Influence of Slag/Fly Ash as Partial Cement Replacement on Printability and Mechanical Properties of 3D-Printed Concrete

Abstract

1. Introduction

2. Experimental Program

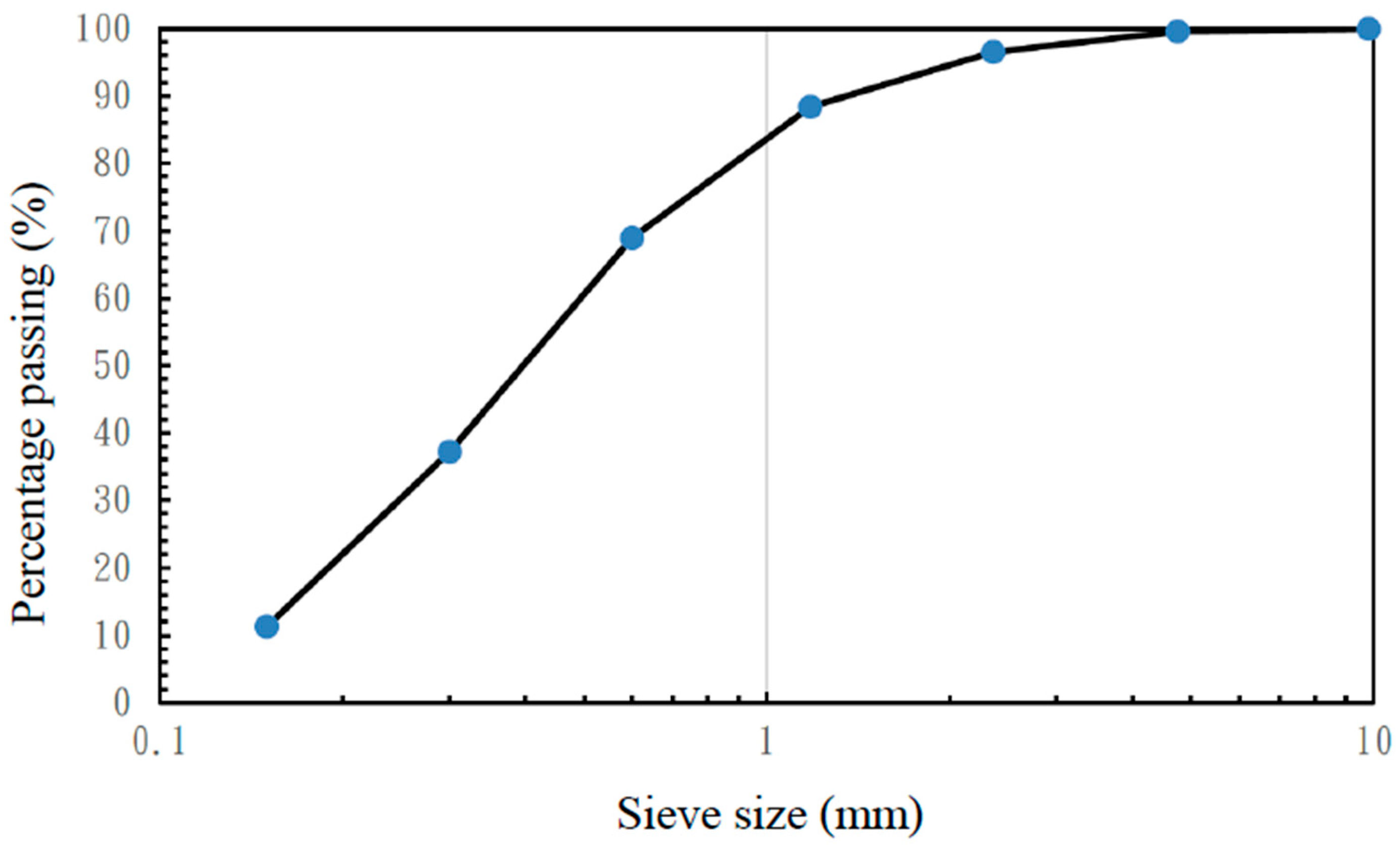

2.1. Materials

2.2. Mix Design and Specimen Preparation

2.3. Test Methods

2.3.1. Slump Flow Test

2.3.2. Slump Test

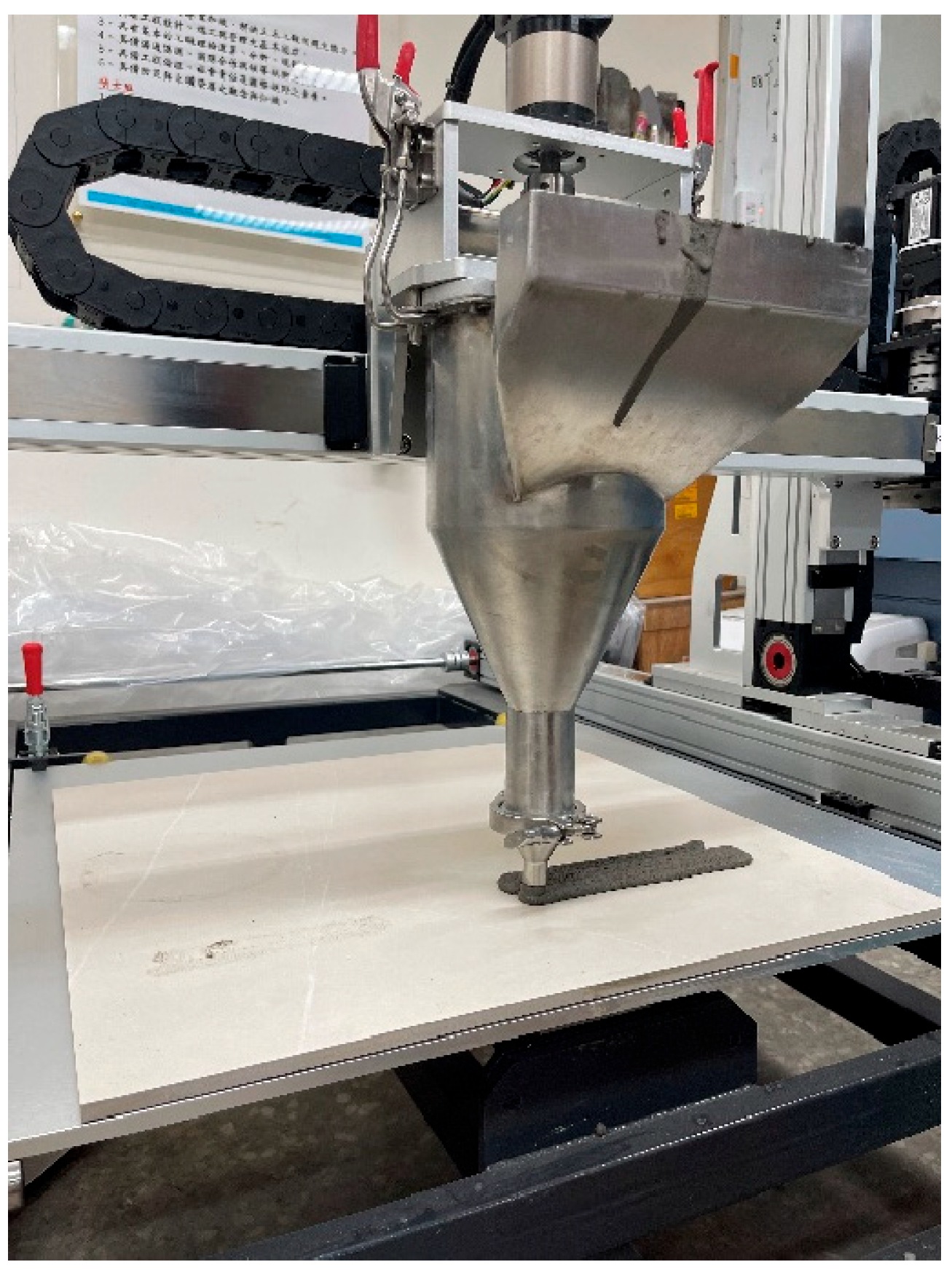

2.3.3. Extrudability Test

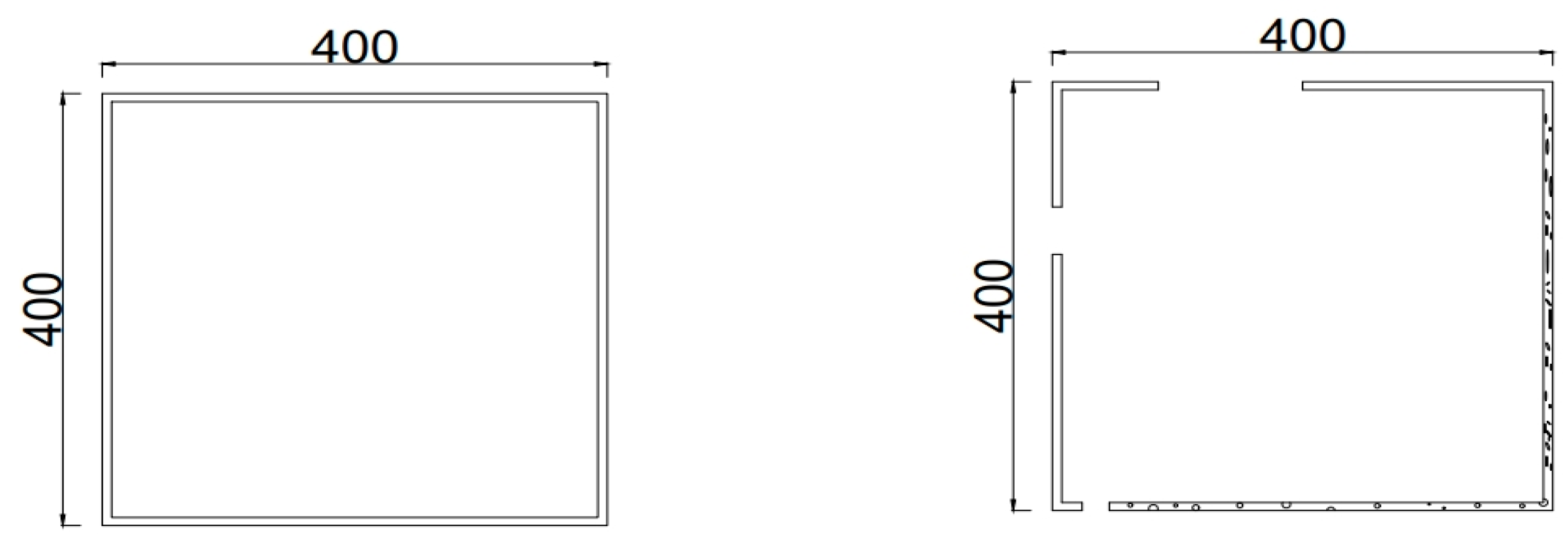

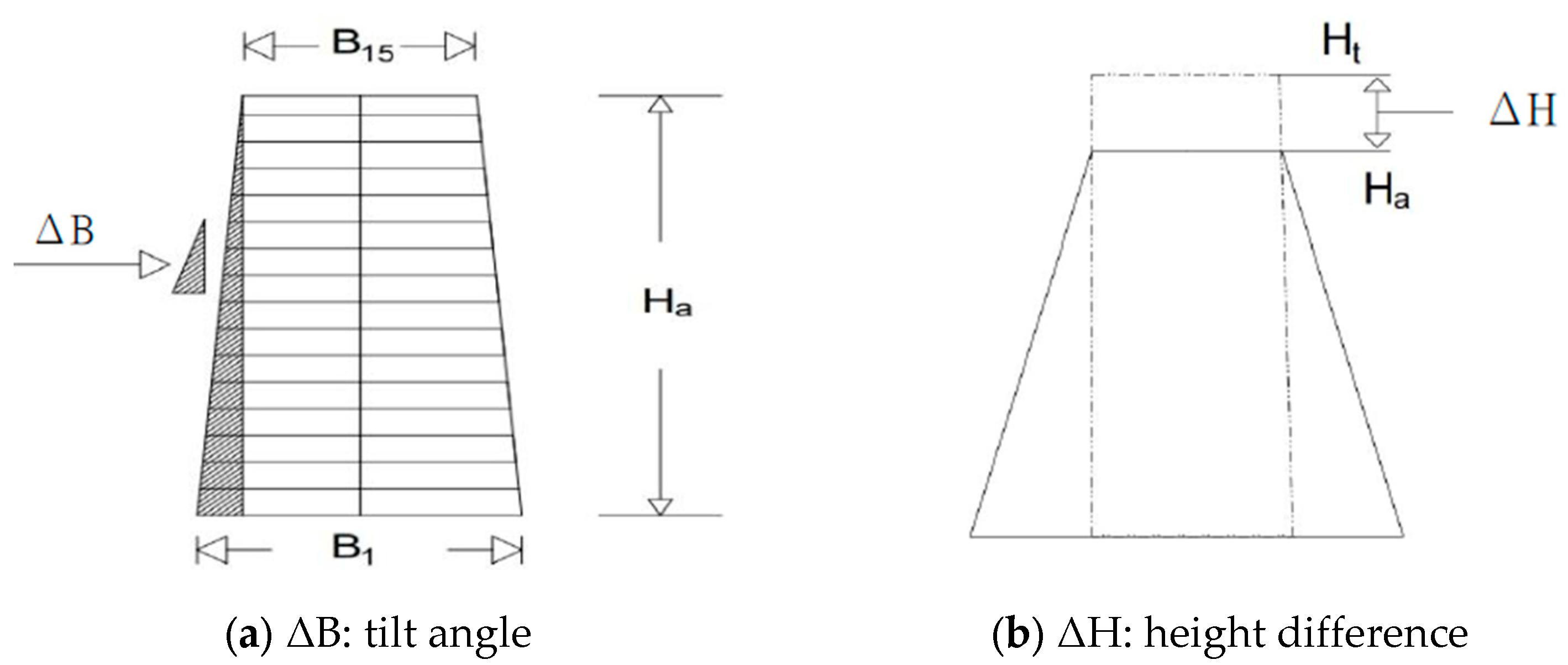

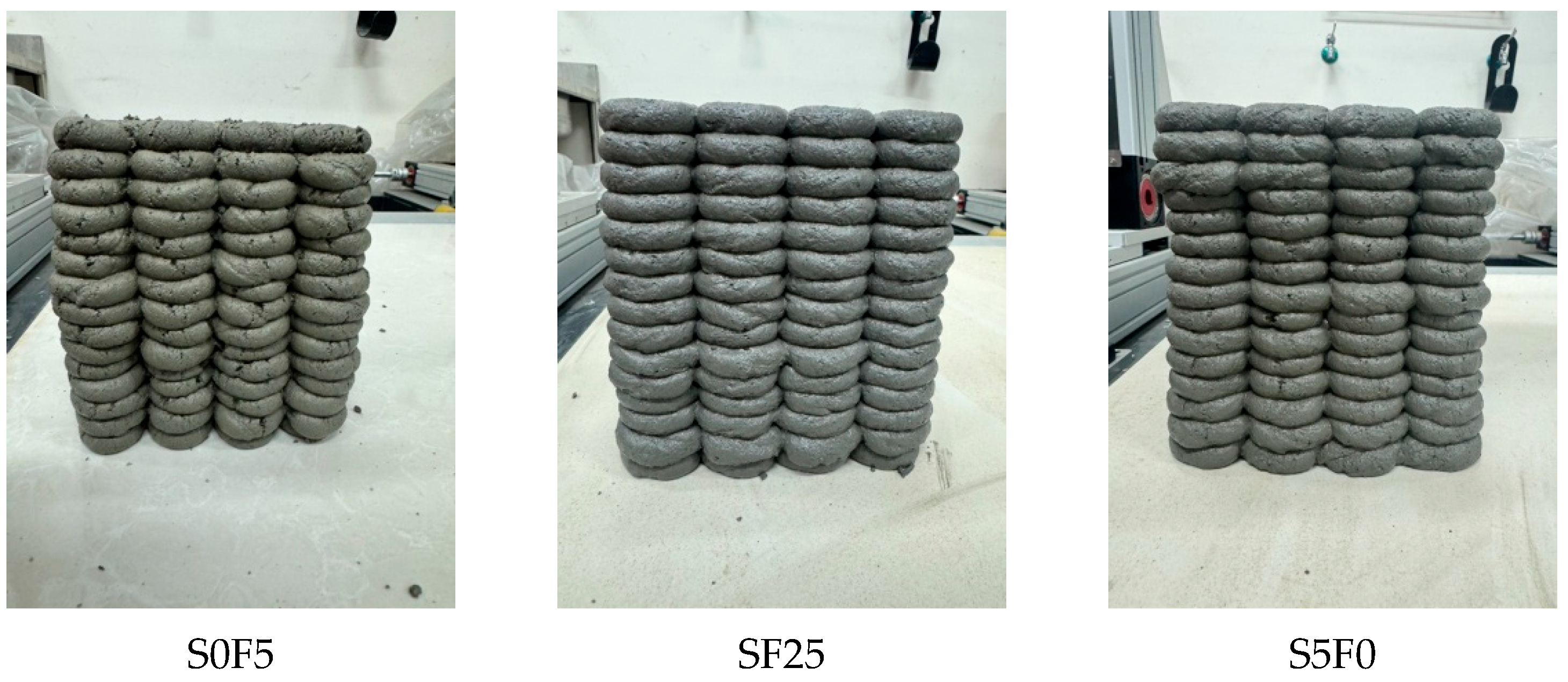

2.3.4. Buildability Test

2.3.5. Unit Weight Test

2.3.6. Compressive Strength Test

2.3.7. Flexural Strength Test

2.3.8. Water Absorption Test

2.3.9. Drying Shrinkage Test

3. Results and Discussion

3.1. Slump Flow

3.2. Slump

3.3. Extrudability

3.4. Buildability

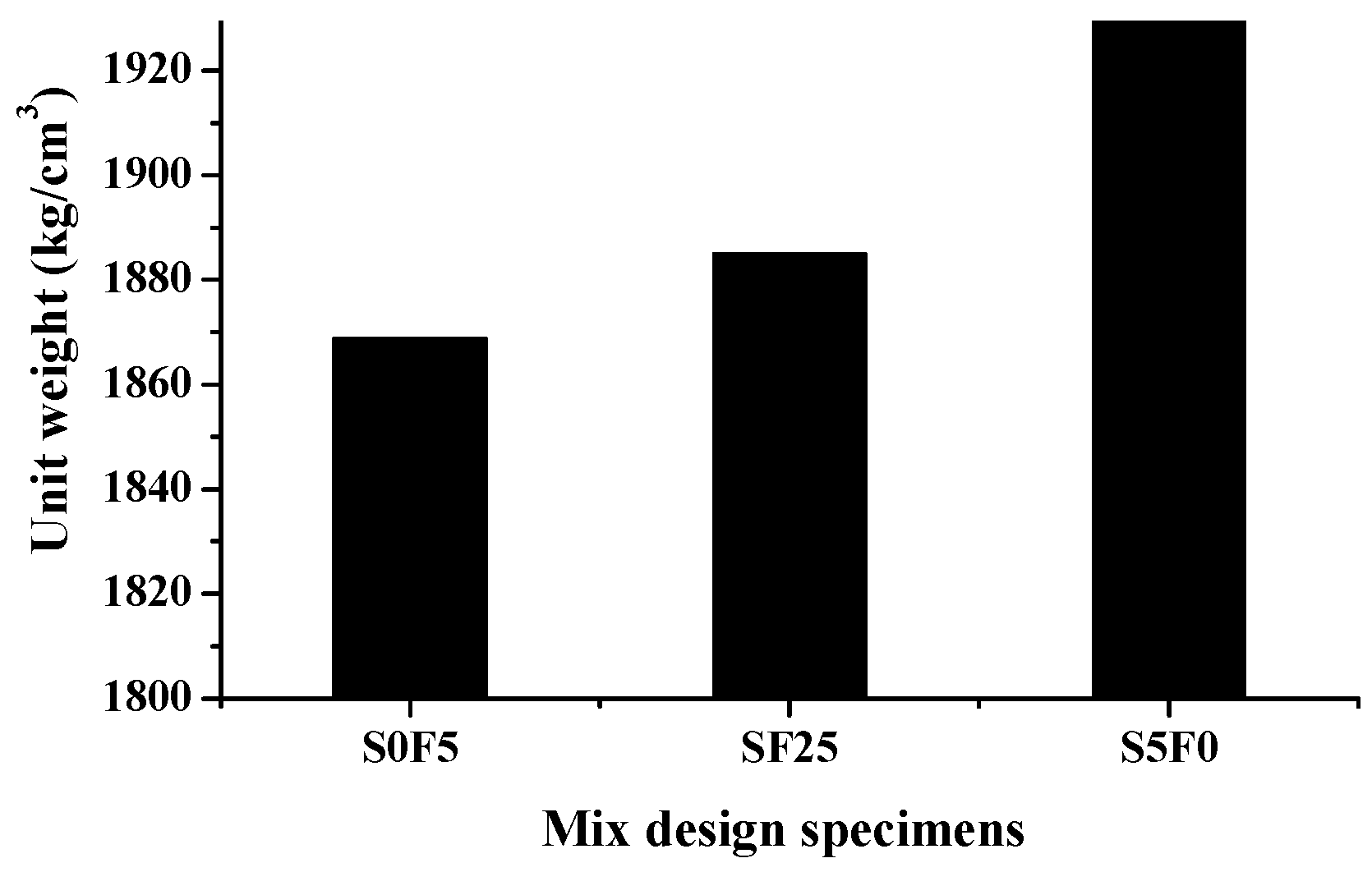

3.5. Unit Weight

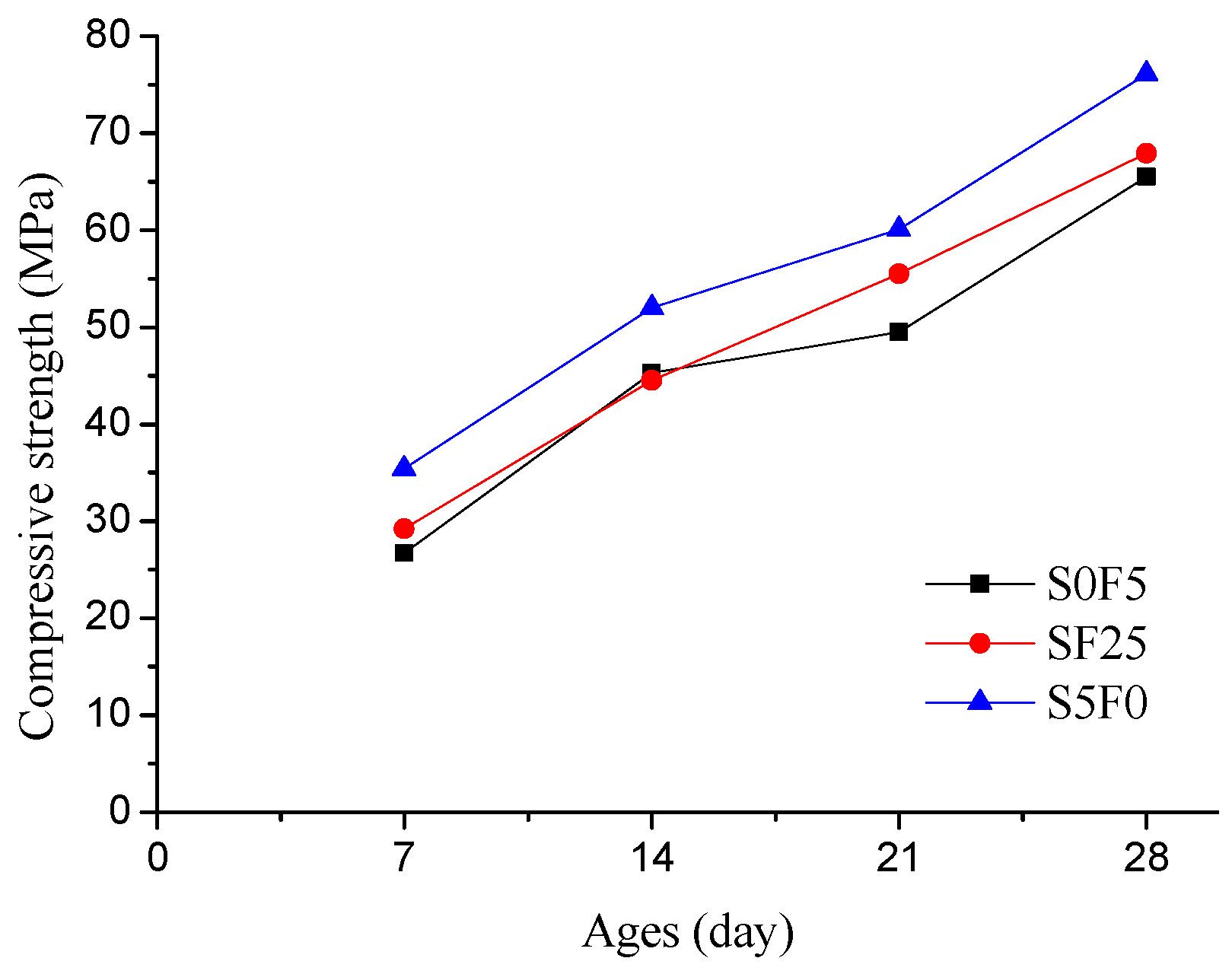

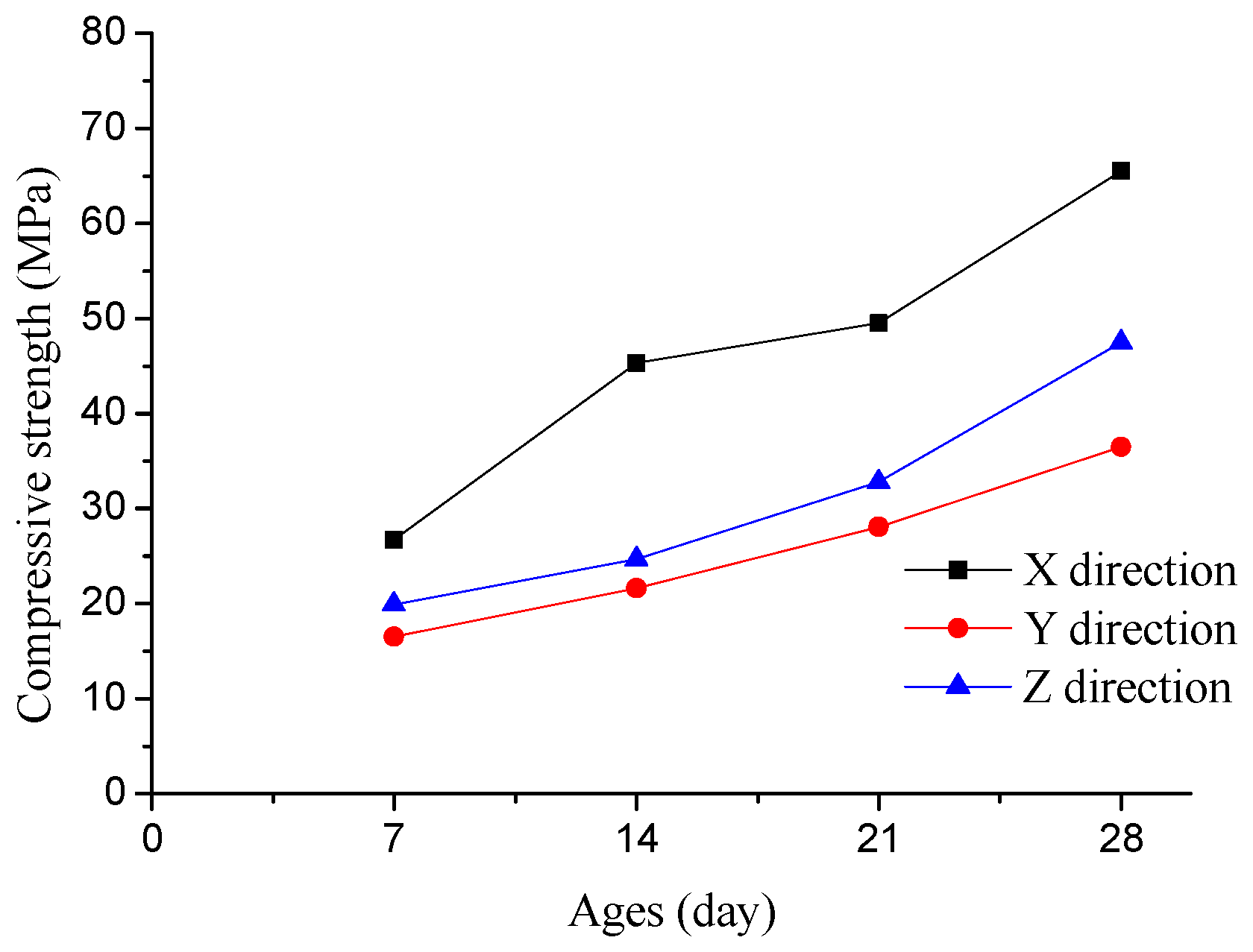

