Abstract

To examine the effect of flocculation treatment on slurry clogging during vacuum preloading, this study conducted vacuum preloading model tests using lime, anionic polyacrylamide (APAM), and the dual use of polyaluminum chloride (PAC) and APAM in conjunction with particle image velocimetry (PIV) analysis. The results demonstrated that flocculation treatment enhanced the efficiency of vacuum preloading and mitigated the clogging of slurry. Compared to untreated slurry, the lime-flocculated slurry exhibited an approximately 248% increase in pore water pressure dissipation, a 462% increase in clogging zone width, and an 80% improvement in slurry strength near the PVD. The dual use of PAC and APAM significantly improved the slurry’s filtration performance by approximately 77 s, resulting in the highest water discharge rate (47% higher than untreated slurry) under vacuum pressure. In contrast, APAM alone enhanced the water discharge rate primarily in the early stages of vacuum preloading but had a limited effect on the final water discharge volume and horizontal strain. Furthermore, this study investigated the evolution of the clogging zone in flocculated slurry and elucidated the underlying mechanism of flocculation in mitigating the clogging of slurry. The findings can provide a theoretical basis for the selection of flocculants and the arrangement of PVDs in large-scale land reclamation and dredged slurry treatment projects.

1. Introduction

With the continuous development of the economy, land resources are becoming increasingly scarce. As a result, coastal countries and regions commonly resort to land reclamation to expand usable land areas [1,2]. The slurry used for land reclamation is primarily sourced from the nearby seabed and is characterized by high initial water content and extremely low strength [3,4,5,6]. Therefore, the development of a rapid and effective dewatering method for dredged slurry has become an urgent challenge in geotechnical engineering [7].

Currently, common slurry dewatering techniques in engineering practice include vacuum preloading, surcharge preloading, and the geotextile tube method [8,9,10,11]. Among these, the vacuum preloading method has been widely adopted in slurry treatment projects [12,13,14] due to its cost-effectiveness and relatively simple construction process [15,16]. However, when applied to slurry with a high clay particle content, the dewatering efficiency of the vacuum preloading method is often significantly reduced [17]. This decline in efficiency is primarily attributed to the formation of clogging zones, where soil particles accumulate near the prefabricated vertical drain (PVD) under vacuum pressure, resulting in an extremely low-permeability region [18,19]. The vacuum pressure experiences substantial losses as it propagates through the clogging zone, ultimately preventing the vacuum preloading method from achieving the desired soil reinforcement effect [20]. Consequently, mitigating clogging remains the most critical challenge in the application of vacuum preloading for slurry treatment.

Flocculants are chemical additives that enhance slurry dewatering performance through mechanisms like electrostatic neutralization, adsorption bridging, and sweep flocculation. These processes reduce the interparticle distance within the slurry and promote the aggregation of particles into floc structures, thereby improving its dewatering efficiency [21,22,23,24]. The integration of flocculants with vacuum preloading, known as the flocculation combined with vacuum preloading method, has been shown to significantly enhance slurry dewatering performance [12,25,26].

Numerous studies have investigated the treatment effects and underlying mechanisms of this method. Han et al. [27] conducted laboratory tests and found that APAM effectively mitigated the clogging of slurry while improving both the consolidation rate and the final consolidation effect. Liu et al. [28] applied APAM and FeCl3 in flocculation combined with vacuum preloading treatment of dredged slurry, reporting increases in water discharge volume by 56.8% and 46.5%, respectively, compared to traditional vacuum preloading. Wang et al. [29] and Zhu et al. [30] investigated the vacuum preloading treatment of lime-flocculated slurry and observed that lime treatment transformed fine micrometer-scale particles into millimeter-scale aggregates. This modification significantly enhanced slurry permeability, reduced the clogging of slurry around prefabricated vertical drains (PVDs), and improved consolidation efficiency. Wang et al. [31] further explored the dual use of lime and APAM in treating high-water-content slurry via vacuum preloading, demonstrating that flocculation treatment improved consolidation efficiency, increased slurry strength, and reduced clogging.

In summary, existing research indicates that flocculation treatment effectively alleviates the clogging of slurry and enhances the efficiency of vacuum preloading. However, its influence on the development of the clogging zone during vacuum preloading tests has primarily been inferred through indirect indicators, such as the water discharge rate and consolidation efficiency. A direct observation method for assessing clogging zone evolution remains lacking.

In recent years, the PIV technique has played a significant role in geotechnical engineering [32,33,34]. PIV is a technique that utilizes MATLAB R2023a to divide slurry into discrete patches and calculates the peak of the autocorrelation function for each patch between consecutive images, thereby obtaining the displacement and strain fields of slurry. As a non-invasive, full-field measurement method, PIV has been widely applied in various geotechnical studies, including the observation of soil deformation distribution near tunnels, soil displacement fields induced by vacuum preloading, and undrained cyclic torsional shear tests [35,36,37]. Consequently, the PIV technique can be effectively employed to observe displacement and strain fields during vacuum preloading tests, enabling a detailed analysis of the development pattern of the clogging zone in slurry.

In this study, the vacuum preloading tests combined with the PIV technique were conducted to investigate the influence of APAM, the dual use of PAC and APAM, and lime at their optimal dosages on the treatment effectiveness of vacuum preloading and the clogging of slurry. This study aims to (a) analyze the influence of different flocculants on the dewaterability and strength of slurry treated using the vacuum preloading method; (b) investigate the displacement and strain fields of flocculated slurry during the vacuum preloading test; (c) propose the development pattern of the clogging zone in flocculated slurry; and (d) elucidate the mechanism through which flocculation treatment mitigates the clogging of slurry.

