The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain

Abstract

1. Introduction

Novelty and Significance

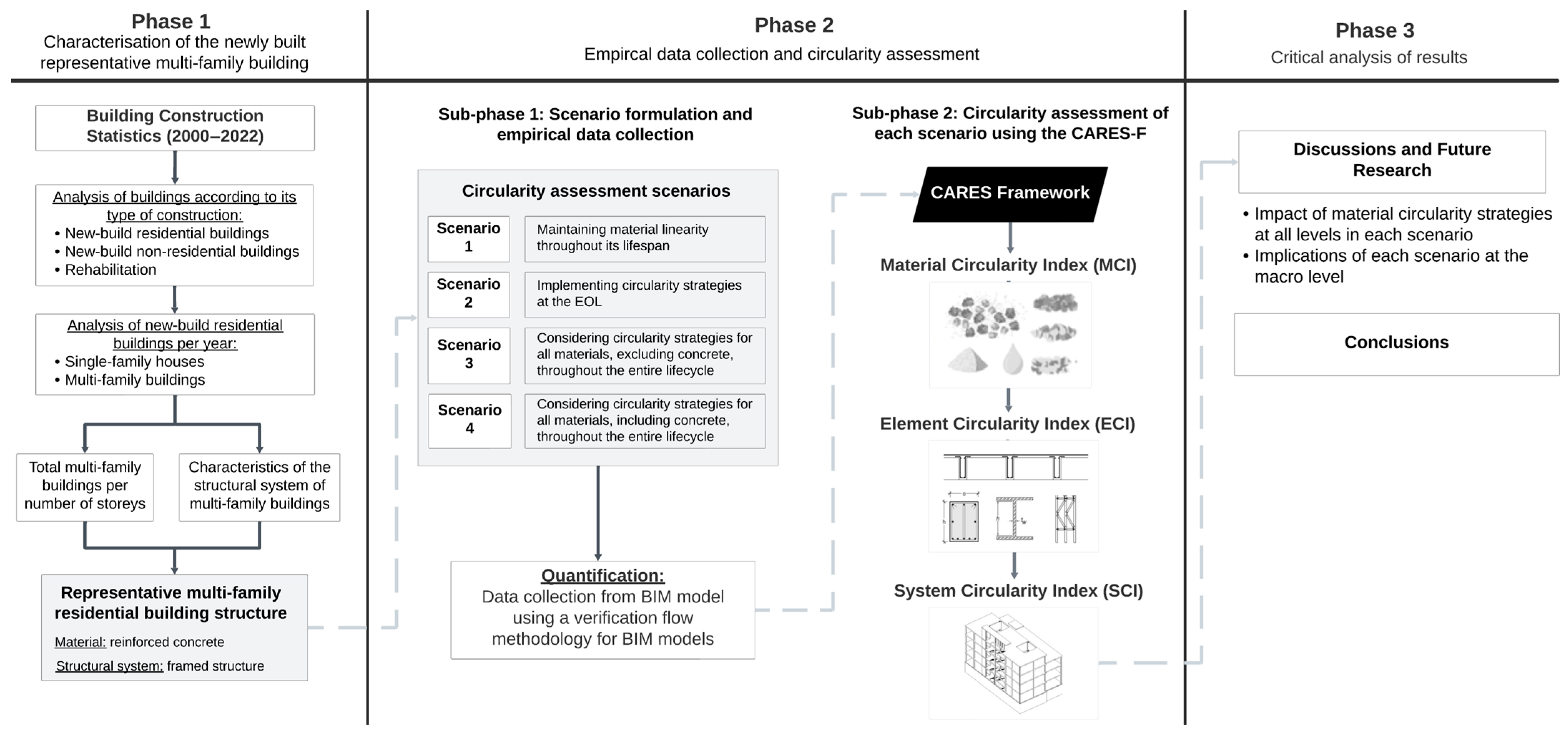

2. Materials and Methods

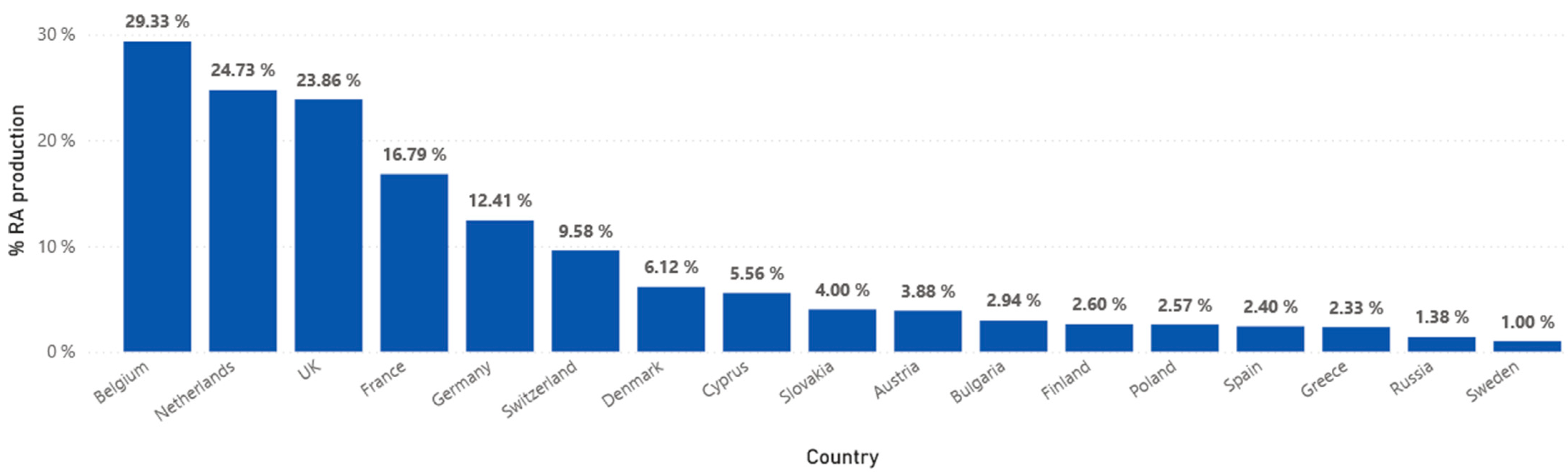

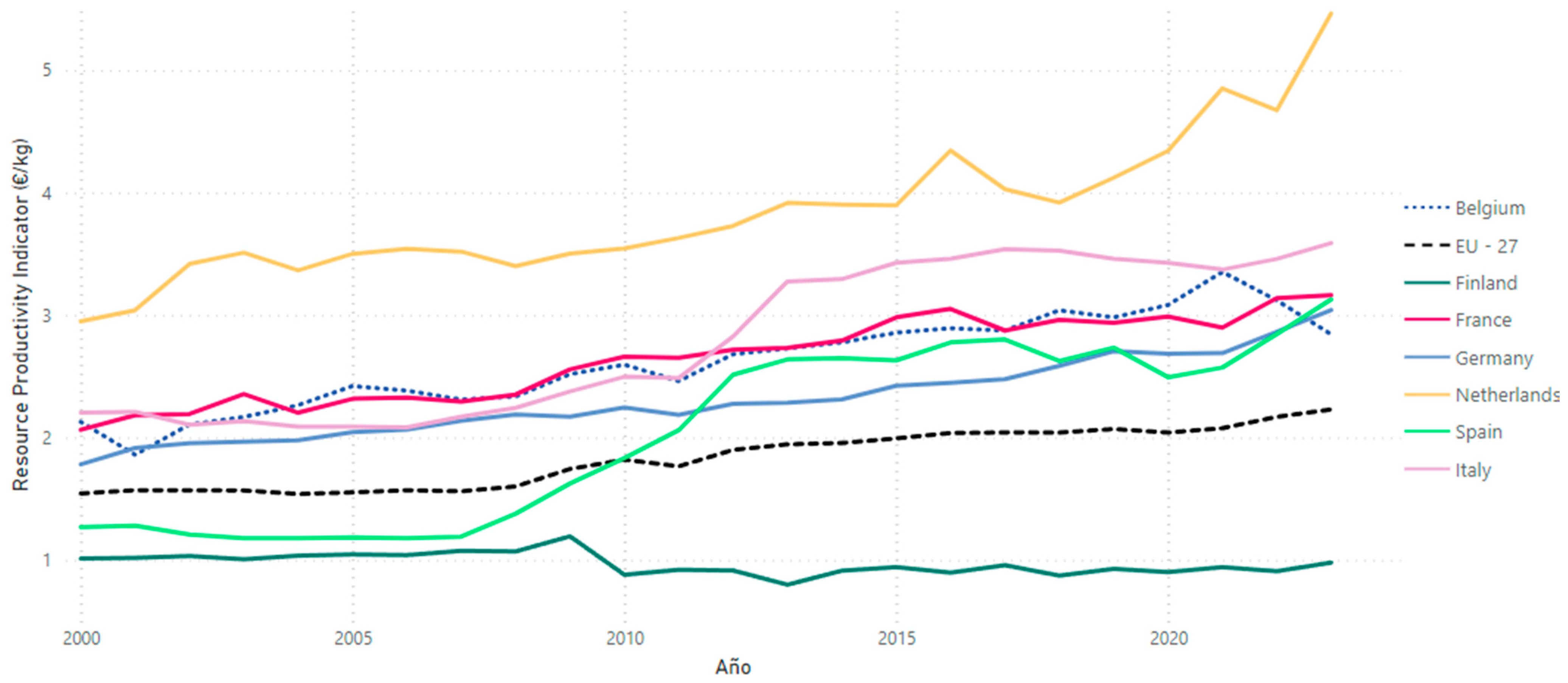

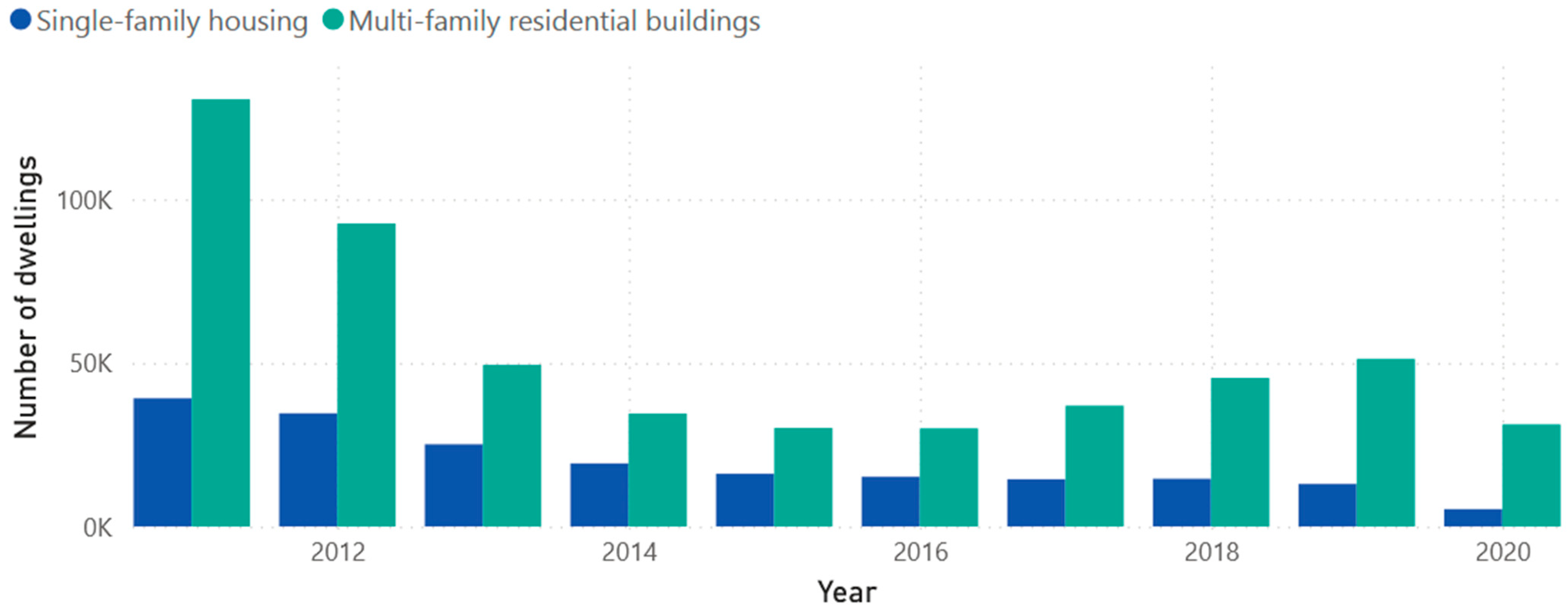

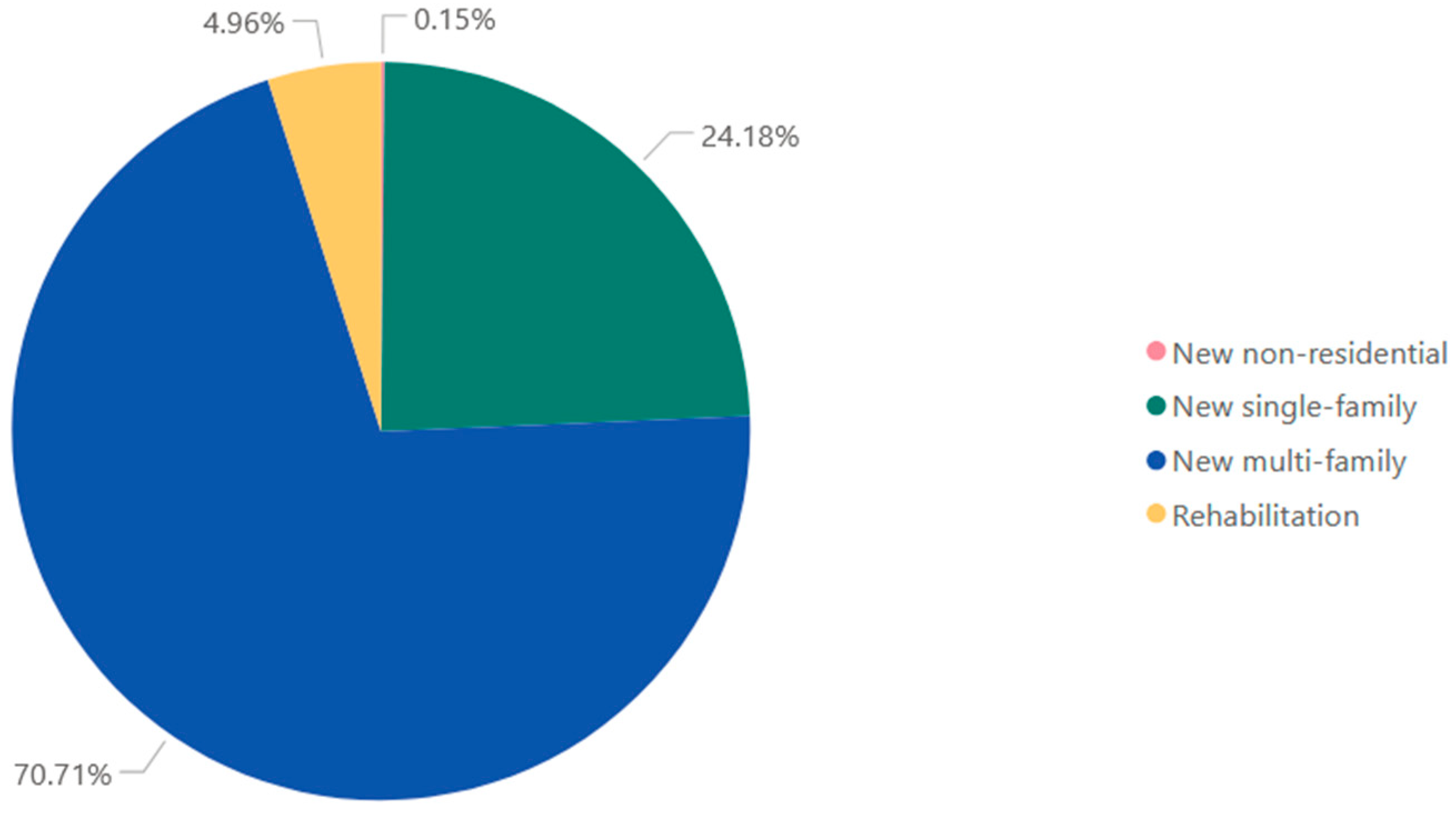

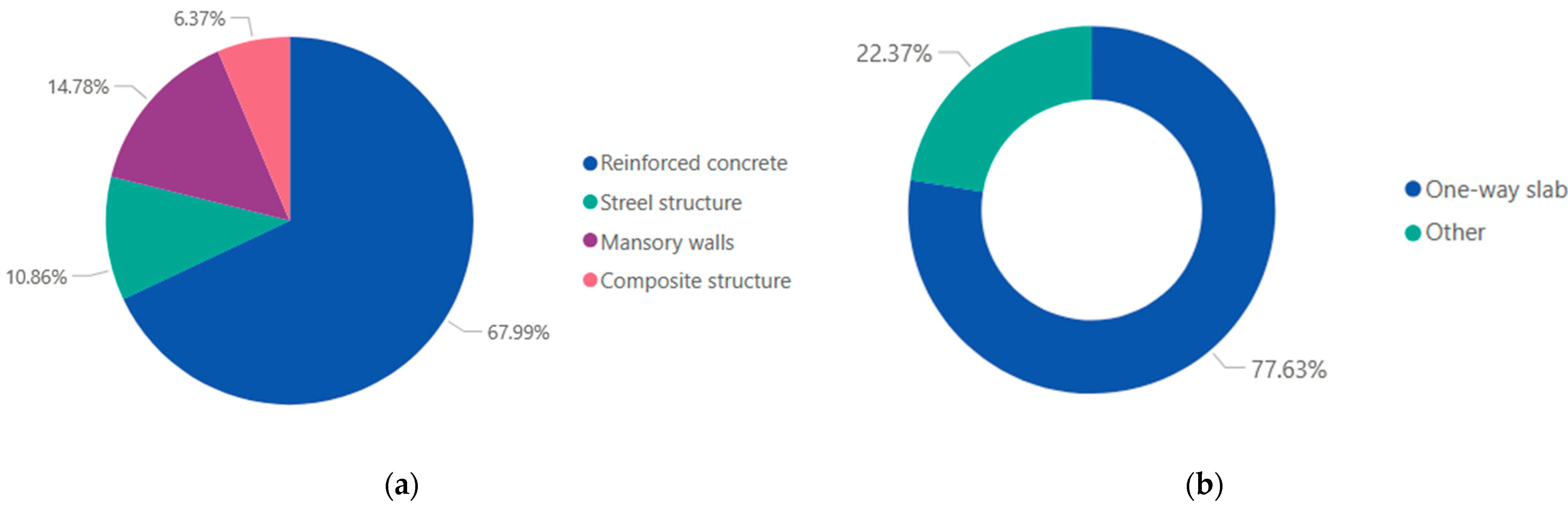

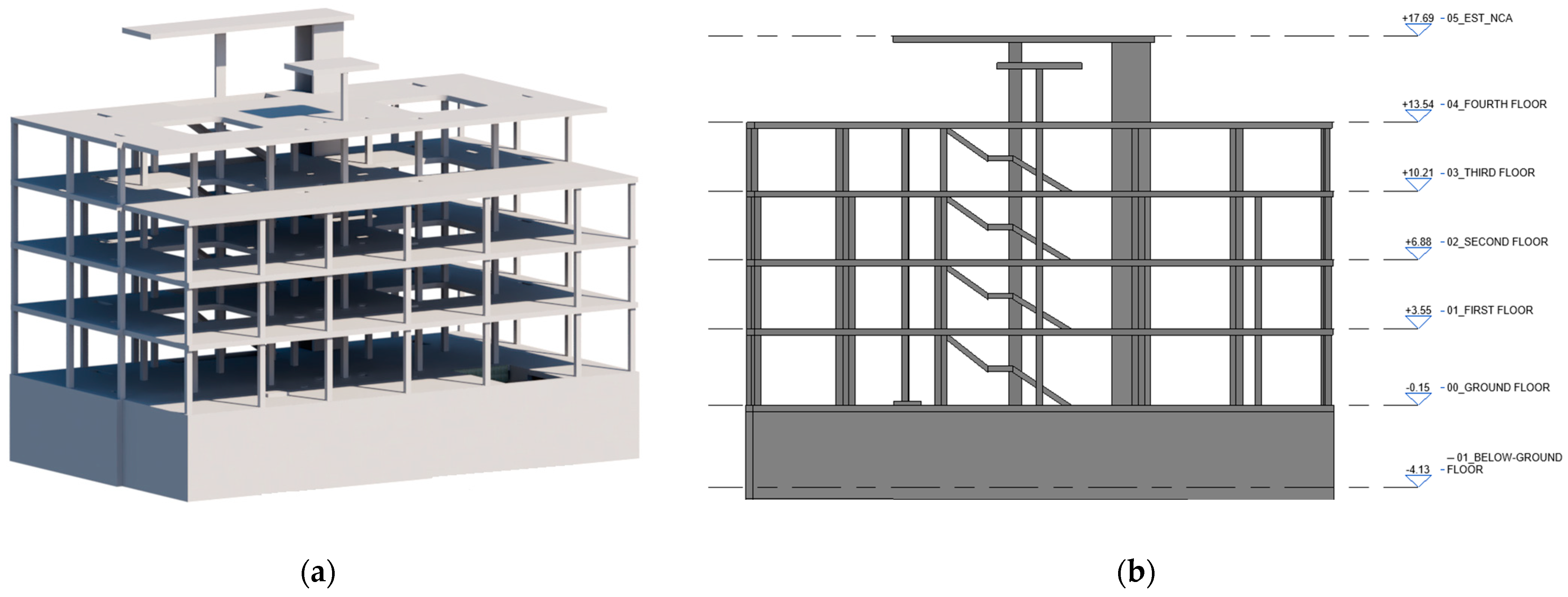

