Featured Application

The obtained product from the proposed technology could be used in the agriculture sector as a bio-fertilizer.

Abstract

The conception of a circular economy is one of the crucial approaches that could accelerate the processes of achieving sustainable development goals, which challenge all industries and societies. Still, the potential of agricultural waste in this area is not fully covered by technologies. This study aims to develop a full-scale technology for self-sustaining double-stage circularity through the utilization of sunflower agriculture’s waste in bio-fertilizers. The investigation is performed in Bulgaria, as available sunflower husk ashes (SHA) are subjected to analyses regarding their applicability for bio-fertilizer production. The design of the technology and full-scale equipment commissioning process are described. The conditions and results from the adjustment tests are presented and, based on these, the optimal operating parameters are defined. The successful granulation of different samples of SHA at these conditions is performed and the final granular bio-fertilizers are characterized with a content of 30 wt. % K2O and 5% wt. P2O. The moisture of the prepared granules is approx. 5 wt. %, and they pass the crushing tests at 2.5 kgf. The biotoxicity of the bio-fertilizer is also analyzed, and the results show its applicability in agriculture. The proposed approach allows the initial sources of K2O and P2O from soil feeding the sunflowers to circulate in different industrial technologies and to reenter the soil through bio-fertilizers.

1. Introduction

The growth of the global human population is frequently associated with an increasing demand for food and natural resources around the world [1]. According to the United Nations, over 430 million tons of food waste is generated annually globally, and over 85 million tons are wasted in the European Union, with wide-ranging economic, social, and environmental consequences [2]. In the OECD countries, there has been a significant development in the area of food waste management and especially its conversion into valuable secondary products [3]. However, nowadays we face significant challenges in regard to the realization of a full-scale circular economy, which requires the development of approaches for the management of waste products from all industrial sectors and households. The need to achieve a circular economy is not only driven by environmental considerations—fast-increasing industrialization is also leading to a gradual depletion of natural resources [4,5]. Considering the waste materials as by-products and their further utilization will allow environmental benefits to be achieved and will increase the availability of natural resources.

Unlike agriculture, which generates mostly biodegradable residues, the wastes from different industries are generally hazardous. Therefore, efforts to process and utilize wastes in many countries have focused mainly on industrial types, while the circular management of agriculture has not been considered [6]. Some of the widely used approaches to reduce environmental damage from different types of waste include waste-to-energy and improving composting, storage and, processing methods [7]. Combined with the introduction of stricter waste management policies, these approaches can lead to positive outcomes, but a key element involves increasing the self-awareness of producers and consumers regarding the need for sustainability. An additional mechanism to incentivise the reprocessing of waste and its transformation into valuable resources could be the creation of economic benefits [8]. The implementation of the conversion of agricultural by-products and/or waste products, such as crop residues, animal waste, etc., into valuable resources will not only lead to a significant reduction in the amount of final waste going to landfill, but may also lead to the reintroduction into the production cycle of organic and inorganic products, such as fertilizers, improvers, dyes, etc. [9,10]. Nowadays, in traditional agriculture, synthetic compounds are used in place of these materials, which is associated with significant pollution [11]. Organic fertilizers, on the other hand, have been proven to be a sustainable alternative that preserves soil integrity, enriches it with essential nutrients, and, at the same time, significantly improves plant productivity and sustainability [12,13,14]. The implementation of this approach to utilizing agricultural waste through the production of bio-fertilizers will represent significant progress not only in terms of achieving the goals of the circular economy, but also in terms of meeting the needs of modern society for organic agriculture [15,16,17]. A significant part of the materials suitable for these purposes are currently landfilled or incinerated, but the realization of their full utilization and the implementation of a transition from a linear to a circular model of the economy will unlock the full potential of agricultural waste [18,19].

Regulatory restrictions on the use of synthetic fertilizers, due to the environmental risks, together with the growing interest in organic farming, are leading to an increase in the demand for organic fertilizers [20]. This leads to new challenges, including the ability to secure the necessary quantities of bio-fertilizers and to ensure their environmentally friendly production. One suitable measure has already implemented through the regulation of the European Commission, targeting a 30% reduction in the non-renewable resources used in fertilizer production by 2030 [21]. The next steps should be aimed at securing sufficient quantities of raw materials suitable for the production of bio-fertilizers. One of the researched approaches is the potential of sunflower husks as a raw material for bio-fertilizer production. Sunflower, as one of the most widely grown crops, plays a crucial role in the agricultural economy of many countries in Europe and the region, and the production of vegetable oil and biodiesel from sunflower seeds are key industries.

