Research on the Time-Dependent Behavior of Uplift Piles in Structured Clay Foundations in Zhanjiang Formation

Abstract

1. Introduction

2. Indoor Model Testing

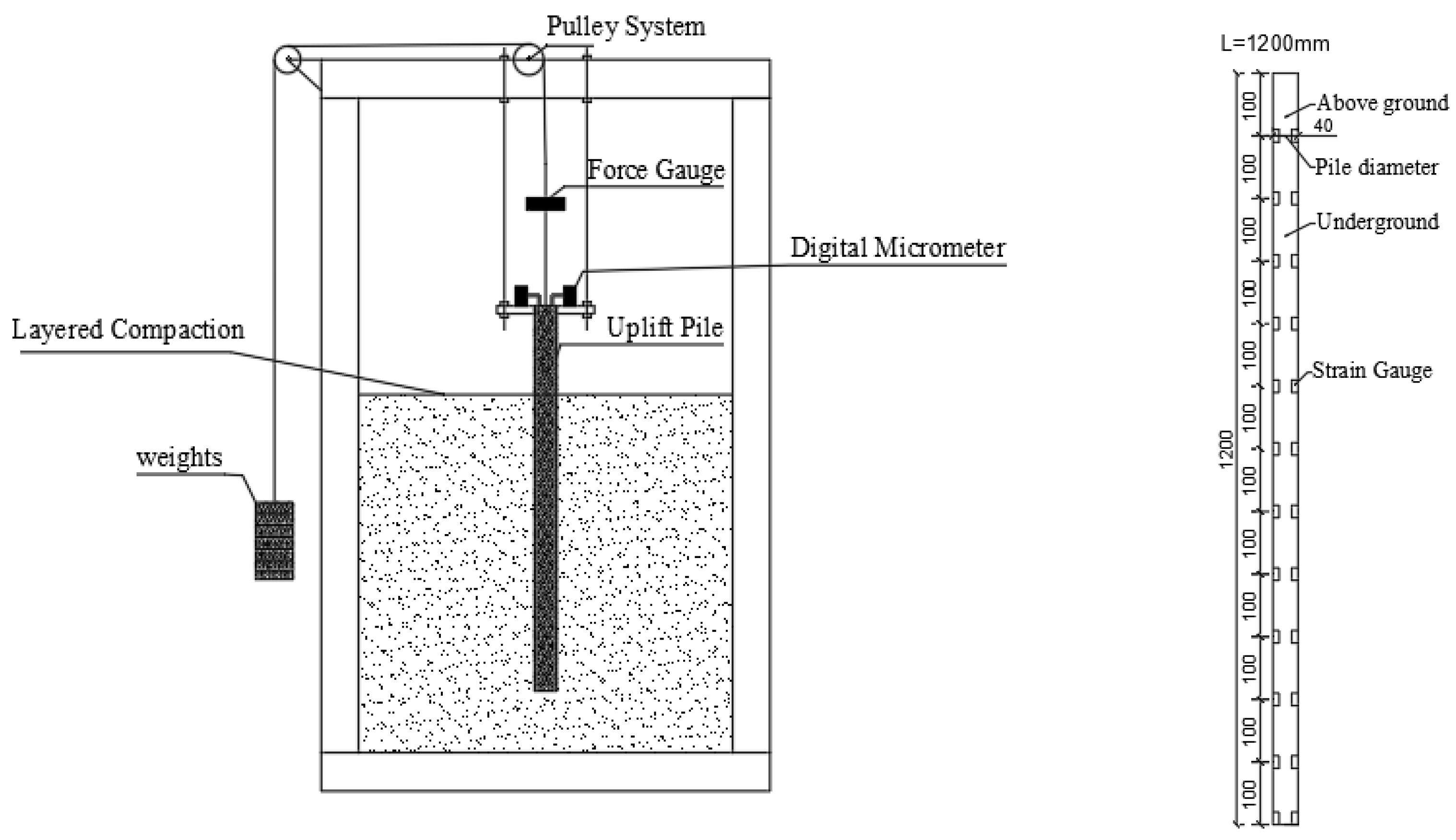

2.1. Model Testing Apparatus

2.1.1. Model Box

2.1.2. Model Pile

2.1.3. Loading Device

2.1.4. Measurement System

2.2. Soil Surrounding the Pile

2.3. Experimental Design

3. Analysis of Test Results

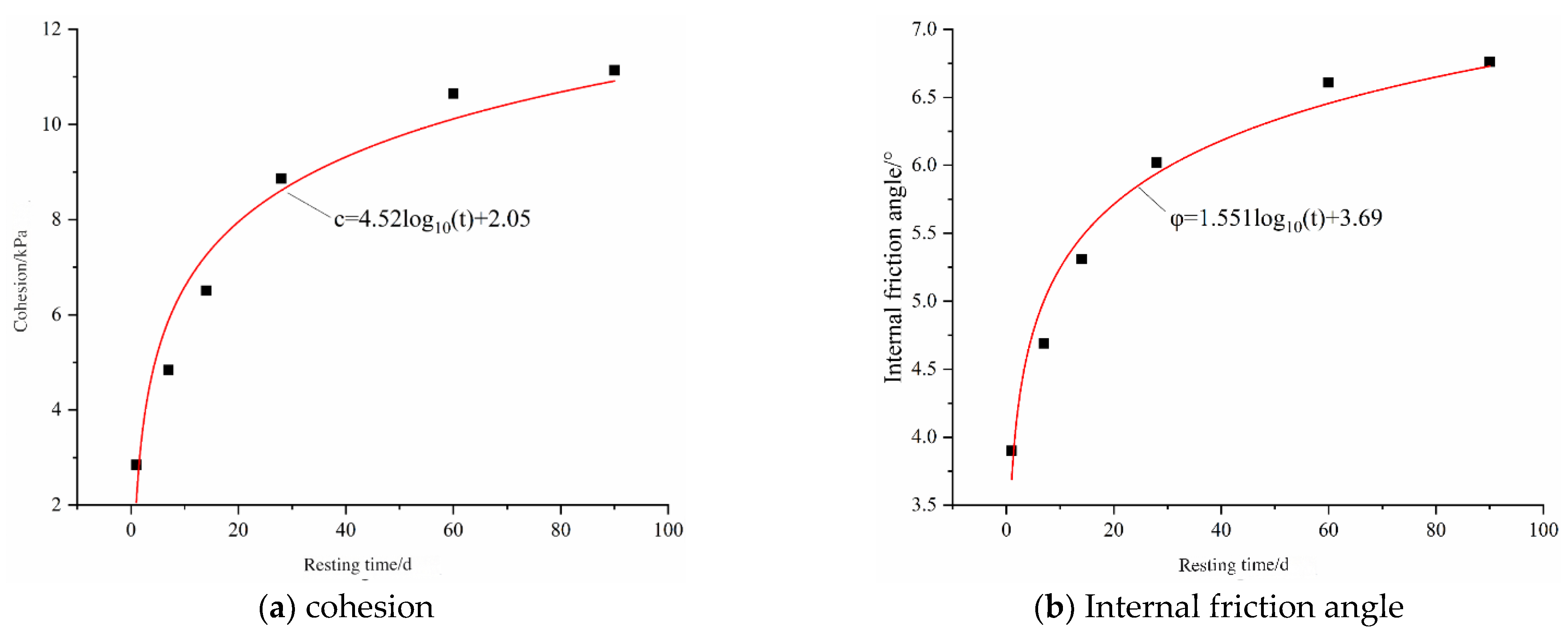

3.1. Thixotropy of Soil Surrounding the Pile

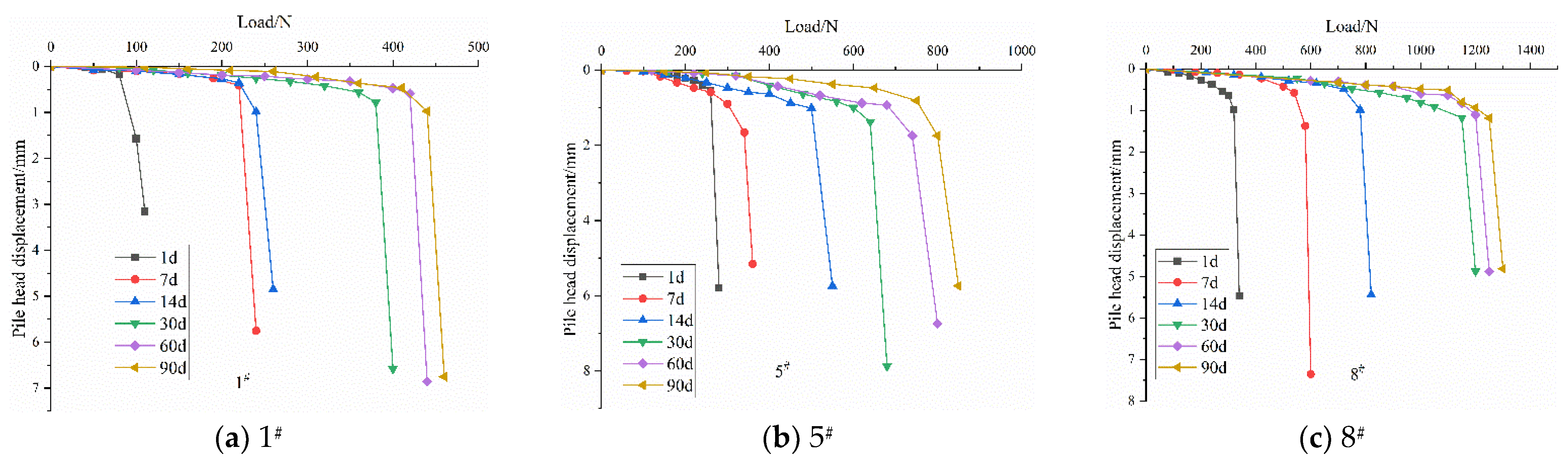

3.2. The Time-Dependent Behavior of the Uplift Pile Bearing Capacity

- (1)

- The U~s curves for each single pile exhibit a sharp decline and have distinct inflection points. When the pile length and diameter are the same, as the resting time increases, the pullout load and the top displacement of the model piles in the ultimate pullout state both increase. This can be attributed to the restoration of the surrounding soil strength with increasing resting time, which enhances the cooperative working ability