Investigation of Impact Behavior of STS304L Steel Plate Under Cryogenic Temperature

Abstract

1. Introduction

2. Experiment Details

2.1. Material and Specimen

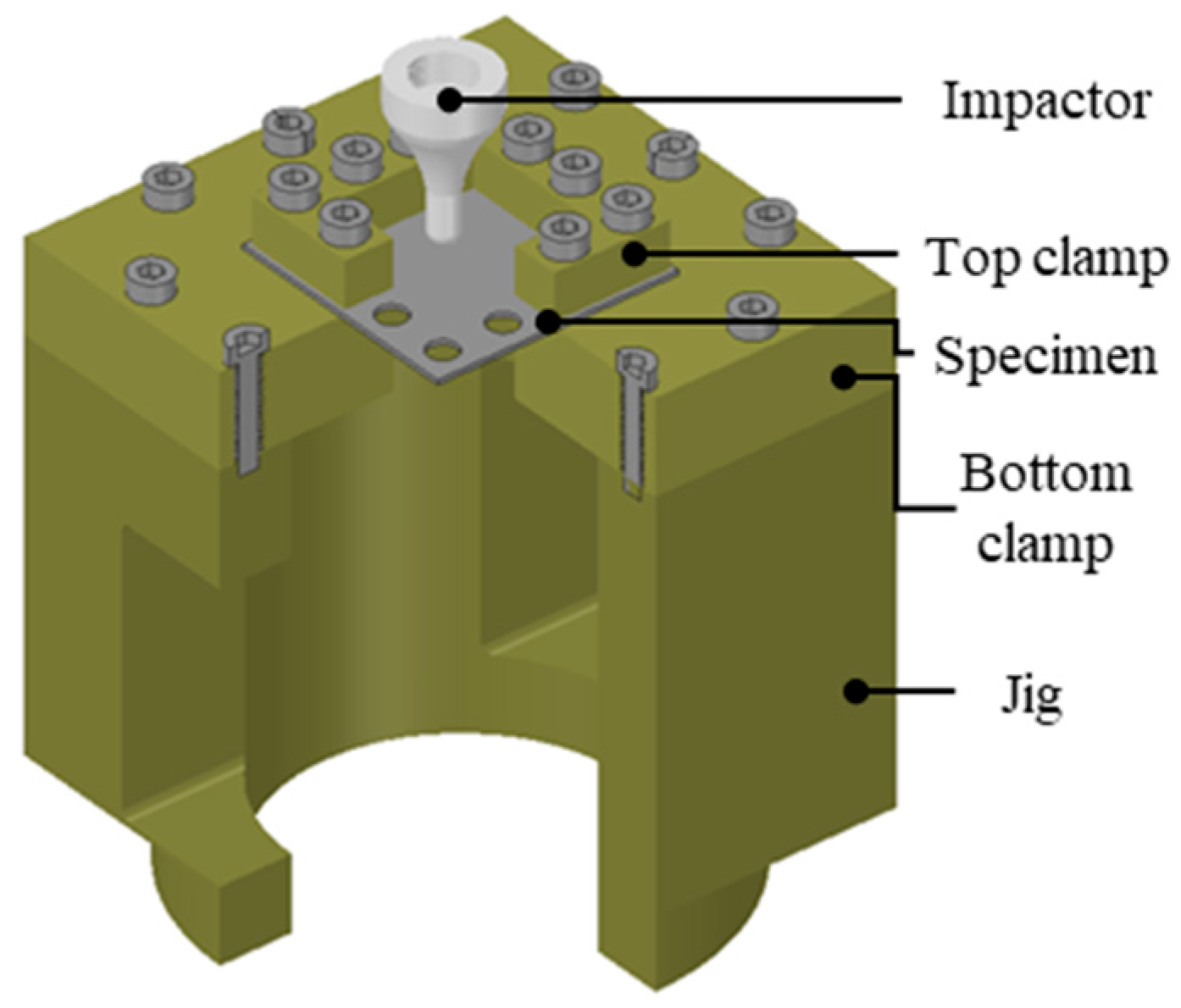

2.2. Drop-Weight Impact Test

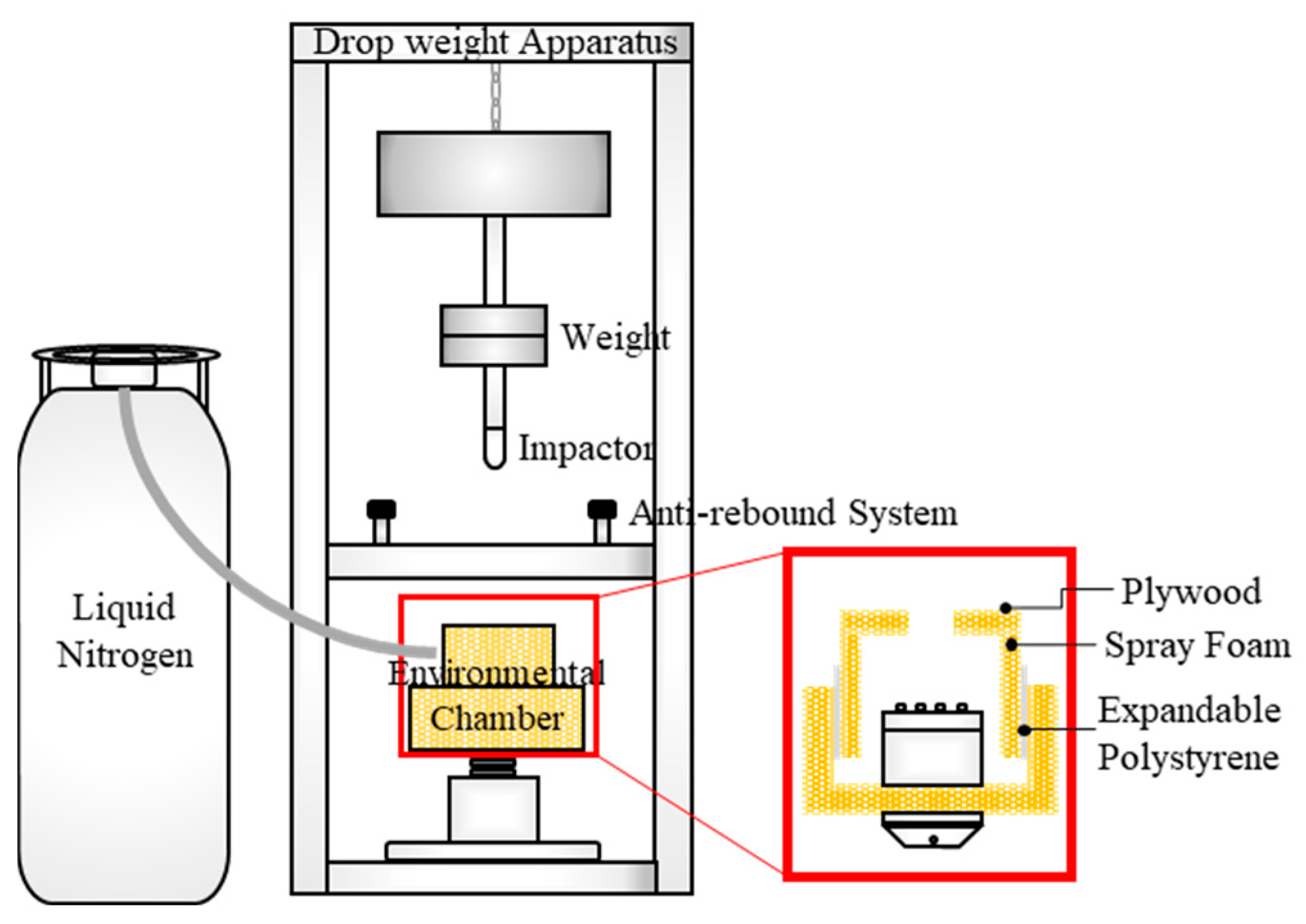

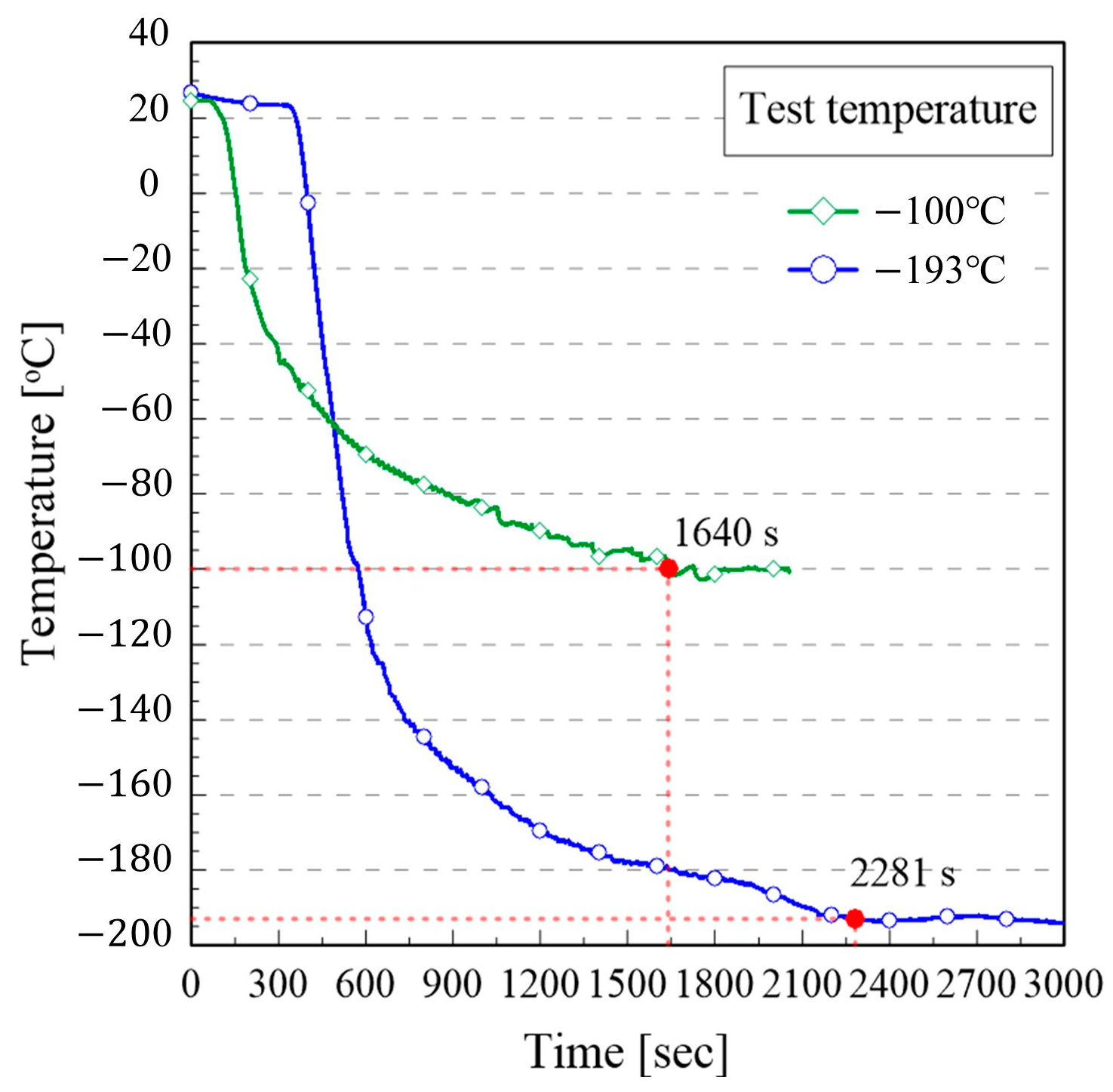

2.3. Environmental Chamber and Temperature Control

2.4. Test Procedure and EBSD Analysis

3. Results and Discussion

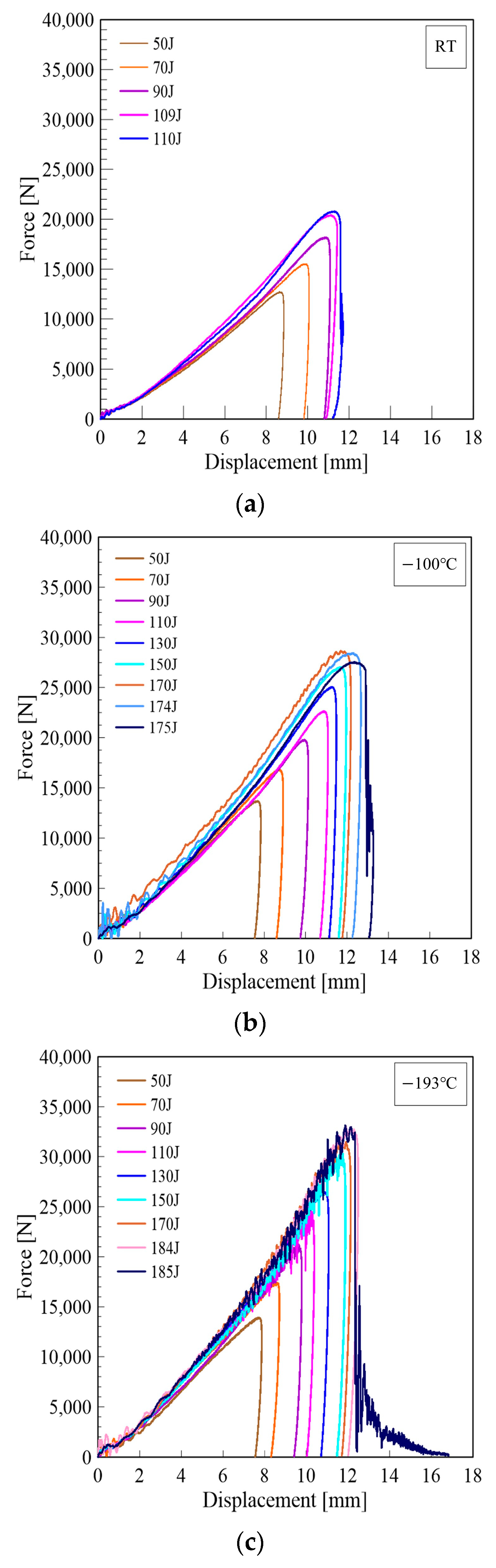

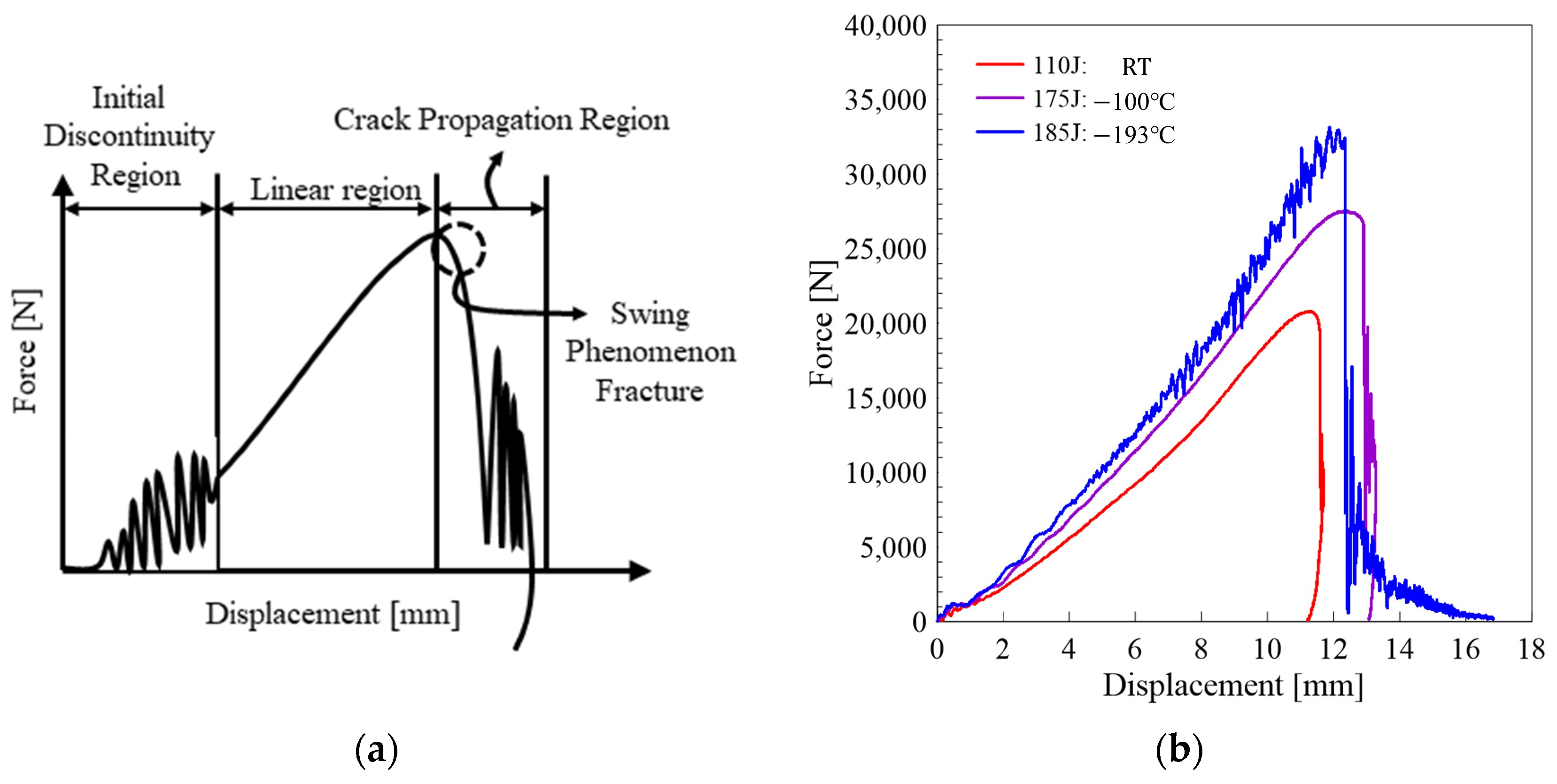

3.1. Mechanical Behavior