According to Eurostat, the EU produced 271.6 million tons of cereals in 2023 [22]. For Bulgaria, as part of the EU, the share of sunflower production from whole agriculture sector reaches 69.7% for 2023 or 1,764,594 tons in total [23]. The crop waste generated in this production in Bulgaria is estimated at about 3 million tons per year, which reveals the significant potential for utilizing sunflower crop waste through the production of bio-fertilizers. During the production of vegetable oil and biodiesel from sunflower seeds, the sunflower husks are a significant part of the residue, and they, like other plant waste, are most often burned or directly landfilled. Sunflower husks, however, contain various nutrients and trace elements that can be beneficial to plants and soil. Applying a two-stage approach to their utilization through initial combustion, in which they will first be utilized for energy production, followed by a second stage of utilization through the production of bio-fertilizers, will lead to significant benefits both in terms of increased energy efficiency and for ensuring ecological agriculture and bio-fertilizer production. Depending on the fertilization products used and the growing conditions of the sunflower, the ash obtained when burning waste sunflower husks can be rich in key elements, such as potassium, calcium, magnesium, and some trace elements, such as zinc, copper, and manganese [24,25,26,27,28]. Potassium carbonate, which is extracted from plant ash, has been used in agriculture for years as a fast-acting fertilizer [29,30,31,32,33,34]. Sunflower husk ash can also be fully used as a biofertilizer with an NPK composition of 0-6-13, which makes it suitable for a wide range of agricultural applications [35]. All this, combined with the proven absence of hazardous substances and heavy metals in sunflower husk ash, defines the proposed approach as a modern ecological alternative [36]. Nonetheless, in the EU, as well as in Bulgaria itself, only the first stage of utilization of sunflower husks is mainly applied, namely their combustion for energy needs.

The aim of this study is to design the full-scale technology necessary for self-sustaining double-stage circularity through the utilization of sunflower agriculture’s waste in bio-fertilizers. The first stage of circularity covers the burning of sunflower husks for the production of thermal energy for industrial processes and heating, and the second one encompasses the bio-fertilizer production from the obtained ash residue. The research experimentally investigates the full-scale technological approach regarding the second stage’s implementation in the industry.

2. Materials and Methods

In Bulgaria there are twelve industrial enterprises that have already implemented the first stage of the considered approach and where the sunflower husk residue is incinerated in industrial boilers. The mineral composition of the sunflower husks released as fly ash is captured by cyclone filters or as bottom ash, both in a powdered form. Storage places situated at the industrial enterprises site collect the mixture of fly and bottom ash. European and local legislation treat these mixtures as waste products, and they have to be managed in a special manner and following certain regimes. For the purpose of this study, we stocked up with SHA samples from all twelve enterprises and used four samples from Romanian enterprises due to their local suitability as source of raw material. Table 1 summarizes the SHA subjected to composition analyses and further experiments for granulation based on the suppliers and sampling zone from the industrial plant.

Table 1.

Sunflower husk ashes subjected to analyses and granulation.

The chemical composition of all SHA was analyzed in an accredited laboratory SGS Bulgaria Ltd., Varna, Bulgaria, with accreditation BAS reg. № 146 LI, from 29 September 2023, valid until 31 May 2026. The ICP method was applied for element identification, and the major components are presented in their oxide forms in wt. % on dry sample. The trace elements are presented as concentration in mg/kg.

After the process of granulation, further composition analyses were performed through the same analytical techniques in the accredited laboratory. For the applicability evaluation as bio-fertilizers, the obtained granules were subjected to extended composition analyses regarding their biotoxicity properties.

During the commissioning activities, we measured the moisture of SHA samples on-site with the help of an infrared analytical scale (Kern DAB 100-3).

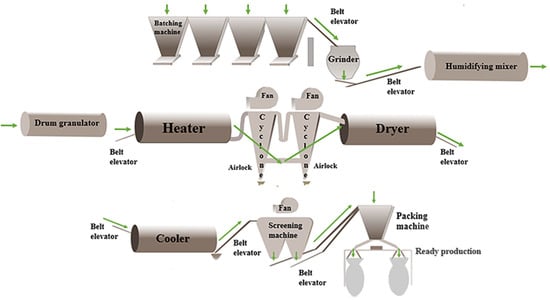

Figure 1 presents the technological scheme on the basis of which the full-scale installation with a capacity of up to 5 t/h was built within the framework of the study.

Figure 1.

Technological scheme of the sunflower husk ash granulation process for bio-fertilizer production.

