ML-Based Materials Evaluation in 3D Printing

Abstract

Featured Application

Abstract

1. Introduction

- The lack of standardized protocols for data collection and reporting results in inconsistent datasets that are difficult to integrate or compare;

- Many ML models act as black boxes, making it difficult for researchers to understand and verify their predictions in the context of materials science [16];

- The computational requirements of ML models, especially for large-scale or real-time applications, still constitute a significant barrier to industrial implementation even using cloud technologies—recently, these are increasingly often limitations related to the cost of electricity required for computation [17];

- ML models trained on specific materials, technologies, or printing conditions often fail to generalize to other materials, systems, or environments, which limits their usefulness [18];

- The integration of the knowledge of physics, chemistry, and mechanics specific to a given 3D printing technology and related printing materials with ML algorithms is still underdeveloped, leading to gaps in the accuracy and reliability of predictions;

- Predicting interactions and optimizing parameters for multi-material or composite 3D printing remains a major challenge;

- Limited research has investigated the role of ML in assessing the environmental impact, recyclability, and life cycle of 3D printing materials;

2. Materials and Methods

2.1. Dataset

- RQ1: what is the most common origin of publications (institutions, country, if possible, funding mode)?

- RQ2: who are the most influential authors and what are their articles?

- RQ3: what are the most popular topics, and, if possible, how are the research topics evolving?

- RQ4: what Sustainable Development Goals (SDGs) are related to the publications included in the review?

2.2. Methods

3. Results

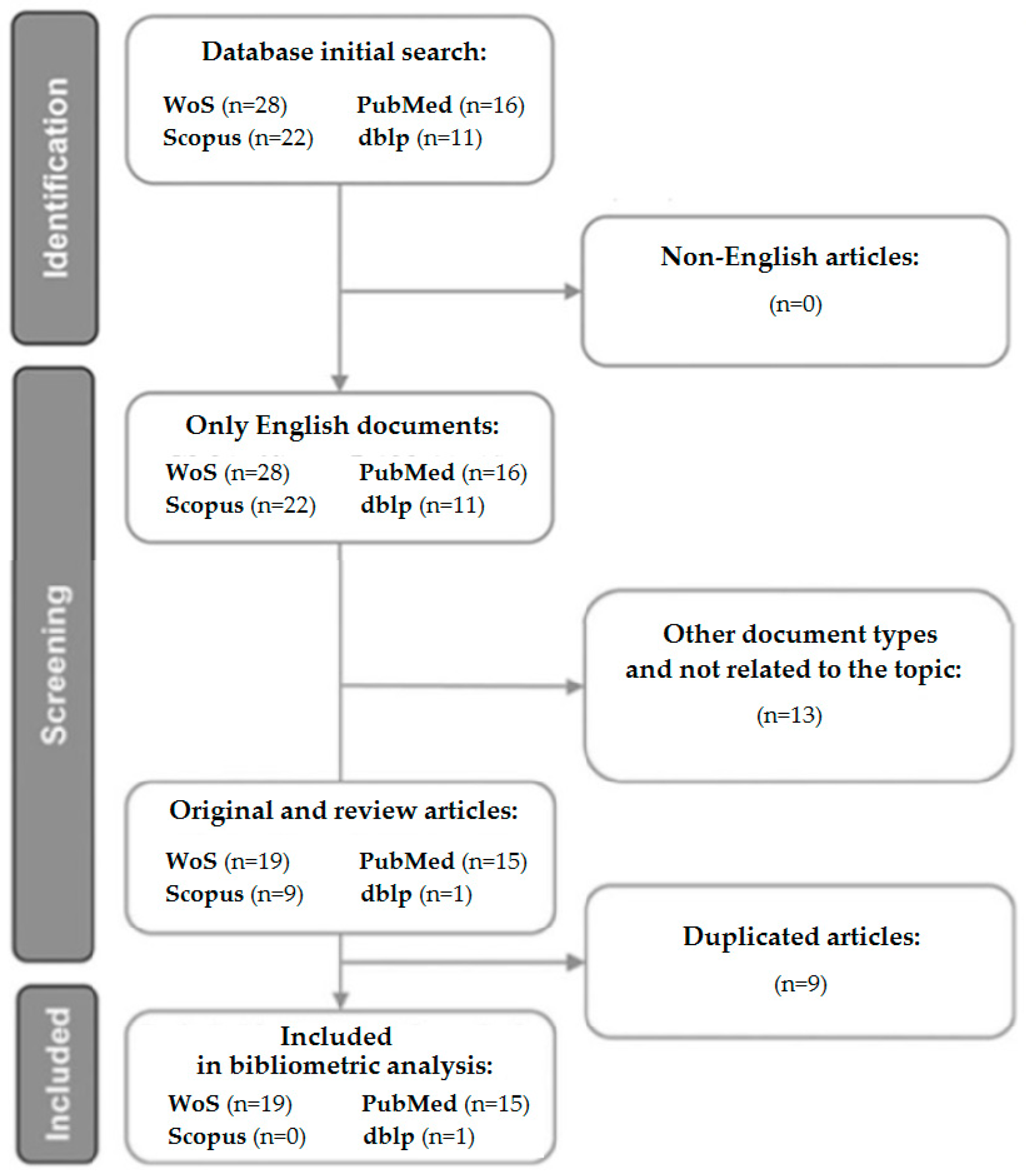

3.1. Data Sources

3.2. General Results of Analysis

- The better or alternative use of existing materials, including improving material preparation procedures to improve the quality, efficiency, and sustainability (energy costs, waste, gases) of printing;

- The development of currently used materials (bio-ink, composites, multi-material printing materials);

- The development of completely new materials (e.g., nanomaterials), complementary or alternative to the current ones.