2.1. Phase 1. Characterisation of the Representative Newly Built Multi-Family Building

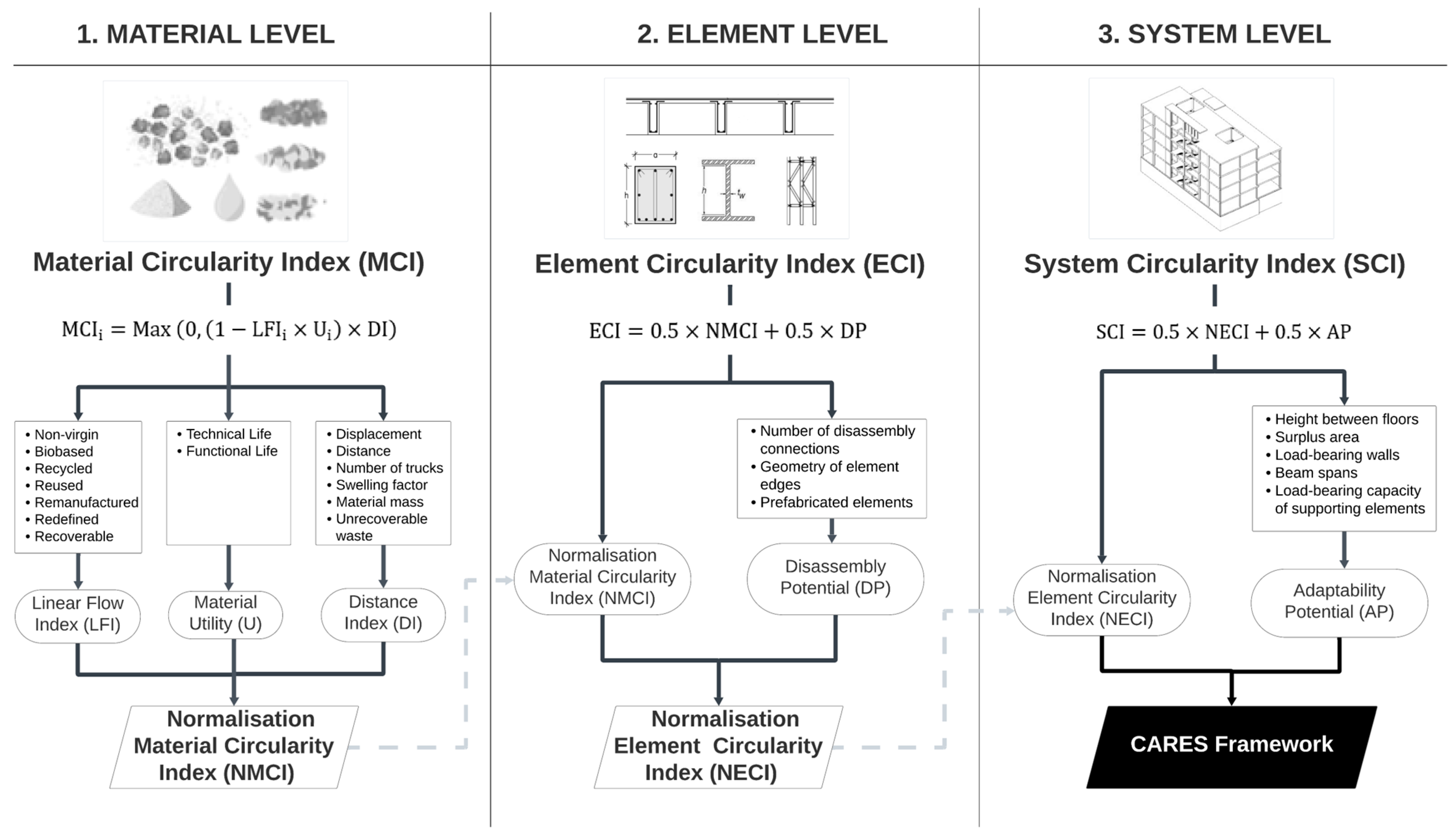

2.2. Phase 2. Empirical Data Collection and Circularity Assessment

2.2.1. Scenario Formulation and Empirical Data Collection

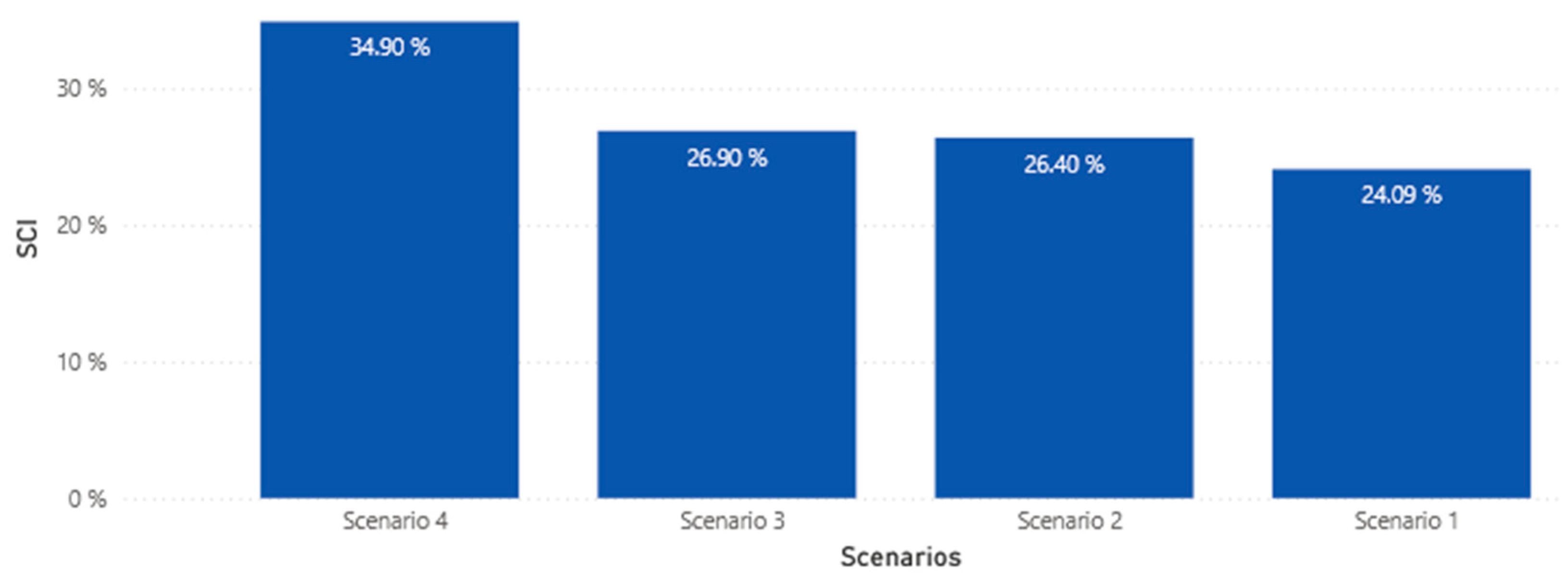

- Scenario 1 (S1) assessed the construction sector’s current practices by analysing material linearity throughout their entire lifespan.

- Scenario 3 (S3) examined circularity strategies applied to all materials, excluding concrete, across the complete lifecycle. This scenario highlighted the industry’s growing interest, particularly within the steel sector, in incorporating a higher percentage of secondary raw materials while ensuring compliance with required physical and mechanical properties [64].

- Scenario 4 (S4) extended these circularity strategies to encompass concrete by adopting RAC as structural concrete, thereby promoting a more sustainable approach to construction materials.

