Mechanical Performance of Group Stud Connectors in Steel–Concrete Composite Beams with Straddle Monorail

Abstract

1. Introduction

2. Experimental Overview

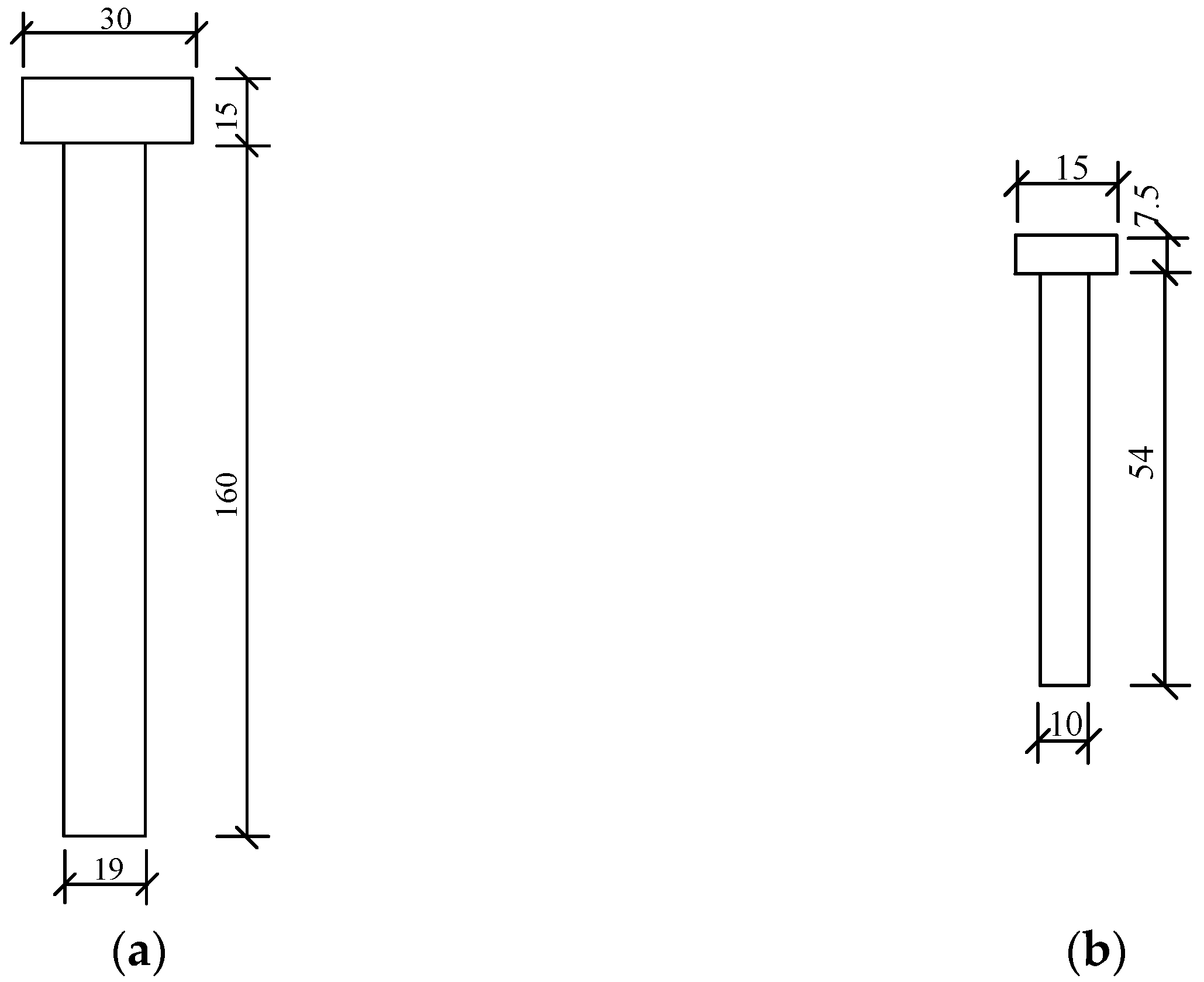

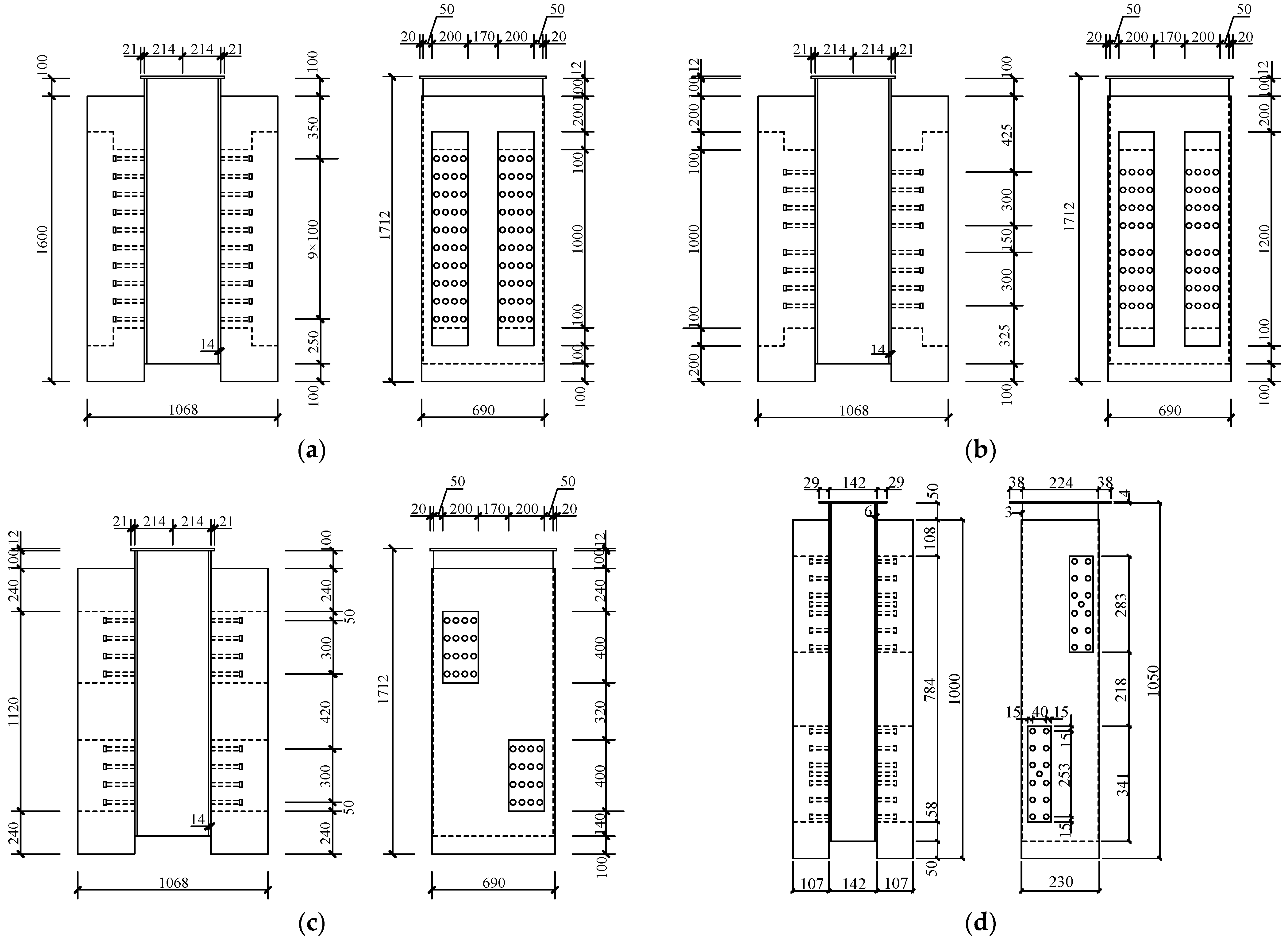

2.1. Specimen Design

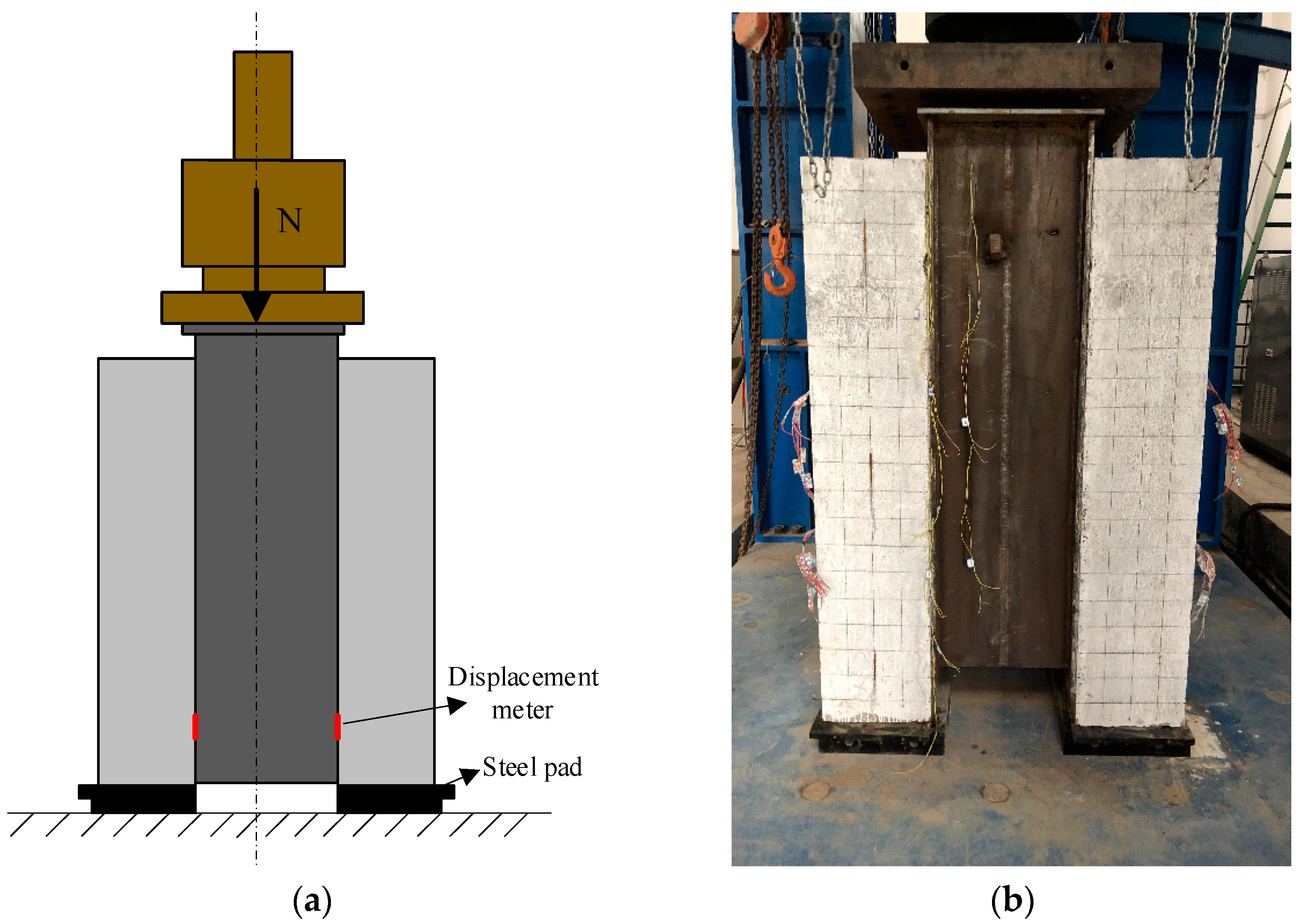

2.2. Test Equipment

2.3. Loading Scheme

2.4. Measurement Scheme

- Load–Slip: Four displacement meters were placed at the same height (bottom of the steel beam) on each specimen to record displacement, with load data obtained in real-time through the control system.

