1. Introduction

Grain storage systems are crucial for ensuring food security. However, global grain storage losses amount to approximately 8% annually, with even more substantial losses among dispersed rural households due to inadequate storage conditions. Storage losses are primarily influenced by two factors: moisture and temperature. Moisture impact is particularly significant, as excessive moisture can lead to localized hotspots (deteriorating regions with elevated temperatures and moisture) within storage facilities. These conditions trigger multiple issues, including seed germination, mold growth, and pest infestation [

1]. Currently, effective methods for the timely detection of these anomalies in deep grain storage areas remain lacking.

In situ moisture detection techniques for grain piles primarily include conventional sensors (temperature, moisture, or chemical sensors) [

2,

3], near-infrared moisture measurement [

4], acoustic temperature detection, and microwave scattering methods [

5]. The first three approaches share a common limitation: shallow detection depth. This constraint arises from two main factors: (1) grain’s excellent thermal insulation properties, which limit sensor sensitivity to nearby grains only; and (2) the limited penetration capabilities of near-infrared and acoustic methods, restricting their application to surface-level detection. These limitations make it difficult to detect hotspots in deep grain layers. In contrast, microwave-based methods show promising potential for deep-layer hotspot detection, primarily due to microwaves’ superior penetration capability.

Current microwave-based methods for detecting moisture anomalies in grain piles primarily comprise two approaches: electromagnetic imaging reconstruction [

6,

7,

8,

9,

10,

11] and electromagnetic wave reflection analysis [

12,

13,

14]. For instance, Joe LoVetri et al. [

7,

8] at the University of Manitoba applied electromagnetic imaging to grain inspection, developing a finite element contrast source inversion (FEM-CSI) method and designing thin coaxial semi-circular antennas for hotspot detection in industrial-scale grain silos. However, significant challenges persist. Methods using Maxwell’s equations to describe microwave scattering phenomena face inherent complexities [

15], including solution non-uniqueness due to non-radiating currents, non-linearity associated with multiple scattering effects, ill-conditioned problems, and high computational costs [

16]. These challenges can result in processing times of several hours and potential artifacts. CHEN et al. [

17] also applied their method to granaries. Similar to humidity sensors, the accuracy of radio-frequency moisture sensors for grain moisture detection was affected to varying degrees by ventilated granary conditions.

Despite microwaves’ strong penetration capability, electromagnetic reflection methods for moisture assessment typically achieve only shallow detection depths [

12,

14]. For example, Zhang et al. [

12] developed an open-ended coaxial wave-guide sensor for direct insertion into grain piles for moisture measurement. However, this sampling-based approach has significant limitations: it may miss anomalies when multiple irregular regions exist, and it proves ineffective for detecting deep-layer anomalies within grain piles.

In summary, deep-layer moisture anomaly detection in grain piles faces multiple challenges, including artifacts, slow computation speeds, limited detection depth, and susceptibility to external interference. Beyond the aforementioned methods, digital beamforming offers an alternative approach to electromagnetic imaging. As a readily implementable and rapid imaging technique, digital beamforming has been successfully applied in radar systems, sonar systems, seismological research, and medical imaging [

18,

19,

20]. This paper presented a novel application of digital beamforming technology [

21] to grain moisture detection, employing the delay-multiply-and-sum (DMAS) algorithm [

20,

22] for rapid localization of moisture anomalies in grain piles. This approach offered distinct advantages: rapid detection speed and accurate positioning, demonstrating significant potential for grain monitoring applications.

This study employed long-grained rice as the test subject, which, after drying, exhibited a moisture content of approximately 10.5%. Generally, moisture levels exceeding 5% above that of dried grain were considered abnormal and unsuitable for long-term storage. Therefore, the primary objective of this research was to locate regions with moisture content greater than 15% within a cubic experimental bin containing long-grained rice dried to 10.5% moisture content. This localization aimed to facilitate subsequent treatment and prevent grain deterioration. The remainder of this paper was organized as follows:

Section 2 presents the detection system based on electromagnetic wave DMAS beamforming techniques, the fundamental principles of DMAS, and the algorithm for localizing abnormal moisture regions within grain piles.

Section 3 shows the impact of electromagnetic transmitter and receiver layouts on the detection area’s resolution capability and determination of the detectable region.

Section 4 discusses the method for assessing the reliability of localization results and localization tests for areas with 15.4% abnormal moisture content within the grain pile.

Section 5 provides a conclusion and insights into potential future research directions.