2.2.2. Circularity Assessment of Each Scenario Using the CARES-F Framework

2.3. Phase 3. Critical Analysis of Results

3. Characterisation of the Multi-Family Building Model

4. Circularity Assessment of Each Scenario

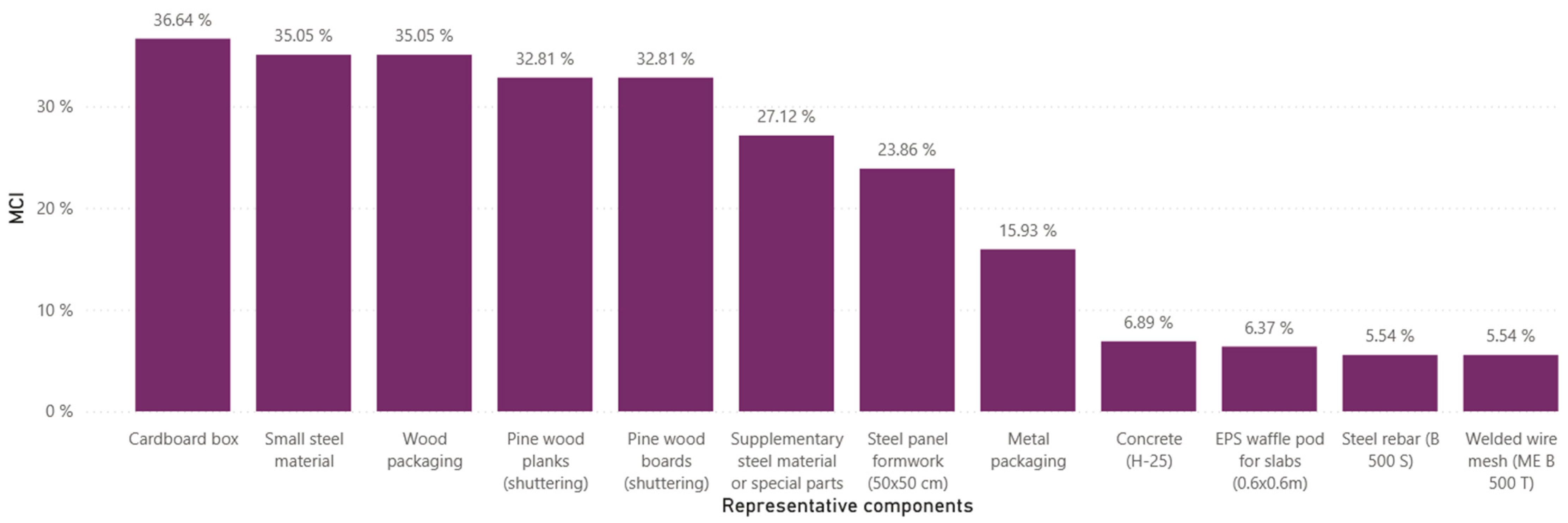

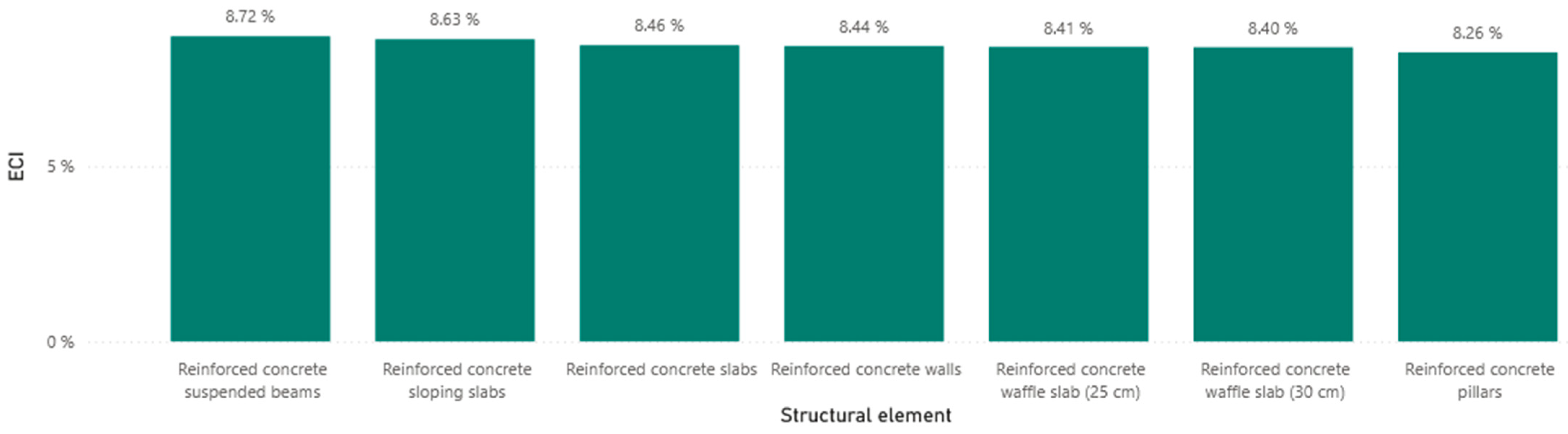

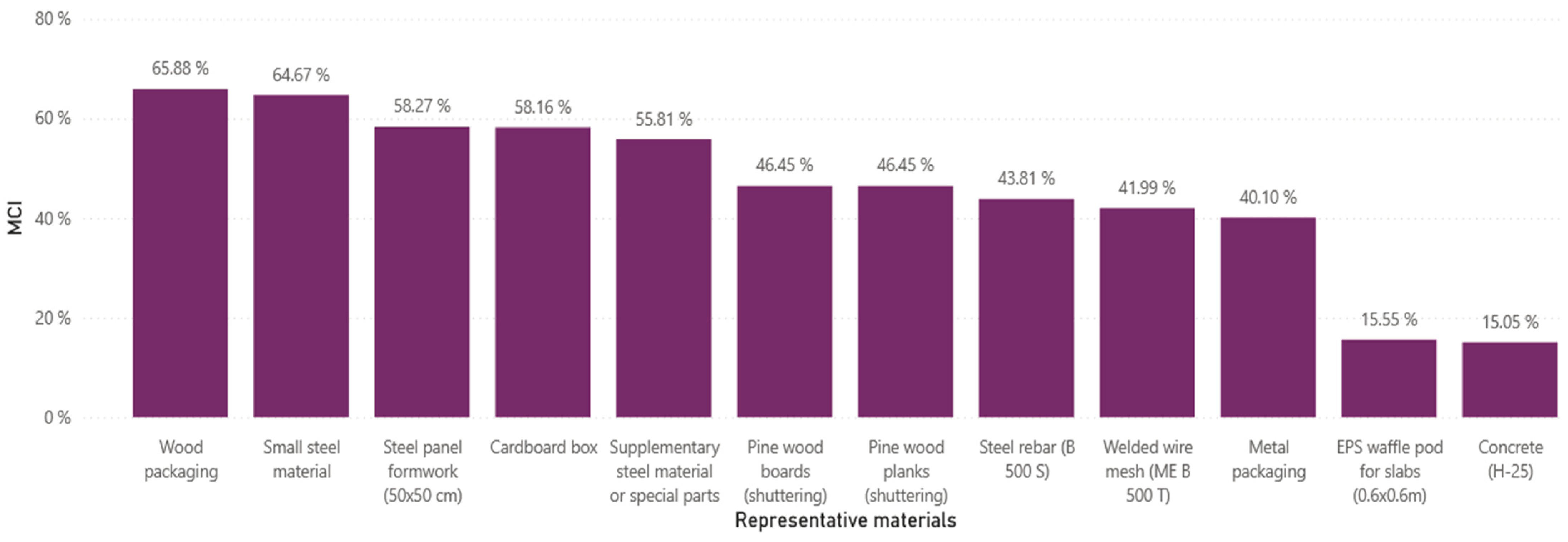

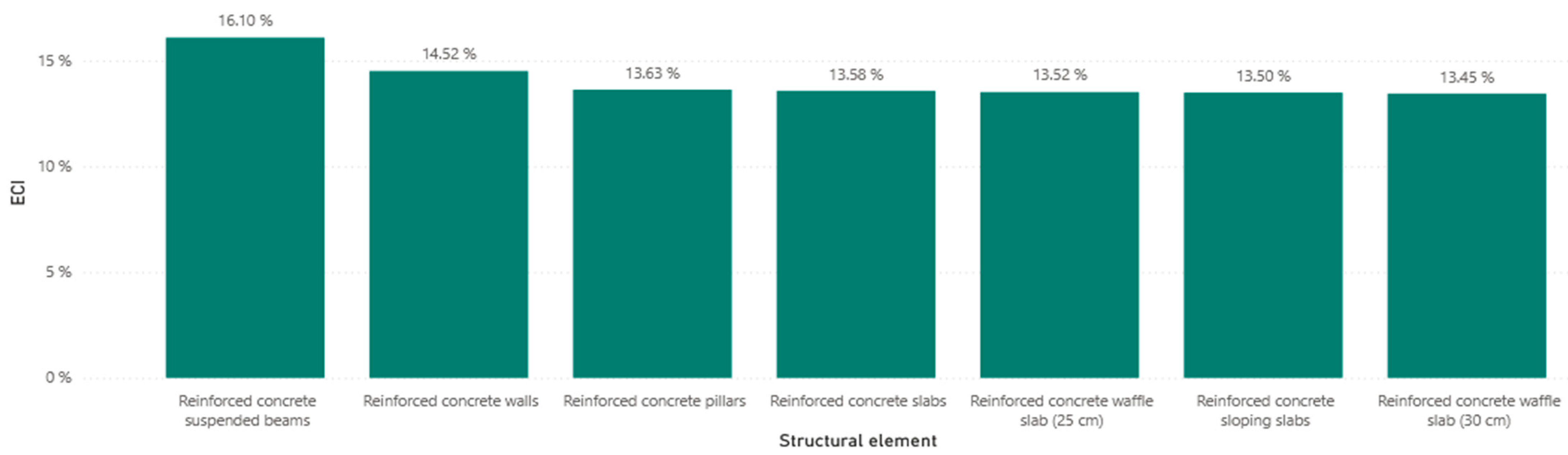

4.1. Scenario 1: Maintaining Material Linearity Throughout Its Lifespan

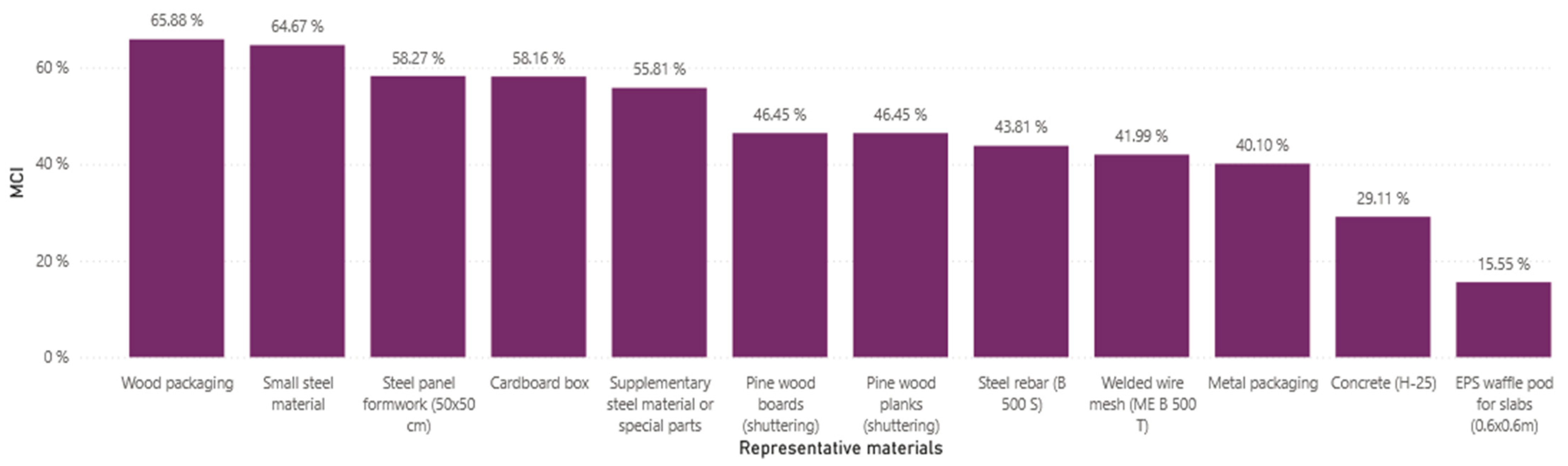

4.2. Scenario 2: Implementing Circularity Strategies at the EOL

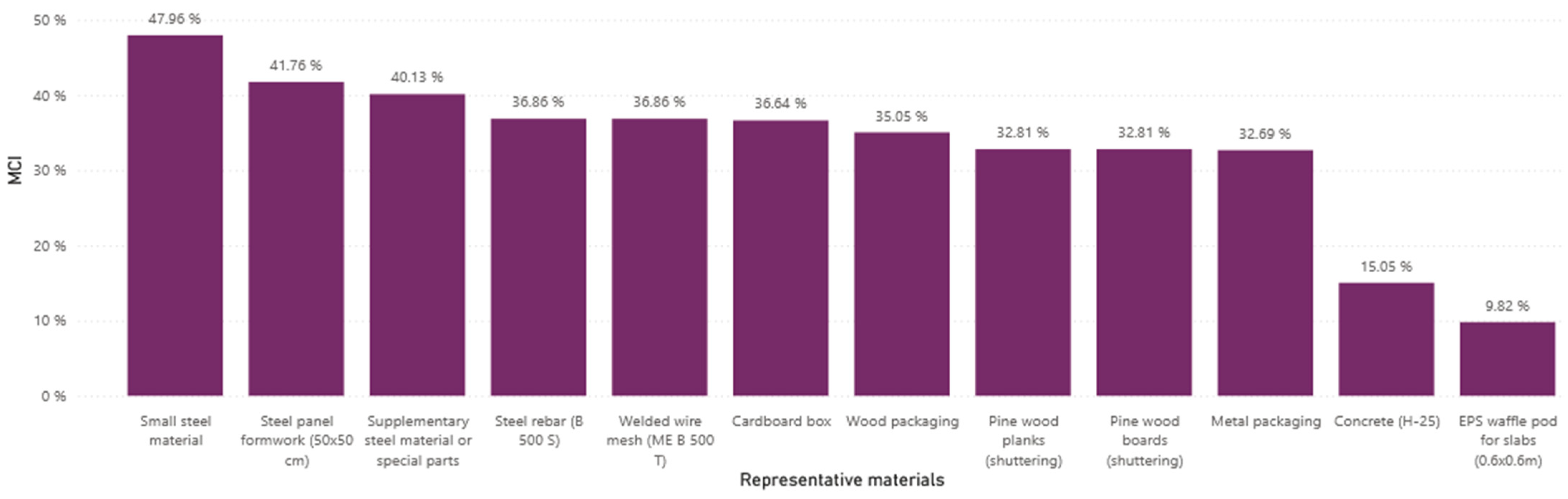

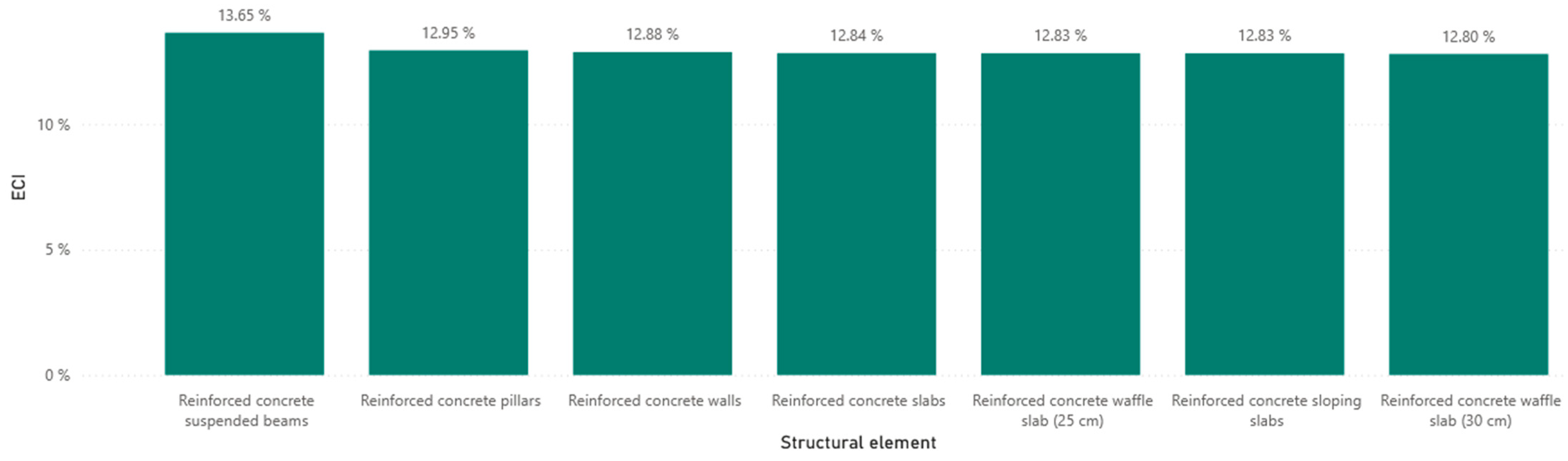

4.3. Scenario 3: Considering Circularity Strategies for All Materials, Excluding Concrete, Throughout the Entire Life Cycle

4.4. Scenario 4: Incorporating Circularity Strategies for All Materials, Including Concrete, Throughout the Entire Life Cycle

5. Discussion and Future Research

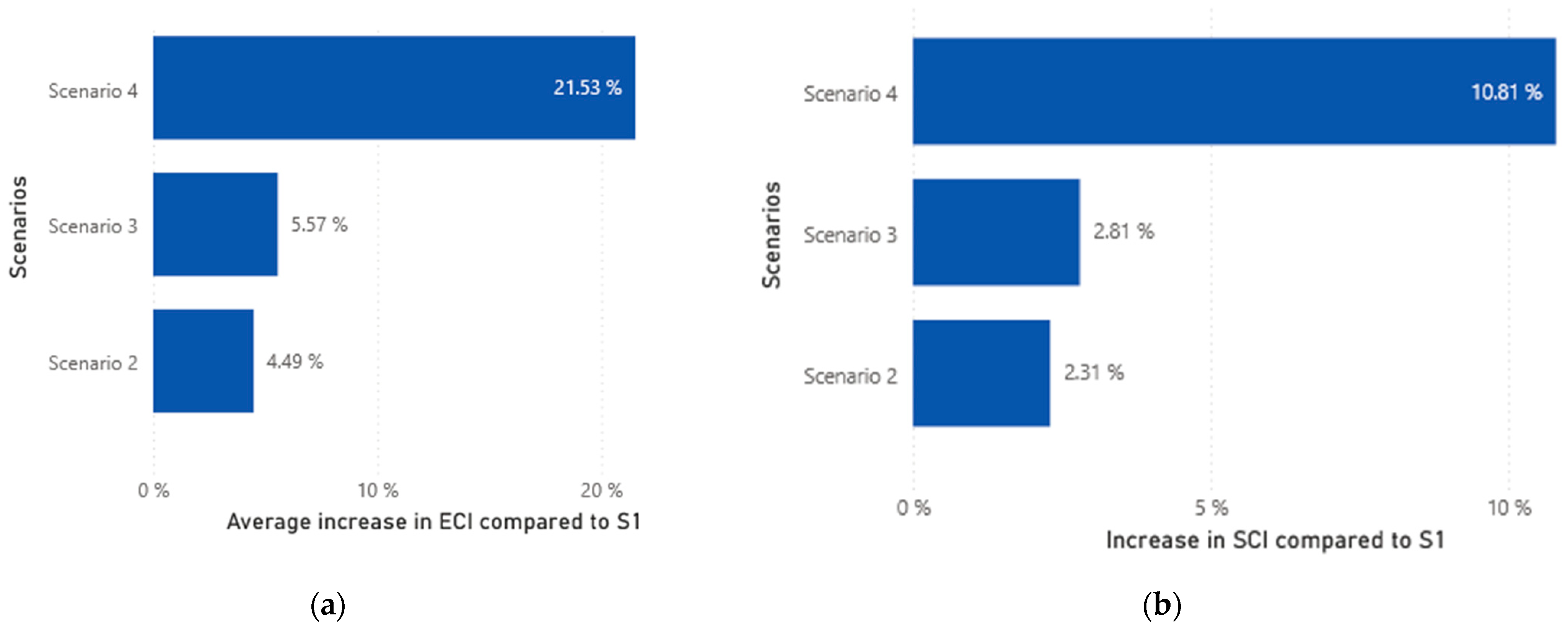

5.1. Impact of Material Circularity Strategies at All Levels in Each Scenario

5.2. Implications of Each Scenario at the Macro Level

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AP | Adaptability Potential |

| CARES-F | Circularity Assessment Method for Residential Structures (CARES Framework) |

| CDW | Construction and Demolition Waste |

| CE | Circular Economy |

| CMR | Circular Material Use Rate |

| CPM | Compressible Packaging Model |

