Featured Application

In the paper, the potential of AM for automotive radar sensors is demonstrated using the use-case of printing a heating coil on the radome of a radar sensor for de-icing using particle-free copper inks and flake-based copper pastes.

Abstract

Radar sensors are critical for obstacle detection and navigation, especially for automated driving. Using the use-case “printing of heating coils on the inside of the front housing (primary radome)” needed for de-icing in winter, it is demonstrated that additive manufacturing (AM) can provide economic and functional benefits for manufacturing of the sensors. AM will allow significant cost reduction by eliminating parts and simplifying the manufacturing process. Different AM technologies for the coils were investigated, first, by applying the conductive traces by fused deposition modeling (FDM), and, second, by printing copper particle-free inks and pastes. The metal layers were electrically and mechanically characterized using a profilometer to measure the trace dimension and a four-point probe to measure the resistance. It was revealed that low-cost conductive filaments with low resistivity and current carrying capacity are commercially still not available. The best option sourced was a copper–polyester-based filament with 6000 µΩcm after printing. Therefore, low-cost particle-free copper inks and commercial copper flake paste were selected to print the heating coil. The Cu particle-free inks were amine-based Cu (II) formate complexes, where the Cu exists in an ionic form. Using contactless printing processes such as ink-jet printing or pneumatic dispensing, the traces could be deposited onto the low-melting temperature (225 °C) polymeric radome structure. After printing, the material needed to be sintered to form the conductive copper traces. To avoid damaging the polymer radome during sintering, two different processes were investigated: low-temperature (<150 °C) sintering in an oven for 30 min or fast laser sintering. The sintered Cu layers achieved the following specific electric resistivities when slowly sintered in the oven: paste 4 µΩcm and ink 8.8 µΩcm. Using laser sintering, the ink achieved 3.2 µΩcm because the locally high temperature provides better sintering. Also, the adhesion was significantly increased to (5 B). Therefore, laser sintering is the preferred technology. In addition, it allows fast processing directly after printing. Commercial equipment is available where printing and laser sintering is integrated. The potential of low-cost copper material and the integration in additive manufacturing of electronic systems using radar sensors as an example are demonstrated in this paper.

1. Introduction

Additive manufacturing (AM) technologies have greatly developed during the past 20 years, increasing structuring accuracy and throughput and reducing cost [1]. AM is moving from prototyping into the manufacturing of plastic or metal parts for end-users [2]. At first, AM was especially used for single part or small batch production, like manufacturing tools and parts for prototypes, or personalized products like medical implants or jewelry. Today, AM is also increasingly used for series production within diverse industrial fields like aerospace, automotive, or sportswear, e.g., shoe manufacturing. In addition, active electronic components like transistors can be realized by printed electronics [3]. These developments inspire researchers to attempt to fully print a microelectronic device like a mobile phone or a radar sensor. However, performance- and size-wise, printed electronic transistors cannot compete presently with the semiconductor technology needed for high-performance devices. But stepwise, AM technologies are also introduced in electronic system production. The AM of printed circuits boards (PCBs) has become popular in prototyping, and advanced equipment is available. For simple single-layer PCBs, additive manufacturing is already competitive, i.e., reducing the manufacturing cost by 50% [4]. This holds if the pattern density is small, i.e., in the range of 10%, because AM is driven by the material cost of the conductive paste. Therefore, the development of low-cost conductive materials is most important. However, when multilayer PCBs, high-speed or high-frequency application are considered, AM is presently not compatible because the inner layers have a large metal coverage [5]. In terms of the reliability required for high-end markets, conventional PCB technologies are predominant in flat electronic assemblies, i.e., laminating copper foil on FR4 (woven glass-reinforced epoxy resin sheets) and structuring the copper by lithography and back-etching. In contrast, AM processes are the predominant solution for manufacturing electronic circuits on complex 3D geometries [6].

Radar technology is one of the most important sensing methods for many application fields like air traffic control or geology [7,8]. In automotive, a radar sensor belongs to the important Advanced Driver Assistant System (ADAS) and enables functions like cruise control, collision warning, emergency breaking by distance and velocity measurement, and object detection [9,10]. Front- and back-looking radar sensors are mounted in the front or rear bumper or behind the car’s front grille. Side radar sensors, used for blind-spot detection and lane-change assistance, are often installed in the side mirrors or doors. Therefore, it is important to note that radar sensors must be able to operate under harsh environmental conditions, e.g., low temperatures in winter, rain, snow, and saltwater conditions. They need to be sealed and withstand many large temperature cycles from −40 °C to 85 °C, in accordance with ISO 16750 [11].

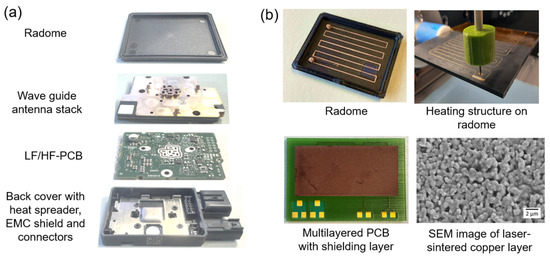

A typical modern radar sensor design is depicted in Figure 1a. A central element is the PCB which includes the low- (LF) and high-frequency (HF) parts of the electronics. On the top side of the PCB, a metallized volume antenna is attached [12,13]. The usage of the volume antenna allows the size of the PCB to be reduced and the HF and LF parts to be combined on one small PCBs, unlike earlier patch antenna designs [14]. The PCB board is inserted into the sensor housing, with the bottom side facing forward. Depending on the range and the integrated data processing, typically between 5 W and 20 W power is dissipated in a radar sensor—with falling tendency due to increasing efficiency.