2. Materials and Methods

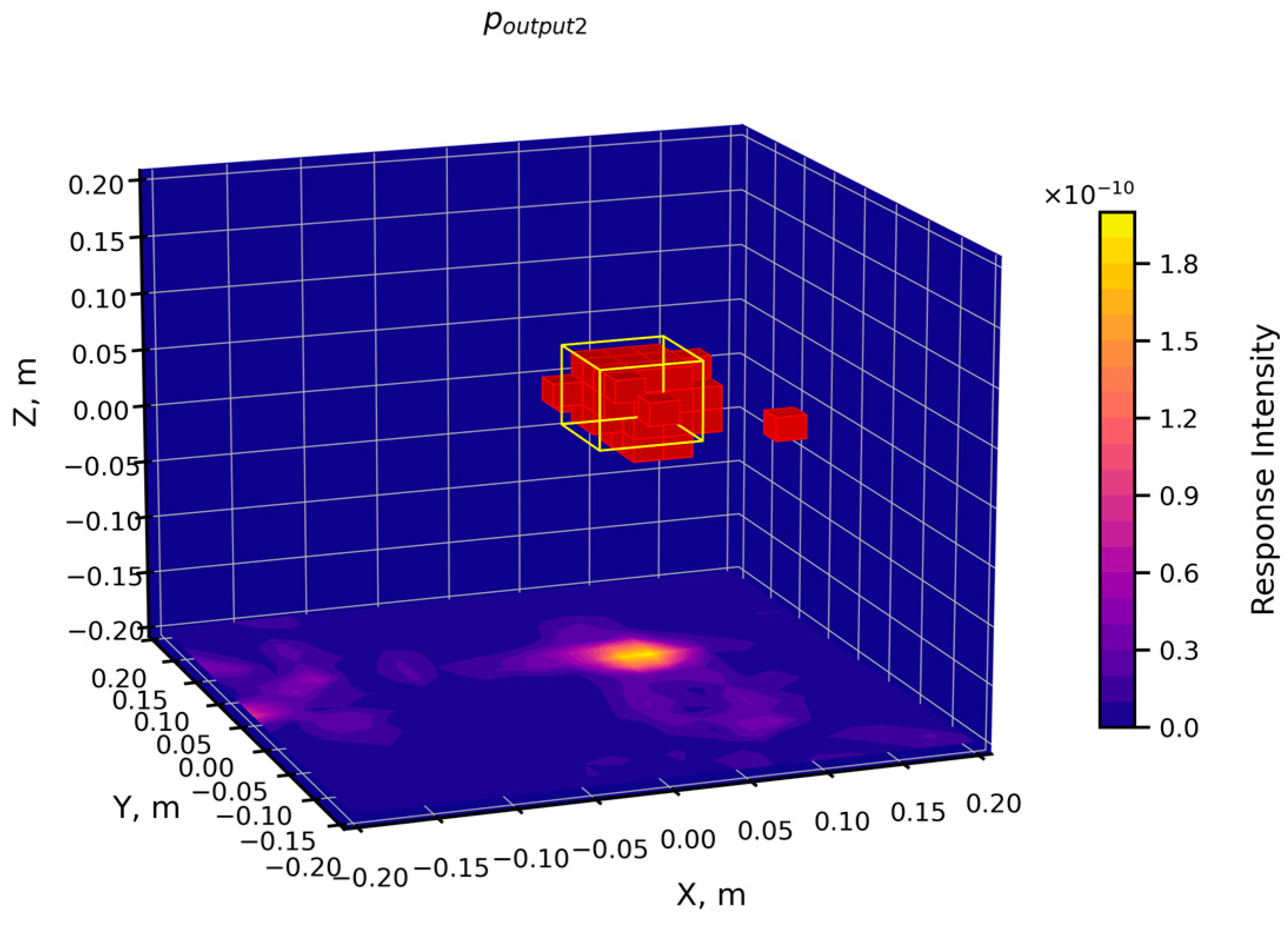

2.1. Experimental Setup of a Detection System for Anomalous Moisture Region in Grain Piles

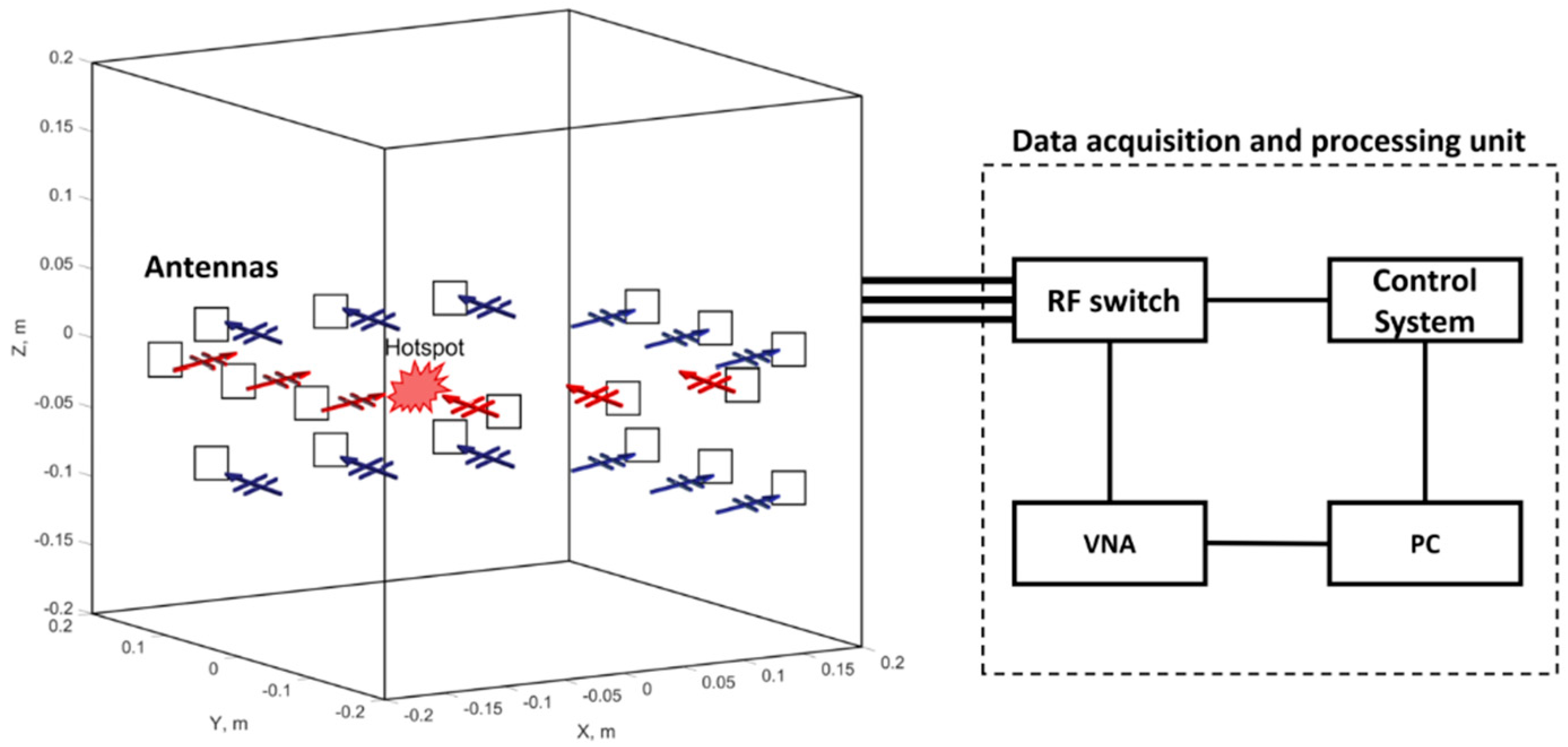

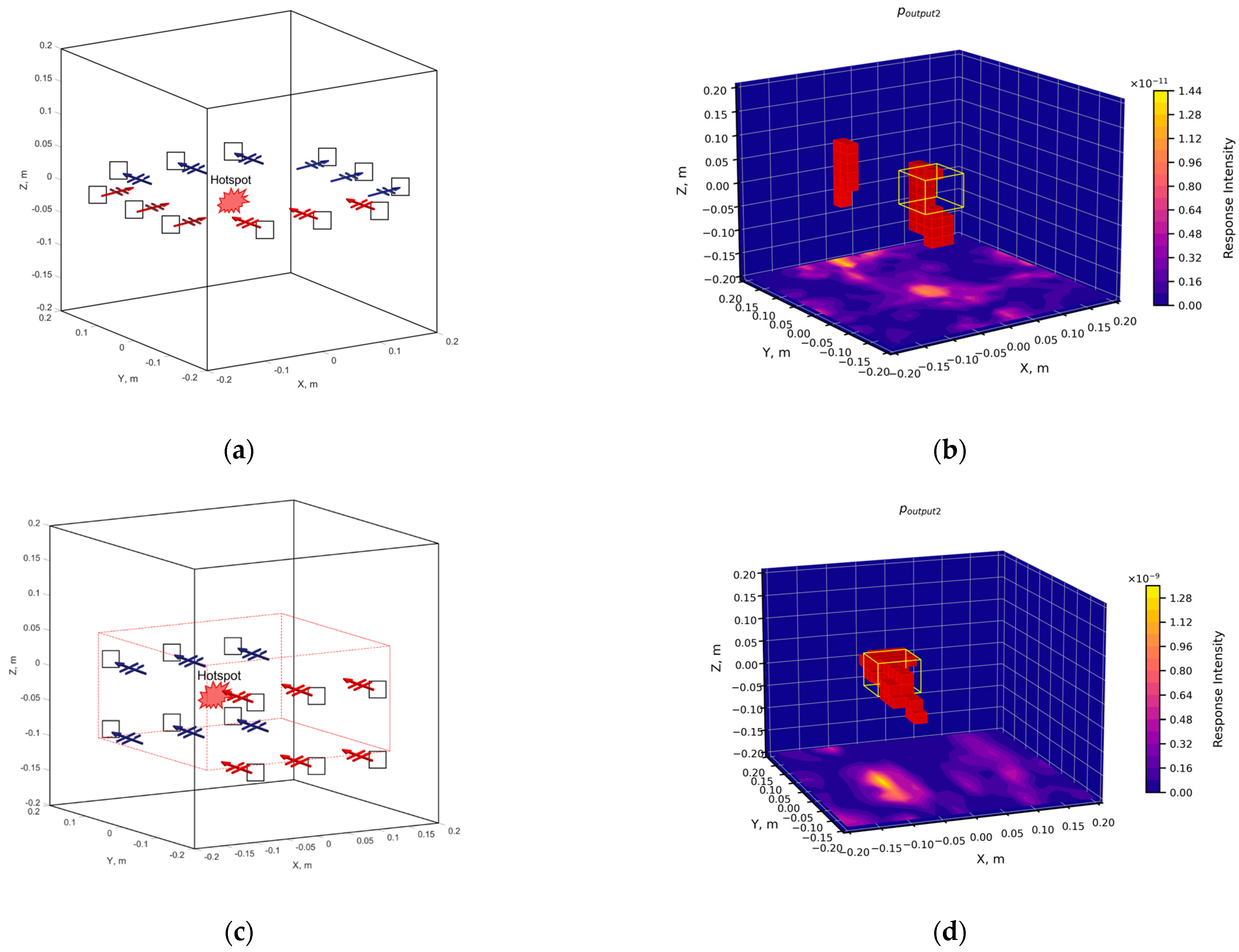

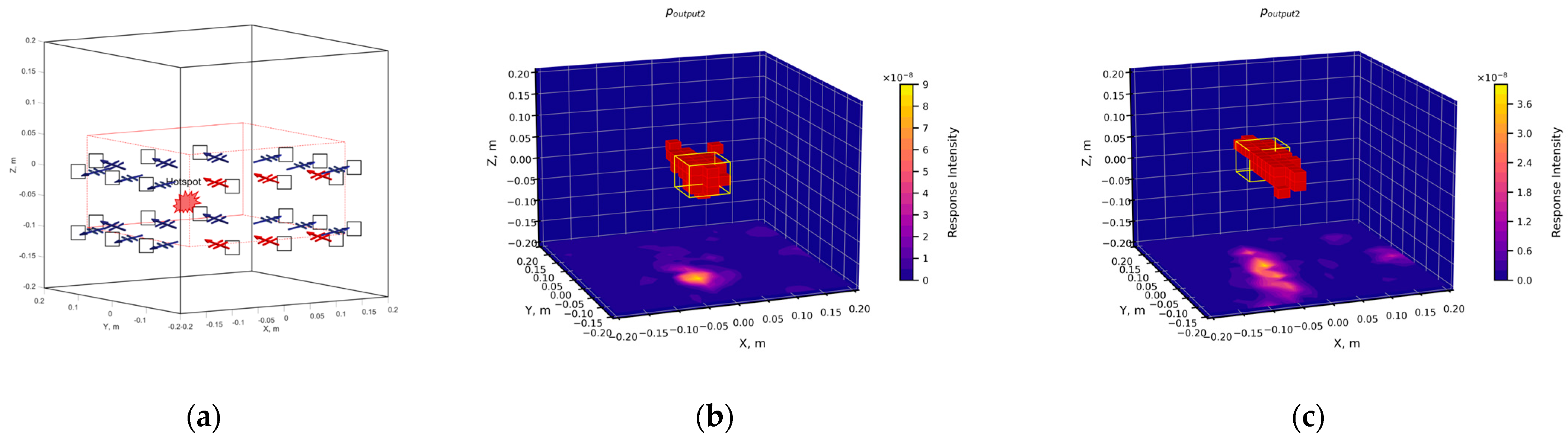

Multiple grain samples with moisture content exceeding 15.0% were prepared for this experiment. These anomalous samples were placed in acrylic cubic containers of 7 cm × 7 cm × 7 cm volume. Dry grain was placed in a 0.4 m × 0.4 m × 0.4 m cubic experimental bin, with the moisture-anomalous samples positioned at arbitrary locations within the bin. Patch antennas were uniformly distributed on all four side walls, with the most effective arrangement of this paper shown in

Figure 1 (the impact of different transmitter and receiver layouts on detection area resolution is discussed in

Section 3.1). These antennas serve as both electromagnetic wave transmitters and receivers. For precise localization, antennas on two side walls were designated as transmitters, while those on the remaining walls functioned as receivers. This study employed ultra-wideband electromagnetic waves with a frequency range of 2–3 GHz. The measurement speed was approximately 2 min. Although computational speed decreased as sampling data increased, improvements in both sampling and calculation speeds could be achieved through hardware optimization.

The data acquisition and processing unit comprised the following components and functionalities: radio frequency (RF) switches were employed to selectively connect electromagnetic wave transmission channels; a micro-controller served as the control circuit, working in conjunction with a host computer to coordinate the channel switching of the RF switches; a vector network analyzer (VNA) (LiteVNA, v1.3), operating through the RF switches, was utilized to collect electromagnetic field data; a master control computer managed the vector network analyzer to acquire data for subsequent processing. This system operated by controlling the emission and reception of electromagnetic waves, collecting electromagnetic field data that contained information about moisture anomalies. The computer then processed and analyzed this data.

