Structural Health Monitoring of Concrete Bridges Through Artificial Intelligence: A Narrative Review

Abstract

1. Introduction

- Challenges in Dataset Collection: Data-driven techniques require large datasets for thorough training. The lengthy and costly process of collecting run-to-failure data makes it impractical for novel systems. Guaranteeing that the data encompasses all possible future operating scenarios is nearly impossible, resulting in model prediction efficacy issues [37].

- Data Quality Issues: The effectiveness of data-driven SHM techniques heavily depends on the quality of the collected data. Elements such as noise, missing data, and inconsistencies may adversely affect the effectiveness of these methods. Despite the critical significance of data quality, there has been very limited focus on establishing comprehensive data quality indicators and metrics within the SHM community [38].

- High-Dimensional Feature Spaces: Data-driven techniques often analyse several features, creating high-dimensional feature spaces. Complexity may limit the model’s generalisation and require dimensionality reduction, which may lose important information [39].

- False Positives and Negatives: Image-based SHM methods using computer vision and Machine Learning (ML) can produce false positives and negatives, especially in changing environments. This vulnerability can misread structural integrity, especially when damage events are rare [40].

- Transfer learning and synthetic data generation [41].

- Deploying large-scale sensor networks across multiple infrastructures can help diversify datasets [41].

- Integrating physical knowledge (such as finite element models) with data-driven approaches reduces dependence on large labelled datasets [42].

- Emphasising data collection for ambiguous cases diminishes the necessity for comprehensive data acquisition [43].

- AI-based imputation methods, such as autoencoders or KNN imputation, may effectively manage missing or noisy data.

- Employing real-time anomaly detection methods, such as statistical outlier detection and AI-driven validation, can improve data integrity.

- Establishing data quality benchmarks guarantees uniformity in SHM datasets.

- SHAP (SHapley Additive exPlanations), Principal Component Analysis (PCA), and autoencoders effectively preserve pertinent features while diminishing dimensionality.

- Developing domain-specific characteristics (e.g., modal frequencies, strain energy measures) enhances model precision.

- Sparse coding and dictionary learning facilitate the extraction of significant features while preserving information integrity.

- Integrating physics-based models with AI classifiers can enhance reliability.

- Employing context-sensitive thresholding that adapts according to environmental factors.

- Employing Bayesian Deep Learning (DL) and ensemble techniques (e.g., Random Forest, XGBoost) to enhance reliability.

- Regular model retraining with updated data mitigates environmental bias.

1.1. Problem Statement

1.2. Motivation

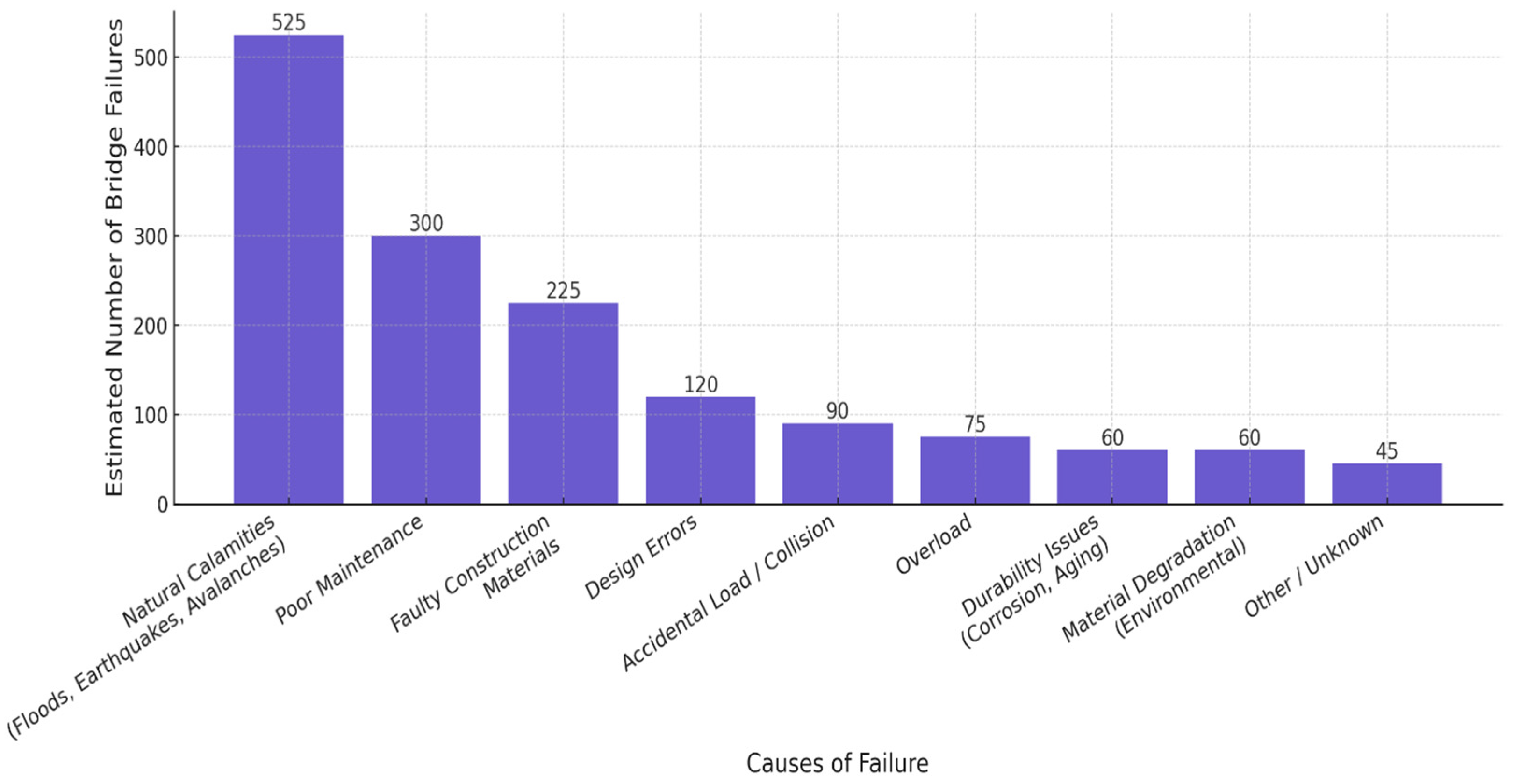

2. Causes of Bridge Failure

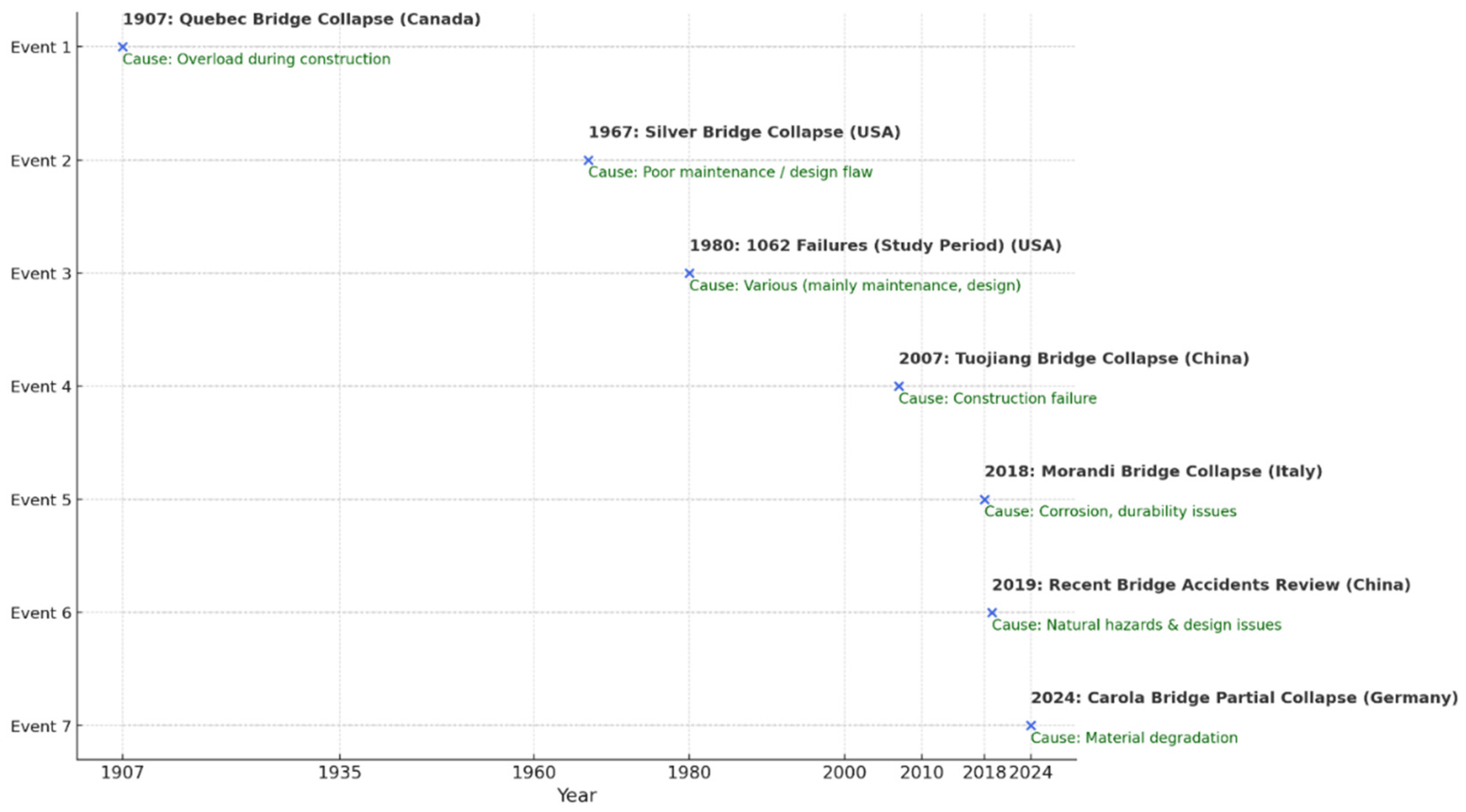

2.1. Historical Bridge Failures

2.2. Natural Causes of Bridge Failure

2.3. Failure Due to Poor Maintenance

3. Bridge Inspection

Structural Health Monitoring

4. Al and ML in Bridge Inspection

4.1. Neural Network-Based Bridge Inspection Techniques

4.2. YOLO-Based Bridge Inspection Techniques

4.3. Other Techniques for Bridge Inspection

5. Discussion

6. Conclusions and Future Scope

- Integrating multimodal data sources like LiDAR, infrared thermography, and ground penetrating radar into AI-driven bridge inspection models. Integrating these data sources improves fault detection, damage categorisation, and bridge integrity evaluation. For resilient, real-time monitoring solutions, self-learning models that adapt to changing structural conditions without manual retraining are essential.

