The Rapid Upper Limb Assessment Among Traditional Krajood (Lepironia articulata) Handicraft Workers: A Case Study in Southern Thailand

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chander, D.S.; Cavatorta, M.P. An Observational Method for Postural Ergonomic Risk Assessment (PERA). Int. J. Ind. Ergon. 2017, 57, 32–41. [Google Scholar] [CrossRef]

- Sarkar, K.; Dev, S.; Das, T.; Chakrabarty, S.; Gangopadhyay, S. Examination of Postures and Frequency of Musculoskeletal Disorders Among Manual Workers in Calcutta, India. Int. J. Occup. Environ. Health 2016, 22, 151–158. [Google Scholar] [CrossRef]

- Cieza, A.; Causey, K.; Kamenov, K.; Hanson, S.W.; Chatterji, S.; Vos, T. Global Estimates of the Need for Rehabilitation Based on the Global Burden of Disease Study 2019: A Systematic Analysis for the Global Burden of Disease Study 2019. Lancet 2020, 396, 2006–2017. [Google Scholar] [CrossRef] [PubMed]

- European Agency for Safety and Health at Work. OSH in Figures: Work-Related Musculoskeletal Disorders in the EU: Facts and Figures; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Kirkhorn, S.R.; Earle-Richardson, G.; Banks, R.J. Ergonomic Risks and Musculoskeletal Disorders in Production Agriculture: Recommendations for Effective Research to Practice. J. Agromed. 2010, 15, 281–299. [Google Scholar] [CrossRef] [PubMed]

- Soodsang, N. Bamboo Basketry Design Development Based on Thai Wisdom Preservation. Int. J. Bus. Soc. Sci. 2015, 6, 139–148. [Google Scholar]

- Maeaid, J.; Nakhapakorn, K.; Jirakajohnkool, S. Change Detection and Identification of Land Potential for Planting Krajood (Lepironia articulata) in Thale Noi, Southern Thailand. Songklanakarin J. Sci. Technol. 2012, 34, 329–336. [Google Scholar]

- Chucheep, K.; Suwanpayak, N.; Phanchindawan, N. A Study of the Feasibility of Using Grey Sedge Residue to Facilitate Zero Waste Production. Recycling 2022, 7, 34. [Google Scholar] [CrossRef]

- Wurochekke, A.A.; Radin Mohamed, R.M.S.; Lokman Halim, S.A.B.; Mohd Kassim, A.H.B.; Hamdan, R.B. Sustainable Extensive On-Site Constructed Wetland for Some Bacteriological Reduction in Kitchen Greywater. Appl. Mech. Mater. 2015, 773–774, 1199–1204. [Google Scholar] [CrossRef]

- Ismail, N.I.; Abdullah, S.R.; Idris, M.; Hasan, H.A.; Sbani, N.H.; Jehawi, O.H. Tolerance and Survival of Scirpus grossus and Lepironia articulata in Synthetic Mining Wastewater. J. Environ. Sci. Technol. 2015, 8, 232–237. [Google Scholar] [CrossRef]

- Sharuddin, S.S.N.; Abdullah, S.R.; Hasan, H.A.; Othman, R.A. Comparative Tolerance and Survival of Scirpus grossus and Lepironia articulata in Real Crude Oil Sludge. Int. J. Eng. Technol. 2017, 8, 24–28. [Google Scholar]

- Sinaga, N.I.; Lense, O.N.; Hendry; Tukayo, R. Association among Lepironia articulata Cyperaceae, Peat Soil, and People in Wanggate, Mappi, Papua. IOP Conf. Ser. Earth Environ. Sci. 2022, 1025, 012003. [Google Scholar] [CrossRef]

- Lindholm, C.; Stricklin, D.; Jaworska, A.; Koivistoinen, A.; Paile, W.; Arvidsson, E.; Deperas-Standylo, J.; Wojcik, A. Premature Chromosome Condensation (PCC) Assay for Dose Assessment in Mass Casualty Accidents. Radiat. Res. 2010, 173, 71–78. [Google Scholar] [CrossRef]