of the pile–soil system. Consequently, the model piles have a greater pullout strength reserve, leading to improved pullout capacity and increased top displacement.

- (2)

- A comparative analysis of 5# (L = 900 mm, D = 25 mm) and 8# (L = 900mm, D = 40 mm) was conducted on the displacement corresponding to the failure load at different rest periods. It was found that when the pile length is 900 mm, as the pile diameter increases from 25 mm to 40 mm, the displacement at the pile head corresponding to the ultimate state of the model pile becomes smaller. The reason for this is that an increase in pile diameter improves the load transfer mechanism, making the load transfer more efficient. A larger pile diameter can better mobilize the shear intension of the soil and leads to a more reasonable stress distribution along the pile shaft, thereby reducing the upward displacement of the pile shaft.

- (3)

- Under the same resting times, for small-diameter short piles 1# (L = 600 mm, D = 20 mm), the load–displacement curve is steep, with a small ultimate displacement, and failure is primarily governed by slip failure at the pile–soil interface, while the effect of embedment time is limited. This analysis suggests that for small-diameter short piles, due to the small length-to-diameter ratio, the distribution of lateral friction resistance is relatively narrow and the recovery space of the soil is limited. As a result, the time effect on the recovery of the soil structure strength is offset by the rapid failure, leading to a weak time effect on the bearing capacity of the pile foundation. Therefore, short-term bearing capacity data should be used for design. For large-diameter long piles 8# (L = 900 mm, D = 40 mm), the load–displacement curve is more gradual and the time effect on the recovery of the bearing capacity is more pronounced. The analysis indicates that for large-diameter long piles, the larger lateral friction area allows for a greater participation of soil in the load-bearing effect, leading to the better long-term performance of large-diameter long piles.

