Abstract

This research paper investigates the integration of sustainable performance metrics into digital maturity models specifically tailored for small and medium-sized manufacturing enterprises (SMMEs), which represent a significant pillar of the Canadian economy. Despite their economic importance, SMMEs face increasing challenges in adopting digital technologies while ensuring sustainable performance. However, traditional digital maturity models often fail to capture the economic, social, and environmental impacts of digital transformation, creating a gap in assessing sustainability within this transition. This study aims to bridge this gap by proposing a framework that integrates sustainable performance indicators into existing digital maturity models. Through a systematic literature review, this study categorises indicators into three main dimensions—economic, social, and environmental—addressing aspects such as resource efficiency, employee well-being, and ecological impact. The proposed framework enables SMMEs to evaluate both their digital maturity and its impact on sustainable performance dimensions. By aligning these metrics with digital maturity assessment, this framework enhances decision-making for SMEs aiming to balance technological adoption with sustainability goals. Furthermore, the study consolidates key performance indicators relevant to SMMEs, providing a structured approach to assess the intersection of digital maturity and sustainability. The results emphasise the importance of incorporating sustainability dimensions into digital transformation strategies, offering SMMEs a structured framework to better access the relationship between digital maturity and sustainable performance while maintaining competitiveness in the digital economy.

1. Introduction

Small and medium-sized manufacturing enterprises (SMMEs) hold an important position in Canada, as they are defined as businesses with between 1 and 500 employees and annual revenues below USD 50 million [1]. They play a crucial role in Canada’s economy, employing 63% of the workforce and significantly contributing to national GDP [2].

This significant position does not prevent SMMEs from facing the same daily challenges as large enterprises. Indeed, they must navigate challenges related to globalisation, increased market competition [3], labour shortages [4,5], and rising climate taxes imposed by the government [6]. Unlike large enterprises, SMMEs do so with limited resources, compelling them to make strategic choices in resource allocation to maintain profitability. As Markley and Davis state, “without economic profitability, any business loses its reason for being”.

With this perspective, business objectives are closely tied to sustainable performance, encompassing economic, social, and environmental aspects. Studies show that owner-managers of SMMEs are motivated by goals related to sustainable development and social responsibility, thus shaping their understanding of performance [7]. Adopting participative management practices, such as involving employees in setting organisational objectives, leads to improved performance and a lasting competitive advantage [8]. In other words, the core objectives of SMMEs are connected to enhancing their sustainable performance. These objectives are defined by improving economic, social, and environmental dimensions [9,10,11,12].

Although these objectives are largely the same for both SMMEs and large enterprises, SMMEs are distinguished by their specific challenges, such as constraints on financial and human resources [13], the complexity of accessing technologies [14], and integration challenges in a competitive environment. In contrast, large enterprises have greater latitude in achieving their strategic objectives [15].

Fortunately, in recent years, I4.0 concepts such as the Internet of Things, cyber-physical systems, and big data have increasingly emerged to help businesses better address their challenges. I4.0 concepts have become essential trends in the industrial world for companies seeking to maintain their market competitiveness [16,17,18]. However, SMMEs must carefully select these technologies, as an incorrect or unsuitable choice could amplify challenges rather than resolve them. Indeed, despite increased investments in digital technologies, only one in twenty companies manages to use them effectively, according to the Business Development Bank of Canada [19]. In the scientific literature, several authors have stated that technologies associated with the Fourth Industrial Revolution can have a significant impact on productivity, operational performance, and business agility, and that by being connected and agile, SMMEs can remain competitive in their market and increase their operational efficiency [20,21,22].

In 2017, additional research offered new approaches to enhance the transition to I4.0 in SMMEs. Certain studies indicated that a lack of guidance and preparation, combined with the shortage of digital resources and skills in SMMEs during their Digital Transformation (DT), were limiting factors affecting their success rates [23]. A search in SCOPUS reveals that no articles introduced the concept of digital maturity in the context of I4.0 before 2017. Using the query “Industry 4.0” and “Digital Maturity”, 109 articles published after 2017 can be found. Digital maturity refers to the level of readiness, skill, and integration of digital technologies within an organisation [22,24,25]. These findings confirm that digital maturity related to I4.0 is a relatively recent concept and that research aimed at adapting this issue to SMMEs is still in its early stages. Since then, based on this new concept, researchers have developed several models aimed at guiding businesses through their DT, primarily by measuring their level of digital maturity.

To provide context, digital performance (or the level of digital maturity) is the metric used to assess progress in executing a DT according to management best practices within a digital environment [26]. In the Québec context, this is particularly significant, as companies, while aware of the potential benefits of DT, face specific barriers related to limited resources [13].

In Québec, the process of evaluating digital performance began in early 2017, when the Ministry of Economy and Innovation (MEI) granted companies that had developed a strategic plan and achieved a certain level of organisational maturity eligibility for subsidies covering digital implementation project costs. To assess eligibility for these subsidies, the MEI assigned various organisations the task of developing a tool to measure digital maturity. These subsidies aimed to alleviate the stressful conditions faced by SMMEs, namely dealing with labour shortages and the constant struggle to remain competitive. To achieve quicker results, the MEI’s tool was developed concurrently with the article by Gamache, Abdul-Nour, and Baril [27]. The tool was largely based on the ongoing research model by Gamache, Abdul-Nour, and Baril [23] in 2017. The importance of this tool is underscored by the context, where digital implementation represents an essential response to the challenges faced by SMMEs.

In summary, this model focuses on the company’s overall level of digital maturity by averaging each of these dimensions. The model’s dimensions include, among others, digital strategy, skills, technological infrastructure, innovation, customer experience, data management, change management, and adaptability [26].

However, studies show that despite all this research, digital maturity models do not focus on companies’ specific objectives [28]. This misalignment between measurement tools and SMMEs’ objectives, particularly those that are economic, social, and environmental, hinders their digital integration. Although many tools are available to them, there remains no evidence of improvement in the success rate of digital projects among Canadian SMMEs. According to the 2022 report by Sous-Traitance Industrielle Québec (STIC), 64% of companies with 10 to 19 employees and 48% of those with 20 to 99 employees had either not yet integrated digital technology into their facilities or had integrated only one, suggesting that digital technology implementation is still not a viable means of achieving SMMEs’ objectives in Québec [29].

A 2023 survey by the MEQ reveals that although 68% of Québec manufacturing companies plan to invest in advanced manufacturing technologies, 49% of smaller companies hesitate or have no intention of investing, indicating a reluctance potentially linked to limited resources and uncertainties about outcomes [30]. This reflects their concerns and a certain hesitation towards the challenges of technological integration and confirms the application gap between SMMEs and larger companies.

This reluctance seems to be reinforced by the absence of indicators directly measuring the impact of digital maturity on SMMEs’ objectives, potentially widening the gap between the level of digital maturity and sustainable performance. In other words, the models encourage SMMEs to improve their digital maturity level without measuring the impacts of a higher level of maturity on the objectives they aim to achieve [28]. There is a significant gap in the scientific literature regarding the effect of digital maturity level and I4.0 technologies on the overall performance of companies. Although various digital maturity models exist, they rarely incorporate key dimensions of sustainable performance—namely social, economic, and environmental aspects. This absence of an integrated framework highlights a critical “research gap”: the need for a model that aligns digital maturity with sustainability indicators, offering a more comprehensive perspective for SMMEs. Therefore, the research problem is:

The digital maturity models designed to assist SMMEs in their DT do not allow for the measurement of social, economic, and environmental benefits from digital implementation; there is a gap between digital maturity measurement and sustainable performance measurement.

Although the ultimate goal is to identify the specific impact of each dimension of I4.0 on every aspect of sustainable performance, the first step is to establish a comprehensive list of indicators, which can be integrated into existing models, to effectively measure these dimensions within SMMEs. This initial step will form the basis for a targeted analysis of the effect of each I4.0 dimension on the specific objectives of businesses, allowing digital practices to be better aligned with their sustainable performance aspirations.

