Experimental Investigation into the Mechanical Performance of Roadway Shotcrete with the Partial Replacement of Cement with Recycled Gangue Powder

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

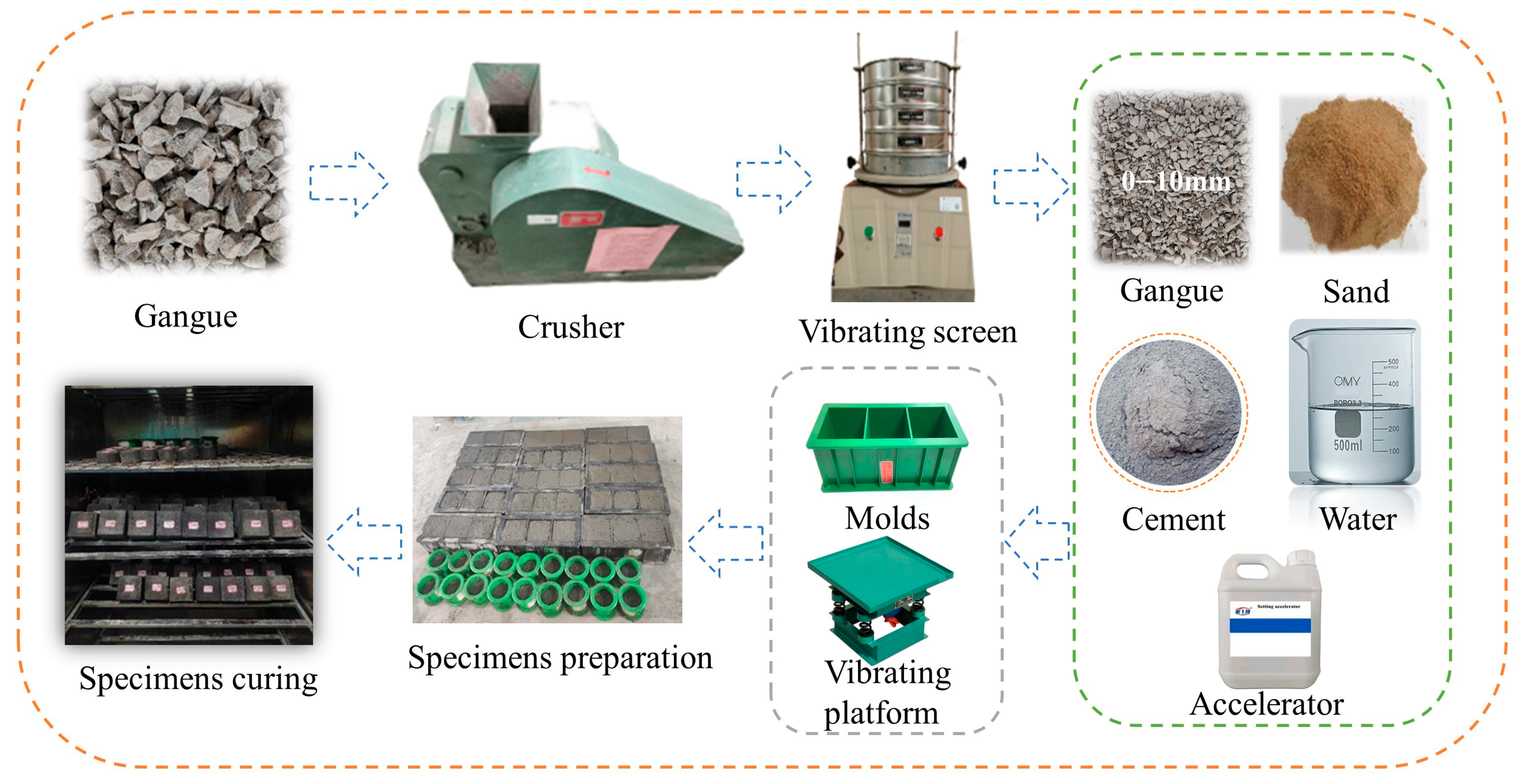

2.2. Specimen Preparation

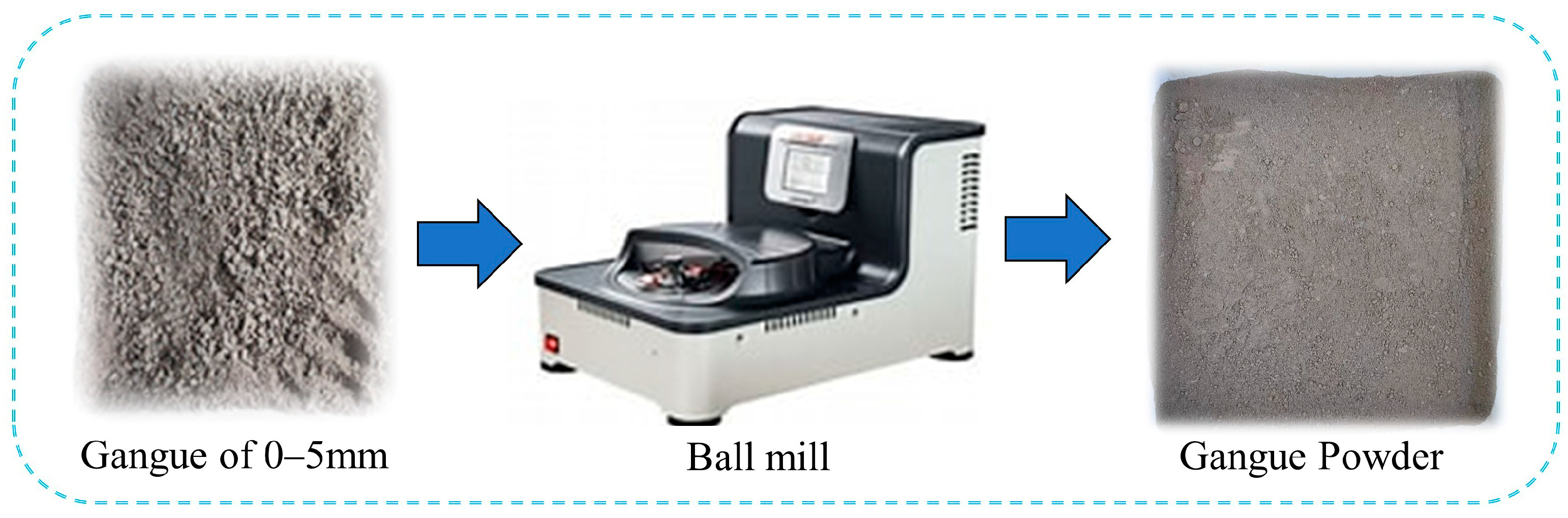

2.3. Preparation of Gangue Powder

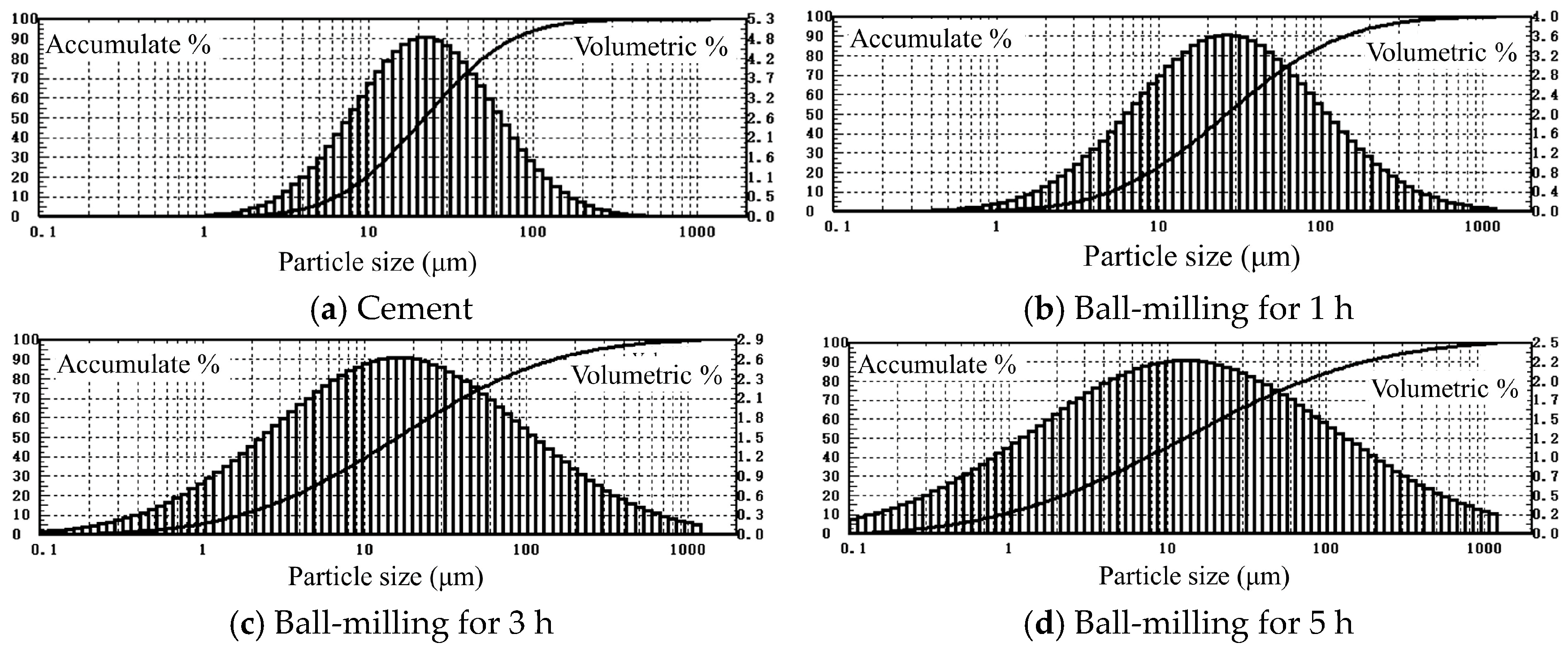

2.3.1. Particle Size Distribution

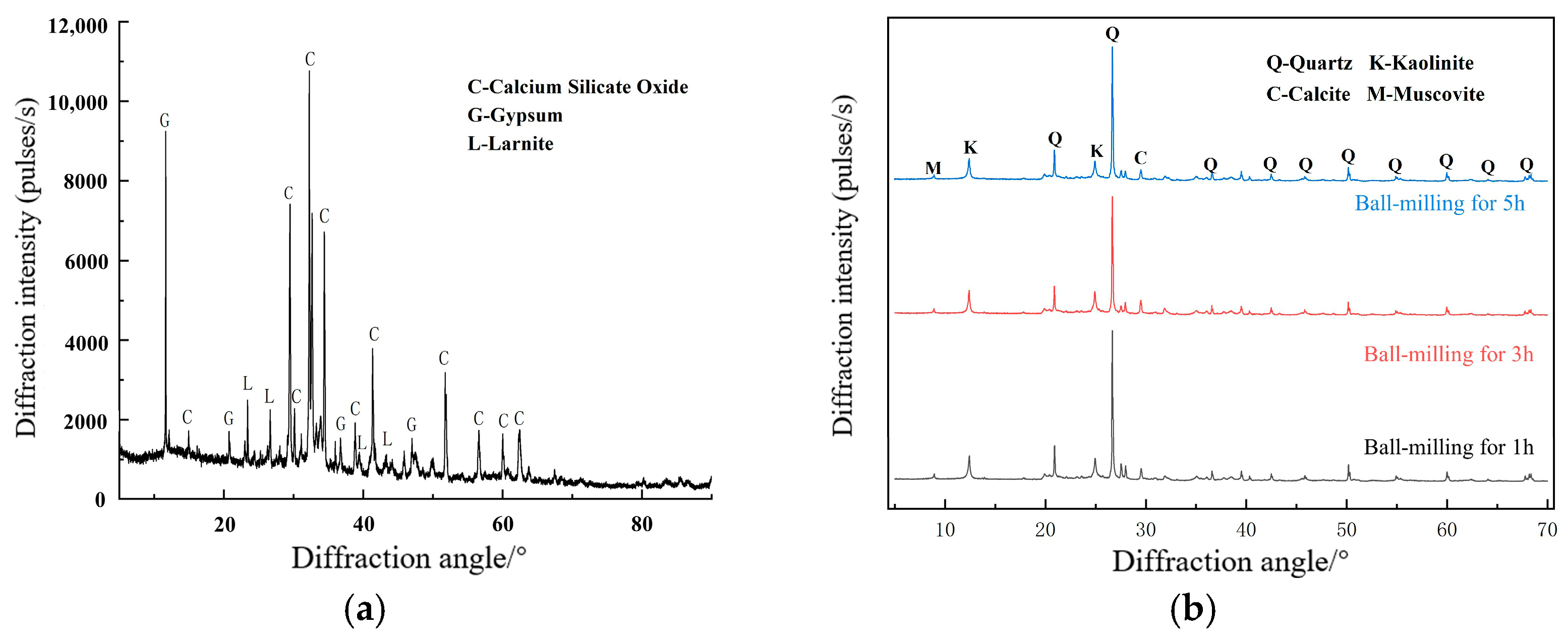

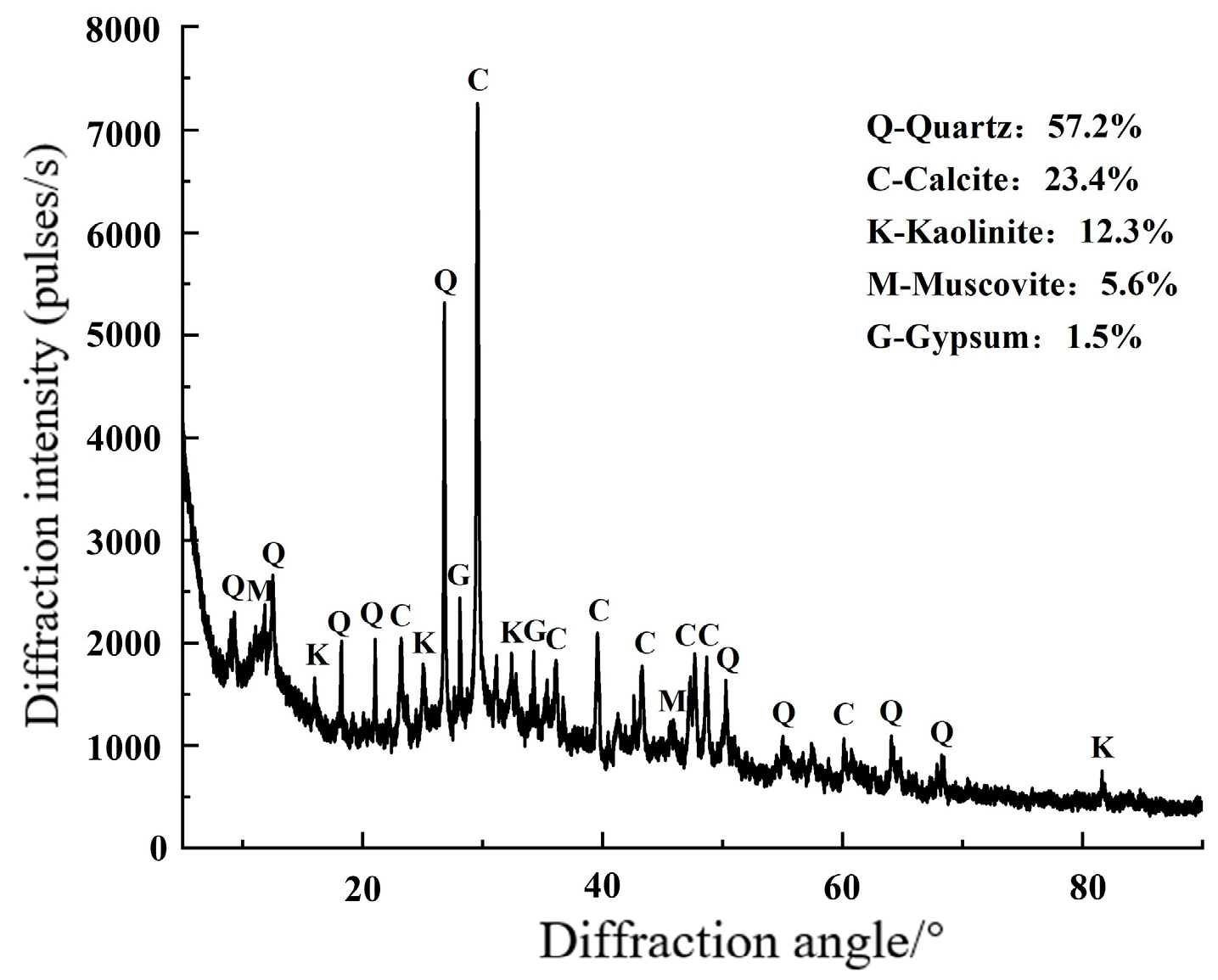

2.3.2. Mineral Compositions of Gangue

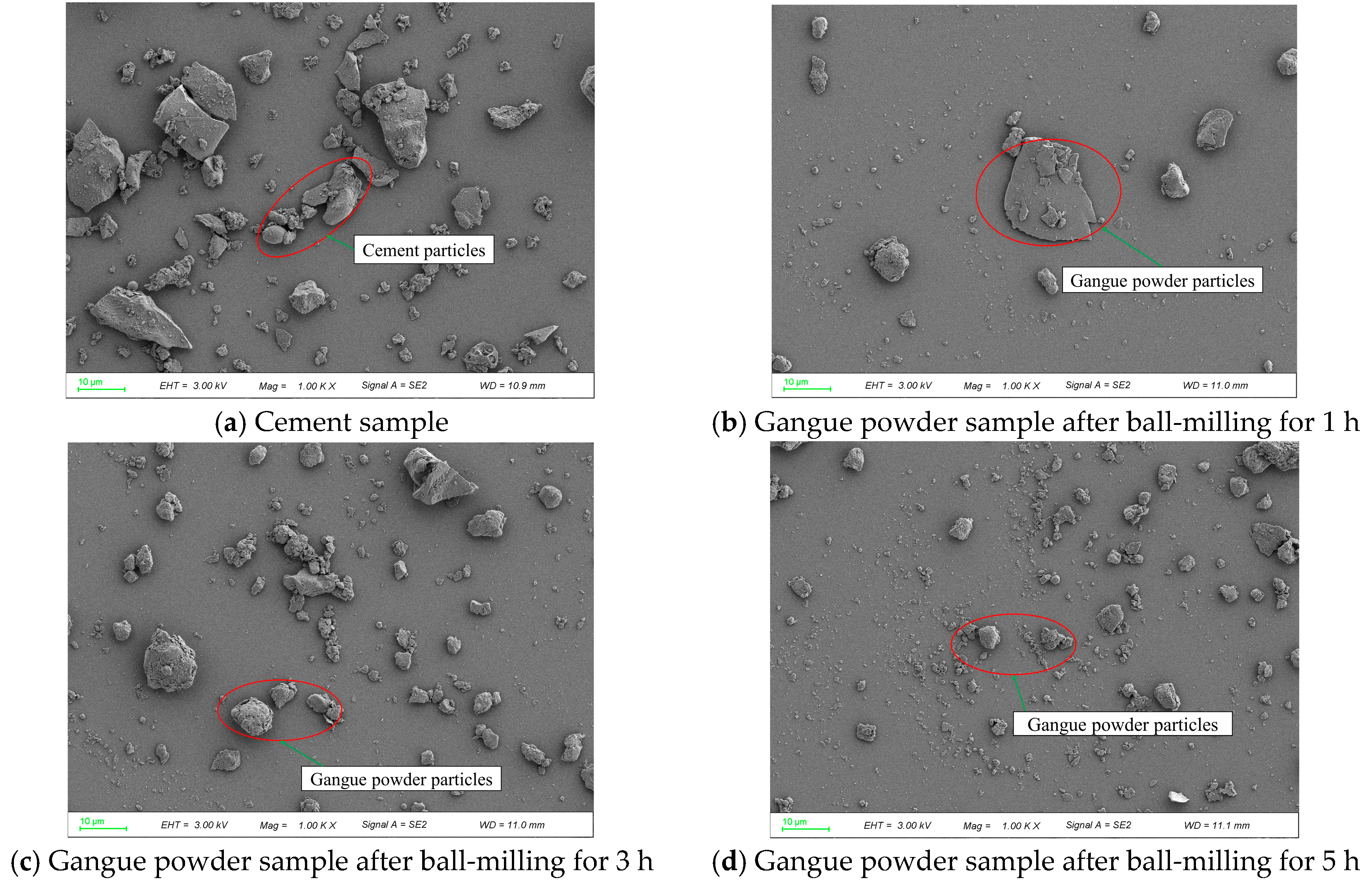

2.3.3. Micro-Morphologies of Gangue

2.4. Experimental Schemes

3. Experimental Results and Discussion

