Creep Model of Weakly Cemented Soft Rock Considering Damage and Secondary Development in FLAC3D

Abstract

1. Introduction

2. Experimental Study on Weakly Cemented Soft Rock

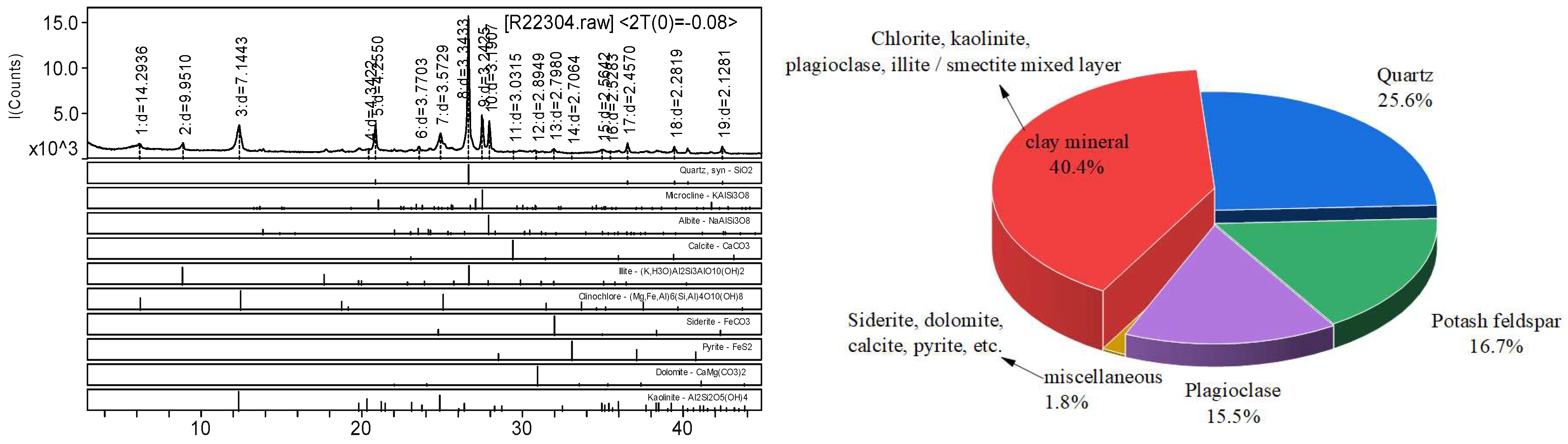

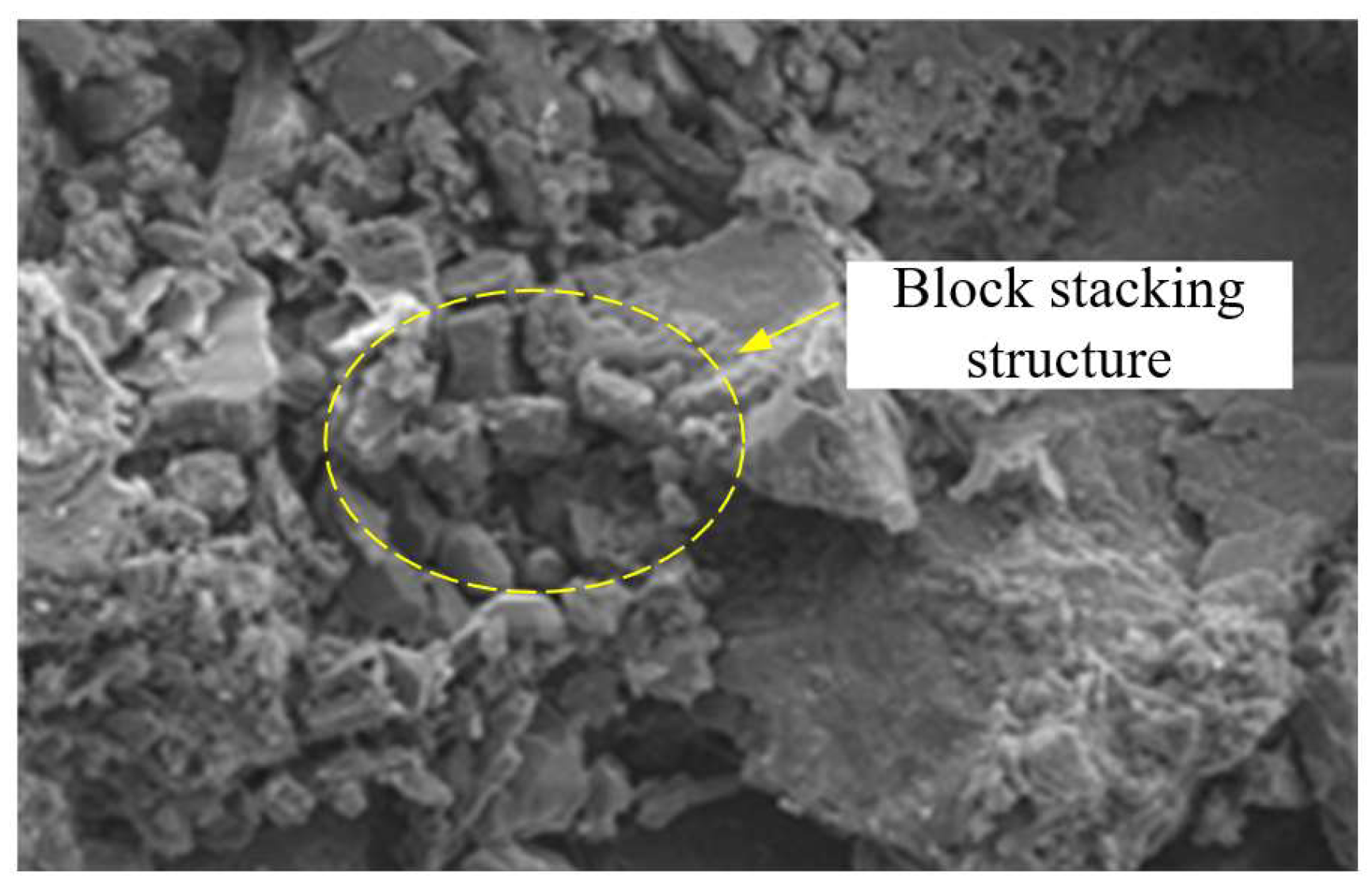

2.1. Microstructure of Weakly Cemented Soft Rock

2.2. Basic Mechanical Properties of Weakly Cemented Soft Rock

