Abstract

Polymer-derived SiOC ceramics (PDCs-SiOC) possess advantages such as high temperature resistance, oxidation resistance, corrosion resistance, and customizable mechanical and dielectric properties. These attributes make them a promising material for high-temperature structural and functional applications. Based on polymer-derived ceramic conversion technology, this study synthesized a photosensitive resin with high ceramic yield and low shrinkage from commercial MK resin, 3-(trimethoxysilyl) propyl methacrylate, and trimethylolpropane triacrylate monomer. Using digital light processing additive manufacturing technology, 3D diamond-structured SiOC ceramic and 3D octahedron-structured SiOC ceramic with high precision were fabricated. The pyrolysis of both structures at different temperatures (1000 °C to 1400 °C) yielded SiOC ceramics, which exhibited uniform shrinkage in all directions, with a linear shrinkage rate ranging from 31% to 36%. The microstructure was characterized by FTIR, XRD, and SEM, respectively. Additionally, the compressive strength and elastic modulus of the three-dimensional SiOC ceramics were studied. The SiOC ceramic diamond lattice structure, fabricated through pyrolysis at 1200 °C, demonstrated good mechanical properties with a geometric density of 0.76 g/cm³. Its compressive strength and elastic modulus were measured at 7.66 MPa and 1.47 GPa, respectively. This study offers valuable insights into the rapid and customized manufacturing of lightweight ceramic structures.

1. Introduction

SiOC ceramic materials possess exceptional mechanical properties, chemical stability, high-temperature resistance, and tunable thermal, optical, electrical, and magnetic characteristics, offering considerable potential across a wide range of applications. These applications span industries such as the chemical industry [1,2], aerospace industry [3], precision machining industry [4], biomedicine industry [5,6], etc., where advanced materials are crucial for improving performance and durability. SiOC ceramics exhibit remarkable high-temperature resistance, superior chemical stability, and excellent mechanical performance, particularly maintaining their strength and stability under extreme environmental conditions. The high-temperature resistance of SiOC ceramics makes them an ideal material for aerospace applications, where they are used in the fabrication of thermal protection systems, engine components, and high-temperature sensors [7]. In the chemical industry, their outstanding chemical stability makes SiOC ceramics widely applicable in the construction of equipment and catalyst supports for corrosive environments [8]. In electronics, the excellent electrical insulating properties of SiOC ceramics make them the preferred choice for packaging electronic devices and high-frequency components [9].

Despite the significant applications of SiOC ceramics in various fields, traditional manufacturing methods typically rely on high-temperature sintering and complex shaping processes, such as injection molding, pressing, and casting. These methods often face challenges related to difficulty in shaping, low precision, and low manufacturing efficiency [10]. The limitations of traditional techniques are particularly evident when producing complex geometries and intricate structures [11,12,13]. Furthermore, the inherent brittleness and high hardness of ceramic materials make conventional processing methods, such as machining and electrical discharge machining, prone to causing material damage, which, in turn, affects the performance and reliability of the final products [14,15]. Consequently, there is an increasing demand for more efficient and cost-effective methods to fabricate complex SiOC ceramic shapes.

Additive manufacturing (3D printing) provides a means for the direct fabrication of complex ceramic components. This technique constructs intricate ceramic structures from digital models by sequentially stacking layers of ceramic powders or liquids [16,17,18]. This approach offers notable advantages in producing complex geometries that are difficult to achieve through traditional molding techniques. Additive manufacturing effectively addresses the challenges inherent in forming the complex structures typically encountered in traditional ceramic manufacturing methods. By facilitating the precise and efficient creation of intricate ceramic geometries, this technology expands the possibilities for fabricating complex ceramic components [19].

Additive manufacturing (3D printing) enables highly flexible and customized production by constructing structures layer by layer from digital models. This technology integrates computer-aided design with material processing, transforming conventional manufacturing processes. Its versatility and precision have resulted in widespread applications across numerous fields [20]. In recent years, additive manufacturing has rapidly developed into one of the most promising methods for producing 3D structures, showcasing considerable potential across multiple fields. Various additive manufacturing techniques have been documented, including stereolithography (SL) [21], inkjet printing (IJP) [22], fused deposition modeling (FDM) [23,24], selective laser sintering (SLS) [25], digital light processing (DLP) [26,27,28], layered object manufacturing (LOM) [29], and direct ink writing (DIW) [30,31,32]. Table 1 presents a performance comparison and the preferred applications of the various 3D printing technologies that were discussed above for ceramic additive manufacturing. These techniques provide diverse capabilities for fabricating complex geometries and advancing manufacturing methodologies. They eliminate the need for molds and present significant advantages, such as high efficiency, a wide range of raw material options, and the ability to produce intricate and precise shapes [33]. Among these techniques, DLP, which employs the layered photopolymerization of light-curing resins, has been widely studied due to its maturity, cost-effectiveness, high molding efficiency, and excellent resolution. DLP printing has been successfully employed to fabricate ceramic samples with complex geometries, including honeycomb and porous structures, as well as materials for electromagnetic applications [34].

Table 1.

Comparison of the different 3D printing technologies used for ceramic fabrication.

At present, the predominant approach for ceramic 3D printing involves processing ceramic powders into uniform, fine particles, incorporating binders and then, subsequently, printing and molding. The final step is sintering, which consolidates the ceramic model into its final form [35,36,37]. To achieve a high ceramic yield, enhance the density of the ceramic part, and minimize shrinkage during molding, it is necessary to increase the solids content of the ceramic powder, which can decrease the fluidity of the ceramic slurry and potentially result in printing failure [38]. Additionally, the particle size and inhomogeneity of the ceramic slurry limit its suitability for fabricating structures with fine feature sizes, thereby affecting printing resolution [39,40]. Finally, ceramic particles are mixed with a liquid to create a solid–liquid slurry that is prone to settling over time. To mitigate this issue, an appropriate dispersant must be selected to maintain uniform dispersion, and the slurry should not be stored for prolonged periods. For ceramics with a high solid content, DLP technology may require additional preparation steps involving a non-ceramic powder–resin slurry route [41].

Integrating polymer-derived ceramic (PDC) technology with 3D printing provides an effective solution to these challenges [42]. PDCs eliminate the need for ceramic particles as raw materials, instead utilizing liquid polymers and resins. This approach mitigates issues related to solid content and viscosity, thereby addressing the problems inherent in conventional ceramic slurries [43]. PDCs are a precursor conversion ceramic technology in which organic polymer precursors (ceramic precursors) are synthesized through chemical methods and then converted into the target ceramics via high-temperature pyrolysis [44]. This process offers several distinct advantages: Firstly, PDC technology provides high design flexibility. The number and type of functional groups can be precisely controlled through molecular design, allowing for the molecular-level customization of the ceramic’s composition, structure, and properties [45,46]. Secondly, PDCs can be prepared at relatively lower temperatures, typically between 1000–1400 °C, when compared to traditional ceramic methods such as solid-state synthesis or powder sintering, which require temperatures above 1500 °C [8]. Thirdly, PDCs do not require the addition of low-melting-point sintering additives. Their simple composition leads to fewer impurities, and fillers can be incorporated to introduce hetero-elements as needed [47]. Lastly, as polymer precursors, PDCs offer excellent processability and moldability, and they also exhibit good high-temperature creep resistance and stability [48].