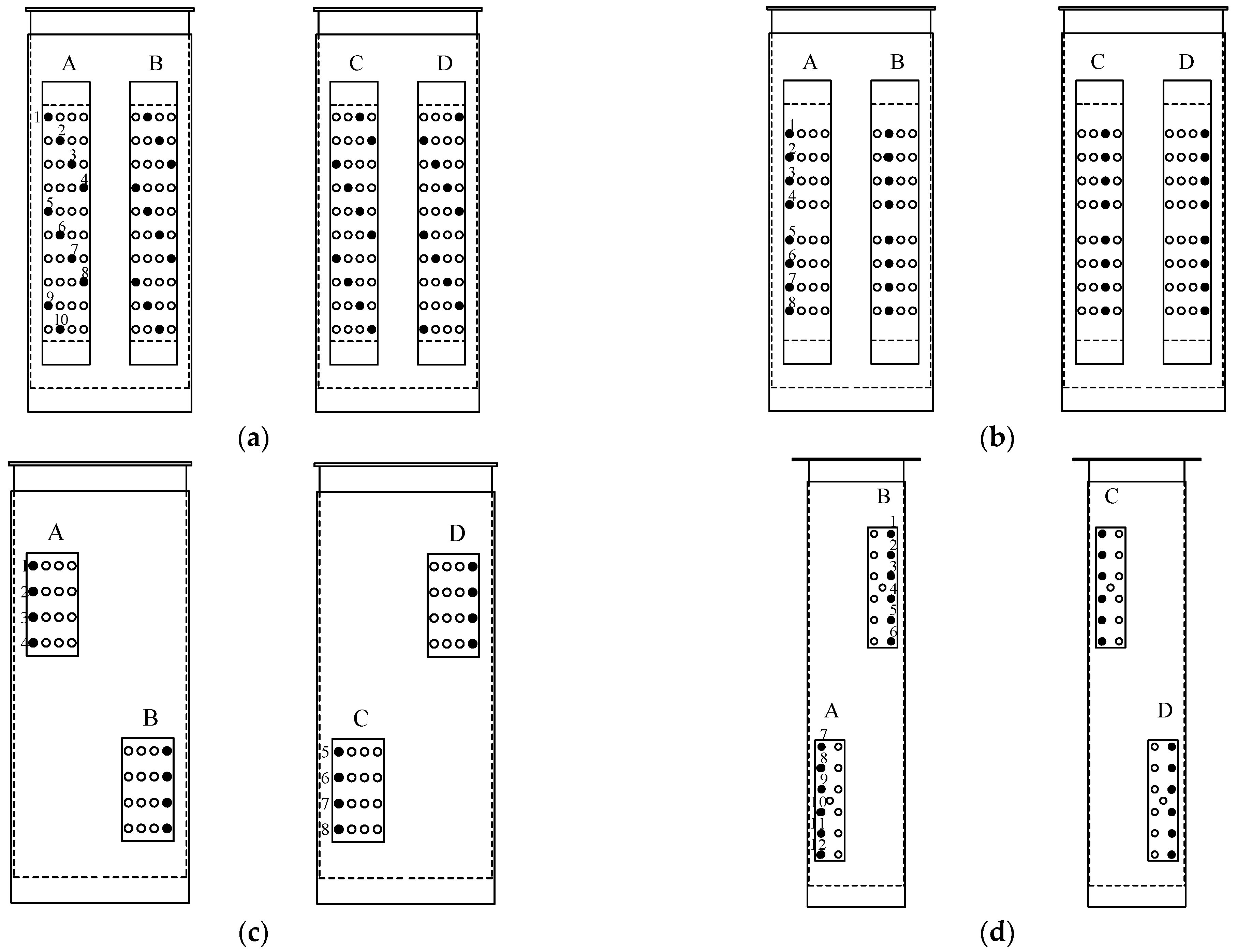

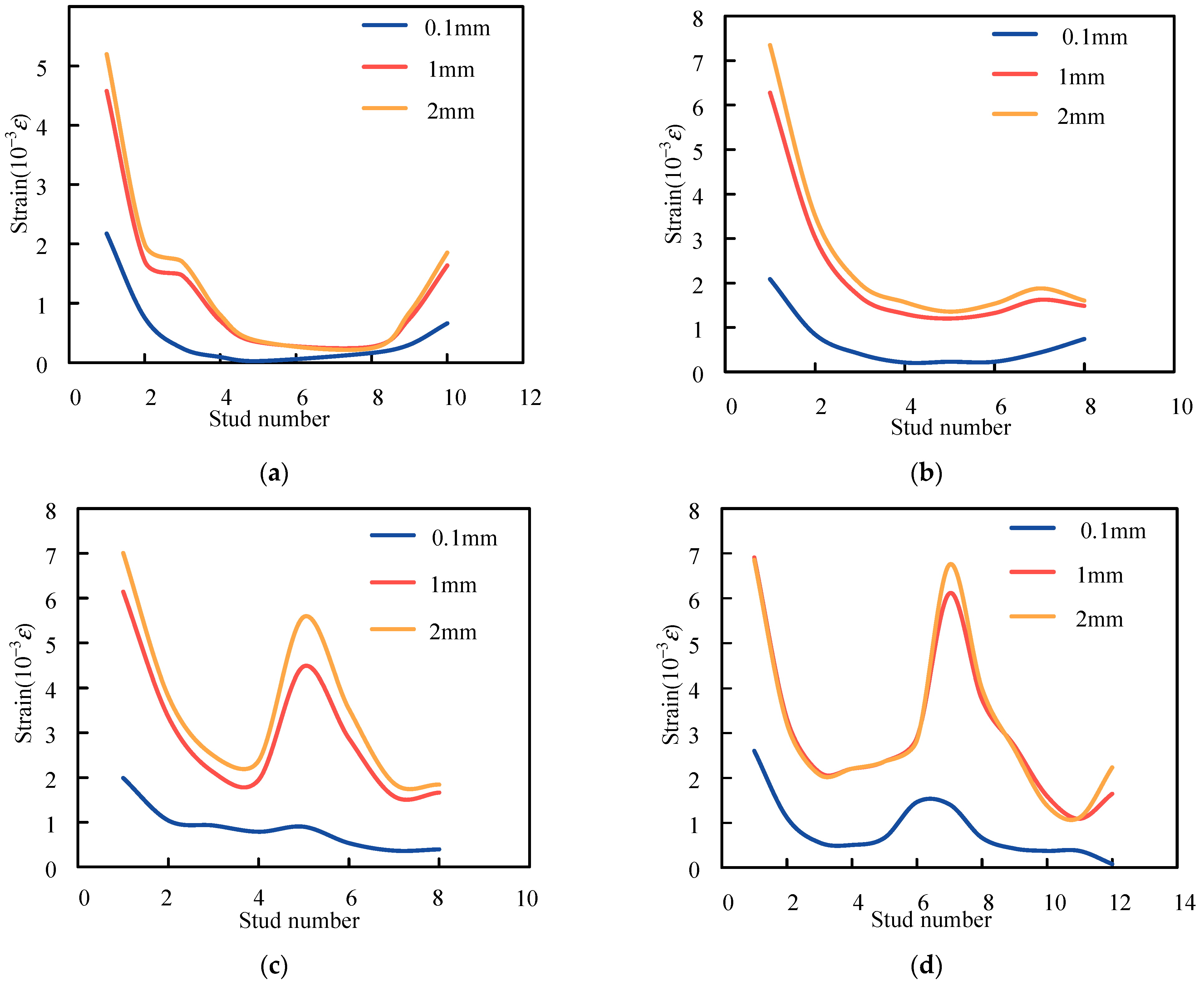

- Stud Strain: For specimen Z-40, 40 strain gauges were placed on the studs, positioned at the upper ends in the loading direction, where shear deformation is maximized, as illustrated in Figure 5a. For specimen Z-32, one strain gauge was placed on each row of studs in each slot, resulting in a total of 64 strain gauges, as shown in Figure 5b. For specimen Z-16, one strain gauge was placed on each row outside the slots, with a total of 16 strain gauges arranged in 4 rows, as shown in Figure 5c. For specimen S-13, one strain gauge was placed on each external stud in each row, resulting in a total of 24 strain gauges, arranged in 4 rows, as shown in Figure 5d.

