Reutilization of Recycled CDW Sand in Mortars, Paving Blocks, and Structural Concrete

Abstract

Featured Application

Abstract

1. Introduction

2. Material and Methods

2.1. Experimental Process

- Characterization of NA and RA;

- Design, preparation, and characterization of mortars and paving blocks;

- Design, preparation, and characterization of structural concrete.

2.2. Materials Used

2.3. Characterization of Aggregates

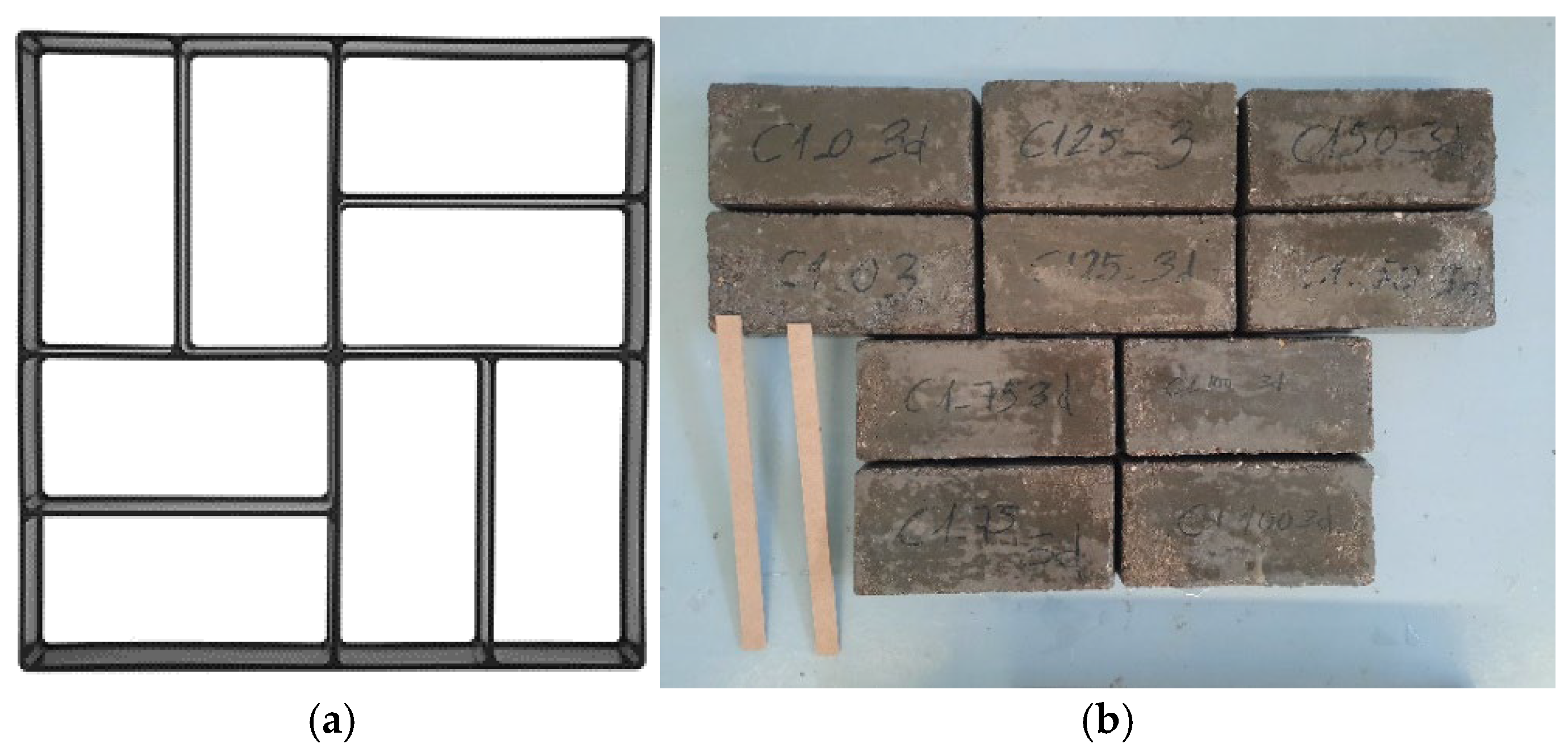

2.4. Design, Preparation, and Characterization of Mortars and Paving Blocks

2.5. Design, Preparation, and Characterization of Structural Concrete

3. Results and Discussion

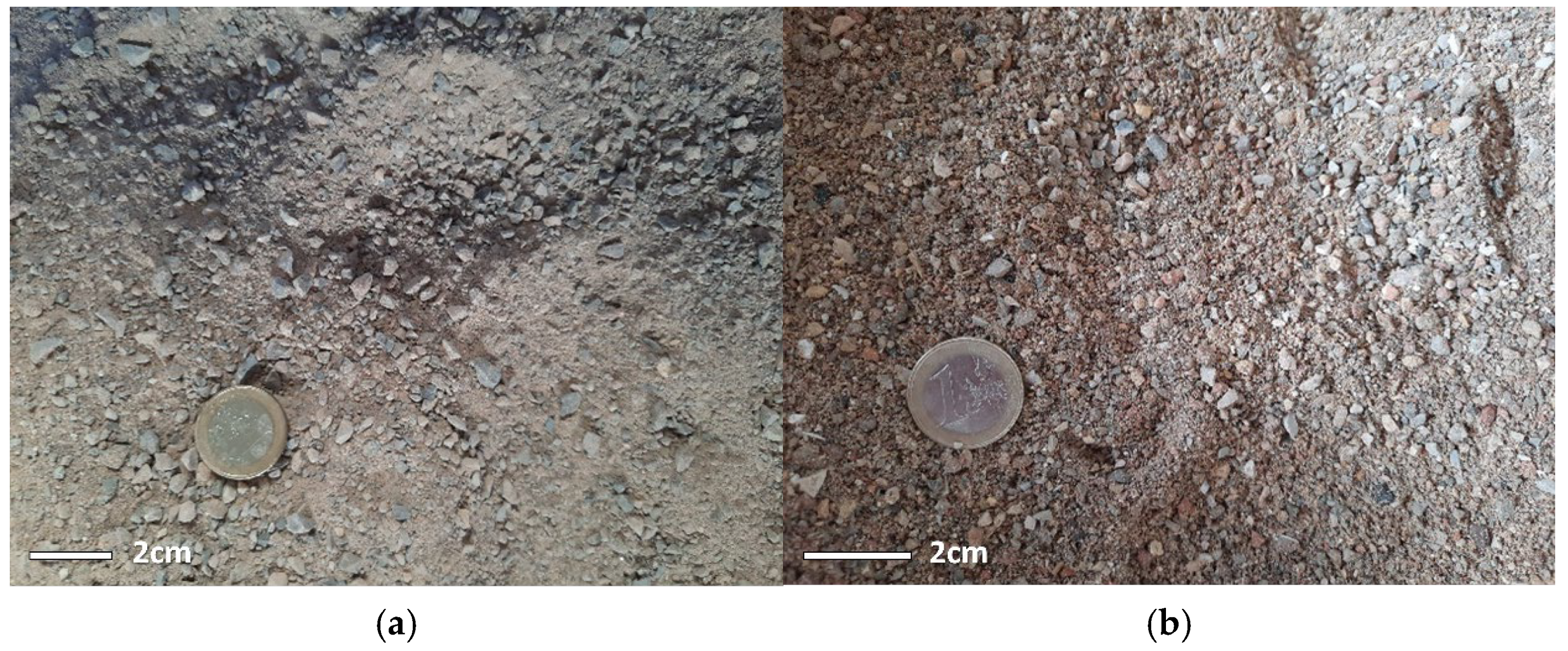

3.1. Properties of Aggregates

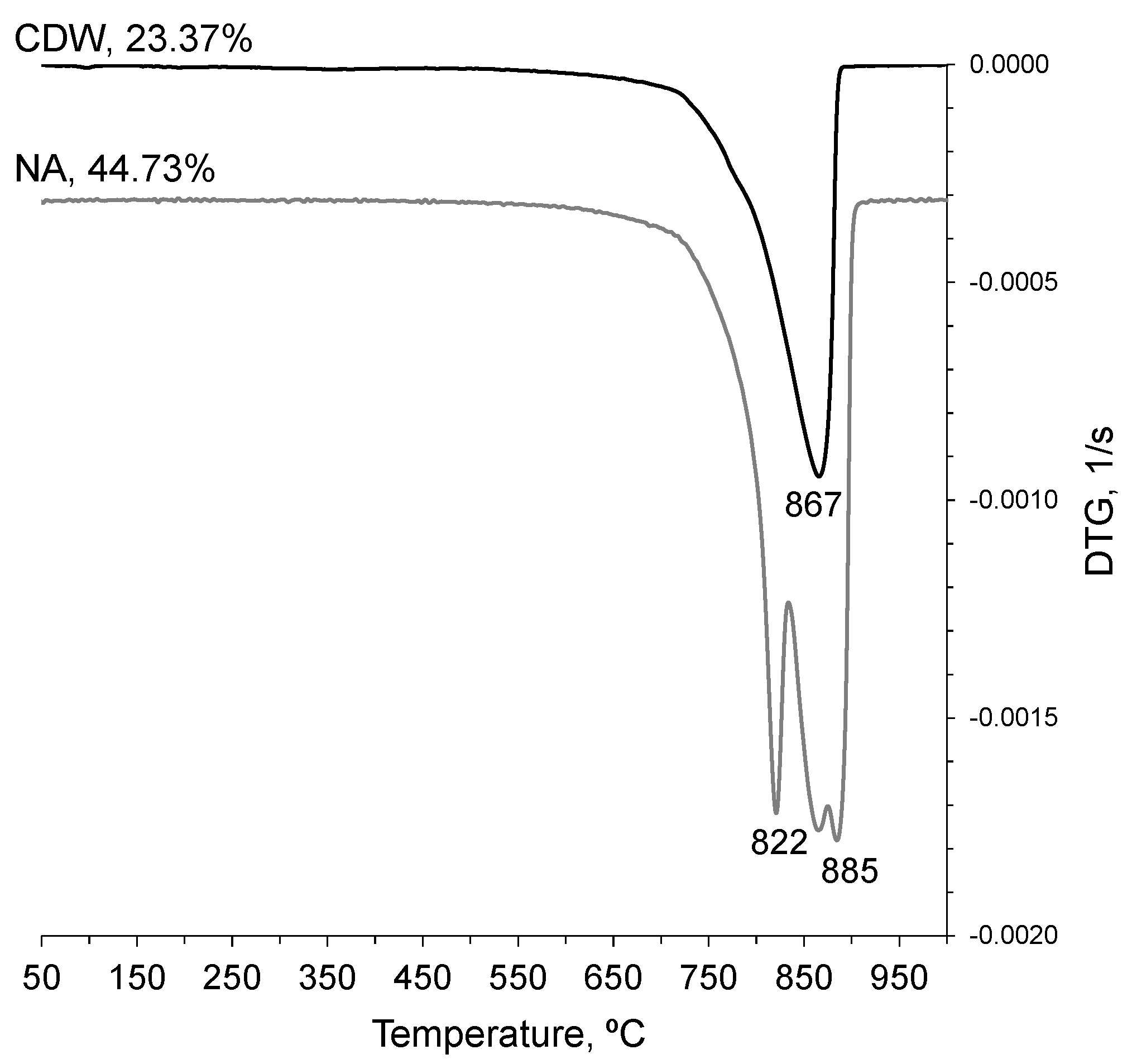

3.1.1. Morphology and Chemical and Mineralogical Composition of Aggregates