Currently, 3D printing technology is widely used in the fabrication of PDCs, successfully printing various porous ceramic structures such as SiOC [49,50], ZrOC [51], SiCN [52], and SiO2 [53]. For instance, Eckel et al. [54] employed digital light processing (DLP) 3D printing to fabricate complex, curved, and porous polymer precursor structures. After subsequent pyrolysis, these structures were transformed into uniformly shrinking and dense SiOC ceramics. Xiao et al. [55] modified polysilazane ceramic precursors with acrylate monomers and incorporated CNTs as absorbers to fabricate SiCN ceramics with complex structures. The results indicated that the introduction of CNTs effectively adjusted the light-curing thickness and enhanced printing accuracy. Compared to previously reported light-curing ceramic precursor polymers, the samples exhibited improved linear shrinkage, porosity, and ceramic yield after pyrolysis at 1300 °C. Chen et al. [56] synthesized a low-viscosity, high-curing strength silicone photosensitive resin co-doped with Zr/Ti using the sol-gel method, and they also prepared lattice-structured green parts through DLP printing. The resulting compact SiOC ceramics were pyrolyzed under a high-temperature and nitrogen atmosphere. After pyrolysis at 1200 °C, the mass loss was 55.9 wt%, and the linear shrinkage was 35.4%. Li et al. [57] developed various photosensitive preceramics by blending pre-ceramic materials with photosensitive resins, achieving high ceramic yields. This approach was used to fabricate high-strength SiOC structures at the micron scale. This method allows for the tuning of SiOC ceramic properties by adjusting the proportions of different preceramics, as demonstrated in subsequent studies [58]. Yang et al. [59] synthesized a novel UV-curable SiOC ceramic precursor, incorporated SiC whiskers, and employed DLP 3D printing technology to fabricate green parts with complex structures. Pyrolysis at 1000 °C yielded SiOC ceramics and SiOC-SiCw ceramic composites, with a linear shrinkage rate of 32.8% and a ceramic yield of 48.5%.

In this study, we prepared and characterized the rheological properties of a homogeneous polyoxysilane pre-precursor slurry suitable for UV curing using methyl-silsesquioxane resin (SILRES MK) resin as the raw material. During the molding process, the polyoxysilane prepolymer (MK-TMSPM), containing methacrylate-based functional groups, underwent rapid cross-linking and curing through ultraviolet light layer-by-layer curing, thereby resulting in the successful fabrication of three-dimensional diamond and octahedral structures with well-defined forms and smooth surfaces. Subsequently, dense SiOC ceramic material was obtained through sintering in a high-temperature argon atmosphere at 1200 °C, exhibiting minimal shrinkage and a high ceramic yield (47.6 ± 0.1%). The microstructure and mechanical properties of the printed ceramic materials were also studied and discussed.

2. Experimental Section

2.1. Materials

SILRES MK, which is primarily composed of polysiloxane, has the chemical formula [(CH3)0.96(OR)0.04SiO1.5]n, where R is H or CH3 and has a molecular weight of about 9100 g/mol. In addition, 3-(trimethoxysilyl) propyl methacrylate (TMSPM), tetrahydrofuran (THF), concentrated hydrochloric acid (HCl), phenylbis (2,4,6-trimethylbenzoyl) phosphine oxide (819), ethyl (2,4,6-trimethylbenzoyl) phenyl phosphonate (TPO-L), trimethylolpropane triacrylate (TMPTA), isobornyl methacrylate (IBOMA), and tripropylene glycol monomethyl ether (TPM) were all of the solvents and reagents that were used directly and required no further distillation or purification.

2.2. Synthesis of UV-Curing Ceramic Precursor Resin

First, 120 g of SILRES MK resin and 30 g of TMSPM were completely dissolved in 120 mL of THF. A total of 400 μL of concentrated hydrochloric acid and 600 μL of ultrapure water were added to the prepared solution, and the mixture was stirred for 2 h at room temperature. After stirring, 15 g of TMPTA, 30 g of IBOMA, and 30 g of TPM were added sequentially, and the mixture was stirred at room temperature for 12 h. The resulting solution was then vacuum-distilled under a 45 °C constant temperature water bath for 2 h to remove the THF and residual hydrochloric acid. Prior to printing with DLP light-curing, mixed photoinitiators were added to the photosensitive resin at concentrations of 5 wt‰ phenylbis (2,4,6-trimethylbenzoyl) 819 and 3 wt% ethyl 2,4,6-trimethylbenzoyl TPO-L. Magnetic stirring was used to fully dissolve it, resulting in a transparent light yellow slurry, which was wrapped with tin foil to protect it from light and then sealed for later use.

2.3. DLP 3D Printing of Ceramic Precursor Resin

A commercially available DLP 3D printer was used for the light-curing printing of polyoxysilane slurry. The basic principle is the bottom exposure module, which projects ultraviolet rays to the bottom of the resin tank. Next, the resin cures to a certain thickness, the lifting mechanism moves up, and the exposure module projects the pattern of another layer to continue the curing of the next layer. The printing process was repeated as described above, and, after printing, the structure was cleaned with ethanol to obtain the printed structure that is consistent with the computer-designed model. We refer to the un-sintered or unprocessed ceramic parts produced through 3D printing as “green parts” [60]. The DLP 3D printer had a wavelength of 405 nm. The printing manufacturing process was conducted layer by layer. The best printing parameters were verified by many experiments, the layer thickness was 100 μm, the bottom layer thickness was 4 layers, and the exposure time was 10 s.

2.4. Pyrolysis

The pyrolysis process was conducted by a tube furnace under an argon atmosphere. First, the green parts prepared by the DLP 3D printer was heated from room temperature to 200 °C at a constant heating rate of 1 °C/min and held for 2 h. These were then heated to 350 °C at a heating rate of 1 °C/min and held for 2 h. Next, they were heated to 450 °C at 1 °C/min and held for 4 h. They continued to be heated to 800 °C at 1 °C/min for 2 h, heated to the target pyrolysis temperature at 1 °C/min, and then held for 2 h. Finally, they were cooled naturally to room temperature. The target pyrolysis temperature in this study was divided into 1000 °C, 1100 °C, 1200 °C, 1300 °C, and 1400 °C, and the heating rate was kept at 1 °C/min.