All delivery and construction activities were carried out by Green Circle Biotech Ltd., Sofia, Bulgaria, at their industrial site located in the town of Polski Trambesh. Our research group participated in the commissioning activities with analyses of the influence of the process parameters over the final product quality and with the adjustment of the operating parameters based on specified initial and boundary conditions described in the experimental part of the article.

3. Results and Discussion

3.1. Sunflower Husk Ashes Composition

The results for the SHA major compounds in their oxide forms are presented in Table 2. The SHA samples consist mainly of K2O in the range of 12.0–44 wt. %, P2O5 in the range of 1.4–10.5 wt. %, MgO in the range of 7.3–16.1 wt. %, SO3 in the range of 3.1–15.8 wt. %, CaO in the range of 11.7–33.8 wt. %, and Fe2O3 up to 1.9 wt. %. The main reason for the wide range of the obtained composition is that the sunflower plants involved in the first industrial processes grow in different soil based on their geographical location and use additives and fertilizers [31].

Table 2.

Composition of the investigated sunflower husk ashes.

The results correspond well with the analyses performed in other studies [32,33]. The key compounds related to our research work are potassium and phosphorous, due to the targeted bio-fertilizers consisting of 30 wt. % K2O and 5 wt. % P2O5. Ash samples SHA7-S and SHA13-S are the only powdered materials that could be directly subjected to granulation due to their similarity of composition to the target. All the other analyzed samples have to be used in mixture by each other; SHA1-F, SHA4-F, SHA5-F, and SHA15-S are additives suitable for increasing the potassium content. Analogously, samples SHA2-F, SHA3-S, SHA9-S, and SHA12-S could be used as additives for phosphorous enrichment of the final product. The results show that the sampling place is crucial for the composition of SHA, as the concentration of K2O drastically reduced in the storage place compared to in the filter collectors, which could be explained by the potassium’s dissolution in rainwater. The presence of SO3 in all samples benefits the properties of the raw materials because sulfur is essential for various plants’ growth functions, like nitrogen metabolism, enzyme activity, and oil synthesis [34].

3.2. Commissioning of Full-Scale Technology and Adjustment of Process Parameters

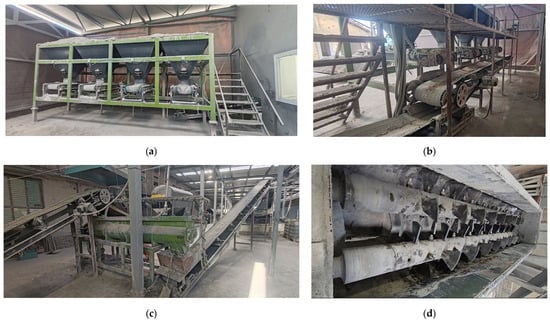

The process begins in a batching machine by feeding raw material into four hoppers, from which different volumes of ash, subject to subsequent granulation, are dosed (Figure 2a). SHA from each hopper is fed along a separate conveyor belt to the main belt elevator (Figure 2b). The SHA feeding volumes are determined by changing the rotation frequency of the individual conveyor belts in the range of 12–120 Hz. The main belt elevator transports the SHA samples to the mechanical grinder where the larger fractions are crushed, and the entire sample volume is brought to a powdery state (Figure 2c). The next stage of the process covers the mixing of SHA samples and it is performed in a humidifying mixer where the sample is prepared for granulation (Figure 2d). The facility includes an open vessel equipped with two counter-rotating shafts, each covered by 20 blades.

Figure 2.

Delivered and constructed facilities by Green Circle Biotech Ltd. at the Polski Trambesh site: (a) the batching sector consists of four bunkers; (b) individual conveyor belts; (c) main belt elevator; (d) humidifying mixer.

According to the commercial granulator facility requirements, the inlet moisture of the samples has to be in the range of 20–25 wt. % to carry out the process of granulating. Since the supplied SHA from different source are characterized with moisture contents in very wide range of 3–30 wt. % because of their different manners of storage and logistic, the preliminary treatment is required. Primary experiments and analyses have shown that very low moisture content in SHA samples (<5 wt. %) leads to a loss of material in the bunkers and the main elevator belt due to its high volatility, while very high moisture content (>15 wt. %) leads to the deposition of SHA on the walls of the facilities. All the supplied samples with a moisture content outside the estimated range are subjected to preliminary exposure to atmospheric conditions, protected from rainwater, to release or adsorb water content.

