3.1. Mineralogy, Chemistry, and Morphology of the Palygorskite Sample

The chemical composition of the palygorskite sample used is presented in

Table 3.

The presence of Si, Al, and Mg demonstrates that the sample is a magnesium–aluminum phyllosilicate. These are the main elements that constitute the chemical composition of palygorskites, which has the ideal formula MgAlSi

8O

20OH

3(OH

2)

4.X[R

2+(H

2O)

4], with X having the possibility to be replaced by Na, Fe, or Mn [

22].

Palygorskite commonly presents higher Al content, close to or greater than 10%, as can be observed in the results reported by Galan and Ferrero, Meireles et al., and Zhang et al. [

23,

24,

25] that studied samples of this clay from Spain, Brazil, and China, respectively. However, for samples extracted from deposits located in Greece, such as the one used in this study, this content tends to be lower (close to or less than 5%). Regarding Al content, similar results to those presented in

Table 3 were reported by Kastritis and Kacandes, Gionis et al., and Georgopoulos et al. [

26,

27,

28]. Furthermore, a high Fe content was also identified (13.11%), which is also common for palygorskite samples from Greece, according to the works already cited. Thus, the chemical composition of the palygorskite used in this study is within the expected range.

Regarding the mineralogical composition of the sample, the XRD pattern and the quantification of the identified phases are presented in

Figure 1 and

Table 4, respectively.

Figure 1 illustrates the XRD pattern of palygorskite. The XRD pattern shows crystalline phases corresponding to the presence of palygorskite, antigorite, and quartz. These constituents were, respectively, identified using the crystallographic file numbers 75975, 98794, and 16331, provided by the Inorganic Crystal Structure Database (ICSD). It is possible to verify that the sample presented a sharp and symmetrical peak at 20°, a value close to 8.50°, which typifies the presence of the clay mineral palygorskite, and main peaks corresponded to the presence of impurities such as antigorite and quartz, close to 12.5° and 26.5°, respectively, in addition to the identification of secondary peaks of these minerals.

Quantification using the Rietveld method, as presented in

Table 4, shows that this clay is rich in palygorskite, with more than 77% of the sample being made up of this clay mineral, as well as a minimal fraction of quartz corresponding to only 1.16%. Antigorite, on the other hand, presented a considerable fraction of 20.94%. Antigorite belongs to the serpentine group and has the ideal formula Mg

6Si

4O

10(OH)

8 [

29], which is in accordance with what was observed in the XRF analysis (

Table 3). The presence of serpentines in palygorskite samples was also identified by Gionis et al., Zotiadis and Argyraki, and Georgopoulos et al. [

27,

28,

30]. Since the clay sample is mostly composed of palygorskite, it is expected that the properties of the investigated fluid formulations will be predominantly influenced by this clay mineral in comparison to antigorite or quartz.