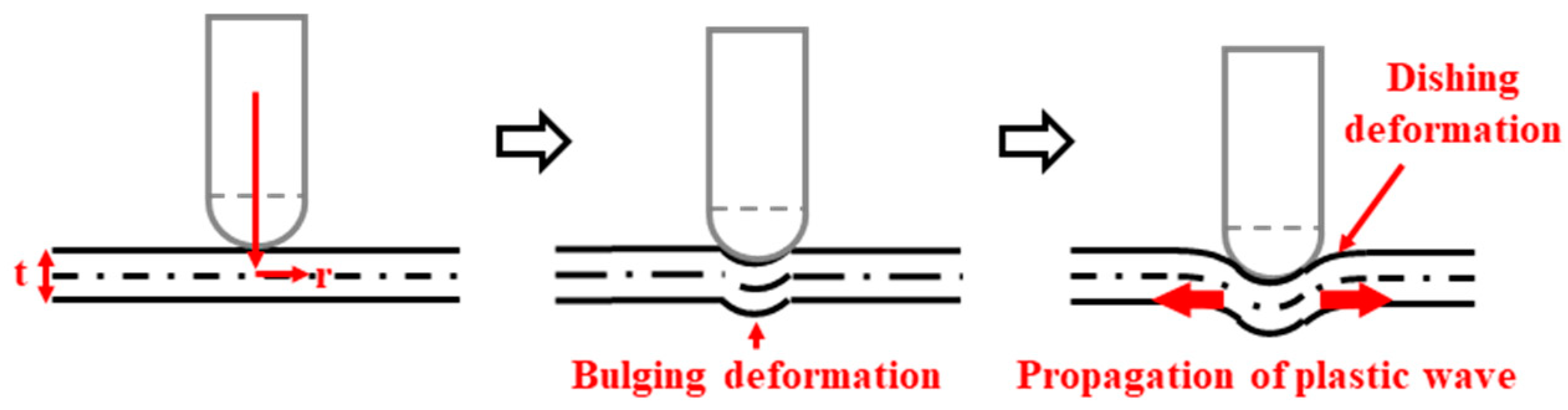

3.2. Impact Energy Absorption Mechanism

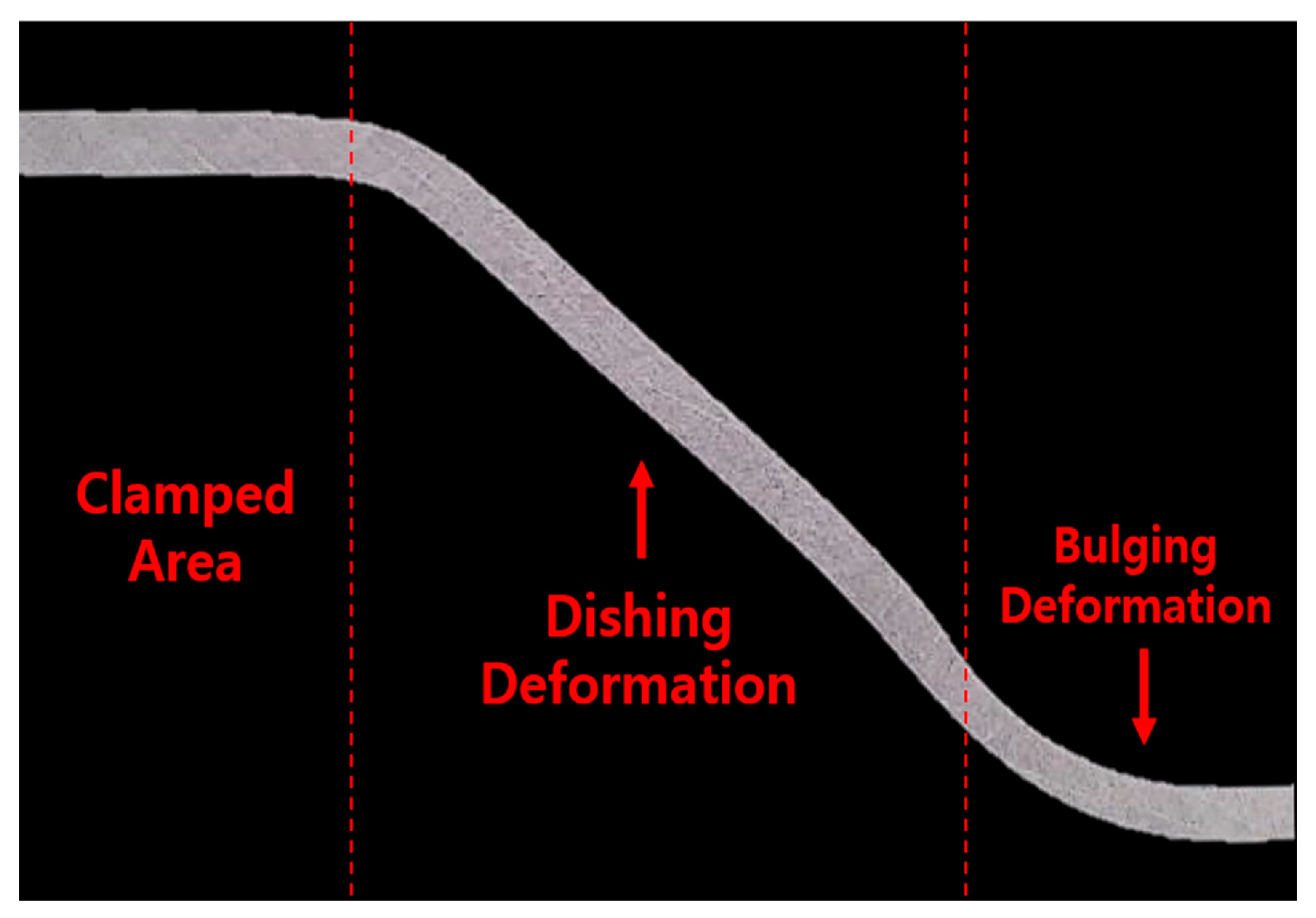

3.3. Plastic Deformation

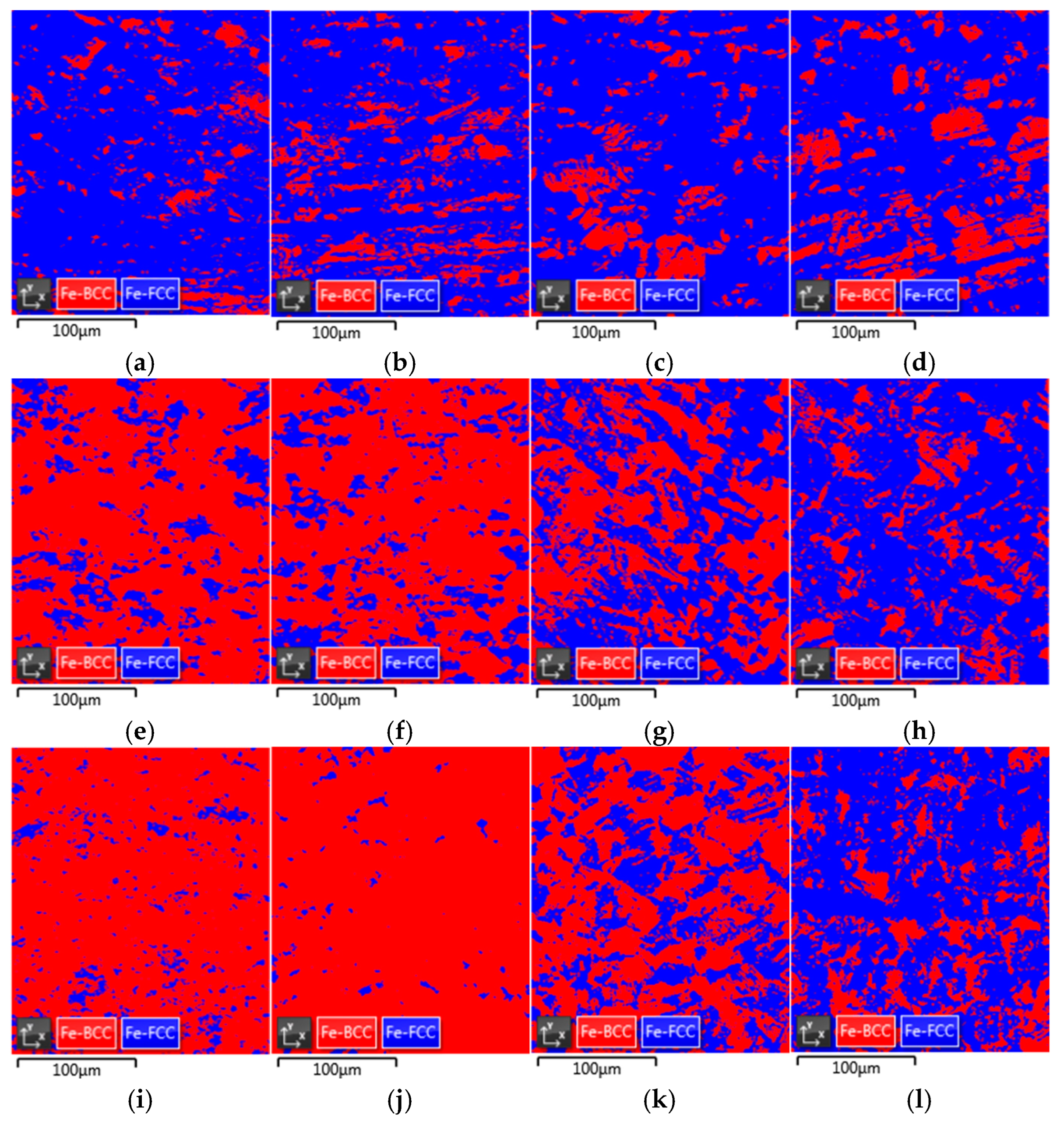

3.4. EBSD Analysis: Volume Fractions of Strain-Induced Martensite

4. Conclusions

- The stiffness of STS304L increased with a decreasing temperature, rising by 59.63% at −100 °C and 68.80% at −193 °C compared with that at 20 °C. The impact energy absorption capacity also increased, reaching 109 J at 20 °C, 174 J at −100 °C, and 184 J at −193 °C. The impact energy