; Ahmed, K.E. Accuracy of three-dimensionally printed full-arch dental models: A systematic review. J. Clin. Med. 2020, 9, 3357. [Google Scholar] [CrossRef] [PubMed]

- Jeong, M.; Radomski, K.; Lopez, D.; Liu, J.T.; Lee, J.D.; Lee, S.J. Materials and applications of 3D printing technology in dentistry: An overview. Dent. J. 2023, 12, 1. [Google Scholar] [CrossRef] [PubMed]

- Arnold, C.; Monsees, D.; Hey, J.; Schweyen, R. Surface quality of 3D-printed models as a function of various printing parameters. Materials 2019, 12, 1970. [Google Scholar] [CrossRef]

- Morón-Conejo, B.; López-Vilagran, J.; Cáceres, D.; Berrendero, S.; Pradíes, G. Accuracy of five different 3D printing workflows for dental models comparing industrial and dental desktop printers. Clin. Oral Investig. 2023, 27, 2521–2532. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Yang, Z.; Lin, W.S.; Tan, J.; Chen, L. The effect of build orientation on the dimensional accuracy of 3D-printed mandibular complete dentures manufactured with a multijet 3D printer. J. Prosthodont. 2021, 30, 684–689. [Google Scholar] [CrossRef]

- Bammani, S.S.; Birajdar, P.R.; Metan, S.S. Application of CAD and SLA Method in Dental Prosthesis. AMAE Int. J. Man. Mat. Sci. 2013, 3, 5. [Google Scholar]

- Dawood, A.; Marti Marti, B.; Sauret-Jackson, V. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, X.; Liu, C.; Sheng, T.F.; Beh, Y.H.; Tew, I.M. Innovative Stackable Multijet-Printed Templates for Precise Veneer Preparation: A Dental Technique. Appl. Sci. 2025, 15, 4975. https://doi.org/10.3390/app15094975

Guan X, Liu C, Sheng TF, Beh YH, Tew IM. Innovative Stackable Multijet-Printed Templates for Precise Veneer Preparation: A Dental Technique. Applied Sciences. 2025; 15(9):4975. https://doi.org/10.3390/app15094975

Chicago/Turabian StyleGuan, Xin, Chunxu Liu, Teoh Feng Sheng, Yew Hin Beh, and In Meei Tew. 2025. "Innovative Stackable Multijet-Printed Templates for Precise Veneer Preparation: A Dental Technique" Applied Sciences 15, no. 9: 4975. https://doi.org/10.3390/app15094975

APA StyleGuan, X., Liu, C., Sheng, T. F., Beh, Y. H., & Tew, I. M. (2025). Innovative Stackable Multijet-Printed Templates for Precise Veneer Preparation: A Dental Technique. Applied Sciences, 15(9), 4975. https://doi.org/10.3390/app15094975