Thus, in attempting to address this issue, certain studies demonstrate that I4.0 offers opportunities to enhance sustainable performance in businesses. In some contexts, the literature shows that I4.0 can enable companies to create sustainable business models, allowing them to reduce their negative impacts on social and environmental aspects [31]. There is evidence that DT in industry can offer much more than economic advantages, contributing to environmental and social sustainability [32]. Furthermore, the study by Braccini and Margherita in 2019 confirms the relevance of factors affecting individual dimensions of sustainable development and helps broaden the understanding of the literature on the different dimensions of sustainability [33]. Research has already highlighted the links between I4.0 and economic, environmental, and operational aspects. These technologies can positively influence performance in these areas, but it is also important to consider several potentially negative impacts on the social aspect [34]. Researchers have already warned that the transition to smart manufacturing could create social challenges, such as the need for specialised skills and risks to employees’ mental health [35]. On the other hand, it is essential to highlight the environmental opportunities that I4.0 can offer, particularly in improving energy efficiency and promoting recycling [33,36,37]. All of this research demonstrates that there is indeed a promising avenue to explore regarding the measurement of sustainable performance to understand the impact of I4.0 on the success of SMMEs. This therefore leads to the research questions:

Q1.

What specific indicators from the literature address both digital maturity and sustainable performance, and how do they contribute to a unified measurement framework?

Q2.

Which types of data or dimensions are necessary to enhance existing digital maturity models to better integrate sustainability considerations?

To address these research questions, it is essential to gather more information regarding the indicators. Therefore, conducting a literature review focused on the dimensions of sustainable performance and I4.0 is a realistic approach. In response to this challenge, this research hypothesises that it is possible to reorganise sustainable performance indicators in the context of DT, as already presented in the literature, to establish a more comprehensive list of factors expressing an SMME’s success. This hypothesis suggests exploring the relevance of sustainable performance indicators in evaluating SMMEs’ digital maturity level and identifying information to be collected to measure it concretely. This brings us to the objective of this article:

This study aims to propose a set of indicators that can enhance digital maturity models by integrating economic, social, and environmental dimensions of sustainable performance. While the study does not fully assess these impacts, it establishes a foundation for future empirical evaluations.

In pursuing these objectives, the article will make significant contributions to understanding DT within Canadian SMMEs. This study’s originality lies in proposing a unified model that integrates sustainability metrics into digital maturity assessment, thereby addressing the overlooked intersection between digital transformation practices and sustainable performance. By bridging this gap, our research contributes to the field by offering both theoretical and practical insights for SMMEs seeking to balance technological adoption with broader economic, social, and environmental objectives. This paper is structured in four sections. Section 2 covers the methodology, Section 3 presents the literature review, Section 4 addresses the study’s contributions, and Section 5 comprises the discussion and conclusion. In Section 5, the main contributions, limitations, and future research directions are discussed.

2. Methodology

Several authors have proposed measuring specific dimensions of I4.0 to gain more insights into the performance and digital maturity of SMMEs. However, by not measuring the link between these metrics and sustainable performance, they only partially address the identified gap. In aiming to bridge the gap between digital maturity measurement and sustainable performance, it is valuable to build upon existing work on digital maturity. This approach allows the results of this literature review to focus on the part of the gap concerning sustainable performance. Therefore, to bridge the gap between digital maturity and sustainable performance, this research proposes integrating sustainable performance indicators into the model from [26]. In addition to reviewing the literature, we adopt a structured approach to identify and organise these indicators, highlighting the conceptual basis for their integration. This integration will enable the evaluation of not only the digital maturity of SMMEs but also their performance in terms of economic, social, and environmental sustainability. This model was chosen for its relevance and timeliness within the Québec context. Québec is known for its industrial base, primarily composed of SMMEs, and its supportive environment for DT, backed by various assistance and funding programs of this kind. The Gamache model is specific to I4.0, making it suitable for studying the digital maturity of SMMEs in this context. The model from [26] has been widely recognised and used in Québec, which enhances its legitimacy and relevance for this study. The presence of distinct dimensions allows for a better alignment between the model and the research objectives. Finally, the model offers flexibility for extension to include sustainable performance indicators, which is essential for the objective of this research. Nonetheless, we acknowledge that the final validation of these extensions requires gathering empirical evidence to confirm the model’s applicability and reliability. In summary, the choice of this model is guided by its relevance, its specificity to I4.0, its capacity to integrate sustainable performance indicators, and its recognition in the academic field, thereby aligning the model with the objectives of the current research.

2.1. Chosen Model

The digital maturity model developed by [27] in collaboration with Productique Québec forms an important foundation for this research. This model, specifically designed for Québec SMMEs, offers a holistic approach to evaluating digital maturity across various dimensions, including leadership, culture and organisation, technology management, data management, measurement systems, and customer experience. Each dimension of the model is subdivided into specific categories, enabling detailed analysis and a deeper understanding of the various aspects of digital maturity.

Several digital maturity models exist in the literature, each with distinct scopes and applications. For instance, the Digital Maturity Model (DMM) by Carnegie Mellon University [38] is a widely used framework that defines five maturity levels based on an organisation’s capabilities in areas such as data management, innovation, and customer experience. However, its structure is primarily designed for large corporations and lacks direct consideration for the specific constraints of SMMEs, such as limited financial and human resources. Another influential model is the Acatech Industrie 4.0 Maturity Index [39], which provides a structured methodology for assessing an enterprise’s digital maturity through six development stages. This model places a strong emphasis on the integration of cyber-physical systems and advanced analytics but remains focused on large-scale industrial operations with high technological investments.

The Gamache model was selected due to its focus on the realities of SMMEs. Unlike broader models that primarily assess technological adoption and IT capabilities, it integrates a multidimensional perspective tailored to the needs of smaller manufacturers. Specifically, it accounts for organisational, operational, and human factors that are critical for SMMEs, including change management, workforce skills, and strategic adaptability. Moreover, the model was developed in partnership with industrial actors in Québec and has been applied within local manufacturing firms, enhancing its contextual relevance.

This selection does not imply that the Gamache model is universally superior. Future research could compare its applicability with other frameworks to assess the effectiveness of different digital maturity models in measuring sustainable performance within SMMEs.