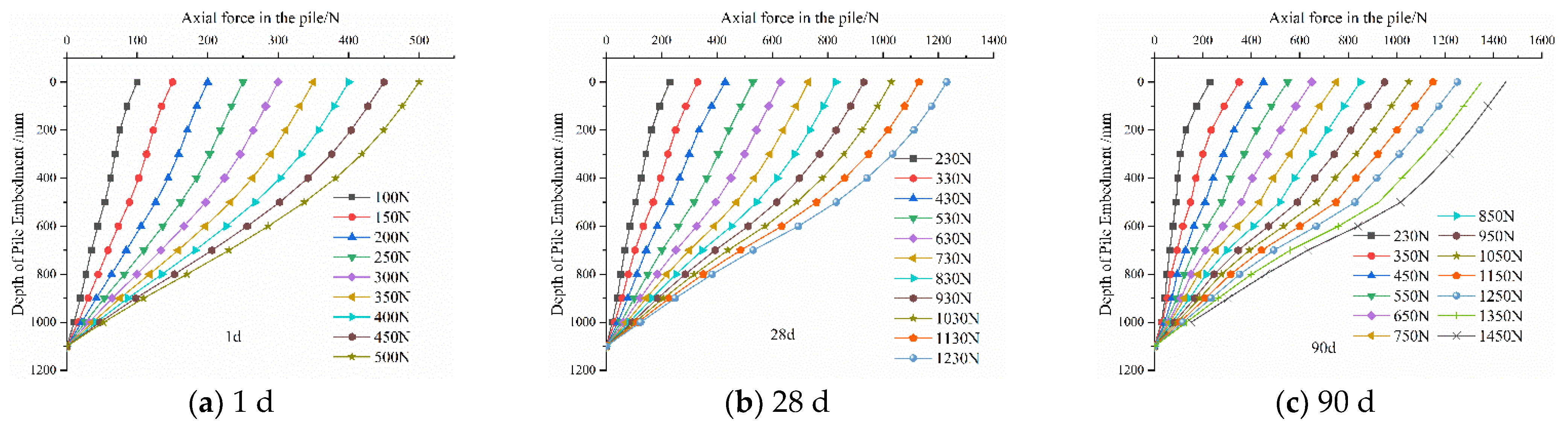

3.3. Analysis of Axial Forces in Piles

3.4. Analysis of Side Friction Resistance of Piles

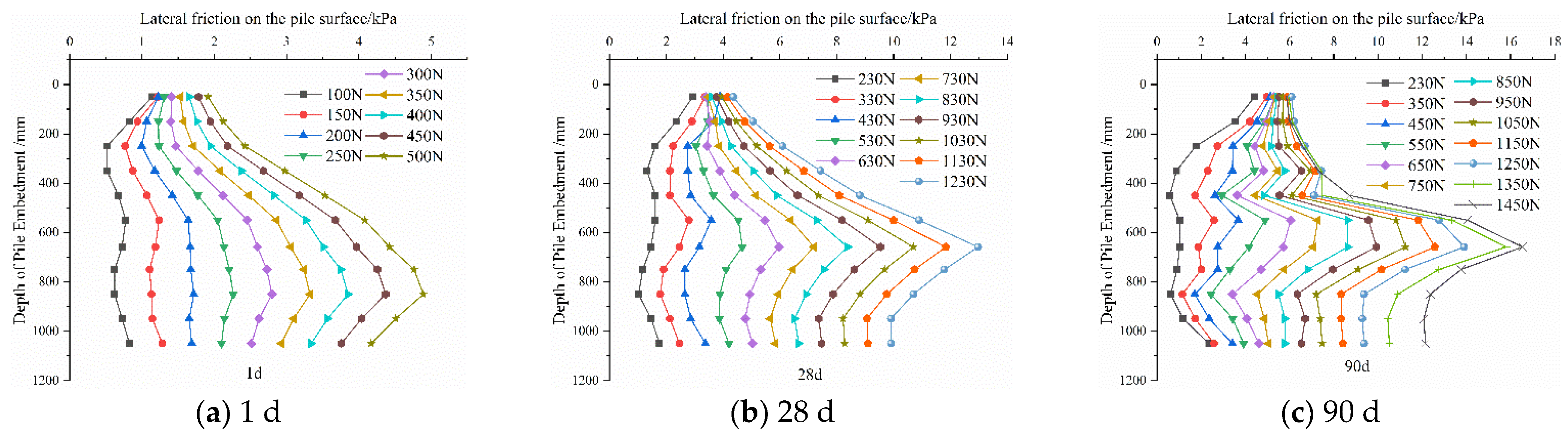

- (1)

- After different rest periods, the side friction resistance of the pile is primarily concentrated in the lower section of the pile body, while the side friction resistance at the pile top and pile toe is relatively small. The ultimate side friction resistance of the pile occurs in the lower segment of the single pile, indicating that the distribution of side friction resistance is related to the position of the pile body.

- (2)

- The development of the side friction resistance is asynchronous; with the increase in load, the side friction resistance in the upper soil layers activates before that in the lower layers. The load at the pile top is gradually transmitted downward, and with an increase in the rest period, there is a significant growth in the ultimate side friction resistance of the pile. Throughout the entire testing period, the ultimate side friction resistance of the pile increased from 4.89 kPa to 16.54 kPa, representing an increase of 238.2%, demonstrating a significant time effect.

- (3)

- As the resting time increases, the lateral friction resistance at the upper part of the pile does not show a significant increase due to the recovery of the surrounding soil strength. The analysis suggests that with an increase in rest time, the recovery of the surrounding soil strength leads to an increase in lateral friction resistance and the uplift bearing capacity of the pile. However, as the uplift bearing capacity increases, the Poisson effect in the pile becomes more pronounced and the reduction in lateral friction resistance due to the loosening of the pile–soil contact offsets the contribution of the recovery of the surrounding soil’s thixotropic properties. Therefore, if the uplift structure has strict requirements for its own displacement, the elastic modulus of the pile should be increased to reduce the elongation deformation caused by tensile forces.

