Analysis of the Correlation of Microstructure, Instrumental Texture, and Consumer Acceptance of Shortbread Biscuits with Selected Sweeteners and Fibre

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Rheological Properties of the Dough

2.3. Measurement of Physical, Structural, and Textural Properties of Shortbread Biscuits

2.4. Measurement of Sensory Properties of Shortbread Biscuits

2.5. Statistical Analysis

3. Results and Discussion

3.1. Rheological Properties

3.2. Physical, Structural, and Textural Properties of Shortbread Biscuits

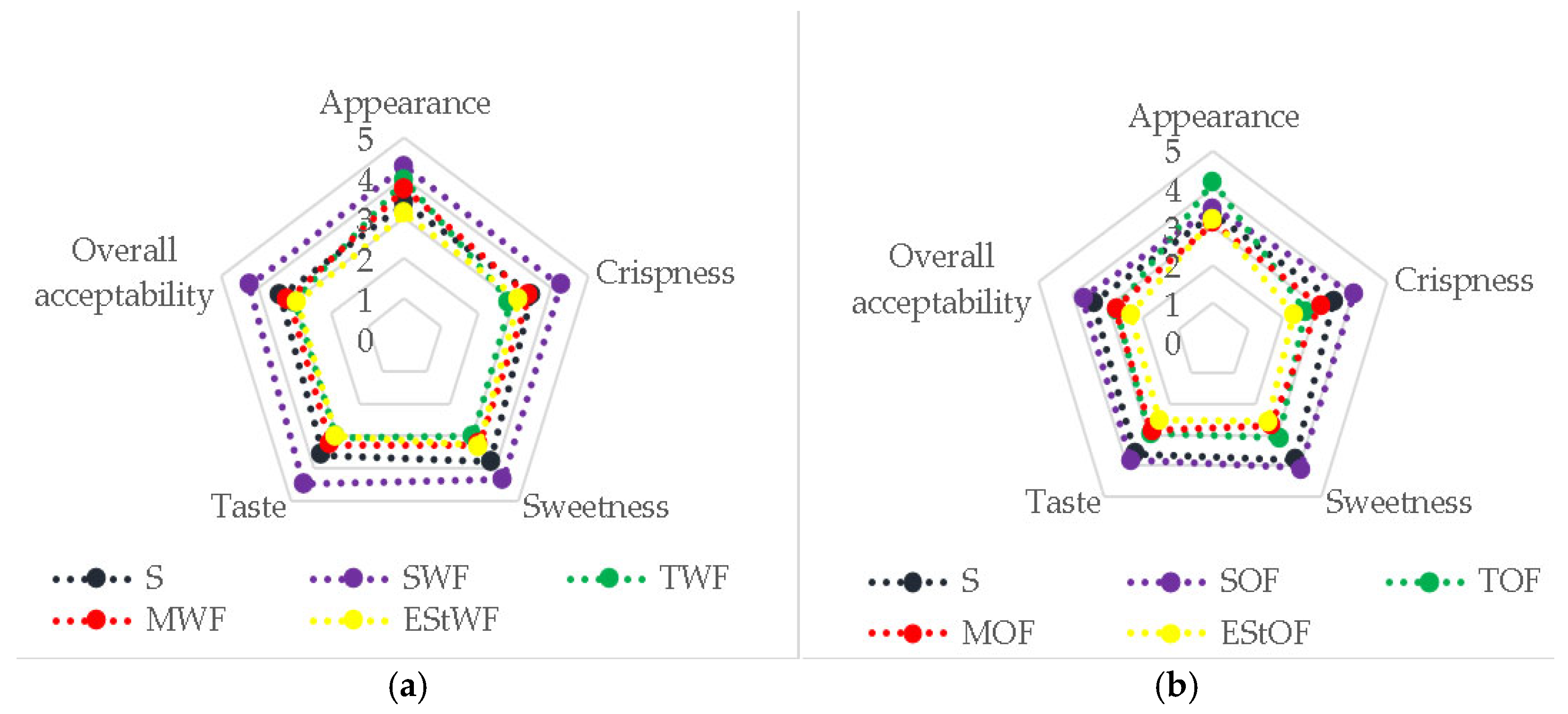

3.3. Sensory Properties of Shortbread Biscuits

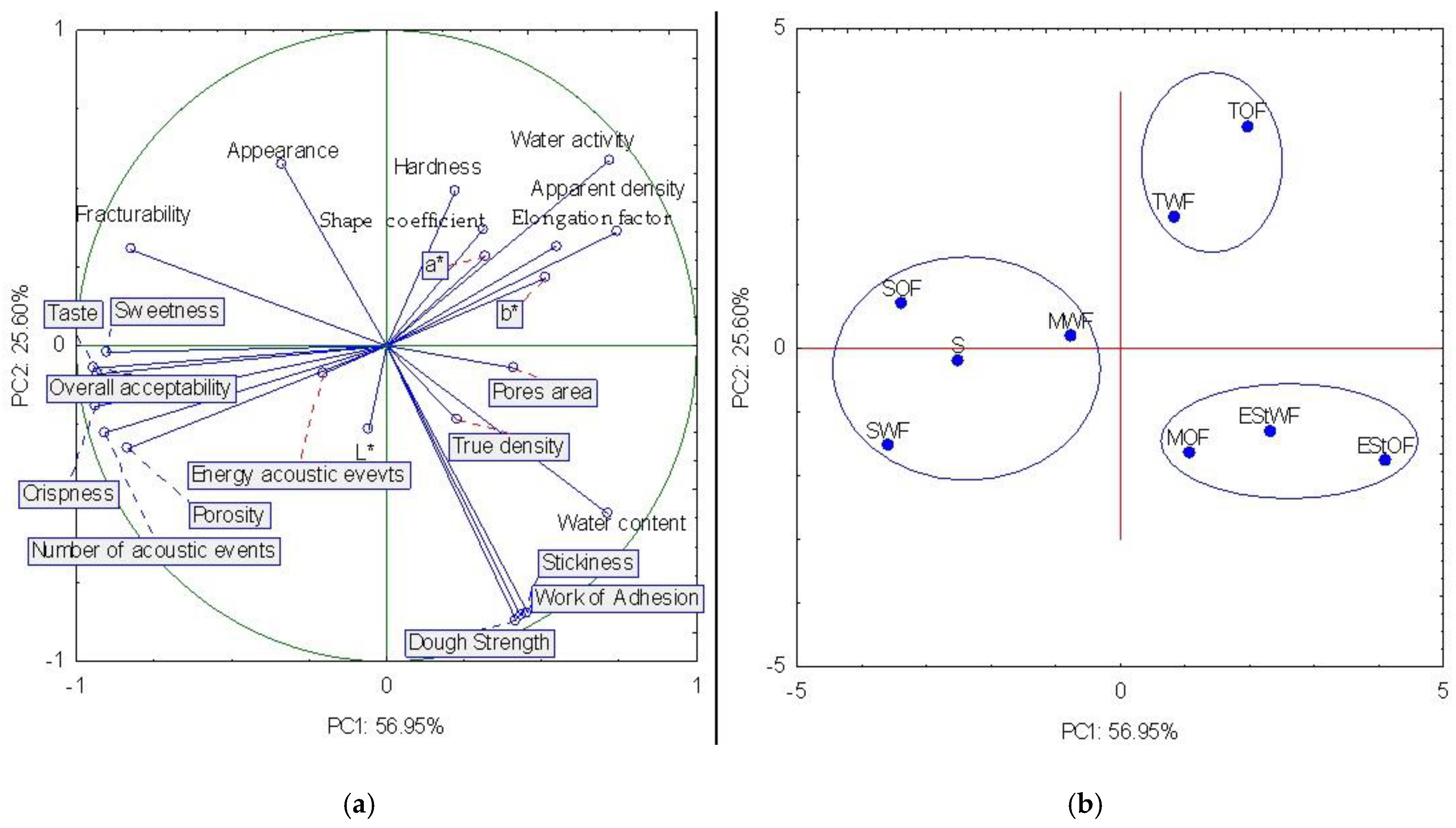

3.4. Correlation Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marzec, A. Właściwości Teksturalne Ciastek Kruchych w Aspekcie ich Struktury; Rozprawy Naukowe i Monografie. 395; Wydawnictwo SGGW: Warszawa, Poland, 2012. [Google Scholar]