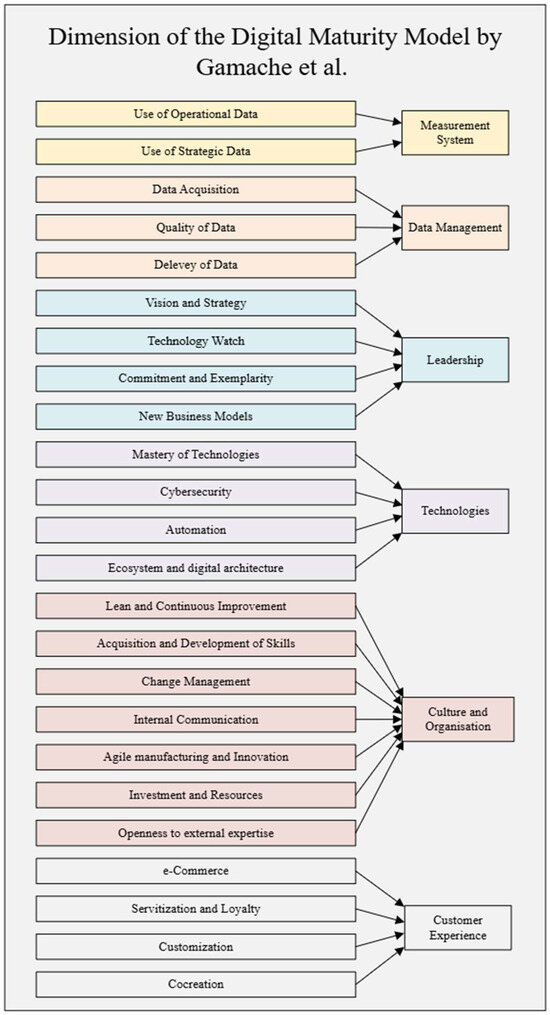

For example, in the Leadership dimension, elements such as vision and strategy, technology watch, commitment and exemplary behaviour, and new business models are examined. These elements are essential for guiding SMMEs in adopting and integrating digital technologies. The Culture and Organisation dimension addresses crucial aspects such as lean and continuous improvement, acquisition and development of skills, change management, and agile manufacturing and innovation. These factors play a decisive role in an SMME’s ability to adapt and evolve in a digital environment. Technology Management focuses on mastery of technologies, cybersecurity, automation, autonomy and intelligence, and the ecosystem and digital architecture. This dimension is vital to ensure that technologies are not only adopted but also effectively integrated and utilised to generate value. Data Management covers data acquisition, integrity of data, quality of data, and delivery of data, which are fundamental aspects for informed and effective decision-making within SMMEs. The Measurement Systems dimension includes the use of strategic and operational data, highlighting the importance of measuring and assessing organisational performance using relevant data. Finally, Customer Experience focuses on e-commerce, service orientation, personalisation, and engagement and co-creation—key elements for enhancing customer interaction and satisfaction. Figure 1 represents the digital maturity model developed by [26].

Figure 1.

Digital maturity model developed by [26].

2.2. Conceptual Framework

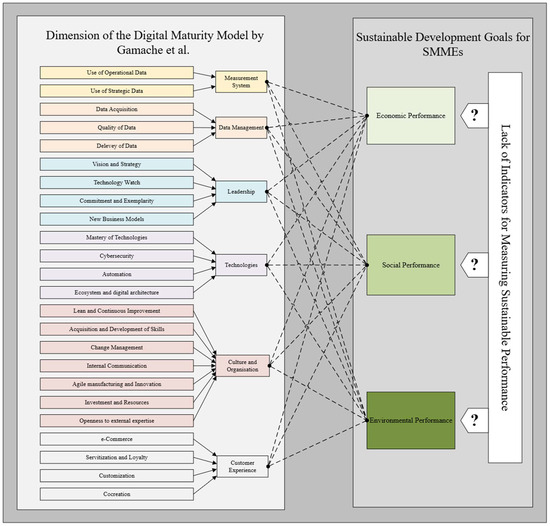

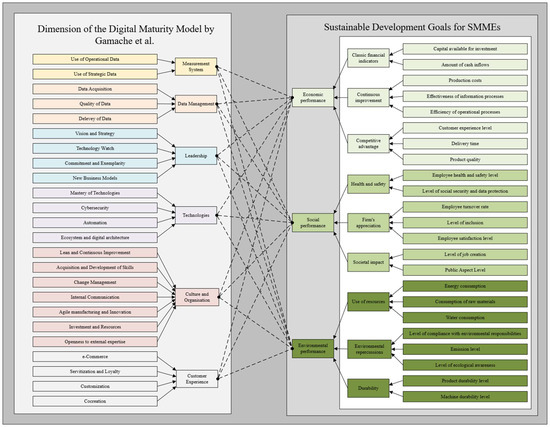

Based on this model, it has been easier to clarify the gap to be addressed in relation to the issue discussed in this article. Indeed, the conceptual framework presented in Figure 2 visually represents the gap that must be bridged to achieve the objective stated previously. Although the Gamache digital maturity model provides valuable indicators of the digital maturity of SMMEs, these indicators do not directly measure core performance aspects related to the organisation’s social, economic, and environmental aspects. The digital maturity evaluation as proposed by this model does not cover the sustainable benefits of a DT, leaving a gap between technology adoption and the achievement of sustainable performance. The right side of Figure 2 shows the lack of indicators to measure sustainable performance. This absence of indicators prevents analysis of the relationships between the dimensions of the Gamache digital maturity model and the dimensions of sustainable development. It is therefore very difficult for SMMEs to understand the impact of their digital actions on their core objectives. In this figure, the dashed lines represent conceptual links between digital maturity dimensions and sustainable performance indicators that are proposed by the authors but have not yet been empirically validated. The question marks (?) highlight areas where no direct or documented indicators could be identified in the literature, illustrating gaps that still need to be addressed through further research.

Figure 2.

Gap to be bridged to establish the link between maturity measurement and sustainable performance (integration of the digital maturity model by [26] on the left side of the conceptual framework).

The methodology adopted to complete this integration includes a literature review aimed at identifying relevant sustainable performance indicators. These indicators were selected based on their applicability to SMMEs, their relevance in the context of I4.0, and their ability to provide concrete and meaningful metrics. The objective is to develop a set of indicators that, when combined with the digital maturity model, will provide a comprehensive evaluation of the overall performance of SMMEs in their digital transition. This approach will enable not only the measurement of digital maturity but also an assessment of its impact on the economic, social, and environmental dimensions of sustainable performance. The next section presents the literature review.

3. Literature Review

The literature review aims to deepen knowledge on sustainable performance indicators to establish a causal link between digital maturity and the success of an SMME while identifying the necessary information to measure this causality. This section is subdivided into multiple subsections to better structure the ideas and key concepts. Section 3.1 is devoted to defining the essential terms for this research. Section 3.2 focuses on the literature strategy employed. Finally, Section 3.3 addresses the various aspects of sustainable performance, including economic, social, and environmental aspects.

3.1. Definitions

To establish a common understanding, this subsection defines the key concepts according to the terms selected by the author of this article. The themes of SMME, I4.0, digital maturity, and sustainable performance are defined.

3.1.1. SMME

The definition used in this article to describe SMMEs includes organisations with between 1 and 500 employees and annual revenues below USD 50 million [1]. This threshold considers the diversity of organisational structures and business models specific to manufacturing companies. In Canada, SMMEs are generally distinguished by their flexibility, responsiveness to market changes, and close relationships with customers. In this research context, an SMME is regarded as an organisation aiming to integrate advanced technologies to optimise its processes, albeit potentially constrained by limited financial and human resources.

3.1.2. I4.0

For the purposes of this research, I4.0 is defined as a set of practices and technologies aimed at interconnecting operations and data through cyber-physical systems, the Internet of Things, and big data analytics [40]. Since 2011, I4.0 has also been the term used to describe the new wave of industrial transformation focused on the use of advanced smart technologies in manufacturing environments. For Québec SMMEs, I4.0 represents an opportunity to modernise their operations and become more competitive on a global scale [20]. DT is, moreover, one of the concepts stemming from I4.0. In the literature, DT represents the process through which companies progress to reach their desired level of maturity.

3.1.3. Digital Maturity

Digital maturity is a key concept in the digital economy and I4.0. This concept refers to the level of adoption and effective use of digital technologies by an organisation to enhance its operations and business model, going beyond the mere acquisition of new technologies [41]. Additionally, one of the key facets of digital maturity is the importance of an organisational design that promotes self-organisation and strategic alignment of digital technologies to improve organisational efficiency and productivity, which is a key aspect of digital maturity [42]. The effective use of digital technologies to drive innovation and enhance the performance of SMMEs is also consistent with the concept of digital maturity [43]. This notion will be explored in depth to identify the information necessary for measuring the causal link between digital maturity and the success of an SMME.

3.1.4. Sustainable Performance

In this research, sustainable performance is defined as a multidimensional concept aiming to integrate economic, social, and environmental aspects into business management. In the Québec and I4.0 context, sustainable performance involves the judicious use of technologies to improve operational efficiency while adhering to ethical and ecological principles [31]. Specifically, performance encompasses three axes: economic performance, social performance, and environmental performance. Economic performance focuses on economic indicators, such as profitability and return on investment (ROI), which are often considered the primary measures of a company’s success [44]. Social performance examines the social impacts of I4.0 adoption, particularly regarding employee well-being [32]. Finally, environmental performance focuses on environmental impacts, such as energy efficiency and the reduction in greenhouse gas emissions [36].

