The Influence of Accidental Overheating on the Microstructure and Hardness of the Inconel 718 Alloy

Abstract

1. Introduction

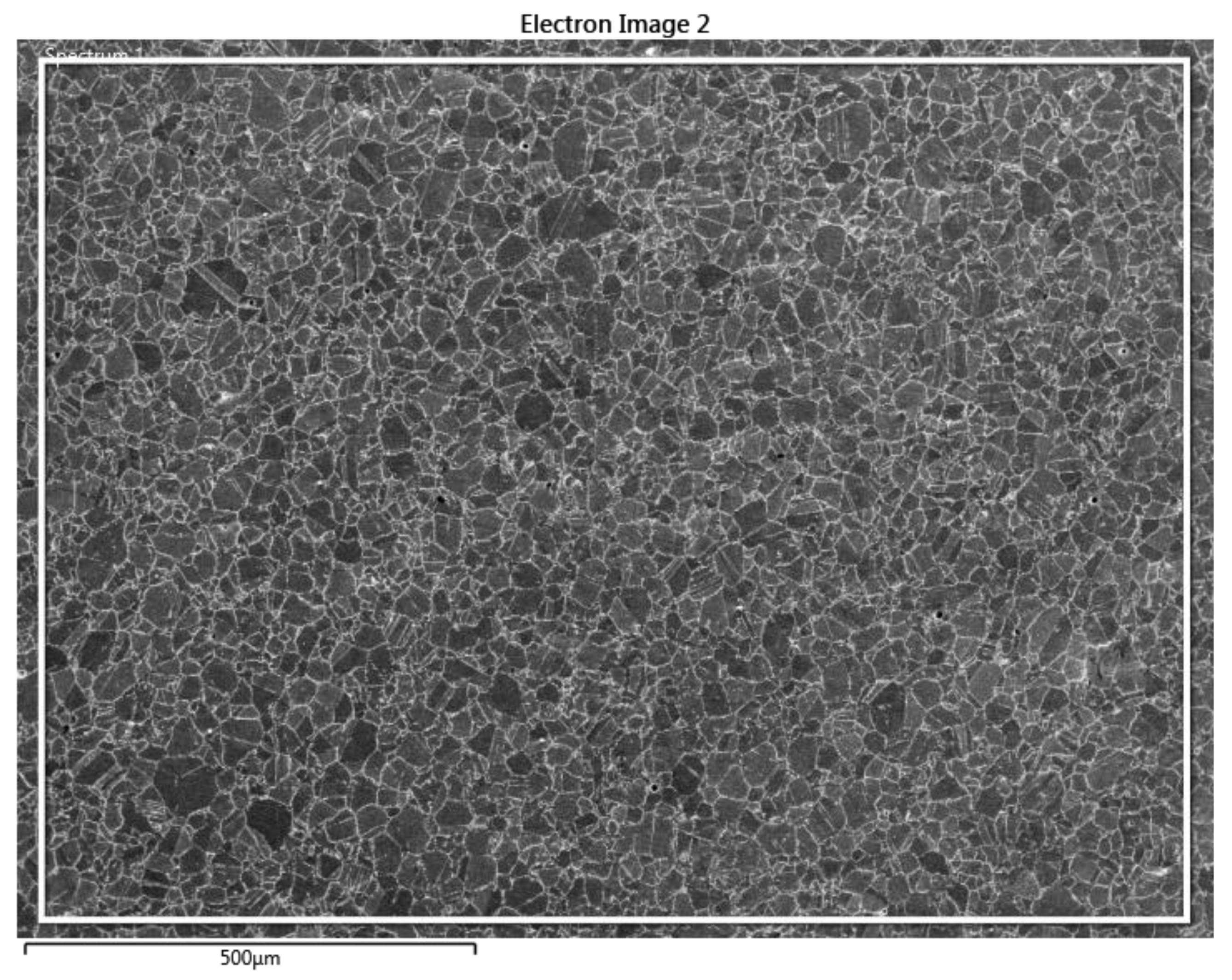

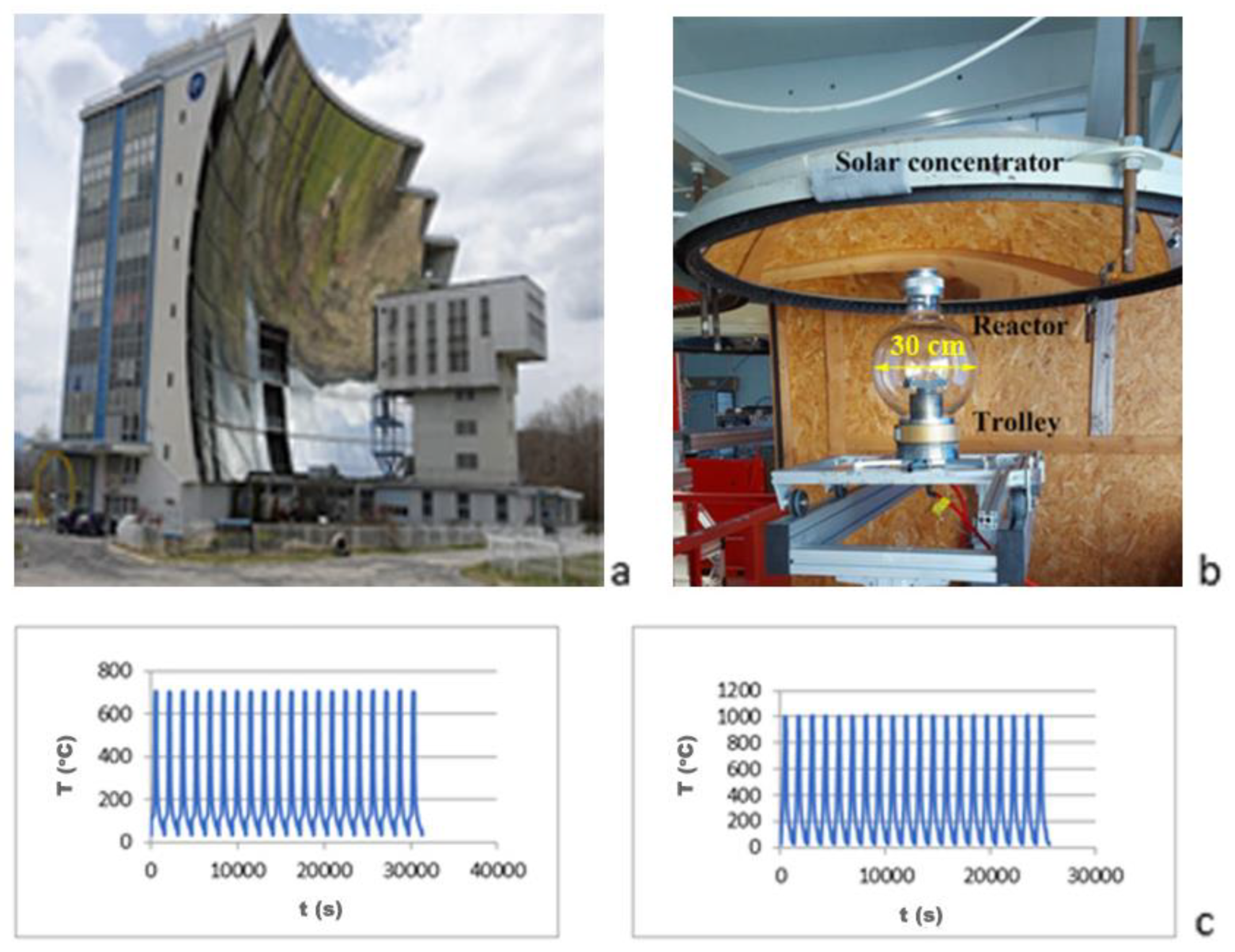

2. Experimental Materials and Methods

3. Experimental Results and Discussion

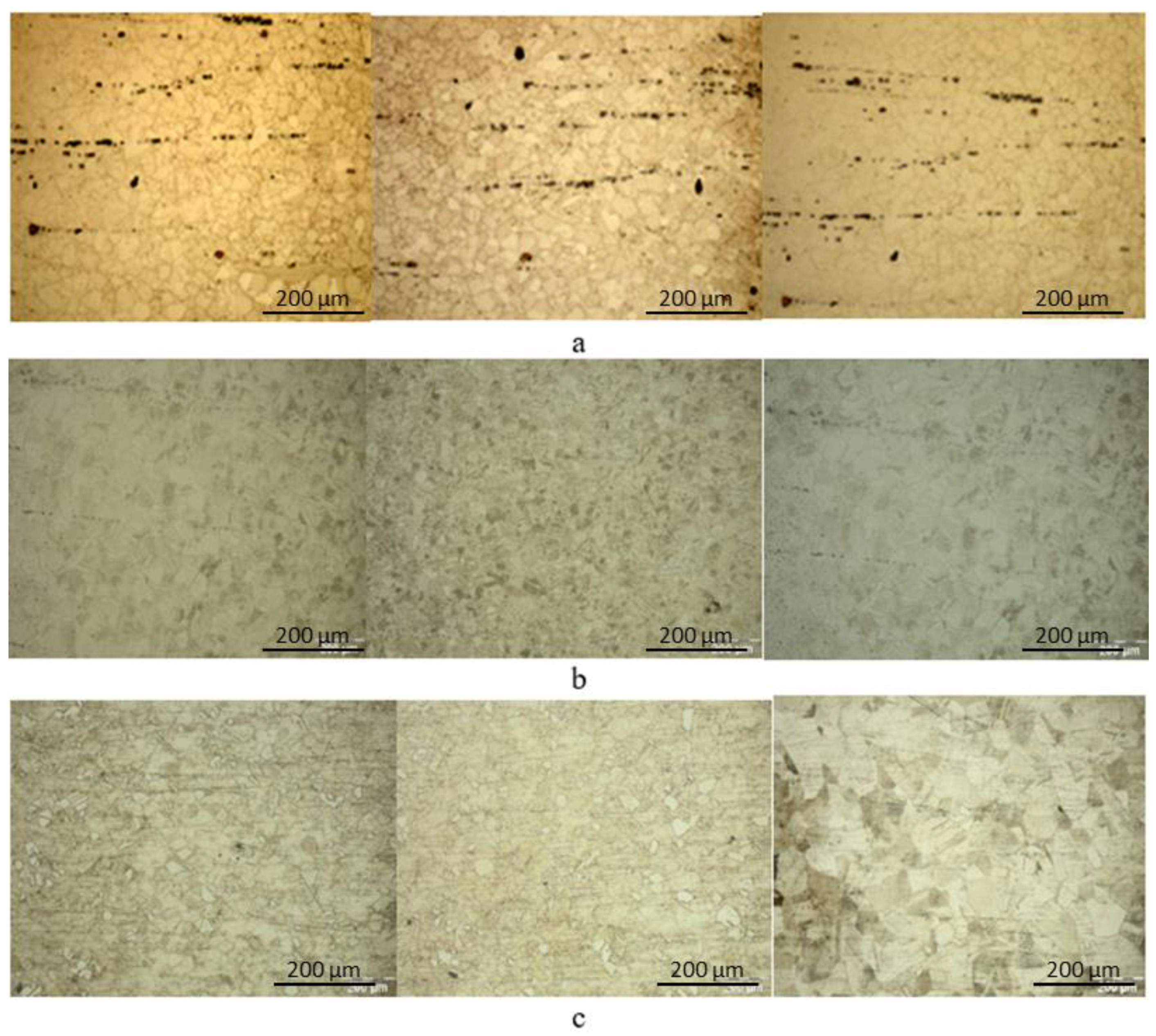