Figure 1.

(a) Burst schematic of a modern radar sensor. (b) Additively manufactured component of radar sensor (radome with Cu layer using FDM, heating structure using material deposition, and multilayered PCB with shielding layer).

One major driver for power consumption in the radar sensor is data processing for object recognition and tracking [15]. Therefore, thermal management for heat dissipation to keep the operation temperature of the semiconductors below 150 °C is a challenging part of the sensor’s housing design. The heat-producing components, which are located at the back, are connected for heat management via insulating, thermal-conducting heat pads to a metal insert that spreads the heat before it is dissipated by the plastic housing. The metal insert also functions as an HF shield to block electromagnetic waves from the surrounding environment interfering with the HF part of the radar sensor. HF shielding can also be performed by AM, e.g., by metallizing the backside of the electronic board after encapsulating the electronic components using an electric non-conductive material. The primary radome is mounted on top of the antenna and sealed to the housing, protecting antenna, and electronics. Often, a secondary radome, protecting the primary radome from water and ice, is used with integrated heating coils for de-icing in winter. Figure 1b shows the Cu heating structure realized through AM on the inner side of the primary radome. Figure 1b also shows a multilayered PCB with a shielding layer prepared through AM and an SEM image of a laser-sintered Cu layer.

This paper explores the potential of additive manufacturing (AM) for automotive radar sensors, with the primary research focus on the printing of conductive copper traces. The case study selected for investigation was radome heating, chosen due to the significant benefits that can be derived from AM. For optimal radar signal transmission under winter conditions, the de-icing of the radome is achieved via joule heating. Around 5 W of heating power is typically required to defrost the radome in a short span of time, i.e., approximately three minutes. Conventionally, thin metal wires are inserted into grooves on the exterior of the radome. To prevent any potential disturbance to microwave radiation and potential destructive interference, the wires need to maintain a minimal distance of 4 mm. Essentially, as soon as thin metal wires are routed in parallel with a 4 mm distance separation, any possible disturbance is greatly minimized, resulting in a dampening effect of only 1.3 dB [16].

This paper describes an innovative approach, which is the AM of heating coils on the inside of the primary radome. This approach can significantly simplify the manufacturing process and reduce the number of components involved. Implementing the traces on the inner side of the radome makes it possible to connect them directly to the main PCB through standard pins, thus eliminating the need to contact the thin wires. Additionally, the electronic driver board for the heating coil can be eliminated, as this function can be integrated into the main board. Consequently, the number of parts and processes can be significantly reduced, leading to cost savings. In accordance with the cost estimation in reference [4], the AM metallization process is a very competitive process for realizing metal wiring on the surfaces. Different AM technologies for printing the heating traces on the inner side of the radome are investigated in this paper: FDM deposition using conductive filaments, inkjet printing of metal particle-free inks, and dispensing metal pastes [17]. Due to the economic implications of using silver conductive paste, this paper’s approach prioritizes low-cost copper materials.

Important factors for the manufacturing of the radome heating structure are the process temperature, which needs to be below 200 °C, and the electric resistance of the coil. Table 1 lists the state-of-the-art materials along with their applicable AM technology, process temperature, and specific resistance. In particular, the copper inks and pastes enable a low-temperature sintering process after printing, which is facilitated by the use of complexed metal salts. This low-temperature sintering process is achieved by the formation of copper nanoparticles, which are sintered together to form copper traces. The creation of these traces can be achieved either through low-temperature sintering in an oven at approximately 150 °C for roughly 30–60 min or through rapid laser sintering. Both processes have their respective advantages and drawbacks [17]. Integrating the laser into the printing machine is a common approach, permitting trace formation in a single machine prior to radome assembly. Conversely, batch oven sintering provides highly productive manufacturing, negating any costs associated with a high-power laser.

Table 1.

State of the art of conductive materials for additive manufacturing (AM) processes.

2. Materials and Methods

2.1. Materials

For the preparation of the Cu complex ink (Cu particle-free ink), the Cu metal precursor—Cu (II) formate tetrahydrate (Cuf) (98%)—was purchased from Thermo Fischer Scientific, Waltham, MA, USA. The complexing agent—amino-2-propanol (A2P) (93%)—was purchased from Sigma-Aldrich, St. Louis, MO, USA. Particle-stabilizing agents were added to limit particle growth under slow decomposition processes. The viscosity and wetting performance were adjusted by adding further organic solvents (alcohol- and glycol-based). In addition to the Cu complex ink, a dispensable Cu engineering paste was obtained from CuNex GmbH, Ingolstadt, Germany (a startup from the University of Applied Science Ingolstadt). The engineering paste targets pressure sintering applications but was used in this study for pressureless sintering. For initial printability and fabrication pretrials, additive-free PET (Melinex® ST506/505-125 µm) and polyimide (Kapton® HPPST-125 µm) films were obtained from DuPont, Wilmington, NC, USA. The test samples (Cu filaments, polymeric substrates, components, and PCBs) for the radar sensor were provided by Conti Temic Microelectronic GmbH, Ingolstadt, Germany. For the cleaning of substrates, isopropanol (99%) was purchased from Carl Roth, Karlsruhe, Germany.