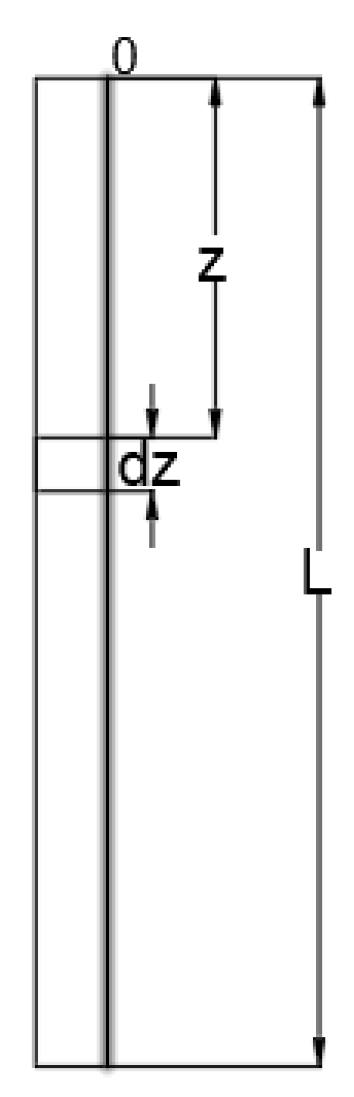

4. Prediction Model for Time-Dependent Capacity of Uplift Piles

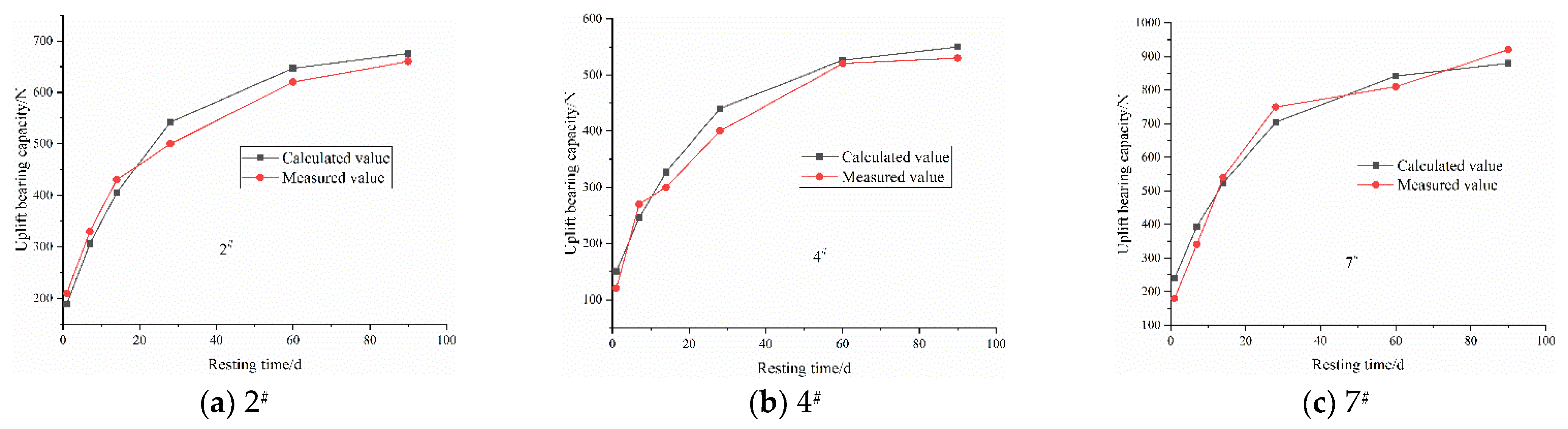

5. Validation of Time-Dependent Prediction Model for Uplift Capacity

6. Conclusions

- (1)

- The internal friction angle and cohesion of the Zhanjiang Group structured clay show a significant time effect as the rest time increases after disturbance. The increase is rapid in the initial stage of the test but slows down in the later stage, which is the primary reason for the increase in uplift capacity of the piles in this foundation soil.

- (2)

- With the increase in rest time, the uplift bearing capacity of the model pile shows a clear time-dependent effect. When the bearing capacity is insufficient in the early stages of pile driving, the increase in pile foundation bearing capacity due to the time effect can be taken into account when reasonably scheduling the project.

- (3)

- The axial force of the model pile decreases rapidly in the lower part of the pile shaft and is nearly zero at the pile tip, indicating that the pullout bearing capacity of the pile is entirely provided by the side friction resistance. The side friction resistance and the ultimate side friction resistance of the pile are mainly distributed in the lower part of the pile shaft, and they show a significant increase with the prolongation of the resting time.

- (4)

- A predictive model for the axial pullout ultimate bearing capacity that considers the time-dependence of Zhanjiang Group structured clay has been established. The validity of the predictive model has been verified through model experiments. This provides a reference for predicting the axial pullout bearing capacity of piles in the Zhanjiang Group structured clay foundation in engineering practices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.D. Antipull Pile Foundation. Geotech. Treat. 1995, 6, 12. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=227373c044c3e96244ae4fe3066fc4d3&site=xueshu_se (accessed on 26 March 2025).