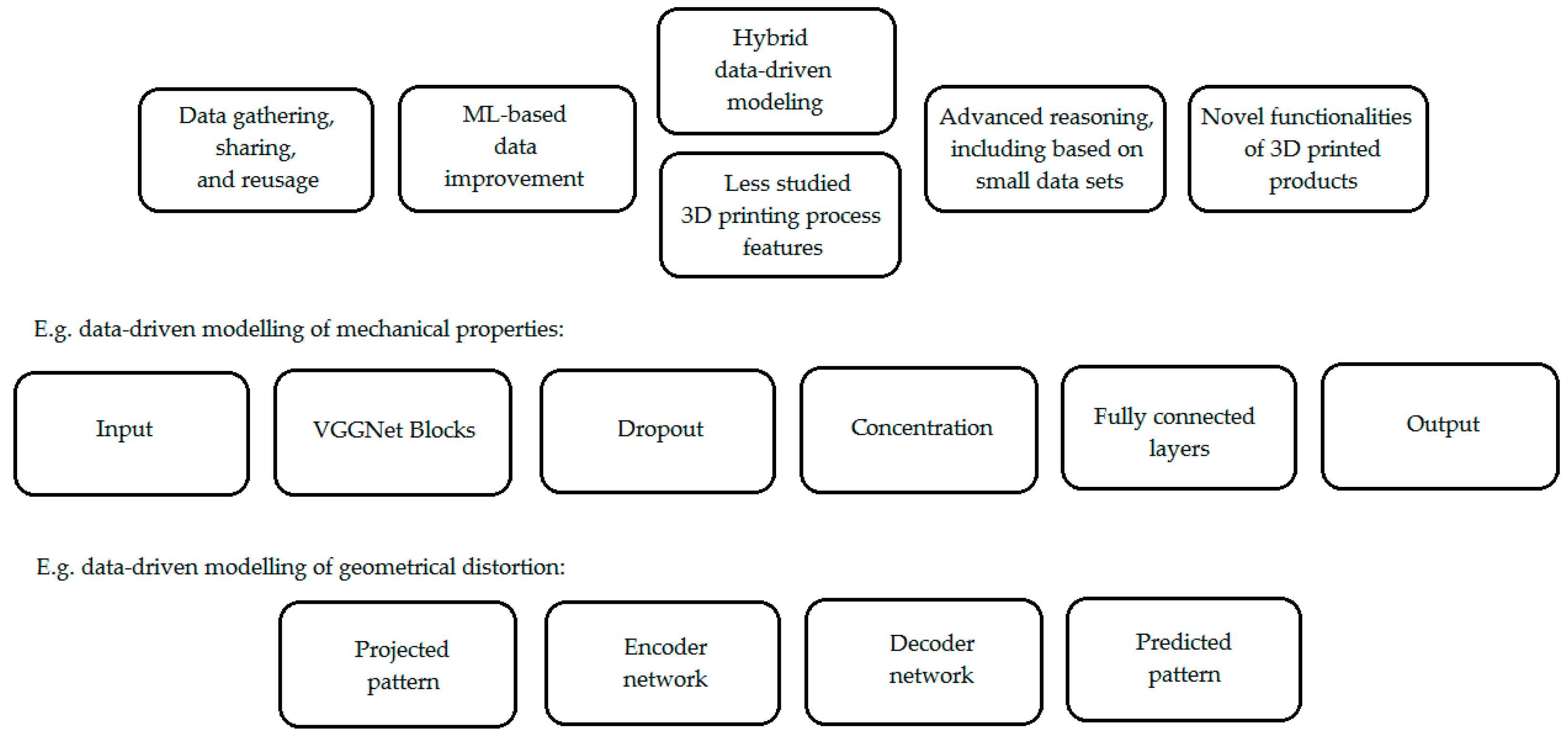

- The modeling of mechanical properties of products, combining the actual microstructure (as input to the network) with descriptors of the structure properties within the network;

- The modeling of geometrical distortions, where a convolutional neural network with an encoder and decoder allows for explicit modeling of geometric distortions of the entire printable shape.

3.3. Detailed Results of Review

4. Discussion

4.1. State-of-the-Art Summary

- ML can rapidly analyze data to discover new materials, reducing development time from years to months;

- By tailoring material properties to specific applications, ML enables highly specialized solutions in various industries such as aerospace and healthcare;

- ML optimizes material usage, minimizing waste and promoting the development of recyclable or bio-based materials;

- Algorithms optimize printing parameters in real time, leading to fewer defects and higher quality results;

- Automated optimization reduces trial-and-error experiments, lowering material and energy costs;

- ML requires vast amounts of high-quality data that can be difficult or expensive to acquire and maintain;

- Poorly trained models can introduce biases or inaccuracies, leading to suboptimal material properties or printing failures;

- As ML integrates with IoT and cloud systems, security flaws can expose proprietary material designs to cyberattacks;

- Models optimized for narrow scenarios may not generalize well to other applications, limiting versatility;

- ML integration requires skilled personnel and advanced infrastructure, which is a challenge for smaller companies;

- The automated development of advanced materials raises concerns about misuse in areas such as weapons or surveillance;

4.2. Limitations

4.3. Directions for Further Studies

- prioritize the development of large, standardized datasets that integrate material properties, printing parameters, and results to enable more robust and transferable models;

- develop physics-based machine learning that combines domain knowledge with data-driven methods to improve accuracy and interpretability;

- improve real-time monitoring and adaptive control using machine learning can enable dynamic tuning of printing parameters to achieve consistent material quality;

- develop multimodal learning that combines imaging, sensor data, and numerical simulations and can help to more holistically assess complex material behaviors;

- focus on interpretable AI to ensure that materials scientists can trust and understand machine learning-based insights;

- develop scalable inverse design framework to automate the discovery of new materials with tailored multifunctional properties;

- integrate sustainability metrics with machine learning assessment can promote eco-friendly materials and reduce waste in 3D printing within all three main stages of ML-modeling: input features, data-driven models, and output (quantity of interests) [96].

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile-butadiene-styrene |

| AI | Artificial intelligence |

| FDM | Fused deposition modeling |

| FFF | Fused filament fabrication |

| FRE | Free-form reversible deposition |

| L-PBF | Laser powder fusion |

| ML | Machine learning |

| PLA | Polylactid acid |

| rPLA | Recycled polylactid acid |

| XAI | eXplainable artificial intelligence |

References

- Rojek, I.; Dostatni, E.; Mikołajewski, D.; Pawłowski, L.; Wegrzyn-Wolska, K. Modern approach to sustainable production in the context of Industry 4.0. Bull. Pol. Acad. Sci. Tech. Sci. 2022, 70, e143828. [Google Scholar] [CrossRef]

- Peed, E.; Lee, N. 3D Printing, History of. In Encyclopedia of Computer Graphics and Games; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Peed, E.; Lee, N. Open Source 3D Printing, History of. In Encyclopedia of Computer Graphics and Games; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Grierson, D.; Rennie, A.E.W.; Quayle, S.D. Machine Learning for Additive Manufacturing. Encyclopedia 2021, 1, 576–588. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Visan, A.I.; Ristoscu, C.; Mihailescu, I.N. Artificial Neural Network Algorithms for 3D Printing. Materials 2021, 14, 163. [Google Scholar] [CrossRef]

- Ghimire, R.; Raji, A. Use of Artificial Intelligence in Design, Development, Additive Manufacturing, and Certification of Multifunctional Composites for Aircraft, Drones, and Spacecraft. Appl. Sci. 2024, 14, 1187. [Google Scholar] [CrossRef]