- Examine how temperature, humidity, and air pollutants affect AI-driven fault detection systems to improve model generalisation across many climates.

- Autonomous UAV-based bridge inspection systems can be used with real-time AI analytics. UAVs could automate bridge inspections. However, flight stability, data processing latency, and problem localisation remain issues. Future advances should concentrate on edge computing with UAV-based SHM systems to enable onboard AI inference, reduce cloud-based post-processing, and improve real-time decision-making.

- Adding XAI methods to SHM models to increase transparency and regulatory acceptance of defect assessment. Standardised AI frameworks and benchmarking datasets are needed to scale and replicate AI-driven structural health monitoring solutions across infrastructure systems.

Author Contributions

Funding

Conflicts of Interest

Abbreviation

| Abbreviation | Full Form |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| ASPP | Atrous Spatial Pyramid Pooling |

| AWCM | Auto-adaptive Window Cropping Method |

| BIM | Building information modelling |

| BN | Batch Normalisation |

| CBD | Concrete Bridge Defect |

| CNN | Convolutional neural network |

| COCO | Common Objects in COntext |

| DBRNet | Dense boundary refinement network |

| DL | Deep Learning |

| ELMs | Extreme learning machines |

| FCNs | Fully Convolutional Networks |

| FRCNN | Fast Region-based CNN |

| FPS | Frames Per Second |

| GA | Genetic Algorithm |

| GIS | Geographic information system |

| GLCM | Grey-Level Co-occurrence Matrix |

| GPR | Ground penetrating radar |

| ICA | Imperial Competitive Algorithm |

| IoU | Intersection over Union |

| InSAR | Interferometric Synthetic Aperture Radar |

| LiDAR | Light detection and ranging |

| MAE | Mean Absolute Error |

| mAP | Mean average precision |

| ML | Machine Learning |

| NDT | Non-Destructive Testing |

| PCA | Pricipal Component Analysis |

| PSPNet | Pyramid scene praising Nntwork |

| ResNet | Residual Network |

| RF | Random Forest |

| RPN | Region Proposal Network |

| SHM | Structural health monitoring |

| SHAP | SHapley Additive exPlanations |

| SPP | Spatial Pyramid Pooling |

| SSD | Single Shot-multibox Detector |

| STDCNet | Short-Term Dense Concatenate Network |

| STL | Step transfer learning |

| SVM | Support Vector Machine |

| TL | Transfer learning |

| UAV | Unmanned Aerial Vehicle |

| VGG | Visual Geometry Group |

| ViT | Visual transformer |

| XAI | Explainable AI |

| YOLO | You Only Look Once |

References

- Brownjohn, J.M.; Kripakaran, P.; Harvey, B.; Kromanis, R.; Jones, P.; Huseynov, F. Structural health monitoring of short to medium span bridges in the United Kingdom. Struct. Monit. Maint. 2016, 3, 259. [Google Scholar] [CrossRef]

- Cook, W.; Barr, P.J.; Halling, M.W. Bridge Failure Rate. J. Perform. Constr. Facil. 2015, 29, 04014080. [Google Scholar] [CrossRef]

- Diaz, E.E.M.; Moreno, F.N.; Mohammadi, J. Investigation of Common Causes of Bridge Collapse in Colombia. Pract. Period. Struct. Des. Constr. 2009, 14, 194–200. [Google Scholar] [CrossRef]

- Smith, D.W. Bridge Failures. In Proceedings of the Institution of Civil Engineers; ASCE Library: Reston, VA, USA, 1976; pp. 367–382. [Google Scholar] [CrossRef]

- Harik, I.E.; Shaaban, A.M.; Gesund, H.; Valli, G.Y.S.; Wang, S.T. United States Bridge Failures, 1951–1988. J. Perform. Constr. Facil. 1990, 4, 272–277. [Google Scholar] [CrossRef]

- Lichtenstein, A.G. The Silver Bridge Collapse Recounted. J. Perform. Constr. Facil. 1993, 7, 249–261. [Google Scholar] [CrossRef]

- Peng, W.B.; Shen, J.D.; Tang, X.; Zhang, Y. Review, Analysis, and Insights on Recent Typical Bridge Accidents. Zhongguo Gonglu Xuebao/China J. Highw. Transp. 2019, 32, 132–144. [Google Scholar] [CrossRef]

- Lee, G.C.; Mohan, S.B.; Huang, C.; Fard, B.N. A Study of U.S. Bridge Failures. MCEER Earthq. Eng. Extrem. Events 2013. Available online: https://www.researchgate.net/profile/Chao_Huang25/publication/321385530_A_Study_of_US_Bridge_Failures_1980-2012/links/5a200434458515341c8382ff/A-Study-of-US-Bridge-Failures-1980-2012.pdf (accessed on 10 February 2025).

- Hu, W.; Wang, W.; Ai, C.; Wang, J.; Wang, W.; Meng, X.; Liu, J.; Tao, H.; Qiu, S. Machine vision-based surface crack analysis for transportation infrastructure. Autom. Constr. 2021, 132, 103973. [Google Scholar] [CrossRef]

- An, Y.; Chatzi, E.; Sim, S.H.; Laflamme, S.; Blachowski, B.; Ou, J. Recent progress and future trends on damage identification methods for bridge structures. Struct. Control Health Monit. 2019, 26, e2416. [Google Scholar] [CrossRef]

- Hoult, N.A.; Fidler, P.R.A.; Hill, P.G.; Middleton, C.R. Long-Term Wireless Structural Health Monitoring of the Ferriby Road Bridge. J. Bridg. Eng. 2010, 15, 153–159. [Google Scholar] [CrossRef]

- Kijewski-Correa, T.; Kwon, D.K.; Kareem, A.; Bentz, A.; Guo, Y.; Bobby, S.; Abdelrazaq, A. SmartSync: An Integrated Real-Time Structural Health Monitoring and Structural Identification System for Tall Buildings. J. Struct. Eng. 2013, 139, 1675–1687. [Google Scholar] [CrossRef]

- Dayan, V.; Chileshe, N.; Hassanli, R. A Scoping Review of Information-Modeling Development in Bridge Management Systems. J. Constr. Eng. Manag. 2022, 148, 03122006. [Google Scholar] [CrossRef]

- Deng, Z.; Huang, M.; Wan, N.; Zhang, J. The Current Development of Structural Health Monitoring for Bridges: A Review. Buildings 2023, 13, 1360. [Google Scholar] [CrossRef]

- Ryall, M.J.; Parke, G.a.R.; Harding, J.E. The Manual of Bridge Engineering; Emerald Publishing Limited: Leeds, England, 2000. [Google Scholar]

- Zhao, R.; Yuan, Y.; Wei, X.; Shen, R.; Zheng, K.; Qian, Y.; Pu, Q.; Zhang, Q.; Liao, H.; Li, X.; et al. Review of annual progress of bridge engineering in 2019. Adv. Bridg. Eng. 2020, 1, 1–57. [Google Scholar] [CrossRef]

- Koch, C.; Georgieva, K.; Kasireddy, V.; Akinci, B.; Fieguth, P. A review on computer vision based defect detection and condition assessment of concrete and asphalt civil infrastructure. Adv. Eng. Inform. 2015, 29, 196–210. [Google Scholar] [CrossRef]

- Mishra, M.; Lourenço, P.B.; Ramana, G.V. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Chen, H.; Ni, Y. Structural Health Monitoring of Large Civil Engineering Structures; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Rao, A.S.; Radanovic, M.; Liu, Y.; Hu, S.; Fang, Y.; Khoshelham, K.; Palaniswami, M.; Ngo, T. Real-time monitoring of construction sites: Sensors, methods, and applications. Autom. Constr. 2022, 136, 104099. [Google Scholar] [CrossRef]

- Wang, J.; Kang, H.; Li, K. Research on health monitoring of concrete structure based on G-S-G. Sci. Rep. 2025, 15, 1393. [Google Scholar] [CrossRef]

- Hassani, S.; Mousavi, M.; Gandomi, A.H. Structural health monitoring in composite structures: A comprehensive review. Sensors 2022, 22, 153. [Google Scholar] [CrossRef]

- A.-440. 1.-15 Committee. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars. 2015. Available online: https://basalt-fibers.com/wp-content/uploads/2021/05/Standart_ACI-4401R15.pdf (accessed on 10 February 2025).

- Zinno, R.; Haghshenas, S.S.; Guido, G.; Rashvand, K.; Vitale, A.; Sarhadi, A. The State of the Art of Artificial Intelligence Approaches and New Technologies in Structural Health Monitoring of Bridges. Appl. Sci. 2023, 13, 11609. [Google Scholar] [CrossRef]

- Mardanshahi, A.; Sreekumar, A.; Yang, X.; Barman, S.K.; Chronopoulos, D. Sensing Techniques for Structural Health Monitoring: A State-of-the-Art Review on Performance Criteria and New-Generation Technologies. Sensors 2025, 25, 1424. [Google Scholar] [CrossRef]

- Sofi, A.; Jane Regita, J.; Rane, B.; Lau, H.H. Structural health monitoring using wireless smart sensor network—An overview. Mech. Syst. Signal Process. 2022, 163, 108113. [Google Scholar] [CrossRef]

- Zhang, B.; Ren, Y.; He, S.; Gao, Z.; Li, B.; Song, J. A review of methods and applications in structural health monitoring (SHM) for bridges. Meas. J. Int. Meas. Confed. 2025, 245, 116575. [Google Scholar] [CrossRef]

- Williams, C. Origins of Form: The Shape of Natural and Man-Made Things—Why They Came to Be the Way They Are and How They Change. 2013. Available online: https://books.google.com/books?hl=en&lr=&id=fOlJKg58o2oC&pgis=1 (accessed on 22 September 2024).

