1. Introduction

Advancements in high-reliability and long-lifespan technologies have made life testing of electromechanical products increasingly costly. Conducting a large number of system-level tests for comprehensive reliability analyses is impractical. Insufficient test information results in the imprecise assessment of product reliability and life, failing to accurately reflect the actual reliability level of these products [

1]. In aerospace engineering, large electromechanical products are usually modeled as series systems consisting of multiple critical components. Therefore, using relatively inexpensive and readily available component test data has become a popular means to improve the accuracy of system reliability assessments [

2,

3,

4].

Assessing the reliability of series systems using component test data has been a significant issue in reliability engineering. Existing methods can generally be classified into three categories [

5]: classical approximation methods, Monte Carlo simulation (MCS) methods, and Bayesian methods. Classical approximation methods, such as the Lindstrom–Madden (LM) [

6] and modified maximum likelihood (MML) [

7] methods, are widely employed in aerospace engineering because of their simplicity in synthesizing system reliability from the bottom up. These methods rely on the principle of invariance of point estimate, which involves the transformation of component-level life test data into system-level binomial data, followed by binomial distribution reliability analysis methods. However, this conversion process causes a substantial loss of test information and reduces the assessment accuracy [

8,

9]. Moreover, the MML method fails to consider the impact of zero-failure components and often gives overly optimistic estimates [

10].

The MCS method is particularly suitable when directly constructing an analytical model of system reliability is difficult [

11]. Liu et al. [

12] investigated a system reliability evaluation algorithm based on MCS and applied it to assess the reliability of grinding machines. Similarly, Cai et al. [

13] used MCS to determine the confidence limit of reliability for a power distribution system, assuming that component life follows an exponential or Weibull distribution. The key to the MCS method is determining the fiducial distributions of component reliability, achieved through the generalized pivot quantity method [

14]. However, it is almost impossible to accurately construct the fiducial distributions when dealing with zero-failure data. In other words, the MCS method cannot handle situations with zero-failure components in a series system.

The Bayesian approach provides an effective means of combining prior information on component lifetime distribution parameters with sample data for system reliability analysis. Guo et al. [

15] developed a hybrid model that combines the Bayesian method with the variance propagation method to estimate the confidence intervals of zero-failure systems, but this approach is limited to binomial data. The Bayesian model proposed by Reese et al. [

16] can naturally integrate life data from different layers of the system, including various types of censored life data. Nevertheless, in the Bayesian framework, the selection of prior distribution and its hyperparameters is subjective. The additional uncertainty introduced by component priors may significantly impact the stability of system reliability estimates [

17,

18].

Existing studies typically assume that sufficient failure time data can be obtained from component-level testing. However, with advancements in industrial manufacturing, many products have become increasingly reliable. Failures of high-quality products are rare during limited testing time, even under accelerated test scenarios [

19]. Moreover, to minimize test time and save test costs, reliability engineers often opt for zero-failure test programs. Consequently, zero-failure data are frequently observed or collected [

20]. Without failure time information, conventional reliability analysis methods tend to be inadequate, even ineffective.

In the industry, the exponential and 2-parameter Weibull distributions are the two most widely and successfully applied lifetime distribution models. Notably, the 2-parameter Weibull distribution simplifies to the exponential distribution when its shape parameter is set to one. Although considerable studies have been published on the statistical inference of Weibull zero-failure models [

21,

22], little research has focused on estimating the lower confidence limits (LCLs) of system reliability under zero-failure conditions. Therefore, investigating reliability assessment methods for series systems composed of Weibull-distributed components based on zero-failure data holds significant engineering value. This research has three primary goals. First, it aims to develop a new method for estimating the LCLs of system reliability and reliable life, along with deriving the corresponding closed-form expressions. The second objective is to improve the accuracy of system reliability assessment by integrating multi-source life data at both the components and system levels. The third objective involves comparing the proposed method with conventional engineering methods through simulation studies and a specific engineering example.

The rest of the paper is organized as follows.

Section 2 describes the system reliability model and zero-failure data.

Section 3 discusses the reliability assessment and reliable life prediction of series systems with Weibull zero-failure data, followed by an update procedure proposed for leveraging system-level zero-failure data.