3.1.2. Particle Size Distribution of Aggregates, Percentage and Quality of Fine Particles

3.1.3. Physico-Mechanical Properties of Aggregates

3.2. Properties of the Developed Mortars

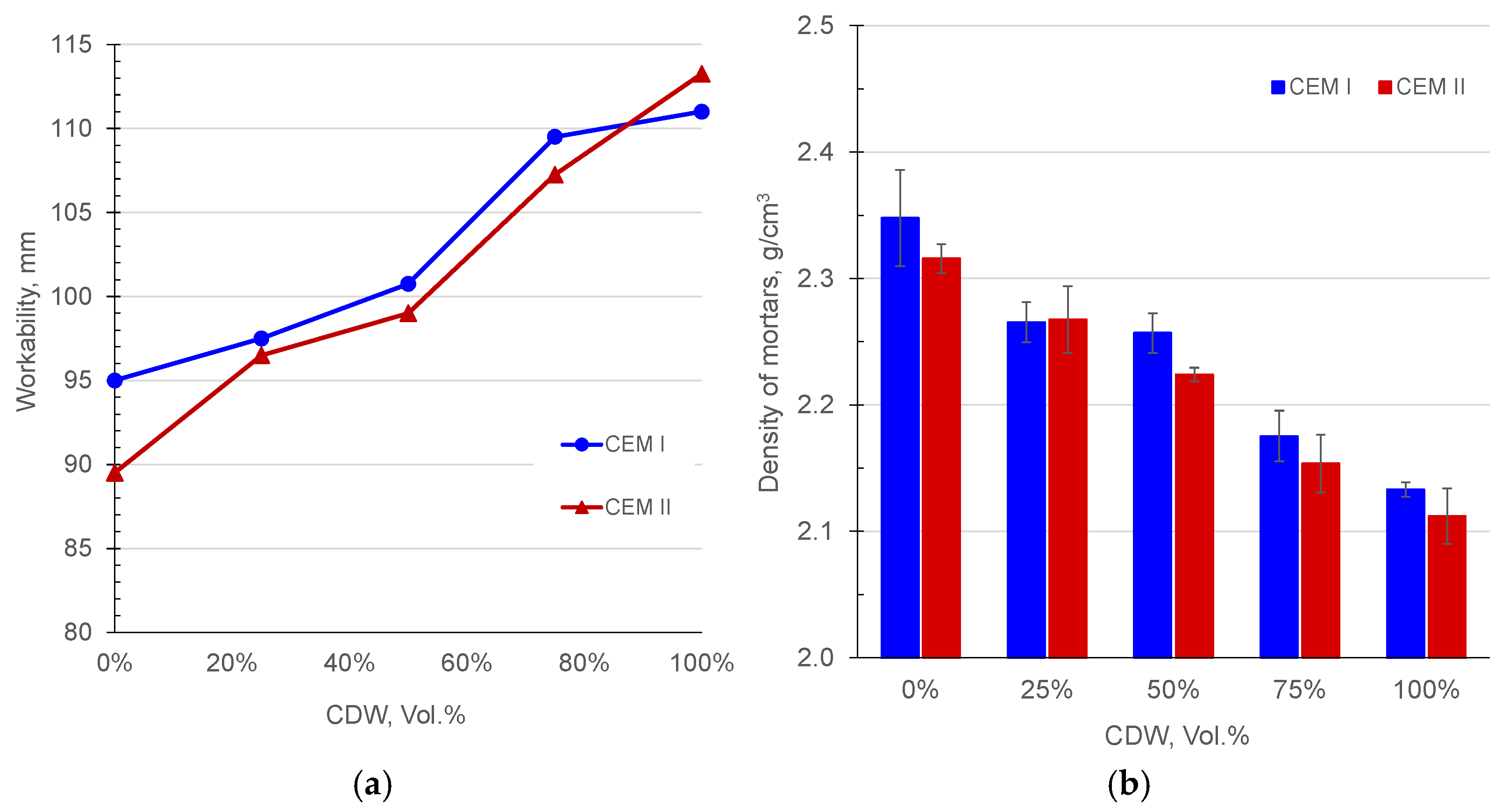

3.2.1. Workability and Density of the Mortar Samples

3.2.2. Compressive Strength of the Mortar Samples

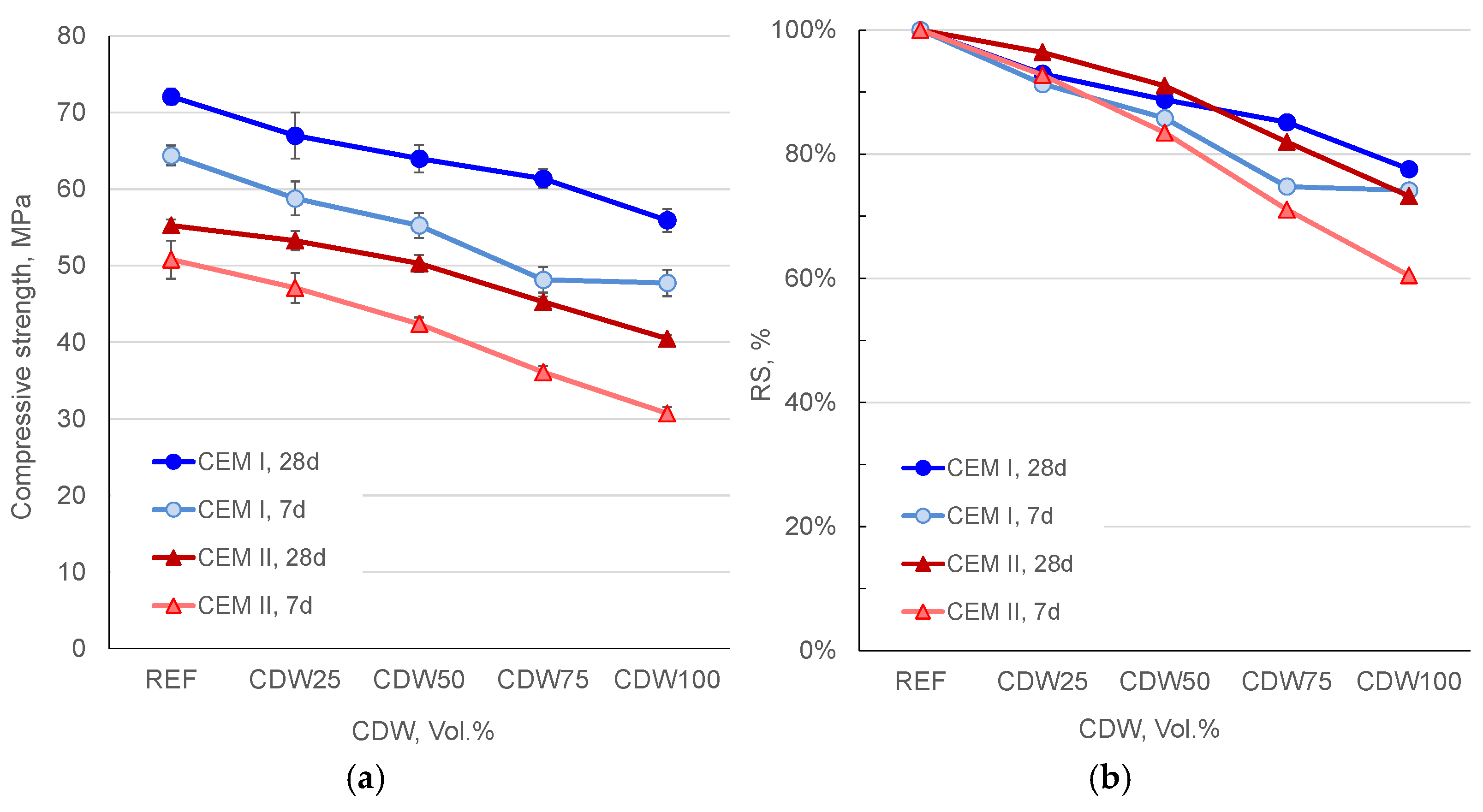

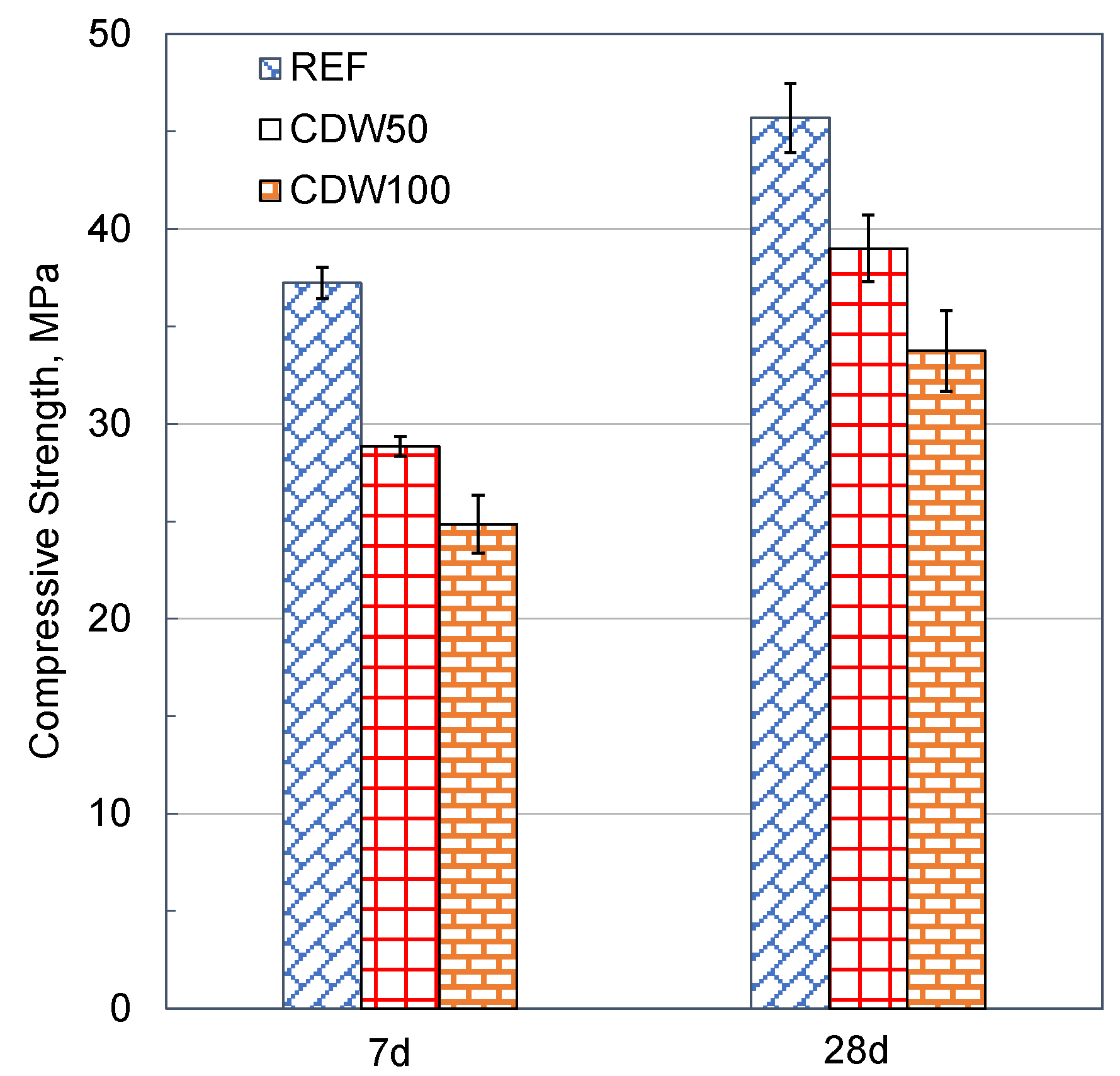

3.3. Properties of the Developed Paving Blocks

3.3.1. Workability of Paving Blocks

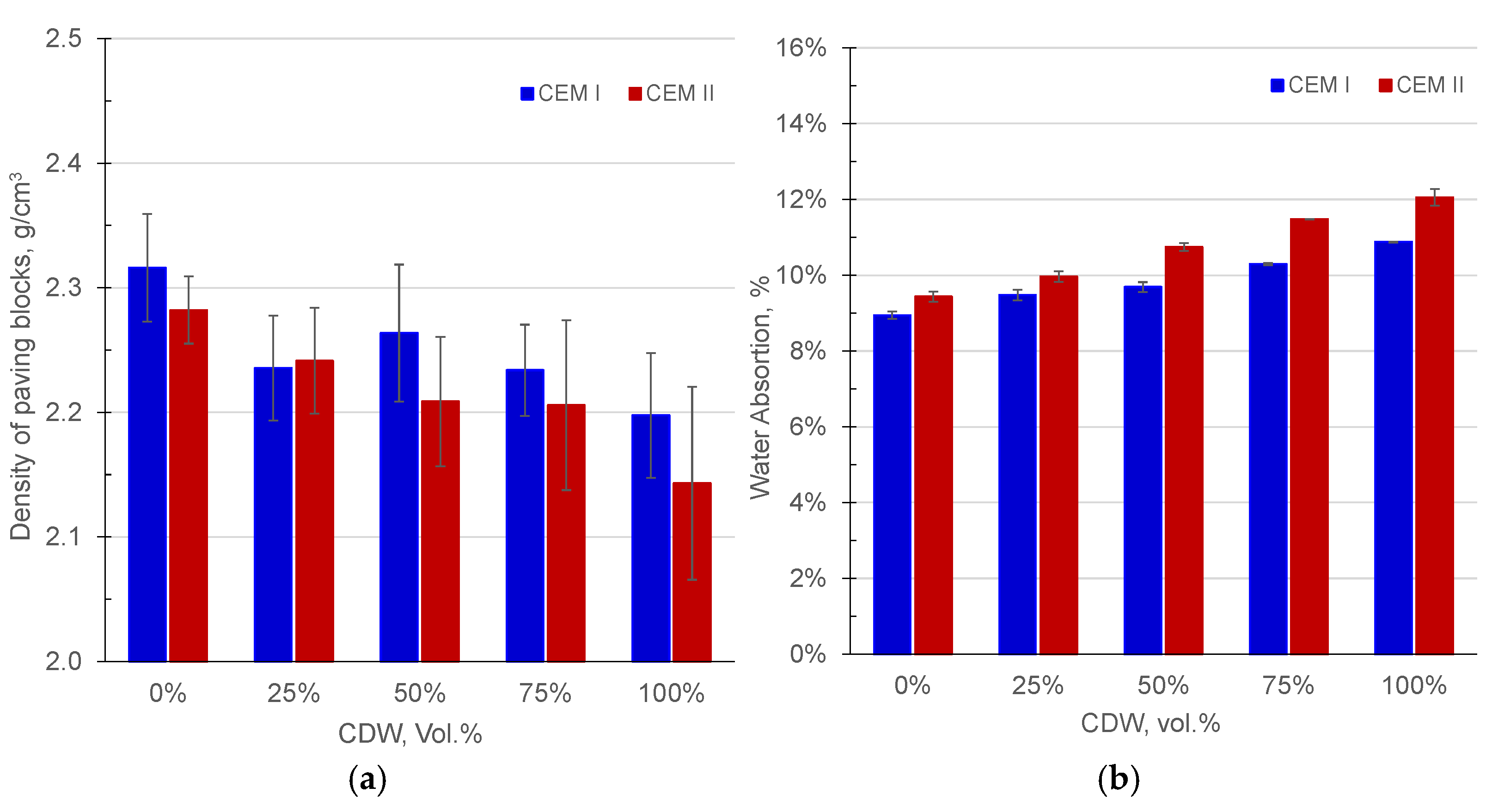

3.3.2. Density and Water Absorption of Paving Blocks

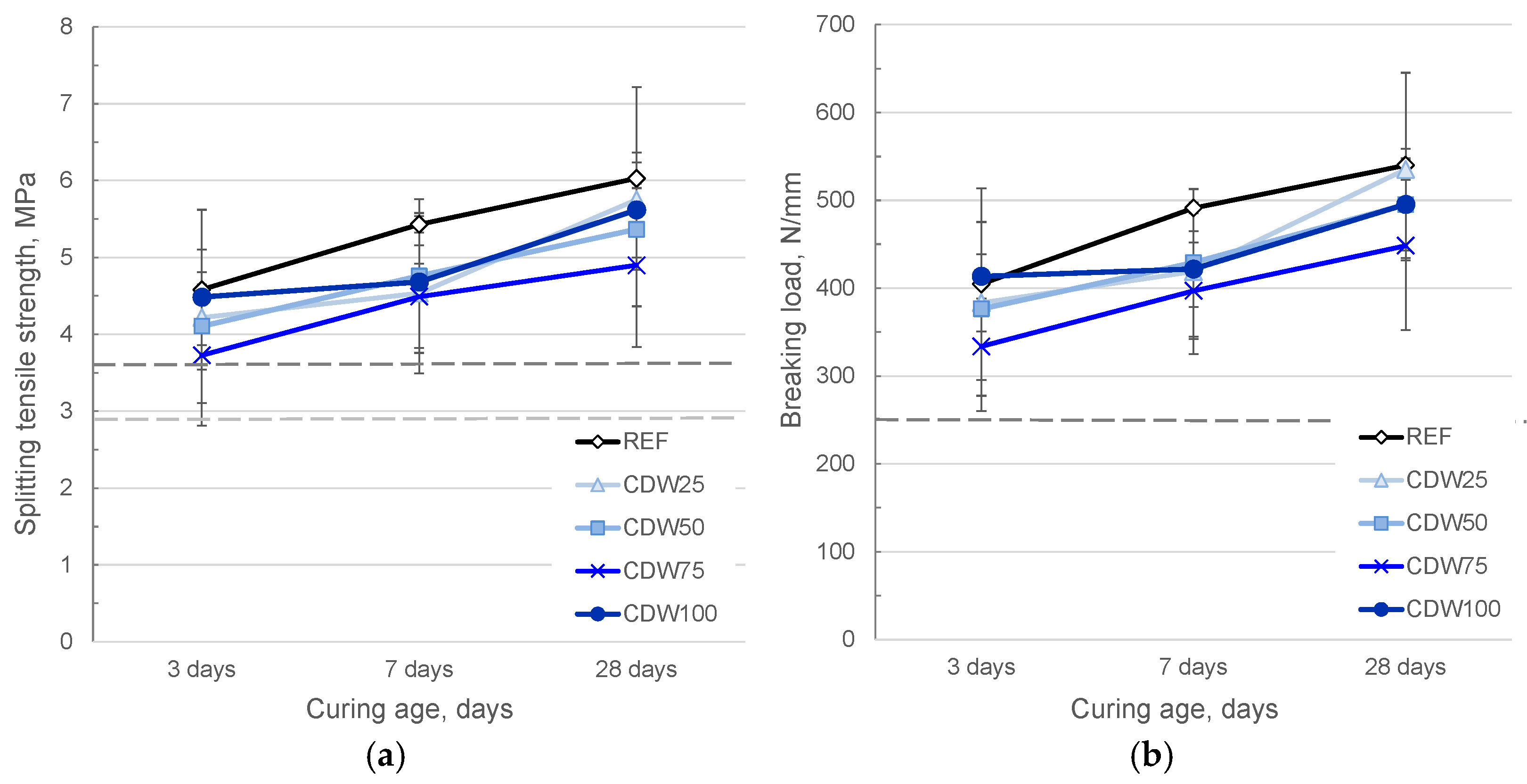

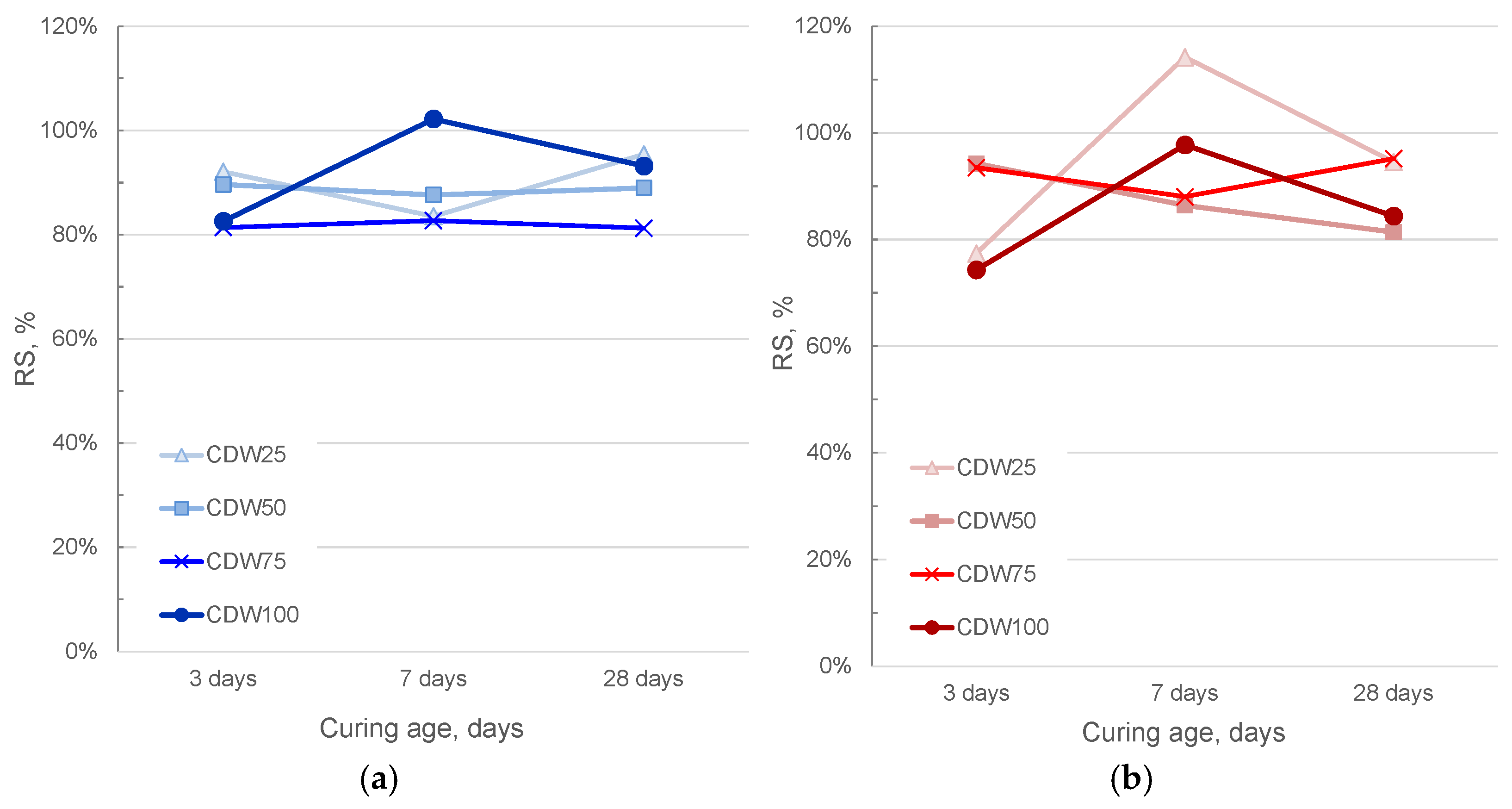

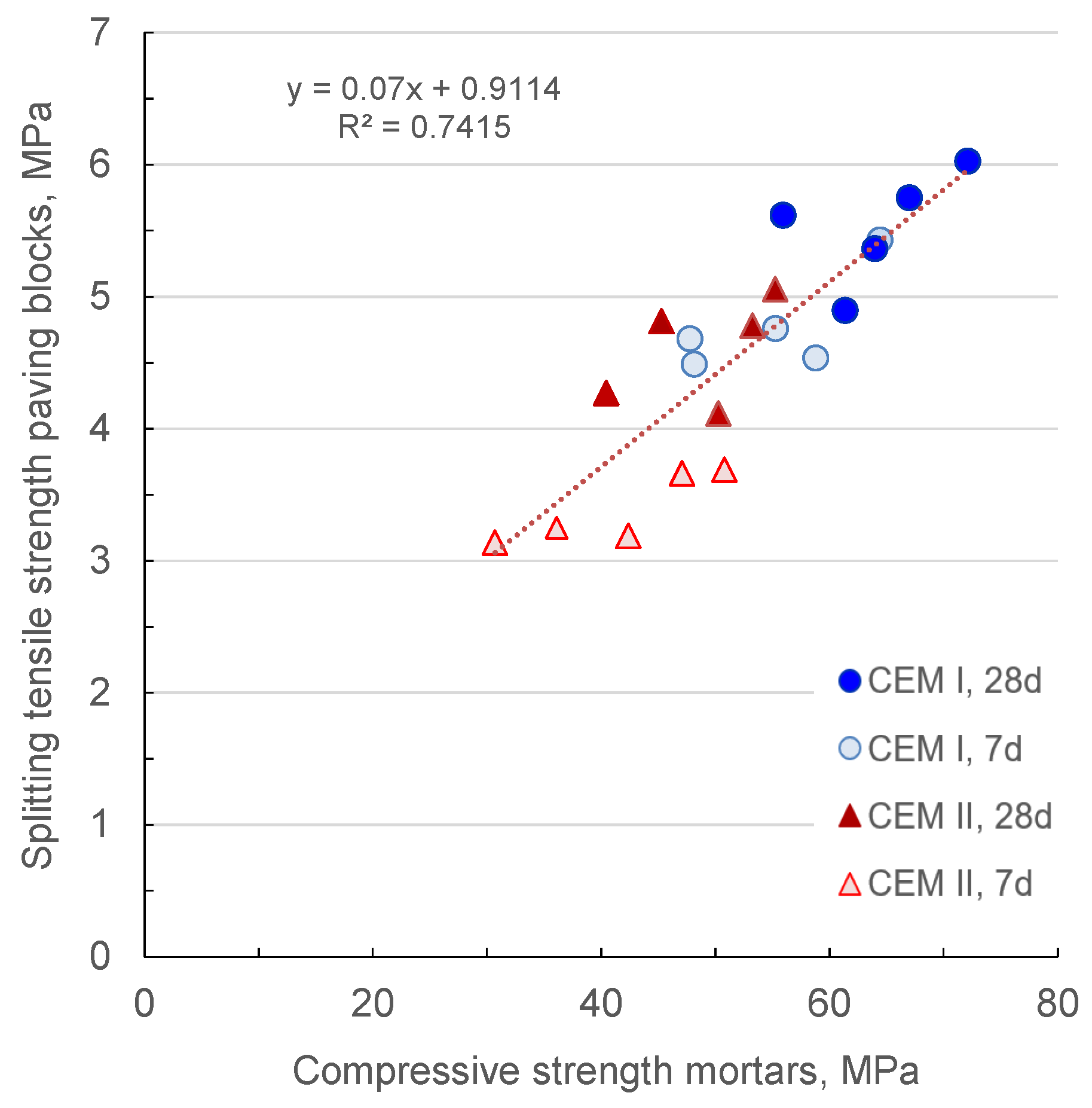

3.3.3. Splitting Tensile Strength of Paving Blocks

3.4. Properties of the Developed Concrete