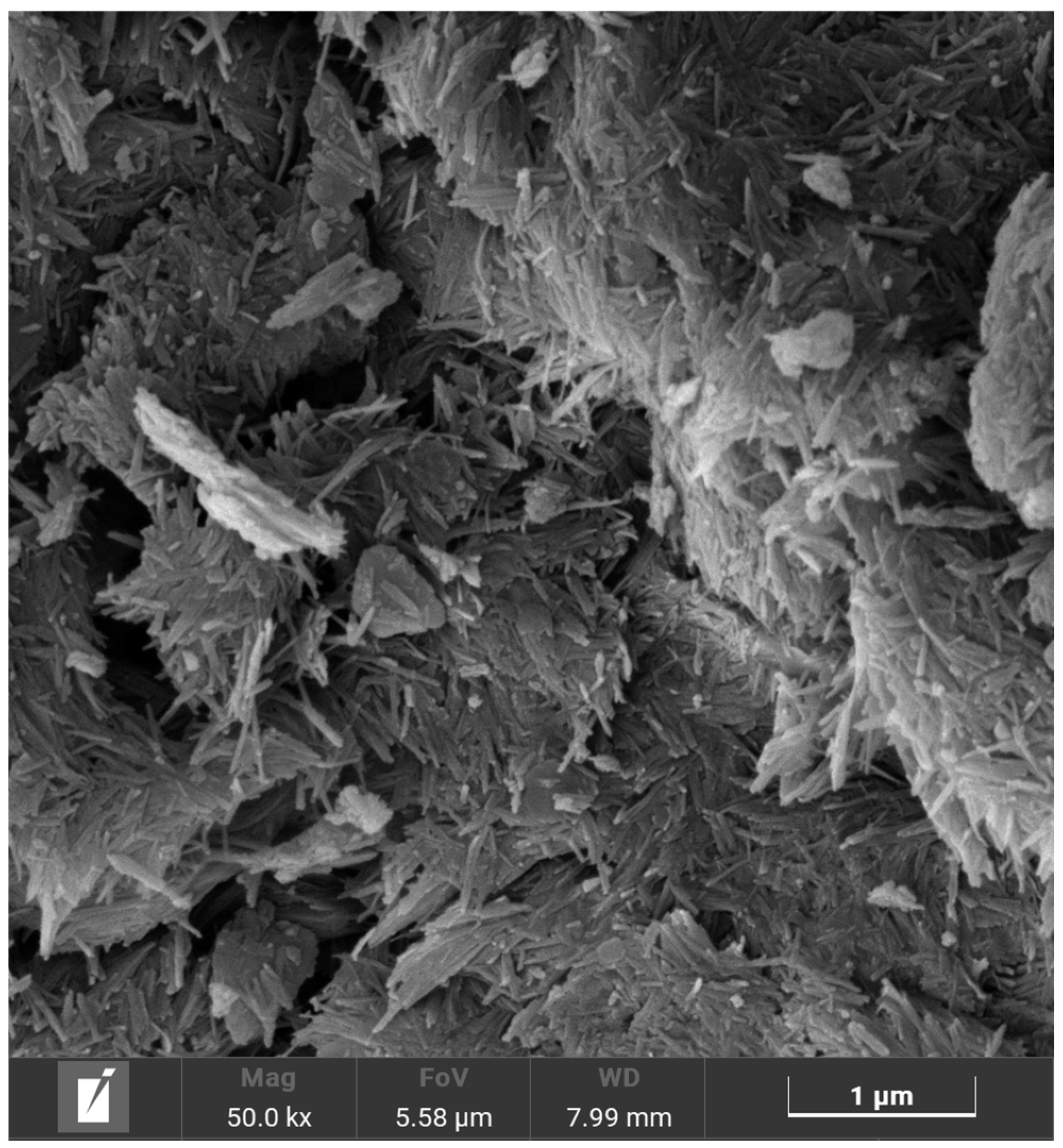

The morphology observed through scanning electron microscopy of the palygorskite sample is shown in

Figure 2.

The microscopy image shows the fibrous morphology of the sample, which is composed of individual bundles. It is also possible to observe that some fibers are grouped, forming larger aggregates. These fibers correspond to the presence of the minerals palygorskite and antigorite, as this last one can also assume a fiber-like morphology [

31,

32].

The fibrous morphology of the particles can hinder the formation of a thin and impermeable filter cake, as observed in the studies conducted by Neaman and Singer and Asghari and Esmaeilzadeh [

33,

34], who used palygorskite as an additive for drilling fluids. The presence of permeable filter cakes results in a considerable loss of the fluid–liquid phase to the formation and can compromise the hydrostatic pressure exerted by the fluid column against the formation. Under these conditions, the fluid formulation needs to be added with a filtrate control agent, since maintaining hydrostatic pressure is essential for the safety of abandonment operations.

On the other hand, the elongated shape of palygorskite particles ensures unique colloidal properties to this clay [

35], such as resistance to high concentrations of electrolytes, since the rheological behavior of these suspensions results from the mechanical interference between the particles and is not influenced by electrostatic forces. In this way, it is possible to guarantee the control of the fluid density with the use of brines, without compromising the rheological behavior, which could lead to the sedimentation of solids. This phenomenon is undesirable as it would compromise the homogeneity of the fluid column and the hydrostatic pressure exerted inside the well.