- Ezzat, A.A.; Tang, J.; Ding, Y. A model-based calibration approach for structural fault diagnosis using piezoelectric impedance measurements and a finite element model. Struct. Health Monit. 2020, 19, 1839–1855. [Google Scholar] [CrossRef]

- Caicedo, J.M.; Dyke, S.J. Experimental validation of structural health monitoring for flexible bridge structures. Struct. Control. Health Monit. 2005, 12, 425–443. [Google Scholar] [CrossRef]

- Xu, L.; Wang, K.; Yang, X.; Su, Y.; Yang, J.; Liao, Y.; Zhou, P.; Su, Z. Model-driven fatigue crack characterization and growth prediction: A two-step, 3-D fatigue damage modeling framework for structural health monitoring. Int. J. Mech. Sci. 2021, 195, 106226. [Google Scholar] [CrossRef]

- Moallemi, A.; Burrello, A.; Brunelli, D.; Benini, L. Model-based vs. Data-driven Approaches for Anomaly Detection in Structural Health Monitoring: A Case Study. In Proceedings of the Conference Record—IEEE Instrumentation and Measurement Technology Conference, Glasgow, UK, 17–20 May 2021. [Google Scholar] [CrossRef]

- Torti, M.; Venanzi, I.; Laflamme, S.; Ubertini, F. Life-cycle management cost analysis of transportation bridges equipped with seismic structural health monitoring systems. Struct. Health Monit. 2022, 21, 100–117. [Google Scholar] [CrossRef]

- Barthorpe, R.J.; Hughes, A.J.; Gardner, P. A Forward Model Driven Structural Health Monitoring Paradigm: Damage Detection. Conf. Proc. Soc. Exp. Mech. Ser. 2022, 3, 119–126. [Google Scholar] [CrossRef]

- Jahan, S.; Hoseinzadeh, Y.; Mojtahedi, A. Steel bridges structural health monitoring based on operational modal analysis accommodating evaluation of uncertainty. J. Struct. Constr. Eng. 2017, 4, 5–17. [Google Scholar]

- Wang, T.; Noori, M.; Altabey, W.A.; Wu, Z.; Ghiasi, R.; Kuok, S.C.; Silik, A.; Farhan, N.S.D.; Sarhosis, V.; Farsangi, E.N. From model-driven to data-driven: A review of hysteresis modeling in structural and mechanical systems. Mech. Syst. Signal Process. 2023, 204, 110785. [Google Scholar] [CrossRef]

- Bull, L.A.; Gardner, P.; Rogers, T.J.; Cross, E.J.; Dervilis, N.; Worden, K. Probabilistic Inference for Structural Health Monitoring: New Modes of Learning from Data. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2021, 7, 03120003. [Google Scholar] [CrossRef]

- Makhoul, N. Review of data quality indicators and metrics, and suggestions for indicators and metrics for structural health monitoring. Adv. Bridg. Eng. 2022, 3, 17. [Google Scholar] [CrossRef]

- Svendsen, B.T.; Frøseth, G.T.; Øiseth, O.; Rønnquist, A. A data-based structural health monitoring approach for damage detection in steel bridges using experimental data. J. Civ. Struct. Health Monit. 2022, 12, 101–115. [Google Scholar] [CrossRef]

- Plevris, V. Assessing uncertainty in image-based monitoring: Addressing false positives, false negatives, and base rate bias in structural health evaluation. Stoch. Environ. Res. Risk Assess. 2025, 39, 959–972. [Google Scholar] [CrossRef]

- Noel, A.B.; Abdaoui, A.; Elfouly, T.; Ahmed, M.H.; Badawy, A.; Shehata, M.S. Structural Health Monitoring Using Wireless Sensor Networks: A Comprehensive Survey. IEEE Commun. Surv. Tutorials 2017, 19, 1403–1423. [Google Scholar] [CrossRef]

- Kalina, K.A.; Linden, L.; Brummund, J.; Kästner, M. FE ANN: An efficient data-driven multiscale approach based on physics-constrained neural networks and automated data mining. Comput. Mech. 2023, 71, 827–851. [Google Scholar] [CrossRef]

- Messaoudi, K.; Oubbati, O.S.; Rachedi, A.; Lakas, A.; Bendouma, T.; Chaib, N. A survey of UAV-based data collection: Challenges, solutions and future perspectives. J. Netw. Comput. Appl. 2023, 216, 103670. [Google Scholar] [CrossRef]

- Corrales, D.C.; Corrales, J.C.; Ledezma, A. How to address the data quality issues in regression models: A guided process for data cleaning. Symmetry 2018, 10, 99. [Google Scholar] [CrossRef]

- Subbiah, S.S.; Chinnappan, J. Opportunities and challenges of feature selection methods for high dimensional data: A review. Ing. des Syst. D’information 2021, 26, 67–77. [Google Scholar] [CrossRef]

- Ohlson, J.A. Researchers’ data analysis choices: An excess of false positives? Rev. Account. Stud. 2022, 27, 649–667. [Google Scholar] [CrossRef]

- Mengesha, G. Integrating AI in Structural Health Monitoring (SHM): A Systematic Review on Advances, Challenges, and Future Directions. Available online: https://ssrn.com/abstract=5004977 (accessed on 30 October 2024).

- Hosen, M.M.; Sabbir, M.M.U.; Hossain, M.I.; Sunny, M.A.U. Leveraging AI And Sensor Technologies For Real-Time Structural Health Monitoring Of In-Service Bridges. Front. Appl. Eng. Technol. 2025, 2, 135–163. [Google Scholar]

- Sonbul, O.S.; Rashid, M. Algorithms and Techniques for the Structural Health Monitoring of Bridges: Systematic Literature Review. Sensors 2023, 23, 4230. [Google Scholar] [CrossRef]

- Lantsoght, E.O.L. Advanced Structural Concrete Materials in Bridges. Materials 2022, 15, 8346. [Google Scholar] [CrossRef]

- Wai-Fah, C.; Lian, D. Bridge Engineering Handbook, Construction and Maintenance; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Žnidarič, A.; Pakrashi, V.; O’Brien, E.; O’Connor, A. A review of road structure data in six European countries. Proc. Inst. Civ. Eng. Urban Des. Plan. 2011, 164, 225–232. [Google Scholar] [CrossRef]

- Federal Highway Administration Archived: Deficient Bridges by Superstructure Material 2016. Available online: https://www.fhwa.dot.gov/bridge/nbi/no10/mat16.cfm (accessed on 15 April 2025).

- Rizzo, P.; Enshaeian, A. Challenges in bridge health monitoring: A review. Sensors 2021, 21, 4336. [Google Scholar] [CrossRef]

- Di Mucci, V.M.; Cardellicchio, A.; Ruggieri, S.; Nettis, A.; Renò, V.; Uva, G. Artificial intelligence in structural health management of existing bridges. Autom. Constr. 2024, 167, 105719. [Google Scholar] [CrossRef]

- Plevris, V.; Papazafeiropoulos, G. AI in Structural Health Monitoring for Infrastructure Maintenance and Safety. Infrastructures 2024, 9, 225. [Google Scholar] [CrossRef]

- Deng, L.; Wang, W.; Yu, Y. State-of-The-Art Review on the Causes and Mechanisms of Bridge Collapse. J. Perform. Constr. Facil. 2016, 30, 04015005. [Google Scholar] [CrossRef]

- Lin, W.; Yoda, T. Materials for Bridge Constructions Author links open overlay panel. In Bridge Engineering Classifications, Design Loading, and Analysis Methods; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–69. [Google Scholar]

- Peng, W.; Zhao, H.; Dai, F.; Taciroglu, E. Analytical Method for Overturning Limit Analysis of Single-Column Pier Bridges. J. Perform. Constr. Facil. 2017, 31, 04017007. [Google Scholar] [CrossRef]

- Artus, M.; Koch, C. State of the art in damage information modeling for RC bridges—A literature review. Adv. Eng. Informatics 2020, 46, 101171. [Google Scholar] [CrossRef]

- Pearson, C.; Delatte, N. Collapse of the Quebec Bridge, 1907. J. Perform. Constr. Facil. 2006, 20, 84–91. [Google Scholar] [CrossRef]

- Morgese, M.; Ansari, F.; Domaneschi, M.; Cimellaro, G.P. Post-collapse analysis of Morandi’s Polcevera viaduct in Genoa Italy. J. Civ. Struct. Health Monit. 2020, 10, 69–85. [Google Scholar] [CrossRef]

- Nuti, C.; Briseghella, B.; Chen, A.; Lavorato, D.; Iori, T.; Vanzi, I. Relevant outcomes from the history of Polcevera Viaduct in Genova, from design to nowadays failure. J. Civ. Struct. Health Monit. 2020, 10, 87–107. [Google Scholar] [CrossRef]

- Major Bridge Partially Collapses into River in German City of Dresden. 2024. Available online: https://www.euronews.com/my-europe/2024/09/12/major-bridge-partially-collapses-into-river-in-dresden (accessed on 10 February 2025).

- Xu, F.Y.; Zhang, M.J.; Wang, L.; Zhang, J.R. Recent Highway Bridge Collapses in China: Review and Discussion. J. Perform. Constr. Facil. 2016, 30, 04016030. [Google Scholar] [CrossRef]

- Wardhana, K.; Hadipriono, F.C. Analysis of Recent Bridge Failures in the United States. J. Perform. Constr. Facil. 2003, 17, 144–150. [Google Scholar] [CrossRef]

- Biezma, M.V.; Schanack, F. Collapse of Steel Bridges. J. Perform. Constr. Facil. 2007, 21, 398–405. [Google Scholar] [CrossRef]

- Scheer, J. Failed Bridges: Case Studies, Causes and Consequences; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Li, Y.D.; Wang, C.J. Research Advances in Long-Life of Worldwide Bridges and Corresponding Reflections. Bridg. Constr. 2019, 49, 17–23. [Google Scholar]

- Zhang, G.; Liu, Y.; Liu, J.; Lan, S.; Yang, J. ScienceDirect Causes and statistical characteristics of bridge failures: A review. J. Traffic Transp. Eng. 2022, 9, 388–406. [Google Scholar] [CrossRef]

- Liu, Y.J.; Gao, Y.M.; Zhou, X.H.; Zhang, Z.J.; Zhang, Z.F. Technical and Economic Analysis in Steel-concrete Composite Girder Bridges with Small and Medium Span. Zhongguo Gonglu Xuebao/China J. Highw. Transp. 2017, 30, 1–13. [Google Scholar]

- Ge, Y.; Xiang, H. Concept and requirements of sustainable development in bridge engineering. Front. Archit. Civ. Eng. China 2011, 5, 432–450. [Google Scholar] [CrossRef]

- Martí-Vargas, J.R.; Castro-Bugallo, C.; Navarro-Gregori, J.; Mateu-Sánchez, J.A. Spanish guides and code specifications on concrete bridges inspection and maintenance: An overview. Ce/Papers 2023, 6, 833–839. [Google Scholar] [CrossRef]