| DAfStb | Guideline of the German Committee for Reinforced Concrete |

| DfA | Design for Adaptability |

| DfC | Design for Circularity |

| DfD | Design for Disassembly |

| DI | Distance Index |

| DMC | Domestic Material Consumption |

| DP | Disassembly Potential |

| EC | European Commission |

| ECI | Element Circularity Index |

| EEEC | CE Spanish Strategy |

| EOL | End Of Life |

| EU | European Union |

| GDP | Gross Domestic Product |

| GHG | Greenhouse Gas |

| IEA | International Energy Agency |

| INE | National Institute of Statistics (acronym in Spanish) |

| MCI | Material Circularity Index |

| MITMA | Ministry of Transport and Sustainable Mobility (acronym in Spanish) |

| NAC | Natural Aggregate Concrete |

| NCA | Natural Coarse Aggregate |

| NFA | Natural Fine Aggregate |

| RA | Recycled Aggregate |

| RAC | Recycled Aggregate Concrete |

| RCA | Recycled Coarse Aggregate |

| RPI | Resource Productivity Indicator |

| S1 | Scenario 1 |

| S2 | Scenario 2 |

| S3 | Scenario 3 |

| S4 | Scenario 4 |

| SCI | System Circularity Index |

| SDG | Sustainable Development Goals |

| SP | Superplasticiser |

References

- Neupane, R.P.; Devi, N.R.; Imjai, T.; Rajput, A.; Noguchi, T. Cutting-Edge Techniques and Environmental Insights in Recycled Concrete Aggregate Production: A Comprehensive Review. Resour. Conserv. Recycl. Adv. 2025, 25, 200241. [Google Scholar] [CrossRef]