2.2. Principle of DMAS-Based Localization Method for Anomalous Moisture Region in Grain Piles

This paper employed a digital beamforming technique based on the DMAS algorithm to localize regions of anomalous moisture content within the grain pile. Data acquisition was performed using an extended multi-static approach: transmitting antennas in the antenna array emitted signals in succession, while the scattered signals were received by all M receiving antennas. Upon completion of the transmission cycle by all elements, a total of scattered signals were recorded. Additionally, for layouts with cross-shaped structures, the number of scattered signals was .

To enhance detection accuracy, this experiment necessitated the reduction of environmental interferences, as the amplitude significantly exceeded that of the response from anomalous regions. These environmental interferences primarily originate from internal metallic structures, foreign matter in the grain, such as insects and pebbles, and biological entities in the surrounding test environment. The presence of these extraneous elements affects the collected scattered field signals.

Consequently, we proposed a calibration method for the scattered field data, . The scattered field data collected under conditions of completely dry grain was utilized as background data . Thus, the calibrated scattered field data could be expressed as . This calibration method was readily implementable, as the condition of completely dry grain could be conveniently achieved and maintained for reference measurements. For measurements involving diverse grain varieties and varying test environments, recalibration using a consistent methodology is imperative. This process includes the separate acquisition of background and scattered field data for each scenario.

The algorithm principle is as follows: First, calculate the round-trip path length from each transmitting antenna to a focal point in the grain and then to the receiving antenna, converting this to a time delay. The calculation considers all media traversed during the round trip, computing signal propagation velocity in each medium by assuming the relative dielectric constant at the excitation pulse’s center frequency. Time shifts are applied to the processed scattered signals based on the calculated time delays, followed by paired multiplication and summation, with the output as

. Finally, the focal point response

is obtained by integrating over a time window

W [

22]:

The time window is

, where a represents the number of time steps in the finite difference time domain (FDTD) method. The paired multiplication refers to the calculation of spatial cross-correlation between all received signals. Specifically, this is achieved by computing the signed geometric mean values between two adjacent signals, which is equivalent to a new signal. Subsequently, all equivalent signals are summed, resulting in the following expression [

22]:

where,

represents the number of the recorded scattered signals.