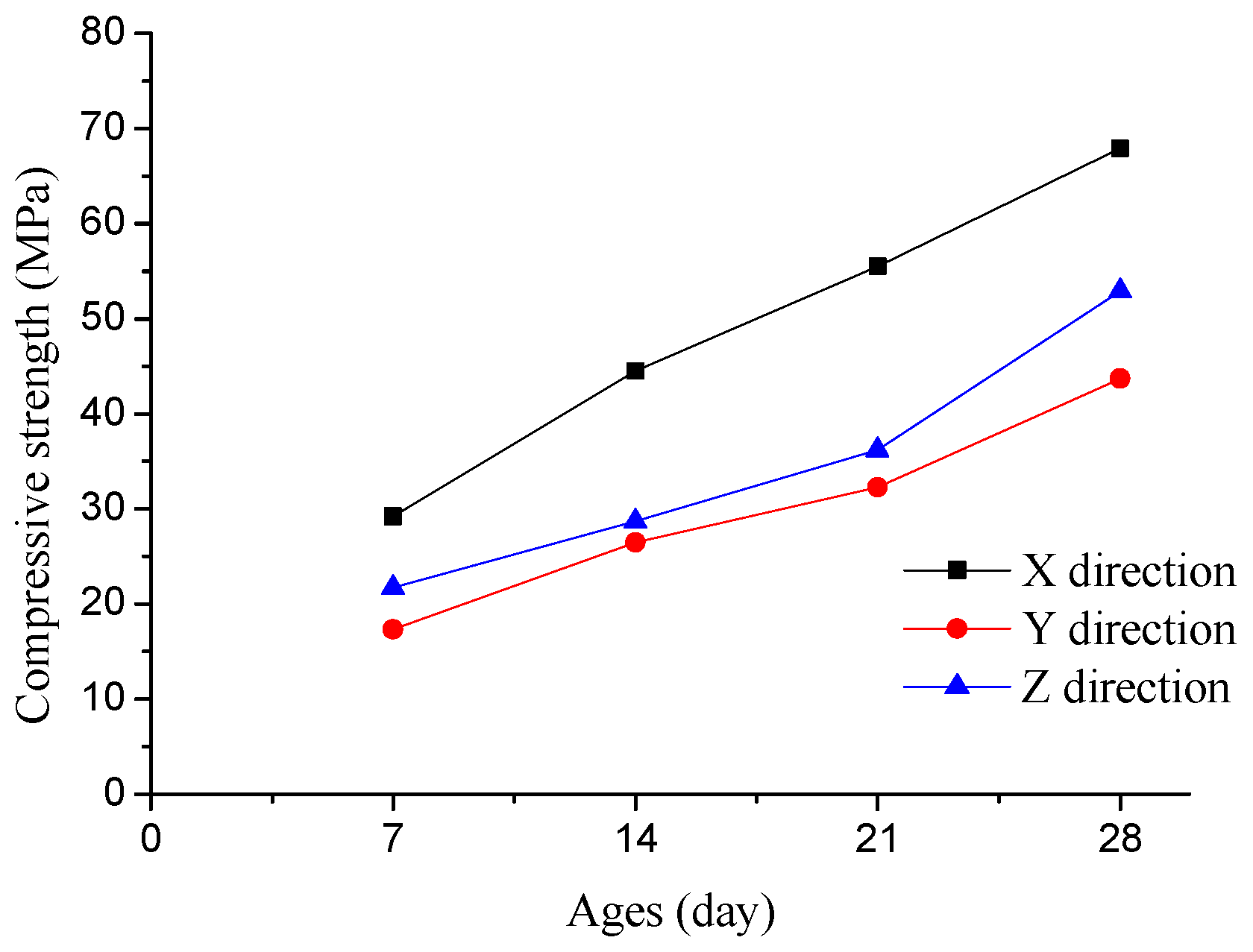

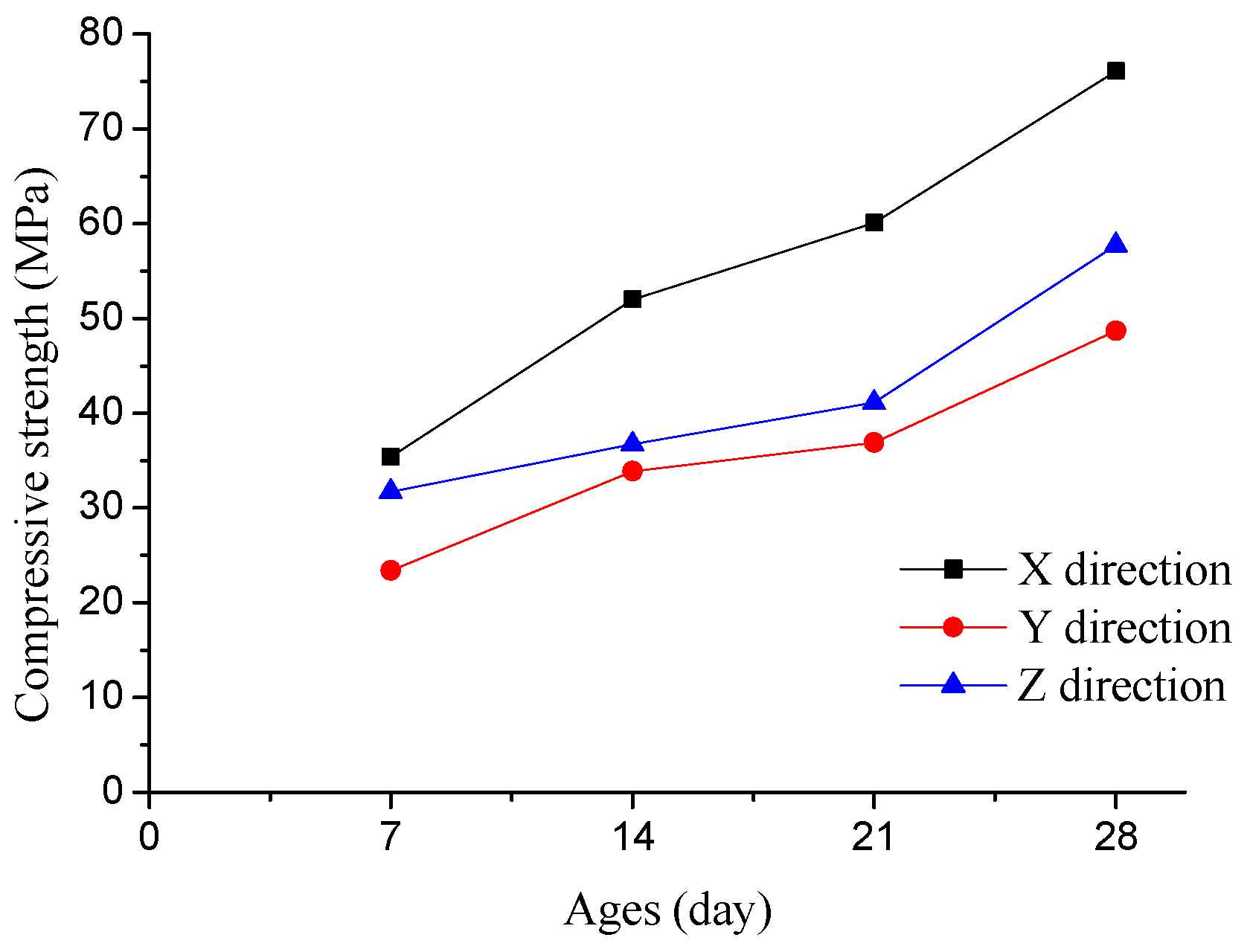

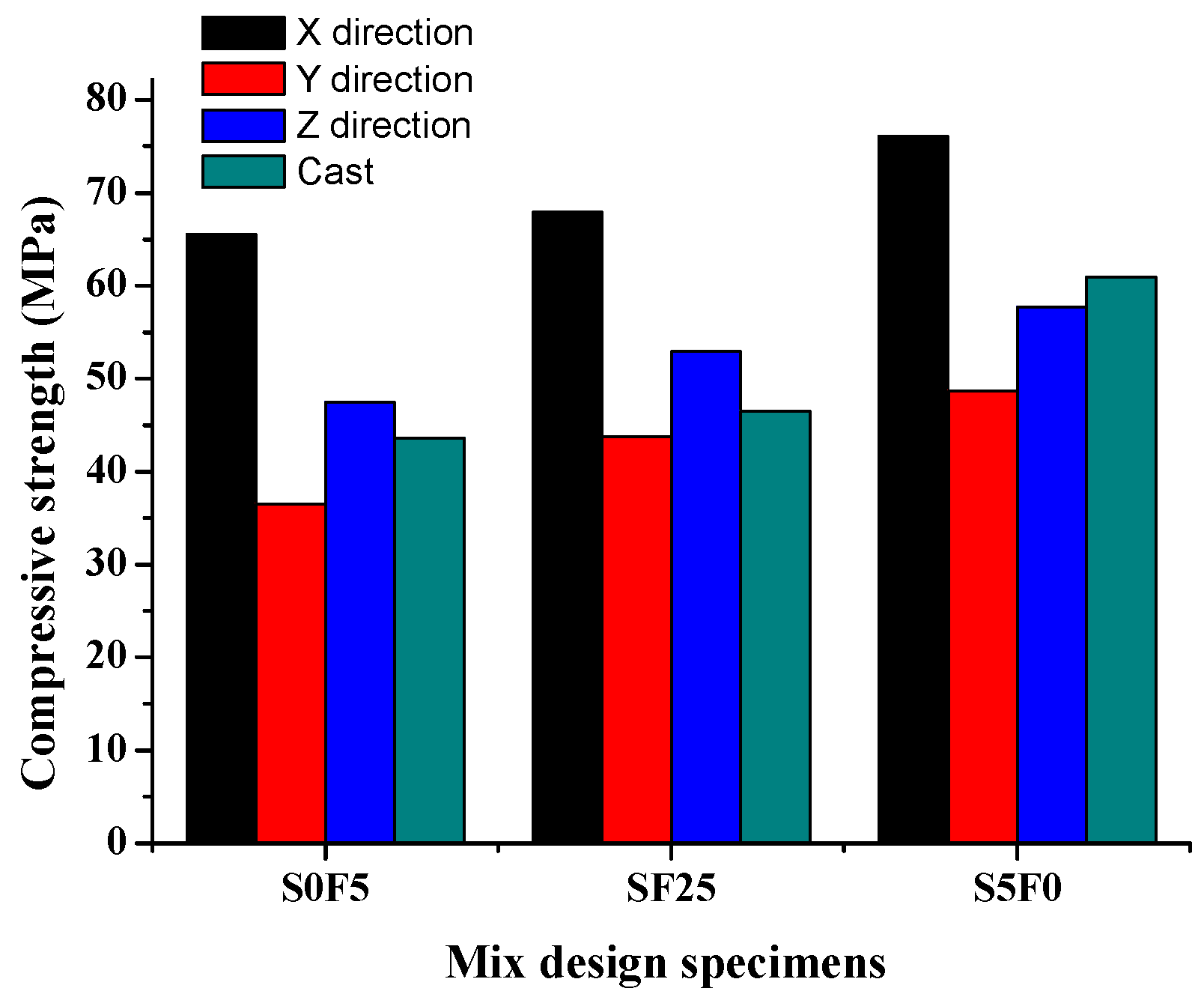

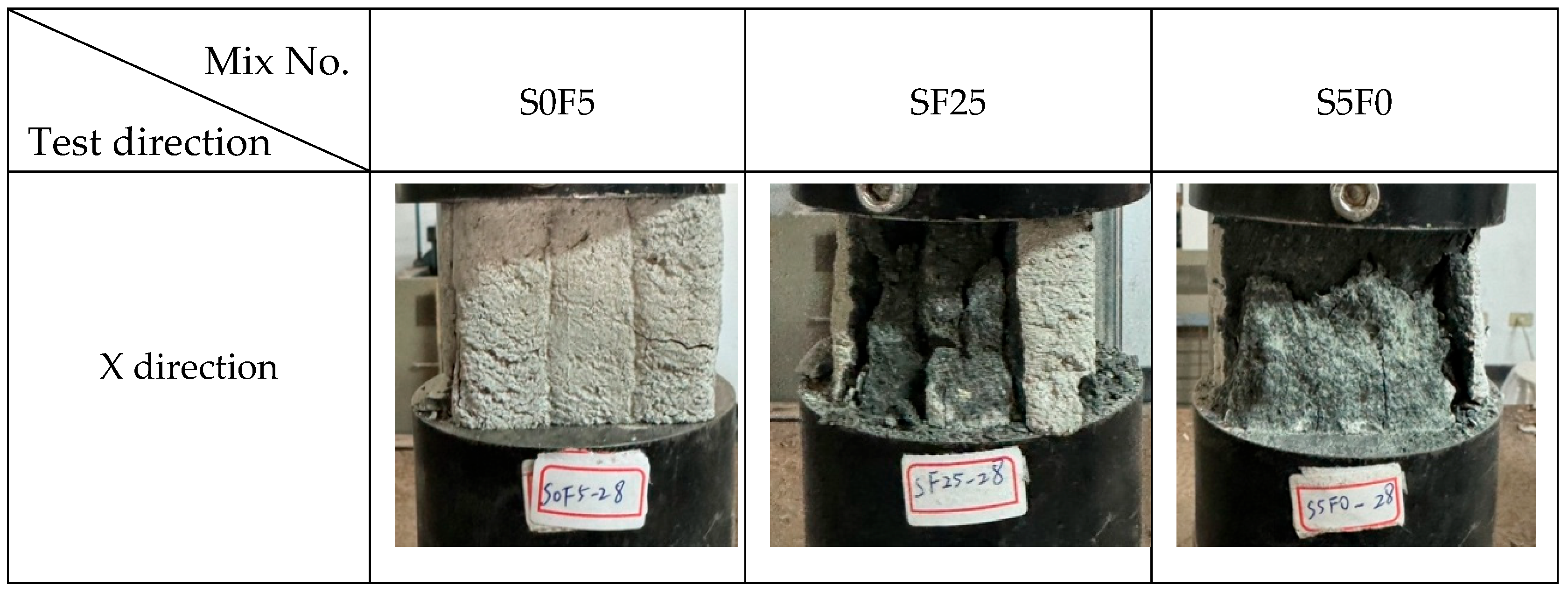

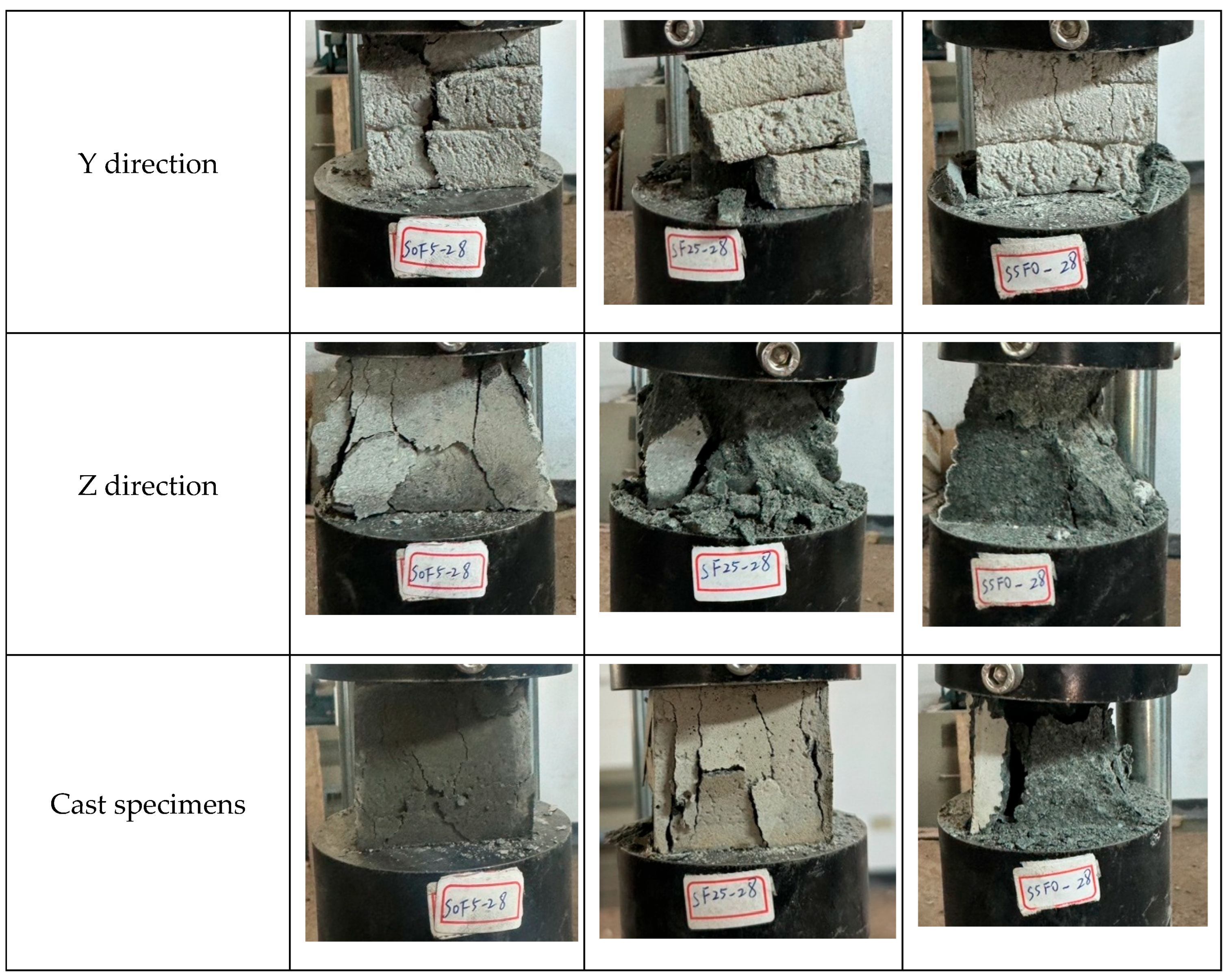

3.6. Compressive Strength

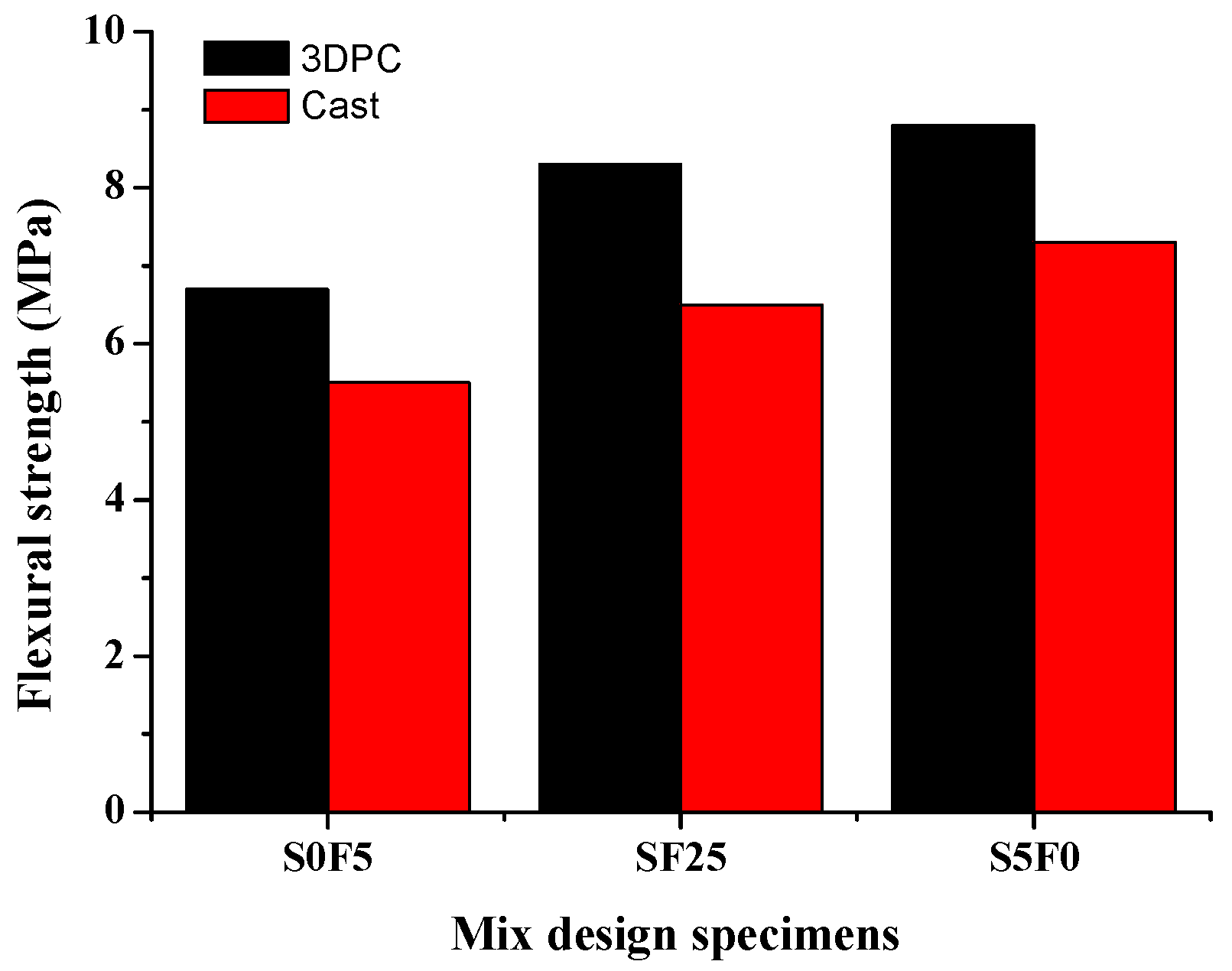

3.7. Flexural Strength

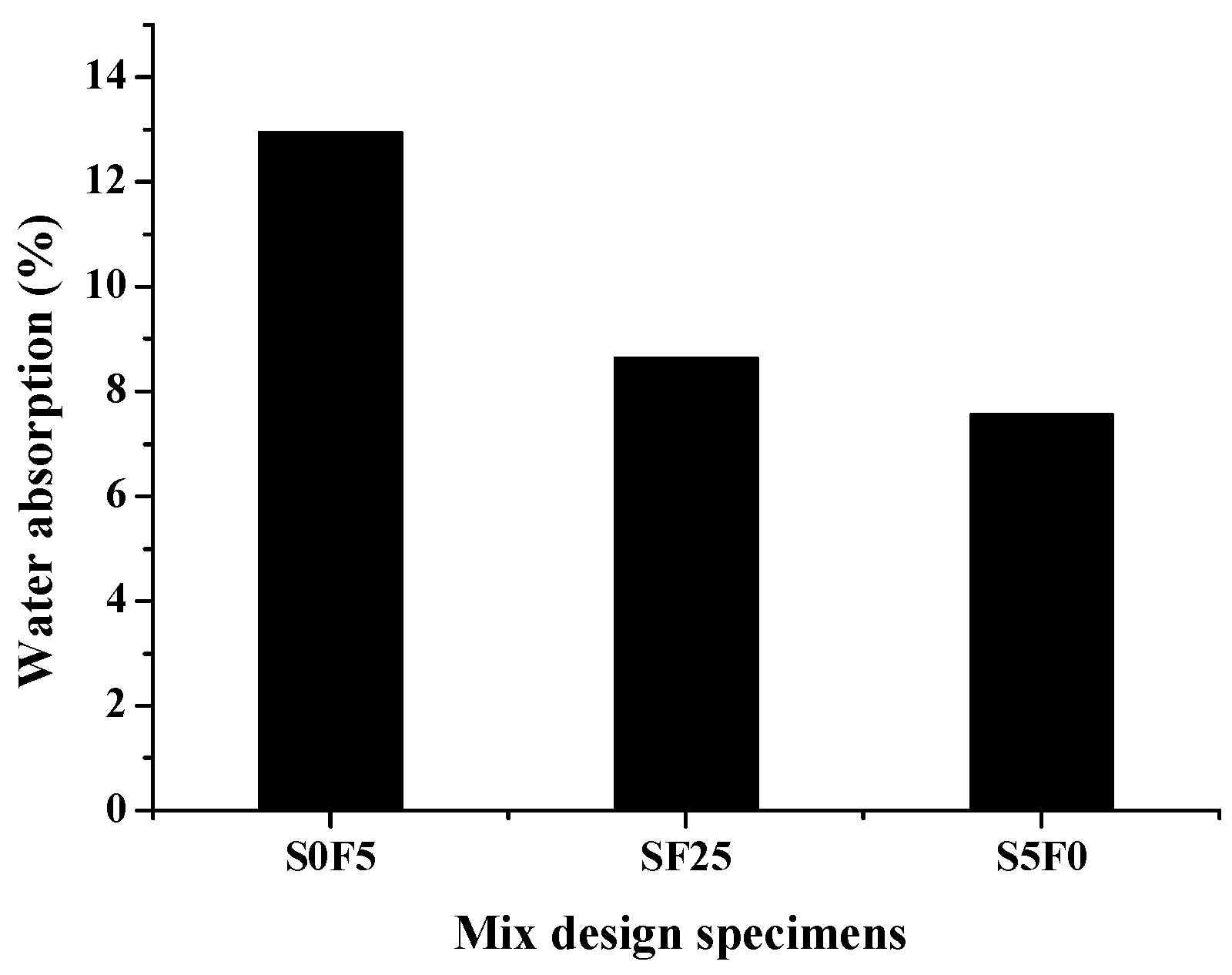

3.8. Water Absorption

3.9. Drying Shrinkage

4. Conclusions

- (1)

- Flowability and printability: The workability values of 3DPC, assessed based on flowability and slump, follow the order S0F5 > S25F25 > S5F0, indicating that higher FA content enhances flowability. Despite these variations, all mix designs demonstrated sufficient extrudability and buildability, meeting the essential printability criteria for 3DPC.

- (2)

- Mechanical and durability performance: The specimens with a higher proportion of GGBFS exhibited superior mechanical properties, including