- Shine, K.M.; Schlegel, L.; Ho, M.; Boyd, K.; Pugliese, R. From the ground up: Understanding the developing infrastructure and resources of 3D printing facilities in hospital-based settings. 3D Print. Med. 2022, 8, 21. [Google Scholar] [CrossRef] [PubMed]

- Hellman, S.; Frisch, P.; Platzman, A.; Booth, P. 3D Printing in a hospital: Centralized clinical implementation and applications for comprehensive care. Digit. Health 2023, 9, 1–12. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Kopowski, J. Specificity of 3D Printing and AI-Based Optimization of Medical Devices Using the Example of a Group of Exoskeletons. Appl. Sci. 2023, 13, 1060. [Google Scholar] [CrossRef]

- Zhang, S.-U. Classifying Thermal Degradation of Polylactic Acid by Using Machine Learning Algorithms Trained on Fourier Transform Infrared Spectroscopy Data. Appl. Sci. 2020, 10, 7470. [Google Scholar] [CrossRef]

- Karna, A.; Gibert, K. From Clustering to Intelligent Decision Support System: An Application to 3D Printing. In Artificial Intelligence Research and Development; IOS Press: Amsterdam, The Netherlands, 2024; pp. 194–203. [Google Scholar]

- Bonacorsi, F.; Capelli, S.; Locatelli, F.; Todeschini, M.; Marconi, S.; Vitali, A.; Lanzarone, E. Communication and Decision Support Tool for an In-Hospital 3D Printing Service. dHealth 2022, 293, 52–58. [Google Scholar]

- Tsai, C.A.; Yeh, C.C. Understanding the decision rules for 3D printing adoption. Technol. Anal. Strateg. Manag. 2019, 31, 1104–1117. [Google Scholar]

- Jignasu, A.; Marshall, K.O.; Kumar Mishra, A.; Rillo, L.N.; Ganapathysubramanian, B.; Balu, A.; Hegde, C.; Krishnamurthy, A. Slice-100K: A Multimodal Dataset for Extrusion-based 3D Printing. arXiv 2024, arXiv:2407.04180. [Google Scholar]

- Paramartha Putra, M.A.; Chijioke Ahakonye, L.A.; Verana, M.; Rachmawati, S.M.; Sampedro, G.A.R.; Kim, D.S.; Lee, J.M. 3DVis: A Layer-wise Fused Deposition Modeling 3D Printer Fault Detection Dataset. IEEE DataPort 2023. Available online: https://ieee-dataport.org/documents/3dvis-layer-wise-fused-deposition-modeling-3d-printer-fault-detection-dataset (accessed on 11 May 2025).

- Yoo, Y. Thermal imaging-based diagnostic process using explainable artificial intelligence for 3D printing system. Soft Comput. 2024, 28, 6741–6752. [Google Scholar] [CrossRef]

- Chen, J.V.; Dang, A.B.C.; Dang, A. Comparing cost and print time estimates for six commercially-available 3D printers obtained through slicing software for clinically relevant anatomical models. 3D Print. Med. 2021, 7, 1. [Google Scholar] [CrossRef]

- Agarwal, P.; Arora, G.; Panwar, A.; Mathur, V.; Srinivasan, V.; Pandita, D.; Vasanthan, K.S. Diverse Applications of Three-Dimensional Printing in Biomedical Engineering: A Review. 3D Print. Addit. Manuf. 2023, 10, 1140–1163. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Kotlarz, P.; Tyburek, K.; Kopowski, J.; Dostatni, E. Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials 2021, 14, 7625. [Google Scholar] [CrossRef]

- Verma, D.; Dong, Y.; Sharma, M.; Chaudhary, A.K. Advanced processing of 3D printed biocomposite materials using artificial intelligence. Mater. Manuf. Process. 2021, 36, 518–538. [Google Scholar]

- Erps, T.; Foshey, M.; Luković, M.K.; Shou, W.; Goetzke, H.H.; Dietsch, H.; Stoll, K.; von Vacano, B.; Matusik, W. Accelerated discovery of 3D printing materials using data-driven multiobjective optimization. Sci. Adv. 2021, 7, eabf7435. [Google Scholar] [CrossRef] [PubMed]

- Sampedro, G.A.R.; Rachmawati, S.M.; Kim, D.-S.; Lee, J.-M. Exploring Machine Learning-Based Fault Monitoring for Polymer-Based Additive Manufacturing: Challenges and Opportunities. Sensors 2022, 22, 9446. [Google Scholar] [CrossRef]

- Shahar, F.S.; Sultan, M.T.H.; Grzejda, R.; Łukaszewicz, A.; Oksiuta, Z.; Krishnamoorthy, R.R. Harnessing the Potential of Natural Composites in Biomedical 3D Printing. Materials 2024, 17, 6045. [Google Scholar] [CrossRef]

- Albelo, I.; Raineri, R.; Salmon, S. Materials and Methods for All-Cellulose 3D Printing in Sustainable Additive Manufacturing. Sustain. Chem. 2024, 5, 98–115. [Google Scholar] [CrossRef]

- O’Connor, H.A.; Adams, L.W.; MacFadden, L.N.; Skelley, N.W. 3D Printed Orthopaedic External Fixation Devices: A Systematic Review. 3D Print. Med. 2023, 9, 15. [Google Scholar] [CrossRef]

- Assad, H.; Assad, A.; Kumar, A. Recent Developments in 3D Bio-Printing and Its Biomedical Applications. Pharmaceutics 2023, 15, 255. [Google Scholar] [CrossRef]

- Mirkhalaf, M.; Men, Y.; Wang, R.; No, Y.; Zreiqat, H. Personalized 3D printed bone scaffolds: A review. Acta Biomater. 2023, 156, 110–124. [Google Scholar] [CrossRef] [PubMed]

- Beitler, B.G.; Abraham, P.F.; Glennon, A.R.; Tommasini, S.M.; Lattanza, L.L.; Morris, J.M.; Wiznia, D.H. Interpretation of regulatory factors for 3D printing at hospitals and medical centers, or at the point of care. 3D Print. Med. 2022, 8, 7. [Google Scholar] [CrossRef] [PubMed]

- Huanbutta, K.; Burapapadh, K.; Sriamornsak, P.; Sangnim, T. Practical Application of 3D Printing for Pharmaceuticals in Hospitals and Pharmacies. Pharmaceutics 2023, 15, 1877. [Google Scholar] [CrossRef]

- García-Domínguez, A.; Claver, J.; Camacho, A.M.; Sebastián, M.A. Analysis of General and Specific Standardization Developments in Additive Manufacturing From a Materials and Technological Approach. IEEE Access 2020, 8, 125056–125075. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Park, Y.H. Highly Productive 3D Printing Process to Transcend Intractability in Materials and Geometries via InteractiveMachine-Learning-Based Technique. Adv. Intell. Syst. 2023, 5, 7. [Google Scholar] [CrossRef]