2.5. Characterization

In the experiment, Fourier transform infrared spectroscopy (FT-IR, Vertex 70, Nengpu Technology Co., Ltd., Shenzhen, China) was employed to analyze the transformation of functional groups in the MK and MK-TMSPM resin, and the rheological properties of the slurry were tested in the static mode by rheometer (DH-RDII, Donghua Testing Instrument Co., Ltd., Suzhou, China). The TG-DTG curve was measured by thermogravimetric analyzer (DTG-60, Dongfang Instrument Co., Ltd., Shanghai, China), the heating rate was set to 10 °C/min, and the test temperature range was 50~800 °C. X-ray diffraction (D8 ADVANCE, Dongfang Science Instrument Co., Ltd., Beijing, China) was used to characterize the crystalline phase of the SiOC ceramic samples after pyrolysis at different temperatures. The free carbon content in the precursor-derived ceramics was determined using a Raman spectrometer (Raman-6000, Spectral Instruments Co., Ltd., Beijing, China), which was equipped with a helium-neon laser and was operated at a wavelength of 514 nm and a power of 5 mW. The surface chemical states of the ceramic materials were characterized using X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi, Agilent Technologies Co., Ltd., Shanghai, China). Scanning electron microscopy (SEM, TESCAN MIRA3, TESCAN Technology Co., Ltd., Tianjin, China) was employed to analyze the surface morphology of the fabricated ceramic structures. Additionally, the linear shrinkage and ceramic yield after pyrolysis were measured. Furthermore, to evaluate the mechanical properties of the SiOC ceramic diamond lattice structure, compression tests were conducted using a universal testing machine (WDW-50S, Materials Testing Institute of Wuhan University of Technology, Wuhan, China) at a crosshead velocity of 0.1 mm/min.

3. Results and Discussion

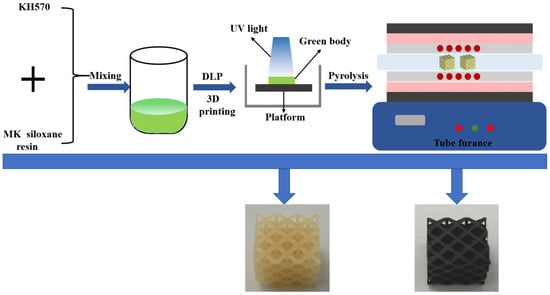

SiOC ceramic samples were prepared from the prepared photosensitive resin by DLP 3D printing and the pyrolysis process described in the previous section. The print model was designed on the computer through CAD software, and the specific process diagram is depicted in Figure 1.

Figure 1.

Process diagram of the DLP-printed SiOC composite ceramics.

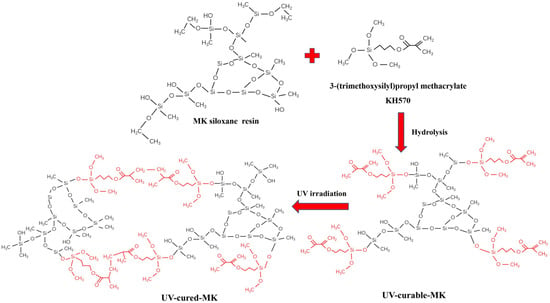

3.1. Blending of the Polymers

The MK resin and TMSPM underwent acid-catalyzed hydrolysis and condensation reactions, as illustrated in Figure 2. During this reaction, the hydroxyl and methoxy groups on the polysiloxane molecules underwent hydrolysis and condensation under acid-catalyzed conditions, forming a chain-like Si-O-Si structure. The condensation reaction enhanced the interchain entanglement of the Si-O bonds, thereby increasing the crosslinking density. During the ultraviolet curing process, photoinitiators induced free radical reactions, promoting the cross-linking of double bonds. This process increased the crosslinking density of the resin, stabilizing its shape and eliminating its fluidity.

Figure 2.

The hydrolysis condensation reaction process.

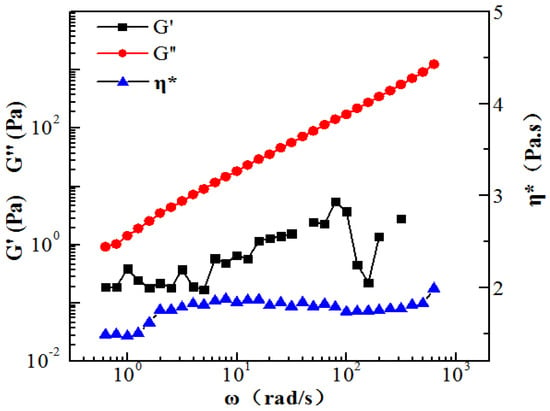

Figure 3 shows the infrared spectra of the MK resin and MK-TMSPM resin samples. Both curves, a and b, exhibited absorption peaks at specific wavenumber positions. For instance, the absorption peaks observed at 1273 cm−1 (symmetrical bending vibration of Si-CH3), 1100 cm−1 (characteristic Si-O-Si bond), 763 cm−1 (stretching vibration of Si-CH3), and 630–480 cm−1 (characteristic Si-C bond) corresponded to the structure of the MK resin [61]. The characteristic absorption peak of -OCH3 at 2840 cm−1, which was associated with incomplete hydrolysis, became notably more pronounced [62], while peaks at 940 cm−1 and 1142 cm−1 also intensified, indicating that hydrolysis and condensation reactions produced additional Si-O-Si structures [63]. Additionally, peaks corresponding to C-H symmetrical and asymmetrical bending vibrations of methylene at 1409 cm−1 and 1471 cm−1 [64], C=O stretching vibrations at 1720 cm−1 [65], and C=C stretching vibrations at 1639 cm−1 confirmed the successful introduction of the methacrylate group into MK resin, thus completing the anticipated hydrolysis and condensation reactions [66].

Figure 3.

The FT-IR spectra of the polysiloxane resin: (a) MK and (b) MK-TMSPM.

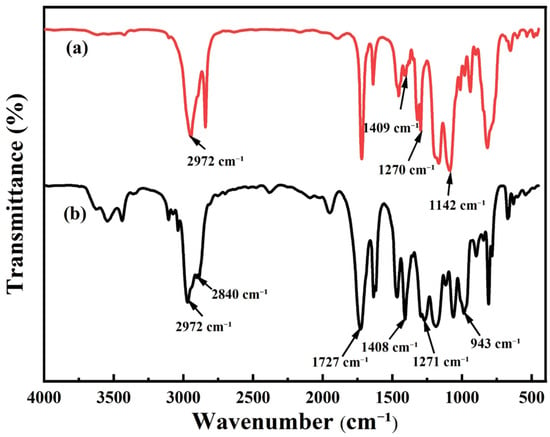

The rheological properties of the MK-TMSPM ceramic slurry were evaluated by measuring the compound viscosity (η*), the storage modulus (G′), and the loss modulus (G″) under static test conditions. Figure 4 presents the composite viscosity (η*) of the slurry as a function of the shear rate, ranging from 1 s−1 to 400 s−1, which was measured under static test conditions at 25 °C. The results demonstrate that the precursor ceramic slurry exhibited shear-thinning behavior, with the viscosity remaining nearly constant at low shear rates (<40 s−1). As the shear rate increased, the η* of the slurry decreased substantially, further confirming its shear-thinning behavior. In its fluid state, the mixed material system demonstrated a low viscosity (~1.5 Pa·s), rendering it highly suitable for light-curing molding with DLP printers.