2. Materials and Methods

2.1. Test Material

2.1.1. Slurry

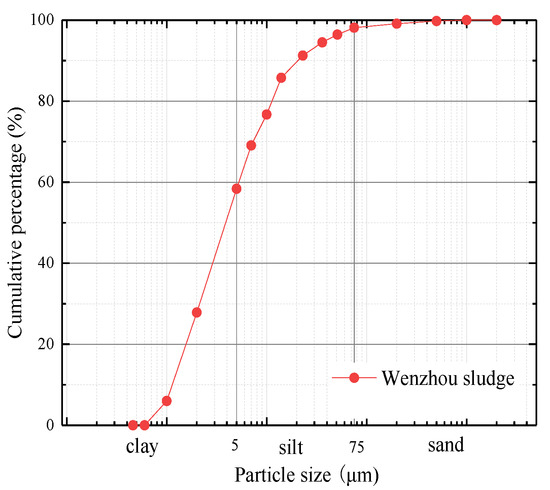

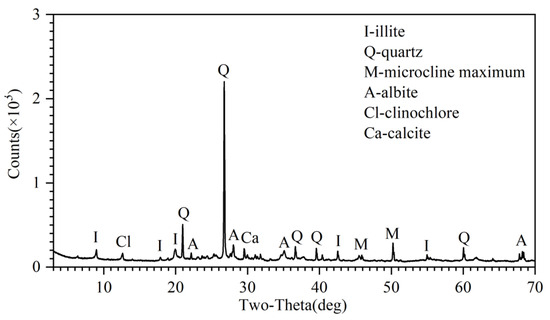

The dredged slurry used in this study was obtained from the Oufei Project in Wenzhou, China. The physical properties of the slurry were determined using laboratory tests conducted in accordance with the Specification of Soil Test (GB/T 50123-2019) [38] and are summarized in Table 1. The particle size distribution was analyzed using a laser particle size analyzer, as shown in Figure 1. Results indicate that approximately 98% of the soil particles in the slurry are smaller than 75 μm and the d50 of slurry is 4 μm. According to the Unified Soil Classification System (USCS), the dredged slurry is classified as high-plasticity clay. The mineral composition of the slurry is shown in Figure 2. As shown in the figure, the slurry is primarily composed of illite, quartz, microcline maximum, albite, clinochlore, and calcite.

Table 1.

Physical properties of the slurry.

Figure 1.

Particle size distribution in the untreated sludge.

Figure 2.

XRD pattern for Wenzhou slurry.

2.1.2. Flocculation

Several commonly used flocculants, including PAC, APAM, and lime [28,29,39] were used in the study. The molecular weight of APAM was 1.2 × 107. The flocculants used in this study were procured from Maclin Biochemical Technology Co., Ltd., Shanghai, China. The price of APAM is CNY 10/kg, the price of PAC is CNY 1.5/kg, and the price of lime is CNY 0.6/kg.

The optimal dosage of each flocculant for the vacuum preloading tests was determined through capillary suction time (CST) tests. The dosing conditions for the flocculants are summarized in Table 2, labeled as Type 1 through Type 3. The dosage for the dual use of PAC and APAM was determined based on Type 1. Under single-dosing conditions, the flocculants were added to the slurry and mixed at 100 rpm for 30 s, followed by additional mixing at 45 rpm for 90 s [40]. For dual-dosing conditioning, the slurry was initially treated with PAC and mixed at 100 rpm for 15 s. Subsequently, APAM was added and mixed for 60 s, followed by an increase in mixing speed to 250 rpm for an additional 40 s. It is important to note that the dosage of flocculant in this study is expressed as the ratio of the dry weight of the flocculant to the dry weight of the slurry.

Table 2.

Flocculant types and dosages.

2.2. Test Apparatus

2.2.1. Capillary Suction Time Test Apparatus

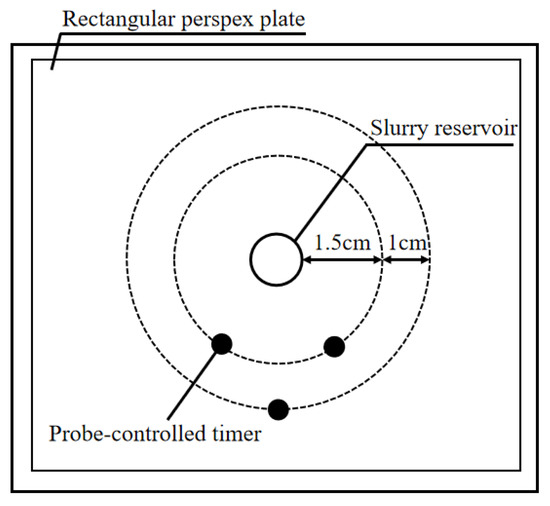

The CST directly reflects the rate at which liquid is discharged from a slurry suspension and is widely used to evaluate the filtration performance of slurry [41,42]. CST tests were conducted on various flocculated slurries using a DFC-10A CST apparatus which was procured from Lidaxin Co., Ltd., Shenzhen, China. (Figure 3). The CST apparatus consists of a rectangular filter paper (70 × 70 mm), a slurry reservoir, two rectangular Perspex plates, and two timers controlled by concentric circular electrodes. During testing, approximately 10 mL of flocculated slurry was added to the reservoir, and the CST was automatically recorded as the time required for the liquid to pass between the two concentric circular electrodes. A lower CST value indicates better filtration performance.

Figure 3.

CST test apparatus schematic diagram.

2.2.2. Vacuum Preloading Combined with PIV Technique Test Apparatus

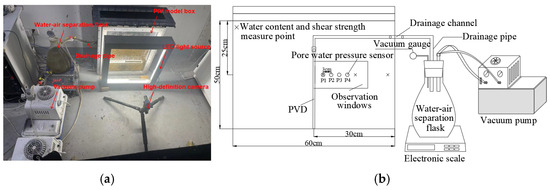

The test apparatus used for the vacuum preloading combined with the PIV technique is shown in Figure 4. It consists of a vacuum preloading model test box, a vacuum system, and a data acquisition system.

Figure 4.

Vacuum preloading combined with PIV technique test apparatus. (a) Physical pictures. (b) Schematic diagram.

The model test box is constructed from stainless steel with dimensions of 60 cm (length) × 20 cm (width) × 50 cm (height). A Perspex sheet is installed as a viewing window on the front side of the box. To ensure airtightness, a geomembrane and a sealing plate are positioned above the model box, with the geomembrane securely fixed between the box and the sealing plate using a flange connection. On the back side of the model box, channels for pore water pressure sensors are installed to facilitate connections with the pore water pressure gauge. A drainage channel is provided on the side of the model box for water discharge. In the center of the box, a PVD bracket is mounted to secure the prefabricated vertical drain (PVD), which is connected to the drainage channel through a geosynthetic cap and a dewatering pipe.

The vacuum system consists of two SHZ-D circulating water vacuum pumps, a water–air separation flask, and an electronic scale. Based on engineering practice, the vacuum pressure is set to −85 kPa. To maintain a stable vacuum degree inside of the model box, the two vacuum pumps operate alternately, each running for 12 h. The water–air separation flask collects water discharged from the slurry during the vacuum preloading test. The electronic scale (HCT-U automatic weighing scale) records the weight of discharged water in real time.

The data acquisition system includes an LED light source, a high-definition camera, and pore water pressure sensors. The LED light source provides uniform and bright illumination to ensure the clarity of captured images. The high-definition camera (MER-1810-21U3C-L which was procured from Daheng Co., Ltd., Beijing, China), with a resolution of 4912 × 3684 pixels, captures high-resolution images for PIV calculations. The pore water pressure sensors continuously monitor real-time changes in pore water pressure during the vacuum preloading test.