2.2. Preparation, Application, and Sintering

A Cuf-A2P complex was prepared by mixing Cuf (6 g) and A2P (4.12 mL) in a specific molar ratio of 1:2, based on previous work [21,22]. Stabilizers and application-dependent solvents were added to adjust the viscosity and wettability of the substrate. Both the Cu ink and commercial paste were mixed in a planetary rotary paste mixer (SR500, Thinky Corporation, Tokyo, Japan) for 15 min at 1000 rpm before application. The viscosity and contact angle of the prepared Cu complex ink were measured using a viscometer (Haake TM ViscotesterTM, Thermo Fisher Scientific, Waltham, MA, USA) and a drop shape analyzer (DSA 30E, Kruss Scientific GmbH, Hamburg, Germany).

Before the dispensing or spray-coating of the Cu ink or Cu paste, the substrates were first cleaned using isopropanol, followed by Ar-O2 plasma pretreatment (Zepto PLS, Diener electronic GmbH & Co.KG, Ebhausen, Germany) to remove organic residues. Additionally, plasma pretreatment varied from 1 to 5 min to improve the wettability of the Cu complex ink on the polymeric substrates. The Cu complex ink and Cu paste were dispensed onto the polymeric substrates using a dispenser from Musashi Engineering Europe GmbH, Munich, Germany. The CAD design of the printed structures was added to the Musashi Image Master 350 PC. For the Cu complex ink, the dispensing and spray-coating parameters were as follows: dispensing pressure: 45 kPa; nozzle diameter: 100 µm; spraying distance: 500 µm; tank pressure for spraying: 5 kPa, achieving a uniform trace and film thickness of ~10 µm. For the Cu paste, the dispensing pressure was 150 kPa and the nozzle diameter was 200 µm. The difference in application parameters is mainly due to the difference in viscosity between the Cu ink (Cu is present in the form of Cu ions; particle-free system) and the paste (Cu microparticles).

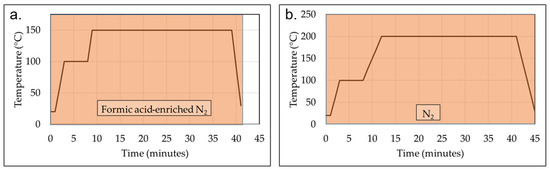

The RSS-160-S reflow oven from UniTemp GmbH, Pfaffenhofen an der Ilm, Germany, was used for the predrying and sintering of the Cu complex ink and Cu paste. The corresponding predrying and sintering profiles for the Cu complex ink and Cu paste are shown in Figure 2. For the Cu complex ink, the peak sintering temperature was 150 °C to facilitate sintering onto low-melting substrates such as PET. Formic acid-enriched N2 was used to prevent surface oxidation in the in situ-formed Cu nanoparticles, since these nanoparticles were < 100 nm, making them highly reactive due to the high surface–volume ratio. For the Cu paste, the peak sintering temperature was 200 °C. Additionally, from the supplier, it was known that the deformation temperature of the radome substrates was <225 °C. Therefore, both materials needed to form conductive sintered Cu metallic traces at a temperature lower than the deformation temperature.

Figure 2.

(a) Predrying and sintering profile of Cu complex ink. (b) Predrying and sintering profile of Cu paste.

Additionally, the laser sintering of the Cu complex inks was performed, ensuring effective sintering without damaging the polymeric substrate, as observed in previous work [23]. These trials were carried out on polyimide substrates. As with oven sintering, the printed traces were first predried at 100 °C for 5 min under air to remove volatile organic solvents that may cause rapid bubbling or degassing during the sintering process. The predried traces were then laser-sintered using an infrared (1064 nm) spot laser (G3 20 W nanosecond pulsed spot laser) supplied by SPI Laser, Rugby, UK. The spot laser can work in continuous-wave and pulsed mode (from 9 ns to 200 ns) with 22 W of maximum power. The expanded laser beam was linked to a galvanometer mirror scanner (Extreme-15-YAG, Nutfield Technology, Londonderry, NH, USA), controlled using SAMLight v3.05 software (SCAPS Gmbh, Oberhaching, Germany). The galvanometer mirror scanner allows the laser beam to move with speeds from 0.01 mm/s to 20,000 mm/s. For FDM (fusion deposition modeling), a 5-axis printer from 5axismaker, London, UK, was used. Commercial filaments were sourced as listed under 3.2.

2.3. Characterization Methods

The optical inspection of the sintered samples was performed using an optical microscope (VHX-900F 3D microscope, Keyence Corporation, Osaka, Japan). An optical profilometer (Nanofocus µ-surf, Nanofocus AG, Oberhausen, Germany) was used to measure the thickness (after printing and sintering) and roughness of the sintered samples. The morphology was investigated and evaluated using a scanning electron microscope (Versa 3D DualBeam FEG FIB-SEM, Thermo Fisher Scientific, Waltham, MA, USA). The bulk resistivity (ρ) of the metallic Cu traces for the radome heating structure was calculated from the thickness of the trace (t) and sheet resistance (Rs) measured using a 4-point probe (Keithley 2461, Keithley Instruments, Cleveland, OH, USA). A standard Tape Test (ASTM D3359) was performed using a pressure sensitive adhesive tape (3M) to evaluate the adhesion quality of the sintered samples [24].