- Zhang, X.W.; Kong, L.W.; Guo, A.G.; Yongfei, T. Physical and mechanical properties of strong structural clay in Zhanjiang and correlation analysis. J. Eng. Geol. 2011, 19, 447–454. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, R.; Lü, H.B. Discussion on regional characteristics of structural clay in Zhanjiang Formation. In Proceedings of the National Academic Conference on Engineering Geology, China Geological Society Engineering Geology Professional Committee, China Geological Survey, Qinghai Provincial Land and Resources Department, Xining, China, 3 August 2011; p. 4. [Google Scholar]

- Shen, J.H.; Wang, R.; Zhu, C.Q. Study on spatial distribution law of gray clay in Zhanjiang Formation. Rock Soil Mech. 2013, 34, 331–336+339. [Google Scholar] [CrossRef]

- Boswell, P.G.H. A preliminary examination of the thixotropy of some sedimentary rocks. Q. J. Geol. Soc. 1948, 104, 499–526. [Google Scholar] [CrossRef]

- Landrou, G.; Brumaud, C.; Pltze, M.L. A fresh look at dense clay paste: Deflocculation and thixotropy mechanisms. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 252–260. [Google Scholar] [CrossRef]

- Chen, B.; Shu, Q.F.; Deng, R.S. Microscopic explanation of clay strength aging considering the interaction between plate-like particles. Chin. J. Geotech. Eng. 2021, 43, 271–280. [Google Scholar]

- Zhang, X.W.; Kong, L.W.; Li, J.; Aiwu, Y. Microscopic mechanism of strength recovery during thixotropic process of clay. Chin. J. Geotech. Eng. 2014, 36, 1407–1413. [Google Scholar]

- Zhao, S.N.; Leng, Y.K.; Liu, X.G. Comprehensive evaluation of thixotropy of structural clay in Zhanjiang Formation based on gray correlation analysis. Soil Found. 2024, 38, 86–89. [Google Scholar]

- Yang, S.; Andersen, K.H. Thixotropy of marine clays. Geotech. Test. J. 2016, 39, 331–339. [Google Scholar] [CrossRef]

- Kul’Chitskii, G.B. Thixotropy of soils of the Middle Ob region and its consideration when constructing pile foundations. Soil Mech. Found. Eng. 1975, 12, 168–170. [Google Scholar]

- Yu, M.Y.; Wu, Z.H.; Wang, Q.; Changjiang, L.I.; Lixiang, C. Time effect analysis of uplift bearing capacity of drilled pile in clay-weathered rock strata. Ind. Archit. 2018, 48, 85–88+96. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Shi, W.; Wang, C.G.; Linjun, P. Aging effect on the ultimate bearing capacity of static load piles. Chin. J. Rock Mech. Eng. 2002, 21, 2601–2604. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Liu, J.W. Time effect study on uplift bearing capacity of drilled piles in sandy weathered rock foundations. Rock Soil Mech. 2008, 29, 3153–3156. [Google Scholar] [CrossRef]

- Hu, X.H.; Huang, B.; Wang, X. Experimental study on the recovery process of bearing capacity of large-diameter steel pipe piles. Waterw. Eng. 2018, 193–197+219. [Google Scholar] [CrossRef]

- Meyerhof, G.G.; Adams, J.I. The ultimate uplift capacity of foundations. Can. Geotech. J. 1968, 5, 225–244. [Google Scholar]

- Das, B.M. A procedure for estimation of uplift capacity of rough piles. Soils Found. 1983, 23, 122–126. [Google Scholar]

- Chattopadhyay, B.C.; Pise, P.J. Uplift capacity of piles in sand. J. Geotech. Eng. 1986, 112, 888–904. [Google Scholar] [CrossRef]

- Shanker, K.; Basudhar, P.K.; Patra, N.R. Uplift capacity of single piles: Predictions and performance. Geotech. Geol. Eng. 2007, 25, 151–161. [Google Scholar] [CrossRef]

- He, S.M. Research on failure characteristics and bearing capacity of uplift piles. Rock Soil Mech. 2001, 308–310. [Google Scholar] [CrossRef]

- Zou, J.S.; Wang, T. Time effect analysis of uplift bearing capacity of driven piles in ocean platforms. Sci. Technol. Eng. 2013, 13, 7143–7147. [Google Scholar] [CrossRef]