2.5. Specimen Construction

3. Results

3.1. Failure Modes

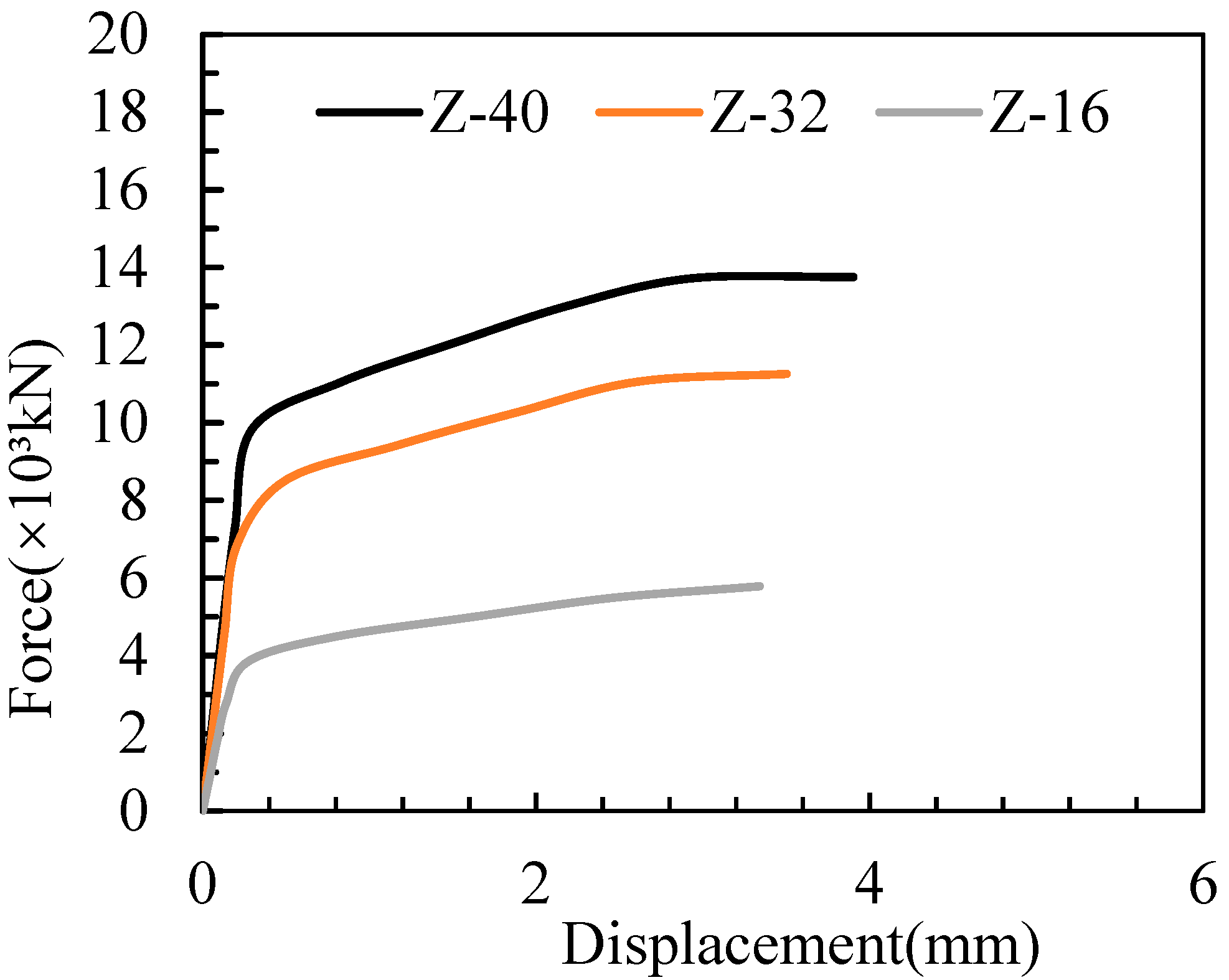

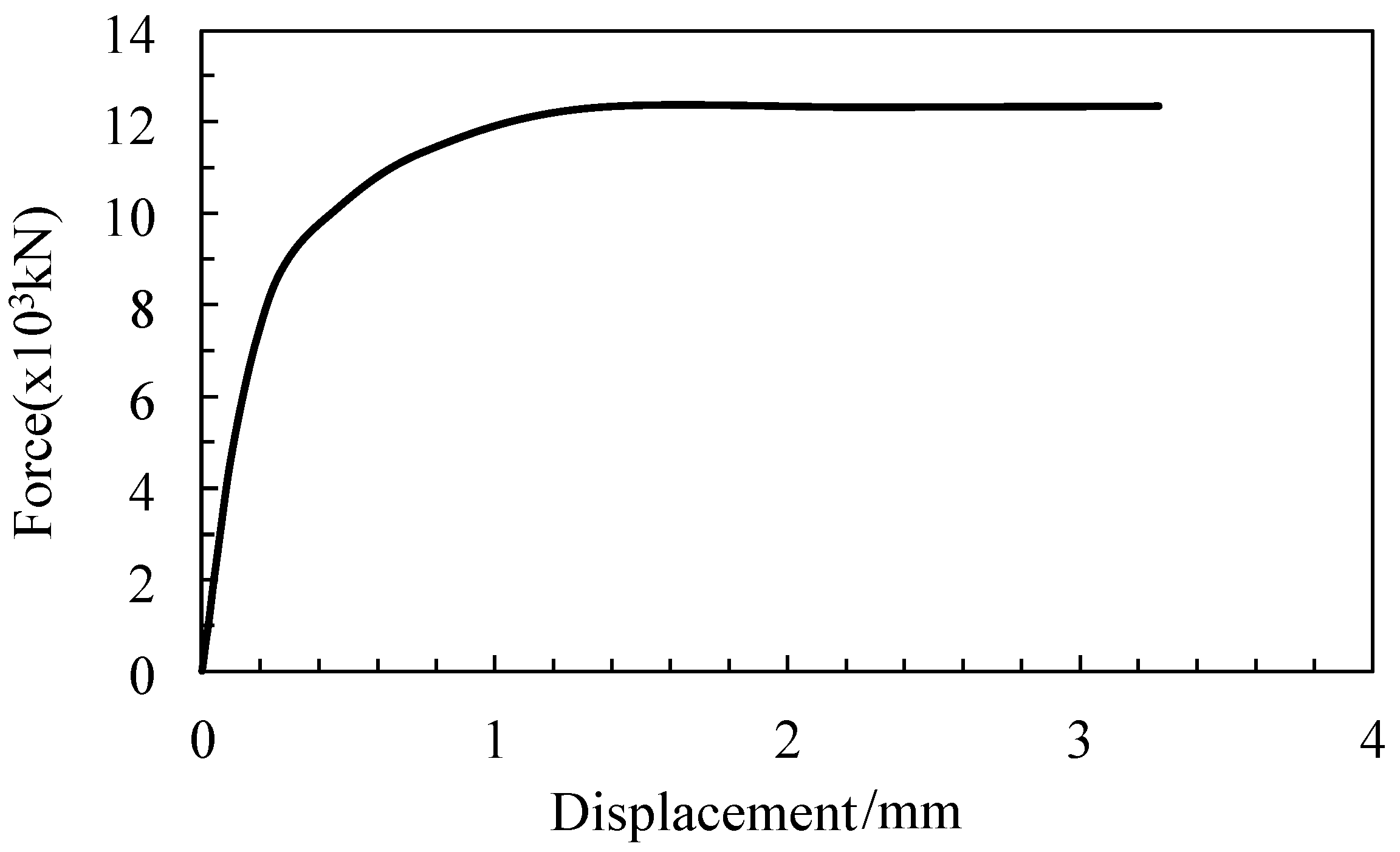

3.2. Load–Slip Curves

3.3. Strain Data of Studs

4. Experimental Result Analysis

4.1. Load-Bearing Capacity of Full-Scale Specimens

4.2. Analysis of Ultimate Deformation of Full-Scale Specimens

4.3. Size Effect Analysis

4.4. Influence of Stud Spacing and Arrangement

4.5. Influence of Material Properties on Group Stud Effect

5. Comparison Between the Shear Capacity Obtained from Tests and Codes

6. Conclusions

- (1)

- Ductile Failure Modes: The group stud connectors exhibited ductile failure modes. Analysis of the load–displacement curves reveals that all full-scale specimens achieved displacement ductility coefficients exceeding 12. At failure, a significant slip occurred between the high-strength concrete and the steel beam due to the shear deformation of the studs, highlighting the strong deformation capacity of the straddle monorail composite beam.

- (2)

- Group Stud Effect: The group stud effect significantly reduced the shear capacity of the studs due to uneven shear force distribution. The outer studs experienced higher loads, while the central studs carried less load. The degree of reduction in shear capacity was proportional to the density of the stud arrangement.

- (3)

- Size Effect: When specimen size was reduced, the mechanical behavior and failure modes of the group stud connectors remained consistent, but the group stud effect was diminished, and deformation capacity was enhanced.

- (4)