3. Results and Discussion

3.1. Simulation-Driven Heating Structure Design

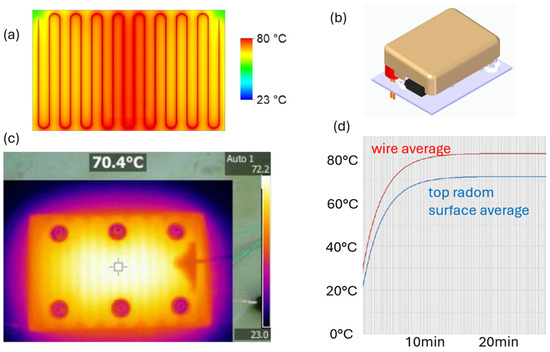

The metallic wires of the heating structure cause the damping of the emitted radar waves. However, the damping can be kept below 1.3 dB when wires of 0.3 mm diameter are routed parallel and spaced more than 4 mm apart [16]. Based on this design input, transient thermal simulations were conducted using SolidWorks Flow (version 2022) to analyze the heating power required for the de-icing of the radome. Natural convection, including radiation, was modeled using external simulation settings, specifically by defining a fluid box around the sensor with atmospheric pressure conditions and air entering at a defined atmospheric temperature. Infrared emissivity was simplified and set to 0.9 for all surfaces, as is typical for painted polymer surfaces. As a requirement, it was specified that the radome must be heated from −40 °C to 5 °C within 3 min. However, the localized overheating of the wire or the radome polymer material must be avoided.

To simplify the electronic driver design, the voltage was considered to be between 8 and 16 V, and the maximum current was restricted to below 3 A. Therefore, a reasonable design to obtain 20 W of heating power using a 10 V driving voltage is a resistance of 5 Ω for the heating coil. Joule heating was simulated by applying the respective 10 V to the end surface of the wire. By adjusting the duty cycle, the heating power could be conveniently varied between 0 W and 20 W. Transient thermal simulation and experimental validation are depicted in Figure 3, showing the heating from room temperature until steady-state conditions were reached. It was demonstrated that heating from −40 °C to 5 °C could be achieved in 3 min using 4 W input power for a radome heater. Validation measurements and simulations were performed under worst-case conditions, i.e., without activating the heat load of the electronic components. The radome in the simulation was from a different radar sensor and approximately twice as large as the one investigated for the AM technologies. Therefore, for heating the smaller radome, 2–3 W of heating power would be sufficient, allowing for an even larger resistance of 30 Ω for the heating coil.

Figure 3.

Transient thermal simulation of radome heating. (a) Radome surface temperature after 10 min for a radome of 90 mm × 58 mm × 3 mm. (b) CAD drawing of the radar sensor. (c) Infrared image of the experimental prototype using wires glued on the radome into CNC-machined grooves. (d) Rise time of average radome surface temperature and average heating wire temperature. The heating power was 4 W. The experimental temperatures were roughly 4 °C below the simulated one which is caused by the fact that the experimental test system was not in a still air box and therefore more air movement could be expected. In addition, the emissivity setting of 0.9 in the simulation might be underestimated.

3.2. Fused Deposition Modeling

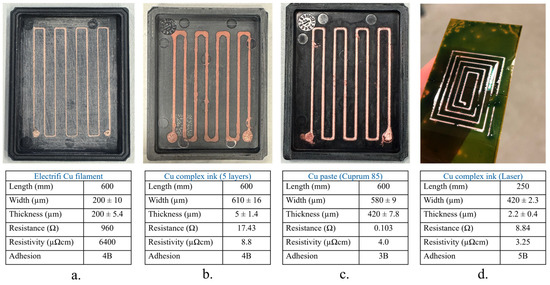

Fused deposition modeling (FDM) is a highly productive AM technology for plastic parts. A polymer fiber is melted and extruded through a heated nozzle. Traces with a width of 0.2 mm can be readily printed using cost-effective printers, including five-axis systems like the 5axismaker, which was employed for prototyping in this paper and is depicted in Figure 4. Conductive filaments are also available; however, the specific resistance of conductive FDM materials is generally quite high. These polymer materials are filled with either carbon or graphite particles or fibers, or with metallic particles. Notably, standard filled filaments are typically non-electrically conductive, even when heavily loaded with metal. Materials from 3DXTECH (Conductive/ESD—PLA), ColorFabb (Bronzefill), ColorFabb (Copperfill), Formfutura (Metalfill Classic Copper), METALFIL (Ancient Bronze), Proto-Pasta (Composite PLA Magnetic Iron), and Proto-Pasta (Composite PLA Stainless Steel) are filled but remain non-conductive. The fillers primarily serve optical purposes, even at high concentrations (e.g., 80% copper). Only three materials were electrically conductive. Materials from Material4Print and Proto-Pasta are designed for ESD protection and offer only very low conductivity. The sole material providing a sufficient low specific resistance of 6000 µΩcm was sourced from Multi3D (Electrifi Filament), which is a non-hazardous, proprietary metal–polymer composite primarily composed of a biodegradable polyester and copper powder. However, the polymer’s melting point is only 125 °C, limiting its use to low-temperature applications.