- Elseicy, A.; Alonso-Díaz, A.; Solla, M.; Rasol, M.; Santos-Assunçao, S. Combined Use of GPR and Other NDTs for Road Pavement Assessment: An Overview. Remote Sens. 2022, 14, 4336. [Google Scholar] [CrossRef]

- Mugnai, F.; Bonora, V.; Tucci, G. Integration, harmonization, and processing of geomatic data for bridge health assessment: The Lastra a Signa case study. Appl. Geomat. 2023, 15, 533–550. [Google Scholar] [CrossRef]

- Tosti, F.; Gagliardi, V.; D’Amico, F.; Alani, A.M. Transport infrastructure monitoring by data fusion of GPR and SAR imagery information. Transp. Res. Procedia 2020, 45, 771–778. [Google Scholar] [CrossRef]

- Selvakumaran, S.; Rossi, C.; Marinoni, A.; Webb, G.; Bennetts, J.; Barton, E.; Plank, S.; Middleton, C. Combined InSAR and Terrestrial Structural Monitoring of Bridges. IEEE Trans. Geosci. Remote Sens. 2020, 58, 7141–7153. [Google Scholar] [CrossRef]

- Cafiso, S.; Di Graziano, A.; Goulias, D.G.; Pappalardo, G. Data Fusion of Non-destructive Testing Methods for Bridge Deck Condition Assessment. Open Transp. J. 2022, 16, e187444782211210. [Google Scholar] [CrossRef]

- He, Z.; Li, W.; Salehi, H.; Zhang, H.; Zhou, H.; Jiao, P. Integrated structural health monitoring in bridge engineering. Autom. Constr. 2022, 136, 104168. [Google Scholar] [CrossRef]

- Comisu, C.C.; Taranu, N.; Boaca, G.; Scutaru, M.C. Structural health monitoring system of bridges. Procedia Eng. 2017, 199, 2054–2059. [Google Scholar] [CrossRef]

- Munawar, H.S.; Ullah, F.; Shahzad, D.; Heravi, A.; Qayyum, S.; Akram, J. Civil Infrastructure Damage and Corrosion Detection: An Application of Machine Learning. Buildings 2022, 12, 156. [Google Scholar] [CrossRef]

- Islam, N.U.; Lee, S. Cross domain image transformation using effective latent space association. In Intelligent Autonomous Systems 15; Springer: Cham, Swizerland, 2019; Volume 867, pp. 706–716. [Google Scholar]

- Munawar, H.S.; Ullah, F.; Heravi, A.; Thaheem, M.J.; Maqsoom, A. Inspecting buildings using drones and computer vision: A machine learning approach to detect cracks and damages. Drones 2022, 6, 5. [Google Scholar] [CrossRef]

- Maqsoom, A.; Aslam, B.; Yousafzai, A.; Ullah, F.; Ullah, S.; Imran, M. Extracting built-up areas from spectro-textural information using machine learning. Soft Comput. 2022, 26, 7789–7808. [Google Scholar] [CrossRef]

- Qiao, W.; Ma, B.; Liu, Q.; Wu, X.; Li, G. Computer vision-based bridge damage detection using deep convolutional networks with expectation maximum attention module. Sensors 2021, 21, 824. [Google Scholar] [CrossRef] [PubMed]

- Ullah, F. Smart Tech 4.0 in the Built Environment: Applications of Disruptive Digital Technologies in Smart Cities, Construction, and Real Estate. Buildings 2022, 12, 1516. [Google Scholar] [CrossRef]

- Sirshar, M.; Paracha, M.F.K.; Akram, M.U.; Alghamdi, N.S.; Zaidi, S.Z.Y.; Fatima, T. Attention based automated radiology report generation using CNN and LSTM. PLoS ONE 2022, 17, e0262209. [Google Scholar] [CrossRef] [PubMed]

- Islam, N.U.; Lee, S. Interpretation of Deep CNN Based on Learning Feature Reconstruction with Feedback Weights. IEEE Access 2019, 7, 25195–25208. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Wang, L.; Zhai, C.; Hu, X.; Sun, L.; Tian, Y.; Huang, X.; Jiang, L. Convolutional neural networks (CNNs)-based multi-category damage detection and recognition of high-speed rail (HSR) reinforced concrete (RC) bridges using test images. Eng. Struct. 2023, 276, 115306. [Google Scholar] [CrossRef]

- Li, R.; Yu, J.; Li, F.; Yang, R.; Wang, Y.; Peng, Z. Automatic bridge crack detection using Unmanned aerial vehicle and Faster R-CNN. Constr. Build. Mater. 2023, 362, 129659. [Google Scholar] [CrossRef]

- Islam, N.U.; Lee, S.; Park, J. Accurate and consistent image-to-image conditional adversarial network. Electronic 2020, 9, 395. [Google Scholar] [CrossRef]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.-Y.; Berg, A.C. SSD: Single shot multibox detector. In Proceedings of the Computer Vision—ECCV 2016, Amsterdam, The Netherlands, 11–14 October 2016. [Google Scholar]

- Liu, C.; Tao, Y.; Liang, J.; Li, K.; Chen, Y. Object detection based on YOLO network. In Proceedings of the 2018 IEEE 4th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 14–16 December 2018; pp. 799–803. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards real-time object detection with region proposal networks. Adv. Neural Inf. Process. Syst. 2015, 2015, 91–99. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Spatial Pyramid Pooling in Deep Convolutional Networks for Visual Recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 37, 1904–1916. [Google Scholar] [CrossRef]

- Fatima, J.; Mohsan, M.; Jameel, A.; Akram, M.U.; Muzaffar Syed, A. Vertebrae localization and spine segmentation on radiographic images for feature-based curvature classification for scoliosis. Concurr. Comput. Pract. Exp. 2022, 34, e7300. [Google Scholar] [CrossRef]

- Bochkovskiy, A.; Wang, C.-Y.; Liao, H.-Y.M. YOLOv4: Optimal Speed and Accuracy of Object Detection. arXiv 2020, arXiv:2004.10934. [Google Scholar]

- Alhassan, M.A.M.; Yılmaz, E. Evaluating YOLOv4 and YOLOv5 for Enhanced Object Detection in UAV-Based Surveillance. Processes 2025, 13, 254. [Google Scholar] [CrossRef]

- Rathod, H.; Gupta, R. Sub-surface simulated damage detection using Non-Destructive Testing Techniques in reinforced-concrete slabs. Constr. Build. Mater. 2019, 215, 754–764. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Tan, X. Review on vibration-based structural health monitoring techniques and technical codes. Symmetry 2021, 13, 1998. [Google Scholar] [CrossRef]

- Baybordi, S.; Esfandiari, A. Model updating and damage detection of jacket type platform using explicit and exact time domain sensitivity equation. Ocean Eng. 2023, 269, 113551. [Google Scholar] [CrossRef]

- Yao, J.; Zeng, B.; Zhou, Z.; Zhang, Q. Damage identification analysis of Cable-stayed arch-truss based on multi-node time-domain data fusion. Lat. Am. J. Solids Struct. 2023, 20, e473. [Google Scholar] [CrossRef]

- Li, Z.; Lan, Y.; Lin, W. Investigation of Frequency-Domain Dimension Reduction for A2M-Based Bridge Damage Detection Using Accelerations of Moving Vehicles. Materials 2023, 16, 1872. [Google Scholar] [CrossRef]

- Chen, M.J.; Sivakumar, K.; Banyay, G.A.; Golchert, B.M.; Walsh, T.F.; Zavlanos, M.M.; Aquino, W. Bayesian Optimal Sensor Placement for Damage Detection in Frequency-Domain Dynamics. J. Eng. Mech. 2022, 148, 04022078. [Google Scholar] [CrossRef]

- Liu, N.; Schumacher, T.; Li, Y.; Xu, L.; Wang, B. Damage Detection in Reinforced Concrete Member Using Local Time-Frequency Transform Applied to Vibration Measurements. Buildings 2023, 13, 148. [Google Scholar] [CrossRef]

- Yang, Y.B.; Li, Z.; Wang, Z.L.; Liu, Z.; Mo, X.Q.; Qiu, F.Q. Closely spaced modes of bridges estimated by a hybrid time–frequency method using a multi-sensor scanning vehicle: Theory and practice. Mech. Syst. Signal Process. 2023, 192, 110236. [Google Scholar] [CrossRef]

- Alavinezhad, M.; Hassanabad, M.G.; Ketabdari, M.J.; Nekooei, M. Numerical and experimental structural damage detection in an offshore flare bridge using a proposed modal strain energy method. Ocean Eng. 2022, 252, 111055. [Google Scholar] [CrossRef]

- Ganguli, R. Modal Curvature Based Damage Detection. In Structural Health Monitoring; Springer: Berlin/Heidelberg, Germany, 2020; pp. 37–78. [Google Scholar] [CrossRef]

- Zhang, Q.; Hou, J.; An, X.; Jankowski, Ł.; Duan, Z.; Hu, X. Vehicle parameter identification based on vehicle frequency response function. J. Sound Vib. 2023, 542, 117375. [Google Scholar] [CrossRef]

- Kurent, B.; Brank, B.; Ao, W.K. Model updating of seven-storey cross-laminated timber building designed on frequency-response-functions-based modal testing. Struct. Infrastruct. Eng. 2023, 19, 178–196. [Google Scholar] [CrossRef]

- Fang, Y.; Liu, X.; Xing, J.; Li, Z.; Zhang, Y. Substructure damage identification based on sensitivity of Power Spectral Density. J. Sound Vib. 2023, 545, 117451. [Google Scholar] [CrossRef]

- Hadizadeh-Bazaz, M.; Navarro, I.J.; Yepes, V. Performance Comparison of Structural Damage Detection Based on Frequency Response Function and Power Spectral Density. Dyna 2022, 97, 493–500. [Google Scholar] [CrossRef] [PubMed]

- Le, T.C.; Ho, D.D. Structural Damage Identification of Plates Using Two-Stage Approach Combining Modal Strain Energy Method and Genetic Algorithm. In Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1004–1017. [Google Scholar] [CrossRef]

- Nilsson, A.; Liu, B. frequency domain. In SpringerReference; Springer: Berlin/Heidelberg, Germany, 2011; Volume 1, pp. 31–36. [Google Scholar] [CrossRef]

- Bayat, M.; Ahmadi, H.R.; Mahdavi, N. Application of power spectral density function for damage diagnosis of bridge piers. Struct. Eng. Mech. 2019, 71, 57–63. [Google Scholar] [CrossRef]

- Hadizadeh-Bazaz, M.; Navarro, I.J.; Yepes, V. Life Cycle Assessment of a Coastal Concrete Bridge Aided by Non-Destructive Damage Detection Methods. J. Mar. Sci. Eng. 2023, 11, 1656. [Google Scholar] [CrossRef]