3.2. Characterization of the Salted Water-Based Fluid Formulations

The regression equation that correlates the palygorskite (P) and PAC LV (C) contents with the filtrate volume, the relevant data for the analysis of variance (ANOVA), the response surface generated based on the model, and the values of this property for each formulation are presented in Equation (4),

Table 5, and

Figure 3a,b, respectively.

The mathematical model, obtained through the regression of the experimental data, presented a good fit, with a coefficient of determination of 97.18%. Furthermore, at a 95% confidence level, it can also be considered statistically significant and useful for predictive purposes, as the Fcalculated/Ftabulated ratio was greater than five [

36].

Equation (1) and the response surface presented in

Figure 3a indicate that only the PAC content exerts a significant influence on the filtrate volume, and the variation in the palygorskite content does not cause changes in this property. Polymers of the same nature as PAC LV have ionized carboxylic groups. Thus, the resulting electrostatic repulsion causes its molecular chains in solution to hydrate and assume an extended conformation, with repulsion also occurring between adjacent chains. Because of this hydration, the filtrate volume is reduced. This mechanism was explained by Damodaran et al. [

37].

Despite not having shown a statistically significant influence on the filtrate volume, palygorskite still plays an important role in this property. As can be seen in

Figure 3b, formulation F0, prepared without the addition of clay and with 8 g of PAC LV, presented a filtrate volume of 15.2 mL. In contrast, formulation F3, for example, which has the same polymer content and 10 g of palygorskite, presented a filtrate volume of 12 mL, which represents a reduction of approximately 21%. When the clay content was increased to 20 g (F4), this reduction was even greater, approximately 26%. This result indicates that the action of clay together with the polymer is essential for filtrate control. The interaction mechanism between PAC LV and palygorskite can be explained through electrostatic interactions. When added to clay-containing suspensions, such as the formulations studied, PAC LV is adsorbed onto the surface of the clay particles, increasing the negative surface charge due to its polyanionic nature. This increase in charge intensifies the electrostatic repulsion between the particles, preventing their aggregation and promoting the stabilization of the system by keeping them in suspension. As a result, the volume of free water available is reduced, which improves fluid properties that depend on this arrangement, such as filtrate control. The interaction of this polymer with clays was studied by Yang et al. [

38].

Although the results obtained from the factorial design have demonstrated the influence of additive content in minimizing the filtrate volume, the interpretation of these results is limited due to the absence of comparative parameters within the international standards in force that allow for the qualification, based on this property, of fluids used as a barrier element for well abandonment. Therefore, the analysis of the results presented in

Figure 4 was conducted based on a comparison with aqueous palygorskite drilling fluids developed for applications in well drilling (

Table 6).

As shown in

Table 6, some palygorskite aqueous drilling fluid formulations presented filtrate volumes lower than or close to those obtained in this work. However, it is worth highlighting that the filtrate volumes of these formulations were, for the most part, obtained in an API filter press and, therefore, under less severe test conditions than those used in this study, which do not represent the field conditions of the petroleum wells to be abandoned.

Even so, it is clear that the most efficient filtration control is obtained with palygorskite fluids whose formulation contains a significant number of additives, such as that proposed by Lijuan et al. [

41], who obtained an HPHT filtrate volume of 11 mL, a value practically equal to the minimum obtained in this work, which was 11.2 mL. However, the formulation proposed by the authors demands a higher cost and complexity in preparation when compared to the one proposed in this study.

Regarding the type and number of additives in the formulation, only the fluid developed by Zou et al. [

39] presents greater similarity with the formulation proposed in this work. However, its performance is inferior in terms of filtration control, so the minimum filtrate volume value (26.2 mL) is considerably higher than the filtrate volumes of the seven fluids formulated based on the factorial design carried out in this work. Thus, it highlights that the interaction between the additives used in the formulations proposed in this work, in appropriate proportions, ensured promising filtration control, especially for formulations with a higher PAC LV content (8 g), that is, F3 and F4, which may present themselves as suitable alternatives as barrier elements for well abandonment.