- Scrivener, K.L. Options for the Future of Cement. Indian Concr. J. 2014, 88, 11–21. [Google Scholar]

- Mindess, S. (Ed.) Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Woodhead Publishing series in civil and structural engineering; Woodhead Publishing: Duxford, UK, 2019; ISBN 978-0-08-102616-8. [Google Scholar]

- Collivignarelli, M.C.; Cillari, G.; Ricciardi, P.; Miino, M.C.; Torretta, V.; Rada, E.C.; Abbà, A. The Production of Sustainable Concrete with the Use of Alternative Aggregates: A Review. Sustainability 2020, 12, 7903. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 22 September 2024).

- European Commission. Joint Research Centre; A New Circular Economy Action Plan For a Cleaner and More Competitive Europe; Renewable Energy Unit: Ispra, Italy, 2020. [Google Scholar]

- Banjerdpaiboon, A.; Limleamthong, P. Assessment of National Circular Economy Performance Using Super-Efficiency Dual Data Envelopment Analysis and Malmquist Productivity Index: Case Study of 27 European Countries. Heliyon 2023, 9, e16584. [Google Scholar] [CrossRef]

- Vásquez-Cabrera, A.; Montes, M.V.; Llatas, C. Meta-Analyses of Available Circular Assessment Methods: An Approach to the Spanish Building Sector. In Proceedings of the I Bienal de Investigación en Arquitectura (I BIAUS 2024), Sevilla, Spain, 17–20 September 2024. [Google Scholar]

- Eurostat Circular Economy—Material Flows. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Circular_economy_-_material_flows (accessed on 29 December 2024).

- Ellen MacArthur Foundation. Circular Economy Introduction. Available online: https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 22 August 2024).

- ISO/DIS 59004; Circular Economy—Terminology, Principles and Guidance for Implementation. ISO: Geneva, Switzerland, 2024.

- Arranz, C.F.A.; Arroyabe, M.F. Institutional Theory and Circular Economy Business Models: The Case of the European Union and the Role of Consumption Policies. J. Environ. Manag. 2023, 340, 117906. [Google Scholar] [CrossRef]

- Gardetti, M.A. 1—Introduction and the Concept of Circular Economy. In Circular Economy in Textiles and Apparel; Muthu, S.S., Ed.; The Textile Institute Book Series; Woodhead Publishing: Sawston, UK, 2019; pp. 1–11. ISBN 978-0-08-102630-4. [Google Scholar]

- Bragança, L.; Griffiths, P.; Askar, R.; Salles, A.; Ungureanu, V.; Tsikaloudaki, K.; Bajare, D.; Zsembinszki, G.; Cvetkovska, M. Circular Economy Design and Management in the Built Environment: A Critical Review of the State of the Art; Springer Tracts in Civil Engineering; Springer Nature: Cham, Switzerland, 2025; ISBN 978-3-031-73489-2. [Google Scholar]

- International Energy Agency. Cement. Available online: https://www.iea.org/energy-system/industry/cement (accessed on 28 December 2024).

- Demirbas, A.; Demirbas, M.F. Biomass and Wastes: Upgrading Alternative Fuels. Energy Sources 2003, 25, 317–329. [Google Scholar] [CrossRef]

- Trancone, G.; Policastro, G.; Spasiano, D.; Race, M.; Parrino, F.; Fratino, U.; Fabbricino, M.; Pirozzi, F. Treatment of Concrete Waste from Construction and Demolition Activities: Application of Organic Acids from Continuous Dark Fermentation in Moving Bed Biofilm Reactors. Chem. Eng. J. 2025, 505, 159536. [Google Scholar] [CrossRef]

- Singh, R.P.; Vanapalli, K.R.; Jadda, K.; Mohanty, B. Durability Assessment of Fly Ash, GGBS, and Silica Fume Based Geopolymer Concrete with Recycled Aggregates against Acid and Sulfate Attack. J. Build. Eng. 2024, 82, 108354. [Google Scholar] [CrossRef]

- Zhang, L.V.; Nehdi, M.L.; Suleiman, A.R.; Allaf, M.M.; Gan, M.; Marani, A.; Tuyan, M.; Bacteria, C.C. Crack Self-Healing in Bio-Green Concrete. Compos. Part B-Eng. 2021, 227, 109397. [Google Scholar] [CrossRef]

- Sangadji, S. Can Self-Healing Mechanism Helps Concrete Structures Sustainable? In Proceedings of the 3rd International Conference on Sustainable Civil Engineering Structures and Construction Materials—Sustainable Structures for Future Generations (SCESCM), Bali, Indonesia, 5–7 September 2016; Tim, T.C., Ueda, T., Mueller, H.S., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2017; Volume 171, pp. 238–249. [Google Scholar]

- Tziviloglou, E.; Pan, Z.; Jonkers, H.M.; Schlangen, E. Bio-Based Self-Healing Mortar: An Experimental and Numerical Study. J. Adv. Concr. Technol. 2017, 15, 536–543. [Google Scholar] [CrossRef]

- Regin, J.J.; Ilanthalir, A.; Shyni, R.L. Optimizing Lightweight Concrete with Coconut Shell Aggregates for High Strength and Sustainability. Glob. Nest. J. 2024, 26, 06214. [Google Scholar] [CrossRef]

- Pacheco, J.; Doniak, L.; Carvalho, M.; Helene, P. The Paradox of High Performance Concrete Used for Reducing Environmental Impact and Sustainability Increase. In Proceedings of the II International Conference on Concrete Sustainability—ICCS16, Madrid, Spain, 13–15 June 2016; Galvez, J.C., DeCea, A.A., FernandezOrdonez, D., Sakai, K., Reyes, E., Casati, M.J., Enfedaque, A., Alberti, M.G., DeLaFuente, A., Eds.; Int Center Numerical Methods Engineering: Barcelona, Spain, 2016; pp. 442–453. [Google Scholar]

- Xargay, H.; Folino, P.; Sambataro, L.; Etse, G. Temperature Effects on Failure Behavior of Self-Compacting High Strength Plain and Fiber Reinforced Concrete. Constr. Build. Mater. 2018, 165, 723–734. [Google Scholar] [CrossRef]

- Lim, S.G.; Tay, Y.W.D.; Paul, S.C.; Lee, J.; Amr, I.T.; Fadhel, B.A.; Jamal, A.; Al-Khowaiter, A.O.; Tan, M.J. Carbon Capture and Sequestration with In-Situ CO2 and Steam Integrated 3D Concrete Printing. Carbon Capture Sci. Technol. 2024, 13, 100306. [Google Scholar] [CrossRef]

- Kline, J.; Kline, C. CO2 Capture from Cement Manufacture and Reuse in Concrete. In Proceedings of the 2018 IEEE-IAS/PCA Cement Industry Technical Conference, Nashville, TN, USA, 6–10 May 2018; IEEE: New York, NY, USA, 2018. [Google Scholar]

- Kim, S.; Park, C. Durability and Mechanical Characteristics of Blast-Furnace Slag Based Activated Carbon-Capturing Concrete with Respect to Cement Content. Appl. Sci. 2020, 10, 2083. [Google Scholar] [CrossRef]

- Folino, P.; Xargay, H. Recycled Aggregate Concrete—Mechanical Behavior under Uniaxial and Triaxial Compression. Constr. Build. Mater. 2014, 56, 21–31. [Google Scholar] [CrossRef]

- Babalola, O.E.; Awoyera, P.O.; Tran, M.T.; Le, D.-H.; Olalusi, O.B.; Viloria, A.; Ovallos-Gazabon, D. Mechanical and Durability Properties of Recycled Aggregate Concrete with Ternary Binder System and Optimized Mix Proportion. J. Mater. Res. Technol. 2020, 9, 6521–6532. [Google Scholar] [CrossRef]

- Vahidi, A.; Mostaani, A.; Teklay Gebremariam, A.; Di Maio, F.; Rem, P. Feasibility of Utilizing Recycled Coarse Aggregates in Commercial Concrete Production. J. Clean. Prod. 2024, 474, 143578. [Google Scholar] [CrossRef]

- Dosho, Y. Development of a Sustainable Concrete Waste Recycling System: Application of Recycled Aggregate Concrete Produced by Aggregate Replacing Method. J. Adv. Concr. Technol. 2007, 5, 27–42. [Google Scholar] [CrossRef]

- Xiao, J.; Li, L.; Shen, L.; Poon, C.S. Compressive Behaviour of Recycled Aggregate Concrete under Impact Loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable Cement Production—Present and Future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Fischer, C.; Werge, M.; Reichel, A. Present Recycling Levels of Municipal Waste and Construction & Demolition Waste in the EU; EU as a Recycling Society; European Environment Agency: Copenhagen, Denmark, 2009; pp. 1–73. [Google Scholar]

- European Aggregates Association. A Sustainable Industry for a Sustainable Europe—Annual Review 2017–2018; European Aggregates Association: Brussels, Belgium, 2021. [Google Scholar]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Influence of Different Treatment Methods on the Mechanical Behavior of Recycled Aggregate Concrete: A Comparative Study. Cem. Concr. Compos. 2019, 104, 103398. [Google Scholar] [CrossRef]