2.3. Anomalous Moisture Region Localization Algorithm

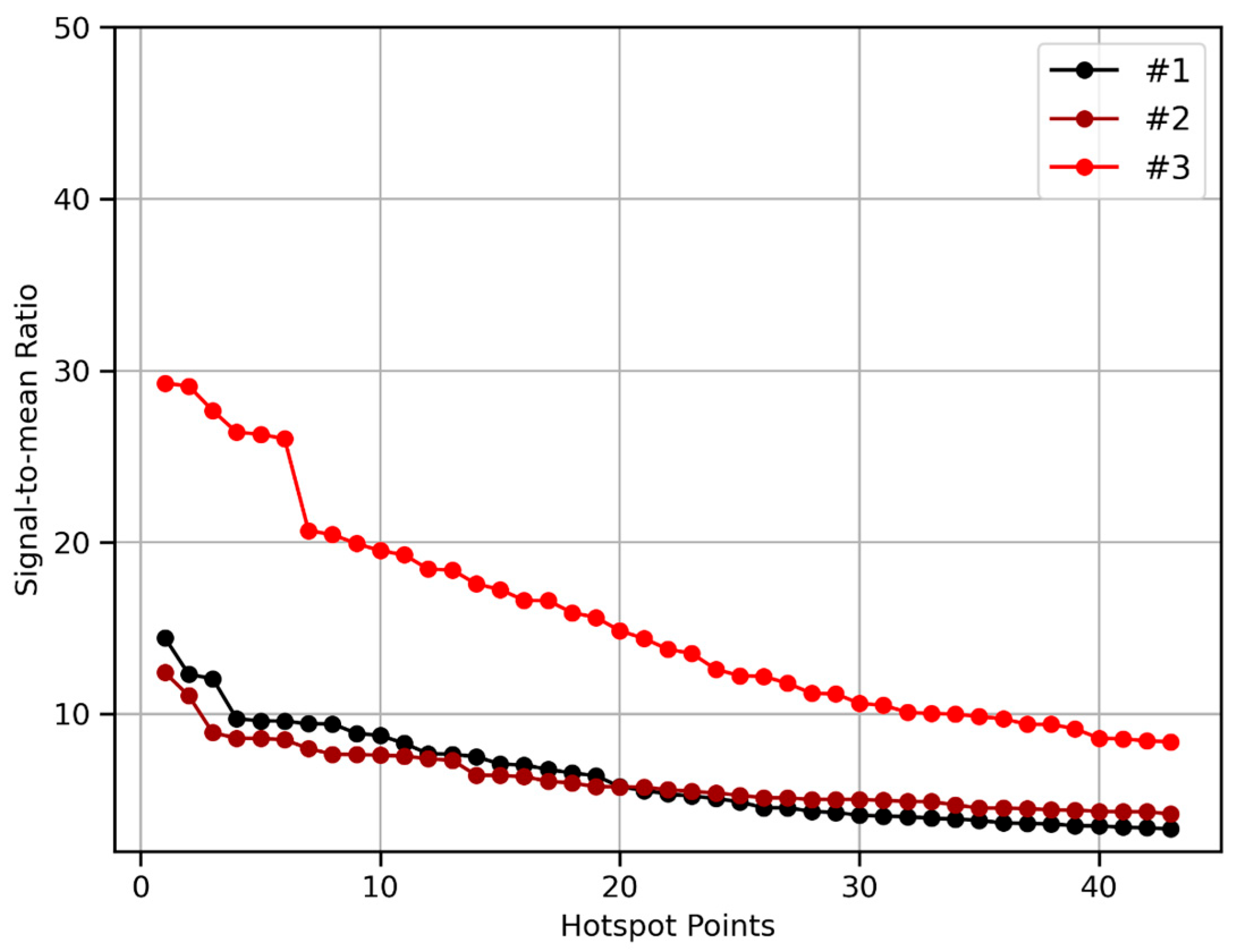

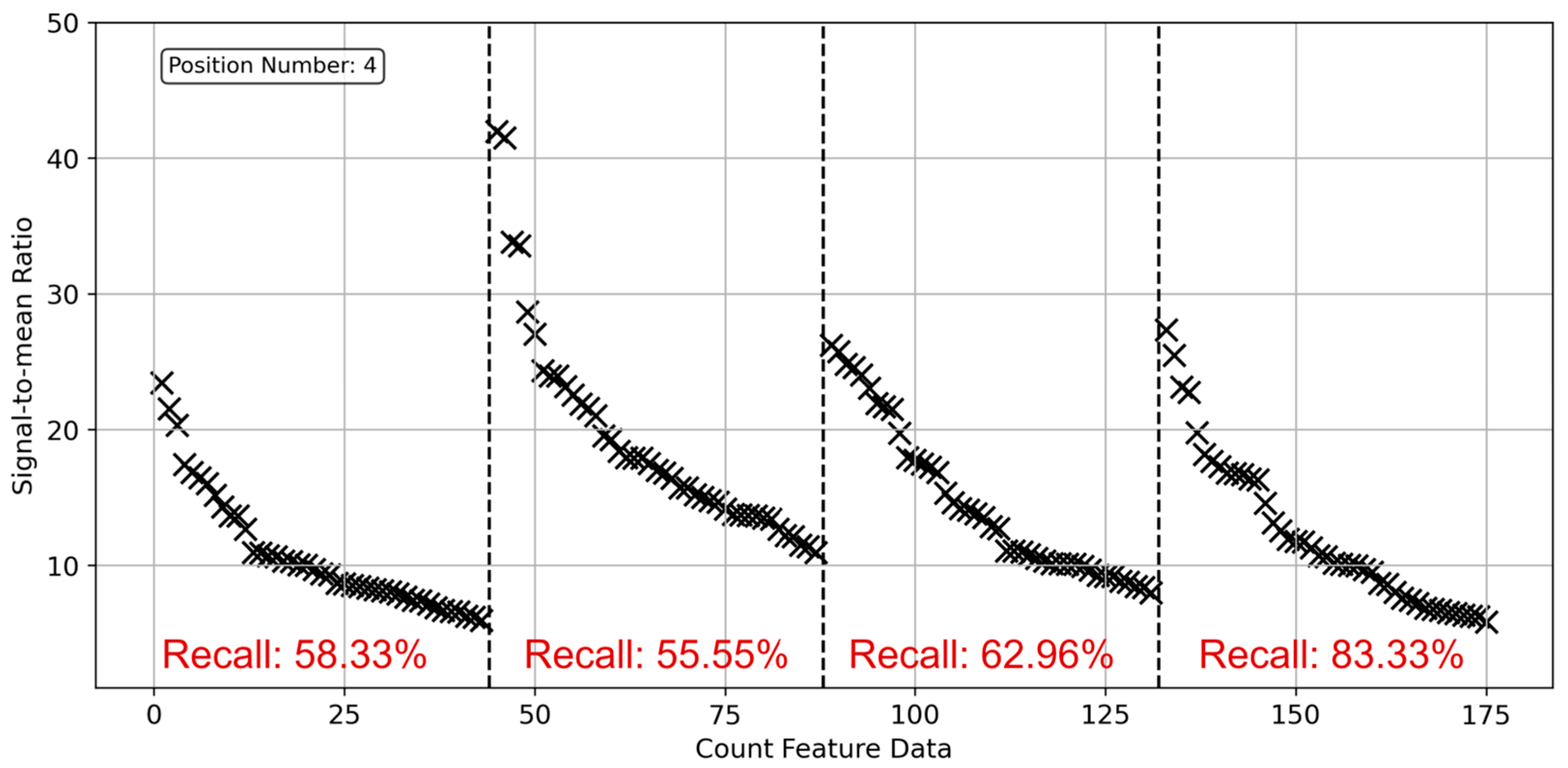

The grain pile anomalous moisture region localization algorithm developed in this paper was designed to locate the anomalous moisture region. It was important to note that the full width at half maximum (FWHM) method, commonly used in tumor detection, could not be directly applied to identify the region with the maximum value as the anomalous moisture area in grain piles. This was because the response from normal regions (10.5% moisture content grain) and anomalous regions (>15% moisture content grain) did not differ significantly, especially for grain with 15% moisture content. The signal-to-mean ratio (SMR) (Equation (A1)) for such cases only differed by approximately 10 (refer to

Section 4.1 and

Section 4.2). In this experiment, smaller maximum values were particularly susceptible to misidentification due to interference. Additionally, there was no definitive solution for determining what percentage of the maximum value should be classified as an anomalous region in grain-related applications. Finally, when using the recall method (Equation (3)) to evaluate localization accuracy, it was necessary to provide the actual target object size. Therefore, the size of the anomalous region to be detected was predetermined. The specific process is illustrated in

