Thermal Behavior and Operation Characteristic of the Planetary Gear for Cutting Reducers

Abstract

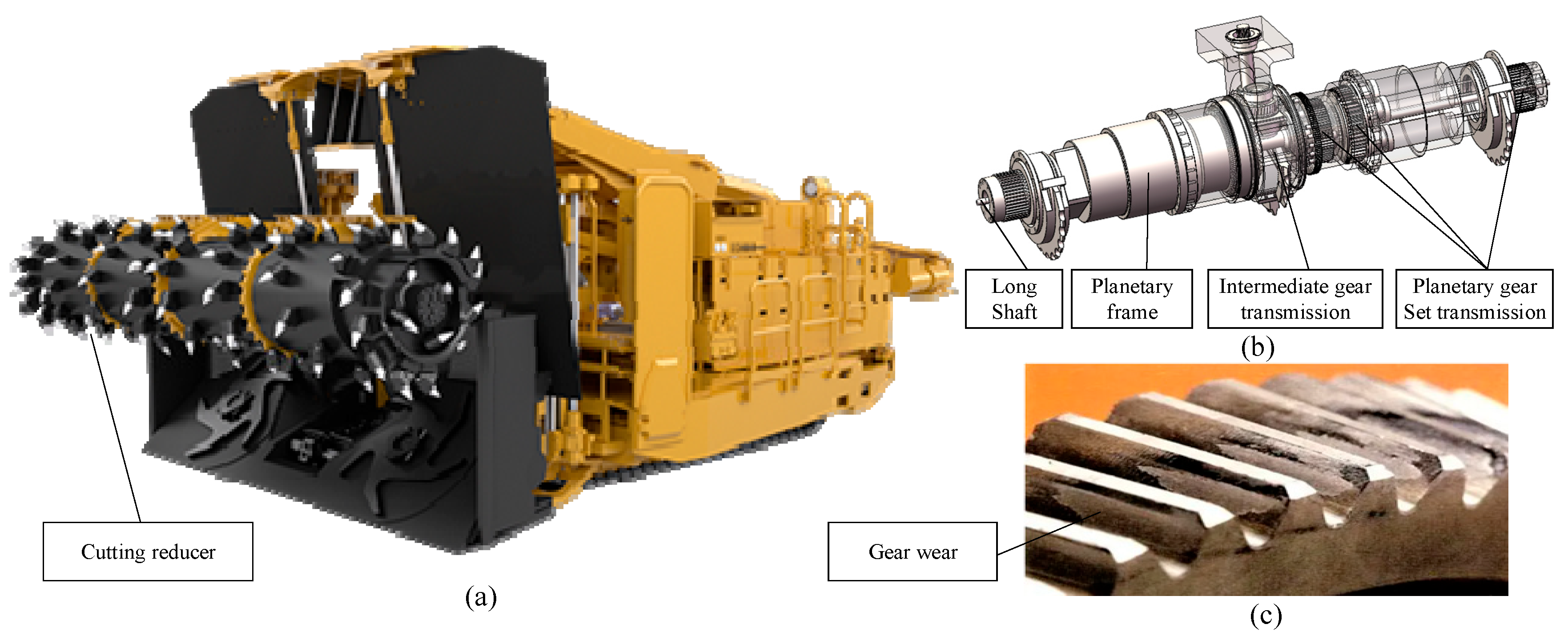

1. Introduction