3.4.1. Workability

3.4.2. Density and Compressive Strength of the Developed Concrete Samples

3.4.3. Concrete Shrinkage

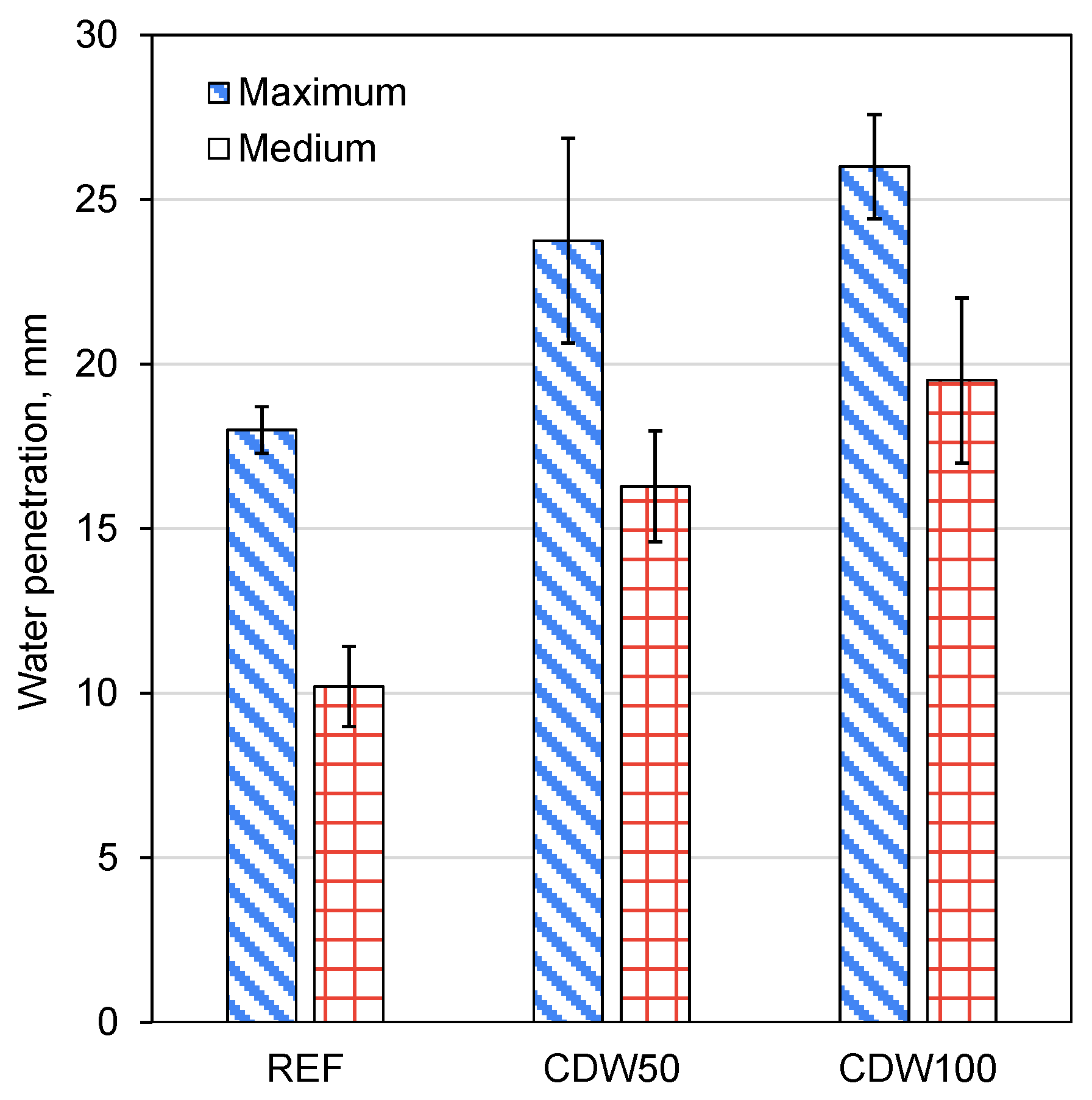

3.4.4. Concrete Permeability

4. Conclusions

- -

- The CDW aggregate was composed of mainly limestone and ceramics, with low sulfur content, lower fine content, and no pozzolanic activity. It was slightly harder than natural limestone, and had lower density and higher water absorption. The similar properties of NA and RA suggest that the CDW sand can be effectively reused in sustainable construction materials.

- -

- The workability of paving blocks slightly improved with 20 vol.% CDW, but decreased with higher content, while mortars and concrete showed improved workability with the CDW sand.

- -