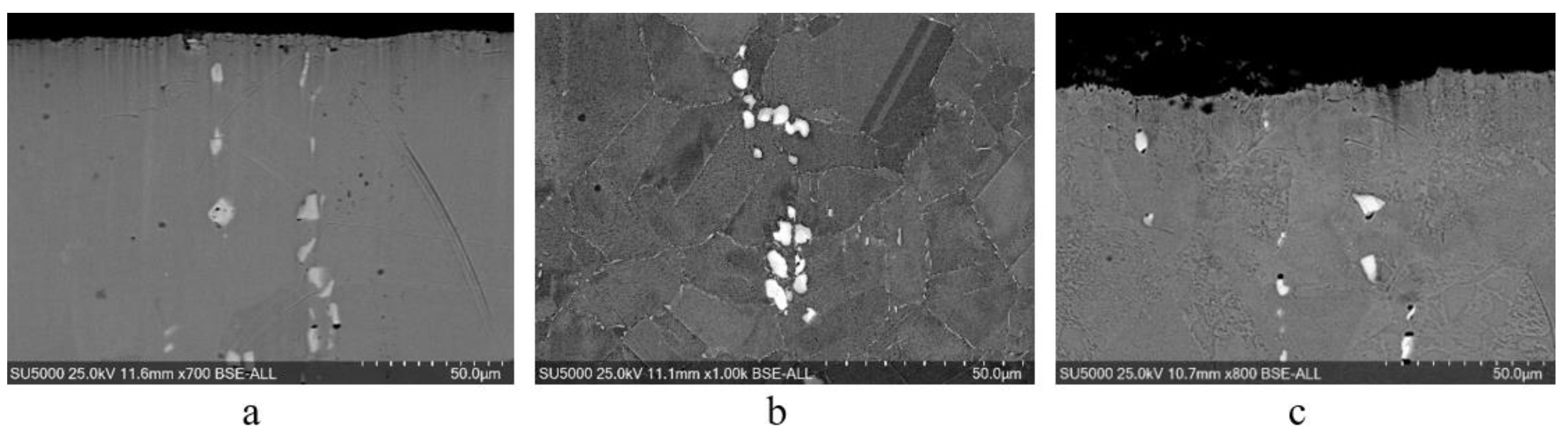

3.1. The Microstructural Analysis

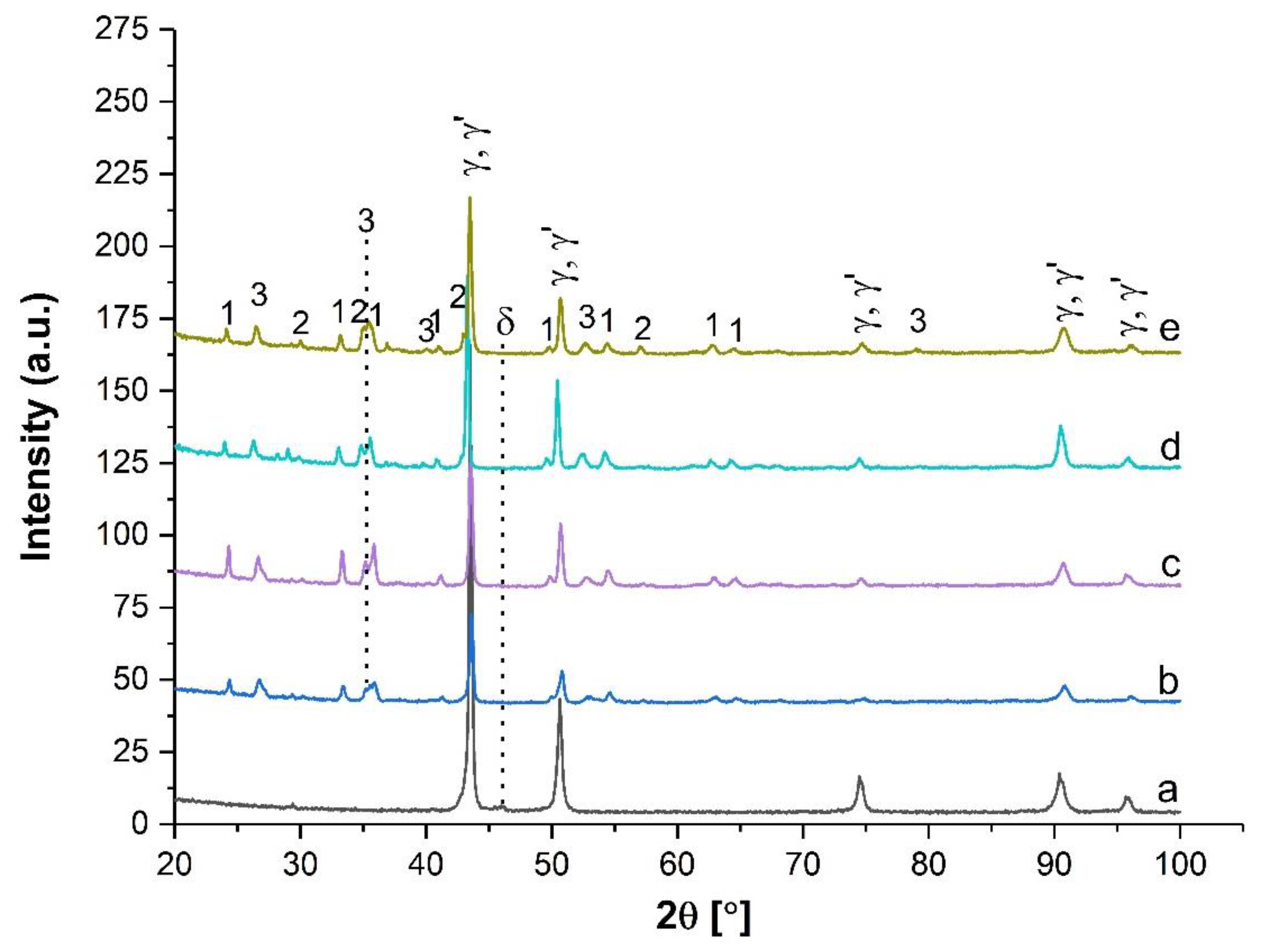

3.2. Qualitative Phase Analysis by X-Ray Diffraction

3.3. The Influence of Thermal Shocks on the Microhardness

4. Conclusions

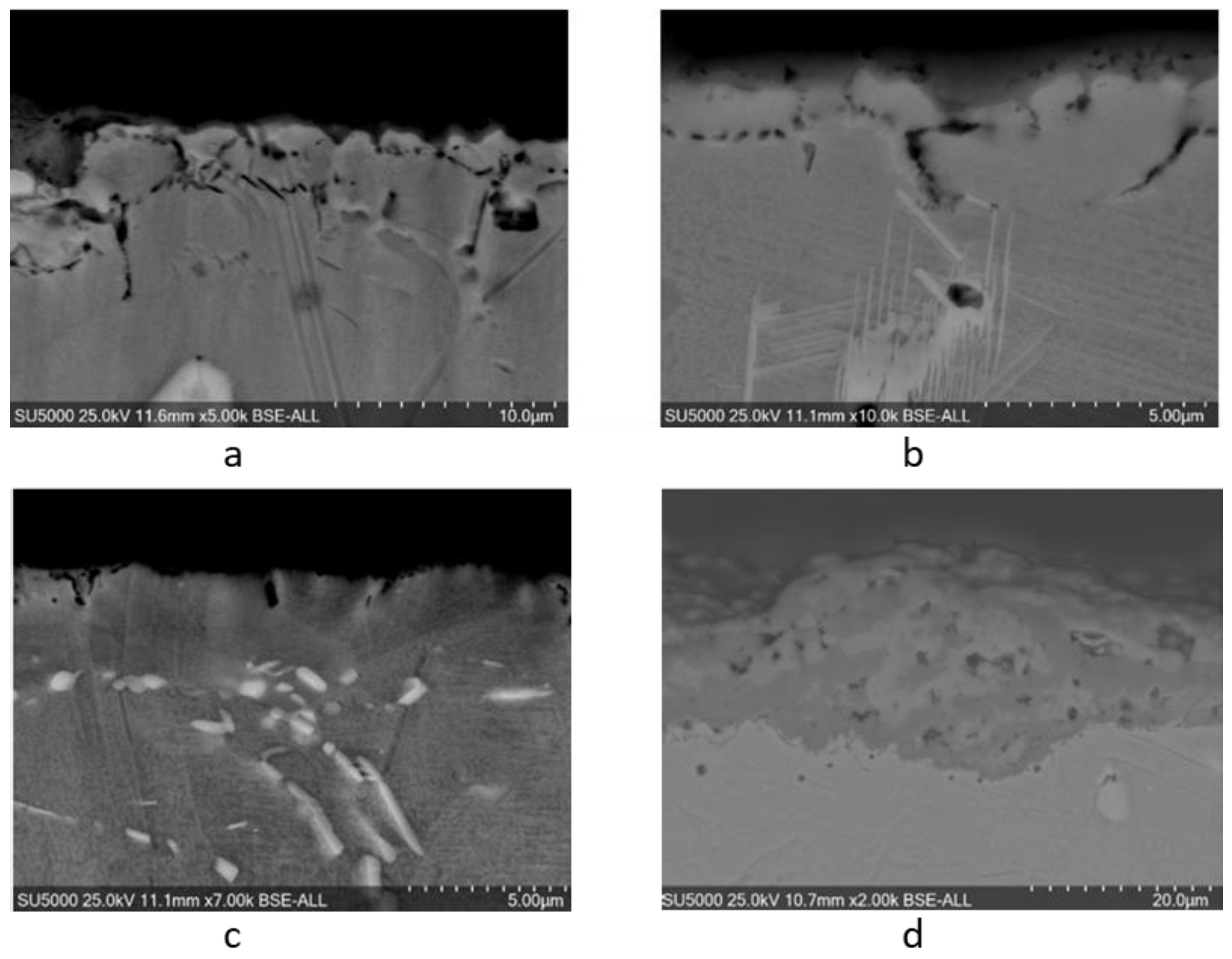