2. Experimental Analysis of Cutting Reducer

2.1. Cutting Reducer Performance

2.2. Running Temperature Analysis

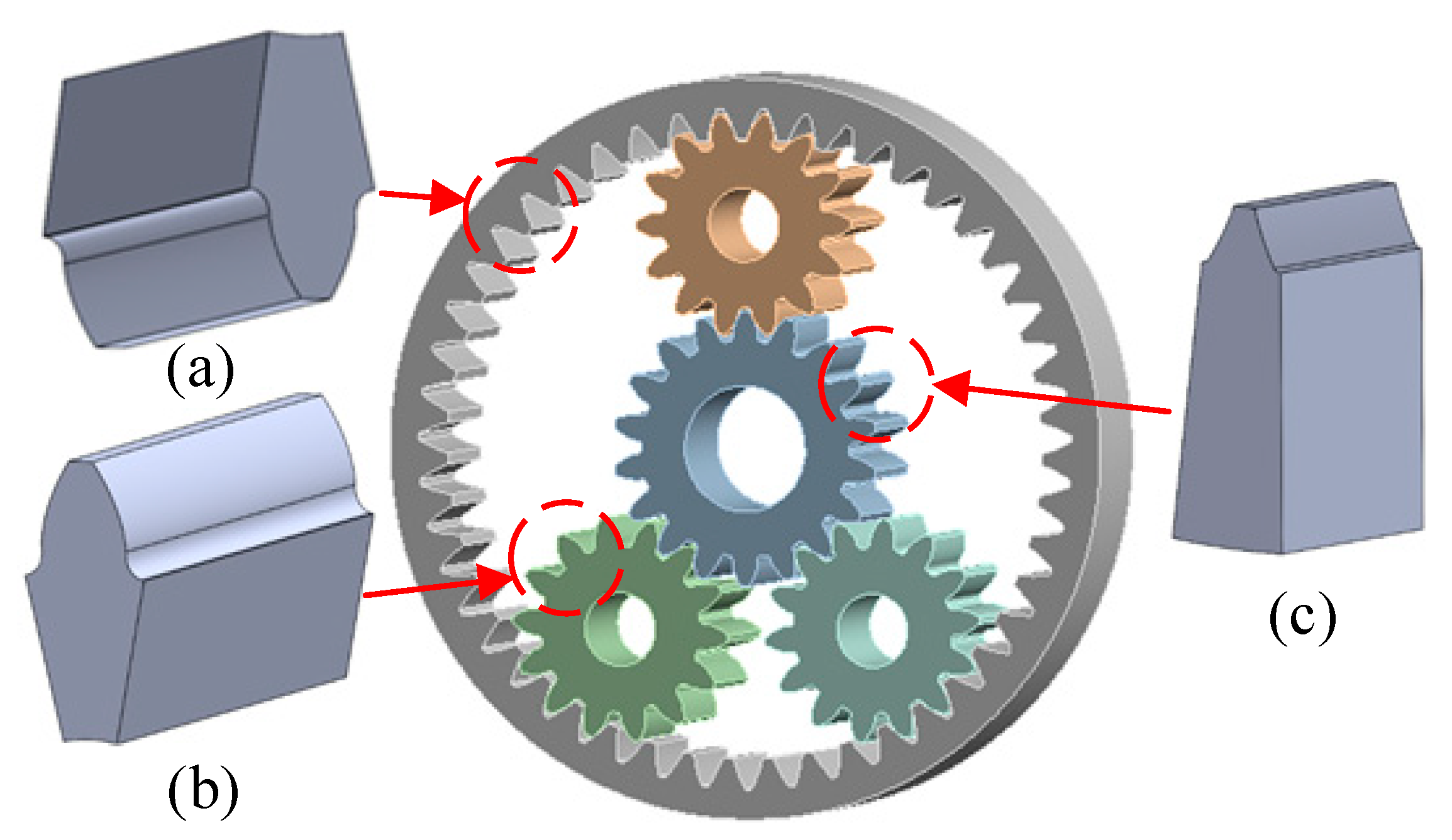

3. Thermal Behavior Analysis of Planetary Gear