2.3. Test Method

In this study, CST tests and vacuum preloading tests combined with the PIV technique were conducted on untreated slurry, APAM-flocculated slurry, dual-use PAC and APAM-flocculated slurry, and lime-flocculated slurry. The detailed test procedure is as follows:

- (1)

- Prepare the flocculated slurries according to the test schemes outlined in Table 2 and perform CST tests to determine the optimal flocculant proportions for the vacuum preloading tests.

- (2)

- Prepare the flocculant solutions based on the determined formulations. Gradually add the flocculant solutions into the slurry barrel in batches, using a hand-held electric mixer to ensure uniform mixing of the flocculants with the slurry.

- (3)

- Charge the viewing window with static electricity through friction, and then spray tracer particles (average particle diameter is 50 μm) onto the inner side of the viewing window using a powder duster. Install and secure the viewing window onto the model box. Next, install the PVD and pore water pressure sensors inside of the model box (Figure 4b). Carefully pour the prepared flocculated slurry into the model box, ensuring that no air cavities form during the process. The slurry fill height is 45 cm.

- (4)

- Turn on the LED light source and adjust the camera position and focal length to achieve a clear and fully captured imaging plane. Set the high-definition camera to capture images at 30 s intervals during the first 24 h of the test and at 10 min intervals thereafter.

- (5)

- Activate the vacuum pump and gradually increase the vacuum pressure inside of the model box to −85 kPa within 3 min. Throughout the test, continuously monitor and record imaging data, pore water pressure, and water discharge volume in real time. The test continues until no further water discharge is observed.

- (6)

- After the test, conduct vane shear tests and water content measurements at the detection points indicated in Figure 4b. Additionally, collect slurry samples within a 3 cm radial distance along the PVD using a ring cutter to perform permeability tests, following the Specification of Soil Test (GB/T 50123-2019).

3. Test Results

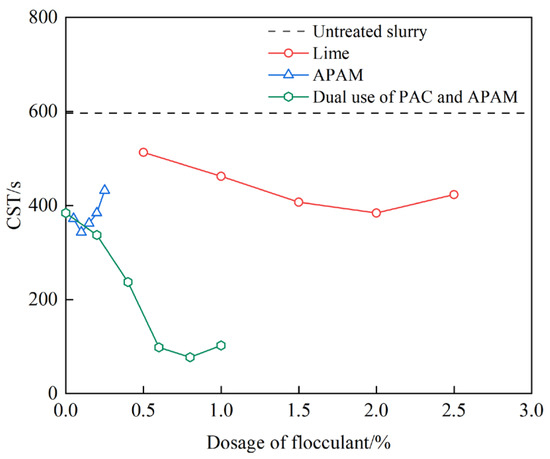

3.1. Capillary Suction Time

The CST values of the tested slurries are presented in Figure 5. The untreated slurry exhibited a CST value of 597 s, indicating poor filtration performance. Flocculation treatment significantly improved the filtration performance of the slurries. Under single-dosing conditions, 0.1% APAM demonstrated the best performance, reducing the CST value to 343 s, followed by 2% lime, which achieved a CST value of 384 s. Under dual-dosing conditions, the dual use of 0.8% PAC and 0.1% APAM exhibited the most effective filtration performance, achieving a CST value of 77 s. This enhancement is attributed to the synergistic effect of PAC and APAM, where the electrostatic neutralization of PAC and the adsorption bridging of APAM jointly promote soil–water separation. Based on these results, 2% lime, 0.1% APAM, and dual use of 0.8% PAC and 0.1% APAM were selected for the follow-up tests.

Figure 5.

CST test results.

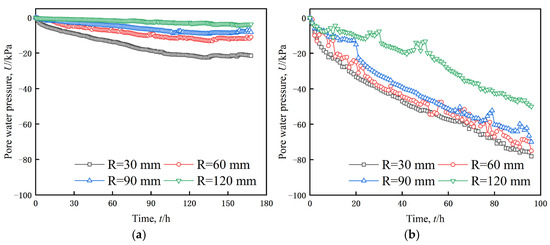

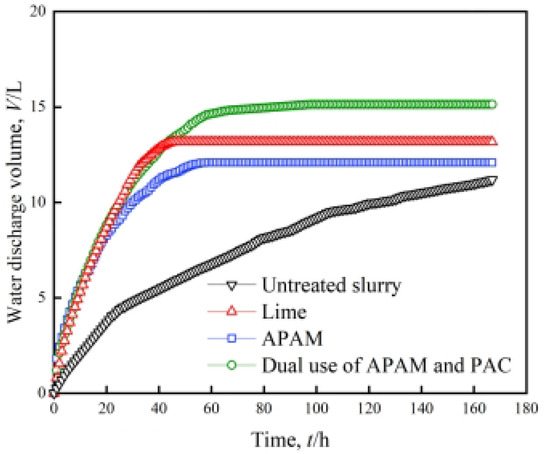

3.2. Pore Water Pressure

The results of pore water pressure dissipation (i.e., the reduction from hydrostatic pressure to vacuum pressure) over time, measured at distances of 30 mm, 60 mm, 90 mm, and 120 mm from the PVD, are presented in Figure 6. The pore water pressure in the slurry gradually dissipates following the initiation of the vacuum preloading test. The closer the measurement point is to the PVD, the faster the dissipation rate. This phenomenon occurs because a clogging zone progressively develops near the PVD during vacuum preloading, impeding the transmission of vacuum pressure to more distant regions, ultimately reducing the pore water pressure dissipation rate.

Figure 6.

Pore water pressure dissipation versus time. (a) Untreated slurry. (b) Lime-treated slurry. (c) APAM-treated slurry. (d) Dual use of PAC and APAM-treated slurry.

At the end of the vacuum preloading test, the pore water pressures measured at R = 30 mm were −21 kPa for untreated slurry, −46 kPa for APAM-flocculated slurry, −72 kPa for dual use of PAC and APAM-flocculated slurry, and −80 kPa for lime-flocculated slurry. The untreated slurry exhibited the slowest pore water pressure dissipation rate at R = 30 mm, indicating the highest degree of clogging. Flocculation treatment enhanced pore water pressure dissipation. Among the tested flocculants, APAM alone improved the dissipation rate only at R = 30 mm, with a relatively limited effect on mitigating the clogging of slurry. However, pretreating the slurry with PAC before adding APAM significantly expanded the effective influence range of vacuum preloading and improved pore water pressure dissipation. At R = 120 mm, the pore water pressure in the dual PAC and APAM-treated slurry decreased to −8 kPa, whereas both the untreated slurry and the APAM-flocculated slurry remained at 0 kPa, indicating a more effective vacuum pressure transmission in the dual-treatment case.