higher unit weight, compressive strength, and flexural strength, while demonstrating lower water absorption and reduced drying shrinkage. This suggests that GGBFS contributes to enhanced material densification and long-term durability in 3DPC.

- (3)

- Anisotropic strength behavior: The compressive strength of 3DPC varied with the printing direction, following the trend X direction > Z direction > Y direction. Notably, the compressive and flexural strength in the X direction exceeded those of the conventionally cast specimens at 28 days, highlighting the structural integrity and potential advantages of the layered deposition process in 3DPC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. 3D concrete printing of eco-friendly geopolymer containing brick waste. Cem. Concr. Compos. 2023, 138, 104943. [Google Scholar]

- Liu, D.; Zhang, Z.; Zhang, X.; Chen, Z. 3D printing concrete structures: State of the art, challenges, and opportunities. Constr. Build. Mater. 2023, 405, 133364. [Google Scholar]

- Ou, Z.; Feng, R.; Li, F.; Liu, G.; Li, N. Development of drying shrinkage model for alkali-activated slag concrete. Constr. Build. Mater. 2022, 323, 126556. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar]

- Ding, T.; Xiao, J.; Qin, F.; Duan, Z. Mechanical behavior of 3D printed mortar with recycled sand at early ages. Constr. Build. Mater. 2020, 248, 118654. [Google Scholar]

- Mohan, M.K.; Rahul, A.V.; Schutter, G.D.; Tittelboom, K.V. Extrusion-based concrete 3D printing from a material perspec-tive: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar]

- Hou, S.; Duan, Z.; Xiao, J.; Ye, J. A review of 3D printed concrete: Performance requirements, testing measurements and mix design. Constr. Build. Mater. 2021, 273, 121745. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Rajeev, P.; Sanjayan, J. Yield stress criteria to assess the buildability of 3D concrete printing. Constr. Build. Mater. 2020, 240, 117989. [Google Scholar] [CrossRef]