- Structural Stability: At temperatures below 700 °C, the alloy retains its forged structure, characterized by twinned polyhedral grains and rows of hard phases aligned with the deformation direction (Figure 3a).

- Microstructural Changes at Higher Temperatures: In the 700–1000 °C range, the alignment of hard phases becomes less distinct, while twinned polyhedral grains persist but with increased grain size (Figure 3b,c). Additionally, secondary-phase precipitates decrease in number and grow in size due to dissolution and coalescence phenomena.

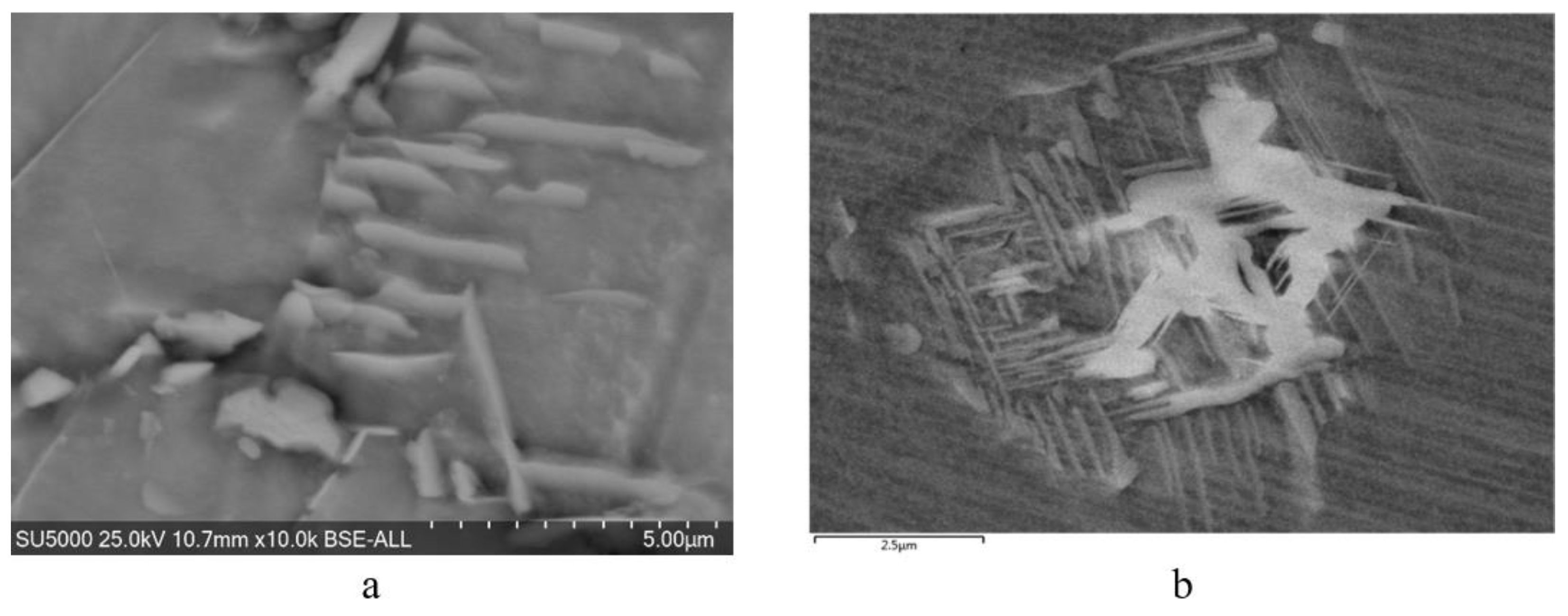

- Delta-Phase Formation: At 800 °C, after 20 overheating cycles, delta-phase precipitates were identified.