was stored in STS304L in the form of elastic deformation, plastic deformation, heat dissipation, and phase transformation (austenite to martensite).

- The deformation mechanism did not exhibit temperature sensitivity under hemispherical impact conditions. The measured plastic deformations were 10.89 mm at 20 °C, 11.02 mm at −100 °C, and 11.12 mm at −193 °C, showing no significant variation. However, the negative temperature sensitivity of the stiffness indicated an increase in stored energy within STS304L.

- Strain-induced martensitic transformation increased as the temperature decreased, as shown in the EBSD analysis. The martensite fraction increased progressively from Region 1 to Region 4, confirming that strain-induced martensitic transformation contributed to the negative temperature sensitivity of STS304L by increasing the stored energy in the form of phase transformation.

- Adiabatic heating due to high strain rates was the primary cause of reduced energy absorption at 20 °C. Localized temperature increases suppressed strain-induced martensitic transformation, leading to premature cracking owing to softening effects.

- The negative temperature sensitivity in stiffness and strain-induced martensitic transformation caused distinct differences in the mechanical behavior of STS304L between cryogenic and 20 °C conditions. Notably, adiabatic heating at 20 °C resulted in significantly altered mechanical behavior compared with that at cryogenic conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bos, R.W.; den Besten, J.H.; Kaminski, M.L. A reduced order model for structural response of the Mark III LNG cargo containment system. Int. Shipbuild. Prog. 2020, 66, 295–313. [Google Scholar] [CrossRef]

- Kim, D.-W.; Roh, M.-I.; Chun, D.-H.; Woo, S.-H.; Kim, Y.-T. A method for the profile optimization of the primary barrier of a membrane-type LNG tank using surrogate modeling. Ocean Eng. 2025, 317, 120054. [Google Scholar] [CrossRef]

- Khan, M.S.; Qyyum, M.A.; Ali, W.; Wazwaz, A.; Ansari, K.B.; Lee, M. Energy Saving through Efficient BOG Prediction and Impact of Static Boil-off-Rate in Full Containment-Type LNG Storage Tank. Energies 2020, 13, 5578. [Google Scholar] [CrossRef]