- Krystyjan, M.; Gumul, D.; Ziobro, R.; Korus, A. The fortification of biscuits with bee pollen and its effect on physicochemical and antioxidant properties in biscuits. LWT Food Sci. Technol. 2015, 63, 640–646. [Google Scholar] [CrossRef]

- Molina, M.T.; Vaz, S.M.; Leiva, A.; Bouchon, P. Rotary-moulded biscuits: Dough expansion, microstructure and sweetness perception as affected by sucrose: Flour ratio and sucrose particle size. Food Struct. 2021, 29, 100199. [Google Scholar] [CrossRef]

- Pareyt, B.; Talhaoui, F.; Kerckhofs, G.; Brijs, K.; Goesaert, H.; Wevers, M.; Delcour, J.A. The role of sugar and fat in sugar-snap cookies: Structural and textural properties. J. Food Eng. 2009, 90, 400–408. [Google Scholar] [CrossRef]

- Mariotti, M.; Lucisano, M. Chapter 11. Sugar and Sweeteners. In Bakery Products Science and Technology, 2nd ed.; Zhou, W., Hui, Y.H., De Leyn, I., Pagani, M.A., Rosell, C.M., Selman, J.D., Therdthai, N., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 199–221. [Google Scholar] [CrossRef]

- Struck, S.; Jaros, D.; Brennan, C.S.; Röhm, H. Sugar replacement in sweetened bakery goods. Int. J. Food Sci. Technol. 2014, 49, 1963–1976. [Google Scholar] [CrossRef]

- Kweon, M.; Slade, L.; Levine, H. Potential sugar reduction in cookies formulated with sucrose alternatives. Cereal Chem. 2016, 93, 576–583. [Google Scholar] [CrossRef]

- Di Monaco, R.; Miele, N.A.; Cabisidan, E.K.; Cavella, S. Strategies to reduce sugars in food. Curr. Opin. Food Sci. 2018, 19, 92–97. [Google Scholar] [CrossRef]

- van der Sman, R.G.M.; Renzetti, S. Understanding functionality of sucrose in biscuits for reformulation purposes. Crit. Rev. Food Sci. Nutr. 2021, 61, 2756–2772. [Google Scholar] [CrossRef]

- Luo, X.; Arcot, J.; Gill, T.; Louie, J.C.Y.; Ranga, A. A review of food reformulation of baked products to reduce added sugar intake. Trends Food Sci. Technol. 2019, 86, 412–425. [Google Scholar] [CrossRef]

- Wee, M.; Tan, V.; Forde, C. A comparison of psychophysical dose-response behaviour across 16 sweeteners. Nutrients 2018, 10, 1632. [Google Scholar] [CrossRef]

- Laguna, L.; Vallons, K.J.R.; Jurgens, A.; Sanz, T. Understanding the effect of sugar and sugar replacement in short dough biscuits. Food Bioprocess Technol. 2013, 6, 3143–3154. [Google Scholar] [CrossRef]

- Hutchings, S.C.; Low, J.Y.Q.; Keast, R.S.J. Sugar reduction without compromising sensory perception. An impossible dream? Crit. Rev. Food Sci. Nutr. 2019, 59, 2287–2307. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Garcia, J.; Ding, R.; Nguyen, T.H.T.; Grasso, S.; Chatzifragkou, A.; Methven, L. Soluble fibres as sucrose replacers: Effects on physical and sensory properties of sugar-reduced short-dough biscuits. LWT Food Sci. Technol. 2022, 167, 113837. [Google Scholar] [CrossRef]

- Ghosh, S.; Sudha, M.L. A review on polyols: New frontiers for health-based bakery products. Int. J. Food Sci. Nutr. 2012, 63, 372–379. [Google Scholar] [CrossRef] [PubMed]

- Van der Sman, R.G.M.; Jurgens, A.; Smith, A.; Renzetti, S. Universal strategy for sugar replacement in foods? Food Hydrocoll. 2022, 133, 107966. [Google Scholar] [CrossRef]