- The density of all the samples decreased as CDW content increased, and ranged from 2.35 g/cm3 in the REF sample to 2.10 g/cm3 with 100% CDW recycled sand.

- -

- The water absorption in the paving blocks increased with the CDW content, limiting their suitability to non-frost areas. Water permeability was higher in RAC, but the water penetration values met the Structural Code limits for all the environmental exposure classes.

- -

- The paving blocks made with CEM I 52.5R met splitting tensile strength requirements after 3 curing days, while those with CEM II/B-M(Q-L) 42.5R met the standard after 28 curing days.

- -

- Compressive strength generally decreased with higher CDW content. The RS of the mortars with up to 50 vol.% CDW remained above 80% at all curing ages, and the RS of all the mortars cured for 28 days exceeded 70%, regardless of the CDW content. The compressive strength of the RAC samples met the minimum requirements for reinforced concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CDW | Construction and demolition waste |

| NAs | Natural aggregates |

| PC | Portland cement |

| RAs | Recycled aggregates |

| RAC | Recycled aggregate concrete |

| Vol.% | Percentage in volume |

| Wt.% | Percentage in weight |

| WA | Water absorption |

| w/c | Effective water-to-cement ratio |

| w’/c | Total water-to-cement ratio |

| RS | Relative strength |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

| TG | Thermogravimetric analysis |

| LOI | Loss on ignition |

| FM | Fineness modulus |

References

- Lyu, Y.; Xiong, N.; Liang, Y.; Lin, S.; Wang, J. Estimation of Construction and Demolition Waste and Assessment of Disposal Facility Location: An Integrated Material Flow Analysis and Geographic Information System Approach. Resour. Conserv. Recycl. 2025, 218, 108226. [Google Scholar] [CrossRef]

- Trancone, G.; Policastro, G.; Spasiano, D.; Race, M.; Parrino, F.; Fratino, U.; Fabbricino, M.; Pirozzi, F. Treatment of Concrete Waste from Construction and Demolition Activities: Application of Organic Acids from Continuous Dark Fermentation in Moving Bed Biofilm Reactors. Chem. Eng. J. 2025, 505, 159536. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. Supporting Environmentally Sound Decisions for Construction and Demolition (C&D) Waste Management a Practical Guide to Life Cycle Thinking (LCT) and Life Cycle Assessment (LCA). Available online: https://eplca.jrc.ec.europa.eu/uploads/waste-Guide-to-LCTLCA-for-C-D-waste-management-Final-ONLINE.pdf (accessed on 20 March 2025).