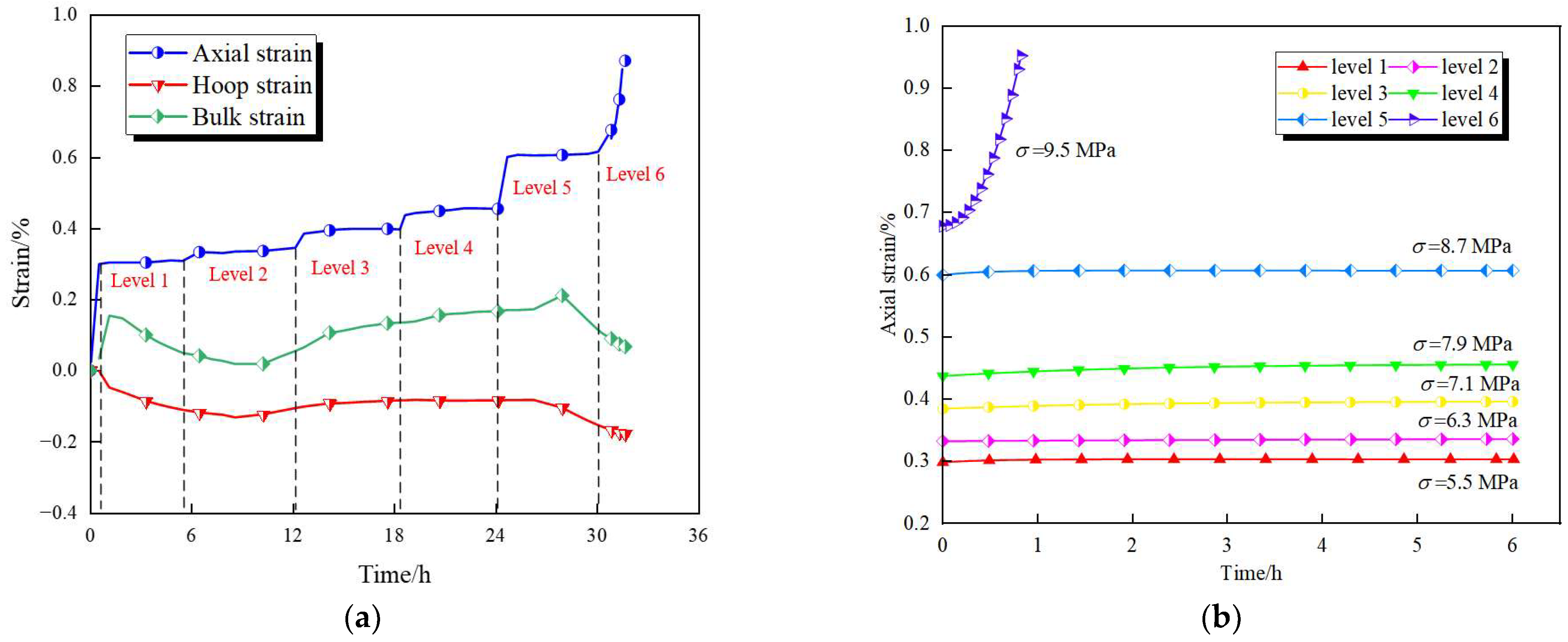

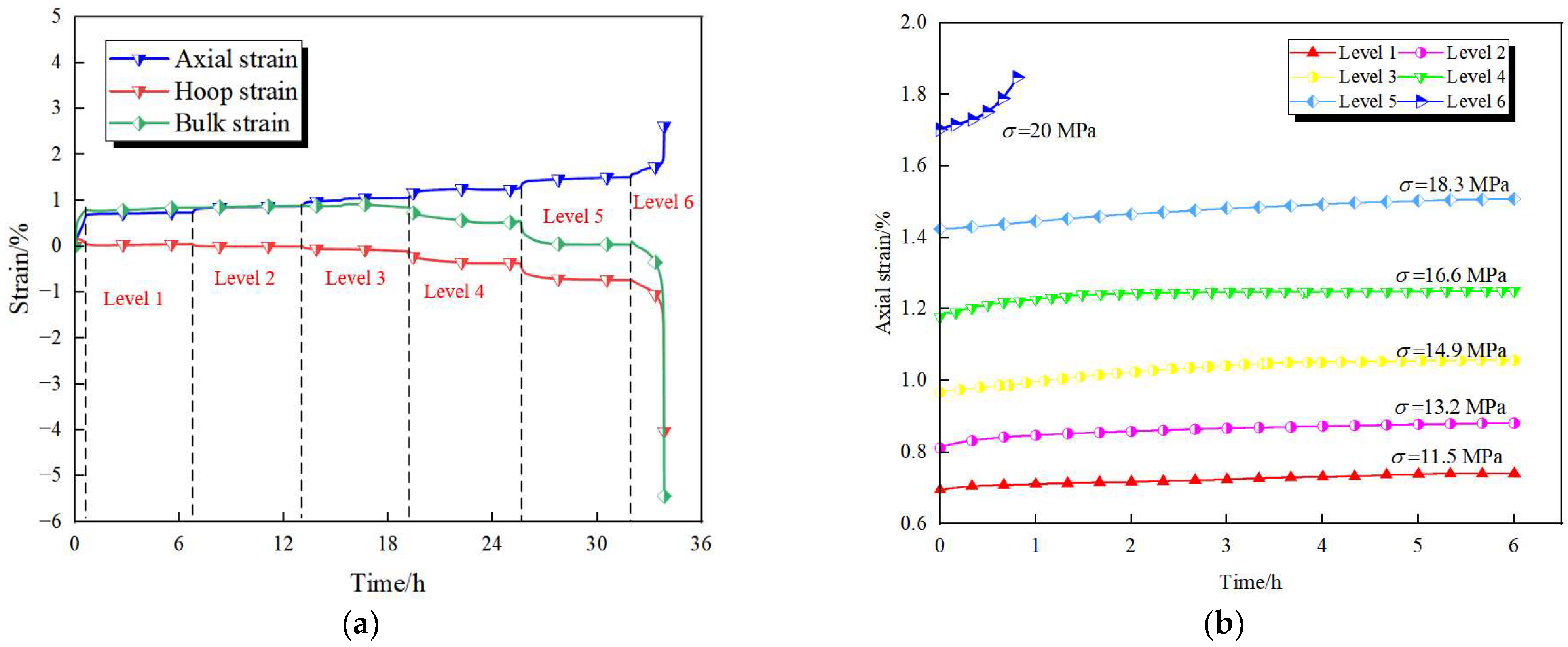

2.3. Creep Test Protocol

2.4. Creep Test Result

3. Creep Damage Constitutive Model Considering Damage for Weakly Cemented Soft Rock

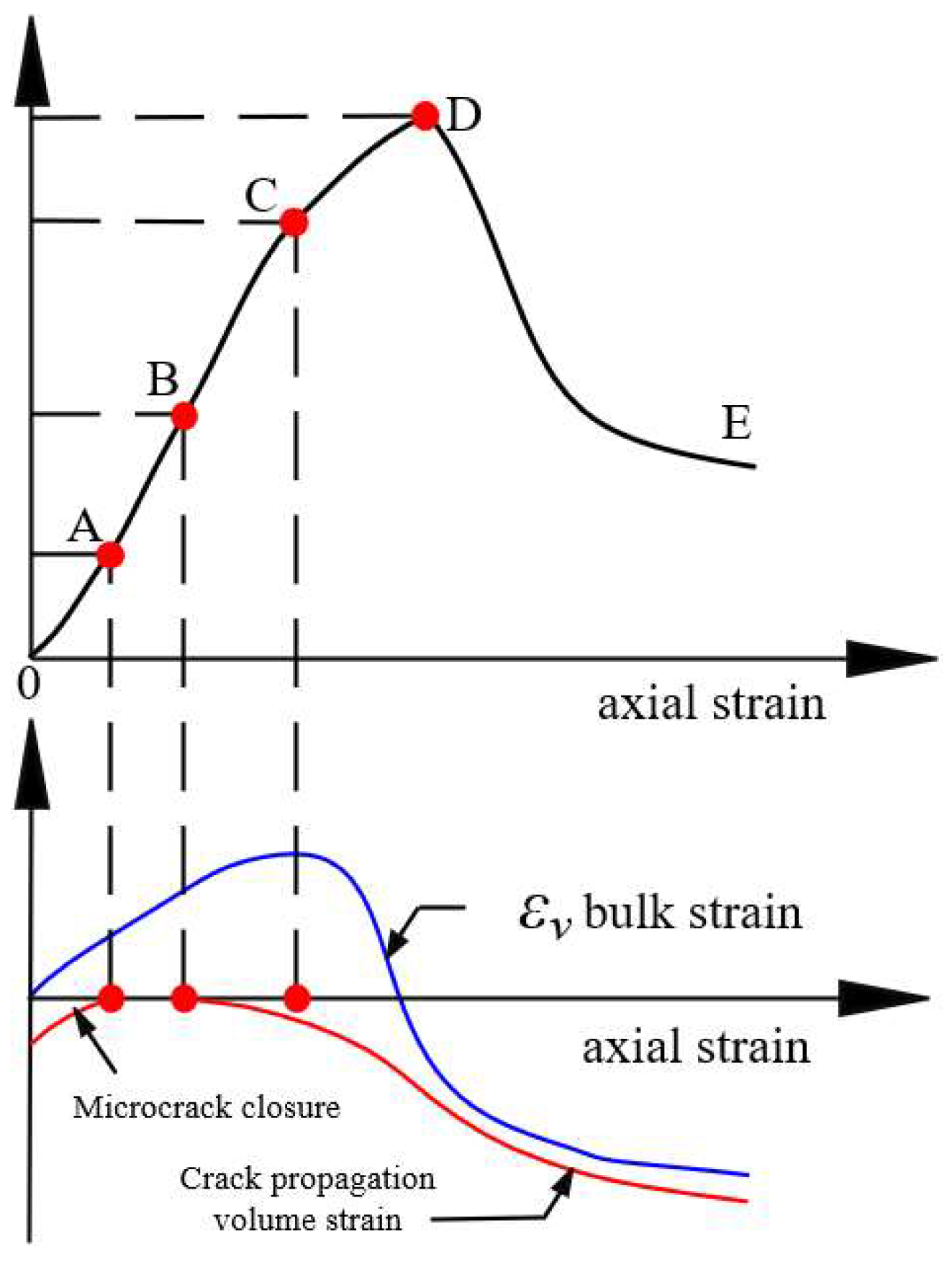

3.1. Determination of Damage Variable and Damage Threshold