Furthermore, vacuum pressure loss was minimal in the lime-flocculated slurry. The pore water pressure at R = 120 mm in the lime-flocculated slurry dissipated to −52 kPa, suggesting an extremely low clogging degree. This can be attributed to the flocculation of slurry particles into clusters, forming a relatively stable soil structure [43], which enhances the permeability of lime-flocculated slurry [44]. As a result, vacuum pressure can propagate over a greater distance without significant attenuation.

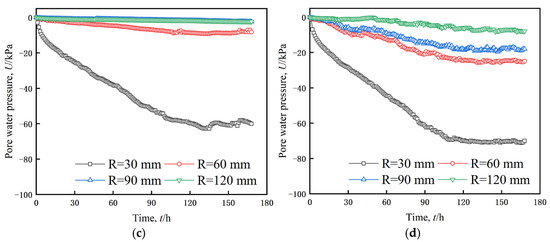

3.3. Water Discharge

Figure 7 illustrates the water discharge volume of the tested slurries over time during the vacuum preloading test. At 24 h after the test began, the water discharge volumes of the lime-flocculated slurry, dual use of PAC and APAM-flocculated slurry, APAM-flocculated slurry, and untreated slurry were 10.8 kg, 10.7 kg, 9.6 kg, and 3.5 kg, respectively. The flocculated slurries exhibited a significantly higher water discharge volume than the untreated slurry, with the lime-flocculated slurry demonstrating the largest water discharge volume at 24 h. However, by the end of the vacuum preloading test, the final water discharge volumes ranked from highest to lowest were dual use of PAC and APAM-flocculated slurry with 15.2 kg, lime-flocculated slurry with 13.4 kg, APAM-flocculated slurry with 12.1 kg, and untreated slurry with 10.1 kg. The final water discharge volume of the lime-flocculated slurry was notably lower than that of the dual use of PAC and APAM-flocculated slurry. This is attributed to the high permeability and low compressibility of lime-flocculated slurry [45]. The high permeability of lime-flocculated slurry facilitates rapid initial dewatering, allowing pore water to be efficiently discharged under vacuum pressure in the early stage of the test. However, due to its low compressibility and the formation of a relatively stable soil structure, further volume reduction and dewatering become challenging in the later stages. Additionally, the dewatering completion times for the lime-flocculated slurry, dual use of PAC and APAM-flocculated slurry, and APAM-flocculated slurry were 46 h, 60 h, and 97 h, respectively, all significantly shorter than that of the untreated slurry. This confirms that flocculation treatment enhances both dewatering efficiency and the consolidation rate in slurry.

Figure 7.

Water discharge volume versus time.

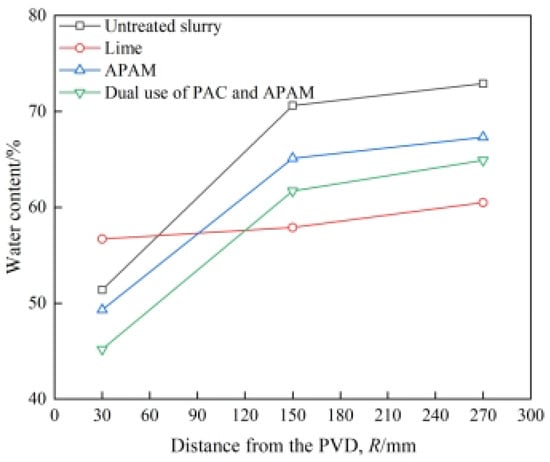

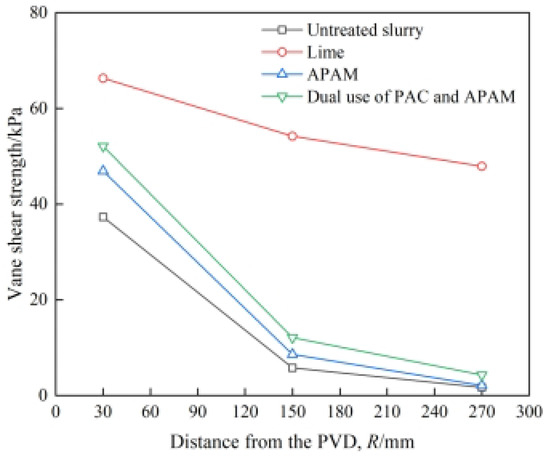

3.4. Water Content and Vane Shear Strength

After the completion of the vacuum preloading test, the water content and vane shear strength at different radial distances from the center of the PVD were measured, as shown in Figure 8 and Figure 9. The water content of the slurry gradually increased with increasing distance from the PVD, while the vane shear strength decreased gradually along the same radial direction. Among all tested slurries, the untreated slurry exhibited the highest water content. At R = 30 mm, the water content of the untreated slurry reached 51.4%, and at all other measurement points, it remained above 70%, indicating the formation of a dense clogging zone near the PVD. The slurry outside of this zone could not be effectively dewatered.

Figure 8.

Water content of slurry after vacuum preloading test.

Figure 9.

Vane shear strength of slurry after vacuum preloading test.

Flocculation treatment significantly reduced the water content after vacuum preloading. Among the tested flocculants, the dual use of PAC and APAM-flocculated slurry exhibited the lowest water content, reaching only 45.2% at R = 30 mm, indicating that this treatment greatly enhanced the dewatering capacity of the slurry. Additionally, the lime-flocculated slurry showed the smallest variation in water content along the radial direction, with the water content at R = 270 mm being only 3.8% higher than that at R = 30 mm. However, the water content of the lime-flocculated slurry at R = 30 mm was notably higher than that of the other slurries. This suggests that lime treatment can effectively mitigate clogging and enhance slurry reinforcement, although it limits further dewatering.

Furthermore, the vane shear strength of the lime-flocculated slurry remained above 45 kPa throughout the entire model box, which was significantly higher than that of the other slurries. This enhancement can be attributed to the reaction between lime and slurry, which generates a large quantity of cementitious materials, such as calcium silicate hydrate (C-S-H). These materials bind to the surface of soil particles, forming a stable soil skeleton and significantly improving the structural strength of the slurry. In contrast, the vane shear strengths of the APAM-flocculated slurry and the dual use of PAC and APAM-flocculated slurry were comparable to that of the untreated slurry, with values of 6.3 kPa and 8.6 kPa at R = 150 mm, respectively. This indicates that organic flocculants had a relatively minor effect on vane shear strength.