Figure 4.

The rheological properties of the MK-TMSPM ceramic slurry.

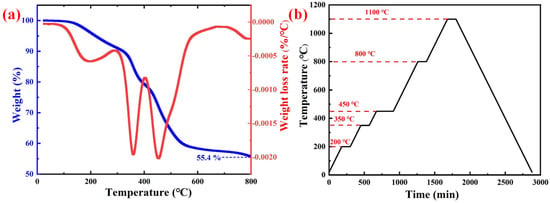

Figure 5 illustrates the pyrolysis process of the MK-TMSPM light-cured products, which were analyzed using a thermogravimetric analyzer. The thermogravimetric analysis revealed that the residual weight of the MK-TMSPM light-cured products at 800 °C was 55.4%, with three distinct mass loss peaks observed at approximately 200 °C, 350 °C, and 450 °C. The weight loss process can be divided into three stages: The first stage (room temperature to 200 °C) primarily involves the removal of residual water, unreacted solvent THF, and small organic molecules. In the second stage (200 °C to 450 °C), the polymer chains undergo cleavage and rearrangement of organic groups, including acrylate groups. In the third stage (450 °C to 800 °C), the silicone side chains and the silicon–oxysilicon backbone undergo cleavage and rearrangement, releasing small molecules such as hydrogen and methane. Above 800 °C, minimal weight changes occur, indicating that the polymer-to-ceramic conversion is nearly complete.

Figure 5.

(a) The TG-DTG curves of the 3D-printed green parts. (b) The pyrolysis process temperature curve of the printed green parts.

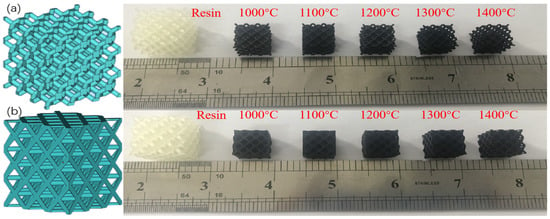

Based on the designed CAD structural model, the MK-TMSPM paste was light-cured using a commercial DLP 3D printer, with each layer exposed for 8 s and a layer thickness of 100 μm to enhance printing efficiency. By optimizing the printing parameters, SiOC pre-ceramic components with complex geometries were successfully fabricated. Figure 6a,b present the CAD models of the 3D diamond and 3D octahedron structures, alongside the corresponding green parts and ceramic structures pyrolyzed at various temperatures. As shown in Figure 6, with increasing processing temperature, the ceramic samples exhibited uniform shrinkage along the X, Y, and Z axes without significant cracks or deformation.

Figure 6.

(a) Diamond structure: the CAD model, green parts, and ceramic parts obtained by sintering at different temperatures. (b) Octahedron structures: the CAD model, green parts, and ceramic parts obtained by sintering at different temperatures.

In this study, the DLP-printed ceramic embryos were pyrolyzed at 1000 °C, 1100 °C, 1200 °C, 1300 °C and 1400 °C, respectively. Table 2 lists some of the ceramic data for SiOC ceramics obtained by pyrolysis at different temperatures. This includes the pyrolysis temperature of the SiOC ceramics, as well as the yield of the ceramics obtained by the mass ratio before and after sintering. In addition, linear shrinkage was assessed by measuring the ratio of the length in the longest direction before and after treatment. The relative density of ceramic samples was determined by the Archimedes method. The samples sintered at 1000 °C showed a linear shrinkage of about 31.5% and a material bulk density of about 0.747 g/cm3. When the pyrolysis temperature was increased to 1200 °C, the linear shrinkage increased to 32.8% and the density increased to 0.756 g/cm3. This change can be attributed to the rearrangement of ceramic particles or the formation of crystals, resulting in a more ordered and compact microstructure.

Table 2.

Typical data of the printed ceramic components after pyrolysis.

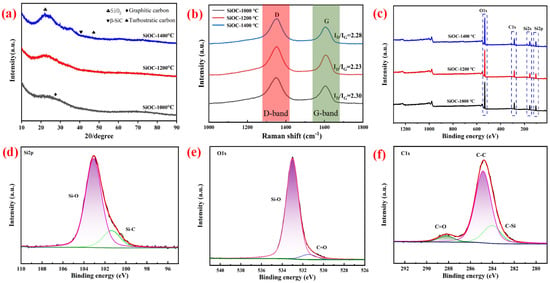

3.2. Microstructure of the Printed Ceramic Components

To study the crystallization behavior of the SiOC precursor transformation ceramics. XRD was used to analyze the SiOC ceramics pyrolyzed at 1000 °C, 1200 °C, and 1400 °C in detail. Figure 7a presents the XRD patterns of the SiOC ceramics during pyrolysis at 1000–1400 °C. The SiOC matrix predominantly exhibited an amorphous state within the tested temperature range. The samples treated at 1000 °C showed no sharp diffraction peaks, but a broad peak around 2θ = 22° was observed, corresponding to the amorphous phase of SiO2 [67]. As the pyrolysis temperature increased, the broad diffraction peak at 2θ = 22.0° intensified, indicating an increase in crystallinity [68]. A weak broad peak at 2θ = 35.6°, corresponding to the (111) crystal plane of β-SiC microcrystals, emerged at 1200 °C due to the low content of β-SiC [69]. Figure 7b shows the Raman spectra of the SiOC ceramics. The Raman spectra at different pyrolysis temperatures exhibited two bands: the D band (~1300 cm−1) and the G band (~1600 cm−1). These confirmed the presence of free carbon [70,71]. Additionally, the intensity ratio of ID to IG (ID/IG) was used to evaluate the degree of graphitization of the free carbon [72]. The ID/IG ratios for SiOC-1000 °C, SiOC-1200 °C, and SiOC-1400 °C were 2.20, 2.23, and 2.28, respectively, indicating a slight decrease in carbon content with increasing pyrolysis temperature. Furthermore, the relatively high ID/IG ratios across all the samples suggest that the free carbon in the samples was predominantly amorphous. The XPS spectra of the full spectrum of SiOC ceramics pyrolyzed at different temperatures (Figure 7c) revealed that, after high-temperature pyrolysis, the SiOC ceramics contained three elements: Si, O, and C. As the pyrolysis temperature increased from 1000 °C to 1200 °C and then to 1400 °C, no significant shifts or intensity changes were observed in the Si 2p and C 1s peaks of the XPS spectra. This suggests that the chemical environment of the ceramic surface remained stable, resulting in minimal changes in the XPS spectra. The sintering process of SiOC ceramics primarily manifested as surface densification and a reduction in porosity without significant phase transitions [73]. The high-resolution Si 2p spectrum (Figure 7d) showed two bonding states of the Si: Si-O and Si-C bonds, corresponding to binding energies of 103.1 eV and 101.4 eV, respectively [74]. Similarly, the high-resolution O 1s spectrum (Figure 7e) indicated the presence of C=O and Si-O bonds, with binding energies of 531.4 eV and 533.1 eV, respectively [75]. Furthermore, the high-resolution C 1s spectrum (Figure 7f) identified the presence of C-Si, C-C, and C=O bonds, corresponding to the binding energies of 284.02 eV, 284.8 eV, and 288.2 eV, respectively [76]. In summary, the SiOC ceramics were predominantly amorphous, containing minor amounts of silica, β-SiC, graphitic carbon, and turbostratic carbon [77,78].