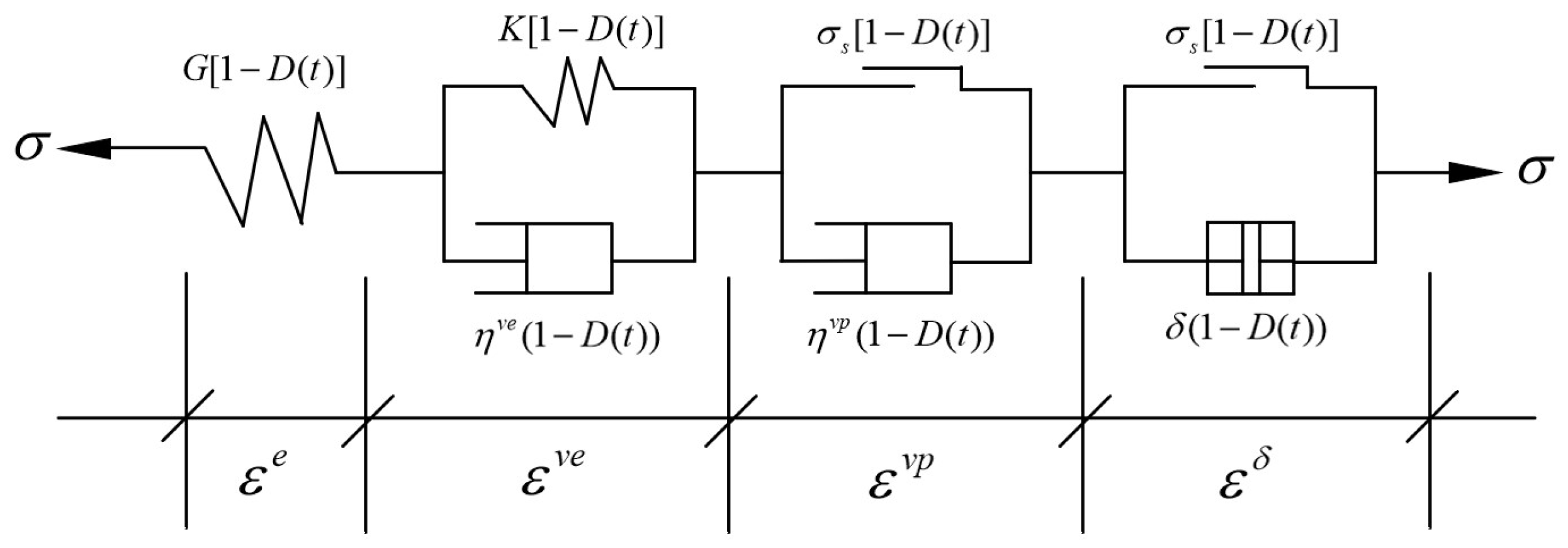

3.2. Improved Nishihara Model Considering Damage

3.3. Three-Dimensional Extension of Improved Nishihara Model

3.4. Model Validation

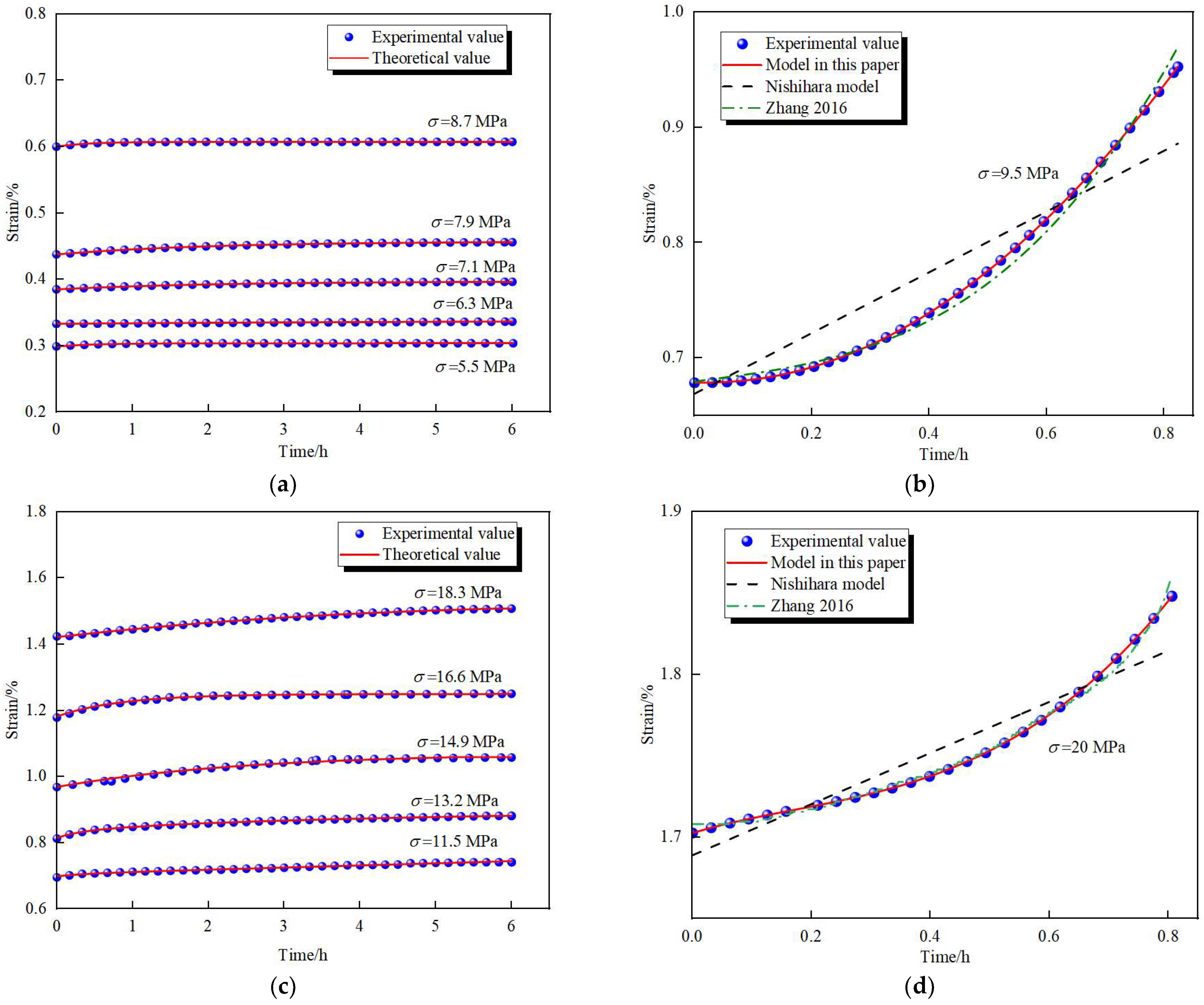

3.4.1. Parameter Identification

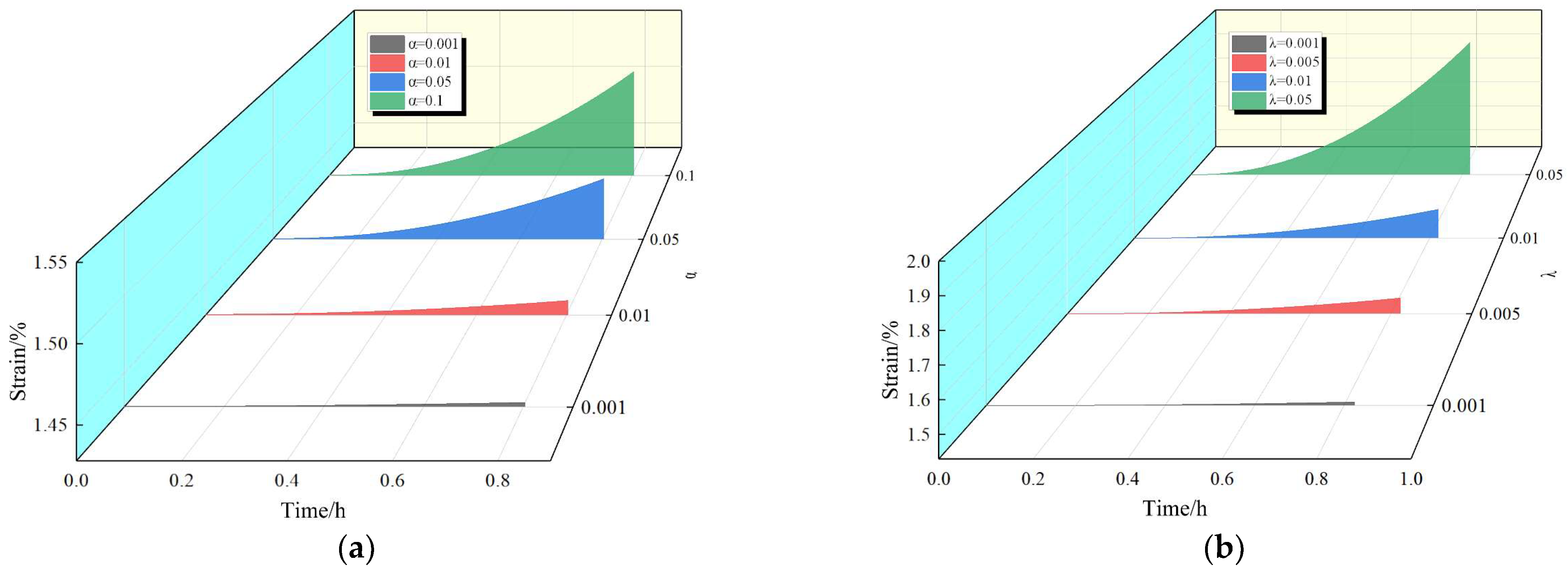

3.4.2. Model Sensitivity Analysis

3.4.3. Applicability Validation