3.5. Horizontal Displacement

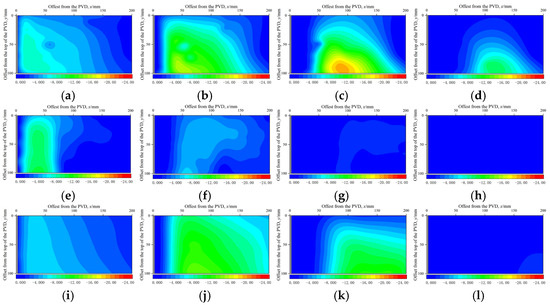

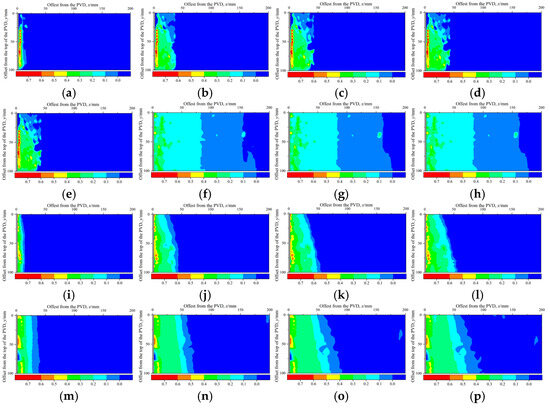

In PIV analysis, the horizontal components of the displacement vector were calculated for each soil patch [35]. The horizontal displacement field of the slurry is presented in Figure 10. Because the flocculated slurry had fully consolidated by 96 h, no horizontal displacement was observed in Figure 10h,l,p.

Figure 10.

Horizontal displacement field of slurry. (a) Untreated slurry, 0–3 h; (b) untreated slurry, 3–24 h; (c) untreated slurry, 24–96 h; (d) untreated slurry, 96–168 h; (e) lime-flocculated slurry, 0–3 h; (f) lime-flocculated slurry, 3–24 h; (g) lime-flocculated slurry, 24–96 h; (h) lime-flocculated slurry, 96–168 h; (i) APAM-flocculated slurry, 0–3 h; (j) APAM-flocculated slurry, 3–24 h; (k) APAM-flocculated slurry, 24–96 h; (l) APAM-flocculated slurry, 96–168 h; (m) dual use of PAC and APAM-flocculated slurry, 0–3 h; (n) dual use of PAC and APAM-flocculated slurry, 3–24 h; (o) dual use of PAC and APAM-flocculated slurry, 24–96 h; (p) dual use of PAC and APAM-flocculated slurry, 96–168 h.

Following the initiation of the vacuum preloading test, a distinct horizontal displacement zone appeared near the PVD. The horizontal displacement of the slurry initially increased along the radial direction from the PVD, reaching a peak value, and then gradually decreased. As the test progressed, the displacement values continued to decline, and a low-displacement zone (dx < 1 mm) formed near the PVD, indicating that the slurry in this region had completed consolidation. By comparing Figure 10a–d with Figure 10e–p, it is evident that flocculation treatment accelerated slurry consolidation. Among the tested flocculants, the lime-flocculated slurry exhibited the fastest consolidation rate. Additionally, during the vacuum preloading test, the peak horizontal displacement values for lime-flocculated slurry, APAM-flocculated slurry, dual use PAC and APAM-flocculated slurry, and untreated slurry were 10 mm, 17 mm, 22 mm, and 18 mm, respectively. The horizontal displacement of the lime-flocculated slurry was significantly lower than that of the other slurries, indicating that lime flocculation effectively reduced lateral deformation of the soil during vacuum preloading.

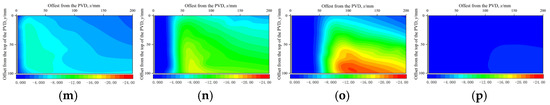

3.6. Horizontal Strain

The horizontal strain of slurry can reflect the degree of uneven consolidation, making it a useful parameter for evaluating the clogging of slurry. Moreover, existing studies on vacuum preloading tests based on PIV technology predominantly use horizontal strain as an indicator to assess slurry clogging [35,46]. Therefore, in this study, horizontal strain was selected as the key parameter for evaluating the clogging of slurry.

The cloud diagrams of the horizontal strain in the flocculated slurry are presented in Figure 11. Following the initiation of the vacuum preloading test, a zone with a horizontal strain greater than zero developed near the PVD, indicating that the slurry in this region had begun to consolidate, leading to the formation of a clogging zone [35]. A higher horizontal strain value within the clogging zone corresponds to greater compression and a higher degree of clogging in the slurry. Considering that the clogging zone varies with depth, this study utilized the average width along the depth to characterize the evolution of the clogging zone over time.

Figure 11.

Horizontal strain fields of slurry. (a) Untreated slurry, 3 h; (b) untreated slurry, 24 h; (c) untreated slurry, 96 h; (d) untreated slurry, 168 h; (e) lime-flocculated slurry, 3 h; (f) lime-flocculated slurry, 24 h; (g) lime-flocculated slurry, 96 h; (h) lime-flocculated slurry, 168 h; (i) APAM-flocculated slurry, 3 h; (j) APAM-flocculated slurry, 24 h; (k) APAM-flocculated slurry, 96 h; (l) APAM-flocculated slurry, 168 h; (m) dual use of PAC and APAM-flocculated slurry, 3 h; (n) dual use of PAC and APAM-flocculated slurry, 24 h; (o) dual use of PAC and APAM-flocculated slurry, 96 h; (p) dual use of PAC and APAM-flocculated slurry, 168 h.

At the completion of the vacuum preloading test, the widths of the clogging zones for the lime-flocculated slurry, the APAM-flocculated slurry, the dual use PAC and APAM-flocculated slurry, and the untreated slurry were 165 mm, 46 mm, 71 mm, and 41 mm, respectively. The average horizontal strain values near the PVD for these slurries were approximately 20%, 35%, 30%, and 40%, respectively. Notably, the horizontal strain value of the slurry gradually decreased along the radial direction from the PVD, indicating a progressive reduction in the degree of clogging with increasing distance from the PVD.

Among the tested slurries, the untreated slurry exhibited the smallest clogging zone width and the highest degree of clogging. The boundary of the clogging zone in the untreated slurry displayed extremely dense horizontal strain gradient lines (Figure 11d), indicating a severe non-uniform consolidation phenomenon. This phenomenon can be attributed to the early-stage development of a high-strain clogging zone near the PVD (Figure 11b) in the untreated slurry, which hindered the further transmission of vacuum pressure and significantly reduced consolidation efficiency.

In contrast, after flocculation treatment, the horizontal strain in the slurry was significantly reduced, and the width of the clogging zone increased considerably. This indicates that flocculation treatment effectively mitigated slurry clogging and facilitated the transmission of vacuum pressure over a greater distance. Among the flocculated slurries, the APAM-flocculated slurry exhibited only a 5 mm increase in the clogging zone width compared to the untreated slurry (Figure 11i), and its horizontal strain values remained relatively close to those of the untreated slurry, suggesting a weaker effect in mitigating clogging. The dual-use PAC and APAM treatment showed a moderate improvement over APAM alone in reducing clogging. The lime-flocculated slurry demonstrated the largest increase in clogging zone width among all treatments (Figure 11h) and exhibited an extremely low horizontal strain, indicating that lime treatment had the most pronounced effect in mitigating clogging caused by vacuum preloading.