Figure 7.

The (a) XRD patterns, (b) Raman spectra, and (c) XPS spectra of the full spectrum of SiOC ceramics pyrolysis at 1000 °C, 1200 °C, and 1400 °C. The (d) Si 2p spectrum, (e) O 1s spectrum, and (f) C 1s spectrum of SiOC ceramics.

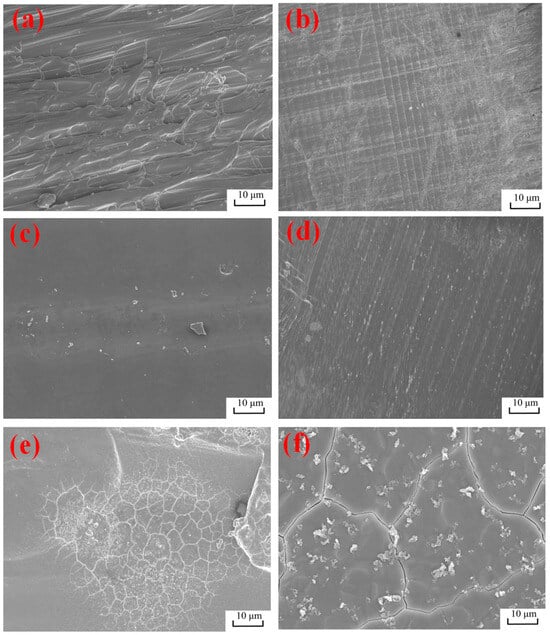

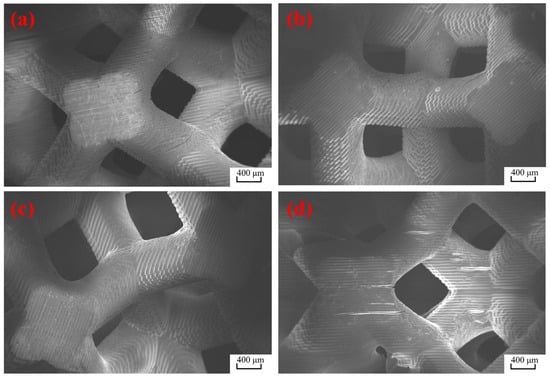

Figure 8 shows the three-dimensional SiOC ceramic diamond structure, which was characterized by SEM at 1000 °C, 1200 °C, and 1400 °C. In the pyrolysis process, the cracks that occur due to the rapid heating and inhibition of material shrinkage can be eliminated by precisely controlling the heating rate and positioning the sample properly in the furnace. As can be seen from Figure 8a,b, the shape of the pyrolyzed ceramic sample at 1000 °C was well maintained and no microcracks were found. The layer pattern on the surface of the printed part (as shown in Figure 8a) was caused by the layer-by-layer printing process. As shown in Figure 8c,d, the surface morphology of the pyrolyzed sample at 1200 °C was good, the characteristics were fine and complex, and there were no obvious microcracks. However, there were multiple cracks of random size distributed on the fracture surface of the sample at 1400 °C, which may have been caused by the rapid escape of volatile gases during pyrolysis. These results reveal the effects of the pyrolysis process on the microstructure, providing key information for the properties and applications of the materials. As shown in Figure 9, the microstructure of the three-dimensional SiOC ceramic diamond skeleton was visible. It can be clearly seen that the surface of the skeleton fibers shown in Figure 9a–c was smooth and that there were no cracks. However, as shown in Figure 9d, there was a significant crack in the skeleton fibers, which confirms the conclusion obtained in Figure 8.

Figure 8.

Surface microstructure of the SiOC ceramic after pyrolysis at different temperatures: (a,b) 1000 °C, (c,d) 1200 °C, and (e,f) 1400 °C.

Figure 9.

Internal microstructure of SiOC ceramics after pyrolysis at different temperatures: (a) 1000 °C, (b) 1200 °C, (c) 1300 °C and (d) 1400 °C.

3.3. The Mechanical Properties of Ceramic Components After Sintering

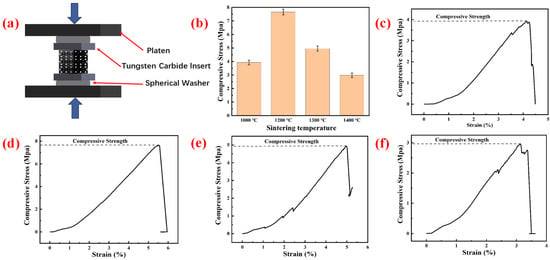

The mechanical properties of the fabricated three-dimensional diamond lattice structure were evaluated, as illustrated in Figure 10. Compression testing was performed using a universal testing machine, and Figure 10b–e depict the typical compressive stress–strain curves at various pyrolysis temperatures (1000 °C, 1200 °C, 1300 °C, and 1400 °C). The results indicate that the compressive stress–strain curves exhibited a jagged pattern, which was attributed to the uneven surface of the ceramic samples and the progressive fracture of the lattice pillars under compression. The compressive strength and elastic modulus of the SiOC ceramic diamond lattice structure were derived from the stress–strain curves, with the highest values observed at 1200 °C, where the compressive strength reached 7.66 MPa and the elastic modulus was 1.47 GPa. Compared to the results reported in [79], the 3D ceramic structures fabricated in this study exhibited higher compressive strength and elastic modulus, demonstrating the effectiveness of our approach. This result can be attributed to the significant influence of phase transformations during the densification process of SiOC ceramics, which greatly affect their mechanical properties. At lower pyrolysis temperatures (1000 °C), SiOC ceramics exhibit high porosity and insufficient densification, resulting in lower compressive strength and elastic modulus. However, as the temperature increases to 1200 °C, optimal sintering occurs, leading to reduced porosity and a stable Si-C-O network, thus enhancing both the compressive strength and elastic modulus. However, at the high pyrolysis temperature of 1400 °C, excessive grain growth and phase transformations (as confirmed by X-ray diffraction and Raman spectroscopy data) lead to the formation of numerous interfaces within the ceramic structure. The presence of these interfaces resulted in a decrease in the mechanical properties. Excessive sintering temperatures lead to structural inhomogeneity within the ceramic, increasing the brittleness of the SiOC ceramics and adversely affecting their mechanical properties. These findings are in good agreement with recent studies on the sintering behavior and mechanical performance of SiOC ceramics [80,81].