3.1. Changes in the Slump

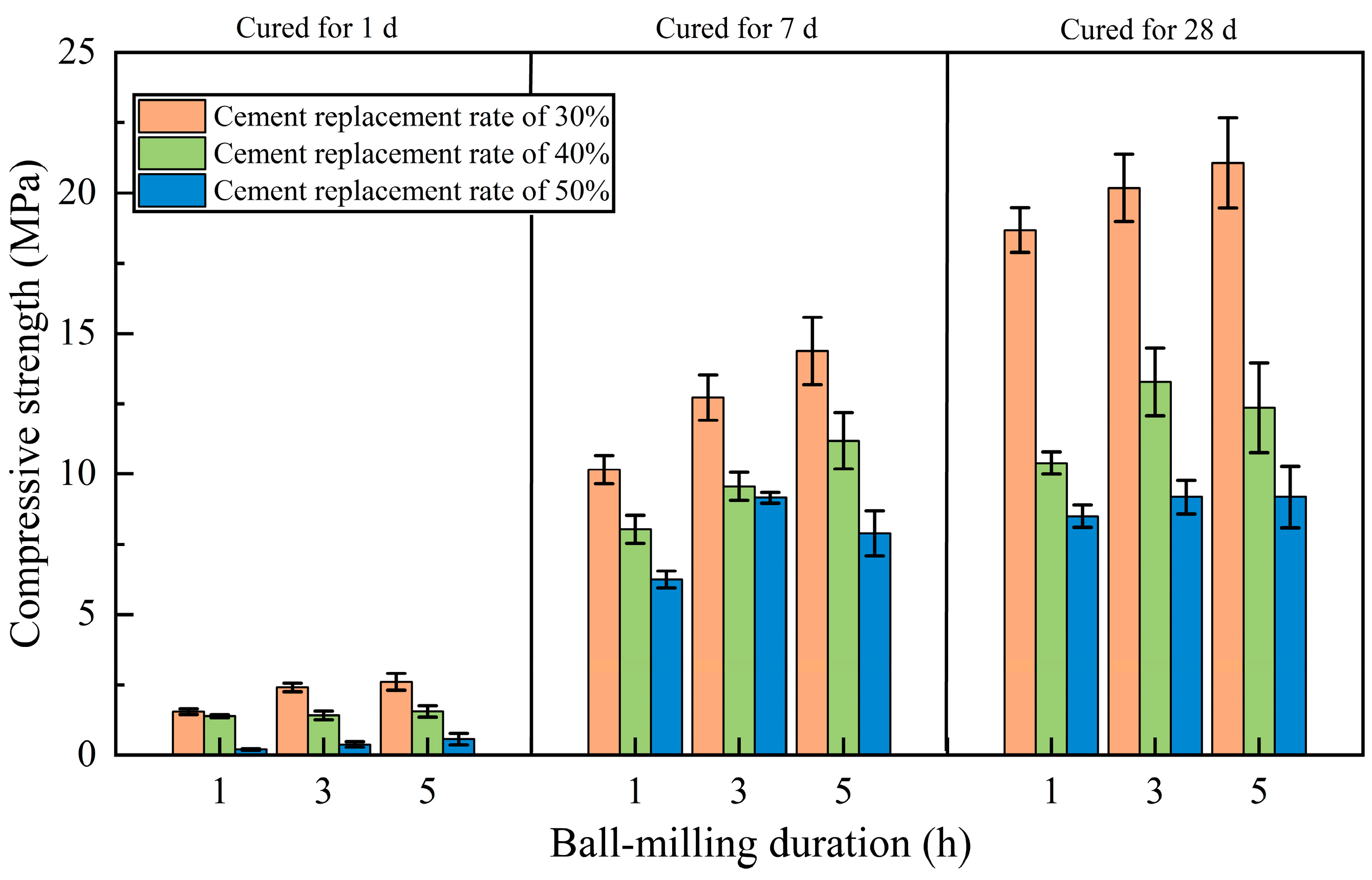

3.2. Evolution of the Compressive Strength

3.3. Changes in the Tensile Strength

3.4. Mineral Compositions and Micro-Morphologies

3.4.1. Mineral Compositions of Specimen

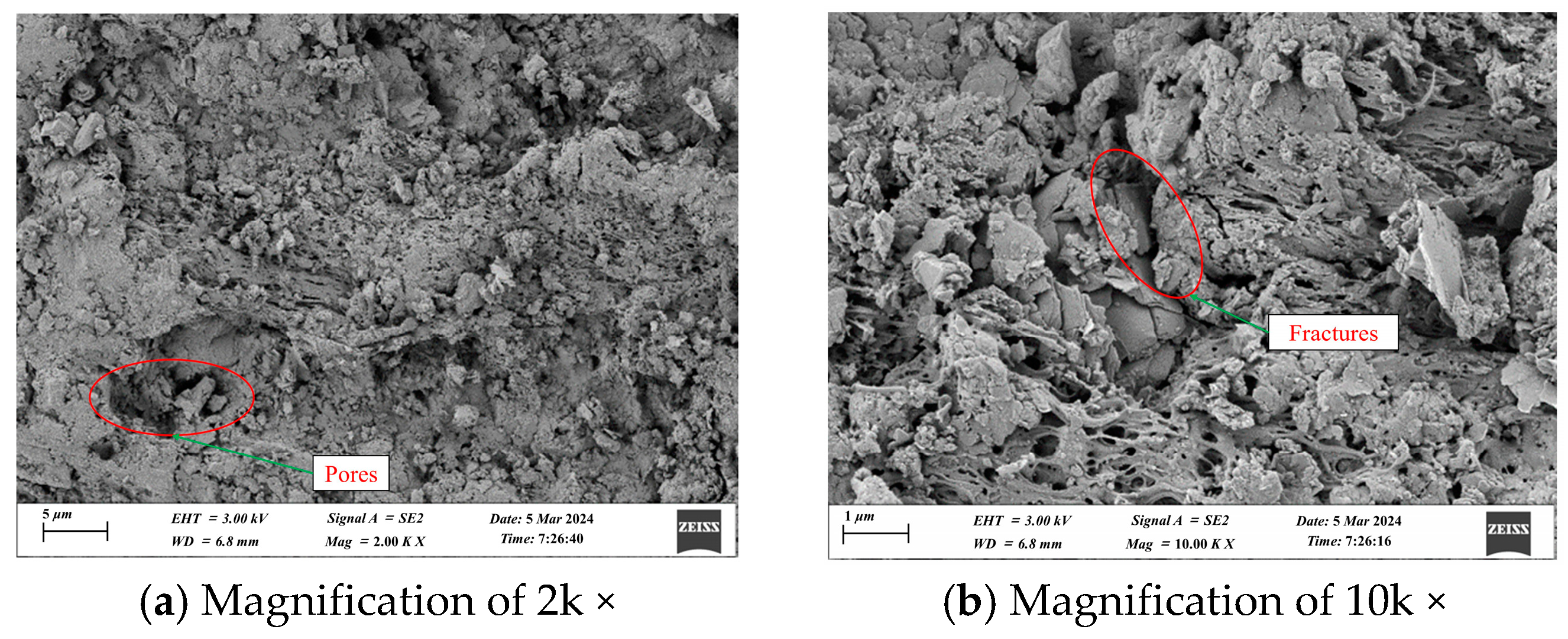

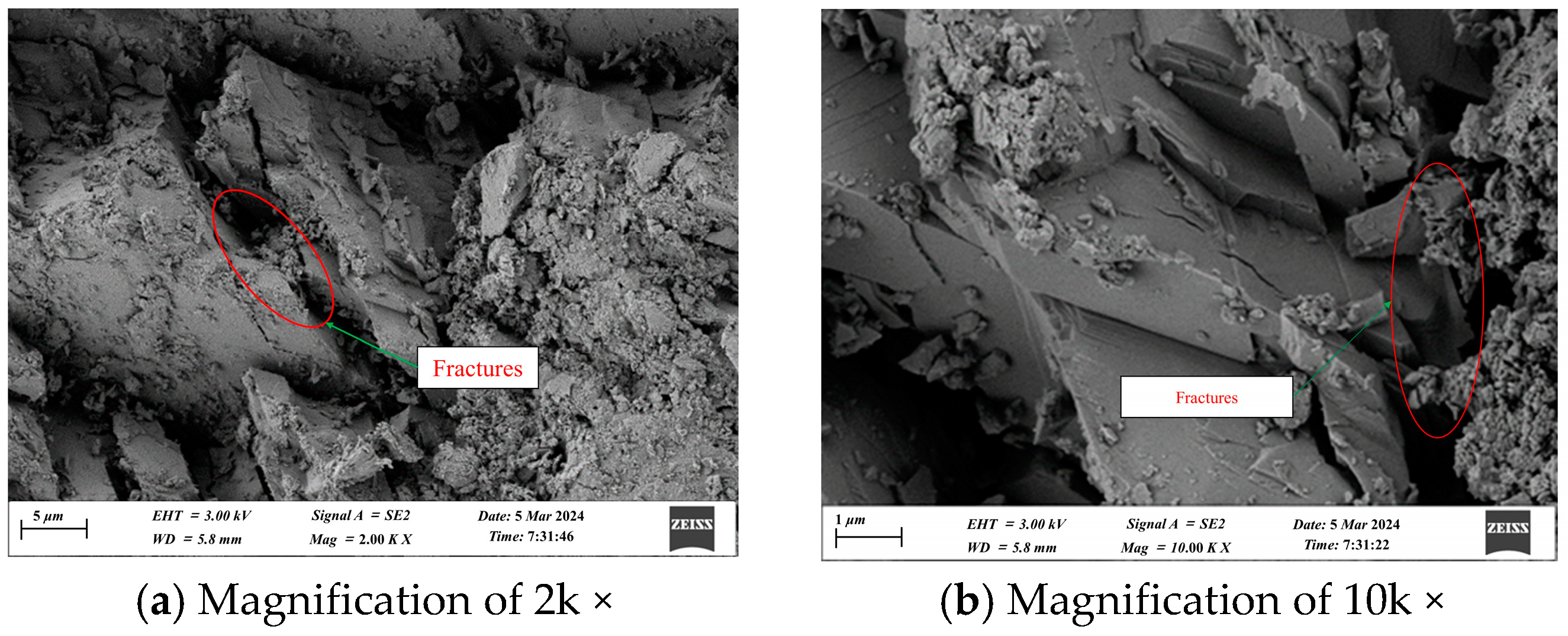

3.4.2. Micro-Morphologies of Specimen

4. Conclusions

- (1)

- By analyzing the experimental results of the conveying performance of shotcrete with the partial replacement of cement with gangue powder, the rate of cement replacement is found to be inversely proportional to the slump of the shotcrete. This is mainly because the ball-milled gangue particles show non-uniform shapes and particle