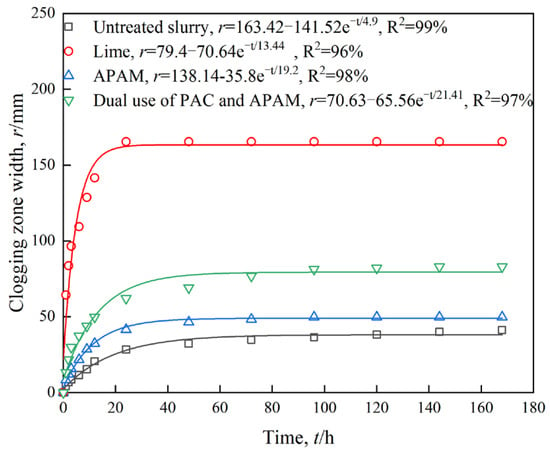

3.7. Clogging Zone

The variation in clogging zone width of the slurry over time is shown in Figure 12. During the first 24 h of the vacuum preloading test, the clogging zones of all four slurry types developed rapidly. The lime-flocculated slurry exhibited the fastest development rate, with the clogging zone reaching 165 mm and stabilizing at 24 h. The development rate of the clogging zone gradually slowed between 24 and 100 h. The clogging zones of the APAM-flocculated slurry and the dual use of PAC and APAM-flocculated slurry stabilized at 68 h and 92 h, respectively, with final widths of 46 mm and 71 mm. After 100 h, only the untreated slurry continued to exhibit a slow increase in clogging zone width, eventually stabilizing at 41 mm.

Figure 12.

Clogging zone width of slurry versus time.

These results indicate that flocculation treatment not only accelerates the development of the clogging zone but also increases its final width. The fitting curves for the clogging zone widths of the lime-flocculated slurry, the dual use of PAC and APAM-flocculated slurry, the APAM-flocculated slurry, and the untreated slurry are as follows:

4. Discussion

The results of the vacuum preloading test demonstrate that flocculation treatment accelerates the development rate of the slurry’s clogging zone and reduces its horizontal strain value, indicating that flocculation treatment effectively mitigates slurry clogging. Among the tested flocculants, lime exhibited the most significant effect in mitigating slurry clogging. This is because lime-flocculated slurry undergoes property modifications through ion exchange and pozzolanic reactions (Equations (5)–(7)). Through ion exchange, lime replaces low-valence cations, such as K⁺ and Na⁺, on the surfaces of slurry particles with high-valence cations like Ca2⁺, which compresses the electric double layer and reduces interparticle spacing. Additionally, the cementitious materials generated by the pozzolanic reaction adhere to the surfaces of slurry particles, resulting in a more stable soil structure. These flocculation effects enhance the permeability and reduce the compressibility of lime-flocculated slurry [43], which minimizes vacuum pressure loss during transmission and alleviates non-uniform consolidation. As a result, lime-flocculated slurry exhibits the fastest clogging zone development, the lowest horizontal strain, and the most effective mitigation of clogging.

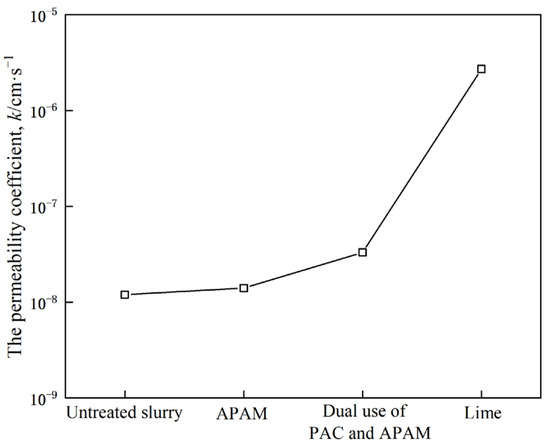

For organic polymer flocculants, the dual-use PAC and APAM treatment is more effective in mitigating clogging in high-water-content slurry compared to the single-dose APAM treatment. This is because the flocculation mechanism of APAM primarily relies on the adsorption of polymer chains onto the surfaces of clay particles [47]. This adsorption occurs through hydrogen bonding between the amide groups of the PAM chain and the hydroxyl groups on the clay particles, reducing interparticle spacing and facilitating the expulsion of trapped water. As a result, APAM flocculation treatment enhances the filtration performance of the slurry (Figure 5), leading to a faster water discharge rate in the early stages of the vacuum preloading test. However, APAM-flocculated slurry tends to form large and loose flocs that trap significant amounts of water, which are difficult to expel under vacuum pressure [48]. These water-retaining flocs accumulate near the PVD, significantly reducing the permeability of the slurry (Figure 13) and hindering the transmission of vacuum pressure. This explains why APAM alone has a relatively limited effect in mitigating slurry clogging.

Figure 13.

The permeability coefficient of slurry in the clogging zone.

In contrast, PAC reduces the zeta potential of the slurry through charge neutralization, thereby disrupting the stability of the colloidal structure and promoting the aggregation of slurry particles into micro-flocs [49]. This process enhances the flocculation efficiency of APAM, ultimately improving the dewatering performance of the dual use of PAC and APAM-flocculated slurry. Additionally, PAC acts as a skeleton builder, forming a more porous and less compressible slurry structure [50]. As a result, the dual use of PAC and APAM-flocculated slurry exhibits better permeability, a larger clogging zone width, and more effective mitigation of slurry clogging compared to APAM alone.

5. Conclusions

The development pattern of the clogging zone, along with the dewatering and consolidation capacities of the lime-flocculated slurry, APAM-flocculated slurry, dual-use PAC and APAM-flocculated slurry, and untreated slurry, were investigated using vacuum preloading tests combined with the PIV technique. The following conclusions can be drawn from this study:

- Severe clogging occurred in the untreated slurry, which hindered vacuum pressure transmission and reduced dewatering efficiency. Flocculation treatment improved the pore water pressure dissipation rate and dewatering performance of the slurry. Among the tested flocculants, the lime-flocculated slurry exhibited the fastest pore water pressure dissipation rate, while the dual use of PAC and APAM-flocculated slurry achieved the largest water discharge volume. In contrast, APAM flocculation treatment had a limited effect on improving the dewaterability of the slurry.

- Lime flocculation treatment significantly enhanced the vane shear strength of the slurry after vacuum preloading, whereas organic polymer flocculants had a relatively minor effect.