Figure 10.

Mechanical compression performance testing: (a) three-dimensional ceramic structure compression testing process schematic diagram, and (b) compressive strength at different pyrolysis temperatures. Typical compression stress–strain curves at different pyrolysis temperatures: (c) 1000 °C, (d) 1200 °C, (e) 1300 °C, and (f) 1400 °C.

4. Conclusions

Additive manufacturing, particularly the integration of DLP with PDCs, offers a promising strategy for fabricating intricate ceramic structures. In this study, DLP-based additive manufacturing and pyrolysis techniques were employed to produce complex SiOC ceramic structures from pre-ceramic polymers. The photosensitive polysiloxane precursor resin was synthesized through the hydrolytic condensation of SILRES MK and TMSPM under acidic conditions. High-precision 3D diamond and 3D octahedral ceramic structures, exhibiting no visible cracks or deformations, were successfully fabricated using commercial DLP printers. The green parts were pyrolyzed at different temperatures (1000 °C, 1100 °C, 1200 °C, 1300 °C, and 1400 °C), and the resulting ceramics were characterized in terms of ceramic yield, linear shrinkage, relative density, phase composition, and microstructure. The compressive properties of the SiOC ceramic structures were evaluated, with the 3D diamond lattice structure prepared at 1200 °C, achieving a compressive strength of 7.66 MPa and an elastic modulus of 1.47 GPa. This study offers valuable insights into the additive manufacturing of SiOC ceramics with DLP-based complex geometries.

Author Contributions

Conceptualization, X.Z., S.Z. and H.L.; methodology, S.Z. and J.L.; validation, X.Z., S.Z. and N.L.; data curation, X.Z., J.L. and L.W.; writing—original draft preparation, X.Z.; writing—review and editing, X.Z., S.Z. and H.L.; supervision, S.Z. and H.L.; project administration, S.Z. and H.L.; funding acquisition, S.Z. and L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Liu, X.; Fechler, N.; Antonietti, M. Salt Melt Synthesis of Ceramics, Semiconductors and Carbon Nanostructures. Chem. Soc. Rev. 2013, 42, 8237–8265. [Google Scholar] [CrossRef] [PubMed]

- Mei, H.; Huang, W.; Liu, H.; Pan, L.; Cheng, L. 3D printed carbon-ceramic structures for enhancing photocatalytic properties. Ceram. Int. 2019, 45, 15223–15229. [Google Scholar] [CrossRef]

- Schmidt, J.; Colombo, P. Digital Light Processing of Ceramic Components from Polysiloxanes; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Zhu, J. Potassium–sodium Niobate Lead-free Piezoelectric Materials: Past, Present, and Future of Phase Boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Vanderbruggen, B. The Use of Nanoparticles in Polymeric and Ceramic Membrane Structures: Review of Manufacturing Procedures and Performance Improvement for Water Treatment. Environ Pollut. 2010, 158, 2335–2349. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Lahiri, D.; Zhang, C.; Agarwal, A. Graphene Reinforced Metal and Ceramic Matrix Composites: A Review. Int. Mater. Rev. 2017, 62, 241–302. [Google Scholar] [CrossRef]

- Ren, B.; Jia, Y.; Chen, H.; Ti, J.; Deng, Y.; Zhuang, Q.; Li, H. SiCnws/CNTs/Cf-C/SiOC composites with multi-scale lossy phases for simultaneous electromagnetic wave absorption and thermal insulation. J. Mater. 2024, 11, 100882. [Google Scholar] [CrossRef]

- Yang, T.; Li, Z.; Chen, Y. Direct ink writing of SiOC ceramics with lattice structures and their mechanical properties. Addit. Manuf. 2021, 35, 101215. [Google Scholar] [CrossRef]

- Camargo, I.L.; de Morais, M.M.; Fortulan, C.A.; Branciforti, M.C. A Review on the Rheological Behavior and Formulations of Ceramic Suspensions for Vat Photopolymerization. Ceram. Int. 2021, 47, 11906–11921. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1600553. [Google Scholar] [CrossRef]

- Scalera, F.; Corcione, C.E.; Montagna, F.; Sannino, A.; Maffezzoli, A. Development and characterization of UV curable epoxy/hydroxyapatite suspensions for stereolithography applied to bone tissue engineering. Ceram. Int. 2014, 40, 15455–15462. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Domingos, M.A.N.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive Manufacturing of Tissues and Organs. Prog. Polym. Sci. 2012, 37, 1079–1104. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.; Gunster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Colombo, P.; Mera, G.; Riedel, R.; Soraru, G. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Gao, Y.; Ding, J. Low Solid Loading, Low Viscosity, High Uniform Shrinkage Ceramic Resin for Stereolithography Based Additive Manufacturing. Procedia Manuf. 2020, 48, 749–754. [Google Scholar] [CrossRef]

- Bae, C.J.; Halloran, J.W. Integrally cored ceramic mold fabricated by ceramic stereolithography. Int. J. Appl. Ceram. Technol. 2011, 8, 1255–1262. [Google Scholar] [CrossRef]

- Li, K.; Zhao, Z. The effect of the surfactants on the formulation of UV-curable SLA alumina suspension. Ceram. Int. 2017, 43, 4761–4767. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Liu, C.; Liu, Y.; Zhu, J.; Lao, C. Preparation of High Solid Loading and Low Viscosity Ceramic Slurries for Photopolymerization-Based 3D Printing. Ceram. Int. 2019, 45, 11549–11557. [Google Scholar] [CrossRef]

- Xu, X.; Li, P.; Ge, C.; Han, W.; Zhao, D.; Zhang, X. 3D printing of complex-type SiOC ceramics derived from liquid photosensitive resin. ChemistrySelect 2019, 4, 6862. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, S.; Mei, H.; Chen, Z. 3D printing of complex-shaped polymer-derived ceramics with enhanced structural retention. Mater. Manuf. Process. 2022, 37, 1267. [Google Scholar] [CrossRef]

- Xiong, S.; Liu, J.; Cao, J.; Li, Z.; Idrees, M.; Lin, X.; Long, Z.; Liu, Z.; Wang, P.; Liu, C. 3D printing of crack-free dense polymer-derived ceramic monoliths and lattice skeletons with improved thickness and mechanical performance. Addit. Manuf. 2022, 57, 102924. [Google Scholar] [CrossRef]

- Balla, V.K.; Bose, S.; Bandyopadhyay, A. Processing of Bulk Alumina Ceramics Using Laser Engineered Net Shaping. Int. J. Appl. Ceram. Technol. 2008, 5, 234–242. [Google Scholar] [CrossRef]