3.2. Search and Selection Strategy

First and foremost, the exclusive use of the SCOPUS search engine in this study is justified by its broad multidisciplinary coverage, essential for addressing the various aspects of sustainable performance and I4.0, and its advanced filtering capabilities, which allow for a rigorous and relevant selection of publications. SCOPUS is widely recognised for its comprehensive indexing of peer-reviewed research in engineering, sustainability, and digital transformation, making it particularly suited to our study’s focus. Additionally, the use of a single database ensures methodological consistency, aligned with the objectives of this research.

While Web of Science and other databases also provide valuable sources, SCOPUS was selected due to its broader coverage of technical and applied research, particularly in the field of industrial engineering. Moreover, SCOPUS’s advanced citation tracking facilitates a structured approach to identifying key contributions in the field.

The criteria used when reviewing articles to assess their consistency throughout the literature review were partially based on factors such as thematic alignment, academic quality, research currency, methodological robustness, and practical relevance of the results. However, the final selection of articles was guided by the research objectives. Indeed, articles were selected based on their relevance for determining whether the measurement of sustainable performance indicators is appropriate and for compiling the list of information necessary to collect within an SMME to measure sustainable performance levels. This approach ensures that the selection of articles was both objective and directly aligned with the research questions, thereby guaranteeing the reproducibility and reliability of the literature review results.

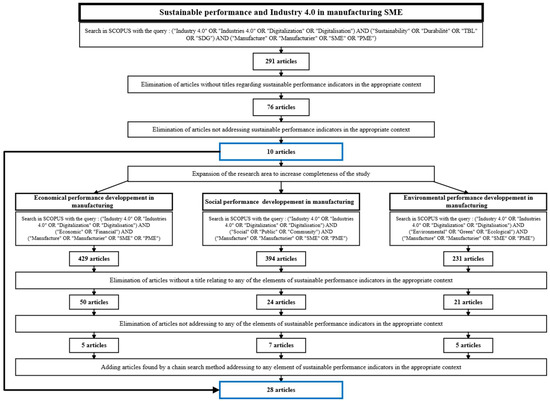

Initially, the literature review was guided by the intersection of the concepts of I4.0, sustainable performance, and SMMEs. The first article search was thus driven by the query: (“Industry 4.0” OR “Industries 4.0” OR “Digitalization” OR “Digitalisation”) AND (“Sustainability” OR “Durabilité” OR “TBL” OR “SDG”) AND (“Manufacture” OR “Manufacturier” OR “SME” OR “PME”) in the SCOPUS search engine. This search yielded 291 articles, of which 76 had titles addressing sustainability or performance in SMMEs. After reviewing the 76 articles, 10 were ultimately deemed relevant to achieving the objective of this research.

The exploratory literature review, in turn, revealed that there were many articles in the literature sharing the concepts of I4.0 and SMMEs but covering only a portion of sustainable performance. To ensure the comprehensiveness of the research, it was relevant to conduct three additional searches related to the concepts of I4.0 and SMMEs, each focusing on one of the individual dimensions of sustainable performance. The following three queries were thus created to enrich the database.

First, a search was conducted on the intersection of the concepts of I4.0, economic performance, and SMMEs. The second article search was therefore conducted using the query: (“Industry 4.0” OR “Industries 4.0” OR “Digitalization” OR “Digitalisation”) AND (“Economic” OR “Financial”) AND (“Manufacture” OR “Manufacturier” OR “SME” OR “PME”) in the SCOPUS search engine. This search yielded 429 articles, of which 50 had titles addressing financial indicators or performance in SMMEs. After reviewing the 50 articles, 5 were ultimately deemed relevant to achieving the research objective.

Secondly, a search was conducted on the intersection of the concepts of I4.0, social performance, and SMMEs. The third article search was thus conducted with the query: (“Industry 4.0” OR “Industries 4.0” OR “Digitalization” OR “Digitalisation”) AND (“Social” OR “Public” OR “Community”) AND (“Manufacture” OR “Manufacturier” OR “SME” OR “PME”) directly in SCOPUS. This search yielded 394 articles, of which 24 had titles addressing social performance in SMMEs. After reviewing the 24 articles, 7 were ultimately deemed relevant within the scope of this query.

Finally, a search was conducted on the intersection of the concepts of I4.0, environmental performance, and SMMEs. The third article search was therefore conducted with the query: (“Industry 4.0” OR “Industries 4.0” OR “Digitalization” OR “Digitalisation”) AND (“Environment” OR “Green” OR “Ecological”) AND (“Manufacture” OR “Manufacturier” OR “SME” OR “PME”) directly in the SCOPUS search engine. This search yielded 231 articles, of which 21 had titles addressing environmental performance within the research context. After reviewing the 21 articles, 5 were ultimately deemed relevant to achieving the research objective.

For this literature review, the PRISMA method was adopted to structure the selection and analysis of articles. This approach ensured a systematic and transparent process, thus facilitating the reproducibility and reliability of the results. In accordance with Prisma principles, the research strategy was developed in four main steps: identification, screening, eligibility, and inclusion. Figure 3 illustrates the article selection process, from the initial search in the SCOPUS database to the final selection of relevant studies, including a review of bibliographic references to expand the corpus. This rigorous process, guided by predefined inclusion and exclusion criteria, resulted in a total of 28 articles deemed relevant for addressing the research objectives.

Figure 3.

Literature strategy used to illustrate the reproducibility of the literature review.

The sustainable performance indicators identified in this review were selected by ensuring they met the SMART criteria (Specific, Measurable, Achievable, Relevant, and Time-based). This approach enabled the identification of concrete, applicable indicators suited to the SMME context, thereby ensuring a rigorous and effective assessment of their sustainable performance and applicability in future practical cases.

In summary, this literature review strategy aims to address the gaps identified in current research by establishing a connection between digital maturity and sustainable performance within the context of SMMEs. As presented in the following section, the sequence of these themes was intentional. It began by establishing the relationship between sustainable performance and I4.0, then breaking down this performance into its economic, social, and environmental components, ultimately integrating these elements into the concept of digital maturity.

3.3. Sustainable Performance Measurement

The results from [45] indicate that the most researched topic by SMMEs in the literature is sustainable development. This section delves deeper into sustainable performance indicators by listing the variables used in the 25 articles reviewed. Each subsection—covering the economic, social, and environmental categories—presents indicators derived from the dependent variables and findings of the 25 articles. The first subsection of the literature review focuses on the economic category.

To justify the selection of relevant indicators from the literature during the review, several factors were considered. Among other criteria, it was essential that the selected indicators be directly related to the research objectives. In this case, the indicators needed to be relevant for assessing the sustainable performance of SMMEs in the context of I4.0. The chosen indicators also had to be quantifiable and cover one of the dimensions of sustainable performance, thereby enabling a uniform analysis of the results. Similarly, the indicators had to be tailored to the specific characteristics of SMMEs, taking into account their resources, capabilities, and unique challenges. The frequency of indicators was also considered, with selection based on how often these indicators appeared across the 25 studies. In summary, the justification for selecting the indicators is based on their relevance to the research objectives, their basis in existing literature, their representation of different dimensions of sustainable performance, their applicability to SMMEs, and their ability to provide concrete and meaningful measures.

3.3.1. Economic Performance

Economic indicators are the most used in the literature to measure business success. Of the 28 articles collected, 24 use at least one economic dependent variable to measure economic performance. This section provides a detailed overview of all economic indicators identified in the literature to deepen knowledge on sustainable performance indicators. The following is divided into three main categories: classic financial indicators, continuous improvement, and competitive advantage.

First, most authors suggest classic financial indicators related to fixed production costs, cash reserves, investments, and available working capital to measure economic performance.