- The horizontal strain near the PVD in the untreated slurry was high, indicating the presence of a dense clogging zone. Flocculation treatment effectively reduced clogging, with lime treatment showing the strongest mitigation effect, while APAM exhibited a relatively weaker impact.

- This study proposes the development pattern of the clogging zone in flocculated slurry and elucidates the mechanisms through which flocculation treatments influence slurry clogging. The findings of this research can provide a theoretical basis for the selection of flocculants and the arrangement of PVDs in large-scale land reclamation and dredged slurry treatment projects.

Author Contributions

Resources, Z.Y.; Data curation, J.L.; Writing—original draft, J.L.; Writing—review & editing, X.Z. and S.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (Grant No. 52108352) and the Zhejiang Provincial Natural Science Foundation (Grant No. LQ22E080020).

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Acknowledgments

This work was supported by College of Civil Engineering of Zhejiang University of technology The authors express their sincere gratitude for the experimental platform provided.

Conflicts of Interest

Author Xuexing Zhang was employed by the company Fangyuan Construction Group, the remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Lei, H.; Lu, H.; Liu, J.; Zheng, G. Experimental Study of the Clogging of Dredger Fills under Vacuum Preloading. Int. J. Geomech. 2017, 17, 04017117. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Ni, J.; Geng, X.; Xu, F. Effect of sand on the vacuum consolidation of dredged slurry. Mar. Georesources Geotechnol. 2018, 36, 238–244. [Google Scholar] [CrossRef]

- Bian, X.; Ren, Z.; Zeng, L.; Zhao, F.; Yao, Y.; Li, X. Effects of biochar on the compressibility of soil with high water content. J. Clean. Prod. 2024, 434, 140032. [Google Scholar] [CrossRef]

- Bian, X.; Zhao, F.; Zeng, L.; Ren, Z.; Li, X. Role of superabsorbent polymer in compression behavior of high water content slurries. Acta Geotech. 2024, 19, 6163–6178. [Google Scholar] [CrossRef]

- Chu, J.; Yan, S.W.; Yang, H. Soil improvement by the vacuum preloading method for an oil storage station. Geotechnique 2000, 50, 625–632. [Google Scholar] [CrossRef]

- Zeng, L.; Bian, X.; Weng, J.; Zhang, T. Wetting-drying effect on the strength and microstructure of cement-phosphogypsum stabilized soils. J. Rock Mech. Geotech. Eng. 2024, 16, 1049–1058. [Google Scholar] [CrossRef]

- Lei, H.; Lou, J.; Li, X.; Jiang, M.; Tu, C. Stabilization Effect of Anionic Polyacrylamide on Marine Clay Treated with Lime. Int. J. Geomech. 2020, 20, 04020050. [Google Scholar] [CrossRef]

- Bian, X.; Gao, Z.; Zhao, P.; Li, X. Quantitative analysis of low carbon effect of urban underground space in Xinjiekou district of Nanjing city, China. Tunn. Undergr. Space Technol. 2024, 143, 105502. [Google Scholar] [CrossRef]

- Chu, J.; Bo, M.; Choa, V. Improvement of ultra-soft soil using prefabricated vertical drains. Geotext. Geomembr. 2006, 24, 339–348. [Google Scholar] [CrossRef]

- Fan, L.; Xun, Z.; Peng, S. A Comparative Case Study on Drainage Consolidation Improvement of Soft Soil under Vacuum Preloading and Surcharge Preloading. Appl. Sci. 2023, 13, 5782. [Google Scholar] [CrossRef]

- Man, X.; Sha, G.; Hu, S.; Liu, G.; Wang, W. Effect of geotextile sewing method on dewatering performance of geotubes: An experimental study. J. Meas. Eng. 2019, 7, 205–213. [Google Scholar] [CrossRef]

- Han, C.; Xie, H.; Bai, B.; Zhang, R.; Gao, Y.; Zhao, Z. Experimental Study on Mechanical Properties of Marine Mud Slurry Treated by Flocculation-Solidification-High Pressure Filtration Combined Method. J. Mar. Sci. Eng. 2023, 11, 2270. [Google Scholar] [CrossRef]

- Jie, P.; Xiong, X. Vacuum preloading combined electroosmotic strengthening of ultra-soft soil. J. Cent. South Univ. 2013, 20, 3282–3295. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Ma, J.; Chu, J.; Fu, H.; Wang, P.; Jin, Y. Improved Vacuum Preloading Method for Consolidation of Dredged Clay-Slurry Fill. J. Geotech. Geoenvironmental Eng. 2016, 142, 06016012. [Google Scholar] [CrossRef]

- Feng, S.; Bai, W.; Lei, H.; Song, X.; Liu, W.; Cheng, X. Vacuum preloading combined with surcharge preloading method for consolidation of clay-slurry ground: A case study. Mar. Georesources Geotechnol. 2024, 42, 348–361. [Google Scholar] [CrossRef]

- Wu, J.; Xuan, Y.; Deng, Y.; Li, X.; Zha, F.; Zhou, A. Combined vacuum and surcharge preloading method to improve lianyungang soft marine clay for embankment widening project: A case. Geotext. Geomembr. 2021, 49, 452–465. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Li, L.; Fu, H.; Liu, F.; Cai, Y.; Hu, X. Effects of fracture grouting with sodium hydroxide during electro-osmosis on clay. Mar. Georesources Geotechnol. 2019, 37, 245–255. [Google Scholar] [CrossRef]

- Lei, H.; Qi, Z.; Zhang, Z.; Zheng, G. New Vacuum-Preloading Technique for Ultrasoft-Soil Foundations Using Model Tests. Int. J. Geomech. 2017, 17, 04017049. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, T.; Wu, Y. Soil drainage clogging mechanism under vacuum preloading: A review. Transp. Geotech. 2024, 45, 101178. [Google Scholar] [CrossRef]

- Wang, P.; Wu, J.; Ge, X.; Chen, F.; Yang, X. Non-uniform Consolidation of Soil and Influence of Corresponding Clogging Effect During Vacuum Preloading. Int. J. Geosynth. Ground Eng. 2022, 8, 58. [Google Scholar] [CrossRef]

- Böhm, N.; Kulicke, W.-M. Optimization of the use of polyelectrolytes for dewatering industrial sludges of various origins. Colloid Polym. Sci. 1997, 275, 73–81. [Google Scholar] [CrossRef]

- Lee, C.H.; Liu, J.C. Enhanced Sludge Dewatering by Dual Polyelectrolytes Conditioning. Water Res. 2000, 34, 4430–4436. [Google Scholar] [CrossRef]

- Thapa, K.B.; Qi, Y.; Clayton, S.A.; Hoadley, A.F.A. Lignite aided dewatering of digested sewage sludge. Water Res. 2009, 43, 623–634. [Google Scholar] [CrossRef] [PubMed]