Figure 4.

FDM five-axis prototype equipment (5axismaker) on the left side, a printed prototype of a meander heating structure in the center, and a parallel heating structure on the right side. The parallel structure was realized because the specific resistance of the conducting FDM filaments was low. A sufficiently small resistance, able to dissipate sufficient power using a 10 V power supply, is not feasible using a single meander structure.

The meander structure depicted in Figure 4, as anticipated, exhibited an excessively high resistance experimentally; specifically, a resistance of 960 Ω was measured. This outcome aligned with expectations based on the datasheet’s specified specific resistance of 6000 µΩcm. Furthermore, it is worth noting that the filament was extruded at a low temperature of 60 °C, while increasing this temperature might further reduce the resistance. The experimentally calculated bulk resistivity of the printed trace was 6400 µΩcm, which is over 3500 times that of bulk copper and consistent with the datasheet. Consequently, the filament was also unsuitable for the heating structure, despite its respectable adhesion rating of 4B.

Therefore, instead of one serial meander structure, a parallel heating structure was designed, achieving a sufficiently low resistance of 20 Ω. However, the trace temperatures became excessively high. The maximum current had to be limited to 100 mA due to the low thermal conductivity, which caused the conductor to exceed the polymer’s melting point. Therefore, solely 0.2 W of heating power could be generated. Multi3D is currently developing new filaments with higher melting temperatures. Thus, it can be concluded that, so far, no suitable filament material has been identified to realize the heating coil on the radome. Nevertheless, given the ongoing developments, it is anticipated that the application of FDM will become feasible in the near future.

3.3. Heating Structure Formed by Copper Ink and Paste

For initial trials to evaluate printability and low-temperature sinterability, the copper complex ink was printed onto a PET substrate. Previous investigations indicated that the onset of the copper reduction process (Cu2+ → Cu1+ → Cu0) is marked by the initiation of the decarboxylation reaction of the copper complex, occurring around 127 °C, where copper nuclei form and grow into copper nanoparticles [16].

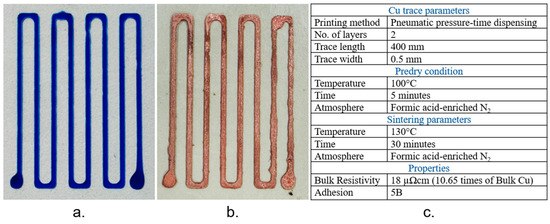

Utilizing a Musashi dispenser, the copper complex ink, with a viscosity of 450 mPa·s and a 15.8 wt.% copper metal content, was printed onto a PET substrate, as illustrated in Figure 5a. Predrying was performed at 100 °C for 5 min under a formic acid-enriched nitrogen atmosphere, followed by low-temperature sintering at 130 °C for 30 min in a reflow oven. The sintered copper trace, after two printing and predrying passes, exhibited a bulk resistivity of 18 µΩcm (10.65 times that of bulk copper) and an adhesion rating of 5B, as shown in Figure 5b.

Figure 5.

Cu complex ink printed and sintered onto a PET substrate. (a) Cu complex ink printed onto a PET substrate. (b) Cu complex ink sintered onto a PET substrate. (c) Printing and processing parameters with Cu trace properties.

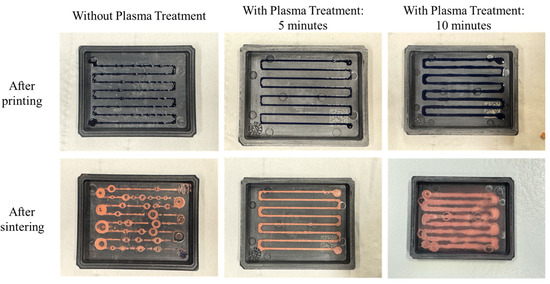

Following the successful realization of conductive copper traces on a PET substrate at a low sintering temperature of 130 °C, the copper complex ink was then printed onto a thicker radome substrate (1 mm). It was observed that the sinterability of the copper complex ink on the radome substrate differed from PET. The significantly greater thickness of the PBT-GF substrate (1 mm vs. 125 µm) increased its thermal mass. This resulted in a longer time for the thicker PBT-GF substrate to heat up and reach a stable temperature during the sintering process. Consequently, the sintering temperature was raised to 150 °C for the radome substrate to achieve a comparable sinterability of the copper complex ink as when using PET. Another challenge encountered was the irregular wetting of the copper complex ink on the radome substrate, as depicted in Figure 6 (left), leading to a discontinuous sintered structure with rapid bubbling (degassing) during sintering. The uneven ink distribution caused gaps or voids in the sintered copper film, compromising its electrical conductivity. To address this issue, an argon–oxygen plasma treatment was performed on the radome substrate for 5 min to enhance the ink’s wettability. The plasma treatment effectively removes contaminants from the radome substrate that impede ink wetting. Additionally, the plasma interacts with the radome substrate’s surface, introducing polar functional groups (such as hydroxyl or carbonyl groups) to elevate the substrate’s surface energy, rendering it more hydrophilic [25,26]. This facilitated the improved spreading and adhesion of the copper ink, resulting in a more uniform and continuous film, as shown in Figure 6 (middle). However, extending the plasma treatment duration to 10 min resulted in the overspreading of the ink, creating unintended connections and short circuits in the sintered structure, as illustrated in Figure 6 (right). The prolonged plasma treatment significantly increased the radome substrate’s surface energy, leading to the excessive wetting of the copper complex ink.