The commissioning process continued with setting the operating parameters of the humidifier mixer. We performed tests in the following sequence: measuring the SHA sample moisture with an IR analytical scale at the inlet of the humidifier mixer (Win in wt. %); dosing of technical water flow through nozzles placed in the shafts (Gtw in L/min); measuring the SHA sample moisture with an IR analytical scale at the outlet of the humidifier mixer (Wout in wt. %). Numerous experimental tests and optimizations were performed, and, as a result, the operating parameters of the water pumps were defined, depending on the necessary flow based on the initial moisture of the SHA samples and the targeted Wout = 22 wt. %. Table 3 presents the established working regimes of the humidifying mixer with an optimal load for a full-scale system of 4 tons per hour for final production.

Table 3.

Established working regimes of the humidifier based on the initial moisture.

After the humidifying mixer, the process continues in the granulator as the SHA sample is transported through another belt elevator. The granulator is a closed vessel with a diameter of 1.8 m, a length of 12 m, a constant rotation speed of 14 rpm, and a 2° slope (Figure 3a). A rubber insert layer with a 0.008 m thickness covers the total inner surface of the vessel. During the commissioning, we observed the adhesion of SHA to the inner walls, and, as such, we installed an additional hammer mechanism outside of the granulator facility.

Figure 3.

Delivered and constructed facilities by Green Circle Biotech Ltd. at the Polski Trambesh site: (a) drum granulator; (b) heater.

The next stage of the process is drying the obtained granules in a rotary drum heater with a diameter of 1.8 m, a length of 18 m, and a constant speed of 4 rpm (Figure 3b). A propane–butane burner produces the heat for the drying process, and a fan with capacity of 20,000 m3/h ensures the air flow.

A series of experiments were conducted to adjust the process parameters of the dryer under different conditions for the temperature of the inlet hot air (tin, °C) and exposure time (τ, min). At the end of the drying process, the granules were subjected to moisture content analyses (Wgran, wt. %), crushing tests at 2.5 kgf, and the determination of K2O and P2O5 content in wt. %. The experimental conditions and the obtained results are listed in Table 4.

Table 4.

Experimental conditions and results from the drying process adjustment.

As can be seen from the results obtained, the low drying temperature, even with a longer exposure time, cannot meet the criteria for the final moisture in the granules or the content of K2O and P2O5. Other authors successfully performed low temperature drying that is more effectively in terms of energy consumption and production costs [37,38,39]. In our technological solution, the low temperature treatment is unsuccessful due to the previous stage of moisturizing in the humidifying mixer, which is a prerequisite for the self-granulation of SHA, eliminating the need of additives. At high temperatures, on the other hand, the desired material composition is obtained, but the crushing tests are unsuccessful due to the embrittlement of the granulate. The optimal conditions of the drying process in the drum heater are obtained for the inlet temperature range of 180–220 °C and an exposure time of 20 min. The lack of additional compounds in the granulation process compensate for the high-temperature drying regime in terms of economic and environmental effectiveness. The obtained relatively high temperature regimes should not have a negative impact on the nutrient properties of the final product due to its mineral composition unlike the negative effect obtained from other authors investigating organic fertilizers [40]. It is important to note that inorganic fertilizers are not used as single additives to soil for long periods because this may lead to a decline in the nutrient content in soil and make the crops more susceptible to various diseases [41].

In the next stage of the processes, the dried granules pass through cyclone filters for the separation of the remaining powder fraction that is redirected by elevator belt to the grinder before returning to the humidifying mixer for retreatment. The granules that pass through the cyclone filter enter a cooler vessel for 15 min to decrease their surface temperature of 55 °C to an ambient condition. The cooler is a closed rotary vessel with a diameter of 1.5 m, a length, of 16 m, and a constant speed of 6 rpm. The cooling process is based on convective heat exchange performed in an air environment ensured by a fan with a capacity of 15,000 m3/h.

A conveyor belt moves the cooled granules to the screening machine for separation into differently sized fractions (Figure 4a). Granules with a diameter <2 mm are returned to the process in front of the humidifying mixer, those with diameter >5 mm are returned to the grinder, and the fraction with a diameter in the range of 2–5 mm is directed to the packing machine (Figure 4b). During the packaging process each batch is examined by crushing tests at 2.5 kgf and by IR analyses to confirm the presence of moisture of approx. 5 wt. %.

Figure 4.

Delivered and constructed facilities by Green Circle Biotech Ltd. at the Polski Trambesh site: (a) screening machine; (b) packing machine.