- Hou, S.; Duan, Z.; Xiao, J.; Li, L.; Bai, Y. Effect of Moisture Condition and Brick Content in Recycled Coarse Aggregate on Rheological Properties of Fresh Concrete. J. Build. Eng. 2021, 35, 102075. [Google Scholar] [CrossRef]

- Neupane, R.P.; Imjai, T.; Makul, N.; Garcia, R.; Kim, B.; Chaudhary, S. Use of Recycled Aggregate Concrete in Structural Members: A Review Focused on Southeast Asia. J. Asian Archit. Build. Eng. 2023, 1–24. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of Pervious Concrete Containing Recycled Concrete Block Aggregate and Recycled Concrete Aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Chakradhara Rao, M. Properties of Recycled Aggregate and Recycled Aggregate Concrete: Effect of Parent Concrete. Asian J. Civ. Eng. 2018, 19, 103–110. [Google Scholar] [CrossRef]

- Rahal, K.N.; Alrefaei, Y.T. Shear Strength of Recycled Aggregate Concrete Beams Containing Stirrups. Constr. Build. Mater. 2018, 191, 866–876. [Google Scholar] [CrossRef]

- Plaza, P.; Bosque, I.; Sánchez, J.; Medina, C. Recycled Eco-Concretes Containing Fine and/or Coarse Concrete Aggregates. Mechanical Performance. Appl. Sci. 2024, 14, 3995. [Google Scholar] [CrossRef]

- Salgado, F.D.A.; Silva, F.D.A. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A Review of Recycled Aggregate in Concrete Applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Spanish Structural Code; Código Estructural (Real Decreto 470/2021). Ministerio de Transportes y Movilidad Sostenible: Madrid, Spain, 2021. Available online: https://www.transportes.gob.es/ministerio/normativa-y-estudios-tecnicos/reglamentacion-vigente-sobre-seguridad-estructural/codigo-estructural (accessed on 18 November 2024).

- UNE-EN 12620; Áridos Para Hormigón. AENOR: Madrid, España, 2009.

- De Brito, J.; Silva, R.V. Current Status on the Use of Recycled Aggregates in Concrete: Where Do We Go from Here? RILEM Tech. Lett. 2016, 1, 1–5. [Google Scholar] [CrossRef]

- E 471-2009; Guia Para a Utilização de Agregados Reciclados Grossos Em Betões de Ligantes Hidráulicos. Especificação LNEC: Lisboa, Portugal, 2009.

- NEN-5905; Aggregates for Concrete. Royal Netherlands Standardization Institute: Delft, The Netherlands, 2005.

- BSI BS 8500-2; Complementary British Standard to BS EN 206—Specification for Constituent Materials and Concrete. Concrete Centre: London, UK, 2023; ISBN 978-0-539-29610-5.

- DAfStb 2010; Concrete in Accordance with DIN EN 206-1 and DIN 1045-2 with Recycled Aggregates in Accordance with DIN EN 12620. Deutscher Ausschuss für Stahlbeton e. V.: Berlin, Germany, 2010.

- Jayasuriya, A.; Shibata, E.S.; Chen, T.; Adams, M.P. Development and Statistical Database Analysis of Hardened Concrete Properties Made with Recycled Concrete Aggregates. Resour. Conserv. Recycl. 2021, 164, 105121. [Google Scholar] [CrossRef]

- Etxeberria, M.; Marí, A.R.; Vázquez, E. Recycled Aggregate Concrete as Structural Material. Mater. Struct. 2007, 40, 529–541. [Google Scholar] [CrossRef]

- Gonçalves, P.; de Brito, J. Recycled Aggregate Concrete (RAC)—Comparative Analysis of Existing Specifications. Mag. Concr. Res. 2010, 62, 339–346. [Google Scholar] [CrossRef]

- McNeil, K.; Kang, T.H.-K. Recycled Concrete Aggregates: A Review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, L.; Le, K.N. Cross-Cultural Comparison of Concrete Recycling Decision-Making and Implementation in Construction Industry. Waste Manag. 2010, 30, 291–297. [Google Scholar] [CrossRef]

- Morató, J.; Jiménez, L.M.; Calleros-Islas, A.; De la Cruz, J.L.; Díaz, L.D.; Martínez, J.; P.-Lagüela, E.; Penagos, G.; Pernas, J.J.; Rovira, S.; et al. Situación y Evolución de La Economía Circular en España; Fundación COTEC: Madrid, España, 2021; Volume 3. [Google Scholar]

- Morató, J.; Jiménez, L.M.; Penagos, G.; Sánchez, O.L.; Villanueva, B.; de la Cruz, J.L.; Martí, C.; Lagüela, E.P.; Pereira, S.; Pernas, J.J.; et al. Situación y Evolución de La Economía Circular en España; Fundación COTEC: Madrid, España, 2023; Volume 4. [Google Scholar]

- Eurostat. Resource Productivity. Available online: https://ec.europa.eu/eurostat/databrowser/product/page/CEI_PC030 (accessed on 11 January 2025).

- Eurostat. Circular Material Use Rate. Available online: https://ec.europa.eu/eurostat/databrowser/view/sdg_12_41/default/map?lang=en (accessed on 10 January 2025).

- EMVISESA. Empresa Municipal de la Vivienda de Sevilla. Available online: https://www.emvisesa.org/ (accessed on 25 September 2024).

- Vásquez-Cabrera, A.; Montes, M.V.; Llatas, C. CARES Framework: A Circularity Assessment Method for Residential Building Structures. Sustainability 2025, 17, 443. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Material Circularity Indicator. Available online: https://www.ellenmacarthurfoundation.org/material-circularity-indicator (accessed on 10 September 2024).

- Ihobe; LKS Ingeniería; Ecoingenium. Guía Para el Uso de Materiales Reciclados en Construcción; Ihobe, Sociedad Pública de Gestión Ambiental: Bilbao, Spain, 2016. [Google Scholar]

- Gonzalez-Vallejo, P. Evaluación Económica y Ambiental de la Construcción de Edificios residenciales. Aplicación a España y Chile. Ph.D. Thesis, Universidad de Sevilla, Sevilla, Spain, 2017. [Google Scholar]

- Lopez-Ochoa, L.M.; Sagredo-Blanco, E.; Las-Heras-Casas, J.; Garcia-Lozano, C. Towards Nearly Zero-Energy Buildings in Cold Rural Mediterranean Zones: The Case of La Rioja (Spain). Buildings 2023, 13, 680. [Google Scholar] [CrossRef]

- Rodriguez Serrano, A.A.; Alvarez, S.P. Life Cycle Assessment in Building: A Case Study on the Energy and Emissions Impact Related to the Choice of Housing Typologies and Construction Process in Spain. Sustainability 2016, 8, 287. [Google Scholar] [CrossRef]

- Castrillon-Mendoza, R.; Rey-Hernandez, J.M.; Castrillon-Mendoza, L.; Rey-Martinez, F.J. Sustainable Building Tool by Energy Baseline: Case Study. Appl. Sci. 2024, 14, 9403. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Anaya-Duran, P.; Romero-Cortes, A. Eco-Efficient Ventilated Facades Based on Circular Economy for Residential Buildings as an Improvement of Energy Conditions. Energies 2021, 14, 7266. [Google Scholar] [CrossRef]

- Llatas, C. A Model for Quantifying Construction Waste in Projects According to the European Waste List. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef]

- Llatas, C.; Osmani, M. Development and Validation of a Building Design Waste Reduction Model. Waste Manag. 2016, 56, 318–336. [Google Scholar] [CrossRef] [PubMed]

- Quiñones, R.; Llatas, C.; Montes, M.V.; Cortés, I. Quantification of Construction Waste in Early Design Stages Using Bim-Based Tool. Recycling 2022, 7, 63. [Google Scholar] [CrossRef]

- Llatas, C.; Quiñones, R.; Bizcocho, N. Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage. Recycling 2022, 7, 82. [Google Scholar] [CrossRef]

- Diaz-Lopez, C.; Carpio, M.; Martin-Morales, M.; Zamorano, M. Defining Strategies to Adopt Level(s) for Bringing Buildings into the Circular Economy. A Case Study of Spain. J. Clean Prod. 2021, 287, 125048. [Google Scholar] [CrossRef]

- Proyecto GEAR. Guía Española de áridos reciclados procedentes de RCD, 2nd ed.; Proyecto GEAR: Ministerio de Medio Ambiente y Medio Rural y Marino: Madrid, Spain, 2012. [Google Scholar]

- Tošić, N.; Torrenti, J.M.; Sedran, T.; Ignjatović, I. Toward a Codified Design of Recycled Aggregate Concrete Structures: Background for the New Fib Model Code 2020 and Eurocode 2. Struct. Concr. 2021, 22, 2916–2938. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and Barriers towards Circular Economy in the Building Sector: Stakeholder Interviews and Analysis of Five European Countries Policies and Practices. J. Clean. Prod. 2022, 336, 130395. [Google Scholar] [CrossRef]

- AlJaber, A.; Martinez-Vazquez, P.; Baniotopoulos, C. Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review. Buildings 2023, 13, 2778. [Google Scholar] [CrossRef]

- Cruz Rios, F.; Grau, D.; Bilec, M. Barriers and Enablers to Circular Building Design in the US: An Empirical Study. J. Constr. Eng. Manag. 2021, 147, 04021117. [Google Scholar] [CrossRef]

- Ministry of Transport and Sustainable. Mobility Statistics of Buildings Constructed. 2022. Available online: https://apps.fomento.gob.es/BoletinOnline/?nivel=2&orden=10000000 (accessed on 12 January 2025).

- Andrich, W.; Daniotti, B.; Pavan, A.; Mirarchi, C. Check and Validation of Building Information Models in Detailed Design Phase: A Check Flow to Pave the Way for BIM Based Renovation and Construction Processes. Buildings 2022, 12, 154. [Google Scholar] [CrossRef]

- INE. Population and Housing Census 2021. Available online: https://www.ine.es/Censo2021/Inicio.do?L=0 (accessed on 17 January 2025).

- Ministry of Transport and Sustainable. Mobility Statistics of Buildings Constructed. 2003–2019. Available online: https://www.transportes.gob.es/informacion-para-el-ciudadano/informacion-estadistica/construccion/construccion-de-edificios/publicaciones-de-construccion-de-edificios-licencias-municipales-de-obra (accessed on 17 January 2025).