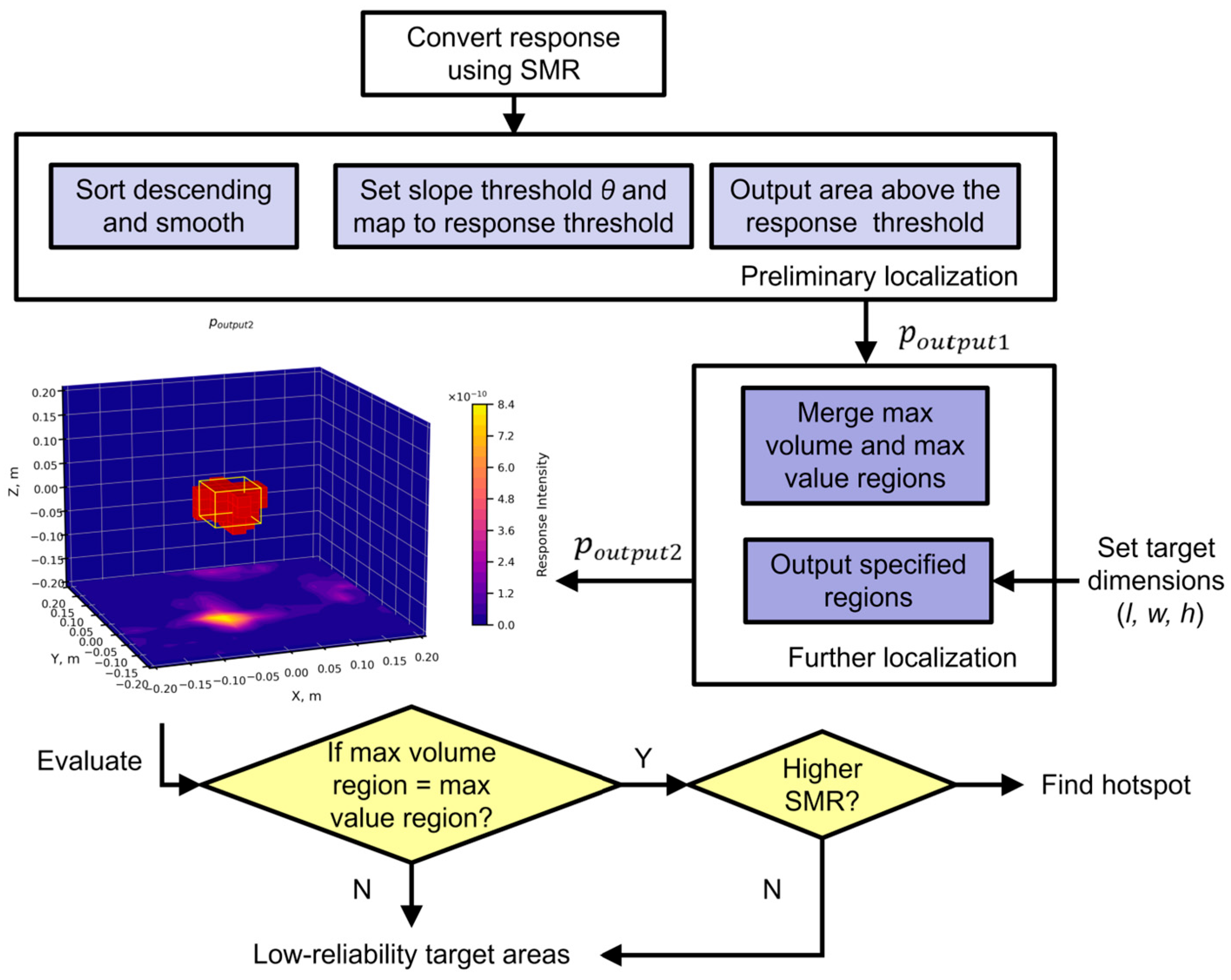

Figure 2. For the detailed algorithm, refer to

Appendix A.