3.3. Mixing of Sunflower Husk Ashes from Different Sources for Granulation

After determining the optimal operation parameters, further tests of granulation were performed with different mixtures of SHA to confirm the stoichiometric calculation based on their composition. The experiments were performed at an optimal load of 4 t/h, a drying temperature of 220 °C, a drying time of 20 min, and with the humidity regulated by the already configured process controller. The final products were analyzed regarding their composition of targeted potassium and phosphorous, moisture and crush resistance. Table 5 presents the experimental mixtures of SHA in terms of volumetric ratio and the obtained results.

Table 5.

Experimental conditions and results from the mixing of different sources.

The obtained final granules during all experiments successfully passed the tests for moisture content and crush resistance. The analytically measured potassium and phosphorous content corresponds well to the stoichiometric calculation based on the raw material composition for the mixtures in experiments 8, 9, and 10. The deviation of K2O and P2O concentration is found for all the mixtures of SHA that consist of three samples. These could be explained by the presence of bottom ash in a volumetric ratio from 0.24 to 0.37, which is typically characterized by an inhomogeneous composition and structure of these materials due to the incomplete combustion of primary source.

3.4. Analyzing of the Applicability of Sunflower Husk Ashes Granules as Bio-Fertilizer

The final product obtained during experimental procedure 8 from the previous section (Table 5) was subjected to detailed chemical and biochemical analyses for the evaluation of its applicability as a bio-fertilizer in an accredited laboratory, as described in Section 2. Table 6 presents the elemental composition of the sample analyzed with ICP and the specific error range where applicable.

Table 6.

Elemental composition of the granulated sunflower husk ash.

The additional analyses regarding organic toxic compounds were performed. The results for the detected polycyclic aromatic hydrocarbon estimated according to BNS EN 17503:2022 are presented in Table 7. Analyses for polychlorinated biphenyls concentrations estimated according to EPA 1668B:2008 are presented in Table 8. The results for long-lived polyhalogenated organic compounds estimated according to EPA 8290A:2007 are listed in Table 9. For all analyses, the specific error range is presented where applicable.

Table 7.

Polycyclic aromatic hydrocarbon concentrations of granulated sunflower husk ash.

Table 8.

Polychlorinated biphenyl concentrations of granulated sunflower husk ash.

Table 9.

Long-lived polyhalogenated organic compounds in granulated sunflower husk ash.

Microbiological analyses were performed for E. coli and Salmonella spp., and both were negative.

The detailed analyses show that the concentrations of macro and trace elements in the investigated granulated SHA allow the product’s utilization in agricultural fields as a bio-fertilizer. Since no other components are added during the technological process, the chemical composition of the SHA and the granules is completely identical, and in subsequent analyses it is not necessary to characterize both. The benefits of applying granular fertilizer rather than directly utilizing ash residue have been studied by other authors. Researchers have investigated the nutrient retention of different granulated agricultural waste ashes and proved that such ashes exhibit complex nutrient release properties compared to the raw materials. Authors have experimentally demonstrated the direct retention of nutrient compounds by plants and their negligible release to the soils. The heavy metals do not leave the granule structure during the fertilizing processes [42,43].

4. Conclusions and Future Work

In this study, self-sustaining double-stage circularity is successfully realized through the utilization of sunflower agriculture’s waste in bio-fertilizers. The applicability of different Bulgarian SHA as a single source or in mixture for the production of bio-fertilizer with 30 wt. % K2O and 5 wt. % P2O5 is established. The process parameters of a full-scale industrial site for the production of granulated material were investigated, and optimal operating conditions were defined. The most important parameters were identified as the moisture content of raw SHA delivered by other industrial sites, where the burning of sunflower husk was performed, the technical water flow during the mixing process, and the drying conditions. The established optimal values are a moisture content in the raw SHA in the range of 5–15 wt. %; a water flow rate in the humidifier at ambient temperature in the range of 2–18 L/min; a temperature of the inlet hot air for drying in the range of 180–220 °C; a drying time of 20 min; and a cooling time of 15 min. After setting the optimal operating regime of the full-scale technology at a 4 t/h load, the obtained final product was characterized by a granule size of 2–5 mm, a moisture of approx. 5 wt. %, and 2.5 kgf crush resistance. The study demonstrates that the proposed process for producing bio-fertilizer complies with all safety, quality, and environmental standards established by local and international regulations (such as Regulation (EC) № 2003/2003 on fertilizers in the EU).