- The shear capacity obtained from four specifications is larger than the test results with a difference of almost 25% for the full-scaled specimens and 10–25% for the scaled -specimen.

- (5)

- The finite element analysis and parameter analysis of the structure will be conducted to improve the generalizability. In addition, the long-term performance of group stud connectors will be considered to replicate the performance of the connections under real conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols meanings | |

| Du | ultimate displacement |

| Dy | yield displacement |

| Du/Dy | displacement ductility coefficient |

| Prd | The design shear capacity of one stud |

| γv | partial factor |

| d | shank diameter |

| hsc | nominal height of shear studs |

| fu | bending moment at the column end |

| fck | characteristic cylinder compressive strength of concrete |

| Ecm | Young’s modulus of concrete |

| Qn | the design stud shear capacity |

| Asc | the cross-sectional area of shear studs |

| Ec | denotes the elastic modulus of concrete |

| fc | the specified compressive strength of concrete |

| Fu | minimum tensile strength of shear studs |

| H | height of shear studs |

| σck | the design strength of concrete |

| Astd | the cross-sectional area of shear studs |

| fstd | tensile strength |

| Ec | elastic modulus of concrete |

| η | the reduction factor of group stud effect |

| ld | longitudinal spacing of shear studs |

References

- Shamsi, M.; Ghanbari, A. Seismic retrofit of monorail bridges considering soil-pile-bridge-train interaction. J. Bridge Eng. 2020, 25, 04020075. [Google Scholar]