sizes, enhanced water absorption, and raised the number of pores. The ball-milling duration of gangue is inversely proportional to the slump of shotcrete mainly because as the ball-milling duration is extended, the gangue particles are gradually refined; their specific surface area gradually increases, and particles are arranged in a less uniform manner;

- (2)

- The analysis of the experimental results pertaining to tests of the mechanical performance of the shotcrete with the partial replacement of cement with gangue powder reveals that the compressive and tensile strengths of the shotcrete are directly proportional to the ball-milling duration of gangue and inversely proportional to the rate of cement replacement. This is mainly because with the extension of ball-milling duration, the gangue particles are refined; the activity is improved, and the filling effect is enhanced. As the rate of cement replacement is increased, the amount of the cementitious material in the shotcrete decreases; the particles show poorer dispersion, and the porosity increases. Moreover, the shotcrete meets the strength requirements for engineering applications only when the cement replacement ratio is 30% with gangue ball-milling durations of 3 h and 5 h;

- (3)

- The mineral compositions and microscopic characteristics of the shotcrete with the partial replacement of cement with gangue powder are analyzed. The results show that, after partially replacing cement with gangue powder, the shotcrete contains more clay minerals such as kaolinite while having a lower cement content than the shotcrete without the replacement of cement. As a result, the content of the cement-based cementitious material reduces accordingly, leading to lower strengths of the shotcrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ulyeva, G.A.; Yemelyanova, O.V. Production of Special Coke for Electrothermal Silicon Production from Central Kazakhstan Coal. Coke Chem. 2024, 67, 243–250. [Google Scholar] [CrossRef]

- Zaostrovsky, A.N.; Murko, V.I. Production and Use of Highly Reactive Water-Coal Fuel. Coke Chem. 2023, 66, 458–464. [Google Scholar] [CrossRef]

- Wang, H.Y.; Tan, B.; Zhang, X.D. Research on the technology of detection and risk assessment of fire areas in gangue hills. Environ. Sci. Pollut. Res. 2020, 27, 38776–38787. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.T.; Yang, Y.L.; Guo, S.D.; Tian, F.C.; Wang, S.F. Combustion mechanism and control approaches of underground coal fires: A review. Int. J. Coal Sci. Technol. 2023, 10, 24. [Google Scholar] [CrossRef]

- Rouhani, A.; Gusiatin, M.Z.; Hejcman, M. An overview of the impacts of coal mining and processing on soil: Assessment, monitoring, and challenges in the Czech Republic. Environ. Geochem. Health 2023, 45, 7459–7490. [Google Scholar] [CrossRef]