Figure 6.

Effect of substrate plasma pretreatment on ink wettability and Cu metallization after sintering: (left) without plasma treatment; (middle) with plasma treatment for a duration of 5 min; (right) with plasma treatment for a duration of 10 min.

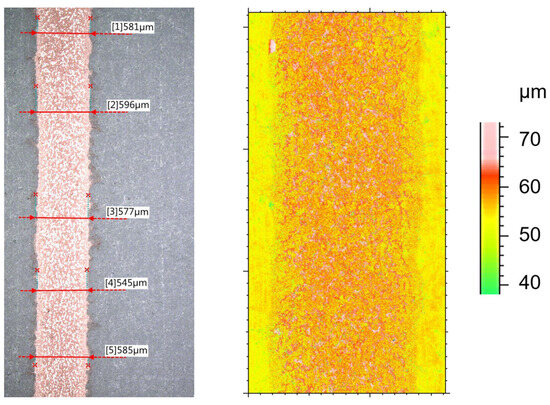

Following the adjustment of wetting through plasma treatment, the dimensions of a five-layer printed and sintered copper metallic trace were analyzed using microscopy and profilometry. The results are presented in Figure 7. A width of 580 µm, with notably smooth edges, and a height of approximately 5–6 µm were measured, which aligns with the dimensional requirements for our heating structure.

Figure 7.

Microscopy and profilometry analysis of the dimensions of a printed and sintered Cu ink.

Assuming a 100% duty cycle for a typical voltage of 10 V, the target electrical resistance should fall within the range of 5–30 Ω to achieve a heating power between 3 W and 20 W. To attain these resistance values, heating structures with specific dimensions were fabricated onto the radome substrate using the copper complex ink and copper paste, as shown in Figure 8a–c, respectively. As previously mentioned, the Multi3D Electrifi conductive copper filament exhibited a resistance of 960 Ω. In the case of the copper complex ink, the sintered structure was formed using five layers of ink, resulting in an overall resistance of 17.43 Ω, which is within the targeted electrical resistance range needed for heating purposes. The bulk resistivity of the sintered traces was 8.8 µΩcm, which is 5.2 times that of bulk copper. However, the adhesion to the radome substrate after sintering was rated as 4B. During the peel test, it was observed that some copper particles on the top layer of the sintered structure did not adhere sufficiently to the trace. This was primarily due to the oven heating process, where heating energy is introduced conductively from the bottom to the top. A similar observation was made after sintering the copper paste, which yielded a resistance of 0.10 Ω and a bulk resistivity of 4.0 µΩcm; however, the adhesion was worse (3B). It is important to note that the copper paste is developed for power electronics applications, involving sintering under low pressure, and not for fully pressureless sintering. Therefore, the results are promising, but further development is necessary. In both cases, using the ink or the paste, applying pressure would be beneficial, as it would allow the copper metallic layers to be sintered from both the top and bottom. This would also improve the densification of the sintered layers and further reduce the specific resistance of the sintered copper. The radome itself has a flat surface where the heating coils are printed, enabling the application of pressure. However, this would introduce additional manufacturing complexity due to the implementation of specific pressure tools, significantly increasing production costs. Furthermore, the application of pressure is generally not feasible for complex 3D applications.

Figure 8.

Cu heating structures prepared using different Cu materials and processes for radome heating structure. (a) Electrifi Cu filament; (b) oven-sintered Cu complex ink (five printed layers); (c) oven-sintered Cu paste; and (d) laser-sintered Cu complex ink.

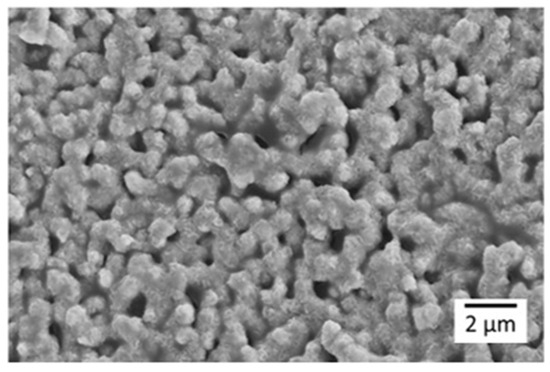

To address the adhesion and resistivity issues, pressureless sintering was performed using a laser. Laser sintering significantly enhanced the properties of the copper complex ink, resulting in lower resistivity (3.25 µΩcm) and optimal adhesion (5B), as depicted in Figure 8d. Laser sintering offers the advantage of achieving higher local temperatures within the copper material. This, coupled with the rapid processing, leads to the formation of smaller particles that are sintered into a denser copper trace.