Indeed, it seems logical to use classic financial indicators to achieve profitability goals. Eighteen authors suggest using production costs as a measure of project benefits, with 15 of these 18 authors, including [46,47], using production cost reduction as a primary profitability indicator. Some authors also use more specific terms. For example, refs. [34,48] introduce measurements for water and electricity consumption costs, inventory costs, and raw material costs to break down production costs in greater detail. Other authors, like [49], suggest that eliminating time losses in production can result in financial gains such as reduced labour costs. For this reason, they use production time savings as an indicator affecting production costs. Most studies using these indicators show that I4.0 has had a positive impact on reducing production costs. However, the opposite can also be true. Ref. [50] suggests that DT can have a negative impact on production costs. Their results show that additional fixed costs may arise, especially when a company relies on external resources for a digital project. They include external assistance costs, among others, as an indicator in their article.

Unlike production costs, several authors also mention cash inflows as an indicator for measuring economic performance. Refs. [51,52] use measures like ROI to assess cash benefits in business studies. Ref. [53] and ref. [50], respectively, use profits and revenues (selling price) to evaluate these benefits. Additionally, ref. [54] reports in their articles that increased sales forecasts, resulting in future revenue growth, also contribute to measuring economic performance related to cash inflows [44]. Moreover, unlike the production costs mentioned by [50], the authors also suggest measuring the percentage of external financial assistance, such as government grant programs [53].

In addition to cash inflows and outflows, refs. [44,49] suggest measuring the level of working capital to quantify the capital available for investment. To operationalise this measure, as done by [55,56], some authors use indicators such as the percentage of investment in research and development (R&D), the percentage of investment in technological infrastructure, and the percentage of investment in I4.0-related projects. These measures somewhat represent the company’s profits reinvested during the year. However, ref. [56] suggests not limiting measurement to the percentage of reinvested funds but also considering the percentage of unused financial capacity to fully gauge economic performance.

Secondly, a large part of the literature also notes that process improvement is closely linked to economic performance. For this reason, several authors also suggest measuring the level of continuous improvement through the efficiency of operational and informational processes [56,57]. Eighteen out of 28 articles discuss the importance of measuring these variables to understand the overall economic impact of a project.

In the articles included in this literature review, such as those by [47,52,58], the primary indicator used to measure a factory’s operational efficiency is the Overall Equipment Effectiveness (OEE). In their article, ref. [44] shows that improving OEE positively impacts competitive advantage and differentiation strategy. The findings of [46] indicate that in some cases, digitalisation significantly contributes to achieving higher productivity, resulting in reduced costs and waste or increased added value within the factory. In addition to overall equipment effectiveness, refs. [54,59] use the number of parts produced per hour to measure operational efficiency. Similarly, ref. [48] mentions measuring the percentage of worker productivity. These indicators are factored into the OEE calculation.

Regarding the efficiency of informational processes, some authors, such as [33,60], use the level of transparency throughout the process, while [36,61] use the time to market. Once again, using the example from [44], the authors suggest that increasing data and process transparency adds value across the three dimensions of sustainable development, thereby increasing economic performance. According to [57], reducing time to market also boosts economic benefits by enabling a project to start sooner.

Thirdly, some literature associates competitive advantage and customer experience level as relevant indicators for measuring economic performance. Authors of 22 articles state that increasing competitive advantage, such as reducing lead times, fostering innovation, and improving quality, enhances customer experience, generating economic benefits for SMMEs.

Ref. [50] simply uses the level of customer satisfaction as an indicator for measuring customer experience level. However, other authors take a more precise approach by focusing on measuring competitive advantage to determine the economic benefits of I4.0. They propose indicators such as agility level, market value creation, and multidisciplinary innovation. For measuring personalisation and agility levels, 14 different authors, including [31,46], suggest that improving this indicator enhances competitive advantage, such as enabling the offering of customisable products. Findings by [31] indicate that manufacturing agility and flexibility are the most immediate opportunities I4.0 offers in terms of sustainability. Concerning market value creation, refs. [55,62] and use the level of sales increase to measure market competitiveness [44]. Ref. [56] uses another example, namely, multidisciplinary innovation level, to measure economic benefits. In their article, they mention that innovation improvement indirectly helps reduce production costs.

According to a small group of authors, reducing lead times also helps improve customer experience. Authors like [54,58] use customer delivery lead time as an economic performance indicator. Additionally, the time-to-market measurement proposed by [57,61] to measure process efficiency can also be used to gauge customer experience level. Ref. [61] also measures design time.

Finally, several authors assert that product quality also impacts economic performance. According to ten authors, including [33,34,62,63], quality can be used to measure customer experience and can also impact production costs. Most authors using quality as an economic indicator measure it through the percentage improvement in quality. More specific indicators, such as the quantity of defective parts and the percentage of production errors, are also used to support quality level measurement, including by [49,57]. I4.0 is not solely known for positively impacting quality; for example, findings by [57] show that in some cases, quality can be negatively affected by I4.0. As mentioned, quality level can also reduce manufacturing costs, which is why, in addition to quantity indicators, ref. [48] also uses monetary indicators such as the cost of reprocessing rejects and the cost of reworking defective parts.

In short, this section presents all the indicators for measuring economic performance encountered in the 28 articles of this literature review. Naturally, some indicators are more concrete, while others relate to somewhat vague performance measures. Nevertheless, this literature review shows that there are many relevant indicators for measuring economic performance in an SMME. However, these are not the only relevant performance indicators for SMMEs. As ref. [64] states, over recent decades, society’s expectations have shifted from traditional profit maximisation toward broader concerns of social responsibility and environmental and social sustainability. This underscores the importance of the following two sections.

3.3.2. Social Performance

Social indicators are increasingly used in the literature to measure a company’s performance. Of the 28 articles collected, 22 consider it important to measure companies’ social performance. Authors use social dependent variables as indicators. This section details all social indicators identified in the literature to deepen understanding of sustainable performance indicators. This section is divided into three categories: health and safety, the firm’s appreciation, and the societal impact of the firm.

First, when studying social indicators in a company, it is essential to consider worker comfort. This is precisely what the authors of the articles in this literature review do. To achieve this, many authors use indicators related to the health and safety of workers as a measure of social performance. The indicators used are related to the number of workers, the level of worker inclusion, and workplace appreciation.

Indeed, worker health and safety are extremely important, which is why many indicators on this topic were found in this literature review. Nineteen authors state that health and safety are relevant to social performance. Among them, almost half, including [31,36,57], directly use employee health and safety levels as an indicator. Similarly, as with [51,53,65], part of the remaining authors use indicators of physical and psychological stress among employees. To quantify worker health and safety more easily, ref. [66], ref. [33], and ref. [54], respectively, use indicators such as noise pollution levels, accident frequency, and air quality. Ref. [50], on the other hand, considers screen time a health risk for users and thus uses screen time as an indicator affecting worker health and safety. Closely related to work improvement, ref. [34] suggests measuring the amount of hazardous materials handled by workers. For the psychological aspect, ref. [48] directly measures worker morale. Refs. [44,50,52] note that security affects more than just workers; there are also risks associated with social security and data protection. They therefore propose measuring data exposure to the public and exposure to cybercrime.

Next, still aiming to measure social performance, 13 articles present different techniques to identify worker appreciation levels. Some propose measuring staff turnover rates, others the level of employee satisfaction within the company, and others the level of worker inclusion.

Ref. [36] directly uses employee turnover rates as an indicator of job appreciation—or conversely, job dissatisfaction in cases where the company struggles to hire. Other authors suggest that the level of inclusion can increase employee appreciation. Most of these authors, such as [49,51,67], use skill levels required to measure inclusion. Ref. [52] notes that significant challenges will arise regarding employees’ acquisition of new skills during the digitalisation process for SMMEs. Additionally, refs. [44,49,67] suggest measuring worker flexibility levels and indirectly assessing employee competence and training levels. Similarly, refs. [50,52] directly measure in-company training duration, while refs. [44,55] measure the percentage of workers meeting I4.0 requirements. Specifically, ref. [44] indicates that qualification and skill development for I4.0 present challenges, which could negatively impact worker inclusion. More concretely, ref. [54] measures inclusion levels using morbidity rates and the percentage of disabled employees.