- Choi, S.W.; Kim, H.S.; Lee, W.I. Analysis of leaked LNG flow and consequent thermal effect for safety in LNG cargo containment system. Ocean Eng. 2016, 113, 276–294. [Google Scholar] [CrossRef]

- Li, M.; Ju, Y. Study on damaged expanded water-repellent perlite insulation integrating neural network and simulation on temperature field and Boil-off Rate in a Liquefied Natural Gas Cargo Containment. Process Saf. Environ. Prot. 2024, 187, 1097–1111. [Google Scholar] [CrossRef]

- Shi, G.; Wang, D.; Wang, Z. Ultimate capacity experiment for containment system of LNG cargo under compression load along normal direction. Ships Offshore Struct. 2025, 1–13. [Google Scholar] [CrossRef]

- Park, S.Y.; Kim, W.T.; Choi, J.H.; On, S.Y.; Kim, S.S. Effects of process-induced residual stress and geometric characteristics on pressure-resisting capability of corrugation in primary barriers of liquefied natural gas carriers. Ocean Eng. 2021, 237, 109613. [Google Scholar] [CrossRef]

- Kim, D.K.; Cho, S.; Park, D.-i.; Jang, B.S.; Cho, N.-K.; Hwang, J. Condition assessment of primary barriers in LNG cargo containment systems under multifaceted loadings: Tension, compression, shear and pressure. Ships Offshore Struct. 2024, 1–16. [Google Scholar] [CrossRef]

- Ibrahim, O.H.; Ibrahim, I.S.; Khalifa, T.A.F. Impact behavior of different stainless steel weldments at low temperatures. Eng. Fail. Anal. 2010, 17, 1069–1076. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kwon, S.-B.; Kim, S.-K.; Kim, J.-H.; Lee, J.-M. Impact failure analysis of corrugated steel plate in LNG containment cargo system. J. Constr. Steel Res. 2019, 156, 287–301. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, J.-H.; Kim, S.-K.; Lee, J.-M. Experimental Investigation of Structural Response of Corrugated Steel Sheet Subjected to Repeated Impact Loading: Performance of LNG Cargo Containment System. Appl. Sci. 2019, 9, 1558. [Google Scholar] [CrossRef]

- Du, F.; Zhang, Y.; Mi, Z.; Gao, P. Structural Characteristics of Corrugated Steel Inner Walls in Liquefied Natural Gas Ship Membrane Compartments. J. Mar. Sci. Eng. 2024, 12, 1987. [Google Scholar] [CrossRef]

- Bader Aljeaan, A.; Samir Mohamed, S. Impact Resistance of AISI 304L Stainless Steel Welded Joints at Low Temperatures. Eng. Res. J. Fac. Eng. 2022, 51, 21–26. [Google Scholar]

- Li, S.; Withers, P.J.; Deng, Y.; Yan, K. Deformation microstructures and martensitic transformation pathways in cryogenically deformed 316L stainless steel. J. Mater. Sci. 2024, 59, 2134–2154. [Google Scholar] [CrossRef]

- Egels, G.; Bussmann, M.; Benito, S.; Weber, S. On the Temperature-Dependence of Deformation-Induced Martensite Formation in AISI 304L Type Steel. Metall. Mater. Trans. A 2023, 54, 4222–4232. [Google Scholar]

- Qin, Z.; Xia, Y. Role of strain-induced martensitic phase transformation in mechanical response of 304L steel at different strain-rates and temperatures. J. Mater. Process. Technol. 2020, 280, 116613. [Google Scholar] [CrossRef]

- Zhang, L.; Wen, M.; Imade, M.; Fukuyama, S.; Yokogawa, K. Effect of nickel equivalent on hydrogen gas embrittlement of austenitic stainless steels based on type 316 at low temperatures. Acta Mater. 2008, 56, 3414–3421. [Google Scholar]

- A240/A240M-17; Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. ASTM International: West Conshohocken, PA, USA, 2017.

- Rodríguez-Martínez, J.A.; Rusinek, A.; Pesci, R.; Zaera, R. Experimental and numerical analysis of the martensitic transformation in AISI 304 steel sheets subjected to perforation by conical and hemispherical projectiles. Int. J. Solids Struct. 2013, 50, 339–351. [Google Scholar] [CrossRef]

- Soleimani, M.; Kalhor, A.; Mirzadeh, H. Transformation-induced plasticity (TRIP) in advanced steels: A review. Mater. Sci. Eng. A 2020, 795, 140023. [Google Scholar] [CrossRef]

- Jia, B.; Rusinek, A.; Bahi, S.; Bernier, R.; Pesci, R.; Bendarma, A. Perforation Behavior of 304 Stainless Steel Plates at Various Temperatures. J. Dyn. Behav. Mater. 2019, 5, 416–431. [Google Scholar] [CrossRef]

- Hubner, W. Phase transformations in austenitic stainless steels during low temperature tribological stressing. Tribol. Int. 2001, 34, 231–236. [Google Scholar] [CrossRef]

- Gurrutxaga-Lerma, B.; Shehadeh, M.A.; Balint, D.S.; Dini, D.; Chen, L.; Eakins, D.E. The effect of temperature on the elastic precursor decay in shock loaded FCC aluminium and BCC iron. Int. J. Plast. 2017, 96, 135–155. [Google Scholar] [CrossRef]