- Alhawamdeh, M.; Ferriz-Papi, J.A.; Lee, A. Examining the Drivers to Support Improved Construction and Demolition Waste Management for a Circular Economy: A Comprehensive Review Using a Systematic Approach. Sustainability 2024, 16, 6014. [Google Scholar] [CrossRef]

- Lee, S.; Chang, H.; Lee, J. Construction and Demolition Waste Management and Its Impacts on the Environment and Human Health: Moving Forward Sustainability Enhancement. Sustain. Cities Soc. 2024, 115, 105855. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Xiao, J.; Lu, D.; Ying, J. Durability of Recycled Aggregate Concrete: An Overview. J. Adv. Concr. Technol. 2013, 11, 347–359. [Google Scholar] [CrossRef]

- Alves, A.V.; Vieira, T.F.; De Brito, J.; Correia, J.R. Mechanical Properties of Structural Concrete with Fine Recycled Ceramic Aggregates. Constr. Build Mater. 2014, 64, 103–113. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and Demolition Waste Generation and Properties of Recycled Aggregate Concrete: A Global Perspective. J. Clean Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, C.; Cai, Z.; Zhu, P.; Liu, R.; Liu, H. Effect of Strength of Parent Concrete on Utilization of Recycled Aggregate Concrete: A Review. J. Build. Eng. 2025, 103, 112187. [Google Scholar]

- Vegas, I.; Ibañez, J.A.; Lisbona, A.; Sáez De Cortazar, A.; Frías, M. Pre-Normative Research on the Use of Mixed Recycled Aggregates in Unbound Road Sections. Constr. Build Mater. 2011, 25, 2674–2682. [Google Scholar] [CrossRef]

- Elchalakani, M.; Elgaali, E. Sustainable Concrete Made of Construction and Demolition Wastes Using Recycled Wastewater in the UAE. J. Adv. Concr. Technol. 2012, 10, 110–125. [Google Scholar] [CrossRef]

- De Brito, J.; Saikia, N. Recycled Aggregate in Concrete: Use of Industrial, Construction and Demolition Waste, Green Energy and Technology, 1st ed.; Springer: London, UK, 2013; ISBN 9781447145400. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A Review of Recycled Aggregate in Concrete Applications (2000–2017). Constr. Build Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Palii, O.; Sirico, A.; Belletti, B.; Bernardi, P. Building a Sustainable Future: Database of Concrete with Recycled Aggregates from Construction and Demolition Waste. Procedia Struct. Integrity. 2024, 59, 167–174. [Google Scholar]

- Borges, P.M.; Rother, L.A.; da Silva, S.R.; Possan, E.; de Oliveira Andrade, J.J. Environmental and Technical Assessment of Mortars Produced with Recycled Aggregate from Construction and Demolition Waste. Constr. Build Mater. 2025, 467, 140407. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Use of Recycled Aggregates in Molded Concrete Bricks and Blocks. Constr. Build Mater. 2002, 16, 281–289. [Google Scholar] [CrossRef]

- Chu, S.H.; Poon, C.S.; Lam, C.S.; Li, L. Effect of Natural and Recycled Aggregate Packing on Properties of Concrete Blocks. Constr. Build Mater. 2021, 278, 122247. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical Behaviour of Non-Structural Concrete Made with Recycled Ceramic Aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Sánchez De Rojas, M.I.; Frías, M. Influence of Mixed Recycled Aggregate on the Physical—Mechanical Properties of Recycled Concrete. J. Clean Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Topçu, I.B.; Şengel, S. Properties of Concretes Produced with Waste Concrete Aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical Properties of Brick Aggregate Concrete. Constr. Build Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Malešev, M.; Radonjanin, V.; Marinković, S. Recycled Concrete as Aggregate for Structural Concrete Production. Sustainability 2010, 2, 1204–1225. [Google Scholar] [CrossRef]

- Medina, C.; Juan, A.; Frías, M.; Sánchez de Rojas, M.I.; Morán, J.M.; Guerra, M.I. Characterization of Concrete Made with Recycled Aggregate from Ceramic Sanitary Ware. Mater. Construcción 2011, 61, 533–546. [Google Scholar] [CrossRef]

- Torkittikul, P.; Chaipanich, A. Utilization of Ceramic Waste as Fine Aggregate within Portland Cement and Fly Ash Concretes. Cem. Concr. Compos. 2010, 32, 440–449. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J.; Lamperti Tornaghi, M. Use of Recycled Aggregates in Concrete: Opportunities for Upscaling in Europe; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. The Use of Recycled Aggregate in Concrete in Hong Kong. Resour. Conserv. Recycl. 2007, 50, 293–305. [Google Scholar] [CrossRef]

- EN 206-1; Concrete—Materials—Rules for Application of EN 206-1 in Denmark. Danish Standards: Copenhaga, Denmark, 2011.

- NEN-EN 206; Concrete—Specification, Performance, Production and Conformity. Beton: Hardenberg, The Netherlands, 2022.

- Mehus, J.; Petkovic, G.; Engelsen, C.J.; Karlsen, J.; Lillestol, B. Recycled Aggregates a Viable Alternative for the Norwegian Building and Construction Industry. Available online: https://www.researchgate.net/profile/Christian-Engelsen-2/publication/228474590_Recycled_Aggregates_a_Viable_Alternative_for_the_Norwegian_Building_and_Construction_Industry/links/02e7e52a576e48c0ca000000/Recycled-Aggregates-a-Viable-Alternative-for-the-Norwegian-Building-and-Construction-Industry.pdf (accessed on 20 March 2025).

- UNE-EN 206:2013+A2; Concrete Specification, Performance, Production and Conformity. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2021.

- Ferro, G.A.; Spoto, C.; Tulliani, J.M.; Restuccia, L. Mortar Made of Recycled Sand from C&D. Procedia Eng. 2015, 109, 240–247. [Google Scholar] [CrossRef]

- Kępniak, M.; Łukowski, P. Multicriteria Analysis of Cement Mortar with Recycled Sand. Sustainability 2024, 16, 1773. [Google Scholar] [CrossRef]

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G. A Sustainable Future for the European Cement and Concrete Industry; ETH Zurich: Zürich, Switzerland, 2018. [Google Scholar] [CrossRef]

- UNE-EN 197-1; Cement. Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2012.

- UNE 146404; Áridos Para Hormigones Medida Del Coeficiente de Friabilidad de Las Arenas. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2018.

- UNE-EN 933-1; Tests for Geometrical Properties of Aggregates. Part 1: Determination of Particle Size Distribution. Sieving Method. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2013.

- UNE-EN 933-8:2012+A1; Tests for Geometrical Properties of Aggregates. Part 8: Assessment of Fines. Sand Equivalent Test. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2015.

- UNE-EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2014.

- UNE-EN 196-1:2018; Methods of Testing Cement. Part 1: Determination of Strength. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2018.

- UNE-EN 1015-3:2000/A2; Methods of Test for Mortar for Masonry. Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2007.

- UNE-EN 1338:2004; Concrete Paving Blocks. Requirements and Test Methods. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2004.

- UNE-EN 12350-2:2020; Testing Fresh Concrete. Part 2: Slump Test. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2020.