3.1. Thermal Boundary Conditions

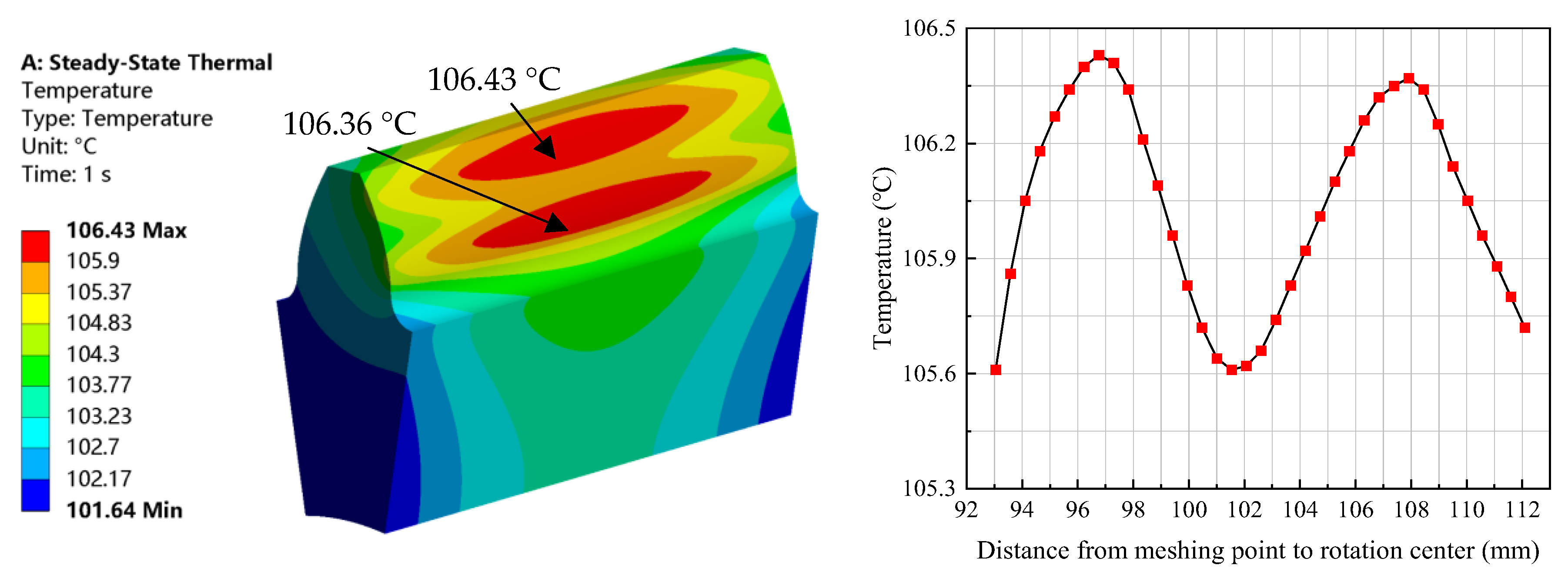

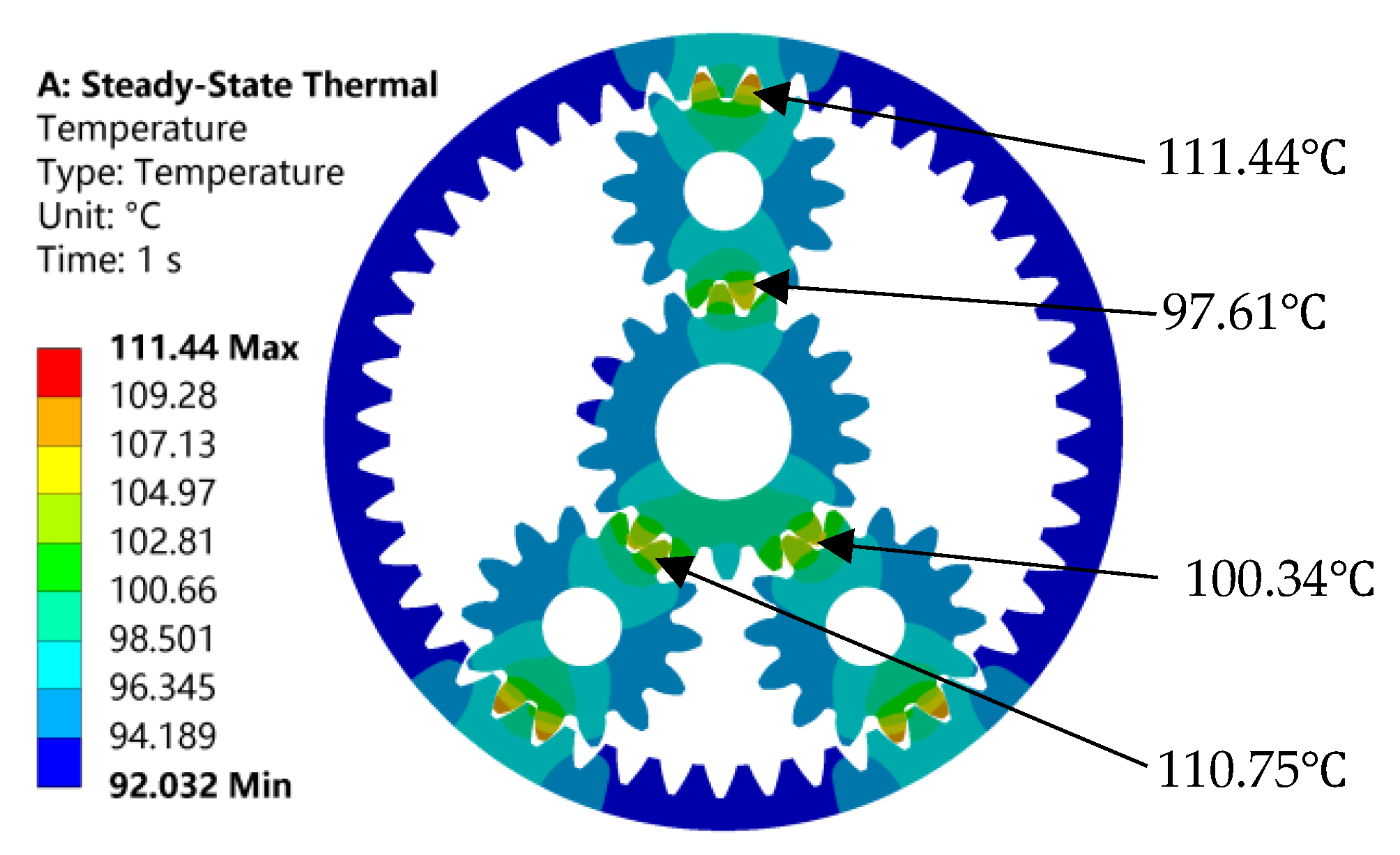

3.2. Planet Gear Temperature Field