- Roquette. A unique source of soluble fibre. promoting well-being foods. Agro Food Ind. Hi-Tech 2008, 19, 2–3. [Google Scholar]

- Van den Heuvel, E.G.H.M.; Wils, D.; Pasman, W.J.; Bakker, M.; Saniez, M.-H.; Kardinaal, A.F.M. Short-term digestive tolerance of different doses of NUTRIOSE®FB, a food dextrin, in adult men. Eur. J. Clin. Nutr. 2004, 58, 1046–1055. [Google Scholar] [CrossRef]

- Martínez, M.M.; Díaz, Á.; Gómez, M. Effect of different microstructural features of soluble and insoluble fibres on gluten-free dough rheology and bread-making. J. Food Eng. 2014, 142, 49–56. [Google Scholar] [CrossRef]

- Tate&Lyle. The Natural, Heart-Healthy, Functional Oat Ingredient, 2013. Simply the Goodness of Oats. Our Ingredients—Your Success©2013 Tate&Lyle. Available online: https://www.tateandlyle.com/sites/default/files/2017-03/PromOat%20Beta%20Glucan_Product%20leaflet_EU_Jan14.pdf (accessed on 5 November 2024).

- Lee, S.; Warner, K.; Inglett, G.E. Rheological properties and baking performance of new oat beta-glucan-rich hydrocolloids. J. Agric. Food Chem. 2005, 53, 9805–9809. [Google Scholar] [CrossRef]

- Thirion, F.; Da Silva, K.; Oñate, P.F.; Alvarez, A.S.; Thabuis, C.; Pons, N.; Berland, M.; Le Chatelier, E.; Galleron, N.; Levenez, F.; et al. Diet Supplementation with NUTRIOSE, a Resistant Dextrin, Increases the Abundance of Parabacteroides distasonis in the Human Gut. Mol. Nutr. Food Res. 2022, 66, 2101091. [Google Scholar] [CrossRef]

- Juhel, C.; Tosini, F.; Steib, M.; Wils, D.; Guerin-Deremaux, L.; Lairon, D.; Cara, L. Cholesterol-lowering effect of non-viscous soluble dietary fibre NUTRIOSE®6 in moderately hypercholesterolemic hamsters. Indian J. Exp. Biol. 2011, 49, 219–228. [Google Scholar]

- Wehrli, F.; Taneri, P.E.; Bano, A.; Bally, L.; Blekkenhorst, L.C.; Bussler, W.; Metzger, B.; Minder, B.; Glisic, M.; Muka, T.; et al. Oat Intake and Risk of Type 2 Diabetes, Cardiovascular Disease and All-Cause Mortality: A Systematic Review and Meta-Analysis. Nutrients 2021, 13, 2560. [Google Scholar] [CrossRef] [PubMed]

- Daou, C.; Zhang, H. Oat Beta-Glucan: Its Role in Health Promotion and Prevention of Diseases. Compr. Rev. Food Sci. Food Saf. 2012, 11, 355–365. [Google Scholar] [CrossRef]

- Benítez-Páez, A.; Hess, A.L.; Krautbauer, S.; Liebisch, G.; Christensen, L.; Hjorth, M.F.; Larsen, T.M.; Sanz, Y.; MyNewGut consortium. Sex, Food, and the Gut Microbiota: Disparate Response to Caloric Restriction Diet with Fibre Supplementation in Women and Men. Mol. Nutr. Food Res. 2021, 65, e2000996. [Google Scholar] [CrossRef]

- Culețu, A.; Mohan, G.; Duță, D.E. Rheological Characterization of the Dough with Added Dietary Fibre by Rheometer: A Review. Bulletin UASVM Food Sci. Technol. 2020, 77, 13–24. [Google Scholar] [CrossRef]

- Kanemaru, N.; Harada, S.; Kasahara, Y. Enhancement of Sucrose Sweetness with Soluble Starch in Humans. Chem. Senses 2002, 27, 67–72. [Google Scholar] [CrossRef][Green Version]

- Canalis, M.S.B.; Steffolani, M.E.; León, A.E.; Ribotta, P.D. Effect of different fibres on dough properties and biscuit quality. J. Sci. Food Agric. 2017, 97, 1607–1615. [Google Scholar] [CrossRef]