Regarding job satisfaction within a company, many authors directly propose measuring employee satisfaction levels. Conversely, another group, including [57,61], suggests measuring resistance to change as an indicator of employee satisfaction. To measure satisfaction more specifically, some authors, such as [48,68], propose using the quality of working conditions, the number of simple, repetitive tasks, and salaries of workers. In their article, the authors cite the example that the Internet of Things can simplify work, adding value to human workers. However, this can lead to a decline in memory and long-term capabilities [50].

Finally, social performance is not limited to working conditions within factory walls. For this reason, 14 authors also use indicators to measure the level of societal impact. Some measure job creation levels, while others measure public perceptions of the company.

Indeed, 8 out of the 14 authors mention that job creation or reduction, especially through reducing the number of employees required, impacts social performance. For instance, refs. [51,67] use the number of jobs as an indicator.

Conversely, regarding the public aspect, refs. [34,44,51] propose directly measuring the company’s public perception as a social performance indicator. Indirectly, refs. [50,52,66] consider that increased transparency and traceability with the public strengthen relationships and trust between companies, which can, in turn, impact the social dimension of those companies. Still in terms of the public aspect, refs. [46,47] believe that a company’s community impact should also be measured. They use the level of value created for the community and society as a measure of social performance.

In summary, this section presents all the indicators found in the literature for measuring social performance. Whether through worker well-being or public perception, this literature review shows that there are many relevant indicators for measuring the social performance of an SMME. Nonetheless, society’s expectations are not limited to social indicators. Indeed, this review also highlights a number of environmental indicators relating to sustainability within the environment. The following section underscores the importance of this dimension.

3.3.3. Environmental Performance

The environmental responsibilities of manufacturing companies are increasing daily [6]. Consequently, the use of environmental indicators is becoming increasingly essential for SMMEs seeking to fulfil their environmental obligations. In this literature review, 22 authors employ environmental variables to evaluate companies’ ecological performance. This section provides a synthesis of environmental indicators identified in the literature and explores three main categories: resource usage, environmental impact, and product durability.

First, resource usage plays a fundamental role in environmental performance. Several studies highlight the positive impact of reduced consumption on the ecosystem. This part sheds light on the indicators used to assess resource usage in SMMEs, including energy consumption, raw material usage, and water consumption.

Many researchers consider energy consumption percentage a relevant indicator for analysing environmental performance. This indicator is cited in 14 publications, including those by [52,57]. The findings of [49] show that adopting Industry 4.0 technologies enables better energy load balancing, thus reducing energy consumption. Furthermore, ref. [66] emphasises the importance of the primary type of energy used, advocating for its inclusion in assessments. Additionally, 13 researchers, including [50,52], stress the necessity of monitoring raw material usage. Seven studies, including [61], directly measure the amount of raw materials consumed to evaluate I4.0’s impact on resource management. To refine this analysis, some authors, such as [59,60], propose using the rejection rate, which reflects the amount of wasted material in production processes. Beyond quantity, the nature of raw materials is crucial for environmental impact. Hence, ref. [66] recommends evaluating the amount of recycled raw materials to better understand their effect. They note a recycling deficit in many industries, leading to significant waste. Not only are these materials not used to their full potential, but they also become unusable in other contexts, potentially having a significantly negative environmental impact. To quantify this issue, refs. [34,65] advocate measuring the percentage of non-reusable materials. Regarding water consumption, several researchers, such as [54,63,65], consider this indicator, with [66] adding a parameter related to water pollution levels caused by production.

Secondly, environmental impact is a key driver prompting companies to track their ecological performance. As indicated by [31], preserving ecosystems and improving human quality of life require adopting sustainable practices, including in the manufacturing sector. This subsection highlights commonly used indicators to assess the environmental repercussions of manufacturing SMMEs. The authors of articles in this literature review primarily use indicators related to environmental repercussions in an SMME to measure environmental performance. The indicators used primarily relate to carbon emissions and ecological awareness levels.

Several studies examine how companies can evaluate their ecological footprint. Some authors, such as [55], suggest using the level of environmental responsibility compliance to assess SMMs’ impact, an approach also shared by [46,48]. Other studies focus on atmospheric emission levels. Eleven out of 28 publications consider air emissions levels to have a notable effect on ecological performance. Specifically, six authors, including [33,36], propose measuring greenhouse gas emissions as an indicator, while ref. [51] recommends using the carbon footprint.

The work of [54] underscores the importance of the energy transition for industrial performance and reducing the carbon footprint, using these indicators to measure the impact of digital technologies on pollutant emissions.

According to some authors, the level of environmental impact can also be measured by a company’s ecological awareness. To quantify this concept more concretely, authors recommend measuring the behaviour of SMMEs in daily operations that may have an impact. Refs. [36,44,59] view reductions in logistics processes, such as reduced overseas transportation, as a measure of ecological awareness regarding environmental impact. Ref. [34], in turn, considers that reducing the number of environmental accidents is an essential indicator for measuring ecological awareness.

Finally, product and equipment durability also play a major role in environmental performance. This section examines indicators related to the longevity of products and machinery.

Developing sustainable products is a key aspect of sustainable development, as noted by [67]. According to [57], product durability is a central factor in industrial sustainability. To measure product durability, they, along with five other authors, use product lifespan. To evaluate it, these authors, along with five other researchers, recommend measuring product lifespan. Refs. [65,67] add that the circular economy strengthens product durability, suggesting a second indicator: the level of product reuse. A small group of researchers suggests measuring indicators related to smart product design. Refs. [48,69] use the percentage of eco-design in product launch to measure improvements in a company’s environmental management.

Regarding machinery, refs. [34,36] suggest assessing the percentage of retrofitting as indicators to measure machinery durability, while refs. [33,55] recommend measuring the repair rate of broken items to estimate the level of predictive maintenance.

In this section, all indicators found in the literature for measuring environmental performance are presented. Some authors mention indicators measuring direct impact, such as the carbon footprint, while others mention indicators for assessing durability within companies. This literature review highlights relevant indicators for measuring environmental performance in an SMME.

In summary, the literature review reveals all prevailing thoughts regarding performance indicators in the context of SMME DT. These indicators fall into three categories. Economically, indicators such as classic financial indicators, continuous improvement indicators, and competitive advantage indicators form the foundation for evaluating a company’s benefits. These indicators are crucial for assessing operational efficiency and financial health—key elements for company longevity. Classic financial indicators provide a clear view of the company’s financial health. By measuring economic performance, an SMME can more easily make informed investment decisions. Continuous improvement allows an SMME to track the efficiency and effectiveness of its operational processes. By identifying areas needing improvement, the company can optimise operations, reduce costs, and enhance product or service quality. Measuring competitive advantage helps an SMME to position itself strategically in the market. This may include aspects such as technology, innovation, customer service quality, or speed to market.

Increasingly prominent in studies, the social dimension is divided into three indicator categories: health and safety, firm’s appreciation, and societal impact of the company. These indicators cover varied aspects, from employee well-being to satisfaction levels to the company’s impact on the community. They reflect a growing awareness of the importance of human capital and corporate social responsibility. Measuring health and safety is essential for ensuring a safe and healthy work environment. This reduces accident risks, enhances employee satisfaction, and may also lower costs related to absenteeism and insurance. Measuring worker appreciation helps determine whether staff are satisfied and engaged, which often also affects productivity and worker retention. By measuring and improving worker appreciation, an SMME can reduce turnover, attract better talent, and improve its employer branding. Societal impact reflects a company’s contribution to society. By measuring this impact, an SMME can enhance its corporate social responsibility, improve its reputation, and create added value for the community.