Table 7 presents the values of the readings obtained from the viscometer for the speeds of 600, 300, 200, 100, 6, and 3 rpm and the values of the apparent viscosity (μ

a), plastic viscosity (μ

p), and yield point (YP) of each formulation.

Since the readings at higher speeds were not obtained for some formulations, as shown in

Table 7, the statistical regression of these data was not possible. However, it is possible to infer that the increase in the PAC LV content acts predominantly on the rheological behavior of the formulations, since very high readings, which exceeded the capacity of the equipment, were verified for all formulations with the maximum content of this additive, including formulation F0, which was prepared without the addition of palygorskite. A similar behavior was described by Al-Hameedi et al. [

42] with a fluid containing bentonite. The authors observed substantial increases in the viscosity and yield point of the fluids as the PAC LV content increased, with the highest concentration of the polymer (4%

w/

w) resulting in values higher than the reading capacity of the equipment used.

On the other hand, when comparing formulations F1 and F2 with the same content of PAC LV (4 g) and 10 and 20 g of palygorskite, respectively, it is noted that the addition of a higher clay content results in increases in the value of all the rheological parameters analyzed. This behavior is due to the mechanism by which palygorskite acts as a viscosifying agent, since the length of the fibers and the number of silanol groups on the surface of the particles help to aggregate the fibers and form a random network that traps water, increasing the viscosity of the suspensions [

43].

The increase observed in the rheological parameters, attributed to the interaction between the PAC LV and palygorskite particles and, above all, to the increase in PAC LV content, demonstrated, preliminarily, a positive aspect of these formulations, since this behavior minimizes the solid sedimentation of the fluids. This was confirmed by the homogeneous appearance of the fluid F4 (

Figure 4), which was prepared with the maximum content of PAC LV and palygorskite, after resting at room temperature for 10 days, with no apparent solid sedimentation.

It is also worth highlighting that the substantial increases in the values of rheological parameters observed for this formulation (F4) do not represent a limitation regarding its use in well abandonment operations when considering a possible overload during its pumping, since in this type of operation, the fluid is not continuously recirculated in the well, as it happens during drilling operations. Therefore, based on the analysis of filtrate volume results and rheological behavior, as well as considering the implications of these parameters on the operational requirements of the abandonment operation, the fluid prepared with a higher content of PAC LV and palygorskite (F4) showed the most promising behavior for application as a barrier element, presenting a smaller filtrate volume and capacity to maintain solids in suspension for 10 days, which guarantees the maintenance of the hydrostatic pressure of the fluid column for temporary abandonment operations.

The pH and density values, in lb/gal, of the palygorskite formulations are presented in

Table 8.

In general, regardless of the formulations, the fluids presented a basic pH, with a range of values between 12.69 and 13.87. Furthermore, it is possible to observe a slight influence of the palygorskite content on this property, since the formulations without palygorskite (F0) and with the lowest content of this clay (F1 and F3) presented the highest pH values, and the formulations with the highest content (F2 and F4) presented the lowest values. A similar trend was observed by Santanna et al. and Choupani et al. [

17,

44], in which palygorskite suspensions in salt water had their pH values slightly reduced with increasing clay concentrations.

Regarding the density of the fluids, the results demonstrated that there was no variation considered significant in this property, with values between 9.4 and 9.6 lb/gal. Considering the application of the palygorskite fluids as barrier elements for well abandonment, it is possible to predict that the density values observed are suitable for the operational window of most of the wells to be abandoned, since they are, in their majority, depleted. For wells whose operational window requires higher densities, it is possible to meet this requirement using more concentrated brines or the addition of weighting agents to the formulation.

Finally, it is important to emphasize that this study focused on developing a fluid formulation considered promising for the temporary abandonment of petroleum wells, with properties suitable for maintaining hydrostatic pressure. However, further testing is required to assess its performance under field conditions, considering the time and temperature to which it will be exposed to throughout the operation.