- Mohammadipour, F.; Pourranjbar, M.; Naderi, S.; Rafie, F. Work-Related Musculoskeletal Disorders in Iranian Office Workers: Prevalence and Risk Factors. J. Med. Life 2018, 11, 328–333. [Google Scholar] [CrossRef] [PubMed]

- Oates, S.; Evans, G.W.; Hedge, A. An Anthropometric and Postural Risk Assessment of Children’s School Computer Work Environments. Comput. Sch. 1999, 14, 55–63. [Google Scholar] [CrossRef]

- Breen, R.; Pyper, S.; Rusk, Y.; Dockrell, S. An Investigation of Children’s Posture and Discomfort During Computer Use. Ergonomics 2007, 50, 1582–1592. [Google Scholar] [CrossRef]

- Kelly, G.; Dockrell, S.; Galvin, R. Computer Use in School: Its Effect on Posture and Discomfort in Schoolchildren. Work 2009, 32, 321–328. [Google Scholar] [CrossRef]

- Dockrell, S.; O’Grady, E.; Bennett, K.; Mullarkey, C.; McConnell, R.; Ruddy, R.; Twomey, S.; Flannery, C. An Investigation of the Reliability of Rapid Upper Limb Assessment (RULA) as a Method of Assessment of Children’s Computing Posture. Appl. Ergonom. 2012, 43, 632–636. [Google Scholar] [CrossRef]

- Takala, E.P.; Pehkonen, I.; Forsman, M.; Hansson, G.Å.; Mathiassen, S.E.; Neumann, W.P.; Sjøgaard, G.; Veiersted, K.B.; Westgaard, R.H.; Winkel, J. Systematic Evaluation of Observational Methods Assessing Biomechanical Exposures at Work. Scand. J. Work Environ. Health 2009, 36, 3–24. [Google Scholar] [CrossRef]

- Roman-Liu, D. Comparison of Concepts in Easy-to-Use Methods for MSD Risk Assessment. Appl. Ergonom. 2014, 45, 420–427. [Google Scholar] [CrossRef]

- Zare, A.; Yazdanirad, S.; Khoshakhlagh, A.; Habibi, E.; Zeinodini, M.; Dehghani, F. Comparing the Effectiveness of Three Ergonomic Risk Assessment Methods-RULA, LUBA, and NERPA-to Predict Upper Extremity Musculoskeletal Disorders. Indian J. Occup. Environ. Med. 2018, 22, 17. [Google Scholar] [CrossRef]

- Chuppawal, W.; Turnbull, N.; Chada, W.; Sae-Ung, K.; Chooppava, C. Prevalence and Work Posture Factors in Relation to Musculoskeletal Disorders Among Sewing Farmers. Res. Dev. Health Syst. J. 2022, 15, 17–27. [Google Scholar]

- Crawford, J.O. The Nordic Musculoskeletal Questionnaire. Occup. Med. 2007, 57, 300–301. [Google Scholar] [CrossRef]

- McAtamney, L.; Corlett, E.N. RULA: A Survey Method for the Investigation of Work-Related Upper Limb Disorders. Appl. Ergonom. 1993, 24, 91–99. [Google Scholar] [CrossRef] [PubMed]

- Rovinelli, R.J.; Hambleton, R.K. On the Use of Content Specialists in the Assessment of Criterion-Referenced Test Item Validity. Tijdschr. Voor Onderwijs Res. 1977, 2, 49–60. [Google Scholar]

- Taber, K.S. The Use of Cronbach’s Alpha When Developing and Reporting Research Instruments in Science Education. Res. Sci. Educ. 2018, 48, 1273–1296. [Google Scholar] [CrossRef]

- McGraw, K.O.; Wong, S.P. Forming Inferences about Some Intraclass Correlation Coefficients. Psychol. Methods 1996, 1, 30–46. [Google Scholar] [CrossRef]

- Keyserling, W.M.; Wiggermann, N.; Werner, R.A.; Gell, N. Inter-Worker Variability in Lower Body Postures During Assembly Line Work: Implications for Exposure Assessment. J. Occup. Environ. Hyg. 2010, 7, 261–271. [Google Scholar] [CrossRef]