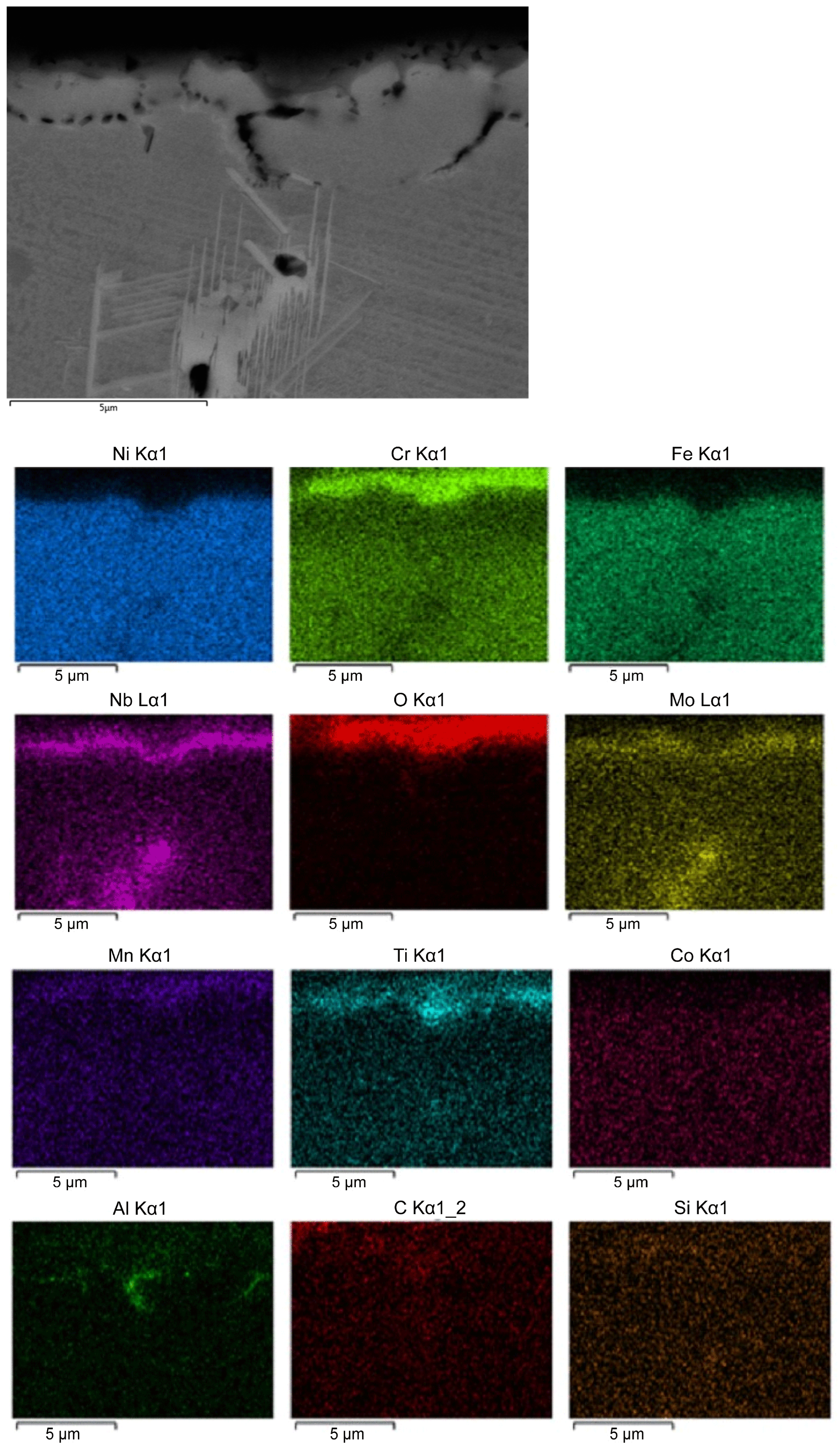

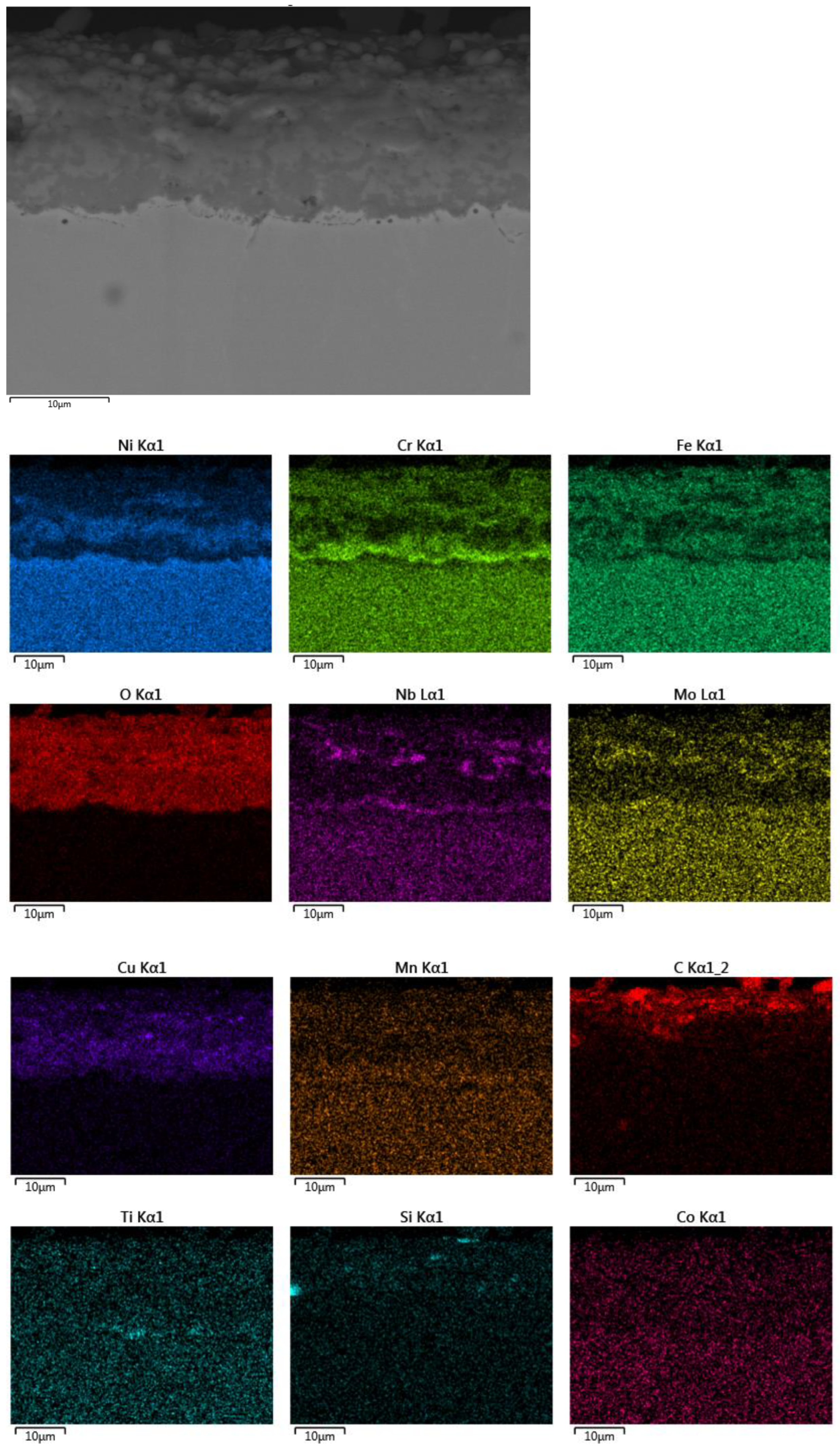

- Surface Layer Integrity and Corrosion Resistance: The protective surface layers formed on the alloy remain compact and continuous at lower temperatures, particularly the chromium-rich layer, which mirrors the underlying metallic surface and enhances corrosion resistance. The diffusion and positioning of alloying elements in the oxide layers have been highlighted. However, increasing the temperature initiates degradation processes in these layers, reducing their compactness and continuity, which subsequently lowers corrosion resistance.