Section 4 performs a simulation comparison study, and

Section 5 provides an example application. Finally,

Section 6 summarizes the results of this paper.

3. Methodology

In the context of the Weibull distribution, Fu et al. [

29] derived a closed-form expression for the reliability LCL of zero-failure components. Specifically, for Weibull zero-failure data

, the LCL of the reliability

at the confidence level

is calculated by the following equation:

where

is the

quantile of the chi-square distribution with 2 degrees of freedom.

Based on Equation (6), this section investigates a reliability assessment methodology for series systems using minimum lifetime distribution theory. Furthermore, a system reliability updating procedure is proposed that enhances the above system reliability assessment results by incorporating system-level life data, achieving a multi-level life data fusion assessment.

3.1. Reliability Assessment Method for Series Systems Under No-Failure Scenarios

This subsection discusses the LCLs for reliability and the reliable life of series systems in two scenarios, depending on whether the series system contains identical components.

3.1.1. All Components Are Different

Theorem 1. Assume that the series system consists of different components. Given the mission time , if we takethen the LCL of the series system reliability with the confidence level can be calculated as Proof of Theorem 1. Firstly, given the confidence level

, the LCL

of the reliability

for component

is obtained by Equation (6), which satisfies

Substituting Equation (6) into Equation (10) yields

and

where

is the minimum life distribution parameter.

For a value of

taken by the random variable

, such that

then the confidence level

can be obtained as

Substituting Equations (13) and (14) into (12), the following inequality holds:

According to the minimum lifetime distribution theory in a series model, let

. Since

are independent of each other, it can be deduced from Equation (15) that

Let

; then, we find

and substitute it into Equation (16) to obtain

By appropriate equivalent transformation, we have

Equation (19) is the definition for the LCL of . □

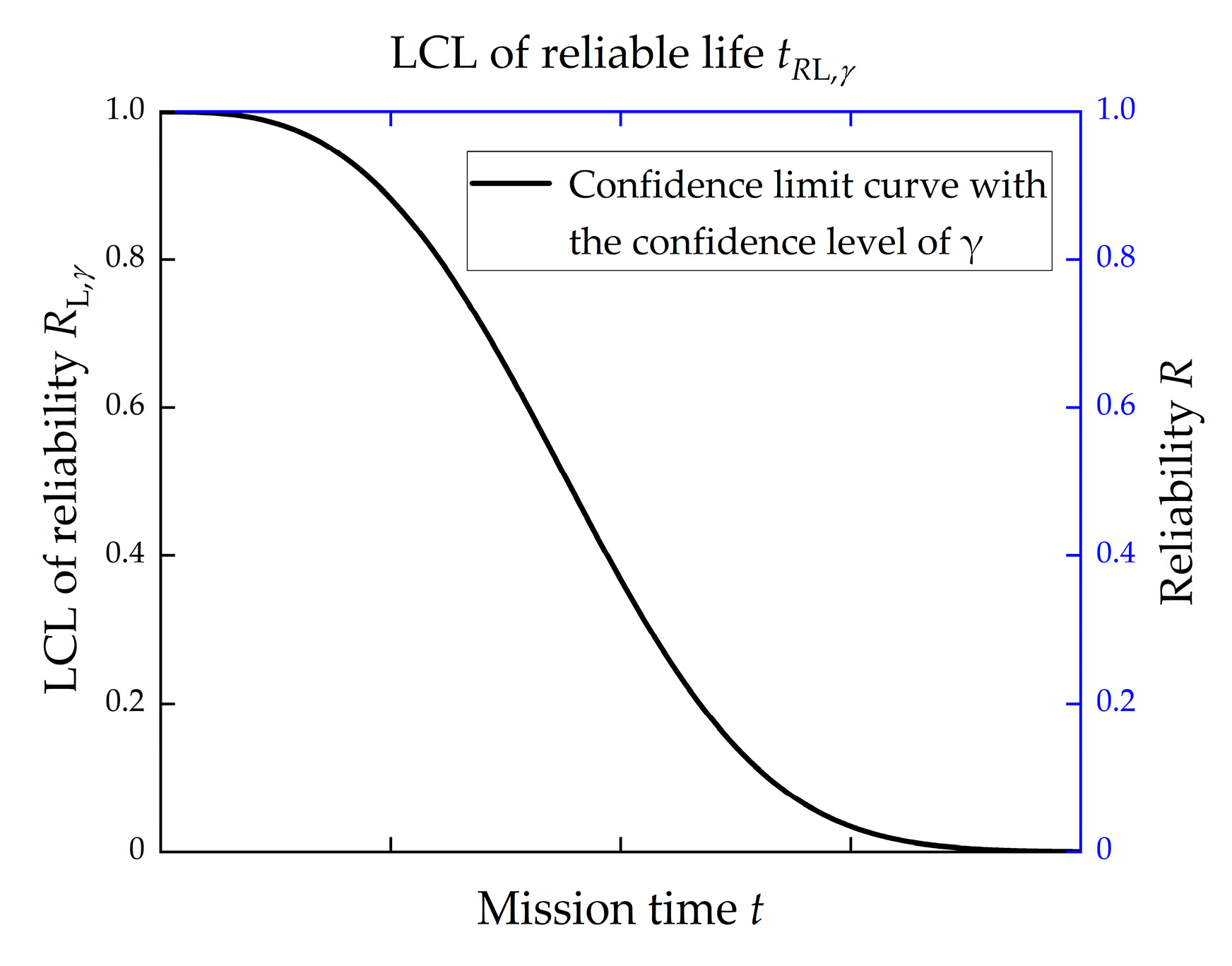

Similar to the system reliability function

, its LCL

also varies with the mission time

. In other words, Equation (8) constructs an LCL curve of the reliability function at the confidence level

. For continuous distributions, the LCL curve of the reliability function is equivalent to that of the reliable life function at the same confidence level [

30].

Figure 1 visualizes this equivalence of LCL curves, revealing the relationship between system reliability and reliable life.

According to the above analysis, for a given reliability

, the LCL of

at the confidence level

can be solved inversely by Equation (8), i.e.,

Since Equation (20) is a strictly monotonic decreasing function of , it is recommended to solve it iteratively using the bisection method. In practical calculation, continuously adjust the mission time in Equation (7) and repeat the series system reliability assessment process until obtained from Equation (8) equals the given reliability . The corresponding time is then the solution for .

3.1.2. Some Components Are Identical

In the case of a series system containing several identical components, these components can be combined into a single equivalent component, and its equivalent test time can be calculated according to Theorem 2.

Theorem 2. Assuming that there are () identical components and the GTT of these components is (no failure), it is equivalent to treating the identical components as a whole and conducting a test with an equivalent GTT of (no failure). is calculated by the following equation: Proof of Theorem 2. Let the Weibull shape parameter of identical components be

; then, the corresponding reliability is defined as

, and

represents the zero-failure data of these components. According to Equation (6), the LCL of

at the confidence level

is

For a new component consisting of

identical components in series, the LCL of its reliability

at the confidence level

is

If these components are treated as a whole and subjected to a life test resulting in zero failure with a GTT of

, as mentioned in

Section 2.1, the lifetime of a series system consisting of identical components obeys a 2-parameter Weibull distribution with a constant shape parameter

. Therefore, the LCL of its reliability

at the confidence level

can still be obtained from Equation (6):

According to the same principle of reliability confidence limits, the values of obtained from Equations (23) and (24) should be equal. By comparing the results of these two equations, Theorem 2 is proved. □

Subsequently, the new equivalent component with a GTT of

is connected in series with the remaining

components, forming a series system with

different components.

Figure 2 illustrates the simplification of the system reliability model when identical components are present. The simplified configuration satisfies the conditions required for the proposed method in

Section 3.1.1. Finally, the LCLs for the reliability and reliable life of the series system can be calculated using Equations (8) and (20), respectively.

3.2. Reliability Updating Procedure for Series Systems Using System-Level Data

For products amenable to whole-machine life testing, system-level test data directly provide crucial life information. During actual product operation, substantial service life data accumulate, reflecting the product’s actual reliability within its operational environment. Incorporating these system-level life data to update the reliability assessment derived from component-level data can significantly improve the accuracy of the system reliability assessment.