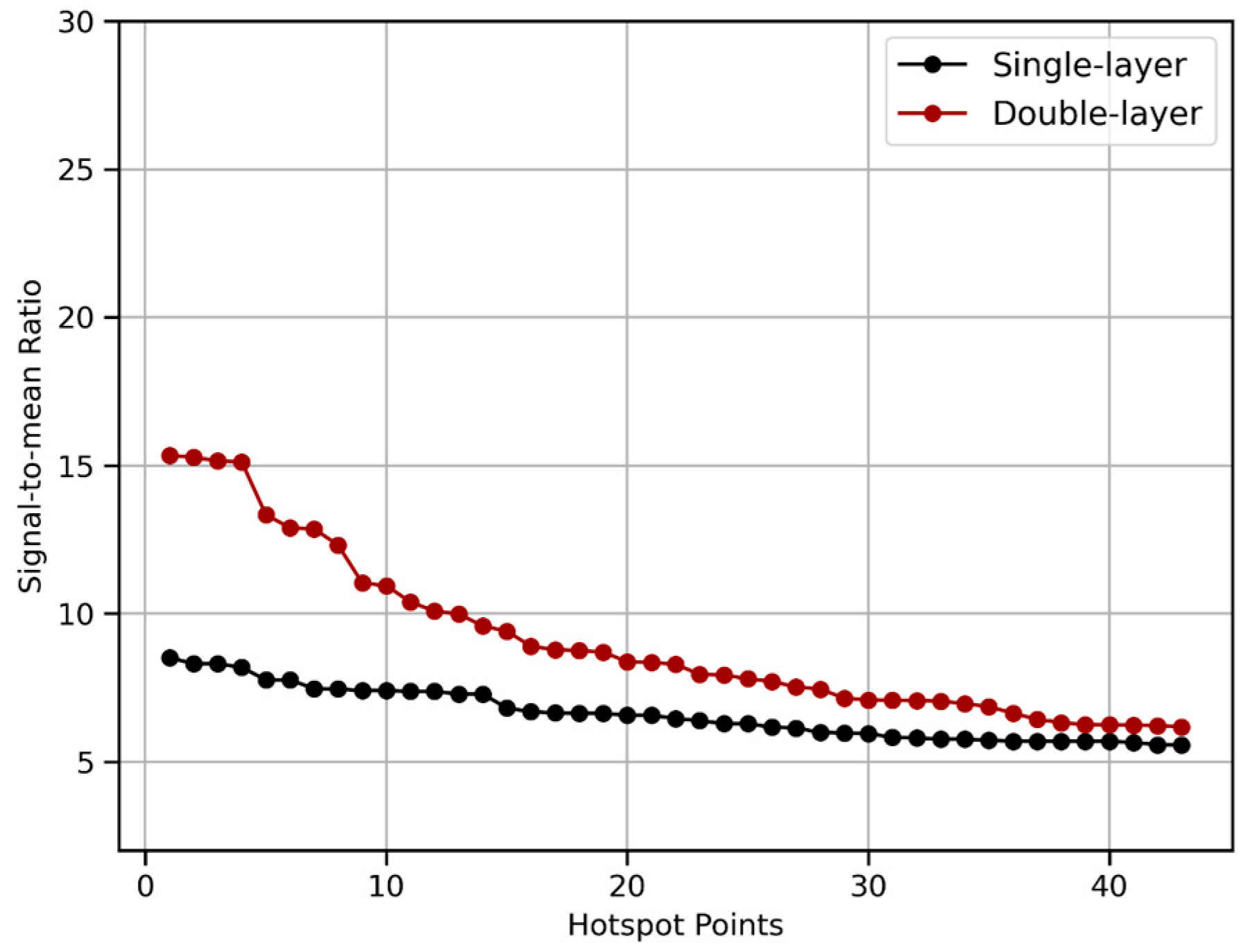

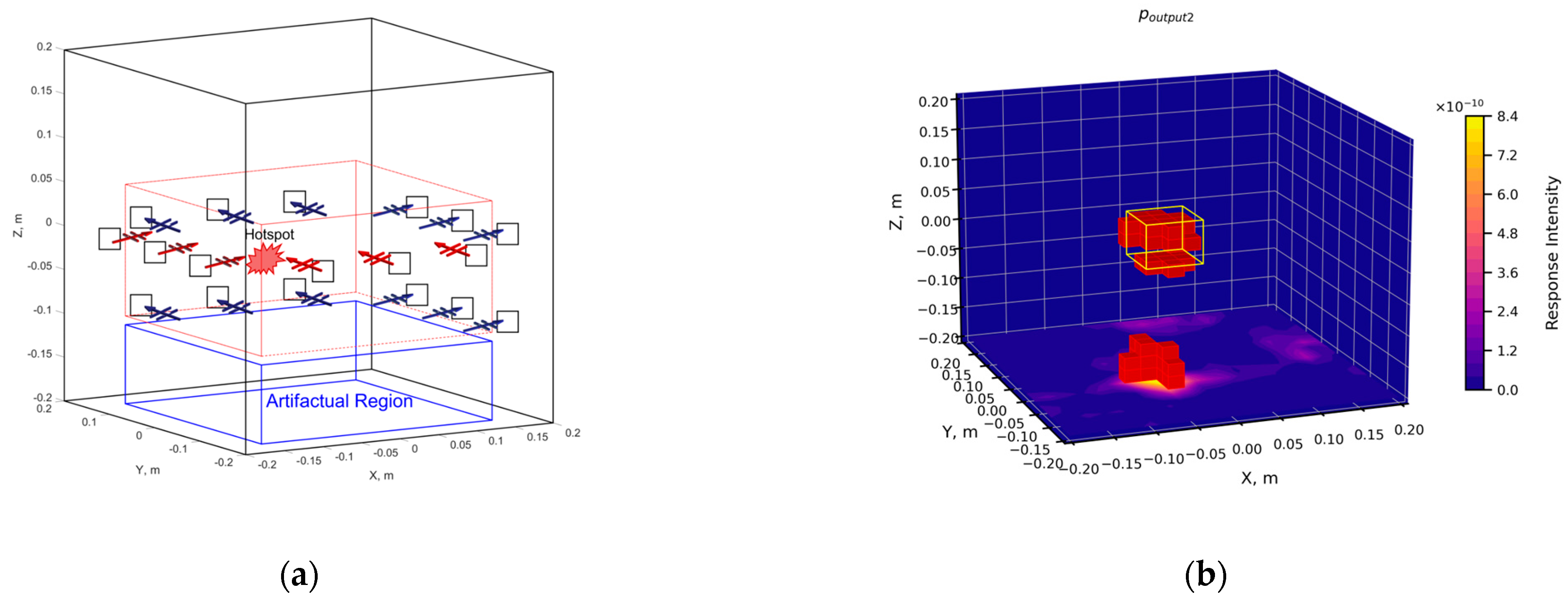

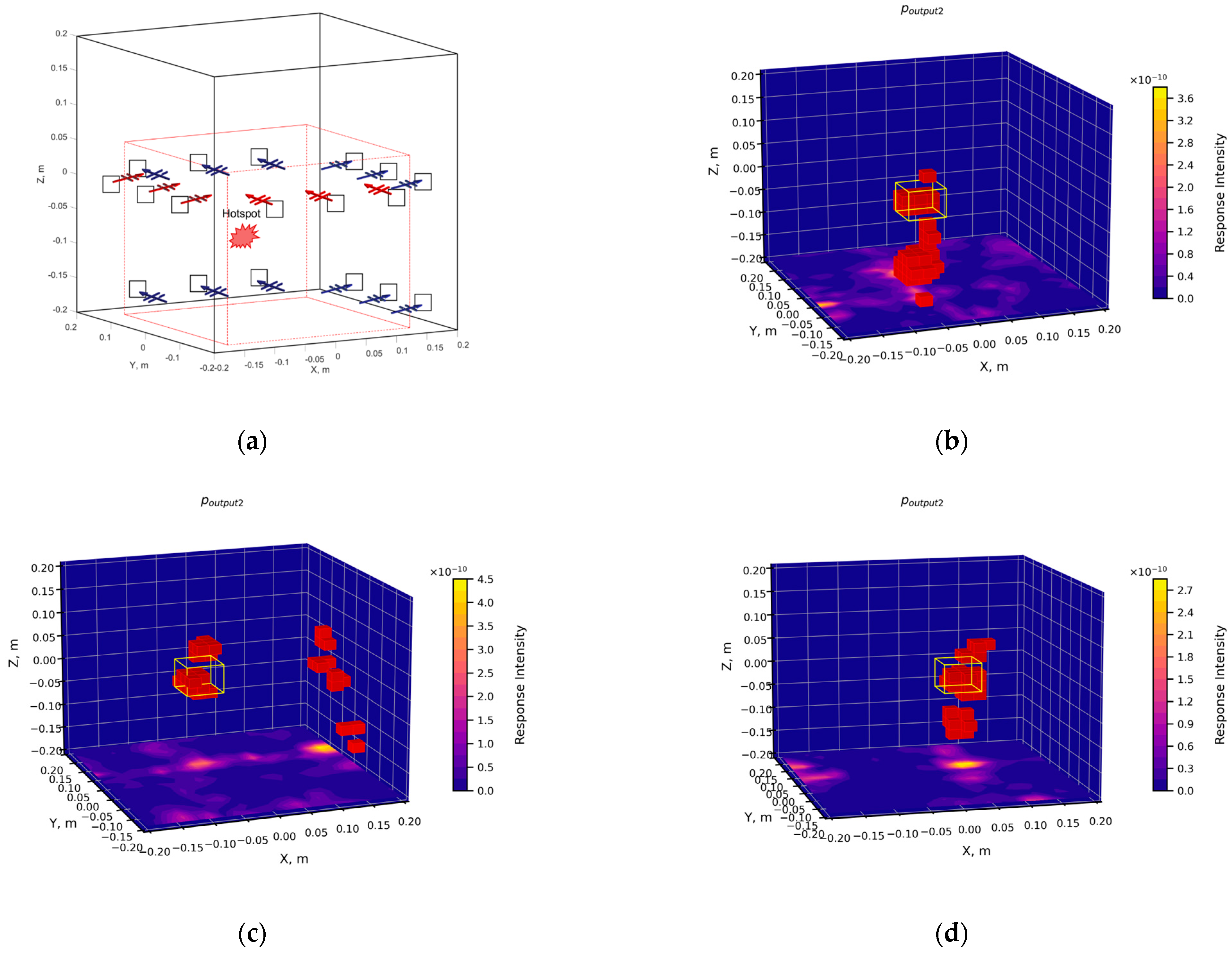

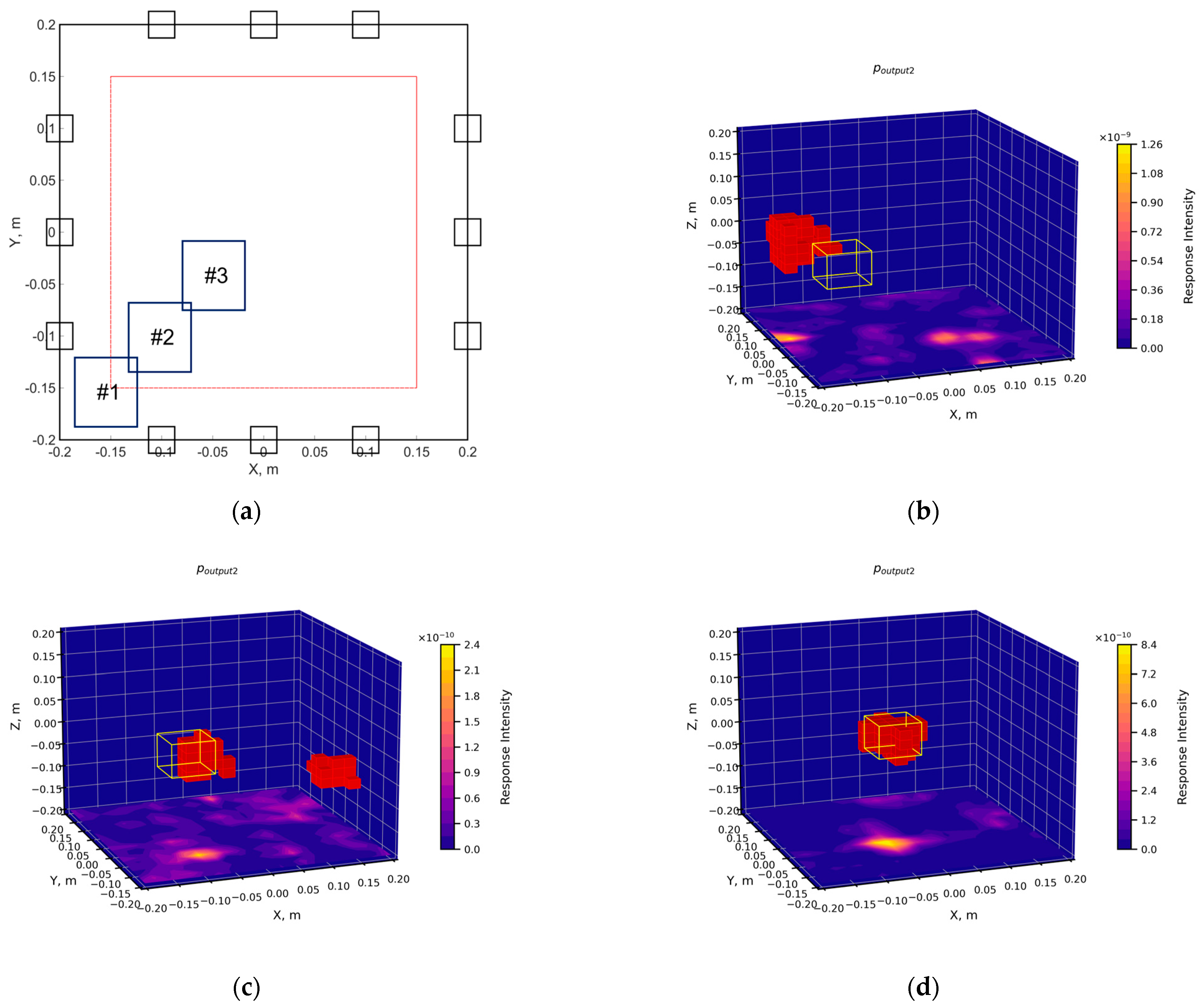

Anomalous regions typically correspond to higher SMR values. To identify these areas, this study employed a two-stage localization process: preliminary and secondary localization.

The objective of preliminary localization is to identify all anomalous regions by detecting areas with rapid SMR decline. It is noteworthy that extensive experimental testing has revealed these regions may include both anomalous and normal areas (refer to

Section 4.1), particularly when grain moisture anomalies are low.

However, distinguishing between normal and anomalous regions is challenging. Due to the emergence of sporadic interference with strong responses from normal regions, the secondary localization process is implemented to identify the area most likely to be a hotspot. In cases of multiple moisture anomalies, it is recommended to remove the initially localized anomalous area and conduct subsequent measures to locate the next anomalous region.

To counteract strong interference, in addition to calculating the region containing the maximum value within these connected domains (), a method for determining the region with the maximum volume () was introduced. When moisture differences are substantial, resulting in strong responses, and yield consistent results. However, when responses are weak, the minimal difference between the maximum value and other values increases the likelihood of misclassification. During experimentation, discrepancies between and frequently arose when the SMR of the anomalous region was approximately 10.

To evaluate the accuracy of the localization of anomalous moisture regions in grain piles, this paper proposed the use of the recall method, commonly employed in the field of image segmentation [

23,

24]. Let

A represent the actual region and

B represent the predicted region. The recall is defined as

Recall can only assess the accuracy of localization for known samples, whereas accuracy cannot be calculated for unknown samples. A validation process for unknown samples was deemed necessary because preliminary localization always produced results, regardless of whether the actual moisture anomaly in the grain pile was successfully located. This paper proposed a method for assessing the reliability of localization results for unknown samples. If

, it typically indicates that the SMR value of the anomalous region is relatively high, and the calculated recall value is also high, suggesting high reliability of the localization results. Occasionally, instances of