- Bae, C.; Halloran, J.W. Influence of Residual Monomer on Cracking in Ceramics Fabricated by Stereolithography. Int. J. Appl. Ceram. Technol. 2011, 8, 1289–1295. [Google Scholar] [CrossRef]

- Bae, C.; Ramachandran, A.; Halloran, J.W. Quantifying Particle Segregation in Sequential Layers Fabricated by Additive Manufacturing. J. Eur. Ceram. Soc. 2018, 38, 4082–4088. [Google Scholar] [CrossRef]

- Santoliquido, O.; Colombo, P.; Ortona, A. Additive Manufacturing of Ceramic Components by Digital Light Processing: A Comparison Between the “bottom-up” and the “top-down” Approaches. J. Eur. Ceram. Soc. 2019, 39, 2140–2148. [Google Scholar] [CrossRef]

- Huang, X.; Dai, H.; Hu, Y.; Zhuang, P.; Shi, Z.; Ma, Y. Development of a High Solid Loading β-TCP Suspension with a Low Refractive Index Contrast for DLP -Based Ceramic Stereolithography. J. Eur. Ceram. Soc. 2021, 41, 3743–3754. [Google Scholar] [CrossRef]

- Das, A.; Madras, G.; Dasgupta, N.; Umarji, A.M. Binder removal studies in ceramic thick shapes made by laminated object manufacturing. J. Eur. Ceram. Soc. 2001, 23, 531–534. [Google Scholar] [CrossRef]

- Ng, W.L.; Lee, J.M.; Zhou, M.; Chen, Y.-W.; Lee, K.-X.A.; Yeong, W.Y.; Shen, Y.-F. Vat Polymerization-based Bioprinting-process, Materials, Applications and Regulatory Challenges. Biofabrication 2020, 12, 22001. [Google Scholar] [CrossRef] [PubMed]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-dimensional Printing of Transparent Fused Silica Glass. Nature 2017, 544, 337. [Google Scholar] [CrossRef]

- Sun, J.B.; Li, B.; Huang, X.-G.; Cai, K.-P.; Zhou, J.; Li, L.-T. Direct write assembly of ceramic three-dimensional structures based on photosensitive inks. J. Inorg. Mater. 2009, 24, 1147–1150. [Google Scholar] [CrossRef]

- Grida, I.; Evans, J.R.G. Extrusion free forming of ceramics through fine nozzles. J. Eur. Ceram. Soc. 2003, 23, 629–635. [Google Scholar] [CrossRef]

- Jana, P.; Santoliquido, O.; Ortona, A.; Colombo, P.; Soraru, G. Polymer-derived SiCN cellular structures from replica of 3D printed lattices. J. Am. Ceram. Soc. 2018, 101, 2732–2738. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon Nitride and Related Materials. J. Am. Ceram. Soc. 2000, 83, 245–265. [Google Scholar] [CrossRef]

- Halloran, J. Ceramic stereolithography: Additive manufacturing for ceramics by photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Colombo, P.; Paulson, T.; Pantano, C. Synthesis of silicon carbide thin films with polycarbosilane (PCS). J. Am. Ceram. Soc. 1997, 80, 2333–2340. [Google Scholar] [CrossRef]

- Ma, B.; Wang, Y.; Wang, K.; Li, X.; Liu, J.; An, L. Frequency-dependent conductive behavior of polymer-derived amorphous silicon carbonitride. Acta Mater. 2015, 89, 215–224. [Google Scholar] [CrossRef]

- Jia, Z.; Liu, F.; Jiang, X.; Wang, L. Engineering Lattice Metamaterials for Extreme Property, Programmability, and Multifunctionality. J. Appl. Phys. 2020, 127, 150901. [Google Scholar] [CrossRef]

- Bernardo, E.; Fiocco, L.; Parcianello, G.; Storti, E.; Colombo, P. Advanced Ceramics from Preceramic Polymers Modified at the Nano-Scale: A Review. Materials 2014, 7, 1927–1956. [Google Scholar] [CrossRef]

- Wu, X.; Lian, Q.; Li, D.; He, X.; Meng, J.; Liu, X.; Jin, Z. Influence of Boundary Masks on Dimensions and Surface Roughness Using Segmented Exposure in Ceramic 3D Printing. Ceram. Int. 2019, 45, 3687–3697. [Google Scholar] [CrossRef]

- Wei, L.; Li, J.; Zhang, S.; Zhou, Y.; Li, B.; Zhang, Z. Construction of EG/SiOC@C Porous Structure by Direct Ink Writing and In-Situ Vapor Self-Deposition to Enhance Microwave Absorption. Ceram. Int. 2023, 49, 25144–25155. [Google Scholar] [CrossRef]

- Peng, E.; Zhang, D.; Ding, J. Ceramic Robocasting: Recent Achievements, Potential, and Future Developments. Adv. Mater. 2018, 30, 1802404. [Google Scholar] [CrossRef]

- Dermeik, B.; Travitzky, N. Laminated object manufacturing of ceramic-based materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, Y.; Liu, J. Fabrication of honeycomb-structured SiOC ceramics via stereolithography and their mechanical performance. Ceram Int. 2023, 49, 3120–3128. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Jang, K.J.; Kang, J.H.; Fisher, J.G.; Park, S.W. Effect of the Volume Fraction of Zirconia Suspensions on the Microstructure and Physical Properties of Products Produced by Additive Manufacturing. Dent. Mater. 2019, 35, e97–e106. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, Z.; Xu, G.; Wei, Y.; Lao, C. Preparation and Stereolithography 3D Printing of Ultralight and Ultrastrong ZrOC Porous Ceramics. J. Alloys Compd. 2019, 789, 867–873. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Kim, S.; Arifuzzaman, A.M.; Saito, T.; Cramer, C.L.; Minary-Jolandan, M. Processing and 3D Printing of SiCN Polymer-Derived Ceramics. Int. J. Appl. Ceram. Technol. 2022, 19, 939–948. [Google Scholar] [CrossRef]

- Wang, H.; Lin, J.; Qi, J.; Cao, J. Joining SiO2-Based Ceramics: Recent Progress and Perspectives. J. Mater. Sci. Technol. 2022, 108, 110–124. [Google Scholar] [CrossRef]

- Eckel, Z.; Zhou, C.; Martin, J.; Jacobsen, A.; Carter, W.; Schaedler, T. Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, D.; Cheng, H.; Jia, Y.; Zhou, S.; Zu, M. Carbon nanotubes as light absorbers in digital light processing three-dimensional printing of SiCN ceramics from preceramic polysilazane. Ceram Int. 2020, 46, 19393–19400. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, G.; Chen, Z.; Liu, C.; Wang, D.; Lao, C. Multiple Metals Doped Polymer-Derived SiOC Ceramics for 3D Printing. Ceram. Int. 2018, 44, 11030–11038. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z.; Liu, J.; Fu, Y.; Liu, C.; Wang, P.; Jiang, M.; Lao, C. Additive manufacturing of lightweight and high-strength polymer-derived SiOC ceramics. Virtual Phys. Prototyp. 2020, 15, 163–177. [Google Scholar] [CrossRef]