Suppose that

zero-failure data

are obtained from a system field test or actual operation. Since all components constituting the series system have not failed at these censored moments, zero-failure data are available for all components. This dataset can be combined with the original component life data

to form a new set of component zero-failure data

, thereby enriching the component-level life information. Subsequently, the series system reliability can be reassessed using the method in

Section 3.1 to obtain more accurate LCLs of the series system reliability and reliable life. For specific calculations, it is sufficient to directly replace the GTT

with

for each component in

Section 3.1,

.

By combining Equation (8) with the new component zero-failure data

, the LCL of system reliability

can be updated from

to

, that is

According to Equation (25) and the equivalence principle of the confidence limit curves, the LCL of the system’s reliable life

can be updated from

to

, that is

Figure 3 illustrates the framework of the system reliability assessment and update algorithm. This algorithm offers several advantages. First, it efficiently integrates multi-source lifetime information, such as test data and operation data of components and the system, providing sufficient data support for accurate system reliability assessment. Second, by simplifying the system reliability model, the framework can handle cases where the system contains identical components. Finally, the algorithm is based on the GTTs of all components and directly derives closed expressions of the LCLs for system reliability and reliable life, which is convenient for engineering applications.

4. Simulation Comparative Study

This section employs the Monte Carlo method to compare the proposed method with the conventional LM method. The LM method is widely accepted in the engineering community due to its simplicity and applicability to cases involving zero-failure components. Numerous simulation comparisons verify that the proposed method outperforms the LM method. For illustration, a series system consisting of three independent Weibull-distributed components is presented as a representative example.

Two combinations of distribution parameters are designed to represent two typical scenarios, as described in the second column of

Table 1. In Scenario 1, the series system consists of a mixture of exponential and Weibull distributions. In Scenario 2, the series system comprises Weibull distributions with different shape parameters, all of which are greater than one. Given the component distribution parameters, the real value of system reliability is calculated using Equation (2), where

.

In each scenario, Weibull zero-failure data are generated for all components. For a given sample size , the simulation steps for the GTT are as follows:

Generate (where should be much larger than ) random numbers from the distribution model of component and arrange them in ascending order;

Select the first data as the failure data of component , where ;

Take the integer slightly less than the failure data as the zero-failure data of component , where , ;

Calculate the for component from Equation (5).

Following the above steps; the GTTs of all components are simulated and listed in the last three columns of

Table 1. Then, at a confidence level of

, both the LM and the proposed methods are used to calculate the LCLs of the series system reliability at different time moments, ranging from 0 to 10. The simulation comparison results under the two scenarios are shown in

Figure 4.

A comparison of the two scenarios in

Figure 4 reveals that the shapes of the system reliability curves differ: Scenario 1 is approximately linear, while Scenario 2 shows a slow and then fast curve. This difference arises because the life of the series system is limited by the weakest component, and its lifetime distribution directly determines the overall reliability characteristics of the system. Numerous simulations show that the system reliability curves follow one of these two patterns, regardless of the combination of component lifetime distribution parameters. Therefore, the two selected sets of distribution parameters are typically representative.

In both scenarios, the LCL curves for system reliability calculated by both the LM and the proposed approaches lie below the real reliability curve, indicating that the evaluation results of both methods are safe and conservative in engineering applications. Furthermore, the LCLs obtained by the proposed method are consistently higher than those from the LM method and closer to the real value at any given time. The advantages of the proposed method become more evident as time increases. In other words, the proposed method offers higher accuracy than the LM method when dealing with component zero-failure data, especially for systems in long-term service. Highly accurate reliability assessment conclusions help engineers make more rational decisions when designing and optimizing systems.

5. Engineering Application

The infrared Earth sensor (IES) is the core attitude measurement subsystem in a satellite. Its main function is to capture Earth boundary information in the far-infrared wavelength range by optical means and then output processed satellite attitude information relative to the geocentric vector. Accurately assessing the reliability of the IES is vital to ensure the safe operation of the satellite and prolong its service lifespan. This section aims to verify whether the reliability of an IES at the end of the 8-year lifespan meets the index requirement of 0.93 with a 90% confidence level using the original dataset of its key components provided in the literature [

31].

The overall reliability of an IES depends on three key components: the electronic circuit, the rotating device, and the infrared detector. During operation, a failure of any component will lead to the failure of the whole system. Accordingly, the reliability assessment model of the IES can be expressed as a series model of the electronic circuit, the rotating device, and the infrared detector. The system reliability block diagram is shown in

Figure 5.