- Ghosh, S.; Johnson, M.V.; Neupane, R.; Hardin, J.; Berrigan, J.D.; Kalidindi, S.R.; Kong, Y.L. Machine learning-enabled feature classification of evaporation-driven multi-scale 3D printing. Flex. Print. Electron. 2022, 7, 014011. [Google Scholar]

- Pardakhti, M.; Chang, S.Y.; Yang, Q.; Ma, A.W.K. Efficient Creation of Jettability Diagrams Using Active Machine Learning. 3D Print.Addit. Manuf. 2024, 11, 1407–1417. [Google Scholar] [CrossRef]

- Jain, A.; Armstrong, C.D.; Joseph, V.R.; Ramprasad, R.; Qi, H.J. Machine-Guided Discovery of Acrylate Photopolymer Compositions. ACS Appl. Mater. Interfaces 2024, 16, 17992–18000. [Google Scholar] [CrossRef] [PubMed]

- Ulkir, O. Conductive Additive Manufactured Acrylonitrile Butadiene Styrene Filaments: Statistical Approach to Mechanical and Electrical Behaviors. 3D Print. Addit. Manuf. 2023, 10, 1423–1438. [Google Scholar] [CrossRef]

- Petrich, J.; Reutzel, E.W. Automated Defect Recognition for Additive Manufactured Parts Using Machine Perception and Visual Saliency. 3D Print. Addit. Manuf. 2023, 10, 406–419. [Google Scholar] [CrossRef]

- Charalampous, P.; Kladovasilakis, N.; Tzovaras, D. Machine Learning-Based Mechanical Behavior Optimization of3D Print Constructs Manufactured Via the FFF Process. J. Mater. Eng. Perform. 2022, 31, 4697–4706. [Google Scholar] [CrossRef]

- Menon, A.; Póczos, B.; Washburn, N.R. Optimization of Silicone 3D Printing with HierarchicalMachine Learning. 3D Print. Addit. Manuf. 2019, 6, 181–189. [Google Scholar]

- Abdullah, A.C.; Ozarslan, O.; Tasoglu, S. Machine learning-enabled optimization of melt electro-writing three-dimensional printing. Aggregate 2024, 5, e495. [Google Scholar] [CrossRef]

- Baldwin, M.; Meisel, N.A.; Mccomb, C. Smooth Like Butter: Evaluating Multi-lattice Transitions in Property-Augmented Latent Spaces. 3D Print. Addit. Manuf. 2024, 12, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Baldwin, M.; Meisel, N.A.; McComb, C. Smoothing the Rough Edges: Evaluating Automatically Generated Multi-Lattice Transitions. 3D Print. Addit. Manuf. 2024, 11, e1555–e1566. [Google Scholar]

- Luo, Q.X.; Shimanek, J.D.; Beese, A.M. An Image-Based Transfer Learning Approach for Using In Situ Processing Data to Predict Laser Powder Bed Fusion Additively Manufactured Ti-6Al-4V Mechanical Properties. 3D Print. Addit. Manuf. 2024, 12, 48–60. [Google Scholar] [CrossRef]

- Rittig, T.; Sumin, D.; Krivánek, J. Neural Acceleration of Scattering-Aware Color 3D Printing. Comput. Graph. Forum 2021, 40, 205–219. [Google Scholar] [CrossRef]

- Rais, M.H.; Ahsan, M.; Ahmed, I. Sabotaging Material Extrusion-Based 3D Printed Parts through Low-Magnitude Kinetic Manipulation Attacks. ACM Trans. Cyber Phys. Syst. 2025, 9, 5:1–5:26. [Google Scholar] [CrossRef]

- Zeng, S.; Zhang, R.; Cai, Y. Research on Digital Morphogenesis and Sustainability of 3D Printing Bionic Materials Based on Convolutional Neural Networks. IEEE Access 2024, 12, 80418–80428. [Google Scholar] [CrossRef]

- Armstrong, C.D.; Macrae Montgomery, S.; Yue, L.; Demoly, F.; Zhou, K.; Qi, H. Robotic Conformal Material Extrusion 3D Printing for Appending Structures on Unstructured Surfaces. Adv. Intell. Syst. 2024, 6, 2300516. [Google Scholar] [CrossRef]

- Chapinal-Heras, D.; Díaz-Sánchez, C.; Gómez-García, N.; España-Chamorro, S.; Pagola-Sánchez, L.; Parada López de Corselas, M.; Rey-Álvarez Zafiria, M.E. Photogrammetry, 3D modelling and printing: The creation of a collection of archaeological and epigraphical materials at the university. Digit. Appl. Archaeol. Cult. Herit. 2024, 33, e00341. [Google Scholar] [CrossRef]

- Montalti, A.; Ferretti, P.; Santi, G.M. A Cost-effective approach for quality control in PLA-based material extrusion 3D printing using 3D scanning. J. Ind. Inf. Integr. 2024, 41, 100660. [Google Scholar] [CrossRef]

- Castillo, M.; Monroy, R.; Ahmad, R. Scientometric analysis and systematic review of smart manufacturing technologies applied to the 3D printing polymer material extrusion system. J. Intell. Manuf. 2024, 35, 3–33. [Google Scholar] [CrossRef]

- Humbert, C.; Barriol, M.; Deniz Varsavas, S.; Nicolay, P.; Brandstötter, M. A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating. Sensors 2024, 24, 3854. [Google Scholar] [CrossRef]

- Kocsis, B.; Orosz, T. Frequency- and Temperature-Dependent Uncertainties in Hysteresis Measurements of a 3D-Printed FeSi wt6.5% Material. Sensors 2024, 24, 2738. [Google Scholar] [CrossRef] [PubMed]

- Bell, F.; Mcclure, E.; Friedman-Gerlicz, C.; Ta, R.; Buechley, L. Shape-Changing Clay-Dough: Taking a Material-Oriented Approach to 3D Printing Ceramic Forms. In CHI’24: Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 11–16 May 2024; Association for Computing Machinery: New York, NY, USA, 2024; pp. 864:1–864:19. [Google Scholar]

- Moon, K.J.; Marciniak, Z.; Suzuki, R.; Bianchi, A. 3D Printing Locally Activated Visual-Displays Embedded in 3D Objects via Electrically Conductive and Thermochromic Materials. In CHI’24: Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 11–16 May 2024; Association for Computing Machinery: New York, NY, USA, 2024; pp. 343:1–343:15. [Google Scholar]

- Hering, M.; Höving, S.; Schilling, M. 3D-Printed Robust Ground Contact Sensors for Haptic Feedback Using Functional Materials. In Walking Robots into Real World. CLAWAR 2024; Springer: Cham, Switzerland, 2024; Volume 1115, pp. 119–130. [Google Scholar]