- Li, Z.; Khuje, S.; Islam, A.; Ren, S. Additive Manufacturing of High-Temperature Preceramic-Derived SiOC Hybrid Functional Ceramics. Adv. Eng. Mater. 2023, 25, 2300957. [Google Scholar] [CrossRef]

- Cullen, A.; Price, A. Digital light processing for the fabrication of 3D intrinsically conductive polymer structures. Synth Met. 2018, 235, 34–41. [Google Scholar] [CrossRef]

- Bae, C.J.; Halloran, J.W. Concentrated Suspension-Based Additive Manufacturing—Viscosity, Packing Density, and Segregation. J. Eur. Ceram. Soc. 2019, 39, 4299–4306. [Google Scholar] [CrossRef]

- Sears, N.; Dhavalikar, P.; Whitely, M.; Cosgriff-Hernandez, E. Fabrication of biomimetic bone grafts with multi-material 3D printing. Biofabrication 2017, 9, 025020. [Google Scholar] [CrossRef]

- Wei, L.; Li, J.; Zhang, S.; Li, B.; Liu, Y.; Wang, F.; Dong, S. Fabrication of SiOC ceramic with cellular structure via UV-Assisted direct ink writing. Ceram. Int. 2019, 46, 3637–3643. [Google Scholar] [CrossRef]

- Huang, K.; Elsayed, H.; Franchin, G.; Colombo, P. 3D printing of polymer-derived SiOC with hierarchical and tunable porosity. Addit. Manuf. 2020, 36, 101549. [Google Scholar] [CrossRef]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC ceramic microcomponents. Adv. Mater. 2016, 28, 370–376. [Google Scholar] [CrossRef]

- Schmidt, J.; Altun, A.A.; Schwentenwein, M.; Colombo, P. Complex mullite structures fabricated via digital light processing of a preceramic polysiloxane with active alumina fillers. J. Eur. Ceram. Soc. 2018, 39, 1336–1343. [Google Scholar] [CrossRef]

- Badev, A.; Abouliatim, Y.; Chartier, T.; Lecamp, L.; Lebaudy, P.; Chaput, C.; Delage, C. Photopolymerization Kinetics of a Polyether Acrylate in the Presence of Ceramic Fillers Used in Stereolithography. J. Photochem. Photobiol. A Chem. 2011, 222, 117–122. [Google Scholar] [CrossRef]

- Long, X.; Shao, C.; Wang, J. Continuous SiCN fibers with interfacial SiCxNy phase as structural materials for electromagnetic absorbing applications. ACS Appl. Mater. Interfaces 2019, 11, 22885–22894. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Ding, G.; Bai, X.; Fang, D. Effects of Fine Grains and Sintering Additives on Stereolithography Additive Manufactured Al2O3 Ceramic. Ceram. Int. 2021, 47, 2303–2310. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, H.; Shi, T.; Xie, D.; Chen, R.; Han, X.; Shen, L.; Wang, C.; Tian, Z. Additive Manufacturing of Hydroxyapatite Bone Scaffolds via Digital Light Processing and in Vitro Compatibility. Ceram. Int. 2019, 45, 11079–11086. [Google Scholar] [CrossRef]

- Jiang, W.; Li, K.; Xiao, J.; Lou, L. Effect of Silica Fiber on the Mechanical and Chemical Behavior of Alumina-Based Ceramic Core Material. J. Asian Ceram. Soc. 2017, 5, 410–417. [Google Scholar] [CrossRef]

- Hu, L.F.; Wang, C.A. Effect of Sintering Temperature on Compressive Strength of Porous Yttria-Stabilized Zirconia Ceramics. Ceram. Int. 2010, 36, 1697–1701. [Google Scholar] [CrossRef]

- Sun, J.; Binner, J.; Bai, J. 3D Printing of Zirconia via Digital Light Processing: Optimization of Slurry and Debinding Process. J. Eur. Ceram. Soc. 2020, 40, 5837–5844. [Google Scholar] [CrossRef]

- Pfaffinger, M.; Hartmann, M.; Schwentenwein, M.; Stampfl, J. Stabilization of tricalcium phosphate slurries against sedimentation for stereolithographic additive manufacturing and influence on the final mechanical properties. Int. J. Appl. Ceram. Technol. 2017, 14, 499–506. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Tang, J.; She, Y.; Huang, Z.; Li, Q.; Yang, J.; Yang, Y. Digital light processing and electromagnetic wave absorption performance tuning of SiOC/SiO2 ceramics. J. Mater. Res. Technol. 2023, 27, 6538–6547. [Google Scholar] [CrossRef]

- Manière, C.; Kerbart, G.; Harnois, C.; Marinel, S. Modeling Sintering Anisotropy in Ceramic Stereolithography of Silica. Acta. Mater. 2020, 182, 163–171. [Google Scholar] [CrossRef]

- Pan, Y.; Li, H.; Liu, Y.; Liu, Y.; Hu, K.; Wang, N.; Lu, Z.; Liang, J.; He, S. Effect of Holding Time During Sintering on Microstructure and Properties of 3D Printed Alumina Ceramics. Front. Mater. 2020, 7, 54. [Google Scholar] [CrossRef]

- Ding, G.; He, R.; Zhang, K.; Xie, C.; Wang, M.; Yang, Y.; Fang, D. Stereolithography-Based Additive Manufacturing of GrayColored SiC Ceramic Green Body. J. Am. Ceram. Soc. 2019, 102, 7198–7209. [Google Scholar] [CrossRef]

- Bernardo, E.; Carlotti, J.-F.; Dias, P.M.; Fiocco, L.; Colombo, P.; Treccani, L.; Hess, U.; Rezwan, K. Novel akermanite-based bioceramics from preceramic polymers and oxide fillers. Ceram. Int. 2014, 40, 1029–1035. [Google Scholar] [CrossRef]

- He, C.; Ma, C.; Li, X.; Yan, L.; Hou, F.; Liu, J.; Guo, A. Polymer-Derived SiOC Ceramic Lattice with Thick Struts Prepared by Digital Light Processing. Addit. Manuf. 2020, 35, 101366. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Zhang, Q. Development of cubic SiOC ceramics by digital light processing and their mechanical and thermal properties. J. Eur. Ceram. Soc. 2022, 42, 4145–4155. [Google Scholar] [CrossRef]

- Wang, X.; Schmidt, F.; Hanaor, D.; Kamm, P.H.; Li, S.; Gurlo, A. Additive manufacturing of ceramics from preceramic polymers: A versatile stereolithographic approach assisted by thiol-ene click chemistry. Addit. Manuf. 2019, 27, 80–90. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).