- Long, W.-J.; Tao, J.-L.; Lin, C.; Gu, Y.-c.; Mei, L.; Duan, H.-B.; Xing, F. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing. J. Clean. Prod. 2019, 239, 118054. [Google Scholar]

- Chen, M.; Li, L.; Zheng, Y.; Zhao, P.; Lu, L.; Cheng, X. Rheological and mechanical properties of admixtures modified 3D printing sulphoaluminate cementitious materials. Constr. Build. Mater. 2018, 189, 601–611. [Google Scholar]

- Liu, C.; Wang, X.; Chen, Y.; Zhang, C.; Ma, L.; Deng, Z.; Chen, C.; Zhang, Y.; Pan, J.; Banthia, N. Influence of hydroxypropyl methylcellulose and silica fume on stability, rheological properties, and printability of 3D printing foam concrete. Cem. Concr. Compos. 2021, 122, 104158. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Lu, B.; Weng, Y.; Li, M.; Qian, Y.; Leong, K.F.; Tan, M.J. A systematical review of 3D printable cementitious materials. Constr. Build. Mater. 2019, 207, 477–490. [Google Scholar]

- Ribeiro, J.; Silva, J.M.; Morais, A.; Cruz, B.F.P.J.S. 3DCP for Complex Sites: Robotic Fabrication of Custom-Fit Slabs in Irregular Pontoons. Archetecture Intell. 2024, 3, 14. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Van Zijl, G.P.; Paul, S.C.; Tan, M.J. Properties of 3D Printable Concrete. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Singapore, 16–19 May 2016; pp. 421–426. [Google Scholar]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix design concepts for 3D printable concrete: A review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar]

- Mohan, M.K.; Rahul, A.V.; Tittelboom, K.V.; Schutter, G.D. Rheological and pumping behaviour of 3D printable cementitious materials with varying aggregate content. Cem. Concr. Res. 2021, 139, 106258. [Google Scholar]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable development and climate change initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar]

- Xu, Z.; Zhang, D.; Li, H.; Sun, X.; Zhao, K.; Wang, Y. Effect of FA and GGBFS on compressive strength, rheology, and printing properties of cement-based 3D printing material. Constr. Build. Mater. 2022, 339, 127685. [Google Scholar]

- Cui, W.; Shen, L.; Ji, D.; Liu, W.; Wang, T.; Hou, D.; Shen, W.; Shi, X.; Tao, Y. Mechanical performance and permeability of low-carbon printable concrete. J. Sustain. Cem.-Based Mater. 2024, 14, 406–416. [Google Scholar] [CrossRef]

- Quan, H.V.; Khoa, N.T.; Tho, P.C. Combined effects of ground granulated blast furnace slag and fly ash on the porosity and chloride penetration of sand concrete. In Proceedings of the 2020 Applying New Technology in Green Buildings (ATiGB), Da Nang, Vietnam, 12–13 March 2021. [Google Scholar] [CrossRef]