- Zhang, D.; Zeng, Y.; Fang, M.; Jin, W. Service life prediction of precast concrete structures exposed to chloride environment. Adv. Civ. Eng. 2019, 2019, 3216328. [Google Scholar] [CrossRef]

- Xiao, F.; LeroyHulsey, J.; Chen, G. Structural health monitoring of the klehini river bridge. J. Vib. Eng. Technol. 2016, 4, 309–318. [Google Scholar]

- Aliyari, M.; Droguett, E.L.; Ayele, Y.Z. Uav-based bridge inspection via transfer learning. Sustainability 2021, 13, 1359. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. SDNET2018: An annotated image dataset for non-contact concrete crack detection using deep convolutional neural networks. Data Br. 2018, 21, 1664–1668. [Google Scholar] [CrossRef] [PubMed]

- Chen, R. Migration Learning-Based Bridge Structure Damage Detection Algorithm. Sci. Program. 2021, 2021, 1102521. [Google Scholar] [CrossRef]

- Yang, J.; Li, H.; Huang, D.; Jiang, S. Concrete Bridge Damage Detection Based on Transfer Learning with Small Training Samples. In Proceedings of the ICSAI 2021—7th International Conference on Systems and Informatics, Chongqing, China, 13–15 November 2021. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, E.; Granello, G.; Loporcaro, G. Drone aided machinelearning tool for post-earthquake bridge damage reconnaissance. In Proceedings of the 17th World Conference on Earthquake Engineering, Earthquake Engineering Association, Sendai, Japan, 27 September–2 October 2020; pp. 1–12. [Google Scholar]

- Gao, Y.; Mosalam, K.M. Deep Transfer Learning for Image-Based Structural Damage Recognition. Comput. Civ. Infrastruct. Eng. 2018, 33, 748–768. [Google Scholar] [CrossRef]

- Rubio, J.J.; Kashiwa, T.; Laiteerapong, T.; Deng, W.; Nagai, K.; Escalera, S.; Nakayama, K.; Matsuo, Y.; Prendinger, H. Multi-class structural damage segmentation using fully convolutional networks. Comput. Ind. 2019, 112, 103121. [Google Scholar] [CrossRef]

- Kim, I.H.; Jeon, H.; Baek, S.C.; Hong, W.H.; Jung, H.J. Application of crack identification techniques for an aging concrete bridge inspection using an unmanned aerial vehicle. Sensors 2018, 18, 1881. [Google Scholar] [CrossRef]

- Dung, C.V.; Sekiya, H.; Hirano, S.; Okatani, T.; Miki, C. A vision-based method for crack detection in gusset plate welded joints of steel bridges using deep convolutional neural networks. Autom. Constr. 2019, 102, 217–229. [Google Scholar] [CrossRef]

- Gomez-Cabrera, A.; Escamilla-Ambrosio, P.J. Review of Machine-Learning Techniques Applied to Structural Health Monitoring Systems for Building and Bridge Structures. Appl. Sci. 2022, 12, 754. [Google Scholar] [CrossRef]

- Gordan, M.; Chao, O.Z.; Sabbagh-Yazdi, S.R.; Wee, L.K.; Ghaedi, K.; Ismail, Z. From Cognitive Bias Toward Advanced Computational Intelligence for Smart Infrastructure Monitoring. Front. Psychol. 2022, 13, 846610. [Google Scholar] [CrossRef]

- Yu, L.; He, S.; Liu, X.; Ma, M.; Xiang, S. Engineering-oriented bridge multiple-damage detection with damage integrity using modified faster region-based convolutional neural network. Multimed. Tools Appl. 2022, 81, 18279–18304. [Google Scholar] [CrossRef]

- Ahmadvand, M.; Dorafshan, S.; Azari, H.; Shams, S. 1D-CNNs for autonomous defect detection in bridge decks using ground penetrating radar. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Online, 22–27 March 2021; p. 18. [Google Scholar] [CrossRef]

- Fan, W.; Chen, Y.; Li, J.; Sun, Y.; Feng, J.; Hassanin, H.; Sareh, P. Machine learning applied to the design and inspection of reinforced concrete bridges: Resilient methods and emerging applications. Structures 2021, 33, 3954–3963. [Google Scholar] [CrossRef]

- Jin Lim, H.; Hwang, S.; Kim, H.; Sohn, H. Steel bridge corrosion inspection with combined vision and thermographic images. Struct. Health Monit. 2021, 20, 3424–3435. [Google Scholar] [CrossRef]

- Gao, J.; Yuan, D.; Tong, Z.; Yang, J.; Yu, D. Autonomous pavement distress detection using ground penetrating radar and region-based deep learning. Meas. J. Int. Meas. Confed. 2020, 164, 108077. [Google Scholar] [CrossRef]

- Al Qurishee, M.; Wu, W.; Atolagbe, B.; Owino, J.; Fomunung, I.; Said, S.E.; Tareq, S.M. Bridge Girder Crack Assessment Using Faster RCNN Inception V2 and Infrared Thermography. J. Transp. Technol. 2020, 10, 110–127. [Google Scholar] [CrossRef][Green Version]

- Cha, Y.-J.; Choi, W.; Büyüköztürk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput. Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Abubakr, M.; Rady, M.; Badran, K.; Mahfouz, S.Y. Application of deep learning in damage classification of reinforced concrete bridges. Ain Shams Eng. J. 2024, 15, 102297. [Google Scholar] [CrossRef]

- Mundt, M.; Majumder, S.; Murali, S.; Panetsos, P.; Ramesh, V. Meta-learning convolutional neural architectures for multi-target concrete defect classification with the concrete defect bridge image dataset. In Proceedings of the 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–20 June 2019; pp. 11188–11197. [Google Scholar] [CrossRef]

- Gan, L.; Liu, H.; Yan, Y.; Chen, A. Bridge bottom crack detection and modeling based on faster R-CNN and BIM. IET Image Process. 2024, 18, 664–677. [Google Scholar] [CrossRef]

- Kang, H.; Zhou, F.; Gao, S.; Xu, Q. Crack Detection of Concrete Based on Improved CenterNet Model. Appl. Sci. 2024, 14, 2527. [Google Scholar] [CrossRef]

- Kim, B.; Natarajan, Y.; Preethaa, K.R.S.; Song, S.; An, J.; Mohan, S. Real-time assessment of surface cracks in concrete structures using integrated deep neural networks with autonomous unmanned aerial vehicle. Eng. Appl. Artif. Intell. 2024, 129, 107537. [Google Scholar] [CrossRef]

- Nyathi, M.A.; Bai, J.; Wilson, I.D. Deep Learning for Concrete Crack Detection and Measurement. Metrology 2024, 4, 66–81. [Google Scholar] [CrossRef]

- Nyathi, M.A.; Bai, J.; Wilson, I.D. NYA-Crack-Data: A High Variability Concrete Crack Dataset for Enhanced Model Generalisation. 2024, Volume 1. Available online: https://data.mendeley.com/datasets/z93rb2m4fk/1 (accessed on 10 February 2025).

- Şermet, F.; Pacal, I. Deep learning approaches for autonomous crack detection in concrete wall, brick deck and pavement. DÜMF Mühendislik Derg. 2024, 15, 503–513. [Google Scholar] [CrossRef]

- Shahin, M.; Chen, F.F.; Maghanaki, M.; Hosseinzadeh, A.; Zand, N.; Khodadadi Koodiani, H. Improving the Concrete Crack Detection Process via a Hybrid Visual Transformer Algorithm. Sensors 2024, 24, 3247. [Google Scholar] [CrossRef]

- Song, F.; Sun, Y.; Yuan, G. Autonomous Identification of Bridge Concrete Cracks Using Unmanned Aircraft Images and Improved Lightweight Deep Convolutional Networks. Struct. Control Health Monit. 2024, 2024, 7857012. [Google Scholar] [CrossRef]

- Zhang, E.; Jiang, T.; Duan, J. A Multi-Stage Feature Aggregation and Structure Awareness Network for Concrete Bridge Crack Detection. Sensors 2024, 24, 1542. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Liu, M.; Peng, Y.; Wu, L.; Wang, Y. HDCB-Net: A Neural Network with the Hybrid Dilated Convolution for Pixel-Level Crack Detection on Concrete Bridges. IEEE Trans. Ind. Informatics 2021, 17, 5485–5494. [Google Scholar] [CrossRef]

- Zou, Q.; Zhang, Z.; Li, Q.; Qi, X.; Wang, Q.; Wang, S. DeepCrack: Learning hierarchical convolutional features for crack detection. IEEE Trans. Image Process. 2019, 28, 1498–1512. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Cui, L.; Qi, Z.; Meng, F.; Chen, Z. Automatic road crack detection using random structured forests. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3434–3445. [Google Scholar] [CrossRef]

- Shashidhar, R.; Manjunath, D.; Shanmukha, S.M. CrackSpot: Deep learning for automated detection of structural cracks in concrete infrastructure. Asian J. Civ. Eng. 2024, 25, 1079–1090. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; Zhou, F.; Chen, Z.; Giannakis, I.; Slob, E. Deep learning–based nondestructive evaluation of reinforcement bars using ground-penetrating radar and electromagnetic induction data. Comput. Civ. Infrastruct. Eng. 2022, 37, 1834–1853. [Google Scholar] [CrossRef]

- Ma, K.; Hao, M.; Meng, X.; Liu, J.; Meng, J.; Xuan, Y. Coarse–Fine Combined Bridge Crack Detection Based on Deep Learning. Appl. Sci. 2024, 14, 5004. [Google Scholar] [CrossRef]

- Sohaib, M.; Hasan, M.J.; Chen, J.; Zheng, Z. Generalizing infrastructure inspection: Step transfer learning aided extreme learning machine for automated crack detection in concrete structures. Meas. Sci. Technol. 2024, 35, 055402. [Google Scholar] [CrossRef]

- Özgenel, F.; Gönenç Sorguç, A. Performance comparison of pretrained convolutional neural networks on crack detection in buildings. In Proceedings of the 35th ISARC, Berlin, Germany, 20–25 July 2018. [Google Scholar] [CrossRef]

- Liu, K.; Chen, B.M. Industrial UAV-Based Unsupervised Domain Adaptive Crack Recognitions: From Database Towards Real-Site Infrastructural Inspections. IEEE Trans. Ind. Electron. 2023, 70, 9410–9420. [Google Scholar] [CrossRef]

- Sohaib, M.; Jamil, S.; Kim, J.M. An Ensemble Approach for Robust Automated Crack Detection and Segmentation in Concrete Structures. Sensors 2024, 24, 257. [Google Scholar] [CrossRef]

- Sun, H.; Lu, D.; Li, X.; Tan, J.; Zhao, J.; Hou, D. Research on multi-apparent defects detection of concrete bridges based on YOLOR. Structures 2024, 65, 106735. [Google Scholar] [CrossRef]

- Tang, H.-E.; Yi, T.-H.; Zhang, S.-H.; Li, C. Multidamage Identification in High-Resolution Concrete Bridge Component Imagery Based on Deep Learning. J. Perform. Constr. Facil. 2024, 38, 04024026. [Google Scholar] [CrossRef]

- Xiong, C.; Zayed, T.; Abdelkader, E.M. A novel YOLOv8-GAM-Wise-IoU model for automated detection of bridge surface cracks. Constr. Build. Mater. 2024, 414, 135025. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, Z.; Ji, J.; Sun, Y.; Tang, H.; Li, Y. Intelligent Surface Cracks Detection in Bridges Using Deep Neural Network. Int. J. Struct. Stab. Dyn. 2024, 24, 24500469. [Google Scholar] [CrossRef]

- Shen, Y. ZJU SYG Crack Data Set. 2020, Volume 3. Available online: https://data.mendeley.com/datasets/y749944ddt/3 (accessed on 10 February 2025).