Finally, the environmental dimension, analysed through indicators measuring resource usage, environmental impact, and durability, highlights companies’ commitment to environmental preservation. This dimension is especially relevant in today’s context of climate change and awareness of ecological issues. By measuring resource usage, an SMME can optimise resource use, reduce waste, and lower costs. In a context where sustainability is increasingly valued, measuring environmental impact is crucial. This helps SMMEs comply with regulations, reduce their ecological footprint, and meet consumer and stakeholder expectations for environmental responsibility. By focusing on product durability, an SMME can not only reduce its environmental impact but also meet the growing consumer demand for sustainable products, thereby opening new market opportunities.

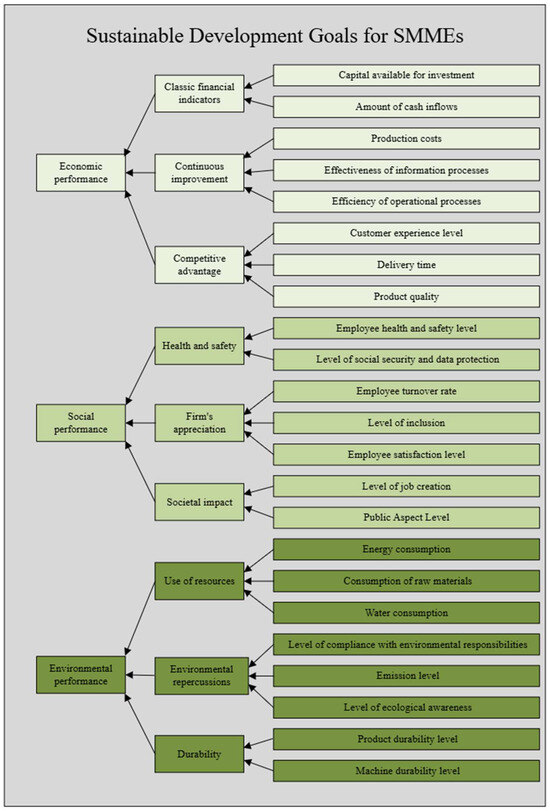

Figure 4 provides an overview of these various dimensions, highlighting the diversity and relevance of indicators in the context of SMME DT. Indeed, this figure summarises the indicators mentioned in each section, representing the indicators a company should measure to understand its sustainable performance level within a DT context. It is based on Table S1, which represents raw results found in the Supplementary Materials. The figure, divided into three sections—economic at the top, social in the centre, and environmental at the bottom—formats the results from Table S1 to be easily integrated into the original conceptual framework. Each section is presented similarly, with the first column identifying each of the three sustainable performance dimensions, the second column showing the main themes for each dimension, and the last column summarising the indicators used for each subcategory. The results of this literature review are discussed in the next section. Before beginning the discussion, it is important to note that these indicators are not independent of each other but interact and reinforce each other.

Figure 4.

Overview of Various Performance Indicators in the Context of DT Found in the Literature Review.

4. Discussion

In this section, the indicators from Figure 4 are combined with the conceptual framework of Figure 2 presented earlier to demonstrate the contribution of the literature review toward achieving the objective. This framework is then analysed to derive insights and conclusions.

4.1. Contribution

Although the ultimate goal is to understand the impact of each dimension of I4.0 on each aspect of sustainable performance, it was first necessary to break down and analyse the model as a whole to fully grasp how each element could be measured and integrated. The objective of the literature review was therefore to identify and group relevant indicators from the literature to bridge the gap between digital maturity measurement and sustainable performance measurement.

The first step toward achieving this objective was confirming the hypothesis. Indeed, the indicators found in Figure 4 support that it was possible to identify and reorganise sustainable performance indicators within the context of DT in the literature to establish a list of key factors. The second step in achieving the objective was consolidating the results from the previous figure with the conceptual framework presented in the methodology by adding the identified indicator categories. As in Figure 2, the left side of the conceptual framework integrates the model from [26] to help bridge the gap between digital maturity and sustainable performance.

The conceptual framework in Figure 5 presents a proposal to improve traditional digital maturity models by integrating sustainable performance indicators, enabling a better measurement of DT outcomes in SMMEs. Unlike Figure 2, which presents a high-level conceptual model, Figure 5 provides a detailed breakdown of how each sustainability dimension is represented through specific indicators, offering a more practical tool for assessment. This figure’s framework uses the original model from [26] as an example, which, on its own, already enables measurement of independent variables in a DT. However, as with other models, the authors do not measure the direct effect of these variables on the economic, social, and environmental benefits sought by SMMEs, but the proposed approach provides a new way to align digital maturity assessment with sustainability outcomes—a perspective that goes beyond a simple literature review by introducing an integrated framework specifically tailored for SMMEs. The integration of the dependent variables found in this work with the independent variables of existing models allows for a comprehensive view of the relationship between digital maturity dimensions and benefits. This approach will not only enable measurement of digital maturity but also evaluation of its impact on the economic, social, and environmental benefits of sustainable performance. In other words, this new conceptual framework contributes to addressing the gap between digital maturity and sustainable performance while also allowing identification of the impact of each dimension of I4.0 on the benefits sought by companies. However, while this framework provides a structured approach, its effectiveness remains to be empirically validated. Future research should focus on testing its applicability through case studies, surveys, or experimental applications within manufacturing SMMEs. By structuring the relationships between maturity dimensions and sustainable performance indicators, this study lays the groundwork for further refinement and empirical validation in real-world settings.

Figure 5.

Contribution to Achieving the Objective of Establishing the Link Between Maturity Measurement and Sustainable Performance [26].

The results of this article provide a general overview of existing indicators in the literature for measuring sustainable performance. Other authors also attempt to bridge the gap between digital maturity and sustainable performance, demonstrating the relevance and timeliness of the proposed issue. However, most of these authors only offer a specific perspective that does not necessarily include all three dimensions of sustainable performance, or they provide a list of facilitators and barriers related to I4.0 that does not allow for measuring the impact of I4.0 on sustainable performance.

A few authors who come close to this research achieve similar results. For example, ref. [34] proposes a framework highlighting indicators of I4.0 and sustainable development dimensions. Their results show that the combined adoption of a circular economy and I4.0 has a positive effect on a company’s social performance. Indeed, one of the differences between the conceptual framework of [34] and that presented in this article is that the authors use a combination of the circular economy and I4.0 as variables affecting the sustainable development of SMMEs. These two approaches are very similar, but the conceptual framework in Figure 5 suggests that it is not necessary to combine the circular economy with I4.0 to measure its benefits on a company’s sustainable performance. One additional contribution of the framework presented in this article is the thoroughness of the measured subcategories. For example, ref. [34] does not consider durability in the measurement of the environmental performance of surveyed companies. This is, in fact, the most recurrent difference across the literature. Similarly, ref. [33] also does not use product durability to measure environmental gains. Furthermore, the model presented by [33] uses I4.0 facilitators and barriers in relation to sustainable development to quantify an institution’s financial gains. Finally, ref. [70] proposes a model very similar to the conceptual framework proposed in this paper, specifically a model measuring the impact of I4.0 technologies on sustainable performance within the supply chain. The two articles are aligned in the same direction, but the contribution of [70] is more specific. Additionally, one aspect aligning the findings of this article with those of others is that the authors do not break down the measurement of each category. They directly use economic, social, and environmental performance as indicators; however, this type of measurement is highly subjective and may lead to biases among responding companies.

While this contribution provides a significant and unique advancement, it also raises several discussion points and considerations that must be addressed. These aspects deserve in-depth exploration to identify the inherent limitations of this research and highlight opportunities for future improvements.

The following sections outline key limitations of this study, including the specificities of SMMEs, the selection process for articles and databases, the choice of the digital maturity model, the lack of empirical validation of the conceptual framework, the weighting of performance indicators, and the need for further empirical research. These discussions provide a comprehensive perspective on the study’s scope and open avenues for future research on digital transformation and sustainable performance in SMMEs.