- Kotseva, G.; Stoimenov, N.; Gyoshev, S.; Georgieva, V. Tribological Processes in TPU and HIPS 3D Printing Materials. In Proceedings of the2024 18th International Conference on Control, Automation, Robotics and Vision (ICARCV), Dubai, United Arab Emirates, 12–15 December 2024; pp. 1136–1141. [Google Scholar]

- Naveed, N.; Naveed Anwar, M. Sustainable Manufacturing through Digital Multi-Material 3D Printing. In Proceedings of the 2024 29th International Conference on Automation and Computing (ICAC), Sunderland, UK, 28–30 August 2024; pp. 1–5. [Google Scholar]

- Fournier-Le Ray, N.; Fillaut, J.L.; Mhanna, R.; Abdallah, S.; Malval, J.P. Surface post-modifications of 3D-printed micro/nano-materials. In Proceedings of the 2024 24th International Conference on Transparent Optical Networks (ICTON), Bari, Italy, 14–18 July 2024; pp. 1–4. [Google Scholar]

- Özbek, D.; Alalawi, M.; Eckroth, T.M.; Wessely, M. Demonstration of AcceloPrint: Fabricating Accelerometers with Multi-Material 3D Printing. In SCF Adjunct‘24: Adjunct Proceedings of the 9th ACM Symposium on Computational Fabrication, Aarhus, Denmark, 7–10 July 2024; Association for Computing Machinery: New York, NY, USA, 2024; pp. 8:1–8:3. [Google Scholar]

- Ashbrook, D.; Lin, W.J.; Bentley, N.; Soponar, D.; Yan, Z.; Savage, V.; Cheng, L.P.; Peng, H.; Kim, H. Rhapso: Automatically Embedding Fiber Materials into 3D Prints for Enhanced Interactivity. In UIST’24: Proceedings of the 37th Annual ACM Symposium on User Interface Software and Technology, Pittsburgh, PA, USA, 13–16 October 2024; Association for Computing Machinery: New York, NY, USA, 2024; pp. 120:1–120:20. [Google Scholar]

- Goshtasbi, A.; Grignaffini, L.; Sadeghi, A. From Problem to Solution: Bio-inspired 3D Printing for Bonding Soft and Rigid Materials via Underextrusions. arXiv 2024, arXiv:2408.01210. [Google Scholar]

- Tajwar Shahid, S. Modeling of non-planar slicer for improved surface quality in material extrusion 3D printing. arXiv 2024, arXiv:2411.07225. [Google Scholar]

- Rais, M.H.; Ahsan, M.; Ahmed, I. FRoMEPP: Digital forensic readiness framework for material extrusion based 3D printing process. Forensic Sci. Int. Digit. Investig. 2023, 44, 301510. [Google Scholar]

- Xie, G.; Wang, K.; Wu, X.; Wang, J.; Li, T.; Peng, Y.; Zhang, H. A hybrid multi-stage decision-making method with probabilistic interval-valued hesitant fuzzy set for 3D printed composite material selection. Eng. Appl. Artif. Intell. 2023, 123 Pt C, 106483. [Google Scholar] [CrossRef]

- Paśnikowska-Łukaszuk, M.; Szulżyk-Cieplak, J.; Wlazło, M.; Zubrzycki, J.; Łazuka, E.; Urzędowski, A.; Suchorab, Z. The Use of 3D Printing Filaments to Build Moisture Sensors in Porous Materials. Materials 2025, 18, 115. [Google Scholar] [CrossRef]

- Szczupak, E.; Małysza, M.; Wilk-Kołodziejczyk, D.; Jaśkowiec, K.; Bitka, A.; Głowacki, M.; Marcjan, Ł. Decision Support Tool in the Selection of Powder for 3D Printing. Materials 2024, 17, 1873. [Google Scholar] [CrossRef]

- Zhou, D.; Yang, Y.; Rao, W.F. 3D Printed Magnetoelectric Composites for Personalized Wearable Multifunctional Sensors. 3D Print. Addit. Manuf. 2024, 11, 1016–1024. [Google Scholar] [CrossRef] [PubMed]

- Tamo, A.K.; Tran, T.A.; Doench, I.; Jahangir, S.; Lall, A.; David, L.; Peniche-Covas, C.; Walther, A.; Osorio-Madrazo, A. 3D Printing of Cellulase-Laden Cellulose Nanofiber/Chitosan Hydrogel Composites: Towards Tissue Engineering Functional Biomaterials with Enzyme-Mediated Biodegradation. Materials 2022, 15, 6039. [Google Scholar] [CrossRef] [PubMed]

- Jakus, A.E.; Shah, R.N. Multi and mixed 3D-printing of graphene-hydroxyapatite hybrid materials for complex tissue engineering. J. Biomed. Mater. Res. A 2017, 105, 274–283. [Google Scholar] [CrossRef]

- Zazoum, B.; Triki, E.; Bachri, A. Modeling of mechanical properties of clay-reinforced polymer nanocomposites using deep neural network. Materials 2020, 13, 4266. [Google Scholar]

- Liu, Y.; Yuan, Y.; Balta, C.; Liu, J. A light-weight deep-learning model with multi-scale features for steel surface defect classification. Materials 2020, 13, 4629. [Google Scholar] [CrossRef]

- Wu, D.; Luo, Q.; Long, W.; Zhang, S.; Geng, S. Advancing Construction 3D Printing with Predictive Interlayer Bonding Strength: A Stacking Model Paradigm. Materials 2024, 17, 1033. [Google Scholar] [CrossRef]

- Hooshmand, M.J.; Sakib-Uz-Zaman, C.; Khondoker, M.A.H. Machine Learning Algorithms for Predicting Mechanical Stiffness of Lattice Structure-Based Polymer Foam. Materials 2023, 16, 7173. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Riaz, R.D.; Malik, U.J.; Abbas, S.B.; Usman, M.; Shah, M.U.; Kim, I.-H.; Hanif, A.; Faizan, M. Machine Learning-Based Predictive Model for Tensile and Flexural Strength of 3D-Printed Concrete. Materials 2023, 16, 4149. [Google Scholar] [CrossRef]

- Pandeya, S.P.; Zou, S.; Roh, B.-M.; Xiao, X. Programmable Thermo-Responsive Self-Morphing Structures Design and Performance. Materials 2022, 15, 8775. [Google Scholar] [CrossRef]

- Kuschmitz, S.; Ring, T.P.; Watschke, H.; Langer, S.C.; Vietor, T. Design and Additive Manufacturing of Porous Sound Absorbers—A Machine-Learning Approach. Materials 2021, 14, 1747. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Mroziński, A.; Macko, M. Machine Learning- and Artificial Intelligence-Derived Prediction for Home Smart Energy Systems with PV Installation and Battery Energy Storage. Energies 2023, 16, 6613. [Google Scholar] [CrossRef]