- The experimental data show the diffusion of carbon into the oxide layer, which, according to the research conducted by Li Yanlei and others [62], can diffuse from the bulk metal towards the surface layer, contributing to the formation of compounds that affect the corrosion behavior of the alloy.

- Hardness Evolution: In the 400–600 °C range, surface hardness values are generally lower than those of the reference sample, except at 600 °C, where aging and secondary-phase precipitation begin, yielding hardness values close to the reference. In the 800–1000 °C range, significant hardness reductions occur near the surface subjected to thermal shock. At 1000 °C, this decrease extends almost through the entire sample thickness, from the exposed surface to the base.

- Operational Limitations: The severe hardness reduction at high temperatures suggests that even short-term overheating can significantly impair the mechanical performance of Inconel 718. Therefore, its use in high-stress applications at elevated temperatures is not recommended.

- For applications in the energy, aerospace, and other highly demanding fields, managing phase equilibrium and structural transformations can prevent processes that lead to the loss of mechanical strength and increased brittleness.

- Continuing research with longer holding times at high temperatures could provide essential data for developing effective thermal regulation strategies, thereby improving the durability and reliability of materials used in extreme conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Gradtl, P.; Tikner, D.; Williams, B.; Smith, T.; Kantsos, C. Extreme Temperature Additively Manufactured GRX-810 Alloy Development and Hot-fire Testing for Liquid Rocket Engines. In Proceedings of the AIAA SciTech Forum and Exposition, Orlando, FL, USA, 8–12 January 2024; Available online: https://ntrs.nasa.gov/citations/20240000067 (accessed on 12 September 2024).

- Bhadeshia. Available online: http://www.phase-trans.msm.cam.ac.uk/2003/Superalloys/superalloys.html (accessed on 10 October 2024).

- Available online: https://www.sciencedirect.com/topics/materials-science/nickel-based-superalloys (accessed on 10 October 2020).

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Bujoreanu, L. Superalloys-Lecture Notes; UTGA: Iasi, Romania, 2017. [Google Scholar]

- Marsh, C. The Mechanical Properties and Deformation Behavior of Heat Treated Versus As-Received Inconel X ed Inconel X-750. Ph.D. Thesis, University of South Carolina, Columbia, SC, USA, 2018. [Google Scholar]

- Maj, P.; Adamczyk-Cieslak, B.; Slesik, M.; Mizera, J. The Precipitation Processes and Mechanical Properties of Aged Inconel 718 Alloy After Annealing. Arch. Metall. Mater. 2017, 62, 1695–1702. [Google Scholar] [CrossRef]

- Vincent, R. Precipitation around and welds in the nickel-base superalloy Inconel 718. Acta Metall. 1985, 33, 1205–1216. [Google Scholar] [CrossRef]

- Feng, Q.; Wu, Y.; Li, J.; Cai, Y.; Zhang, Y.; Liu, J.; Liu, T. Effects of intermediate temperature on the grain boundary and γ’ precipitates of nickel-based powder superalloy under interrupted cooling. J. Alloys Compd. 2022, 922, 166310. [Google Scholar] [CrossRef]

- Schwartz, M.; Ciucă, I. Research on Structural Changes of the Materials Used for Manufacturing Extrusion Tools. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 2016. [Google Scholar]

- Huang, H.; Liu, G.; Wang, H.; Wang, Z.; Zhang, H.; Shao, Y. Effect of cooling rate and resulting microstructure on tensile properties and deformation mechanisms of an advanced PM nickel-based superalloy. J. Alloys Compd. 2019, 805, 1254–1259. [Google Scholar] [CrossRef]

- Babu, S.; Miller, M.K.; Vitek, J.M.; David, S.A. Characterization of the microstructure evolution in a nickel base superalloy during continuous cooling conditions. Acta Mater. 2001, 49, 4149–4160. [Google Scholar] [CrossRef]

- Wu, H.; Li, J.; Liu, F.; Huang, L.; Zeng, X.; Fang, Q.; Huang, Z.; Jiang, L. A high-throughput methodology search for the optimum cooling rate in an advanced polycrystalline nickel base superalloy. Mater. Des. 2017, 128, 176–181. [Google Scholar] [CrossRef]

- Singh, A.R.P.; Nag, R.J.; Hwang, J.Y.; Viswanathan, G.B.; Tiley, J.; Srinivasan, R.; Fraser, H.L.; Banerjee, R. Influence of cooling rate on the development of multiple generations of γ’ precipitates in a commercial nickel base superalloy. Mater. Charact. 2011, 62, 878–886. [Google Scholar] [CrossRef]

- Sarosi, P.; Wang, B.; Simmons, J.; Wang, Y.; Mills, M. Formation and multimodal distributions of γ′ in a nickel-base superalloy during interrupted continuous cooling. Scr. Mater. 2007, 57, 767–770. [Google Scholar] [CrossRef]

- Liao, Y.S.; Shiue, R.H. Carbide tool wear mechanism in turning of Inconel 718 superalloy. Wear 1996, 193, 16–24. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Carbide Formation in Nickel-Base Superalloy MAR-M247 Processed Through Scanning Laser Epitaxy (SLE). In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Ranganath, S.; Guo, C.; Holt, S. Experimental Investigations into the Carbide Cracking Phenomenon on Inconel 718 Superalloy Material. In Proceedings of the ASME 2009 International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 4–7 October 2010; pp. 33–39. [Google Scholar] [CrossRef]

- Tang, Y.T.; Wilkinson, A.J.; Reed, R.C. Grain Boundary Serration in Nickel-Based Superalloy Inconel 600: Generation and Effects on Mechanical Behavior, Topical Collection: Superalloys and Their Applications. Metall. Mater. Trans. 2018, 49, 4324–4342. [Google Scholar] [CrossRef]

- Mitchell, R.J.; Preuss, M.; Tin, S.; Hardy, M.C. The influence of cooling rate from temperatures above the γ′ solvus on morphology, mismatch and hardness in advanced polycrystalline nickel-base superalloys. Mater. Sci. Eng. 2008, 473, 158–165. [Google Scholar] [CrossRef]

- Osada, T.; Gu, Y.; Nagashima, N.; Yuan, Y.; Yokokawa, T.; Harada, H. Optimum microstructure combination for maximizing tensile strength in a polycrystalline superalloy with a two-phase structure. Acta Mater. 2013, 61, 1820–1829. [Google Scholar] [CrossRef]