- Li, C.H.; Lu, Z.J. An innovative straddle monorail track switch design for the personal rapid transit. Int. J. Heavy Veh. Syst. 2021, 28, 370. [Google Scholar]

- Zhou, S.; Liu, Z.; Fang, C. Study on equivalent stiffness of prefabricated steel-concrete composite track beam with straddle monorail group nail connection. Constr. Technol. 2020, 49, 56–59. (In Chinese) [Google Scholar]

- Wang, S.D.; Fang, Z.C.; Chen, G.F.; Teng, S. Numerical Analysis on Shear Behavior of Grouped Head Stud Shear Connectors between Steel Girders and Precast Concrete Slabs with High-Strength Concrete-Filled Shear Pockets. J. Bridge Eng. 2021, 26, 04021030. [Google Scholar] [CrossRef]

- Lu, S.; Zhao, W.; Guo, Z. Experimental Study of the New Type Stud Shear Connector for Assembled Steel–Concrete Beams. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 3119–3130. [Google Scholar] [CrossRef]

- Daou, A.; Mahayri, A.R.; Daou, Y.; Baalbaki, O.; Khatib, M. The Use of Shear Connectors for Enhancing the Performance of Steel–Concrete Composite Beams: Experimental and Numerical Assessment. Int. J. Steel Struct. 2021, 21, 1966–1976. [Google Scholar] [CrossRef]

- Zhou, S.; Nie, J.G.; Fang, C. Study on mechanical characteristics of assembled composite track beam connected by group nails. China Railw. Sci. 2021, 42, 59–65. (In Chinese) [Google Scholar]

- Fang, Z.; Fang, H.; Huang, J.; Jiang, H.; Chen, G. Static Behavior of Grouped Stud Shear Connectors in Steel–Precast UHPC Composite Structures Containing Thin Full-Depth Slabs. Eng. Struct. 2022, 252, 113484. [Google Scholar]

- Zou, Y.; Qin, F.J.; Zhou, J.T.; Zheng, Z.C.; Huang, Z.L.; Zhang, Z.Y. Shear behavior of a novel bearing-shear connector for prefabricated concrete decks. Constr. Build. Mater. 2021, 268, 121090. [Google Scholar] [CrossRef]

- Chai, W.; Di, J.; Lu, Y.; Qin, F.; Men, P.; Su, Y. Experimental Investigation on Static Mechanical Performance of Grouped-Stud Shear Connectors in Steel–UHPC Composite Beams. Eng. Struct. 2024, 306, 117836. [Google Scholar] [CrossRef]

- Lu, W.; Huang, Y.; Xu, W. Study on the Shear Resistance Performance of Grouped Stud Connectors. Materials 2023, 16, 6625. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, S.; Zhang, X.; Xu, H.; Xu, F.; Liu, Y.; Yang, C.; Xia, Q.; Wang, H.; Ding, F. Investigations on the Shearing Performance of Composite Beams with Group Studs. Adv. Struct. Eng. 2023, 26, 1783–1802. [Google Scholar] [CrossRef]

- Zhao, G.-Y.; Zhu, L.; Liu, W.; Zhao, J.-C.; Huo, J.-X. Numerical Study on the Effect of Interface Dynamic Damage of Steel–Concrete Composite Beam Bridge Caused by High–Frequency Impact Load. Buildings 2023, 13, 545. [Google Scholar] [CrossRef]

- Liu, Y. 3D finite element analysis of grouped shear stud connectors in composite beams. J. Constr. Steel Res. 2021, 181, 106652. [Google Scholar]

- Ding, J.; Zhu, J.; Shi, T. Performance of Grouped Stud Connectors in Precast Steel-UHPC Composite Bridges under Combined Shear and Tension Loads. Eng. Struct. 2023, 277, 115470. [Google Scholar]

- Kim, Y. Influence of grouped shear connectors on the fatigue behavior of composite beams. Int. J. Fatigue 2019, 126, 246–257. [Google Scholar]

- Yu, J.; Wang, Y.-H.; Liu, J.-P.; Frank Chen, Y.; Xue, S.-L.; Yu, Z. Stiffness Analysis of Shear Stud Group Connectors in Precast Concrete Deck. Eng. Struct. 2023, 274, 115148. [Google Scholar] [CrossRef]

- Zhou, S.; Yu, P.; Nie, J.G. Static and Dynamic Characteristics of Steel-Concrete Composite Track Beam of Straddle Monorail with Cluster-Distributed Studs. Adv. Civ. Eng. 2022, 2022, 9570045. [Google Scholar]