- Thapa, K.B.; Qi, Y.; Hoadley, A.F.A. Interaction of polyelectrolyte with digested sewage sludge and lignite in sludge dewatering. Colloids Surf. A Physicochem. Eng. Asp. 2009, 334, 66–73. [Google Scholar] [CrossRef]

- Lin, W.; Zhan, X.; Zhan, T.L.; Chen, Y.; Jin, Y.; Jiang, J. Effect of FeCl3-conditioning on consolidation property of sewage sludge and vacuum preloading test with integrated PVDs at the Changan landfill, China. Geotext. Geomembr. 2014, 42, 181–190. [Google Scholar] [CrossRef]

- Wang, P. Enhanced consolidation and removal of accumulated flocculants in dredged soil via leaching with vacuum preloading. Environ. Geochem. Health 2024, 46. early access. [Google Scholar] [CrossRef]

- Han, C.; Fan, Z.; Zhang, R.; Cheng, J.; Sun, K.; Peng, Q. Consolidation characteristics of high-water-content slurries improved by flocculation-enhanced surcharge (vacuum) preloading method. Front. Mater. 2023, 10, 1166551. [Google Scholar] [CrossRef]

- Liu, F.; Wu, W.; Fu, H.; Wang, J.; Hai, J.; Cai, Y.; Hu, X.; Yuan, W.; Lou, X. Application of flocculation combined with vacuum preloading to reduce river-dredged sludge. Mar. Georesources Geotechnol. 2020, 38, 164–173. [Google Scholar] [CrossRef]

- Wang, J.; Ni, J.; Cai, Y.; Fu, H.; Wang, P. Combination of vacuum preloading and lime treatment for improvement of dredged fill. Eng. Geol. 2017, 227, 149–158. [Google Scholar] [CrossRef]

- Zhu, X.; Anda, R.; Gao, S.; Yuan, G.; Hai, J.; Ye, Q. Effect of water content on lime additive content in vacuum preloading with PVDs. Mar. Georesources Geotechnol. 2021, 39, 333–342. [Google Scholar] [CrossRef]

- Wang, J.; Huang, G.; Fu, H.; Cai, Y.; Hu, X.; Lou, X.; Jin, Y.; Hai, J.; Ni, J.; Zou, J. Vacuum preloading combined with multiple-flocculant treatment for dredged fill improvement. Eng. Geol. 2019, 259, 105194. [Google Scholar] [CrossRef]

- Adamidis, O.; Madabhushi, S.P.G. Deformation mechanisms under shallow foundations on liquefiable layers of varying thickness. Géotechnique 2017, 68, 602–613. [Google Scholar] [CrossRef]

- Teh, K.L.; Cassidy, M.J.; Leung, C.F.; Chow, Y.K.; Randolph, M.F.; Quah, C.K. Revealing the bearing capacity mechanisms of a penetrating spudcan through sand overlying clay. Géotechnique 2008, 58, 793–804. [Google Scholar] [CrossRef]

- White, D.J.; Bolton, M.D. Displacement and strain paths during plane-strain model pile installation in sand. Géotechnique 2004, 54, 375–397. [Google Scholar] [CrossRef]

- He, Z.; Shen, M.; Yu, Z.; Sun, H.; Cai, Y.; Yu, M.; Zhang, Q. Effect of water content on clogging of dredged slurry under vacuum preloading from PIV perspective. Mar. Georesources Geotechnol. 2024, 42, 634–646. [Google Scholar] [CrossRef]

- White, D.J.; Cheuk, C.Y.; Bolton, M.D. The uplift resistance of pipes and plate anchors buried in sand. Géotechnique 2008, 58, 771–779. [Google Scholar] [CrossRef]

- White, D.J.; Dingle, H.R.C. The mechanism of steady friction between seabed pipelines and clay soils. Géotechnique 2011, 61, 1035–1041. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Beijing China Planning Publishing House: Beijing, China, 2019.

- Ren, G.; Zhang, J.; Feng, T.; Liang, Y.; Yin, Y. Mechanism and Influence of Dispersants on the Action of Polymer Flocculants Used in Slurry Separation. Polymers 2023, 15, 4073. [Google Scholar] [CrossRef]

- Lee, C.H.; Liu, J.C. Sludge dewaterability and floc structure in dual polymer conditioning. Adv. Environ. Res. 2001, 5, 129–136. [Google Scholar] [CrossRef]

- Cobbledick, J.; Nguyen, A.; Latulippe, D.R. Demonstration of FBRM as process analytical technology tool for dewatering processes via CST correlation. Water Res. 2014, 58, 132–140. [Google Scholar] [CrossRef]

- Sawalha, O.; Scholz, M. Modeling the Relationship between Capillary Suction Time and Specific Resistance to Filtration. J. Environ. Eng. 2010, 136, 983–991. [Google Scholar] [CrossRef]

- Sun, H.; Weng, Z.; Liu, S.; Geng, X.; Pan, X.; Cai, Y.; Shi, L. Compression and consolidation behaviors of lime-treated dredging slurry under vacuum pressure. Eng. Geol. 2020, 270, 105573. [Google Scholar] [CrossRef]

- Weng, Z.; Zheng, Y.; Zhu, Q.; Sun, H.; Ni, D. Effects of Granular Gradation on the Compressibility and Permeability of Lime-Stabilized Slurry with High Water Content. Appl. Sci. 2023, 13, 4101. [Google Scholar] [CrossRef]

- Sun, H.; Lu, J.; Xu, S.; Weng, Z.; Zhang, H.; Deng, J.; Cui, C. Effects of lime and polymer flocculants on consolidation behaviours of high-water content sludge. Mar. Georesources Geotechnol. 2024, 42, 1783–1794. [Google Scholar] [CrossRef]

- Cai, J.; He, Z.; Xu, B.; Yu, M. The effect of PVD layout on the consolidation characteristics of dredged slurry under vacuum preloading. Front. Mar. Sci. 2023, 10, 1213820. [Google Scholar] [CrossRef]

- Hogg, R. Flocculation and dewatering. Int. J. Miner. Process. 2000, 58, 223–236. [Google Scholar] [CrossRef]

- Lee, J.-F.; Liao, P.-M.; Seng, D.-H.; Wen, P.-T. Behavior of organic polymers in drinking water purification. Chemosphere 1998, 37, 1045–1061. [Google Scholar] [CrossRef]

- Xu, S.; Shi, J.; Deng, J.; Sun, H.; Wu, J.; Ye, Z. Flocculation and dewatering of the Kaolin slurry treated by single- and dual-polymer flocculants. Chemosphere 2023, 328, 138445. [Google Scholar] [CrossRef]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).