- Premalatha, B.; Prakasam, P. A Review on FoG Computing in 5G Wireless Technologies: Research Challenges, Issues and Solutions. Wirel. Pers. Commun. 2024, 134, 2455–2484. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Q. Mine Water Treatment, Resource Utilization and Prospects in Coal Mining Areas of Western China. Mine Water Environ. 2024, 43, 210–230. [Google Scholar] [CrossRef]

- Wang, N.; Chai, X.X.; Guo, Z.Q.; Guo, C.Y.; Liu, J.X.; Zhang, J. Hierarchy performance assessment of industrial solid waste utilization—Tracking resource recycling and utilization centers in China. Environ. Sci. Pollut. Res. 2023, 30, 83330–83340. [Google Scholar] [CrossRef]

- Dogra, A.K.; Rupali, S. Effect of tuned mass dampers in shotcrete reinforced coal mine under the influence of low velocity impact: An experimental approach. Sādhanā 2024, 49, 214. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Shi, X.Z.; Qiu, X.Y.; Ouyang, J.; Wang, W.Y. In Situ Tests Comparing the Support Effects of Thin Spray-on Liner and Shotcrete on a Roadway Subjected to Blasting. Rock Mech. Rock Eng. 2024, 57, 1669–1693. [Google Scholar] [CrossRef]

- Yan, L.H.; Chang, J.C.; Shi, W.B.; Wang, T.; Qiao, L.Q.; Guo, Y.J.; Wang, H.D. Creep deformation characteristics and control technology in deep mine soft rock roadway. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 144. [Google Scholar] [CrossRef]

- Wu, J.X.; Jiao, J.K.; Zhou, S.S. Controlling large deformations in soft rock roadways with integrated anchor shotcrete and grouting techniques. Sci. Rep. 2024, 14, 28339. [Google Scholar] [CrossRef]

- Chen, S.H.; Tsao, J.X. The Application of Uniform Design and Fuzzy Analysis to CNC Machine Tool Leveling Accuracy Adjustment. Int. J. Precis. Eng. Manuf. 2024, 25, 1651–1667. [Google Scholar] [CrossRef]

- Kang, H.P.; Yang, J.W.; Jiang, P.F.; Gao, F.Q.; Li, W.Z.; Li, J.F.; Chen, H.Y. Theory, technology and application of grouted bolting in soft rock roadways of deep coal mines. Int. J. Miner. Metall. Mater. 2024, 31, 1463–1479. [Google Scholar] [CrossRef]

- Meng, B.; Yin, Q.; Jing, H.W.; Liu, S.D.; Jia, B.G. Stability control of deep-buried roadways using large deformation and increasing resistance anchor cables. J. Cent. South Univ. 2024, 31, 558–575. [Google Scholar] [CrossRef]

- David, M.; Freund, N.; Dröder, K.; Lowke, D. The effects of nozzle diameter and length on the resulting strand properties for shotcrete 3D printing. Mater. Struct. 2023, 56, 157. [Google Scholar] [CrossRef]

- Süzen, A.A.; Cakiroglu, M.A.; Ince, G.; Kabas, H.T. Experimental Examination of the Behavior of Shotcrete-Reinforced Masonry Walls and Xgboost Neural Network Prediction Model. Arab. J. Sci. Eng. 2021, 46, 10613–10630. [Google Scholar]

- Maurya, K.K.; Rawat, A.; Shanker, R. Health monitoring of bacterial concrete structure under dynamic loading using electro-mechanical impedance technique: A numerical approach. Environ. Sci. Pollut. Res. 2023, 30, 25382–25401. [Google Scholar] [CrossRef]

- Wang, T.C.; Liang, Y.; Zhang, X.Y.; Ruan, Z.H.; Mei, G.X. Investigation of the seismic behavior of grouted sandy gravel foundations using shaking table tests. Front. Struct. Civ. Eng. 2022, 16, 1196–1211. [Google Scholar] [CrossRef]

- Salehi, B.; Golshani, A.; Rostami, J.; Schneider-Muntau, B. Simulation of Complex Support Systems for Large Span Tunnels: Investigation on Support Interferences and Effects of Constitutive Models. KSCE J. Civ. Eng. 2024, 28, 5309–5324. [Google Scholar] [CrossRef]

- Monsberger, C.M.; Bauer, P.; Buchmayer, F.; Lienhart, W. Large-scale distributed fiber optic sensing network for short and long-term integrity monitoring of tunnel linings. J. Civ. Struct. Health Monit. 2022, 12, 1317–1327. [Google Scholar] [CrossRef]

- Monsberger, C.M.; Lienhart, W. Distributed fiber optic shape sensing along shotcrete tunnel linings: Methodology, field applications, and monitoring results. J. Civ. Struct. Health Monit. 2021, 11, 337–350. [Google Scholar] [CrossRef]

- Kolapo, P.; Onifade, M.; Said, K.O.; Amwaama, M.; Aladejare, A.E.; Lawal, A.I.; Akinseye, P.O. On the Application of the Novel Thin Spray-on Liner (TSL): A Progress Report in Mining Operations. Geotech. Geol. Eng. 2021, 39, 5445–5477. [Google Scholar] [CrossRef]

- Serati, M.; Jakson, N.; Asche, H.; Basireddy, S.; Malgotra, G. Sustainable shotcrete production with waste glass aggregates. SN Appl. Sci. 2022, 4, 82. [Google Scholar] [CrossRef]

- Alcayaga, R.A.; Gutiérrez, S.M.V.; Avudaiappan, S.; Gómez Puigpinos, R.E.; Betancourt, C.F.E. Towards sustainable shotcrete in mining: A literature review on the utilization of tailings as a partial replacement for fine aggregate. Recent Adv. Mech. Behav. Mater. 2024, 462, 197–207. [Google Scholar]