- Hong, H.U.; Kim, I.S.; Choi, B.G.; Kim, M.Y.; Jo, C.Y. The effect of grain boundary serration on creep resistance in a wrought nickel-based superalloy. Mater. Sci. Eng. 2009, 517, 125–131. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, H.; Chen, Y.; Di, H.; Xu, W. The strengthening effects and mechanisms of alloying elements on interfaces for multiphase Ni-based superalloys: A first-principles study. J. Mater. Res. Technol. 2023, 23, 4802–4848. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S. The morphology and formation of gamma prime in nickel-base superalloy. J. Mater. Sci. Lett. 1990, 9, 516–517. [Google Scholar] [CrossRef]

- Jia, L.; Cui, H.; Yang, S.; Lv, S.; Xie, X.; Qu, J. As-cast microstructure and homogenization kinetics of a typical hard-to-deform Ni-base superalloy. J. Mater. Res. Technol. 2023, 23, 5368–5381. [Google Scholar] [CrossRef]

- Jovanović, M.; Tadić, S. Influence of high-temperature exposure on the microstructure and creep resistance of IN-100 superalloy. J. Mater. Sci. Lett. 1993, 30, 3–12. [Google Scholar] [CrossRef]

- Grosdidier, T.; Hazotte, A.; Simon, A. Precipitation and dissolution processes in γ/γ′ single crystal nickel-based superalloys. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 1998, 256, 183–196. [Google Scholar] [CrossRef]

- Nunes, R.M.; Pereira, D.; Clarke, T.; Hirsch, T.K. Delta Phase Characterization in Inconel 718 Alloys Through X-ray Diffraction. ISIJ Int. 2015, 55, 2450–2454. [Google Scholar] [CrossRef]

- Guan, H.; Jiang, W.; Lu, J.; Zhang, Y.; Zhang, Z. Precipitation of δ phase in Inconel 718 superalloy: The role of grain boundary and plastic deformation. Mater. Today Commun. 2023, 36, 106582. [Google Scholar] [CrossRef]

- Xu, L.; Chai, Z.; Peng, B.; Zhou, W.; Chen, X. Effect of heat treatment on microstructures and mechanical properties of Inconel 718 additively manufactured using gradient laser power. Mater. Sci. Eng. A 2023, 868, 144754. [Google Scholar] [CrossRef]

- Deng, D.; Moverare, J.; Peng, R.L.; Söderberg, H. Microstructure and anisotropic mechanical properties of EBM manufactured Inconel 718 and effects of post heat treatments. Mater. Sci. Eng. A 2017, 693, 151–163. [Google Scholar] [CrossRef]

- Bansal, A.; Zafar, S.; Sharma, A.K. Influence of heat treatment on microstructure of Inconel 718 microwave clads. Surf. Eng. 2017, 33, 167–174. [Google Scholar] [CrossRef]

- Li, P.; Zhou, J.; Gong, Y.; Meng, X.; Lu, J. Effect of post-heat treatment on the microstructure and mechanical properties of laser metal deposition Inconel 718. J. Mech. Sci. Technol. 2021, 35, 2871–2878. [Google Scholar] [CrossRef]

- Anbarasan, N.; Gupta, B.K.; Prakash, S.; Muthukumar, P.; Oyyaravelu, R.; Kumar, R.J.F.; Jerome, S. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718. Mater. Today Proc. 2018, 5, 7716–7724. [Google Scholar] [CrossRef]

- Yadav, P.C.; Sahu, S.; Subramaniam, A.; Shekhar, S. Effect of heat-treatment on microstructural evolution and mechanical behaviour of severely deformed Inconel 718. Mater. Sci. Eng. A 2018, 715, 295–306. [Google Scholar] [CrossRef]

- Fan, Q.; Li, J.; Zheng, L.; Hao, C.; Zhang, Q.; Wang, Y. Effect of heat treatment on microstructure and mechanical properties of selective laser melted Inconel 718 alloy. PLoS ONE 2024, 19, e0309156. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cui, Y.; Zhang, F.; Yang, R. Effect of heat treatment on microstructure and mechanical properties of the hot-isostatic-pressed Inconel 718 powder compact. J. Alloys Compd. 2014, 590, 227–232. [Google Scholar] [CrossRef]

- Raghavan, S.; Zhang, B.; Wang, P.; Sun, C.N.; Nai, M.L.S.; Li, T.; Wei, J. Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater. Manuf. Process. 2017, 32, 1588–1595. [Google Scholar] [CrossRef]

- Popovich, A.A.; Sufiiarov, V.S.; Polozov, I.A.; Borisov, E.V. Microstructure and mechanical properties of Inconel 718 produced by SLM and subsequent heat treatment. Key Eng. Mater. 2015, 651, 665–670. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Impact of heat treatment on mechanical behaviour of Inconel 718 processed with tailored microstructure by selective laser melting. Mater. Des. 2017, 131, 12–22. [Google Scholar] [CrossRef]

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 750, 98–107. [Google Scholar] [CrossRef]

- Tajyar, A.; Brooks, N.; Holtham, N.; Rowe, R.; Newell, D.J.; Palazotto, A.N.; Davami, K. Effects of a modified heat-treatment on microstructure and mechanical properties of additively manufactured Inconel 718. Mater. Sci. Eng. A 2022, 838, 142770. [Google Scholar] [CrossRef]

- Schneider, J.; Lund, B.; Fullen, M. Effect of heat treatment variations on the mechanical properties of Inconel 718 selective laser melted specimens. Addit. Manuf. 2018, 21, 248–254. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured Inconel 718. Metall. Mater. Trans. A 2009, 40, 2410–2422. Available online: https://experts.illinois.edu/en/publications/studies-of-standard-heat-treatment-effects-on-microstructure-and- (accessed on 21 October 2024). [CrossRef]

- Li, X.; Shi, J.; Wang, C.; Cao, G.; Russell, A.; Zhou, Z.; Li, C.; Chen, G. Effect of heat treatment on microstructure evolution of Inconel 718 alloy fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 639–649. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Huang, L.; Cao, Y.; Zhang, J.; Gao, X.; Li, G.; Wang, Y. Effect of heat treatment on the microstructure evolution and mechanical behaviour of a selective laser melted Inconel 718 alloy. J. Alloys Compd. 2021, 865, 158613. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Z.; Bai, P.; Qu, H.; Liu, B.; Li, L.; Wu, L.; Guan, R.; Liu, H.; Guo, Z. Microstructural evolution and mechanical properties of IN718 alloy fabricated by selective laser melting following different heat treatments. J. Alloys Compd. 2019, 772, 861–870. [Google Scholar] [CrossRef]