- Mehralizadeh, S.; Dehdashti, A.; Motalebi Kashani, M. Structural Equation Model of Interactions Between Risk Factors and Work-Related Musculoskeletal Complaints Among Iranian Hospital Nurses. Work 2017, 57, 137–146. [Google Scholar] [CrossRef]

- Dimou, V.; Basilios, M.; Kitikidou, K. Evaluation of Musculoskeletal Disorders Risks in Forestry. Work 2022, 72, 373–393. [Google Scholar] [CrossRef]

- Alwahaibi, N.; Al Sadairi, M.; Al Abri, I.; Al Rawahi, S. Prevalence of Laboratory-Related Musculoskeletal Disorders Among Biomedical Scientists. Work 2021, 75, 223–232. [Google Scholar] [CrossRef]

- Das, B. Work-Related Musculoskeletal Disorders in Agriculture: Ergonomics Risk Assessment and Its Prevention Among Indian Farmers. Work 2023, 76, 225–241. [Google Scholar] [CrossRef] [PubMed]

- Sealetsa, O.J.; Thatcher, A. Ergonomics Issues Among Sewing Machine Operators in the Textile Manufacturing Industry in Botswana. Work 2011, 38, 279–289. [Google Scholar] [CrossRef]

- Roquelaure, Y. Active Epidemiological Surveillance of Musculoskeletal Disorders in a Shoe Factory. Occup. Environ. Med. 2002, 59, 452–458. [Google Scholar] [CrossRef]

- Nazari, J.; Mahmoudi, N.; Dianat, I.; Graveling, R. Working Conditions in Carpet Weaving Workshops and Musculoskeletal Complaints Among Workers in Tabriz, Iran. Health Promot. Perspect. 2012, 2, 265–273. [Google Scholar] [PubMed][Green Version]

- Simon, S.; Laurendi, L.; Meining, J.; Dully, J.; Dindorf, C.; Maurer, L.; Fröhlich, M. Measuring the Effect of an Ergonomic Lecture on the Rapid Upper Limb Assessment Scores of Dental Assistant Students Using Inertial Sensor-Based Motion Capture—A Randomized Controlled Study. Healthcare 2024, 12, 1670. [Google Scholar] [CrossRef] [PubMed]

- Chaiklieng, S.; Suggaravetsiri, P.; Pruktharathikul, V. Risk Factors for Developing Occupational Back Pain in Electronics Industry Workers: A Cross-Sectional Study. Safety 2024, 10, 90. [Google Scholar] [CrossRef]

- Dianat, I.; Kord, M.; Yahyazade, P.; Karimi, M.A.; Stedmon, A.W. Association of Individual and Work-Related Risk Factors with Musculoskeletal Symptoms Among Iranian Sewing Machine Operators. Appl. Ergonom. 2015, 51, 180–188. [Google Scholar] [CrossRef]

- Jacquier-Bret, J.; Gorce, P. Prevalence of Body Area Work-Related Musculoskeletal Disorders Among Healthcare Professionals: A Systematic Review. Int. J. Environ. Res. Public Health 2023, 20, 841. [Google Scholar] [CrossRef]

- Vitale, E.; Vella, F.; Matera, S.; Rizzo, G.C.; Rapisarda, L.; Roggio, F.; Musumeci, G.; Rapisarda, V.; Romano, E.; Filetti, V. Precision Agriculture: Assessment of Ergonomic Risks of Assisted Driving System. Appl. Sci. 2024, 14, 3738. [Google Scholar] [CrossRef]

- Mohammad, W.S.; Alotaibi, S.; AlSayeid, S.; AlKhalif, N.; AlShaibani, A.; Elsais, W. Exploring the Relationship between Muscular Strength, Flexibility, and mSEBT Test Performance in Saudi Arabian Women. Appl. Sci. 2023, 13, 12355. [Google Scholar] [CrossRef]

- Jeong, S.-O.; Kook, J. CREBAS: Computer-Based REBA Evaluation System for Wood Manufacturers Using MediaPipe. Appl. Sci. 2023, 13, 938. [Google Scholar] [CrossRef]