- Laguna, L.; Primo-Martín, C.; Salvador, A.; Sanz, T. Inulin and erythritol as sucrose replacers in short-dough cookies: Sensory, Fracture, and acoustic properties. J. Food Sci. 2013, 78, S777–S784. [Google Scholar] [CrossRef]

- Roudaut, G.; Dacremont, C.; Vallès Pàmies, B.; Colas, B.; Le Meste, M. Crispness: A critical review on sensory and material science approaches. Trends Food Sci. Technol. 2002, 13, 217–227. [Google Scholar] [CrossRef]

- Marzec, A.; Ziółkowski, T. Structure analysis of selected cereal products in the aspect of their acoustic properties. Pol. J. Food Nutr. Sci. 2007, 57, 89–93. [Google Scholar]

- Marzec, A.; Lewicki, P.P.; Ranachowski, Z. Influence of water activity on acoustic properties of flat extruded bread. J. Food Eng. 2007, 79, 410–422. [Google Scholar] [CrossRef]

- Mieszkowska, A.; Marzec, A. Effect of polydextrose and inulin on texture and consumer preference of short-dough biscuits with chickpea flour. LWT Food Sci. Technol. 2016, 73, 60–66. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Attabi, Z.H.; Al-Habsi, N.; Al-Khusaibi, M. Measurement of Instrumental Texture Profile Analysis (TPA) of Foods. In Techniques to Measure Food Safety and Quality; Khan, M.S., Rahman, S.M., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Błońska, A.; Marzec, A.; Błaszczyk, A. Instrumental Evaluation of Acoustic and Mechanical Texture Properties of Short-Dough Biscuits with Different Content of Fat and Inulin. J. Texture Stud. 2014, 45, 226–234. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Marzec, A.; Ranachowski, Z. Chapter 24. Acoustic properties of foods. In Food Properties Handbook, 2nd ed.; Shafiur Rahman, M., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2009; pp. 811–841. [Google Scholar]

- Grausgruber, H.; Hatzenbichler, E.; Ruckenbauer, P. Analysis of repeated stickiness measures of wheat dough using a texture analyzer. J. Texture Stud. 2003, 34, 69–82. [Google Scholar] [CrossRef]

- Zbikowska, A.; Kowalska, M.; Zbikowska, K.; Onacik-Gür, S.; Łempicka, U.; Turek, P. Study on the incorporation of oat and yeast β-glucan into shortbread biscuits as a basis for designing healthier and high quality food products. Molecules 2022, 27, 1393. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Rodrıguez, P.; Martınez, M.M.; Gomez, M. Effect of the addition of soluble (nutriose, inulin and polydextrose) and insoluble (bamboo, potato and pea) fibres on the quality of sugar-snap cookies. Int. J. Food Sci. Technol. 2018, 53, 129–136. [Google Scholar] [CrossRef]

- Laguna, L.; Sanz, T.; Sarab, S.; Fiszman, S.M. Role of fibre morphology in some quality features of fibre-enriched biscuits. Int. J. Food Prop. 2013, 17, 163–178. [Google Scholar] [CrossRef]

- Raymundo, A.; Fradinho, P.; Nunesa, M.C. Effect of Psyllium fibre content on the textural and rheological characteristics of biscuit and biscuit dough. Bioact. Carbohydr. Diet. Fibre 2014, 3, 96–105. [Google Scholar] [CrossRef]

- Luyten, H.; Plijter, J.J.; Vliet, T.V. Crisp/Crunchy crusts of cellular foods: A literature review with discussion. J. Texture Stud. 2004, 35, 445–492. [Google Scholar] [CrossRef]

- Sayar, S.; Jannink, J.L.; White, P.J. Textural and bile acid-binding properties of muffins impacted by oat β-glucan with different molecular weights. Cereal Chem. J. 2011, 88, 564–569. [Google Scholar] [CrossRef]

- Pareyt, B.; Brijs, K.; Delcour, J.A. Sugar-snap cookie dough setting: The impact of sucrose on gluten functionality. J. Agric. Food Chem. 2009, 57, 7814–7818. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Duizer, L. A review of acoustic research for studying the sensory perception of crisp, crunchy and crackly textures. Trends Food Sci. Technol. 2001, 12, 17–24. [Google Scholar] [CrossRef]