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for Existing Buildings—Literature Review and Future Needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Ciribini, A.L.C.; Bolpagni, M.; Oliveri, E. An Innovative Approach to E-Public Tendering Based on Model Checking. Procedia Econ. Financ. 2015, 21, 32–39. [Google Scholar] [CrossRef]

- Getuli, V.; Ventura, S.M.; Capone, P.; Ciribini, A.L.C. BIM-Based Code Checking for Construction Health and Safety. Procedia Eng. 2017, 196, 454–461. [Google Scholar] [CrossRef]

- González-Vallejo, P.; Solís-Guzmán, J.; Llácer, R.; Marrero, M. La construcción de edificios residenciales en España en el período 2007–2010 y su impacto según el indicador Huella Ecológica. Inf. Constr. 2015, 67, e111. [Google Scholar] [CrossRef]

- IMPARGO. CargoApps 2.0 TMS Para Transportistas y Empresas de Transporte. Available online: https://company.impargo.de/es/tms-cargo-app-2.0 (accessed on 3 December 2024).

- Ministerio de la Presidencia. BOE-A-1999-1826 Real Decreto 2822/1998, de 23 de Diciembre, Por El Que Se Aprueba El Reglamento General de Vehículos. Available online: https://www.boe.es/buscar/act.php?id=BOE-A-1999-1826 (accessed on 3 December 2024).

- Ministerio de la Presidencia. Relaciones con las Cortes e Igualdad Real Decreto 1514/2018, de 28 de Diciembre, Por El Que Se Modifica El Reglamento General de Circulación, Aprobado Por El Real Decreto 1428/2003, de 21 de Noviembre; Ministerio de la Presidencia: Madrid, Spain, 2018; Volume BOE-A-2018-18002, pp. 130043–130045. [Google Scholar]

- Emblem, H.J. Packaging and Environmental Sustainability. In Packaging Technology; Emblem, A., Emblem, H., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 65–86. ISBN 978-1-84569-665-8. [Google Scholar]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance); European Commission: Luxembourg, 2008; Volume 312. [Google Scholar]

- Sander, K.; Schilling, S.; Lüskow, H.; Gonser, J.; Schwedtje, A.; Küchen, V. Review of the European List of Waste; European commission in Cooperation with Ökopol GmbH and ARGUS GmbH; European Commission: Luxembourg, 2008. [Google Scholar]

- Eurostat Database Trade in Recyclable Raw Materials (Cei_srm020). Available online: https://ec.europa.eu/eurostat/cache/metadata/en/cei_srm020_esmsip2.htm (accessed on 25 September 2024).

- EGGA. Acero Galvanizado y Construcción Sostenible; European General Galvanizers Association: Madrid, España, 2021. [Google Scholar]

- Eurostat Database Contribution of Recycled Materials to Raw Materials Demand—End-of-Life Recycling Input Rates (EOL-RIR) (Cei_srm010). Available online: https://ec.europa.eu/eurostat/cache/metadata/en/cei_srm010_esmsip2.htm (accessed on 25 September 2024).

- Plastics Europe. The CE of Plastics; Plastics Europe: Madrid, España, 2022. [Google Scholar]

- EuRIC AISBL. Metal Recycling Factsheet; EuRIC AISBL: Schaerbeek, Belgium, 2020. [Google Scholar]

- Eurostat Database Packaging Waste by Waste Management Operations (Env_Waspac). Available online: https://ec.europa.eu/eurostat/cache/metadata/en/env_waspac_esms.htm (accessed on 25 September 2024).

- Döhler, N.; Wellenreuther, C.; Wolf, A. Market dynamics of biodegradable bio-based plastics: Projections and linkages to European policies. EFB Bioecon. J. 2022, 2, 100028. [Google Scholar] [CrossRef]

- Amario, M.; Rangel, C.S.; Pepe, M.; Toledo Filho, R.D. Optimization of Normal and High Strength Recycled Aggregate Concrete Mixtures by Using Packing Model. Cem. Concr. Compos. 2017, 84, 83–92. [Google Scholar] [CrossRef]

- Vaz, A.; Shehata, I.; Shehata, L.; Gomes, R.B. Comportamento de Vigas Reforçadas Sob Ação de Carregamento Cíclico. Rev. IBRACON Estrut. E Mater. 2017, 10, 1245–1272. [Google Scholar] [CrossRef]

- WRAP. Designing out Waste: A Design Team Guide for Buildings; Waste and Resources Action Program: Oxon, UK, 2023. [Google Scholar]

- Durmisevic, E. Transformable Building Structures. Design for Disassembly as a Way to Introduce Sustainable Engineering to Building Design & Construction. Ph.D. Thesis, Technische Universiteit Delft, Delf, The Netherlands, 2006. [Google Scholar]

- Dodd, N.; Donatello, S.; Cordella, M.; Perez, Z. Indicador 2.4 de Level(s): Diseño Para la Deconstrucción; European Commission: Luxembourg, 2021. [Google Scholar]

- Geraedts, R. FLEX 4.0, A Practical Instrument to Assess the Adaptive Capacity of Buildings. Energy Procedia 2016, 96, 568–579. [Google Scholar] [CrossRef]

- Dodd, N.; Donatello, S.; Cordella, M. Indicador 2.3 de Level(s): Diseño Con Fines de Adaptabilidad y Reforma; European Commission: Luxembourg, 2021. [Google Scholar]

- Yao, Y.; Hong, B. Evolution of Recycled Concrete Research: A Data-Driven Scientometric Review. Low-Carbon Mater. Green Constr. 2024, 2, 16. [Google Scholar] [CrossRef]

- Subdirección General de Economía Circular. Estrategia Española de Economía Circular. España Circular 2030; Ministerio para la Transición Ecológica y el Reto Demográfico (MITECO): Madrid, Spain, 2018. [Google Scholar]

- Tejas, S.; Pasla, D. Assessment of Mechanical and Durability Properties of Composite Cement-Based Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 387, 131620. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Publishers: The Hague, The Netherlands, 2017. [Google Scholar]

- AlJaber, A.; Martinez-Vazquez, P.; Baniotopoulos, C. Exploring Circular Economy Strategies in Buildings: Evaluating Feasibility, Stakeholders Influence, and the Role of the Building Lifecycle in Effective Adoption. Appl. Sci. 2025, 15, 1174. [Google Scholar] [CrossRef]

- Abera, Y.A. Sustainable Building Materials: A Comprehensive Study on Eco-Friendly Alternatives for Construction. Compos. Adv. Mater. 2024, 33, 26349833241255957. [Google Scholar] [CrossRef]

| LoW 1 Code and Description | Representative Material | Participation Mass Ratio | |

|---|---|---|---|

| 170101 | Concrete | Concrete (H-25) | 93.33% |

| 170405 | Iron and steel | Steel rebar (B 500 S) | 2.82% |

| 170405 | Iron and steel | Small steel material | 1.08% |

| 150111 * | Metallic packaging containing a hazardous solid porous matrix | Metallic packaging | 0.55% |

| 170405 | Iron and steel | Supplementary steel material or special parts | 0.54% |

| 170201 | Wood | Pinewood planks (shuttering) | 0.45% |

| 170201 | Wood | Pinewood boards (shuttering) | 0.43% |

| 170405 | Iron and steel | Welded wire mesh (ME B 500 T) | 0.13% |

| 170604 | Insulation materials | EPS waffle pod for slabs (0.6 × 0.6 m) | 0.11% |

| 150103 | Wooden packaging | Wooden packaging | 0.10% |

| 170405 | Iron and steel | Steel panel formwork (50 × 50 cm) | 0.10% |

| 150101 | Paper and cardboard packaging | Cardboard box | 0.10% |

| LoW Code and Description | Title | Author | Year | |

|---|---|---|---|---|

| 170101 | Concrete | Spanish Guide to Recycled Aggregates from RCD | GEAR [75] | 2012 |

| 170405 | Iron and steel | Guideline for recycled materials reused in construction Trade in Recyclable Raw Materials (database) Galvanised steel and sustainable construction (report) | Ihobe [64] Eurostat [94] EGGA [95] | 2016 2022 2021 |

| 170201 | Wood | Contribution of Recycled Materials to Raw Materials Demand (database) | Eurostat [96] | 2020 |

| 170203 | Plastic | The CE of plastics (report) Packaging and environmental sustainability | Plastics Europe [97] Emblem et al. [91] | 2022 2012 |

| 150111 * | Metallic packaging | Metal Recycling Factsheet | EuRIC AISBL [98] | 2022 |

| 150103 | Wooden packaging | Packaging Waste by Waste Management Operations (database) Trade in Recyclable Raw Materials (database) | Eurostat [99] | 2023 |

| 170604 | Insulation materials | Eurostat [94] | ||

| 150101 | Paper and cardboard packaging | 2022 | ||

| Composition | Properties | ||

|---|---|---|---|

| Cement | 266.4 kg/m3 | Compressive strength | 25 MPa |

| Free water | 170.0 kg/m3 | % of RCA | 20% |

| Natural Fine Aggregate (NFA) | 844.4 kg/m3 | Effective water-cement ratio | 0.64 |

| Natural Coarse Aggregate (NCA) | 803.0 kg/m3 | ||

| Recycled Coarse Aggregate (RCA) | 195.6 kg/m3 | ||

| Superplasticiser (SP) | 2.7 kg/m3 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vásquez-Cabrera, A.; Montes, M.V.; Llatas, C. The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain. Appl. Sci. 2025, 15, 3265. https://doi.org/10.3390/app15063265

Vásquez-Cabrera A, Montes MV, Llatas C. The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain. Applied Sciences. 2025; 15(6):3265. https://doi.org/10.3390/app15063265

Chicago/Turabian StyleVásquez-Cabrera, Alicia, Maria Victoria Montes, and Carmen Llatas. 2025. "The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain" Applied Sciences 15, no. 6: 3265. https://doi.org/10.3390/app15063265

APA StyleVásquez-Cabrera, A., Montes, M. V., & Llatas, C. (2025). The Incorporation of Recycled Aggregate Concrete as a Strategy to Enhance the Circular Performance of Residential Building Structures in Spain. Applied Sciences, 15(6), 3265. https://doi.org/10.3390/app15063265