- Davoudi Kakhki, F.; Moghadam, A.; Nieto, A.; Vora, H. Evaluating the Efficacy of a Passive Exoskeleton for Enhancing Ergonomics in Manufacturing. Appl. Sci. 2024, 14, 5810. [Google Scholar] [CrossRef]

| Health Condition | Participant (n) | Percentage (%) |

|---|---|---|

| Health issues | ||

| None | 16 | 80 |

| Medical history | 4 | 20 |

| 1 * | 5 ** |

| 4 * | 20 ** |

| 1 * | 5 ** |

| Ever had a serious accident | ||

| Ever | 18 | 90 |

| Never | 2 | 10 |

| Smoking | ||

| Smoker | 0 | 0 |

| Non-smoker | 20 | 100 |

| Drinking | ||

| Every day | 0 | 0 |

| Sometime | 5 | 25 |

| Never | 15 | 75 |

| Issue | Participant (n) | Percentage (%) |

|---|---|---|

| Feeling tired after work | ||

| Never | 0 | 0 |

| Sometime | 13 | 65 |

| Often | 5 | 25 |

| Always | 2 | 10 |

| Has any musculoskeletal trouble occurred in the last 12 months? | ||

| Yes | 20 | 100 |

| No | 0 | 0 |

| In a single year felt discomfort in body | ||

| Ever | 20 | 100 |

| Never | 0 | 0 |

| Body region with abnormal symptoms * | ||

| Lower back | 8 | 40 |

| Upper back | 5 | 25 |

| Wrists/hands | 4 | 20 |

| Upper arms | 2 | 10 |

| Right forearm | 2 | 10 |

| How long have the abnormal symptoms lasted? | ||

| 1 year | 4 | 20 |

| 2–3 years | 8 | 40 |

| 4–5 years | 6 | 30 |

| >5 years | 2 | 10 |

| In the past year, how many times such abnormal symptoms have occurred? | ||

| 1–5 times | 15 | 75 |

| 6–10 times | 4 | 20 |

| >10 times | 1 | 5 |

| What is causing this? | ||

| Sitting at work for a long time | 12 | 60 |

| Using hands to work | 2 | 10 |

| Sitting on the floor | 1 | 5 |

| Tightening arms while working | 5 | 25 |

| Symptom and Its Severity Score | Left | Right | Both side | |||

|---|---|---|---|---|---|---|

| Participant (n) | Percentage (%) | Participant (n) | Percentage (%) | Participant (n) | Percentage (%) | |