- Miura, M.; Ito, N.; Miyoshi, T. Evaluation of the crispness of porous foods using the acoustic emission technique. J. Soc. Rheol. Japan 2023, 51, 73–84. [Google Scholar] [CrossRef]

- Mieszkowska, A.; Marzec, A. Structure Analysis of Short-Dough Biscuits and Its Correlation with Sensory Discriminants. J. Texture Stud. 2015, 46, 313–320. [Google Scholar] [CrossRef]

- Andreani, P.; de Moraes, J.O.; Murta, B.H.P.; Link, J.V.; Tribuzi, G.; Laurindo, J.B.; Paul, S.; Carciofi, B.A.M. Spectrum crispness sensory scale correlation with instrumental acoustic high-sampling rate and mechanical analyses. Food Res. Int. 2020, 129, 108886. [Google Scholar] [CrossRef]

| Shortbread Biscuits Variant | S | SWF | SOF | TWF | TOF | MWF | MOF | EStWF | EStOF |

|---|---|---|---|---|---|---|---|---|---|

| Sweeteners | Sucrose | Tagatesse | Maltitol | Erytrithol–stevia | |||||

| 36.7 | 36.7 | 36.7 | 36.7 | 36.7 | 36.7 | 36.7 | 17.0 | 17.0 | |

| Flour | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Nutriose® (WF) | 0 | 11.2 | 0 | 11.2 | 0 | 11.2 | 0 | 9.3 | 0 |

| PromOat (OF) | 0 | 0 | 11.2 | 0 | 11.2 | 0 | 11.2 | 0 | 9.3 |

| Fat | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 | 11.7 |

| Wheat starch | 2.8 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 2.8 | 2.8 |

| Powder milk | 2.8 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 2.8 | 2.8 |

| Sodium bicarbonate | 1.40 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Ammonium bicarbonate | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Rapeseed lecithin | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Salt | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Butter flavour | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Water | 21 | 21 | 21 | 25 | 25 | 25 | 25 | 25 | 25 |

| Shortbread Biscuits Variant | Dough | Shortbread Biscuits | |||||

|---|---|---|---|---|---|---|---|

| Stickiness (g) | Work of Adhesion (g·s) | Dough Strength (mm) | L* | a* | b* | ΔE | |

| S | 7.75 ± 1.70 b | 0.22 ± 0.05 b | 0.46 ± 0.03 b | 71.24 ± 0.28 c | 0.40 ± 0.07 a | 17.60 ± 0.22 a | - |

| SWF | 14.09 ± 2.56 cZ | 0.44 ± 0.09 cY | 0.54 ± 0.02 cU | 67.87 ± 0.31 bU | 0.51 ± 0.13 bX | 17.78 ± 0.24 aX | 3.4 ± 0.2 aY |

| SOF | 4.23 ± 0.33 aX | 0.11 ± 0.01 aX | 0.38 ± 0.02 aXY | 59.59 ± 0.59 aX | 3.71 ± 0.03 cU | 23.6 ± 0.67 bU | 13.5 ± 0.2 bW |

| TWF | 6.67 ± 2.49 XY | 0.19 ± 0.09 X | 0.43 ± 0.05 YZ | 68.37 ± 0.43 U | 1.24 ± 0.09 Y | 19.27 ± 0.32 Y | 3.4 ± 0.3 Yy |

| TOF | 4.40 ± 0.58 X | 0.11 ± 0.02 X | 0.38 ± 0.02 X | 61.49 ± 0.12 Y | 3.52 ± 0.11 U | 24.82 ± 0.82 W | 12.5 ± 0.4 W |

| MWF | 7.89 ± 1.91 Y | 0.23 ± 0.06 X | 0.46 ± 0.05 Z | 64.53 ± 0.68 Z | 0.99 ± 0.19 Y | 19.06 ± 0.38 Y | 6.9 ± 2.9 Z |

| MOF | 14.36 ± 2.64 ZU | 0.45 ± 0.09 Y | 0.54 ± 0.02 U | 62.32 ± 0.36 Y | 2.81 ± 0.17 Z | 22.47 ± 0.33 Z | 10.5 ± 0.4 U |