- Qi, X.; Chen, G.; Li, Y.; Cheng, X.; Li, C. Applying Neural-Network-Based Machine Learning to Additive Manufacturing: Current Applications, Challenges, and Future Perspectives. Engineering 2019, 5, 721–729. [Google Scholar]

- Grimaldo Ruiz, O.; Rodriguez Reinoso, M.; Ingrassia, E.; Vecchio, F.; Maniero, F.; Burgio, V.; Civera, M.; Bitan, I.; Lacidogna, G.; Surace, C. Design and Mechanical Characterization Using Digital Image Correlation of Soft Tissue-Mimicking Polymers. Polymers 2022, 14, 2639. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, Z.; Long, J.; Li, C.; Bai, Y. Dynamic condition monitoring for 3D printers by using error fusion of multiple sparse auto-encoders. Comput. Ind. 2019, 105, 164–176. [Google Scholar]

- Zhang, S.; Sun, Z.; Wang, M.; Long, J.; Bai, Y.; Li, C. Deep Fuzzy Echo State Networks for Machinery Fault Diagnosis. IEEE Trans. Fuzzy Syst. 2020, 28, 1205–1218. [Google Scholar] [CrossRef]

- Szymanik, B.; Psuj, G.; Hashemi, M.; Lopato, P. Detection and identification of defects in 3D-printed dielectric structures via thermographic inspection and deep neural networks. Materials 2021, 14, 4168. [Google Scholar] [CrossRef]

- Czeczot, G.; Rojek, I.; Mikołajewski, D.; Sangho, B. AI in IIoT Management of Cybersecurity for Industry 4.0 and Industry 5.0 Purposes. Electronics 2023, 12, 3800. [Google Scholar] [CrossRef]

- Costa, C.M.d.; Baltus, P. Design Methodology for Industrial Internet-of-Things Wireless Systems. IEEE Sens. J. 2021, 21, 5529–5542. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. Additive Manufacturing Modification by Artificial Intelligence, Machine Learning, and Deep Learning: A Review. Addit. Manuf. Front. 2025, 4, 200198. [Google Scholar] [CrossRef]

- Bhushan, B.; Caspers, M. An overview of additive manufacturing (3D printing) for microfabrication. Microsyst. Technol. 2017, 23, 1117–1124. [Google Scholar] [CrossRef]

- Corradini, F.; Silvestri, M. A digital twin based self-calibration tool for fault prediction of fdm additive manufacturing systems. Ann. DAAAM Proc. 2021, 10, 607–616. [Google Scholar]

- Lambos, N.; Vosniakos, G.C.; Papazetis, G. Low-cost automatic identification of nozzle clogging in material extrusion 3D printers. Procedia Manuf. 2020, 51, 274–279. [Google Scholar]

- Tlegenov, Y.; Lu, W.F.; Hong, G.S. A dynamic model for current-based nozzle condition monitoring in fused deposition modelling. Prog. Addit. Manuf. 2019, 4, 211–223. [Google Scholar] [CrossRef]

- Grira, S.; Mozumder, M.S.; Mourad, A.-H.I.; Ramadan, M.; Khalifeh, H.A.; Alkhedher, M. 3D bioprinting of natural materials and their AI-Enhanced printability: A review. Bioprinting 2025, 46, e00385. [Google Scholar] [CrossRef]

- Rojek, I.; Kopowski, J.; Lewandowski, J.; Mikołajewski, D. Use of Machine Learning to Improve Additive Manufacturing Processes. Appl. Sci. 2024, 14, 6730. [Google Scholar] [CrossRef]

- Monaco, C.; Kronenberger, R.; Talevi, G.; Pannone, L.; Cappello, I.A.; Candelari, M.; Ramak, R.; Della Rocca, D.G.; Bori, E.; Terryn, H.; et al. Advancing Surgical Arrhythmia Ablation: Novel Insights on 3D Printing Applications and Two Biocompatible Materials. Biomedicines 2024, 12, 869. [Google Scholar] [CrossRef]

- Jauk, J.; Vašatko, H.; Gosch, L.; Ristoski, K.; Füssl, J.; Stavric, M. Coextrusion of Clay-Based Composites: Using a Multi-Material Approach to Achieve Gradient Porosity in 3D-Printed Ceramics. Ceramics 2023, 6, 2243–2255. [Google Scholar] [CrossRef]

- Prasittisopin, L. How 3D Printing Technology Makes Cities Smarter: A Review, Thematic Analysis, and Perspectives. Smart Cities 2024, 7, 3458–3488. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers 2023, 15, 4688. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Liu, Q.; Zhao, Y.; Liu, P.; Wu, D.; Banu, M.; Chen, L. Data-driven modeling of process, structure and property in additive manufacturing: A review and future directions. J. Manuf. Process. 2022, 77, 13–31. [Google Scholar] [CrossRef]

| Stage Name | Tasks |

|---|---|

| Defining research objectives | Defining goals of the bibliometric analysis |

| Selecting data bases and data collections | Choosing appropriate dataset(s) and developing research queries according to the study goals |

| Data preprocessing | Cleaning the collected data to remove duplicates and irrelevant records |

| Bibliometric software selection | Choosing suitable bibliometric software/tools for analysis |

| Data analysis | Description, author, journal, area, topics, institution, country, etc. |

| Visualization (if possible) | Visualizing the analysis results to present insights |

| Interpretation and discussion | Interpreting findings in the context of the research goals |

| Parameter/Feature | Detailed Description |

|---|---|

| Inclusion criteria | Books (and chapters in books), articles (original, reviews, communication, editorials), and conference proceedings, in English |

| Exclusion criteria | Books older than 10 years, letters, conference abstracts without full text, other languages than English |

| Keywords used | deep learning, energy optimization/optimization, smart city |

| Used field codes (WoS) | “Subject” field (consisting of title, abstract, keyword plus and other keywords) |

| Used field codes (Sopus) | article title, abstract and keywords |

| Used field codes (PubMed) | manually |

| Used field codes (dblp) | manually |

| Boolean operators used | Yes, e.g.,“3D print” AND (“optimization” OR “optimization”) AND “machine learning” |

| Applied filters | Results refined by publication year, document type (e.g., articles, reviews), and subject area (e.g., industry, engineering). |

| Iteration and validation options | Queries are run iteratively, refined based on results, and validated by ensuring that relevant publications appear among the top results |

| Leverage truncation and wildcards used | Used symbols like * for word variations (e.g., “3D print*” for “3D print” or “3D printing”) and ? for alternative spellings (e.g., “optimi?ation” for “optimisation” or “optimization”) |