- Zoubir, H.; Rguig, M.; El Aroussi, M.; Saadane, R.; Chehri, A. Pixel-level concrete bridge crack detection using Convolutional Neural Networks, gabor filters, and attention mechanisms. Eng. Struct. 2024, 314, 118343. [Google Scholar] [CrossRef]

- Wu, Y.; Han, Q.; Jin, Q.; Li, J.; Zhang, Y. LCA-YOLOv8-Seg: An Improved Lightweight YOLOv8-Seg for Real-Time Pixel-Level Crack Detection of Dams and Bridges. Appl. Sci. 2023, 13, 583. [Google Scholar] [CrossRef]

- Jang, K.; Jung, H.; An, Y.K. Automated bridge crack evaluation through deep super resolution network-based hybrid image matching. Autom. Constr. 2022, 137, 104229. [Google Scholar] [CrossRef]

- Li, G.; Liu, T.; Fang, Z.; Shen, Q.; Ali, J. Automatic bridge crack detection using boundary refinement based on real-time segmentation network. Struct. Control Health Monit. 2022, 29, e2991. [Google Scholar] [CrossRef]

- Pozzer, S.; Rezazadeh Azar, E.; Dalla Rosa, F.; Chamberlain Pravia, Z.M. Semantic Segmentation of Defects in Infrared Thermographic Images of Highly Damaged Concrete Structures. J. Perform. Constr. Facil. 2021, 35, 04020131. [Google Scholar] [CrossRef]

- Zhang, Y.-C.; Yi, T.-H.; Lin, S.; Li, H.-N.; Lv, S. Automatic Corrosive Environment Detection of RC Bridge Decks from Ground-Penetrating Radar Data Based on Deep Learning. J. Perform. Constr. Facil. 2022, 36, 04022011. [Google Scholar] [CrossRef]

- Shi, J.; Dang, J.; Cui, M.; Zuo, R.; Shimizu, K.; Tsunoda, A.; Suzuki, Y. Improvement of damage segmentation based on pixel-level data balance using vgg-unet. Appl. Sci. 2021, 11, 518. [Google Scholar] [CrossRef]

- Avendaño, J.C.; Leander, J.; Karoumi, R. Image-Based Concrete Crack Detection Method Using the Median Absolute Deviation. Sensors 2024, 24, 2736. [Google Scholar] [CrossRef]

- Hu, D.; Yee, T.; Goff, D. Automated crack detection and mapping of bridge decks using deep learning and drones. J. Civ. Struct. Health Monit. 2024, 14, 729–743. [Google Scholar] [CrossRef]

- Shalaby, Y.M.; Badawy, M.; Ebrahim, G.A.; Abdelalim, A.M. Condition Assessment of Concrete Structures using Automated Crack Detection Method for Different Concrete Surface Types Based on Image Processing. Discov. Civ. Eng. 2024, 1, 81. [Google Scholar] [CrossRef]

- Song, F.; Liu, B.; Yuan, G. Pixel-Level Crack Identification for Bridge Concrete Structures Using Unmanned Aerial Vehicle Photography and Deep Learning. Struct. Control Health Monit. 2024, 2024, 1299095. [Google Scholar] [CrossRef]

- Yuan, J.; Ren, Q.; Jia, C.; Zhang, J.; Fu, J.; Li, M. Automated pixel-level crack detection and quantification using deep convolutional neural networks for structural condition assessment. Structures 2024, 59, 105780. [Google Scholar] [CrossRef]

- Ren, Z.; Fang, F.; Yan, N.; Wu, Y. State of the Art in Defect Detection Based on Machine Vision. Int. J. Precis. Eng. Manuf.—Green Technol. 2022, 9, 661–691. [Google Scholar] [CrossRef]

- Pal, M.; Palevičius, P.; Landauskas, M.; Orinaitė, U.; Timofejeva, I.; Ragulskis, M. An overview of challenges associated with automatic detection of concrete cracks in the presence of shadows. Appl. Sci. 2021, 11, 11396. [Google Scholar] [CrossRef]

- Omidi, Z. Enhancing Concrete Infrastructure Integrity: Integrating Active Thermography and Ground Penetrating Radar for Delamination Detection. 2024. Available online: https://corpus.ulaval.ca/server/api/core/bitstreams/23eb757c-10e1-4e3e-9e1c-ef1e76117264/content (accessed on 10 February 2025).

- Rainieri, C.; Rosati, I.; Cieri, L.; Fabbrocino, G. Development of the Digital Twin of a Historical Structure for SHM Purposes. Lect. Notes Civ. Eng. 2023, 254, 639–646. [Google Scholar] [CrossRef]

| S. No. | Technical Aspects of SHM | Function Performed | References |

|---|---|---|---|

| 1. | Impregnation of sensors | Monitor the condition of the specific structure | [24,25,26] |

| 2. | Data acquisition techniques | Gather real-time data that help to track structural integrity | [24,25] |

| 3. | Signal processing tools | Help to analyse data collected in the previous step | [27] |

| 4. | Damage detection | Assist in damage detection | [24,27] |

| 5. | Remote monitoring | Help in monitoring structures remotely | [24,26] |

| 6. | Acoustic emission | Detect and locate different damage in reinforced concrete structure | [26] |

| Reference | Objective | Place of Study | Technique | Dataset | Special Highlight | Outcome | Limitations/Future Direction |

|---|---|---|---|---|---|---|---|

| [118] | SHM | United States | Vibration-based mechanisms, along with ML | NA | Fibre optic system for harsh cold conditions. | The study deployed local measurement sensors, train and displacement sensors, and Artificial Intelligence algorithms. | An extensive focus on vibration-based analysis was laid out, but no attention was paid to feature extraction. |

| [119] | Crack detection in UAV-based bridge inspection | Norway | CNN | SDNET2018 [120], Hetrogenious (308 images), Homogeneous (400 images) UAV-based images of 3000 × 4000 pixels | Extensive training time, a multitude of parameters RCNN, and YOLO. | Crack identification accuracy of CNN is 81%. | Proposed that the Atrous convolution method permits the usage of a sizeable receptive field without compromising the resolution. |

| [121] | Identification and classification of cracks in concrete bridges | China | A fully connected layer comprising 256 neurons was placed ahead of the Softmax layer in the VGG network | 2000 images of 224 × 224 pixels were used in 4:1 ratio of training and testing | BN layer amidst convolution and pooling layers normalised gradient depression. TL reduced the network’s training time. | Achieved more than 90% training and testing accuracies. | Although high accuracy was achieved, practical application is attainable only with CNN. Overfitting was successfully managed. |

| [122] | Cracks, spallings, and water erosion detection in concrete bridges | China | A model based on FCN pixel-level identification was used to study concrete bridge delamination and reinforcement exposure | 1647 images of 224 × 224 pixels | A pre-trained model was utilised for TL and tested on data exhibiting damage to concrete bridges. | Twin fold improvement viz. the SPP module showcased a 1.3% mAP improvement, and 21% (20.9%) mAP improvement was attained through TL. | The pre-training sample deployed was relatively small. |

| [123] | Structural damage detection in bridges | New Zealand | A model based on YOLO v3 with the help of the Spatial Pyramid Pooling (SPP) module | Structural ImageNet [124], and 330 images of high resolution | It also works in emergencies, like just after an active earthquake. | After the sensitivity analysis, an accuracy of 84.7% was obtained. | Achieved results included 88% for damage detection, while for spalling, it was 63%. |

| [125] | Damage segmentation of the bridge using FCN | Japan | FCN pixel-level identification for concrete bridge delamination and reinforcement exposure | 734 images of very low resolution of 1 Mpx | FCN surface damage detection was accomplished (automated semantic segmentation). | Despite using a large dataset, an accuracy of 89.7% for delamination was achieved. Reinforcement exposure was just 78.4%; however, the weighted F1 score was around 81.9%. | A large dataset was assembled to justify the proposed model on regions of agreement, thereby diminishing the risks of highly unpredictable in-field inspections. |

| [90] | Bridge crack detection with UAV | China | Bridges were studied for damage detection induced by earthquakes and other seismic events | 6069 images of 224 × 224 pixels | An end-to-end CNN model was used, with a total of 28 layers (16 were convolutional layers, while 3 were max-pooling layers) 10 CNN layers were attributed to the Atrous Spatial Pyramid Pooling (ASPP) module. | No pre-trained model but achieved 96.37% accuracy in crack identification. Data augmentation was used to fulfil the required data. | Developed CNN outperformed conventional models. The adaptable model can be ingrained in any CNN for feature extraction. |

| [126] | Bridge crack detection with UAV | Korea | UAVs and R-CNN were applied to expose and pinpoint cracks in bridge surfaces | 384 images of 256 × 256 pixels | With the help of extracted crack image blocks, both area-based and width-dependent crack parameters were exhibited. | It was a two-step process: initially, a basic background model formulated using a point cloud-based method was made. Surface cracks were later identified using R-CNN and TL. | It was based on CNN. The Cifar-10 dataset was used. |

| Reference | Objective | Technique | Dataset | Outcome | Feature/Limitations |

|---|---|---|---|---|---|

| [127] | To develop a crack detection model using TL. | Image augmentation was achieved using rotation, offset, flip, fill, clip, and zoom. CNN and VGG16 | A total of 167 RGB images of 1024 × 768 pixels. | Enhanced accuracy and robustness, along with a stupendous F1 score. | 5% enhancement in accuracy. Model was trained on a very small dataset. |