with incorrect localization might occur, manifesting as lower SMR values. Therefore, incorporating SMR value analysis could enhance the reliability of localization results. Conversely, if

, the recall value tends to be relatively low, indicating a decrease in the reliability of the results, as explained in

Section 4.1.

5. Conclusions

This paper, based on DMAS beamforming techniques and the grain pile anomalous moisture region localization algorithm, successfully located a 7 cm × 7 cm × 7 cm region with 15.4% moisture content within an experimental cubic bin containing 10.5% dry long-grained rice. The average localization accuracy recall exceeded 50%.

Through testing various layouts of electromagnetic wave transmitters and receivers, an effective configuration and detectable space were identified. Detection capabilities varied across different positions, with stronger detection observed when the target was penetrated by more electromagnetic fields. To achieve enhanced spatial resolution and reduce artifacts, at least three rows of electromagnetic wave transmitters or receivers were arranged along each axis.

Extensive experimental validation revealed that after preliminary localization using the grain pile anomalous moisture region localization algorithm, the reliability of unknown sample localization results could be effectively assessed by the SMR value and comparing and . When with higher SMR, reliability was high, with the anomalous region exhibiting improved recall. Conversely, when , reliability decreased, typically accompanied by lower SMR values and reduced recall.

While the developed method demonstrated rapid detection and accurate localization, several challenges remained for practical application. Future research directions include adaptation for larger grain storage facilities; improvement in detection speed; and reduction of external interference.

For application in large-scale grain storage facilities, specialized hardware is required to meet practical performance needs in terms of increased penetration depth and resolution. Furthermore, due to large volume constraints in such facilities, the detection resolution requirements are reduced to 1 m3.

The method’s sensitivity to interference was attributed to the small difference in moisture content between anomalous and normal regions, resulting in similar calculated responses. While increasing sampling data could enhance the response, this approach would increase both cost and computation time. Moreover, moisture content evaluation remained a significant challenge. The relationship between moisture content, size, location of anomalous regions, and response intensity exhibited complex non-linear characteristics.