| Parameter/Feature | Value |

|---|---|

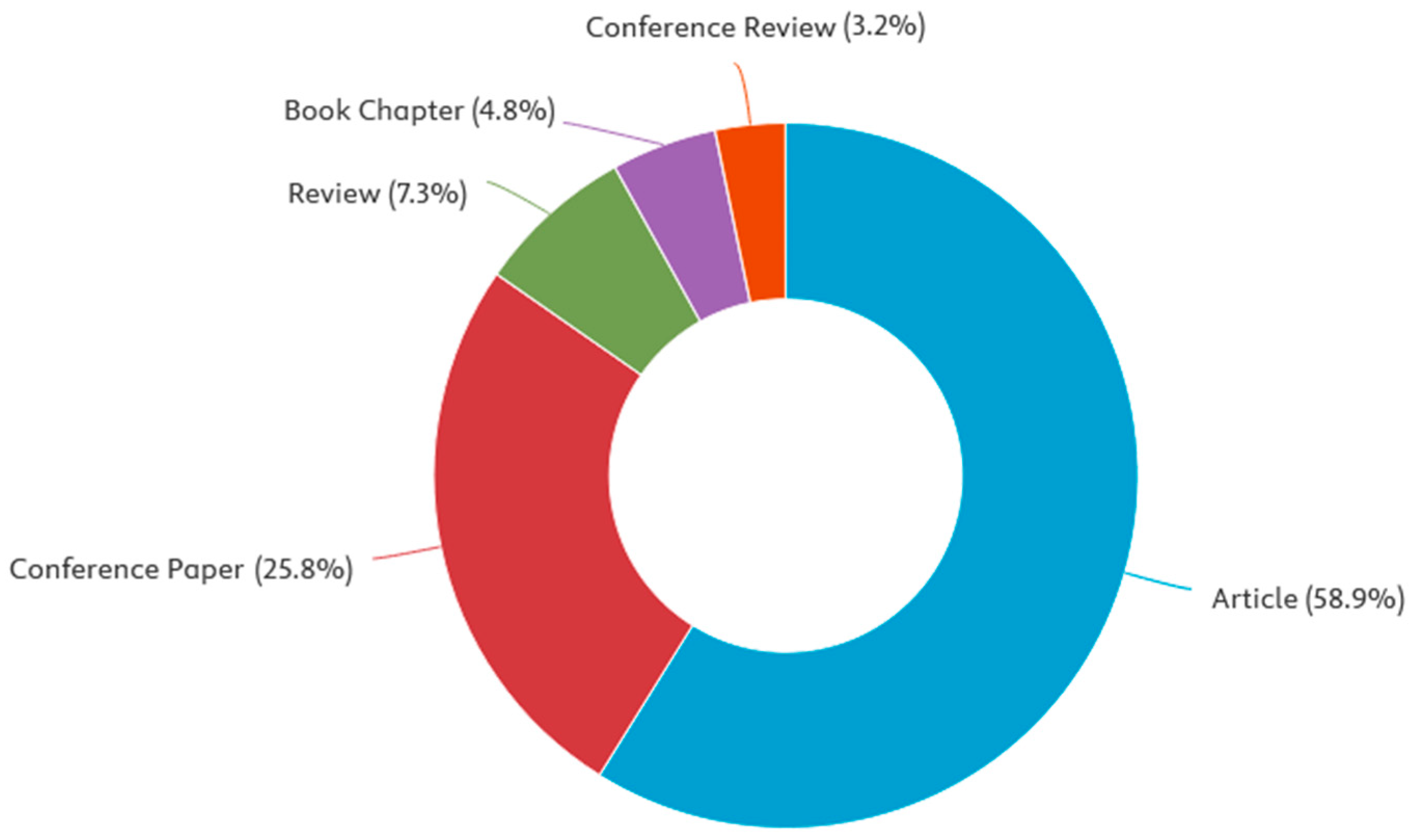

| Leading types of publication | Article (58.9%), proceeding paper (25.8%), review (7.3%) (Figure 2) |