- Ding, Y.; Jia, Y.; Zhang, G.; Wang, J. Experimental and Numerical Study of the Flexural Behavior of a Full-Scale Steel-Concrete Composite Beam. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 305–314. [Google Scholar] [CrossRef]

- Wang, S.; Tang, C.; Fu, Y.; Zhu, J.; Di, J.; Li, G. Methodology for Calculating Load Capacity Reduction and Slip Relationship of Clustered Group Nail Connectors. Adv. Bridg. Eng. 2024, 5, 7. [Google Scholar] [CrossRef]

- GB/T 50152; Standard for Test Methods of Concrete Structures. Architecture & Building Press: Beijing, China, 2012. (In Chinese)

- GB/T 10433-2002; Cheese Head Studs for Arc Stud Welding. Architecture & Building Press: Beijing, China, 2002. (In Chinese)

- JGJ 138-2016; Technical Specification for Steel–Concrete Composite Structures. Architecture & Building Press: Beijing, China, 2016. (In Chinese)

- EN 1994; EUROCODE 4: Design of Composite Steel and Concrete Structures. Part 2 General Rules and Rules for Bridges. British Standards Institution (BSI): London, UK, 2005.

- AASHTO. LFRD Bridge Design Specifications, 4th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007. [Google Scholar]

- JSCE. Standard Specification for Steel and Composite Structures (Design Edition); Japan Society of Civil Engineers: Tokyo, Japan, 2007. (In Japanese) [Google Scholar]

- GB50917-2013; Code for Design of Steel and Concrete Composite Bridges. Architecture & Building Press: Beijing, China, 2013. (In Chinese)

| Stud | Precast Concrete Slab | Steel Beam Stud Base Plate | Steel Beam Web Plate | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Height | Height | Width | Thickness | Height | Width | Thickness | Height | Width | Thickness | |

| Full-scale specimen | 19 | 160 | 1600 | 690 | 320 | 1600 | 670 | 14 | 1600 | 400 | 12 |

| Scaled specimen | 10 | 54 | 1050 | 230 | 107 | 1000 | 224 | 6 | 1000 | 130 | 4 |

| Specimen | Compressive Strength of Precast Concrete/(MPa) | Compressive Strength of Cast-In-Place Concrete for Notch/(MPa) | Stud Ultimate Strength/(MPa) | Stud Connector Grad |

|---|---|---|---|---|

| Z-40 | 55.9 | 81.2 | 595 | 4.6 |

| Z-32 | 62.8 | 108.5 | 595 | 4.6 |

| Z-16 | 66.4 | 112.2 | 595 | 4.6 |

| Z-13 | 62.8 | 108.5 | 516 | 4.6 |

| Specimen | Z-40 | Z-32 | Z-16 |

|---|---|---|---|

| Final load/kN | 13,757 | 11,261 | 5789 |

| Final deformation/mm | 3.90 | 3.50 | 3.34 |

| Shear capacity of single stud/kN | 85.98 | 87.98 | 90.46 |

| Specimen | Du | Dy | Du/Dy |

|---|---|---|---|

| Z-40 | 3.90 | 0.31 | 12.58 |

| Z-32 | 3.50 | 0.29 | 12.06 |

| Z-16 | 3.34 | 0.24 | 13.92 |

| Specimen | Stud Diameter/(mm) | Tests/(kN) | EC4/(kN) | AASHTO/(kN) | JSCE/(kN) | GB/(kN) |

|---|---|---|---|---|---|---|

| Z-40 | 19 | 86.0 | 108.9 | 105.1 | 106.8 | 107.3 |

| Z-32 | 19 | 88.0 | 108.9 | 105.1 | 106.8 | 107.3 |

| Z-16 | 19 | 90.5 | 108.9 | 105.1 | 106.8 | 107.3 |

| Z-13 | 10 | 23.7 | 30.2 | 29.1 | 29.6 | 25.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, L.-T.; Wu, Z.-H.; Zhao, Y.-F.; Zhao, J.-Z.; Wang, S.-K. Mechanical Performance of Group Stud Connectors in Steel–Concrete Composite Beams with Straddle Monorail. Appl. Sci. 2025, 15, 4051. https://doi.org/10.3390/app15074051

Jiao L-T, Wu Z-H, Zhao Y-F, Zhao J-Z, Wang S-K. Mechanical Performance of Group Stud Connectors in Steel–Concrete Composite Beams with Straddle Monorail. Applied Sciences. 2025; 15(7):4051. https://doi.org/10.3390/app15074051

Chicago/Turabian StyleJiao, Lei-Ting, Zhen-Hao Wu, Yong-Fei Zhao, Ji-Zhi Zhao, and Shu-Ke Wang. 2025. "Mechanical Performance of Group Stud Connectors in Steel–Concrete Composite Beams with Straddle Monorail" Applied Sciences 15, no. 7: 4051. https://doi.org/10.3390/app15074051

APA StyleJiao, L.-T., Wu, Z.-H., Zhao, Y.-F., Zhao, J.-Z., & Wang, S.-K. (2025). Mechanical Performance of Group Stud Connectors in Steel–Concrete Composite Beams with Straddle Monorail. Applied Sciences, 15(7), 4051. https://doi.org/10.3390/app15074051