4.2. The Reality of SMMEs

First, it is important to consider the scope of the study; by integrating the model from [26] with the literature review results, the presented conceptual framework is particularly relevant for the geographical region of Quebec. It could be generalised to contexts like Quebec, in regions where the government is highly involved and active in economic aid and development. Also, regarding scope, it should be noted that the study focuses exclusively on SMMEs. Indicator research was directed toward SMMEs due to their distinctive characteristics, which set them apart from large companies, such as their constraints in financial and human resources and their limited capacity to invest in advanced technologies. However, this does not preclude adapting the conceptual framework to other regions or types of businesses.

Additionally, each SMME may interpret the resulting conceptual framework differently. Indeed, while overall objectives may be quite similar, specific interests in sustainable performance may vary from one SMME to another, depending on their size, available resources, and industry sector. For example, some SMMEs may prioritise economic indicators related to operational efficiency, while others may place greater emphasis on social indicators, such as improving working conditions or engaging with the local community. It may therefore be relevant in future work to group similar SMMEs together based on their characteristics (size, sector, location, resources) to compare them without the bias of differing contexts. This grouping would provide a better understanding of the unique challenges and opportunities for each segment. In summary, partitioning work would enable tailored solutions for each type of business, thereby creating specific and adapted solutions that consider differences in technological integration capacity and sustainability priorities.

4.3. Article Selection

Next, it is also necessary to consider that the selection of articles and indicators could be a limitation. Although a literature strategy was established to justify article selection, a degree of judgement was nonetheless used during this process, based on relevance criteria that, despite their rigour, may reflect unconscious biases or preferences in weighing certain sources over others. Unfortunately, this may affect the reproducibility of the research, which is a limitation. Similarly, the judgement used in interpreting results may include ambiguity and be influenced by the researcher’s prior knowledge, introducing a certain level of subjectivity into the analysis and classification of indicators. As with all research, the temporal context also represents a certain limitation. The rapid evolution of research always brings a risk that the relevance of the article’s findings may be outdated over time, particularly in a constantly evolving field like I4.0, where new technologies and practices quickly emerge and may alter the needs and priorities of SMMEs in terms of DT and sustainability.

4.4. Database Selection and Limitations

One potential limitation of this study is the reliance on a single database, SCOPUS, for the literature review. While SCOPUS provides extensive multidisciplinary coverage and robust citation tracking, it does not encompass all relevant academic sources. Future research could benefit from a cross-validation approach, incorporating other databases such as Web of Science or domain-specific repositories, to ensure a more comprehensive literature selection.

4.5. Selection of the Digital Maturity Model

Another limitation of this study is the exclusive reliance on the Gamache model for assessing digital maturity. While this model was chosen for its relevance to SMMEs and its application within the Quebec industrial context, other frameworks such as the DMM by Carnegie Mellon University and the Acatech Industrie 4.0 Maturity Index offer different perspectives on digital transformation assessment [38]. Future research could explore a comparative analysis of these models to evaluate their effectiveness in integrating sustainable performance dimensions within SMMEs.

4.6. Empirical Validation of the Conceptual Framework

One key limitation of this study is that the proposed conceptual framework has not yet been empirically validated. While the framework is based on an extensive literature review and aligns with existing digital maturity and sustainability models, its applicability in real-world settings remains to be tested. Future research should focus on empirical validation through case studies, surveys, or experimental applications within manufacturing SMMEs to assess its effectiveness in measuring sustainable performance outcomes.

Additionally, while this study focuses on integrating sustainability indicators into digital maturity models, it does not specifically isolate the impact of artificial intelligence (AI) on digital transformation. AI is an integral part of I4.0 and contributes to automation, data-driven decision-making, and process optimisation. However, its distinct influence on sustainable performance within SMMEs was not within the primary scope of this research. Future studies could explore how AI-driven technologies influence sustainability metrics and whether digital maturity models should incorporate AI readiness as a separate dimension.

4.7. Indicator Weighting

Finally, the results present all sustainable performance indicators without specific weighting among them, suggesting that each has an equal impact on a company’s benefits. However, it is documented that the different categories of sustainable performance are often weighted unevenly in the literature. Companies seem to place greater importance on monetary benefits, followed by social benefits, and finally, environmental benefits. This suggests there may be a limitation regarding indicator weighting in this research, which could underestimate the differentiated impact of each category of sustainable performance.

The literature review highlights the varying frequency of sustainable performance indicators across different studies, suggesting that some indicators are more commonly used than others. However, frequency does not necessarily imply greater relevance or impact. While indicators such as financial profitability and energy efficiency appear frequently in research, their actual importance may vary depending on industry context, company size, and strategic priorities.

To further refine the assessment of sustainable performance, future studies should consider methods for weighting indicators based on empirical data rather than solely on frequency in the literature. Approaches such as multi-criteria decision analysis (MCDA) or the analytic hierarchy process (AHP) could help establish a structured ranking of indicators according to their perceived impact by industry experts and practitioners.

While these limitations highlight areas that require further attention in this literature review, they also provide promising avenues for future research on the subject. They invite a deeper exploration of the impact of various sustainable performance dimensions in the context of I4.0. The final section of this research introduces future work related to analysing the obtained results and proposes an approach to overcome these limitations through appropriate indicator weighting.

4.8. Future Work

Building on this research, future work will focus on applying and testing the developed conceptual framework, with a focus on Quebec’s manufacturing companies. The primary objective will be to validate the results by collecting concrete company data to establish precise causal links between I4.0 dimensions and sustainable performance dimensions. To achieve this, a future project will aim to replace the dashed lines in the conceptual framework with causal connections based on empirical data, thus refining the understanding of the impacts of each I4.0 dimension on sustainability objectives.

Thus, the first step will be to collect, through a questionnaire in the manufacturing sector, information on the indicators identified in Figure 5. This questionnaire will aim to measure the impact of DT on the sustainable development of companies in the region. The objective is to identify not only direct relationships but also potential interactions between I4.0 dimensions and specific sustainable performances, such as economic gains, social advancements, and environmental benefits. In other words, future work will not only test the conceptual framework proposed in this article but will also aim to test new research hypotheses.

The project postulates that the different dimensions of I4.0 have a significant impact on companies’ sustainable performance. To address this first hypothesis, a second hypothesis suggests that using a data partitioning method will allow for grouping companies into different profiles to better analyse impact variations based on each group’s distinctive characteristics. This will help identify the most high-performing companies within each group in terms of sustainable performance and generate specific and tailored recommendations for each company profile.

In summary, future research represents a crucial step in understanding and applying I4.0 in the specific context of Quebec’s SMMEs. These in-depth studies will not only strengthen the current conceptual framework but will also pave the way for exploring emerging concepts, where humanity and sustainability take centre stage.

5. Conclusions

This article has contributed to bridging the gap between digital maturity measurement and sustainable performance in the context of SMME DT. The objectives were achieved through the identification and integration of sustainable performance indicators into the digital maturity model of Gamache. By integrating these indicators, this work allows not only for the measurement of digital maturity but also the evaluation of its impact on the economic, social, and environmental benefits sought by SMMEs, thus addressing the initial issue. This will enable SMMEs to better guide their DT and achieve overall sustainable performance. In addressing this gap, the study specifically sought to answer two key research questions:

First, which indicators from the literature address both digital maturity and sustainable performance, and how do they contribute to a unified measurement framework? This research identified a structured set of economic, social, and environmental indicators that are relevant to both digital maturity and sustainability. These indicators, sourced from the literature, provide a quantifiable basis for assessing the dual impact of digital transformation on operational efficiency and sustainable performance. By integrating them into the digital maturity model, the study creates a unified measurement framework that links I4.0 adoption with broader sustainability objectives. This structured integration ensures that digital transformation efforts are evaluated not only in terms of technological readiness but also in their contributions to long-term economic viability, social responsibility, and environmental impact.