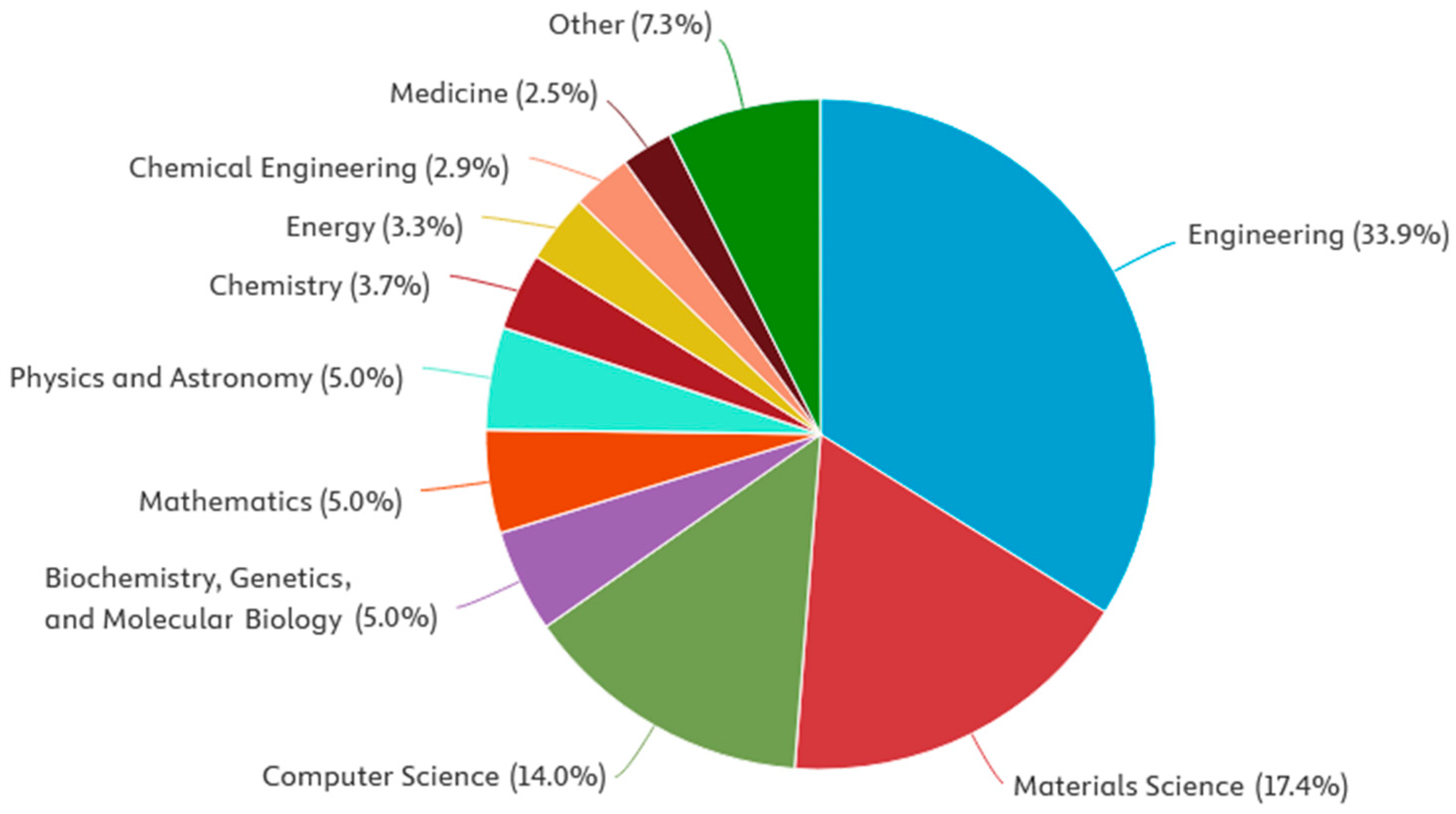

| Leading areas of science | Engineering manufacturing (33.9%), Materials science (17.4%), Computer science (14.0%) (Figure 3) |

| Leading topics | Nanofibers, scaffolds and fabrication, Mechanics |

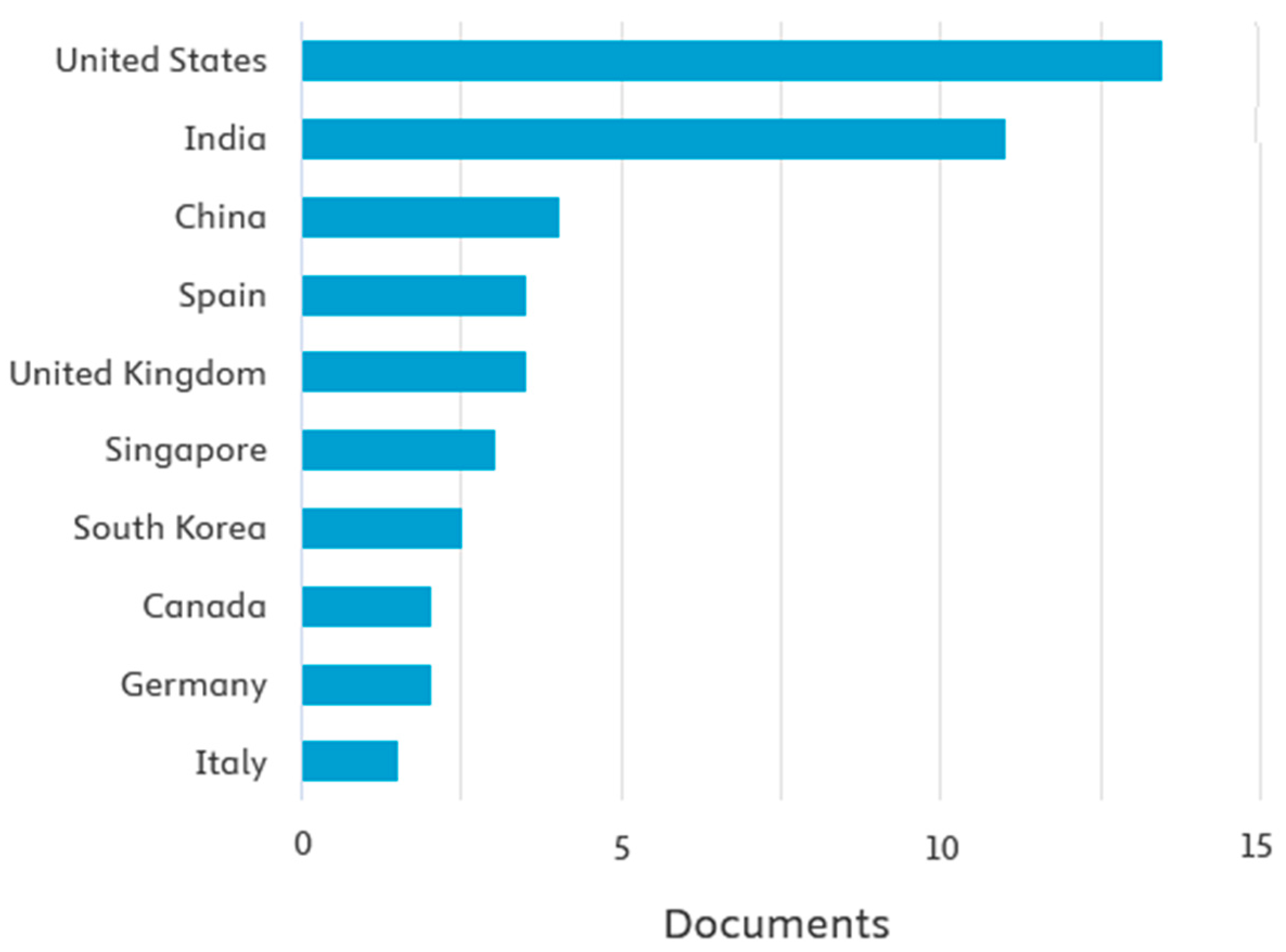

| Leading countries | USA, India, China (Figure 4) |

| Leading scientists | Baldwin M., McComb C.; Meisel N.A. |

| Leading affiliations | Pennsylvania State University, Carnegie Mellon University, Georgia Institute of Technology |

| Leading funders (where information available) | National Science Foundation, United States Department of Defence, United States Department of Energy, European Commission (Figure 5) |

| Sustainable development goals | Industry innovation and infrastructure, Good health and well being |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojek, I.; Mikołajewski, D.; Galas, K.; Kopowski, J. ML-Based Materials Evaluation in 3D Printing. Appl. Sci. 2025, 15, 5523. https://doi.org/10.3390/app15105523

Rojek I, Mikołajewski D, Galas K, Kopowski J. ML-Based Materials Evaluation in 3D Printing. Applied Sciences. 2025; 15(10):5523. https://doi.org/10.3390/app15105523

Chicago/Turabian StyleRojek, Izabela, Dariusz Mikołajewski, Krzysztof Galas, and Jakub Kopowski. 2025. "ML-Based Materials Evaluation in 3D Printing" Applied Sciences 15, no. 10: 5523. https://doi.org/10.3390/app15105523

APA StyleRojek, I., Mikołajewski, D., Galas, K., & Kopowski, J. (2025). ML-Based Materials Evaluation in 3D Printing. Applied Sciences, 15(10), 5523. https://doi.org/10.3390/app15105523