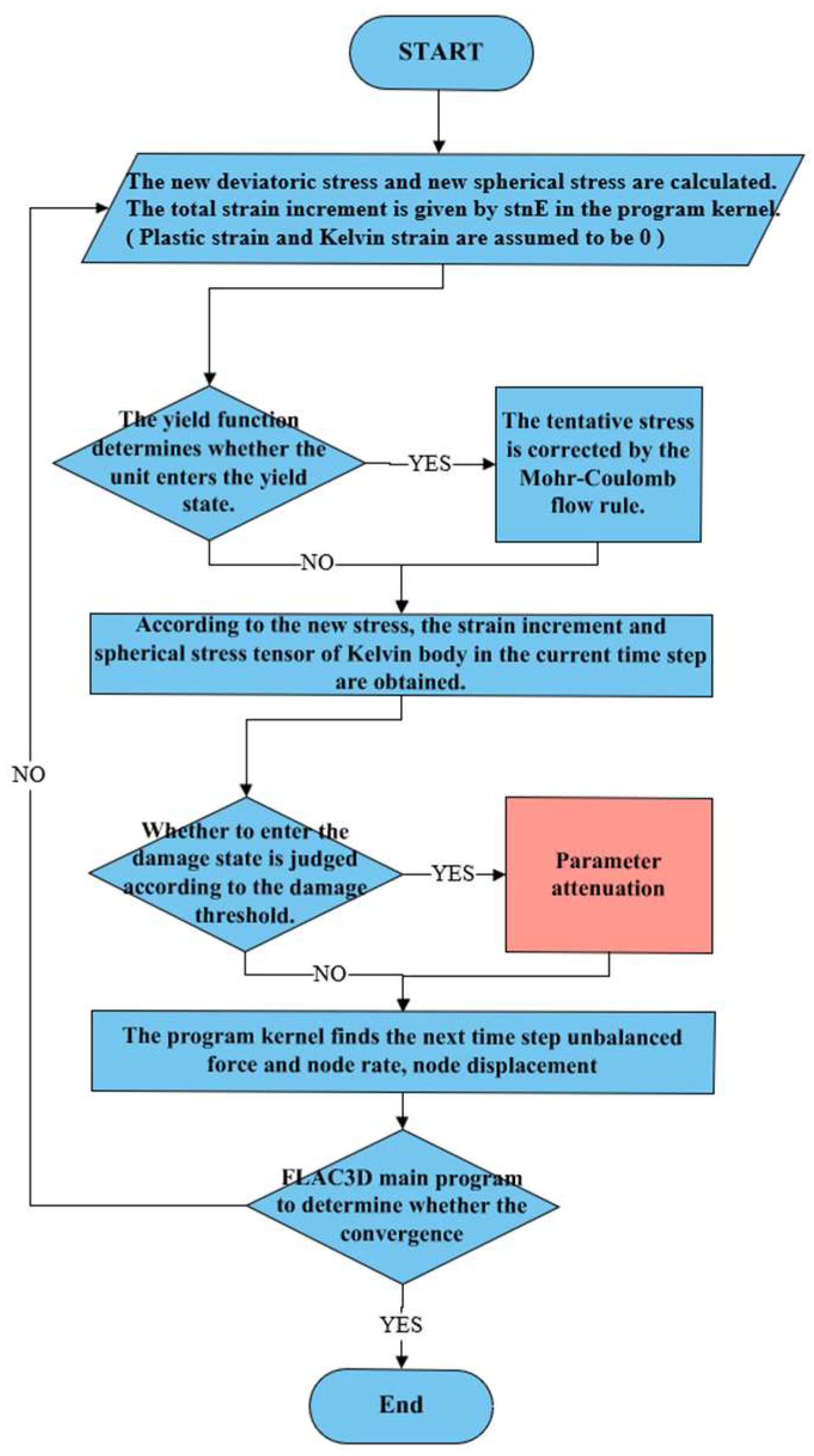

4. Secondary Development of Creep Damage Constitutive Model

4.1. Differential Form of Constitutive Model

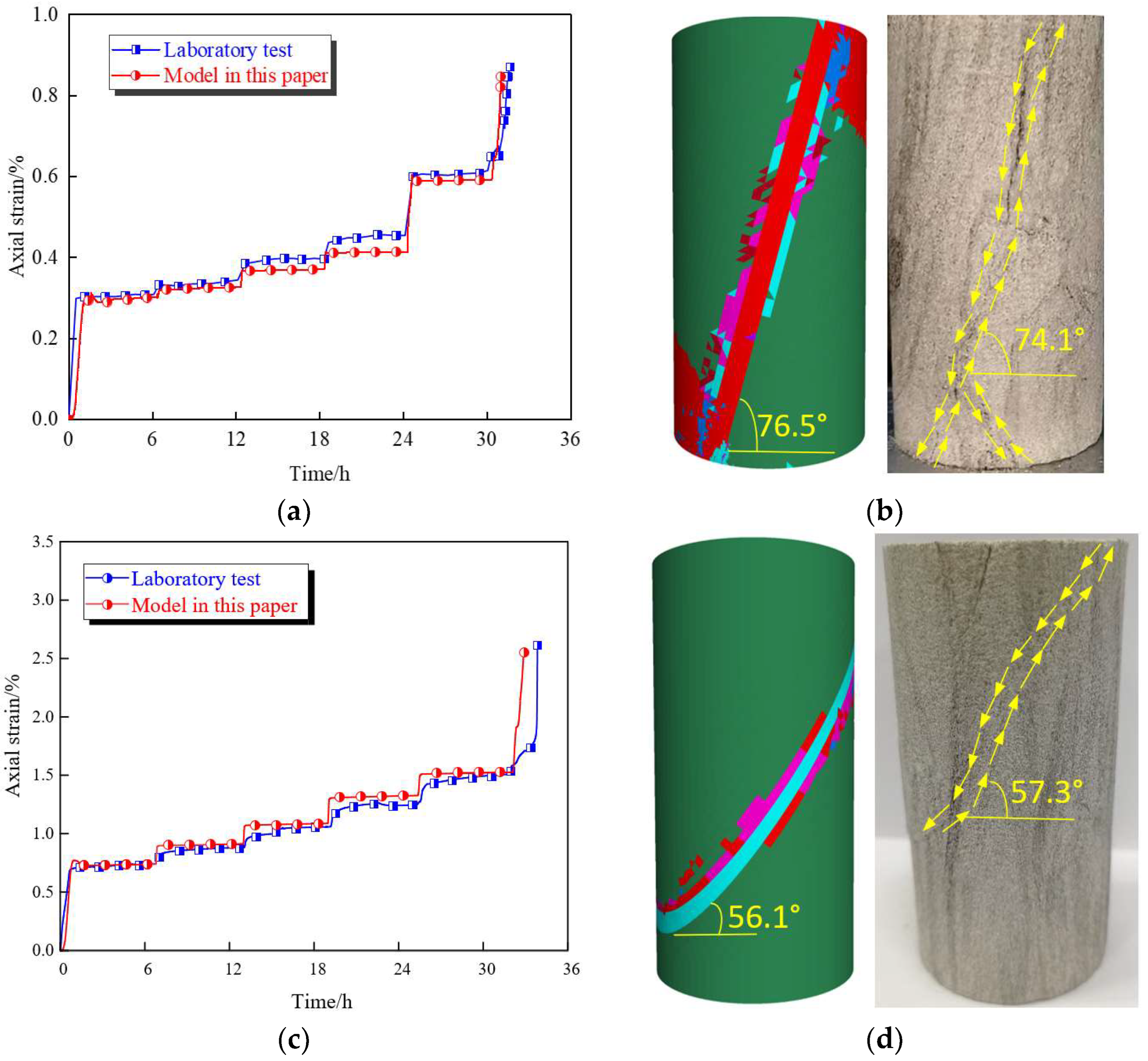

4.2. Verification of Axial Stress–Strain

4.2.1. Numerical Modeling Setup

4.2.2. Numerical Modeling Results

5. Conclusions

- Microstructural analysis revealed that the high clay mineral content (40.4%) and the loose structure characterized by face-to-face and cemented connections are the primary factors contributing to creep in weakly cemented mudstone. Under external forces, the fracture of clay minerals leads to the continuous propagation of microcracks, ultimately resulting in accelerated creep.