- Teng, Q.; Li, S.; Wei, Q.; Shi, Y. Investigation on the influence of heat treatment on Inconel 718 fabricated by selective laser melting: Microstructure and high temperature tensile property. J. Manuf. Process. 2021, 61, 35–45. [Google Scholar] [CrossRef]

- Zhao, R.; Zhao, Z.; Bai, P.; Du, W.; Zhang, L.; Qu, H. Effect of heat treatment on the microstructure and properties of inconel 718 alloy fabricated by selective laser melting. J. Mater. Eng. Perform. 2022, 31, 353–364. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Wang, H.; Wu, Y.; Wang, H. Microstructure, mechanical property and heat treatment schedule of the Inconel 718 manufactured by low and high power laser powder bed fusion. Mater. Sci. Eng. A 2023, 863, 144517. [Google Scholar] [CrossRef]

- Schröder, J.; Mishurova, T.; Fritsch, T.; Serrano-Munoz, I.; Evans, A.; Sprengel, M.; Klaus, M.; Genzel, C.; Schneider, J.; Bruno, G. On the influence of heat treatment on microstructure and mechanical behavior of laser powder bed fused Inconel 718. Mater. Sci. Eng. A 2021, 805, 140555. [Google Scholar] [CrossRef]

- Song, K.H.; Nakata, K. Microstructural and mechanical properties of friction-stir-welded and post-heat-treated Inconel 718 alloy. J. Alloys Compd. 2010, 505, 144–150. [Google Scholar] [CrossRef]

- Damodaram, R.; Raman, S.G.S.; Rao, K.P. Effect of post-weld heat treatments on microstructure and mechanical properties of friction welded alloy 718 joints. Mater. Des. 2014, 53, 954–961. [Google Scholar] [CrossRef]

- Ghiban, B.; Guragata, C.M.; Serban, N.; Raiciu, A.D.; Balkan, I. Hot Working Behaviour Of Inconel 718 Superalloy. U.P.B. Sci. Bull. Ser. B 2019, 81, 4. [Google Scholar]

- Guo, X.; Liang, Z.; Nan, X.; Jiang, C.; Li, Y.; Li, L.; He, L.; Yang, S. Effect of Overheating Temperature on Thermal Cycling Creep Properties of K465 Superalloy. Crystals 2021, 11, 1458. [Google Scholar] [CrossRef]

- Utada, S.; Sasaki, R.; Reed, R.C.; Tang, Y.T. Overheating of Waspaloy: Effect of cooling rate on flow stress behavior. Mater. Des. 2021, 221, 110911. [Google Scholar] [CrossRef]

- Araujo, L.S.; de Melo, C.H.; Gonçalves, R.P.; Varela, A.d.V.; de Almeida, L.H. The effect of a very high overheating on the microstructural degradation of superalloy 718. J. Mater. Res. Technol. 2018, 8, 683–689. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, Y.; Guo, Y.; Liu, Y.; Zhang, J.; Luo, Y.; Yao, Z. Effect of Overheating Events on Microstructure and Low-Cycle Fatigue Properties of a Nickel-Based Single-Crystal Superalloy. Met. Mater. Trans. A 2022, 53, 2214–2225. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Ke, Z.-J.; Li, R.-H.; Song, J.-Q.; Ruan, J.-J. Study of Grain Growth in a Ni-Based Superalloy by Experiments and Cellular Automaton Model. Materials 2021, 14, 6922. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- ISO 6507-1/2023; Metallic Materials—Vickers Hardness Test, Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2023.

- Li, Y.; Yang, S.; Peng, Z.; Wang, Z.; Gao, Z. Effects of Heat Treatment and Carbon Element Invasion on Microstructure and Mechanical Properties of Inconel 718 Alloys Fabricated by Selective Laser Melting. J. Mater. Eng. Perform. 2024, 33, 8015–8032. [Google Scholar] [CrossRef]

| Statistics | Al | Si | Ti | Cr | Mn | Fe | Co | Ni | Nb | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| Concentration (Wt%) | 0.53 | 0.22 | 0.92 | 18.44 | 0.21 | 18.71 | 0.42 | 51.64 | 5.66 | 3.25 |

| Wt% Sigma | ±0.05 | ±0.03 | ±0.03 | ±0.09 | ±0.05 | ±0.10 | ±0.06 | ±0.16 | ±0.14 | ±0.15 |

| Symbol | Phase | PDF4+ 2023 DB Card |

|---|---|---|

| γ | Fe-Cr-Ni | 01-071-7594 |

| γ′ | Ni3(Al,Ti) | 00-018-0872 |

| δ | Ni3Nb | 01-081-6808 |

| 1 | Cr2O3 | 01-078-5443 |

| 2 | NiCr2O4 | 01-083-6556 |

| 3 | TiNbO4 | 01-081-0911 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizea, A.-D.; Arva Ungureanu, E.R.; Negrea, D.A.; Moga, S.G.; Abrudeanu, M.; Petrescu, M.I.; Stefanoiu, R.; Haeussler, A.; Anghel, D.-C.; Constantinescu, L.M. The Influence of Accidental Overheating on the Microstructure and Hardness of the Inconel 718 Alloy. Appl. Sci. 2025, 15, 3057. https://doi.org/10.3390/app15063057

Rizea A-D, Arva Ungureanu ER, Negrea DA, Moga SG, Abrudeanu M, Petrescu MI, Stefanoiu R, Haeussler A, Anghel D-C, Constantinescu LM. The Influence of Accidental Overheating on the Microstructure and Hardness of the Inconel 718 Alloy. Applied Sciences. 2025; 15(6):3057. https://doi.org/10.3390/app15063057

Chicago/Turabian StyleRizea, Alin-Daniel, Elisabeta Roxana Arva Ungureanu, Denis Aurelian Negrea, Sorin Georgian Moga, Marioara Abrudeanu, Mircea Ionut Petrescu, Radu Stefanoiu, Anita Haeussler, Daniel-Constantin Anghel, and Luminita Mirela Constantinescu. 2025. "The Influence of Accidental Overheating on the Microstructure and Hardness of the Inconel 718 Alloy" Applied Sciences 15, no. 6: 3057. https://doi.org/10.3390/app15063057

APA StyleRizea, A.-D., Arva Ungureanu, E. R., Negrea, D. A., Moga, S. G., Abrudeanu, M., Petrescu, M. I., Stefanoiu, R., Haeussler, A., Anghel, D.-C., & Constantinescu, L. M. (2025). The Influence of Accidental Overheating on the Microstructure and Hardness of the Inconel 718 Alloy. Applied Sciences, 15(6), 3057. https://doi.org/10.3390/app15063057