- Polat, H.; Özel, C. Investigation of ferrochrome slag utilization in wet mix shotcrete: Mechanical strength and radiation shielding performance. Radiat. Phys. Chem. 2024, 223, 111963. [Google Scholar] [CrossRef]

- Fan, Y.Y.; Wang, X.; Jiang, M.W.; Liu, X.Q. The microstructure and mechanical property of tailings and its application in artificial concrete. Arab. J. Geosci. 2021, 14, 2105. [Google Scholar]

- Xiao, M.; Ju, F.; He, Z.Q. Research on shotcrete in mine using non-activated waste coal gangue aggregate. J. Clean. Prod. 2020, 259, 120810. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Hassan, H.; El-Mir, A.; Assaad, J.J.; El-Maaddawy, T. Development of geopolymer and cement-based shotcrete mortar: Impact of mix design parameters and spraying process. Constr. Build. Mater. 2024, 449, 138457. [Google Scholar] [CrossRef]

- Zou, X.G.; Zhang, Y.P.; Liu, B.; Xu, X.M.; Lu, Z.G.; Jiang, W.W. Study on mechanical properties and ratio parameter optimization of fly ash wet shotcrete under the influence of multiple factors. Case Stud. Constr. Mater. 2023, 19, e02679. [Google Scholar] [CrossRef]

- Zan, J.C.; Ren, W.X.; Guo, Q. Experimental study on the utilization of fly ash solid waste in tunnel shotcrete materials. Energy Sci. Eng. 2024, 12, 4753–4762. [Google Scholar]

- Park, C.; Kim, K.N. Practical recycling application of power plant coal ash for high performance shotcrete material. Mater. Sci. Forum 2009, 620–622, 251–254. [Google Scholar] [CrossRef]

- Zheng, L. Preparation and Performance Optimization of Mine Shotcrete Materials with Red Mud. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

| Material | Replaced Materials | Replacement Ratio | Results |

|---|---|---|---|

| Scrap glass | Sand | 0~100% | Enhanced low-substitution efficiency |

| Tailings | Sand | 100% | Mechanical compliance achieved |

| Ferrochrome slag | Natural aggregates | 50% | Enhanced mechanical–durability performance |

| Tailings | Natural aggregates and sand | 100% | Mechanical compliance achieved |

| Gangue | Natural aggregates | 100% | Mechanical compliance achieved |

| Geopolymer | Cement | 100% | Spray mechanical compliance achieved |

| Fly ash | Cement | 4~33% | Mechanical compliance achieved |

| Red mud | Cement | 10~25% | Mechanical compliance achieved |

| Materials | Chemical Composition (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | SO3 | Others | |

| Gangue | 62.58 | 18.81 | 2.64 | 3.27 | 1.78 | 2.86 | 0.33 | 7.73 |

| Ordinary Portland cement | 22.53 | 5.22 | 3.53 | 61.04 | 1.73 | 0.56 | 2.31 | 3.08 |

| No. | Ball-Milling Duration (for Gangue)/h | Rate of Cement Replacement/% |

|---|---|---|

| A1 | 1 | 30 |

| A2 | 1 | 40 |

| A3 | 1 | 50 |

| B1 | 3 | 30 |

| B2 | 3 | 40 |

| B3 | 3 | 50 |

| C1 | 5 | 30 |

| C2 | 5 | 40 |

| C3 | 5 | 50 |

| No. | Ball-Milling Duration (for Gangue)/h | Gangue/kg·m−3 | Sand/kg·m−3 | Gangue Powder/kg·m−3 | Cement/kg·m−3 | Water/kg·m−3 | Accelerator/kg·m−3 |

|---|---|---|---|---|---|---|---|

| A1 | 1 | 801.25 | 801.25 | 135 | 315 | 247.5 | 18 |

| A2 | 1 | 801.25 | 801.25 | 180 | 270 | 247.5 | 18 |

| A3 | 1 | 801.25 | 801.25 | 225 | 225 | 247.5 | 18 |

| B1 | 3 | 801.25 | 801.25 | 135 | 315 | 247.5 | 18 |

| B2 | 3 | 801.25 | 801.25 | 180 | 270 | 247.5 | 18 |

| B3 | 3 | 801.25 | 801.25 | 225 | 225 | 247.5 | 18 |

| C1 | 5 | 801.25 | 801.25 | 135 | 315 | 247.5 | 18 |

| C2 | 5 | 801.25 | 801.25 | 180 | 270 | 247.5 | 18 |

| C3 | 5 | 801.25 | 801.25 | 225 | 225 | 247.5 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wang, X.; He, R.; Zhang, Y.; Kang, S. Experimental Investigation into the Mechanical Performance of Roadway Shotcrete with the Partial Replacement of Cement with Recycled Gangue Powder. Appl. Sci. 2025, 15, 3180. https://doi.org/10.3390/app15063180

Li S, Wang X, He R, Zhang Y, Kang S. Experimental Investigation into the Mechanical Performance of Roadway Shotcrete with the Partial Replacement of Cement with Recycled Gangue Powder. Applied Sciences. 2025; 15(6):3180. https://doi.org/10.3390/app15063180

Chicago/Turabian StyleLi, Shoubiao, Xiaolong Wang, Ruimin He, Yong Zhang, and Shilong Kang. 2025. "Experimental Investigation into the Mechanical Performance of Roadway Shotcrete with the Partial Replacement of Cement with Recycled Gangue Powder" Applied Sciences 15, no. 6: 3180. https://doi.org/10.3390/app15063180

APA StyleLi, S., Wang, X., He, R., Zhang, Y., & Kang, S. (2025). Experimental Investigation into the Mechanical Performance of Roadway Shotcrete with the Partial Replacement of Cement with Recycled Gangue Powder. Applied Sciences, 15(6), 3180. https://doi.org/10.3390/app15063180