| [128] | Reviewed ML-based algorithms used for the SHM of buildings. | ANN, CNN, and SVM | NA | Data processing achieved by the Hilbert–Huang transform or the wavelet packet transform yielded good results. | Emphasis was placed only on using fog devices to minimise noise filtering and enhance data compression and data fusion after seismic events. |

| [129] | To investigate the link between enhanced computational intelligence and SHM solutions. | ANN, Hybrid ANN- ICA, Hybrid ANN-GA | NA | ICA and GA were intermingled with pre-developed ANN and hybrid ANN to formulate two hybrid models. Improved prediction error. | Learning outcomes of pre-developed networks improved along with the prediction error with the help of advancements in ANN. The study used vibration data from controlled laboratory conditions. No explicit comparison with real-world damage scenarios. |

| [130] | To Improve the mAP. | R-CNN | Canon EOS 5DS R camera captured 1000 digital images of 8688 × 5792 pixels | The results were better than those of faster R-CNN with predefined anchor points. 84.56% was the average identification accuracy achieved. | Besides cracks, other types of damage, like spalling and exposed reinforcement, were also detected. Damage quantification was not conducted. No consideration of environmental and operational variations. |

| [131] | To detect sub-surface damage in bridges using NDT technology and GPR. | CNN | The training dataset (75%) contains 17,388 CNN data points. The testing dataset featured 2898 GPR signals. The validation dataset uses a sample with the same amount of samples. | A high accuracy of around 84% was obtained with the proposed model. | The proposed model has already surpassed ML-based GPR data networks. The dependability of the 1D-CNN is dependent on the quality and uniformity of GPR data. Disparities in data gathering techniques, climatic conditions, and device calibration may influence model efficacy. |

| [132] | To explore several ML techniques in structural design, construction quality management, bridge engineering, and reinforced concrete bridge inspection. | ANN CNN SVM | NA | ANN is best suited for classification and regression tasks. CNN is best suited for image information, processing. | Reinforced concrete bridges were explored in microscopic detail; however, feature extraction techniques are missing. |

| [133] | Identify and classify surface and sub-surface corrosion in steel bridges. | Faster R-CNN | A dataset of 36 3D CbCr-IR images. The training included 72 images, including 36 rotated versions (180 degrees) of the original images. | Promising results were obtained: 88.64% mAP for surface corrosion and 88.59% for sub-surface corrosion. | The combination approach (vision and infrared images) enhanced the reliability of damage detection. The model was trained and tested on only two bridges’ data (First Jindo Grand Bridge and Deung-Sun Bridge in South Korea). |

| [134] | To propose a deep-learning system, Faster R-ConvNet, to detect pavement distress. | Faster R- CNN | The testing dataset was divided into 300, 500, and 900 MHz transmission frequencies. The ratio of GPR images in the three transmitting frequencies was 1:1:1. | Maximum effective results in terms of accuracy were attained by the proposed Faster R-CNN when there were 0.3 anchors and a 0.7 ratio. Results in accuracy were reflection cracks (88.31%), water-damage pits (90.56%) and uneven settlements (88.51%); While IoU was- reflection cracks (86.53%). | Not only cracks were detected, but other damage types, such as reflection cracks, water damage pits, and uneven settlements, were also detected. GPR’s data lower resolution or unsuitable frequency ranges can reduce detection accuracy due to image detail loss. |

| [135] | An automated computerised system can reduce time, faulty inspection, and inspection cost. | CNN | Cellular phones and FLIR 6.8 mm f/1.3 thermal imaging drones captured 2086 crack and non-crack images of 838 × 638 pixels. | Inception V2 was applied to a faster R-CNN model and exhibited about 80.35% accuracy. | The combination approach delivered enhanced damage detection and accuracy. The post-training model displayed 98% accuracy. The dataset was collected from the University of Tennessee at Chattanooga’s old library parking garage ceiling. |

| [136] | The vision-based solution uses deep convolutional neural networks (CNNs) to detect concrete cracks without calculating fault attributes. | CNN | Out of 332 raw images, 277 images of 4928 × 3264 pixels were utilised for training and validation, while 55 images of 5888 × 3584 were used for testing. | A comparison of the proposed model with Canny and Sobel edge detection methods revealed better results. The designed CNN is trained achieving around 98% accuracy. | Extravagant crack detection of minute cracks was achieved despite of limiting environmental factors. The study lacks specifics regarding the model’s performance across various cracking types, widths, and orientations. |

| [137] | Multiple damage detection in reinforced concrete (RC) bridges. | CNN Xception and Vanilla | CODEBRIM [138]. | Xception was better, with 94.95% accuracy. Vanilla rendered 85.71% accuracy. | Detected five types of bridge damage: cracks, corrosion, efflorescence, spalling, and exposed steel reinforcement. Real-world validation of the model is missing. |

| [139] | Detect cracks at the bottom of bridges. | Faster R-CNN and BIM | A total of 637 images, each 512 × 512 pixels, were captured using a DJI M210-RTK UAV. | Promising corollaries were attained, viz. 96.54% recall and 92.03% accuracy. | Different types of crack families, viz. longitudinal/ transverse/turtle cracks could be identified. The study fails to consider potential difficulties in synchronising and updating BIM models with real-time inspection data. |

| [140] | Drone photography of concrete cracks was studied in detail using ML tools. | CNN | 3000 Images having a size of 512 × 512 pixels are captured using UAV. | The improved CenterNet model reduced FPS by 123.7 Hz, with 62 MB GPU memory enhancement. | Stable GPU memory occupancy while training. Remarkable real-time performance, accuracy, and robustness were encountered. The study lacks sufficient details regarding the dataset utilised, encompassing its provenance, image dimensions, and collection methodologies. |

| [141] | Assessing cracks on concrete surfaces using UAVs. | A combination version of FRCNN and ResNet model | 1000 images of 640 × 480 pixels from diverse datasets were used. | The proposed combination model gave a 93.3% precision rate and a quick inference time of 59.7 ms. | Unremitting real-time crack, especially, was possible within a reasonable budget. The investigation may inadequately assess the model’s capacity to generalise across diverse concrete constructions with varying textures, colours, and compositions. |

| [142] | To detect cracks in millimetre units (not in pixels). | Custom CNN and U-Net models | NYA-Crack-Data [143]. | Attained accuracy of 99.22% for the classification model and 96.54% for the segmentation model. | Crack detection in millimetres rather than pixels is more accurate and practically applicable. The study is dependent on laser calibration to measure the crack in millimetres. |

| [144] | Crack detection in structures including bridges. | CNN ViT | SDNET2018 [120] dataset. | About 92.81% accuracy was achieved in bridge crack detection. | A combination model was developed using vision transformers and CNN. The model’s effectiveness in detecting very fine or hairline cracks is not thoroughly evaluated. |

| [145] | Crack detection in concrete bridges. | CNN | A total of 20,000 images of 227 × 227 pixels in each category of cracked and non-cracked dataset. | A 99% accuracy was featured with moderate expenditure. | All examined models had a minimum of 99.1% G-mean values. The model’s performance across varied environmental conditions, such as different lighting scenarios, surface textures, and crack morphologies. |

| [146] | Crack detection in concrete bridges. | Lightweight deep CNN and unmanned aircraft system (UAS) | A total of 6000 images with image resolution of 200 × 200 pixels were used for training, validation and testing in 7:2:1 ratio. | The model exhibited 97.42% accuracy, 97.62% precision, and 97.23% recall and attained 93.25% IOU. | The technical changes made the proposed model suitable for local cross-channel interaction, securing the dimensionality element. The effectiveness of the model in detecting very fine or hairline cracks is not thoroughly evaluated. |

| [147] | Crack detection in concrete bridge. | CNN Square/strip convolution | BlurredCrack [148], CrackLS315 [149], CFD [150]. | Precision: 73.74%, recall: 77.04%, F1: 75.30%, IoU: 60.48%. | Performed better than CNNs as they fail in background noises and long-range dependencies between crack regions; background noises. The study does not elaborate on how MFSA-Net’s outputs can be integrated into broader structural health monitoring frameworks. |

| [151] | Crack detection on the surface of concrete infrastructure. | TensorFlow CNN and image processing | 6000 images of 227 × 227 pixels. | The proposed model exhibited an accuracy of 97.11% and 97% F1 score. | Effective and accurate crack identification was possible. The study fail to perceive long-range dependencies between crack regions, and has weak suppression ability for background noises, leading to low detection precision of bridge cracks. |

| Reference | Objective | Technique | Dataset | Outcome | Features/Limitations |

|---|---|---|---|---|---|

| [152] | To accurately and autonomously calculate reinforcing bar cover thickness and diameter. | The extracted thickness range became the input data for a 1D CNN, besides EMI (electromechanical impedance) data | EMI data for 1D CNN training. GPR data for YOLOv3 training. | Accuracy obtained in sand pit experiments was 96.8% for overburden thickness and 90.3% for reinforcement diameter. | Besides CNN, other methods usually used, like ANN, were overlooked. The models were trained and validated on a limited dataset. Pre-processing data from GPR and EMI in all fields is not possible. |

| [153] | Coarse and fine crack analysis of concrete bridges based on double detection and single segmentation. | Object detection network model (ODNM); YOLOv5; U-Net | A total of 2068 images of 1024 × 1024 pixels with various disturbances, including mud stains, water spots, shadows, and blurriness were used in 8:1:1 ratio of training, testing, and validation. | U-Net model’s accuracy was 98.37%. | U-Net is used for semantic segmentation. Detecting cracks that occupy a very small area relative to the overall image remains challenging. |

| [154] | Detecting fine-grained concrete cracks using pseudo-labelling techniques. | STL-ELM | SDNET2018 [120], METU Campus Buildings dataset [155], 28309 images of 450 × 450 pixels [156]. | The proposed method was better in mAP by around 2.62%, and the F1 value improved by 4.40% compared to existing studies. | Efficiency was better than other normally used methods. The proposed approach erroneously identified some samples from the no-crack category as images depicting cracks. |

| [157] | Automatic and robust crack detection in concrete installations. | YOLOv8 models | A total of 6315 crack images of 450 × 450 pixels with labels derived from a crack segmentation dataset. | The study reports 89.62% precision and 0.88 scores for IoU. The minimum inference time/image was 27 milliseconds, representing at least a 5% improvement. | Three types of YOLOV8 models were compared, with YOLOv8x giving the best results with a precision of 93.13%, recall of 91%, and mAP of 90.13%. These are better results compared to the U-NET and U-NET++ models. Combining inference results with IoU thresholding may not consistently yield the most effective fusion, particularly when overlapping or unclear cracks are present. |