- Tang, B.; Tu, W.J.; Yu, X. Experimental Study on the Creep Behavior of Single Piles in Zhanjiang Structural Clay. J. Wuhan Univ. Technol. (Mater. Sci. Ed.) 2018, 51, 516–521. [Google Scholar] [CrossRef]

| Pile Number | Pile Length L/mm | Depth of Pile Embedment/mm | Pile Diameter D/mm |

|---|---|---|---|

| 1# | 700 | 600 | 20 |

| 2# | 1000 | 900 | 20 |

| 3# | 1200 | 1100 | 20 |

| 4# | 700 | 600 | 25 |

| 5# | 1000 | 900 | 25 |

| 6# | 1200 | 1100 | 25 |

| 7# | 700 | 600 | 40 |

| 8# | 1000 | 900 | 40 |

| 9# | 1200 | 1100 | 40 |

| Dry Density/g·cm−3 | Moisture Content/% | Cohesion/kPa | Internal Friction Angle/° | Sensitivity |

|---|---|---|---|---|

| 1.19 | 46 | 52.25 | 11.21 | 3.89 |

| Strength Indicators | Different Curing Times of Pile Foundations/d | Magnitude of Growth% | |||||

|---|---|---|---|---|---|---|---|

| 1 d | 7 d | 14 d | 28 d | 60 d | 90 d | ||

| c/kPa | 2.85 | 4.84 | 6.51 | 8.86 | 10.65 | 11.14 | 291 |

| φ/° | 3.9 | 4.69 | 5.31 | 6.02 | 6.61 | 6.76 | 73 |

| Pile Number | Pullout Ultimate Bearing Capacity of Piles After Different Resting Times/N | Magnitude of Growth % | |||||

|---|---|---|---|---|---|---|---|

| 1 d | 7 d | 14 d | 28 d | 60 d | 90 d | ||

| 1# | 100 | 220 | 240 | 380 | 430 | 450 | 330 |

| 2# | 210 | 330 | 430 | 500 | 620 | 660 | 195 |

| 3# | 200 | 360 | 540 | 640 | 830 | 840 | 315 |

| 4# | 120 | 270 | 300 | 400 | 520 | 530 | 333 |

| 5# | 260 | 350 | 530 | 640 | 750 | 800 | 188 |

| 6# | 250 | 430 | 670 | 810 | 900 | 950 | 260 |

| 7# | 180 | 340 | 540 | 750 | 810 | 920 | 350 |

| 8# | 320 | 580 | 770 | 1150 | 1200 | 1250 | 275 |

| 9# | 500 | 720 | 850 | 1230 | 1400 | 1450 | 180 |

| Pile Number | Different Curing Times of Pile Foundations t/d | |||||

|---|---|---|---|---|---|---|

| 1 d | 7 d | 14 d | 30 d | 60 d | 90 d | |

| 2# | 189 | 306 | 405 | 542 | 647 | 675 |

| 4# | 150 | 246 | 327 | 440 | 526 | 550 |

| 7# | 239 | 394 | 523 | 704 | 842 | 880 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Bin, T.; Wang, Y.; Huang, X.; Yu, Z. Research on the Time-Dependent Behavior of Uplift Piles in Structured Clay Foundations in Zhanjiang Formation. Appl. Sci. 2025, 15, 3814. https://doi.org/10.3390/app15073814

Yang Y, Bin T, Wang Y, Huang X, Yu Z. Research on the Time-Dependent Behavior of Uplift Piles in Structured Clay Foundations in Zhanjiang Formation. Applied Sciences. 2025; 15(7):3814. https://doi.org/10.3390/app15073814

Chicago/Turabian StyleYang, Yonghui, Tang Bin, Yinchuan Wang, Xingyun Huang, and Zuyuan Yu. 2025. "Research on the Time-Dependent Behavior of Uplift Piles in Structured Clay Foundations in Zhanjiang Formation" Applied Sciences 15, no. 7: 3814. https://doi.org/10.3390/app15073814

APA StyleYang, Y., Bin, T., Wang, Y., Huang, X., & Yu, Z. (2025). Research on the Time-Dependent Behavior of Uplift Piles in Structured Clay Foundations in Zhanjiang Formation. Applied Sciences, 15(7), 3814. https://doi.org/10.3390/app15073814