The proposed technological approach is economically feasible due to the cost-free raw material and the transport costs that are covered by the suppliers. Suppliers also economically benefit because in a linear economic model they have to pay for both the transportation and disposal of sunflower husk ashes because they are treated as a waste product according to the current legislation. It is important to note that both the economic and environmental benefits depend on the geolocation of the supplier and the bio-fertilizer producer. In terms of the process’s carbon footprint, a short distance for transportation is preferred. The proposed approach in the study could be applied directly as a technological solution in different agricultural regions, but the economic, logistical, and legislation challenges have to be individually assessed.

The next stage of investigation will consider the evaluation of the carbon footprint of proposed bio-fertilizer material during its whole life cycle from the generating of sunflower husk ash to the final stage of commercial production. Other challenges that we will address in our future work will be the identification of nitrogen-enriched by-products, which will be suitable for mixing with sunflower husk ash for NPK bio-fertilizer production.

Author Contributions

Conceptualization, D.Z.-F.; methodology, D.Z.-F., V.N. and L.K.; software, K.F.; validation, D.Z.-F. and K.F.; formal analysis, V.N. and L.K.; investigation, D.Z.-F., V.N. and L.K.; resources, D.Z.-F.; data curation, D.Z.-F. and K.F.; writing—original draft preparation, D.Z.-F., V.N. and L.K.; writing—review and editing, D.Z.-F. and K.F.; visualization, V.N. and L.K.; supervision, K.F.; project administration, D.Z.-F.; funding acquisition, D.Z.-F. and K.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union—NextGenerationEU, through the National Recovery and Resilience Plan of the Republic of Bulgaria, grant number BG-RRP-2.004-0005. Green Circle Biotech Ltd., Bulgaria funds and owns the full-scale installation. The APC was funded the European Union—NextGenerationEU, through the National Recovery and Resilience Plan of the Republic of Bulgaria, grant number BG-RRP-2.004-0005.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some data are unavailable due to the privacy requirements of Green Circle Biotech Ltd. The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the management team of Green Circle Biotech Ltd. for technical support and for the research team involved in the commission process.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Food and Agriculture Organization. Available online: https://www.fao.org/about/about-fao/en/ (accessed on 20 January 2025).

- UNEP Food Waste Index Report 2021. Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021?utm_source=chatgpt.com (accessed on 20 January 2025).

- Ng, H.S.; Kee, P.E.; Yim, H.S.; Chen, P.; Wei, H.; Lan, J.W. Recent advances on the sustainable approaches for conversion and reutilization of food wastes to valuable bioproducts. Bioresour. Technol. 2020, 302, 122889. [Google Scholar] [CrossRef]

- Ngangnchi, F.H.; Aquilas, N.A.; Mbella, M.E. Natural resource use, industrialization and climate change in Africa: Blueprints for sustainable regional development. Res. Glob. 2024, 9, 100245. [Google Scholar] [CrossRef]

- Usman, M.; Balsalobre-Lorente, D. Environmental concern in the era of industrialization: Can financial development, renewable energy and natural resources alleviate some load? Energy Policy 2022, 162, 112780. [Google Scholar] [CrossRef]

- Pagey, S.V.; Nagar, C.S. Waste Management in Food and Agricultural Industries. Futuristic Trends in Agriculture Engineering & Food Sciences; Iterative International Publishers (IIP), Selfypage Developers Pvt Ltd.: Chikkamagaluru, India, 2024; pp. 555–561. [Google Scholar]

- Petrov, P.; Zgureva-Filipova, D.; Filipov, K.; Ganev, I. Analysis of the overall potential for electricity production from farm animals manure in Bulgaria. IOP Conf. Ser. Earth Environ. Sci. 2023, 1128, 012001. [Google Scholar] [CrossRef]

- Hale, A.; Köker, A.R. Analyzing and mapping agricultural waste recycling research:An integrative review for conceptual framework and future directions. Resour. Policy 2023, 85, 103987. [Google Scholar] [CrossRef]

- Raimi, A.; Roopnarain, A.; Adeleke, R. Biofertilizer production in Africa: Current status, factors impeding adoption and strategies for success. Sci. Afr. 2021, 11, e00694. [Google Scholar] [CrossRef]

- Yunus, M.U.; Silas, K.; Yaum, A.L.; Kwaji, B.H. A Review of Biofertilizer Production: Bioreactor, Feedstocks and Kinetics. SSRG Int. J. Recent Eng. Sci. 2022, 9, 39–49. [Google Scholar] [CrossRef]

- Tripathi, S.; Srivastava, P.; Devi, R.S.; Bhadouria, R. Influence of Synthetic Fertilizers and Pesticides on Soil Health and Soil Microbiology; Majeti Narasimha Vara Prasad, M.N.P., Ed.; Agrochemicals Detection, Treatment and Remediation; Butterworth-Heinemann: Oxford, UK, 2020; Chapter 2; pp. 25–54. ISBN 9780081030172. [Google Scholar] [CrossRef]