The reliability mathematical model of the IES is

where

,

, and

are the reliabilities of the electronic circuit, rotating device, and infrared detector, respectively.

is the reliability of the IES.

5.1. Preliminary Assessment of the IES Reliability

During the design and development stage, the IES lacks test and operational data of the whole system and must rely on the life data of its key components to assess system reliability. Historical life data are available for electronic circuits and rotating devices. The 91 electronic circuits have accumulated a total flight time of approximately

= 395.10 years with no failures. Similarly, the past service life data of the 74 rotating devices, presented in

Table 2, also show no failures.

Given that the infrared detector is a newly designed product without available historical data, a constant stress accelerated life test was performed. Temperature served as the accelerating stress, and the noise factor was used as the performance index. A total of 127 specimens were tested across four selected temperature stress levels, with specimens at each level tested for 143 days. At the end of the test, none of the specimens failed. The test results are shown in

Table 3, and the process of determining the acceleration factor is illustrated in

Figure 6.

Based on the total flight time of the electronic circuits, and the zero-failure data for the rotating device and infrared detector presented in

Table 2 and

Table 3, the following is a preliminary assessment for the LCL of the IES reliability at a confidence level of

.

First, it is necessary to determine the component lifetime distributions. Since failure time data are unavailable, verifying the lifetime distribution models through goodness-of-fit tests is difficult. Instead, the suitability of the modes must be analyzed in conjunction with the failure pattern and the model characteristics. Electronic circuits are mainly prone to random failures, and their life usually follows an exponential distribution. Rotating devices are susceptible to wear-type failures, making the Weibull distribution appropriate for modeling their life. Zhu [

32] conducted an accelerated life test study of infrared detectors based on the assumption that the life of optoelectronic products follows an exponential distribution. On this basis, the shape parameter values corresponding to the lifetime distributions are provided. Next, the GTT

of the three components is calculated using Equation (5). The results of the above analyses and calculations are summarized in

Table 4.

The lifespan requirement for the IES is 8 years (i.e.,

t = 8 years). According to Equation (7), it follows that

Using Equation (8), the LCL of the IES reliability at a confidence level of

can be obtained. For comparison, the LM method is also performed. The results are summarized in

Table 5.

The preliminary assessment of the two methods concluded that the IES does not satisfy the reliability index requirement of 0.93. This is because, despite collecting a substantial number of component life data samples, all available data are zero failures, providing minimal informative content. Consequently, the precision of LCL for the system reliability, derived at a high confidence level, is low and cannot accurately reflect the actual reliability level of the IES. Given this situation, it is recommended to conduct additional life tests on components with insufficient reliability information to fully verify the reliability index of the IES and yield more accurate and credible assessment conclusions.

5.2. Reassessment of IES Reliability After Supplementary Life Testing

Analyzing Equation (28), it is evident that among the three components, the rotating device provides the least life information, significantly impacting the LCL of the system’s reliability. The historical data of the rotating device alone are insufficient to support a high-precision reliability assessment of the IES. To address this issue, eight rotating devices were put into service for life testing: three samples underwent a 5-fold accelerated life test, three samples underwent a 3-fold accelerated life test, and two samples underwent a standard 1:1 life test. The test results are presented in

Table 6.

Combining the historical flight data in

Table 2 with the supplementary life test data in

Table 6, the GTT for the rotating device is recalculated to

= 780.77, while the life information of the other components remains unchanged. The LCL for the reliability of the IES is then reassessed using both the LM and the proposed methods.

Table 7 shows that after supplemental life testing, the LCL of the IES reliability estimated by the LM method is only 0.9142, which falls short of the reliability index requirement of 0.93. Continuing with the LM method would necessitate additional component data, making the engineering effort unaffordable. In contrast, the proposed method demonstrates higher accuracy, confirming that the IES meets the reliability index requirement of 0.93 at a confidence level of

.

In summary, the proposed method exhibits a clear accuracy advantage over the LM method, fulfilling the requirements of high-precision reliability assessment in engineering while saving tests and resources. This conclusion aligns with the simulation results in

Section 4, further validating the accuracy and applicability of the new method.