- UNE-EN 12390-1:2022; Testing Hardened Concrete. Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2022.

- UNE-EN 12390-3:2020; Testing Hardened Concrete. Part 3: Compressive Strength of Test Specimens. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2020.

- UNE-EN 12390-16:2020; Testing Hardened Concrete. Part 16: Determination of the Shrinkage of Concrete. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2020.

- UNE-EN 12390-8:2020; Testing Hardened Concrete. Part 8: Depth of Penetration of Water under Pressure. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2020.

- UNE-EN 450-1; Fly Ash for Concrete Part 1: Definition, Specifications and Conformity Criteria. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2013.

- Gunasekaran, S.; Anbalagan, G. Thermal Decomposition of Natural Dolomite. Bull. Mater. Sci. 2007, 30, 339–344. [Google Scholar]

- Pitarch, A.M.; Reig, L.; Tomás, A.E.; Forcada, G.; Soriano, L.; Borrachero, M.V.; Payá, J.; Monzó, J.M. Pozzolanic Activity of Tiles, Bricks and Ceramic Sanitary-Ware in Eco-Friendly Portland Blended Cements. J. Clean Prod. 2021, 279, 123713. [Google Scholar] [CrossRef]

- Pitarch, A.M.; Reig, L.; Tomás, A.E.; López, F.J. Effect of Tiles, Bricks and Ceramic Sanitary-Ware Recycled Aggregates on Structural Concrete Properties. Waste Biomass Valorization 2019, 10, 1779–1793. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete. Constr. Build Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Tavakolia, D.; Heidari, A. Properties of Concretes Produced with Waste Ceramic Tile Aggregate. Asian J. Civ. Eng. 2013, 14, 369–382. [Google Scholar]

- Cabral, A.E.B.; Schalch, V.; Molin, D.C.C.D.; Ribeiro, J.L.D. Mechanical Properties Modeling of Recycled Aggregate Concrete. Constr. Build Mater. 2010, 24, 421–430. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vegas, I. Effect of Fine Ceramic Recycled Aggregate (RA) and Mixed Fine RA on Hardened Properties of Concrete. Mag. Concr. Res. 2015, 67, 645–655. [Google Scholar] [CrossRef]

- López, V.; Llamas, B.; Juan, A.; Morán, J.M.; Guerra, I. Eco-Efficient Concretes: Impact of the Use of White Ceramic Powder on the Mechanical Properties of Concrete. Biosyst. Eng. 2007, 96, 559–564. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Reig, L.; Albero, V.; Hernández-Figueirido, D.; Melchor-Eixea, A.; Pitarch, Á.M.; Piquer, A. Utilisation of Ceramic Stoneware Tile Waste as Recycled Aggregate in Concrete. Buildings 2023, 13, 1968. [Google Scholar] [CrossRef]

- Zhang, W.; Zakaria, M.; Hama, Y. Influence of Aggregate Materials Characteristics on the Drying Shrinkage Properties of Mortar and Concrete. Constr. Build Mater. 2013, 49, 500–510. [Google Scholar] [CrossRef]

| Property | Test | Standard |

|---|---|---|

| Particle size distribution | Sieve analysis | UNE-EN 933-1 [38] |

| Percentage of fines (<0.063 mm) | Sieve analysis | UNE-EN 933-1 [38] |

| Assessment of fines | Sand equivalent | UNE-EN 933-8 [39] |

| Specific weight | Pycnometer | UNE-EN 1097-6 [40] |

| Water absorption | Sand absorption cone | UNE-EN 1097-6 [40] |

| Resistance to wear | Micro-Deval * | UNE 146404 [37] |

| Aggregate | Substitution Vol.% | Designation | Cement (*) kg/m3 | Effective Water, L | Effective w/c | NA kg/m3 | CDW kg/m3 |

|---|---|---|---|---|---|---|---|

| Limestone | 0 | REF | 586 | 264 | 0.45 | 1757.8 | 0 |

| CDW | 25 | CDW25 | 1318.4 | 381.9 | |||

| 50 | CDW50 | 878.9 | 763.8 | ||||

| 75 | CDW75 | 439.5 | 1145.6 | ||||

| 100 | CDW100 | 0 | 1527.5 |

| Aggregate | Subs. Vol.% | Desig. | Cement kg/m3 | Effective Water, L | Effective w/c | Gravel NA kg/m3 | Sand | |

|---|---|---|---|---|---|---|---|---|

| NA kg/m3 | CDW kg/m3 | |||||||

| Limestone | 0 | REF | 370 | 185 | 0.5 | 890 | 0 | |

| CDW | 50 | CDW50 | 890 | 445 | 386.7 | |||

| 100 | CDW100 | 0 | 773.5 | |||||

| Al2O3 | SiO2 | CaO | MgO | K2O | Na2O | Fe2O3 | SO3 | Other | LOI * | |

|---|---|---|---|---|---|---|---|---|---|---|

| CDW | 8.2 | 32.1 | 30.5 | 1.8 | 1.1 | 1.1 | 1.0 | 0.5 | 0.4 | 23.4 |

| Property | NA | CDW |

|---|---|---|

| FM | 3.1 | 3.2 |

| Percentage of fine particles, wt.% | 14.4 | 4.4 |

| Sand equivalent | 53 | 73 |

| Property | NA | CDW |

|---|---|---|

| Specific weight, kg/m3 | 2808.9 | 2441.2 |

| Water absorption, wt.% | 2.01 | 5.62 |

| Resistance to wear, wt.% | 29.2 | 23.9 |

| Designation | Cone, mm |

|---|---|

| REF | 100 |

| CDW50 | 190 |

| CDW100 | 170 |

| Compressive Strength | |||||||

|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | ||||||

| Density, kg/m3 | Mean MPa | Std. Deviation MPa | RS % | Mean MPa | Std. Deviation MPa | RS % | |

| REF | 2343.4 | 37.2 | 0.8 | - | 45.7 | 1.8 | - |

| CDW50 | 2245.3 | 28.9 | 0.5 | 77.7 | 39.0 | 1.7 | 85.3 |

| CDW100 | 2184.9 | 24.9 | 1.5 | 66.9 | 33.7 | 2.1 | 73.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pitarch, Á.M.; Piquer, A.; Reig, L.; Roig-Flores, M.; Albero, V.; Hernández-Figueirido, D.; Melchor-Eixea, A. Reutilization of Recycled CDW Sand in Mortars, Paving Blocks, and Structural Concrete. Appl. Sci. 2025, 15, 3652. https://doi.org/10.3390/app15073652

Pitarch ÁM, Piquer A, Reig L, Roig-Flores M, Albero V, Hernández-Figueirido D, Melchor-Eixea A. Reutilization of Recycled CDW Sand in Mortars, Paving Blocks, and Structural Concrete. Applied Sciences. 2025; 15(7):3652. https://doi.org/10.3390/app15073652

Chicago/Turabian StylePitarch, Ángel M., Ana Piquer, Lucía Reig, Marta Roig-Flores, Vicente Albero, David Hernández-Figueirido, and Antonio Melchor-Eixea. 2025. "Reutilization of Recycled CDW Sand in Mortars, Paving Blocks, and Structural Concrete" Applied Sciences 15, no. 7: 3652. https://doi.org/10.3390/app15073652

APA StylePitarch, Á. M., Piquer, A., Reig, L., Roig-Flores, M., Albero, V., Hernández-Figueirido, D., & Melchor-Eixea, A. (2025). Reutilization of Recycled CDW Sand in Mortars, Paving Blocks, and Structural Concrete. Applied Sciences, 15(7), 3652. https://doi.org/10.3390/app15073652