- Bharti, N.; Suryavansh, M. Chapter 10-Quality control and regulations of biofertilizers: Current scenario and future prospects. Biofertilizers 2021, 1, 133–141. [Google Scholar] [CrossRef]

- Hassan, D.U.; Abdulsalam, S. Assessement of Bio-fertilizer Quality of Anaerobic Digestion of Watermelon Peels and Cow Dung. Chem. Biomol. Eng. 2017, 2, 135–141. [Google Scholar] [CrossRef]

- Shehata, M.M.; El-Khawas, S.S. Effect of Two Biofertilizers on Growth Parameters, Yield Characters, Nitrogenous Components, Nucleic Acids Content, Minerals, Oil Content, Protein Profiles and DNA Banding Pattern of Sunflower (Helianthus annus L. cv. Vedock) Yield. Pak. J. Biol. Sci. 2003, 6, 1257–1268. [Google Scholar] [CrossRef]

- Finore, I.; Romano, I.; Leone, L.; Di Donato, P.; Nicolaus, B.; Poli, A.; Lama, L. Biomass Valorization: Sustainable Methods for the Production of Hemicellulolytic Catalysts from Thermoanaerobacterium thermostercoris strain BUFF. Resources 2021, 10, 115. [Google Scholar] [CrossRef]

- Pociene, O.; Šlinkšiene, R. Properties and Production Assumptions of Organic Biofertilisers Based on Solid and Liquid Waste from the Food Industry. Appl. Sci. 2024, 14, 9784. [Google Scholar] [CrossRef]

- Przygocka-Cyna, K.; Barłóg, P.; Spizewski, T.; Grzebisz, W. Bio-Fertilizers Based on Digestate and Biomass Ash as an Alternative to Commercial Fertilizers—The Case of Tomato. Agronomy 2021, 11, 1716. [Google Scholar] [CrossRef]

- Nramat, W.; Traiphat, W.; Sukruan, P.; Utaprom, P.; Namgaew, S.; Sodajaroen, S.; Chatpuk, R.; Phetduang, L. Development of a Bio-Fertilizer Machine (Holmon Egg) Integrated with NPK Sensor Technology for Enhancing Organic Vegetable Production in Sufficiency Community Enterprises. Int. J. Geoinform. 2024, 20, 8–16. [Google Scholar] [CrossRef]

- Czekała, W.; Jeżowska, A.; Chełkowski, D. The Use of Biochar for the Production of Organic Fertilizers. J. Ecol. Eng. 2019, 20, 1–8. [Google Scholar] [CrossRef]

- Ibáñez, A.; Garrido-Chamorro, S.; Vasco-Cárdenas, M.F.; Barreiro, C. From Lab to Field: Biofertilizers inthe 21st Century. Horticulturae 2023, 9, 1306. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K.; Witek-Krowiak, A. Bio-based fertilizers: A practical approach towards circular economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. Available online: https://ec.europa.eu/eurostat/statisticsexplained/index.php?title=Agricultural_production_-_crops (accessed on 20 January 2025).

- Report of Bulgarian Ministry of Agriculture and Food. Yields from Field Crops–(June 2024) Harvest 2023 No. 441. Available online: https://www.mzh.government.bg/en/ (accessed on 20 January 2025).

- Isemin, R.; Tabet, F.; Nebyvaev, A.; Kokh-Tatarenko, V.; Kuzmin, S.; Milovanov, O.; Klimov, D.; Mikhalev, A.; Dobkin, S.; Zhulaev, Y. Prediction of the Behavior of Sunflower Husk Ash after Its Processing by Various Torrefaction Methods. Energies 2022, 15, 7483. [Google Scholar] [CrossRef]

- Paleckienė, R.; Sviklas, A.M.; Šlinkšienė, R.; Štreimikis, V. Complex Fertilizers Produced from the Sunflower Husk Ash. Pol. J. Environ. Stud. 2010, 19, 973–979. [Google Scholar]

- Akca, M.O.; Bozkurt, P.A.; Gokmen, F.; Akca, H.; Yagcıogluq, K.D.; Uygur, V. Engineering the biochar surfaces through feedstock variations and pyrolysis temperatures. Ind. Crops Prod. 2024, 218, 118819. [Google Scholar] [CrossRef]