5.3. Reliable Life Prediction and Real-Time Update of IES

According to Equation (20), the LCL of the reliable life for the IES can be obtained at a given reliability of

. For comparison, the calculation results using the LM method are also presented. As shown in

Table 8, the proposed method predicts a reliable life of 8.46 years, which is 23.5% higher than the 6.85 years estimated using the LM method. This demonstrates the superior accuracy of the proposed approach.

Assume that 10 IESs of the same type have been in orbit up to time

without any failures (if IESs are as reliable as claimed, it is not expected to fall in a reasonable number of devices within their design life). For these system-level flight data, the system reliability and reliable life derived from component life data can be updated, as outlined in

Section 3.2.

Figure 7 shows the reliable life update results of the IES with increasing in-orbit flight time

at a confidence level of 0.9. As shown, the updated reliable life increases monotonically with

as long as the flight data remain zero failure. For example, if 10 IESs operate in orbit for 8 years without failure, the system’s reliable life is updated to 10.02 years. In comparison with the previously calculated reliable life of 8.46 years, the updating method increases the reliable life by 1.56 years, resulting in an 18.4% improvement. This significantly enhances the accuracy of the system’s reliable life prediction.

5.4. Application Analysis in the Field of Aeronautical Engineering

The proposed methodology is not only applicable to long-life products in space engineering but also provides a new theoretical tool for the reliability assessment of large-scale aviation systems. Taking civil aircraft as an example, only one aircraft can typically be allocated for a full-scale life test due to limitations in development cycles and test costs. Moreover, the test results may not even show failure [

33]. This very small sample size leads to a significant underestimation of the aircraft’s safe life. Conversely, abundant component test data—such as those for the fuselage, wings, and tail—have been accumulated during aircraft development. With the new method, component life test data and aircraft life test data can be fused, increasing the available information. Compared to the traditional method of reliable life assessment based solely on aircraft life test data, the proposed method significantly improves the accuracy of aircraft life prediction.

Regarding life extension, once an aircraft reaches its reliable life, the traditional method often selects one aircraft for a life extension test. However, because of the small number of test samples and limited information, the precision of life extension is not high [

34]. As this type of aircraft is put into service, a large amount of service life data will be accumulated. The proposed method can exploit these system-level data for updating life assessment results, enabling low-cost life extension.

6. Conclusions

With the continuous improvement of product integration and reliability, the problem of reliability assessment for zero-failure models has become an important challenge in reliability engineering. This paper proposes a reliability assessment method for series systems with Weibull zero-failure data, addressing the low accuracy or inapplicability of the traditional method in zero-failure scenarios. The main research results are summarized as follows:

- (1)

Based on the minimum lifetime distribution theory, a reliability assessment method for series systems is established when the component life follows the Weibull distribution. Closed-form expressions for the LCLs of system reliability and reliable life are derived from zero-failure data of different components. The special case of a series system containing several identical components is also discussed, and the equivalent zero-failure time conversion formula is provided.

- (2)

A reliability updating procedure for series systems is proposed, using the system-level operation data to update the system reliability assessment results initially derived from component life data. This method further improves the accuracy of system reliability assessment.

- (3)

Monte Carlo simulations demonstrate that the LCLs of system reliability obtained by this paper’s method are very close to the real value and have higher accuracy than those obtained by the LM method. This improvement is due to the new method’s ability to fully exploit the life information in the component zero-failure data, thereby effectively improving the analysis accuracy.

- (4)

Through an engineering application in the reliability assessment of an IES, the effectiveness of the new method in integrating zero-failure life data from multiple levels (components and system) and multiple sources (field test and actual operation) is verified.

In this study, component life is assumed to follow a Weibull distribution. Future research should aim to explore more efficient strategies to address other reliability models, such as lognormal and gamma distributions. The current update method assumes that the system operates without failures, but the probability of failure rises with increased time in service. Therefore, developing updated models that can integrate system-level failure time data is necessary. In addition, existing case studies mainly focus on aerospace products. In the future, there remains a need to scientifically validate the applicability of this method in other engineering fields (e.g., weaponry and nuclear power equipment). In conclusion, the robustness and applicability of the model are expected to be further improved by relaxing component distribution restrictions, incorporating system-level failure time data, and diversifying the engineering domains.