| EStWF | 16.68 ± 3.37 ZU | 0.54 ± 0.13 YZ | 0.57 ± 0.03 UW | 70.68 ± 0.64 W | 0.96 ± 0.06 Y | 19.42 ± 0.51 Y | 2.0 ± 0.2 X |

| EStOF | 17.43 ± 5.47 U | 0.60 ± 0.24 Z | 0.60 ± 0.09 W | 64.05 ± 0.83 Z | 3.01 ± 0.16 Z | 24.98 ± 0.33 W | 10.6 ± 1.7 U |

| One-way analysis of variance (ANOVA) | |||||||

| Effect added fibre | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Two-way analysis of variance (ANOVA) | |||||||

| Effect of sweeteners | <0.001 | <0.001 | <0.001 | <0.001 | 0.014 | <0.001 | 0.014 |

| Effect of fibre | 0.021 | 0.114 | 0.005 | <0.001 | <0.001 | <0.001 | <0.001 |

| Sweeteners × fibre | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Shortbread Biscuits Variant | Water Content (g/100 g) | Water Activity (-) | Apparent Density (kg/m3) | True Density (kg/m3) | Porosity (%) | Pores Area (mm2) | Shape Coefficient (-) | Elongation Factor (-) |

|---|---|---|---|---|---|---|---|---|

| S | 4.87 ± 0.30 | 0.354 ± 0.004 | 319 ± 38 a | 1595 ± 200 | 79.99 ± 2.36 c | 0.010 ± 0.014 a | 0.502 ± 0.269 a | 1.197 ± 0.387 ab |

| SWF | 4.71 ± 0.75 X | 0.317 ± 0.004 XY | 383 ± 32 bX | 1461 ± 262 | 76.00 ± 2.00 bZ | 0.011 ± 0.019 ab | 0.501 ± 0.327 aX | 1.153 ± 0.436 aX |

| SOF | 4.48 ± 0.28 X | 0.289 ± 0.043 X | 394 ± 17 bXY | 1474 ± 339 | 75.33 ± 1.04 aZ | 0.015 ± 0.014 b | 0.598 ± 0.282 bXYZ | 1.271 ± 0.478 bXY |

| TWF | 4.73 ± 1.48 X | 0.540 ± 0.072 ZU | 495 ± 15 Z | 1458 ± 267 | 69.00 ± 0.90 Y | 0.013 ± 0.011 | 0.568 ± 0.245 XYZ | 1.414 ± 0.539 YZ |

| TOF | 5.07 ± 0.09 XY | 0.648 ± 0.013 U | 595 ± 20 U | 1498 ± 381 | 62.68 ± 1.28 X | 0.018 ± 0.021 | 0.636 ± 0.306 YZ | 1.603 ± 0.598 ZU |

| MWF | 6.32 ± 0.16 X | 0.365 ± 0.020 XYZ | 420 ± 26 Y | 1422 ± 295 | 73.69 ± 1.64 Z | 0.029 ± 0.080 | 0.694 ± 0.601 Z | 1.360 ± 0.540 YZ |

| MOF | 6.20 ± 0.84 X | 0.390 ± 0.008 XYZ | 402 ± 20 XY | 1487 ± 322 | 74.80 ± 1.26 Z | 0.013 ± 0.030 | 0.541 ± 0.355 XY | 1.267 ± 0.417 XY |

| EStWF | 8.29 ± 0.25 Y | 0.503 ± 0.121 YZU | 488 ± 29 Z | 1512 ± 270 | 69.42 ± 1.80 Y | 0.032 ± 0.147 | 0.673 ± 0.677 Z | 1.445 ± 0.682 ZU |

| EStOF | 7.51 ± 0.31 XY | 0.445 ± 0.025 XYZU | 594 ± 36 U | 1558 ± 397 | 62.76 ± 2.27 X | 0.018 ± 0.019 | 0.567 ± 0.294 XYZ | 1.629 ± 0.632 XYZU |