Various processes were investigated: (1) Spraying the copper complex ink onto a polymeric substrate (polyimide) using the Musashi dispenser equipped with a spray coating tool head. Following drying, the copper trace was sintered using a spot laser with a galvanometric scanner. This method facilitated the direct patterning of copper traces using a CAD file, leveraging the combination of a galvanometer mirror scanner and a laser beam. After the patterning process, any remaining copper complex ink can be washed off using isopropanol in an ultrasonic bath. (2) Patterning the ink, drying, and subsequently sintering with a beam or spot laser profile.

By utilizing laser sintering, selective pressureless sintering can be performed on radome substrates without compromising their structural design or integrity. Further trials are currently underway with laser sintering to evaluate the feasibility of creating finer heating structures with sintered trace widths of 30–40 µm and to achieve more finely sintered structures, as illustrated in Figure 9.

Figure 9.

SEM image of laser-sintered copper layer.

4. Conclusions

This study demonstrated the feasibility of additively manufacturing metal traces as heating structures directly onto the radome of radar sensors. Several additive manufacturing (AM) technologies were evaluated, including fused deposition modeling (FDM), inkjet printing of metal particle-free inks, and dispensing of inks and sinter pastes. FDM, while a productive AM technology for plastic parts, revealed that, so far, no sufficient highly electrically conductive filaments are available. However, further material development is required before FDM can be effectively implemented for printing conductive traces in the near future. This caused the exploration of alternative AM methods for printing the heating structure, utilizing a copper complex ink and a copper paste. Low-cost copper materials are very promising for the AM of electrical wiring, as the material costs significantly impact the AM costs. Both the copper complex ink and copper paste were successfully printed, achieving the targeted specific electrical resistance of below 10 µΩcm. The pressureless oven sintering of the copper traces still exhibited limitations concerning the adhesion of the trace to the substrate. Further material and process development is ongoing to enable the application of pastes and inks without pressure. However, pressureless laser sintering was identified as an effective process, yielding the lowest specific resistivity (3.25 µΩcm) and the best adhesion. Based on these findings, the laser sintering of copper structures using the available copper materials is ready for implementation in patterning traces on 3D polymer structures. Automated AM machines, such as 3D dispensers or inkjet printers with integrated lasers, are readily available. The processing times for creating the heating structures are sufficiently fast, allowing these machines to be integrated into automated assembly lines for sensors.

Author Contributions

Conceptualization, N.M. and G.E.; methodology, N.M.; software, N.M.; validation, N.M., F.S. and G.E.; formal analysis, N.M.; investigation, N.M., F.S. and G.E.; resources, S.W., H.E. and G.E.; data curation, N.M., F.S. and G.E.; writing—original draft preparation, N.M. and G.E.; writing—review and editing, N.M., F.S. and G.E.; visualization, N.M. and G.E.; supervision, G.E.; project administration, H.E. and G.E.; funding acquisition, H.E. and G.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research “Additive Fertigung zur Miniaturisierung Hochperformanter und Robuster Radarsensoren—ADDIRA” was funded by Bayerisches Staatsministerium für Wirtschaft, Landesentwicklung und Energie under grant number DIE-2107-005//DIE0159/01.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank Elena Scheiermann from Conti Temic microelectronics GmbH, Ingolstadt, and Nicola Ballin and Hannes Schwan from the University of Applied Science Ingolstadt for their support of the project. The authors thank Sri Krishna Bhogaraju for providing the copper engineering paste for testing in pressureless sintering applications.

Conflicts of Interest

Authors Sonja Wächter and Hüseyin Erdogan were employed by the company “Continental Autonomous Mobility Germany GmbH”. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Mallaiah, M.; Thapliyal, S.; Bose, S.C. Recent Advances in Additive Manufacturing; Springer Nature: Singapore, 2022; Volume 1, ISBN 978-981-97-6016-9. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Massetti, M.; Zhang, S.; Harikesh, P.C.; Burtscher, B.; Diacci, C.; Simon, D.T.; Liu, X.; Fahlman, M.; Tu, D.; Berggren, M.; et al. Fully 3D-printed organic electrochemical transistors. npj Flex Electron 2023, 7, 11. [Google Scholar] [CrossRef]

- Dong, Y.; Bao, C.; Kim, W.S. Sustainable additive manufacturing of printed circuit boards. Joule 2018, 2, 579–582. [Google Scholar] [CrossRef]

- Lüngen, S.; Tiedje, T.; Meier, K.; Nieweglowski, K.; Bock, K. Reliability of 3D Additive Manufactured Packages. In Proceedings of the 7th Electronic System-Integration Technology Conference (ESTC), Dresden, Germany, 18–21 September 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Tan, H.W.; Tran, T.; Chua, C.K. A Review of Printed Passive Electronic Components through Fully Additive Manufacturing Methods. Virtual Phys. Prototyp. 2016, 11, 271–288. [Google Scholar] [CrossRef]

- Perry, T.S. In Search of the Future of Air Traffic Control. IEEE Spectr. 1997, 34, 18–35. [Google Scholar] [CrossRef]

- Schmullius, C.C.; Evans, D.L. Synthetic Aperture Radar (SAR) Frequency and Polarization Requirements for Applications in Ecology, Geology, Hydrology, and Oceanography: A Tabular Status Quo After SIR-C/X-SAR. Int. J. Remote Sens. 1997, 18, 2713–2722. [Google Scholar] [CrossRef]

- Steigemann, M.; Vaucher, C.S. Modern Radar Sensors in Advanced Automotive Architectures. In Radar for Fully Autonomous Driving; Markel, M., Ed.; Artech House: London, UK, 2022; pp. 3–24. ISBN 9781630818975. [Google Scholar]

- Mohammad, E. Radar Technology. In Advanced Driver Assistance Systems and Autonomous Vehicles from Fundamentals to Applications; Li, E., Shi, H., Eds.; Springer Nature: Singapore, 2022; pp. 265–304. [Google Scholar]

- ISO 16750-1:2023Road Vehicles—Environmental Conditions and Testing for Electrical and Electronic Equipment; International Organization for Standardization: Geneva, Switzerland, 2023.