- The proposed damage creep model dynamically captures parameter weakening through a time-dependent damage factor and accurately represents the three stages of creep by incorporating nonlinear winding elements. Its three-dimensional extension enhances its applicability to real-world engineering problems. Parameter inversion using the Levenberg–Marquardt (L-M) algorithm confirmed a fitting accuracy exceeding 98%. Sensitivity analysis indicated that the acceleration stage was significantly affected by the damage coefficients α and λ.

- The numerical feasibility of the model was validated through secondary development in FLAC3D. The deviation between simulation and experimental results was within 5%, and the model successfully replicated the creep behavior of salt rock, anthracite, and mica–quartz schist, demonstrating strong universality. These findings provide a theoretical foundation for predicting time-dependent deformation and supporting disaster prevention and control in deep underground engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ru, W.K. Creep Damage and Engineering Application of Weakly Cemented Soft Rock Based on Energy Analysis. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2021. [Google Scholar]

- Hu, S.; Zhang, C.; Ru, W.; Han, J.; Guo, S.; Zhou, X.; Yang, L. Creep properties and energy evolution characteristics of weakly cemented rock under step loading. Int. J. Rock Mech. Min. Sci. 2023, 170, 105428. [Google Scholar] [CrossRef]

- Li, X.; Chen, D.; Li, Z.; Liu, S.; Zhai, M.; Li, Y.; Gong, B.; Sun, Z.; Wang, Y.; Wang, D. Roadway Portal and Self-Moving Hydraulic Support for Rockburst Prevention in Coal Mine and Its Application. Phys. Fluids 2024, 36, 124136. [Google Scholar] [CrossRef]

- Yang, X.; Yu, F.; Ma, C.; Zhang, T.; Wang, B.; Zhao, X. Study on Floor Heave Characteristics and the Control Method of Gob-Side Entry Driving in Weakly Cemented Soft Rock. Sustainability 2023, 15, 3969. [Google Scholar] [CrossRef]

- Boukharov, G.N.; Chanda, M.W.; Boukharov, N.G. The three processes of brittle crystalline rock creep. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 325–335. [Google Scholar] [CrossRef]

- Maranini, E.; Brignoli, M. Creep behaviour of a weak rock: Experimental characterization. Int. J. Rock Mech. Min. Sci. 1999, 36, 127–138. [Google Scholar] [CrossRef]

- Li, X.; Cao, Z.; Xu, Y. Characteristics and Trends of Coal Mine Safety Development. Energy Sources Part A Recovery Util. Environ. Eff. 2025, 47, 2316–2334. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J.; Zhang, Q.; Damascene, N.J.; Guo, Y. Nonlinear Creep Model of Deep Gangue Backfilling Material and Time-Dependent Characteristics of Roof Deformation in Backfilling Mining. Geofluids 2020, 2020, 8816871. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J.; Damascene, N.J.; Dong, C.; Wang, Z. A fractional order viscoelastic-plastic creep model for coal sample considering initial damage accumulation. Alex. Eng. J. 2021, 60, 3921–3930. [Google Scholar] [CrossRef]

- Li, M.; Pu, H.; Cao, L.; Sha, Z.; Yu, H.; Zhang, J.; Zhang, L. Damage Creep Model of Viscoelastic Rock Based on the Distributed Order Calculus. Appl. Sci. 2023, 13, 4404. [Google Scholar] [CrossRef]

- Frenelus, W.; Peng, H.; Zhang, J. Creep Behavior of Rocks and Its Application to the Long-Term Stability of Deep Rock Tunnels. Appl. Sci. 2022, 12, 8451. [Google Scholar] [CrossRef]

- Tarifard, A.; Török, Á.; Görög, P. Review of the creep constitutive models for rocks and the application of creep analysis in geomechanics. Rock Mech Rock Eng. 2024, 57, 7727–7757. [Google Scholar] [CrossRef]

- Xu, H.F. Study on time effect of strength and elastic modulus of soft rock. Chin. J. Rock Mech. Eng. 1997, 3, 47–52. [Google Scholar]

- Gao, X.; Hu, T.; Su, Z. Nonlinear Nishihara model of soft rock based on damage mechanics and its parameter identification. Mater. Today Commun. 2024, 39, 108715. [Google Scholar] [CrossRef]

- Deng, X.; Shi, J.; Li, X.; Wang, R.; Zhang, J.; Yang, X. The secondary development and application of the improved Nishihara creep model in soft rock tunnels. Buildings 2023, 13, 2082. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, S. An improved unsteady creep model based on the time-dependent mechanical parameters. Mech. Adv. Mater. Struct. 2020, 28, 1838–1848. [Google Scholar] [CrossRef]

- Sun, X.M.; Miao, C.Y.; Jiang, M.; Zhang, Y.; Yang, L.; Guo, B. Experimental and theoretical study on creep behaviors of sandstone with different moisture contents based on modified Nishihara model. Chin. J. Rock Mech. Eng. 2021, 40, 2411–2420. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, H.; Lv, J.; He, X.; Qin, Y.; Sun, K. Triaxial Creep Damage Model for Salt Rock Based on Fractional Derivative. Sustainability 2023, 15, 10369. [Google Scholar] [CrossRef]

- Jiang, Q.; Qi, Y.; Wang, Z.; Zhou, C. An extended Nishihara model for the description of three stages of sandstone creep. Geophys. J. Int. 2013, 193, 841–854. [Google Scholar] [CrossRef]

- He, Z.; Dai, B. Secondary development of a nonlinear creep model based on fractional derivative in FLAC3D. In Proceedings of the 2018 11th International Conference on Intelligent Computation Technology and Automation (ICICTA), Changsha, China, 22–23 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 67–71. [Google Scholar]

- Liu, X.; Yang, X.; Wang, J. A nonlinear creep model of rock salt and its numerical implement in FLAC3D. Adv. Mater. Sci. Eng. 2015, 2015, 285158. [Google Scholar] [CrossRef]

- Yu, M.; Liu, Y.; Liu, B.; Liu, K.; Deng, T. Numerical implementation of a hydraulic interaction creep model and its application to the support reinforcement of water-rich cracked tunnel. Tunn. Undergr. Space Technol. 2024, 154, 106098. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.; Ding, Z. A secondary development based on the Hoek-Brown criterion for rapid numerical simulation prediction of mountainous tunnels in China. Geomech. Eng. 2023, 34, 69–86. [Google Scholar] [CrossRef]