| One-way analysis of variance (ANOVA) | ||||||||

| Effect added fibre | 0.745 | 0.171 | <0.001 | 0.081 | <0.001 | 0.015 | 0.020 | <0.001 |

| Two-way analysis of variance (ANOVA) | ||||||||

| Effect of sweeteners | 0.002 | <0.001 | <0.001 | 0.172 | <0.001 | 0.259 | 0.115 | <0.001 |

| Effect of fibre | 0.660 | 0.676 | <0.001 | 0.135 | 0.003 | 0.343 | 0.537 | 0.034 |

| Sweeteners × fibre | 0.837 | 0.216 | <0.001 | 0.919 | 0.015 | 0.068 | <0.001 | 0.001 |

| Shortbread Biscuits Variant | Fracturability (mm) | Hardness (N) | Energy of Acoustic Event (mJ) | Number of AE Events |

|---|---|---|---|---|

| S | 41.21 ± 0.80 b | 30.39 ± 10.32 b | 2025 ± 510 b | 443 ± 210 a |

| SWF | 40.14 ± 0.67 aZ | 16.84 ± 6.11 aX | 1089 ± 321 aX | 631 ± 299 bU |

| SOF | 40.41 ± 0.32 aZ | 25.93 ± 9.09 abXY | 1468 ± 576 abX | 610 ± 198 bUZ |

| TWF | 40.23 ± 0.32 Z | 42.35 ± 9.56 Z | 898 ± 300 X | 20 ± 7 X |

| TOF | 39.15 ± 0.55 Y | 30.61 ± 4.42 Y | 1274 ± 198 X | 11 ± 5 X |

| MWF | 38.99 ± 0.32 Y | 44.36 ± 8.83 Z | 3742 ± 700 Z | 476 ± 80 Z |

| MOF | 39.00 ± 0.54 Y | 26.22 ± 4.53 XY | 2347 ± 352 Y | 316 ± 70 Y |

| EStWF | 38.65 ± 0.44 Y | 24.27 ± 8.35 XY | 940 ± 231 X | 29 ± 14 X |

| EStOF | 37.47 ± 0.36 X | 29.55 ± 8.69 Y | 1181 ± 430 X | 34 ± 11 X |

| One-way analysis of variance (ANOVA) | ||||

| Effect added fibre | 0.002 | 0.005 | 0.018 | <0.001 |

| Two-way analysis of variance (ANOVA) | ||||

| Effect of sweeteners | <0.001 | <0.001 | 0.045 | <0.001 |

| Effect of fibre | <0.001 | 0.027 | 0.030 | <0.001 |

| Sweeteners × fibre | <0.001 | <0.001 | 0.025 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marzec, A.; Stępień, A.; Goclik, A.; Kowalska, H.; Kowalska, J.; Salamon, A. Analysis of the Correlation of Microstructure, Instrumental Texture, and Consumer Acceptance of Shortbread Biscuits with Selected Sweeteners and Fibre. Appl. Sci. 2025, 15, 1137. https://doi.org/10.3390/app15031137

Marzec A, Stępień A, Goclik A, Kowalska H, Kowalska J, Salamon A. Analysis of the Correlation of Microstructure, Instrumental Texture, and Consumer Acceptance of Shortbread Biscuits with Selected Sweeteners and Fibre. Applied Sciences. 2025; 15(3):1137. https://doi.org/10.3390/app15031137

Chicago/Turabian StyleMarzec, Agata, Alicja Stępień, Agnieszka Goclik, Hanna Kowalska, Jolanta Kowalska, and Agnieszka Salamon. 2025. "Analysis of the Correlation of Microstructure, Instrumental Texture, and Consumer Acceptance of Shortbread Biscuits with Selected Sweeteners and Fibre" Applied Sciences 15, no. 3: 1137. https://doi.org/10.3390/app15031137

APA StyleMarzec, A., Stępień, A., Goclik, A., Kowalska, H., Kowalska, J., & Salamon, A. (2025). Analysis of the Correlation of Microstructure, Instrumental Texture, and Consumer Acceptance of Shortbread Biscuits with Selected Sweeteners and Fibre. Applied Sciences, 15(3), 1137. https://doi.org/10.3390/app15031137