- Huegel, U.; Garcia-Tejero, A.; Glogowski, R.; Willmann, E.; Pieper, M.; Merli, F. 3D Waveguide Metallized Plastic Antennas Aim to Revolutionize Automotive Radar. Microw. J. 2022, 65, 32. [Google Scholar]

- Jozwicka, M.; Garcia-Tejero, A.; Bekker, E.; Kowalewski, J.; Merli, F.; Zwick, T. 3D Printed Metallized Polymer Slotted Waveguide Antenna Array for Automotive Radar Applications at 140 GHz. In Proceedings of the IEEE/MTT-S International Microwave Symposium—IMS, San Diego, CA, USA, 11–16 June 2023. [Google Scholar] [CrossRef]

- Menzel, W. Antennas in Automobile Radar. In Handbook of Antenna Technologies; Chen, Z., Liu, D., Nakano, H., Qing, X., Zwick, T., Eds.; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Di Fabrizio, G.; Calisti, L.; Contoli, C.; Kania, N.; Lattanzi, E. A Study on the Energy-Efficiency of the Object Tracking Algorithms in Edge Devices. In Proceedings of the IEEE/ACM 16th International Conference on Utility and Cloud Computing (UCC ’23), Taormina, Italy, 4–7 December 2023. [Google Scholar] [CrossRef]

- Momberg, M. Optimierung Eines Beheizten Sekundär-Radoms im Vorverbau für Radarsensoren mit Hilfe Eines Parametrierten Thermischen Simulationsmodells. Bachelor’s Thesis, University of Applied Science Ingolstadt, Ingolstadt, Germany, 2020. [Google Scholar]

- Siah, K.S.; Ramaiya, U.B.; Häußler, F.; Dörfler, M.; Utsch, D.; Voigt, C.; Franke, J.; Erdogan, H. Additively Printed Heating Structure for Radome De-Icing Application. In Proceedings of the 2024 47th International Spring Seminar on Electronics Technology (ISSE), Prague, Czech Republic, 15–19 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Lei, Z.; Chen, Z.; Peng, H.; Shen, Y.; Feng, W.; Liu, Y.; Zhang, Z.; Chen, Y. Fabrication of highly electrical conductive composite filaments for 3D-printing circuits. J. Mater. Sci. 2018, 53, 14495–14505. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.; Wajahat, M.; Ahn, J.; Pyo, J.; Chang, W.S.; Seol, S.K. 3D printing of highly conductive silver architectures enabled to sinter at low temperatures. Nanoscale 2019, 11, 17682–17688. [Google Scholar] [CrossRef]

- Sun, H.; Zettl, J.; Willenbacher, N. Highly conductive and stretchable filament for flexible electronics. Addit. Manuf. 2023, 78, 103872. [Google Scholar] [CrossRef]

- Mohan, N.; Ahuir-Torres, J.; Bhogaraju, S.K.; Webler, R.; Kotadia, H.; Erdoğan, H.; Elger, G. Decomposition Mechanism and Morphological Evolution of in-situ Realized Cu Nanoparticles in Cu Complex Inks. New J. Chem. 2024, 48, 6796–6808. [Google Scholar] [CrossRef]

- Bhogaraju, S.K.; Elger, G.; Conti, F.; Mokhtari, O. Die-Attach Bonding for High Temperature Applications Using Thermal Decomposition of Copper(II) Formate with Polyethylene Glycol. Scr. Mater. 2020, 182, 74–80. [Google Scholar] [CrossRef]

- Mohan, N.; Torres, J.A.; Bhogaraju, S.K.; Kotadia, H.; Elger, G. Rapid Sintering of Inkjet Printed Cu Complex Inks Using Laser in Air. In Proceedings of the 24th European Microelectronics and Packaging Conference & Exhibition (EMPC), Cambridge, UK, 11–14 September 2023; pp. 1–7. [Google Scholar] [CrossRef]

- ASTM D3359-23; Standard Test Methods for Rating Adhesion by Tape Test. ASTM International: West Conshohocken, PA, USA, 2023.

- Vassallo, E.; Cremona, A.; Ghezzi, F.; Ricci, D. Characterization by Optical Emission Spectroscopy of an Oxygen Plasma Used for Improving PET Wettability. Vacuum 2010, 84, 902–906. [Google Scholar] [CrossRef]

- Park, H.Y.; Kang, B.J.; Lee, D.; Oh, J.H. Control of Surface Wettability for Inkjet Printing by Combining Hydrophobic Coating and Plasma Treatment. Thin Solid Film. 2013, 546, 162–166. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).