| 1. Neck | ||||||

| 4 | 20 | 4 | 20 | 4 | 20 |

| 16 | 80 | 16 | 80 | 16 | 80 |

| 2. Shoulders | ||||||

| 0 | 0 | 0 | 0 | 0 | 0 |

| 20 | 100 | 20 | 100 | 20 | 100 |

| 3. Upper back | ||||||

| 0 | 0 | 0 | 0 | 0 | 0 |

| 20 | 100 | 20 | 100 | 20 | 100 |

| 4. Lower back | ||||||

| 0 | 0 | 0 | 0 | 0 | 0 |

| 20 | 100 | 20 | 100 | 20 | 100 |

| 5. Upper arms | ||||||

| 1 | 5 | 1 | 5 | 1 | 5 |

| 19 | 95 | 19 | 95 | 19 | 95 |

| 6. Lower arms | ||||||

| 1 | 5 | 1 | 5 | 1 | 5 |

| 19 | 95 | 19 | 95 | 19 | 95 |

| 7. Elbows | ||||||

| 10 | 50 | 10 | 50 | 10 | 50 |

| 10 | 50 | 10 | 50 | 10 | 50 |

| 8. Wrists/hands | ||||||

| 0 | 0 | 0 | 0 | 0 | 0 |

| 20 | 100 | 20 | 100 | 20 | 100 |

| 9. Hips/thighs | ||||||

| 7 | 35 | 7 | 35 | 7 | 35 |

| 13 | 65 | 13 | 65 | 13 | 65 |

| 10. Knees | ||||||

| 5 | 25 | 5 | 25 | 5 | 25 |

| 15 | 75 | 15 | 75 | 15 | 75 |

| 11. Calves | ||||||

| 8 | 40 | 8 | 40 | 8 | 40 |

| 12 | 60 | 12 | 60 | 12 | 60 |

| 12. Ankles/feet | ||||||

| 11 | 55 | 11 | 55 | 11 | 55 |

| 9 | 45 | 9 | 45 | 9 | 45 |

| Worker | RULA Score | |||||||

|---|---|---|---|---|---|---|---|---|

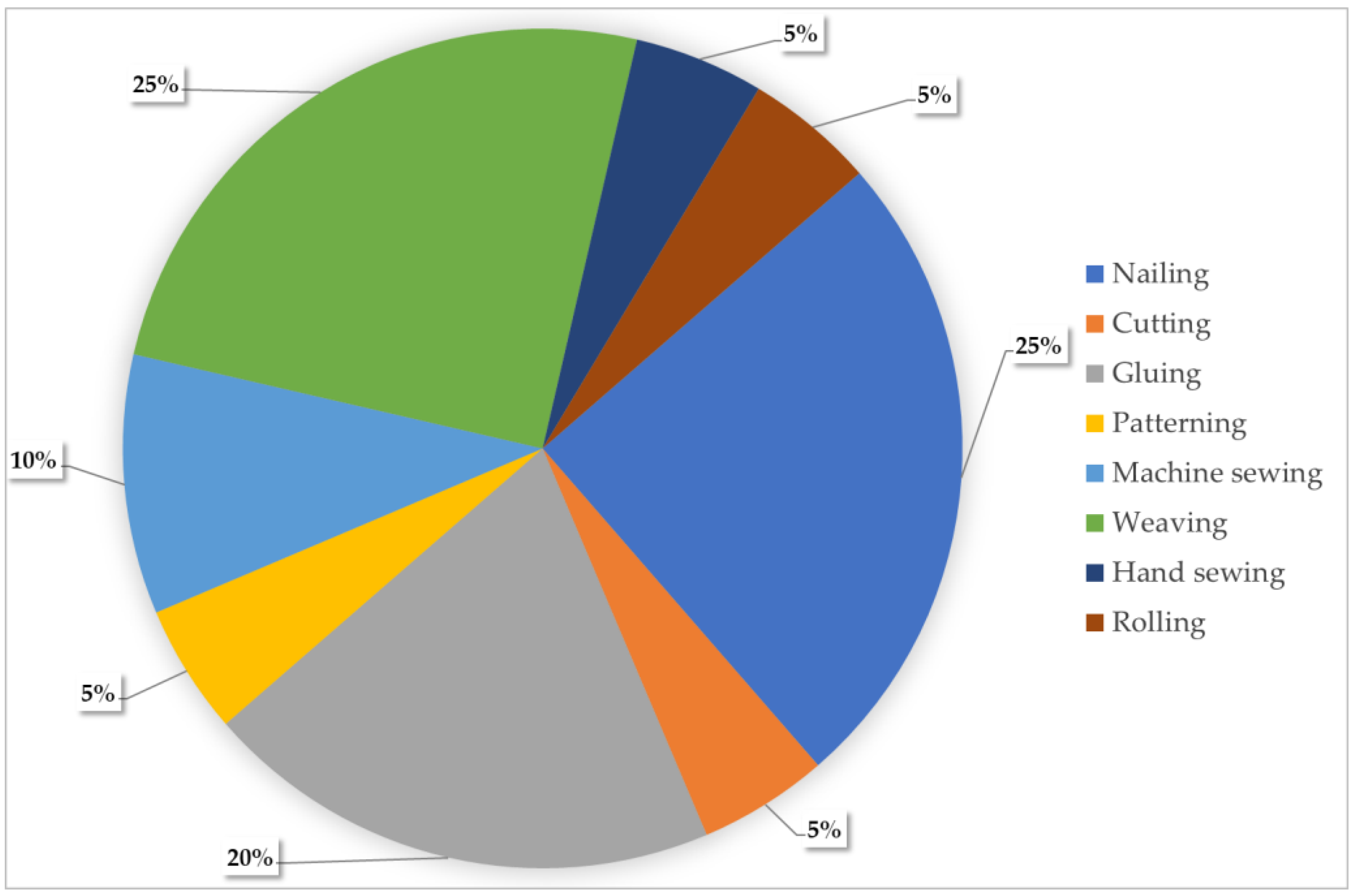

| Nailing | Cutting | Gluing | Patterning | Machine Sewing | Weaving | Hand Sewing | Rolling | |