- Wang, M.; Song, Z.F.; Zheng, D.J.; Shen, W.L.; Gou, P.F.; Wei, S.J. Development and application of rock energy dissipation model in FLAC3D. J. China Coal Soc. 2021, 46, 2565–2573. [Google Scholar] [CrossRef]

- Xiao, Y.; Qiao, Y.; He, M.; Li, H.; Cheng, T.; Tang, J. A unified strain-hardening and strain-softening elastoplastic constitutive model for intact rocks. Comput. Geotech. 2022, 148, 104789. [Google Scholar] [CrossRef]

- Gutiérrez-Ch, J.G.; Senent, S.; Zeng, P.; Jimenez, R. DEM simulation of rock creep in tunnels using rate process theory. Comput. Geotech. 2022, 142, 104559. [Google Scholar] [CrossRef]

- Nikolić, M.; Karavelić, E.; Ibrahimbegovic, A.; Miščević, P. Lattice element models and their peculiarities. Arch. Comput. Methods Eng. 2018, 25, 753–784. [Google Scholar] [CrossRef]

- Wang, X.S.; Fan, T.T.; Kitmeng, L. Finite element analysis on the creep constitutive equation of high modulus asphalt concrete. Adv. Mater. Sci. Eng. 2015, 1, 860454. [Google Scholar] [CrossRef]

- Park, J.M.; Lee, G.Y.; Kim, D.H.; Jung, H.M. Creep simulation and validation for a finite element analysis of expanded polystyrene-based cushioning systems. Appl. Sci. 2022, 12, 12663. [Google Scholar] [CrossRef]

- Bidadi, J.; Googarchin, H.S. Experimental study on mode I fracture response of adhesive joints subjected to systematic creep damage. Theor. Appl. Fract. Mech. 2025, 136, 104868. [Google Scholar] [CrossRef]

- Su, T.; Liu, Z.; Zhou, H.; Wang, H.; Hu, X.; Zhang, F. A Three-Dimensional Fractional Calculus-Based Creep Model for Granite Considering Thermal Effects. Int. J. Appl. Mech. 2025, 58, 95. [Google Scholar] [CrossRef]

- Wang, X.; Xiang, J.; Xie, W.; Xia, C.; Yang, J.; Wei, W. Experimental investigation of the long-term creep behavior of extremely soft coal rocks and novel nonlinear creep mathematical model with a nonstationary viscous coefficient. Bull. Eng. Geol. Environ. 2025, 84, 11. [Google Scholar] [CrossRef]

- Ma, L.; Lei, M.; Wang, L.; Hu, B.; Zhao, Y.; Zhang, J. An Improved Nishihara Model Considering the Influence of Moisture Content on the Whole Shear Creep Process of Shale. Processes 2025, 13, 783. [Google Scholar] [CrossRef]

- Liu, C.; Dong, T.; Qi, Y.; Guo, X. Variable-Order Time-Fractional Kelvin Peridynamics for Rock Steady Creep. Fractal Fract. 2025, 9, 197. [Google Scholar] [CrossRef]

- Shi, X.; Jing, H.W.; Chen, W.Q.; Gao, Y.; Zhao, Z.L. Investigation on the creep failure mechanism of sandy mudstone based on micromesoscopic mechanics. Geofluids 2021, 1, 5550733. [Google Scholar] [CrossRef]

- Kang, J.; Zhou, F.B.; Liu, C.; Liu, Y.K. A fractional non-linear creep model for coal considering damage effect and experimental validation. Int. J. Non-Linear Mech. 2015, 76, 20–28. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, X.; Zhou, Y. Features and Constitutive Model of Hydrate-Bearing Sandy Sediment’s Triaxial Creep Failure. Water 2024, 16, 2947. [Google Scholar] [CrossRef]

- Li, J.; Hu, B.; Sheng, J.; Huang, L. A Fractional-Order Creep-Damage Model for Carbonaceous Shale Describing Coupled Damage Caused by Rainfall and Blasting. Fractal Fract. 2024, 8, 459. [Google Scholar] [CrossRef]

- Song, Z.P.; Wang, B.W.; Fan, S.Y.; Zhang, Y.T.; Wang, J.B. Nonlinear creep intrinsic modeling of hard rock considering aging damage. Chin. J. Rock Mech. Eng. 2024, 43, 2368–2380. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, C.; Hu, K.; Xie, S.; Jia, W.; Song, L. A Fractional Creep Model for Deep Coal Based on Conformable Derivative Considering Thermo-Mechanical Damage. Processes 2024, 12, 1121. [Google Scholar] [CrossRef]

- Wu, J.; Wang, W.; Cao, Y.J.; Liu, S.F.; Zhang, Q.; Chu, W.J. A novel nonlinear fractional viscoelastic–viscoplastic damage creep model for rock-like geomaterials. Comput. Geotech. 2023, 163, 105691. [Google Scholar] [CrossRef]

- Zhang, Q.G.; Liang, Y.C.; Fan, X.Y.; Li, G.Z.; Li, W.T.; Yang, B.Z.; Tong, M. A modified Nishihara model based on the law of the conservation of energy and experimental verification. J. Chongqing Univ. 2016, 39, 117–124. [Google Scholar]

- Li, G.; Yan, G.; Kong, S.; Bai, X.; Du, C.; Li, J.; Zhang, J. Design of an Anthracite Creep Model Based on Fractional Order Theory: Experiments and Simulations. Appl. Sci. 2023, 13, 6522. [Google Scholar] [CrossRef]

- Sun, J. Rock rheological mechanics and its advance in engineering applications. Chin. J. Rock Mech. Eng. 2007, 6, 1081–1106. [Google Scholar]

- Zhang, Q.Y.; Yang, W.D.; Zhang, J.G.; Yang, C.H. Variable parameters-based creep damage constitutive model and its engineering application. Chin. J. Rock Mech. Eng. 2009, 28, 732–739. [Google Scholar]

- Zhang, J.C.; Xu, W.Y.; Wang, H.L.; Wang, R.B.; Meng, Q.X. Testing and modeling of the mechanical behavior of dolomite in the Wudongde hydropower plant. Geomech. Geoengin. 2016, 11, 270–280. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Zhang, G. Three-dimensional elasto-plastic damage model for gravelly soil-structure interface considering the shear coupling effect. Comput. Geotech. 2021, 129, 103868. [Google Scholar] [CrossRef]

- Wang, X.; Wei, Y.; Jiang, T.; Hao, F.; Xu, H. Elastic–plastic criterion solution of deep roadway surrounding rock based on intermediate principal stress and Drucker—Prager criterion. Energy Sci Eng. 2024, 12, 2472–2492. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Luo, F.; Wang, T.; Zhang, G. Large-scale test study on the three-dimensional behavior of the gravel–concrete interface of a CFR dam. Int. J. Geomech. 2020, 26, 04020046. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Fu, J.; Zhu, N.; Chen, D.; Wang, Y.; Ding, S. Experimental Study on Compressive Behavior and Failure Characteristics of Imitation Steel Fiber Concrete under Uniaxial Load. Constr. Build. Mater. 2023, 399, 132599. [Google Scholar] [CrossRef]