- Fathollah, S.; Razak, H.A. The effect of chemical activators on early strength of ordinary Portland cement-slag mortars. Constr. Build. Mater. 2010, 24, 1944–1951. [Google Scholar]

- Li, G.; Zhao, X. Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar]

- Taqa, A.A.; Mohsen, M.O.; Aburumman, M.O.; Naji, K.; Taha, R.; Senouci, A. Nano-fly ash and clay for 3D-Printing concrete buildings: A fundamental study of rheological, mechanical and microstructural properties. J. Build. Eng. 2024, 92, 109718. [Google Scholar]

- Guo, X.; Yang, J.; Xiong, G. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar]

- Li, D.; Cui, X.; Jang, J.-s.; Wang, G. Sustainable Application of Blast Furnace Slag in the Field of 3D Printing: Material Configuration and Machine Optimization. Sustainability 2024, 16, 4058. [Google Scholar] [CrossRef]

- Yu, Q.; Zhu, B.; Li, X.; Meng, L.; Cai, J.; Zhang, Y.; Pan, J. Investigation of the rheological and mechanical properties of 3D printed eco-friendly concrete with steel slag. J. Build. Eng. 2023, 72, 106621. [Google Scholar]

- Ma, G.; Yan, Y.; Zhang, M.; Sanjayan, J. Effect of steel slag on 3D concrete printing of geopolymer with quaternary binders. Ceram. Int. 2022, 48, 26233–26247. [Google Scholar]

- Samrani, P.; Cao, Y.; Fimbres-Weihs, G.; Sanjaya, E.; Abbas, A. Effect of fly ash and ground waste glass as cement replacement in concrete 3D-Printing for sustainable construction. Front. Built Environ. 2024, 10, 1430174. [Google Scholar] [CrossRef]

- ASTM C150-07; Standard Specification for Portland Cement. American Society for Testing and Materials: West Conshehoken, PA, USA, 2012.

- CNS 1010, R3032; Method of Test for Compressive Strength of Hydraulic Cement Mortars (Using 50 mm or 2 in. Cube Specimens). Chinese National Standards: Taiwan, China, 1993.

- ASTM C 143; Standard Test Method for Slump of Hydraulic-Cement Concrete. American Society for Testing and Materials: West Conshehoken, PA, USA, 2015.

- ASTM C94; Standard Specification for Ready-Mixed Concrete. American Society for Testing and Materials: West Conshehoken, PA, USA, 2023.

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by the Water Displacement Method. American Society for Testing and Materials: West Conshehoken, PA, USA, 2023.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). American Society for Testing and Materials: West Conshehoken, PA, USA, 2016.

- ASTM C78; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). American Society for Testing and Materials: West Conshehoken, PA, USA, 2010.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials: West Conshehoken, PA, USA, 2013.

- ASTM C596; Standard Test Method for Drying Shrinkage of Mortar containing Hydraulic Cement. American Society for Testing and Materials: West Conshehoken, PA, USA, 2009.

- Qian, Y.; Schutter, G.D. Enhancing thixotropy of fresh cement pastes with nanoclay in presence of polycarboxylate ether superplasticizer (PCE). Cem. Concr. Res. 2018, 111, 15–22. [Google Scholar]

- Rushing, T.S.; Al-Chaar, G.; Eick, B.; Burroughs, J.; Shannon, J.; Barna, L.; Case, M. Investigation of concrete mixtures for additive construction. Rapid Prototyp. J. 2017, 23, 74–80. [Google Scholar]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Tan, M.J.; Qian, S.Z.; Leong, K.F.; Chua, C.K. Processing and Properties of Construction Materials for 3D Printing. Mater. Sci. Forum 2016, 861, 177–181. [Google Scholar]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material-An emerging technique for construction. Sci. China Ser. E Technol. Sci. 2017, 61, 475–495. [Google Scholar]

- Sanjayan, J.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and harden properties of the high-thixotropy 3D printing concrete. Constr. Build. Mater. 2019, 201, 278–285. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; Prentice-Hall Inc.: New York, NY, USA, 2013. [Google Scholar]

- Bissonnette, B.; Pierre, P.; Pigeon, M. Influence of key parameters on drying shrinkage of cementitious materials. Cem. Concr. Res. 1999, 29, 1655–1662. [Google Scholar]

| Physical Properties | PC | GGBFS | FA |

|---|---|---|---|

| Specific gravity | 3.15 | 2.90 | 2.08 |

| Specific surface area (m2/kg) | 364 | 520 | 237 |

| Chemical Composition (%) | PC | GGBFS | FA |

|---|---|---|---|

| Calcium oxide, CaO | 63.57 | 40.53 | 2.82 |

| Silicon dioxide, SiO2 | 21.03 | 33.59 | 56.48 |

| Aluminum oxide, Al2O3 | 5.47 | 14.70 | 20.34 |

| Ferric oxide, Fe2O3 | 2.98 | 0.48 | 6.61 |

| Sulfur trioxide, SO3 | 2.01 | 0.61 | 0.25 |

| Sodium oxide, Na2O | 0.32 | --- | 0.33 |

| Potassium oxide, K2O | 0.70 | 0.35 | 0.80 |

| Magnesium oxide, MgO | 2.51 | 7.65 | 0.93 |

| Loss on ignition, L.O.I. | 1.38 | 1.34 | 2.76 |

| Others | 0.03 | 0.75 | 8.68 |

| Physical Properties | Anhydrous Na2SiO3 | PCE |

|---|---|---|

| Appearance | Colorless crystal | Light yellow |

| Density (g/mL) | 2.61 | 1.08~1.12 |

| Solid content (%) | --- | 43.0~45.0 |

| pH | 12.5 | 5.5~7.5 |

| Sieve No. | Mass Retained (kg) | Percentage Retained (%) | Cumulative Percentage Retained (%) |

|---|---|---|---|

| #4 | 0.004 | 0.4 | 0.4 |

| #8 | 0.031 | 3.1 | 3.5 |

| #16 | 0.081 | 8.1 | 11.6 |

| #30 | 0.195 | 19.5 | 31.1 |

| #50 | 0.317 | 31.7 | 62.8 |

| #100 | 0.258 | 25.8 | 88.6 |

| Bottom plate | 0.114 | 11.4 | 100 |

| F.M. | 1.98 | ||

| Mix No. | Water (kg/m3) | Cement (kg/m3) | GGBFS | FA (kg/m3) | Fine Agg. (kg/m3) | Additive (kg/m3) | |

|---|---|---|---|---|---|---|---|

| (kg/m3) | Anhydrous Na2SiO3 | PCE | |||||

| S5F0 | 400 | 500 | 500 | 0 | 1500 | 50 | 5 |

| SF25 | 400 | 500 | 250 | 250 | 1500 | 50 | 5 |

| S0F5 | 400 | 500 | 0 | 500 | 1500 | 50 | 5 |

| Mix No. | Horizontal (cm) | Vertical (cm) | Average (cm) | Flowability (%) | Slump (cm) |

|---|---|---|---|---|---|

| S5F0 | 21.8 | 21.8 | 21.8 | 118 | 5.9 |

| SF25 | 21.5 | 21.3 | 21.4 | 114 | 5.4 |

| S0F5 | 20.6 | 20.4 | 20.5 | 105 | 4.5 |

| Mix No. | ΔH (cm) | Tilt Angle (Degree) |

|---|---|---|

| S5F0 | 0.2 | 1.51 |

| SF25 | 0.1 | 1.33 |

| S0F5 | 0.3 | 1.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseng, K.-C.; Chi, M.; Yeih, W.; Huang, R. Influence of Slag/Fly Ash as Partial Cement Replacement on Printability and Mechanical Properties of 3D-Printed Concrete. Appl. Sci. 2025, 15, 3933. https://doi.org/10.3390/app15073933

Tseng K-C, Chi M, Yeih W, Huang R. Influence of Slag/Fly Ash as Partial Cement Replacement on Printability and Mechanical Properties of 3D-Printed Concrete. Applied Sciences. 2025; 15(7):3933. https://doi.org/10.3390/app15073933

Chicago/Turabian StyleTseng, Kuo-Chang, Maochieh Chi, Weichung Yeih, and Ran Huang. 2025. "Influence of Slag/Fly Ash as Partial Cement Replacement on Printability and Mechanical Properties of 3D-Printed Concrete" Applied Sciences 15, no. 7: 3933. https://doi.org/10.3390/app15073933

APA StyleTseng, K.-C., Chi, M., Yeih, W., & Huang, R. (2025). Influence of Slag/Fly Ash as Partial Cement Replacement on Printability and Mechanical Properties of 3D-Printed Concrete. Applied Sciences, 15(7), 3933. https://doi.org/10.3390/app15073933