| 1 | 6 | |||||||

| 2 | 5 | |||||||

| 3 | 3 | |||||||

| 4 | 7 | |||||||

| 5 | 7 | |||||||

| 6 | 6 | |||||||

| 7 | 6 | |||||||

| 8 | 7 | |||||||

| 9 | 5 | |||||||

| 10 | 7 | |||||||

| 11 | 5 | |||||||

| 12 | 4 | |||||||

| 13 | 6 | |||||||

| 14 | 6 | |||||||

| 15 | 3 | |||||||

| 16 | 7 | |||||||

| 17 | 7 | |||||||

| 18 | 7 | |||||||

| 19 | 7 | |||||||

| 20 | 7 | |||||||

| Activities | Postures | Stick Diagram |

|---|---|---|

| Nailing | Sitting on the chair, back bent forward and twisted, both arms below shoulder level, holding right hand with a hammer, sitting with both knees bent, a weight of 10 kg or less |  |

| Cutting | Sitting on the floor, back bent forward and twisted, both arms below shoulder level, sitting with legs crossed, a weight of 10 kg or less |  |

| Gluing | Sitting on the floor, back bent forward and twisted, both arms below shoulder level, sitting with legs crossed, a weight of 10 kg or less |  |

| Patterning | Sitting on the floor, back bent forward and twisted, both arms below shoulder level, sitting with legs crossed, a weight of 10 kg or less |  |

| Machine Sewing | Sitting on the chair, back bent forward and twisted, both arms below shoulder level, sitting with both knees bent, a weight of 10 kg or less |  |

| Weaving | Sitting on the floor, back bent forward and twisted, both arms below shoulder level, sitting with legs crossed, a weight of 10 kg or less |  |

| Hand sewing | Sitting on the floor paddling, back bent forward and twisted, both arms below shoulder level, sitting with legs crossed, a weight of 10 kg or less |  |

| Rolling | Sitting on the floor, back bent forward and twisted, both arms below shoulder level, sitting with legs crossed, a weight of 10 kg or less |  |

| Score Range | Interpretation | Participant (n) | Prevalence (%) |

|---|---|---|---|

| 1 or 2 | This is acceptable but there may be some ergonomic problems with repeated operations. | 0 | 0 |

| 3 or 4 | Further studies are required and monitoring for new design work. | 2 | 10 |

| 5 or 6 | The job was starting to get problematic. More studies should be required and should be improved. | 9 | 45 |

| 7 or more | The job had an ergonomic problem and must be updated immediately. | 9 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chonsin, K.; Buaphet, S.; Intarasombut, J.; Chotikhun, A.; Kittijaruwattana, J. The Rapid Upper Limb Assessment Among Traditional Krajood (Lepironia articulata) Handicraft Workers: A Case Study in Southern Thailand. Appl. Sci. 2025, 15, 3142. https://doi.org/10.3390/app15063142

Chonsin K, Buaphet S, Intarasombut J, Chotikhun A, Kittijaruwattana J. The Rapid Upper Limb Assessment Among Traditional Krajood (Lepironia articulata) Handicraft Workers: A Case Study in Southern Thailand. Applied Sciences. 2025; 15(6):3142. https://doi.org/10.3390/app15063142

Chicago/Turabian StyleChonsin, Kaknokrat, Suthasini Buaphet, Jutamas Intarasombut, Aujchariya Chotikhun, and Jitralada Kittijaruwattana. 2025. "The Rapid Upper Limb Assessment Among Traditional Krajood (Lepironia articulata) Handicraft Workers: A Case Study in Southern Thailand" Applied Sciences 15, no. 6: 3142. https://doi.org/10.3390/app15063142

APA StyleChonsin, K., Buaphet, S., Intarasombut, J., Chotikhun, A., & Kittijaruwattana, J. (2025). The Rapid Upper Limb Assessment Among Traditional Krajood (Lepironia articulata) Handicraft Workers: A Case Study in Southern Thailand. Applied Sciences, 15(6), 3142. https://doi.org/10.3390/app15063142