- Qi, Y.J.; Jiang, Q.H.; Wang, Z.J.; Zhou, C.B. 3D creep constitutive equation of modified Nishihara model and its parameters identification. Chin. J. Rock Mech. Eng. 2012, 31, 347–355. [Google Scholar]

- Wang, J.B.; Liu, X.R.; Song, Z.P.; Zhao, B.Y.; Jiang, B.; Huang, T.Z. A whole process creeping model of salt rock under uniaxial compression based on inverse S function. Chin. J. Rock Mech. Eng. 2018, 37, 2446–2459. [Google Scholar] [CrossRef]

- Li, G.; Yan, G.C.; Xiang, H.T.; Bai, X.Y.; Li, J.J.; Zhang, J.W. Creep model of anthracite and FLAC3D secondary development. Coal Sci. Technol. 2023, 43, 103–110. [Google Scholar] [CrossRef]

- Liu, H.Z.; Xie, H.Q.; He, J.D.; Xiao, M.L.; Zhuo, L. Nonlinear creep damage constitutive model for soft rocks. Mech. Time-Depend. Mater. 2017, 21, 73–96. [Google Scholar] [CrossRef]

| Confining Pressure/MPa | Elastic Modulus/GPa | Cohesion/MPa | Angle of Internal Friction/° | Poisson Ratio | Compressive Strength/MPa |

|---|---|---|---|---|---|

| 0 | 1.96 | 4.2 | 24.3 | - | 10.31 |

| 2.0 | 2.24 | 0.46 | 21.19 |

| Confining Pressure/MPa | Level 1/MPa | Level 2/MPa | Level 3/MPa | Level 4/MPa | Level 5/MPa | Level 6/MPa |

|---|---|---|---|---|---|---|

| 0 | 5.5 | 6.3 | 7.1 | 7.9 | 8.7 | 9.5 |

| 2.0 | 11.5 | 13.2 | 14.9 | 16.6 | 18.3 | 20 |

| σ3 = 0 MPa | Stress level/MPa | 5.5 | 6.3 | 7.1 | 7.9 | 8.7 | 9.5 |

| Modulus of instantaneous elasticity/GPa | 1.84 | 1.89 | 1.84 | 1.81 | 1.45 | 1.42 | |

| σ3 = 2 MPa | Stress level/MPa | 11.5 | 13.2 | 14.9 | 16.6 | 18.3 | 20 |

| Modulus of instantaneous elasticity/GPa | 2.03 | 2.01 | 1.93 | 1.78 | 1.69 | 1.56 |

| Model Type | Confining Pressure | Stress/MPa | G or E0/GPa | K/GPa | ηve/(GPa·h) | ηvp/(GPa·h) | λ | α | R2 |

|---|---|---|---|---|---|---|---|---|---|

| Model in this study | 0 | 5.5 | 1.84 | 49.12 | 6.51 | - | - | - | 0.992 |

| 6.3 | 1.89 | 28.53 | 2.79 | - | - | - | 0.986 | ||

| 7.1 | 1.84 | 18.57 | 2.92 | - | - | - | 0.99 | ||

| 7.9 | 1.80 | 17.71 | 2.12 | - | - | - | 0.982 | ||

| 8.7 | 1.45 | 10.32 | 1.34 | - | - | 59.35 | 0.962 | ||

| 9.5 | 1.42 | 29.66 | 5.31 | 5.51 | 0.32 | 0.02 | 0.997 | ||

| 2 | 11.5 | 1.67 | 54.42 | 1.01 | - | - | - | 0.992 | |

| 13.2 | 1.64 | 20.04 | 0.26 | - | - | - | 0.999 | ||

| 14.9 | 1.55 | 4.83 | 0.51 | - | - | 0.34 | 0.992 | ||

| 16.6 | 1.41 | 4.21 | 0.16 | - | - | 26.44 | 0.997 | ||

| 18.3 | 1.29 | 0.95 | 0.49 | - | - | 0.196 | 0.999 | ||

| 20.0 | 1.18 | 25.68 | 0.54 | 7.08 | 0.43 | 2.46 × 105 | 0.992 | ||

| Model in reference [42] | 0 | 9.5 | 1.41 | 8.2 × 103 | 0.16 | 0.62 | 6.22 × 10−6 | - | 0.98 |

| 2 | 20 | 1.18 | 138.52 | 0.43 | 1.23 × 1011 | 7.51 × 10−5 | - | 0.95 |

| G/GPa | K/GPa | ηve/(GPa·h) | ηvp/(GPa·h) | C/(MPa) | φ/(°) |

|---|---|---|---|---|---|

| 1.96 | 2.2 | 5.31 | 5.51 | 4.2 | 24.3 |

| estart/(GPa) | eend/(GPa) | /(MPa) | λ | α | L |

| 1.84 | 1.42 | 8.7 | 0.32 | 0.2 | 0.1 |

| G/GPa | K/GPa | ηve/(GPa·h) | ηvp/(GPa·h) | C/(MPa) | φ/(°) |

|---|---|---|---|---|---|

| 2.24 | 3.1 | 0.54 | 7.08 | 4.2 | 24.3 |

| estart/(GPa) | eend/(GPa) | /(MPa) | λ | α | L |

| 2.03 | 1.56 | 18.3 | 0.43 | 0.35 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Hu, S.; Li, X.; Guo, S.; Zhang, C.; Gao, Z.; Dou, J.; Yin, D.; Cheng, Y. Creep Model of Weakly Cemented Soft Rock Considering Damage and Secondary Development in FLAC3D. Appl. Sci. 2025, 15, 4838. https://doi.org/10.3390/app15094838

Huang J, Hu S, Li X, Guo S, Zhang C, Gao Z, Dou J, Yin D, Cheng Y. Creep Model of Weakly Cemented Soft Rock Considering Damage and Secondary Development in FLAC3D. Applied Sciences. 2025; 15(9):4838. https://doi.org/10.3390/app15094838

Chicago/Turabian StyleHuang, Junhong, Shanchao Hu, Xuelong Li, Shihao Guo, Chenxi Zhang, Zhihao Gao, Jinhao Dou, Dawang Yin, and Yafei Cheng. 2025. "Creep Model of Weakly Cemented Soft Rock Considering Damage and Secondary Development in FLAC3D" Applied Sciences 15, no. 9: 4838. https://doi.org/10.3390/app15094838

APA StyleHuang, J., Hu, S., Li, X., Guo, S., Zhang, C., Gao, Z., Dou, J., Yin, D., & Cheng, Y. (2025). Creep Model of Weakly Cemented Soft Rock Considering Damage and Secondary Development in FLAC3D. Applied Sciences, 15(9), 4838. https://doi.org/10.3390/app15094838