- Kim, J.-H.; Choi, S.-W.; Park, D.-H.; Lee, J.-M. Charpy impact properties of stainless steel weldment in liquefied natural gas pipelines: Effect of low temperatures. Mater. Des. 2015, 65, 914–922. [Google Scholar] [CrossRef]

- Woodward, R.L. The interrelation of failure modes observed in the penetration of metallic targets. Int. J. Impact Eng. 1984, 2, 121–129. [Google Scholar] [CrossRef]

- Yang, J.; Jo, Y.H.; An, W.; Kim, H.S.; Lee, B.-J.; Lee, S.; Sung, H.; Sohn, S.S. Effects of deformation-induced martensitic transformation on cryogenic fracture toughness for metastable Si8V2Fe45Cr10Mn5Co30 high-entropy alloy. Acta Mater. 2022, 225, 117568. [Google Scholar] [CrossRef]

- Rusinek, A.; Rodríguez-Martínez, J.A.; Zaera, R.; Klepaczko, J.R.; Arias, A.; Sauvelet, C. Experimental and numerical study on the perforation process of mild steel sheets subjected to perpendicular impact by hemispherical projectiles. Int. J. Impact Eng. 2009, 36, 565–587. [Google Scholar] [CrossRef]

- Chen, C.-h.; Zhu, X.; Hou, H.-l.; Tian, X.-b.; Shen, X.-l. A new analytical model for the low-velocity perforation of thin steel plates by hemispherical-nosed projectiles. Def. Technol. 2017, 13, 327–337. [Google Scholar] [CrossRef]

- Mallick, P.; Tewary, N.K.; Ghosh, S.K.; Chattopadhyay, P.P. Effect of cryogenic deformation on microstructure and mechanical properties of 304 austenitic stainless steel. Mater. Charact. 2017, 133, 77–86. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H.; Nenonen, P.; Pape, G. Effect of strain rate on the strain-induced γ→ α′-martensite transformation and mechanical properties of austenitic stainless steels. Metall. Mater. Trans. A 2005, 36, 421–432. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.018 | 0.4 | 1.63 | 0.03 | 0.001 | 8.2 | 18.1 | 0.22 |

| Impact Weight [kg] | Temperature [°C] | Impact Energy [J] | Impact Velocity [m/s] |

|---|---|---|---|

| 32.546 | 20 | 50 | 1.824 |

| 70 | 2.159 | ||

| … | … | ||

| Crack initiation energy | |||

| −100 | 50 | 1.824 | |

| 70 | 2.159 | ||

| … | … | ||

| Crack initiation energy | |||

| −193 | 50 | 1.824 | |

| 70 | 2.159 | ||

| … | … | ||

| Crack initiation energy |

| Test Temperature [°C] | Crack Initiation Energy [J] | Peak Force [N] | Stiffness [N/mm] |

|---|---|---|---|

| 20 | 110 | 19,137 | 2064.8 |

| −100 | 175 | 27,561 | 2673.8 |

| −193 | 185 | 32,607 | 3018.2 |

| Temperature [°C] | Fraction | Region 1 [%] | Region 2 [%] | Region 3 [%] | Region 4 [%] |

|---|---|---|---|---|---|

| 20 | Martensite | 13.94 | 19.26 | 16.99 | 23.78 |

| Austenite | 86.06 | 80.74 | 83.01 | 76.22 | |

| −100 | Martensite | 76.29 | 77.85 | 46.54 | 24.61 |

| Austenite | 23.71 | 22.15 | 53.46 | 75.39 | |

| −193 | Martensite | 89.56 | 96.87 | 60.65 | 26.97 |

| Austenite | 10.44 | 3.13 | 39.35 | 73.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-M.; Hwang, B.-K.; Kim, H.-T.; Lee, D.-H.; Kim, J.-H.; Lee, J.-M. Investigation of Impact Behavior of STS304L Steel Plate Under Cryogenic Temperature. Appl. Sci. 2025, 15, 3767. https://doi.org/10.3390/app15073767

Kim S-M, Hwang B-K, Kim H-T, Lee D-H, Kim J-H, Lee J-M. Investigation of Impact Behavior of STS304L Steel Plate Under Cryogenic Temperature. Applied Sciences. 2025; 15(7):3767. https://doi.org/10.3390/app15073767

Chicago/Turabian StyleKim, Seok-Min, Byeong-Kwan Hwang, Hee-Tae Kim, Dong-Ha Lee, Jeong-Hyeon Kim, and Jae-Myung Lee. 2025. "Investigation of Impact Behavior of STS304L Steel Plate Under Cryogenic Temperature" Applied Sciences 15, no. 7: 3767. https://doi.org/10.3390/app15073767

APA StyleKim, S.-M., Hwang, B.-K., Kim, H.-T., Lee, D.-H., Kim, J.-H., & Lee, J.-M. (2025). Investigation of Impact Behavior of STS304L Steel Plate Under Cryogenic Temperature. Applied Sciences, 15(7), 3767. https://doi.org/10.3390/app15073767