| [158] | Crack detection using YOLO in concrete bridges. | Different types of YOLO and YOLOR are used for crack detection in concrete bridges. | A total of 7009 images of 3264 × 2448 pixels from concrete bridge defect (CBD) dataset. | The proposed model’s efficiency was enhanced, with an accuracy of 97.5% and an mAP improvement of 2.7 %. | Not only concrete cracks but nine different types of bridge damage were identified (including cavity, leakage, and reticular/single crack). The model’s testing in real-world circumstances, such as on-site bridge inspections, is not addressed. The model’s efficacy in identifying subtle or early-stage defects that are less conspicuous is not addressed. |

| [159] | Multidamage identification in high-resolution concrete bridge. | YOLOv5 and AWCM | A dataset was created having cracks (4980), spallation (5225), holes (5211), and rebar (5020). | 94.2% mAP for all classes was attained; other values were as high as spallation 98.1% and rebar 99.4%. | Several types of concrete bridge damage, including cracks, were successfully identified. Fluctuations in light, shadows, and image resolutions can influence detection precision and accuracy. |

| [160] | Concrete damage detection in reinforced bridges in Hong Kong. | YOLOv8, with slight modification, a decoupled head with two components, viz. Detection head and classification head. | A total of 3960 images (3320 images of 224 × 224 from BSD dataset and 640 images from Hong Kong bridge crack dataset (HKBCD). | A precision of around 97% and almost 95% recall was obtained. | Superordinate flexibility so that one can grapple with disparate tasks. The model may encounter difficulties detecting minute or faint cracks, especially in intricate backdrops or when cracks are partially concealed. |

| [161] | Identified cracks in concrete bridges. | YOLOv5-TS with the following output features- mAP@0.5 (0.752), mAP@0.5:0.95 (0.518), and recall (0.794) | ZJU SYG [162]. | Four types of mechanical cracks were distinguished viz. horizontal cracks (0°–20°), low-angle cracks (20°–45°), vertical cracks (70°–90°), and high-angle cracks (45°–70°). | Twin benefits were achieved by using transposed convolution–enhanced network capacity that enabled it to self-learn weights and minimise characteristic information loss. Although DCGAN is utilised to enhance the dataset, the initial deficiency of authentic crack images presents difficulties. |

| [163] | Crack detection in concrete bridges at pixel-level. | A combination of U-Net, Gabor filters, and Convolutional Block Attention Modules. | The authors created a multi-source, annotated crack dataset of 1200 images of 200 × 200 pixels, | Outcomes surpassed Intersection over Union (IoU) of 60.62% and an F1 score of 74.49%. | A generalised investigation takes care of detecting cracks across various domains and backgrounds. The integration of UNet with Gabor filters and CBAM increases the model’s complexity. |

| Reference | Objective | Technique | Dataset | Outcome | Features/Limitations |

|---|---|---|---|---|---|

| [164] | Develop real-time, pixel-level crack detection. | The mask branch ProtoC1 keeps the quality of the instance masks the same as the original branch, reduces parameters and complexity, and speeds up the processing speed of the prototype branch. | The 600 underwater concrete crack images of 704 480 pixels include uneven cracks of varying degrees. | Accuracy was achieved at 0.945 at 129 FPS. Reduction in volume; suitable for low-lying devices. | Training cost was minimised, and enhanced robustness was achieved. Model volume can be achieved by replacing the backbone with LCANet, slightly altering the accuracy. Compared to the baseline YOLOv8n-seg model, there is a 3% reduction in detection accuracy. |

| [24] | Advancements in AI and new technologies for bridge SHM. | Drone technology and 3D printers. | NA | Urged to replace visual inspection with drone-aided technology. Drones can fly at high altitudes and have hi-tech cameras. | Along with several AI tools, other methods of drone technology and 3D printers were also discussed. The performance of SHM systems using AI, drones, and sensors is not deeply analysed in this study. |

| [165] | Develop an automated bridge crack evaluation method. | Sub-surface bridge damage and delamination were detected. | 800 high-resolution (HR) images and 100 low-resolution (LR) images were randomly picked from the DIV2 K dataset for training and validation. | Only actual damage (cracks) was detected. False results were efficiently diminished (accuracy by 49.91% and recall by 13.31%). | Poor bridge condition was held responsible for the false indication. Identifying very fine or propagating cracks remains challenging. Fluctuations in light and surface conditions might influence the precision of crack identification algorithms, resulting in either false positives or negatives. |

| [166] | Prioritise bridge safety maintenance due to noise and hazy images. | STDC-Net. | The training dataset has 28,800 images, the testing set has 9600, and the validation set has 9600. | The proposed DBR-Net was tested on three datasets, rendering 97.54% accuracy on the authors’ self-made dataset. | The combination of STDC-Net creates a new DBR-Net. In the case of real-time, the crack detection rate was as good as 37.0 images/sec. The technique may exhibit diminished efficacy in identifying minute cracks owing to the resolution constraints of the input images. The model may have difficulty differentiating cracks from background noise, resulting in either false positives or missed detections. |

| [167] | Detect different types of defects in both regular and thermographic images in a timely and cost-effective manner. | VGG 16 model. | NA | MobileNetV2 detected several damage types in thermal images, identifying 79.7% damage. | A study on infrared thermography and the VGG 16 model and its applicability in concrete damage detection; however, other ML tools were overlooked. The chances of false detection were minimal. The study focuses on severely compromised concrete structures, potentially restricting the relevance of the findings to those with milder damage. |

| [168] | Automatic corrosive environment detection of bridge decks from GPR data. | SSD. | Trained on 10316 B Scan images of 300 × 300 pixels and tested on 2578 images. | SSD was able to figure out 677 bars; accuracy—98%. | With the assistance of this extracted reinforcement information, a contour map could be created displaying bridge deck corrosion. Establishing precise ground truth for model training and validation is difficult. |

| [169] | Perform damage segmentation by entering varying data sizes. | Pre-trained VGG was used to pre-train U-Net. | The data were collected by manually labelling 200 steel corrosion images and 500 rubber-bearing crack images. | HR images were compressed into the network. In the next step, the HR image was cropped to 224 × 224 pixels, which was also input into the network. | The second method was better for large damage (corrosion), while the first method was successful for large damage (corrosion). Relatively small and specific dataset used for training and evaluation. |

| [170] | Pixel-level crack detection in concrete. | Median Absolute Deviation (MAD); Median Absolute Deviation (for edges). | This study collected images of concrete cracks between 0.1 and 1.5 mm. An AF-s Nikon 24–70 mm f/2.8 G ED lens and Nikon D810 digital camera were used for imaging. | Performance was determined using probability of detection (POD) curves that displayed 94% success in narrow crack detection and 100% for wider cracks. | Cracks as small as 0.1 mm was also detected. The system used performed well compared to conventional Otsu and Niblack methods. Overestimated the width of the cracks due to selection of higher k-value. Some noise is still detected as cracks, which may lead to false positives due to the detection of cracks up to 1 mm. |

| [171] | Crack detection in concrete bridges using drones, Deep Learning geofencing. | Cracks were segmented and identified as per their georeferenced coordinates. | A total of 15298 images were extracted from the 11 existing public datasets. | The spawned framework gave a precision of 77.5% and 76.5% recall. | The practical application of the proposed model on a real bridge delivered accurate and relevant outcomes. Environmental variables, including light fluctuations, shadows, and surface reflections, can affect the accuracy of crack detection during drone operations. |

| [172] | Concrete crack detection on structures, including bridges. | Varied image (taken by Nikon camera and iPhone 7 Plus) processing methods were used. | A subset of the public dataset SDNET2018 [120], along with the experimental laboratory sample. | The result for crack detection in terms of the F1 score was 98.87% in the case of bridges. | Cost-effective and user-friendly model adept in crack exploration on discriminable concrete structures. No large training data were sought. Furthermore, images were captured using iPhone. Poor image quality can lead to inaccurate detection results. |

| [173] | Crack detection in concrete bridges at pixel-level with the help of drones and Deep Learning. | Computer vision and Deep Learning. | A self-prepared dataset of 2500 images of 600 × 400 and 1200 × 800 pixels. | The loss function of the presented model confirmed a smooth decline. Real-time efficient crack detection was justified by 35.04 FPS detection efficiency. | The model performed well even in diffused/dim light and a complex background. The research fails to address the issue of perspective distortion that may arise when UAV cameras are not perpendicular to the inspected surface. |

| [174] | Pixel-level concrete crack identification with quantification. | ResNet-50. | A large-scale concrete crack image dataset consists of 1242 images of 227 × 227 pixels. | Segmentation performance was better than regular models, giving an 83.07% IoU. | Pixel-level quantitative analysis of the exigent geometric parameters, including crack area, crack length, crack mean width, and crack max-width, was applied. The current dataset is self-made and relatively small. The existing dataset comprises pictures taken using standard cameras, constrained by ambient factors like lighting. These cameras are limited to capturing two-dimensional images and lack the capability to convey further spatial information such as distance or depth. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakash, V.; Debono, C.J.; Musarat, M.A.; Borg, R.P.; Seychell, D.; Ding, W.; Shu, J. Structural Health Monitoring of Concrete Bridges Through Artificial Intelligence: A Narrative Review. Appl. Sci. 2025, 15, 4855. https://doi.org/10.3390/app15094855

Prakash V, Debono CJ, Musarat MA, Borg RP, Seychell D, Ding W, Shu J. Structural Health Monitoring of Concrete Bridges Through Artificial Intelligence: A Narrative Review. Applied Sciences. 2025; 15(9):4855. https://doi.org/10.3390/app15094855

Chicago/Turabian StylePrakash, Vijay, Carl James Debono, Muhammad Ali Musarat, Ruben Paul Borg, Dylan Seychell, Wei Ding, and Jiangpeng Shu. 2025. "Structural Health Monitoring of Concrete Bridges Through Artificial Intelligence: A Narrative Review" Applied Sciences 15, no. 9: 4855. https://doi.org/10.3390/app15094855

APA StylePrakash, V., Debono, C. J., Musarat, M. A., Borg, R. P., Seychell, D., Ding, W., & Shu, J. (2025). Structural Health Monitoring of Concrete Bridges Through Artificial Intelligence: A Narrative Review. Applied Sciences, 15(9), 4855. https://doi.org/10.3390/app15094855