- Somba, B.E.; Napitupulu, M.; Walanda, D.K.; Anshary, A.; Talo, W.S. Optimizing the Performance of Sunflower (Helianthus annuus L.) Seed Shell-Derived Biochar for Lead Ion Adsorption. Int. J. Des. Nat. Ecodyn. 2024, 19, 259–265. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, C.; Liu, R.; Li, S.; Wang, M. Sunflower straw ash as an alternative activator in alkali-activated grouts: A new 100% waste-based material. Ceram. Int. 2023, 49, 32308–32312. [Google Scholar] [CrossRef]

- Dahunsi, S.O.; Ogunwole, O.J. Biofertilizer production systems: Industrial insights. Biofertilizers 2021, 1, 21–30. [Google Scholar] [CrossRef]

- Romanowska-Duda, Z.; Janas, R.; Grzesik, M. Increasing Fertilization Efficiency of Biomass Ash by the Synergistically Acting Digestate and Extract fromWater Plants Sequestering CO2 in Sorghum Crops. Molecules 2024, 29, 4397. [Google Scholar] [CrossRef] [PubMed]

- Rushan, G.; Sotnikov, V. Characteristics of granulated activated carbon from a mixture of plant raw material waste. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2024, 335, 196–205. [Google Scholar] [CrossRef]

- Mirparsa, T.; Ganjali, H.R.; Dahmardeh, M. The Effect of Bio Fertilizers on Yield and Yield Components of Sunflower Oil Seed and Nut. Int. J. Agric. Biosci. 2016, 5, 46–49. [Google Scholar]

- Yelatontsev, D.; Mukhachev, A. Utilizing of sunflower ash in the wet conversion of phosphogypsum—A comparative study. Environ. Chall. 2021, 5, 100241. [Google Scholar] [CrossRef]

- Șerbănoiu, A.A.; Gradinaru, C.M.; Cimpoesu, N.; Filipeanu, D.; Serbanoiu, B.V.; Chereches, C.C. Study of an Ecological Cement-Based Composite with a Sustainable Raw Material, Sunflower Stalk Ash. Materials 2021, 14, 7177. [Google Scholar] [CrossRef] [PubMed]

- Bondarenko, A.M.; Lipkovich, E.I.; Kachanova, L.S. Control of Technological Processes of Organic Fertilizers Application as a Tool to Ensure Food Safety. J. Environ. Manag. Tour. 2018, 9, 5–11. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Mohanty, S.; Sahu, G.; Rana, M.; Pilli, K. Biochar: A Sustainable Approach for Improving Soil Health and Environment. In Soil Erosion-Current Challenges and Future Perspectives in a Changing World; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Abelenda, A.M.; Amaechi, C.V. Manufacturing of a Granular Fertilizer Based on Organic Slurry and Hardening Agent. Inventions 2022, 7, 26. [Google Scholar] [CrossRef]

- Sarlaki, E.; Kermani, A.M.; Kianmehr, M.H.; Vakilian, K.A.; Bandbafha, H.H.; Ma, N.L.; Aghbashlo, M.; Tabatabaei, M.; Lam, S.S. Improving sustainability and mitigating environmental impacts of agro-biowaste compost fertilizer by pelletizing-drying. Inventions 2021, 285, 117412. [Google Scholar] [CrossRef]

- Prabhakaran, K.; Warrier, K.G.K.; Rohatgi, P.K. Preparation of free flowing fly ash granules containing multifunctional molecules. Ceram. Int. 2001, 27, 749–754. [Google Scholar] [CrossRef]

- ElGamal, R.; Song, C.; Rayan, A.M.; Liu, C.; Al-Rejaie, S.; ElMasry, G. Thermal Degradation of Bioactive Compounds during Drying Process of Horticultural and Agronomic Products:A Comprehensive Overview. Agronomy 2023, 13, 1580. [Google Scholar] [CrossRef]

- Mącik, M.; Gryta, A.; Frąc, M. Chapter Two-Biofertilizers in agriculture: An overview on concepts, strategies and effects on soil microorganisms. Adv. Agron. 2020, 162, 31–87. [Google Scholar] [CrossRef]

- Buneviciene, K.; Drapanauskaite, D.; Mazeika, R.; Tilvikiene, V.; Baltrusaitis, J. Granulated biofuel ash as a sustainable source of plant nutrients. Waste Manag. Res. 2021, 39, 806–817. [Google Scholar] [CrossRef] [PubMed]

- Pesonen, J.; Kuokkanen, T.; Rautio, P.; Lassi, U. Bioavailability of nutrients and harmful elements in ash fertilizers:Effect of granulation. Biomass Bioenergy 2017, 100, 92–97. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).