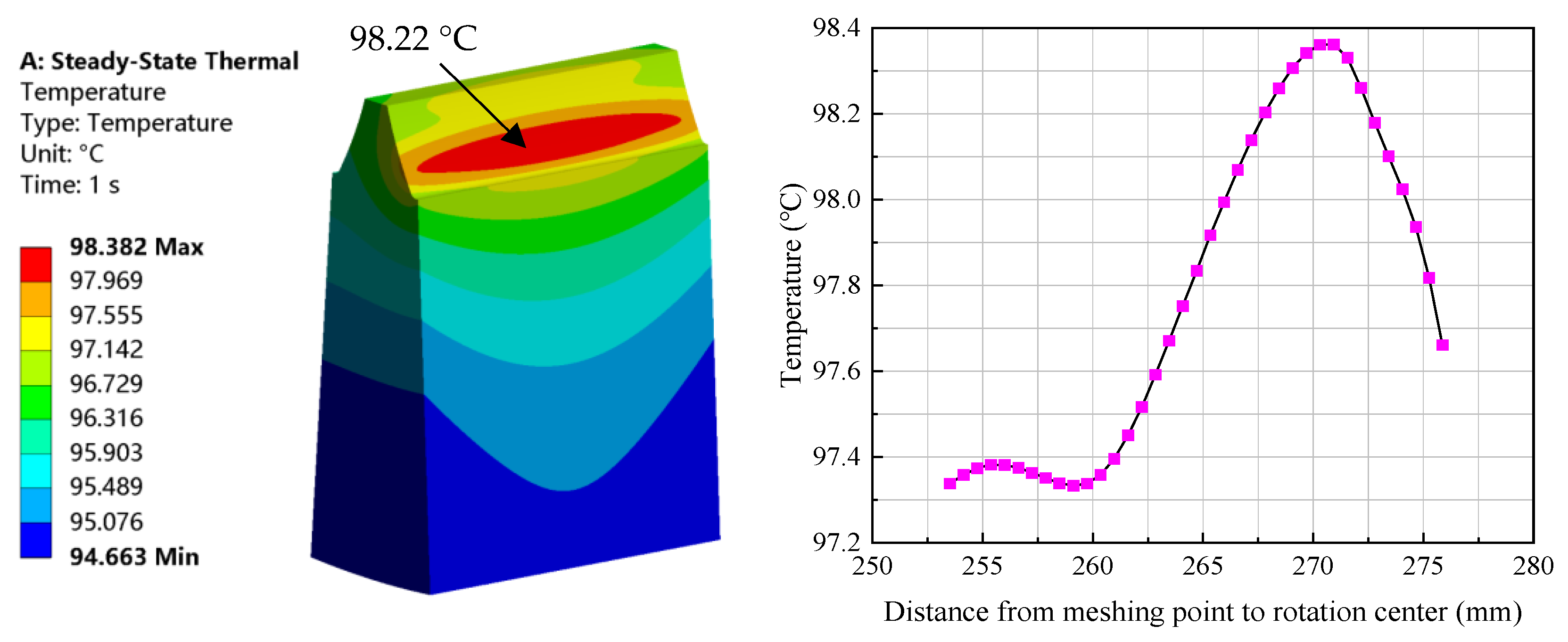

3.3. Sun Gear Temperature Field

3.4. Internal Gear Temperature Field

4. Thermal–Structural Coupling of Planetary Gear Set

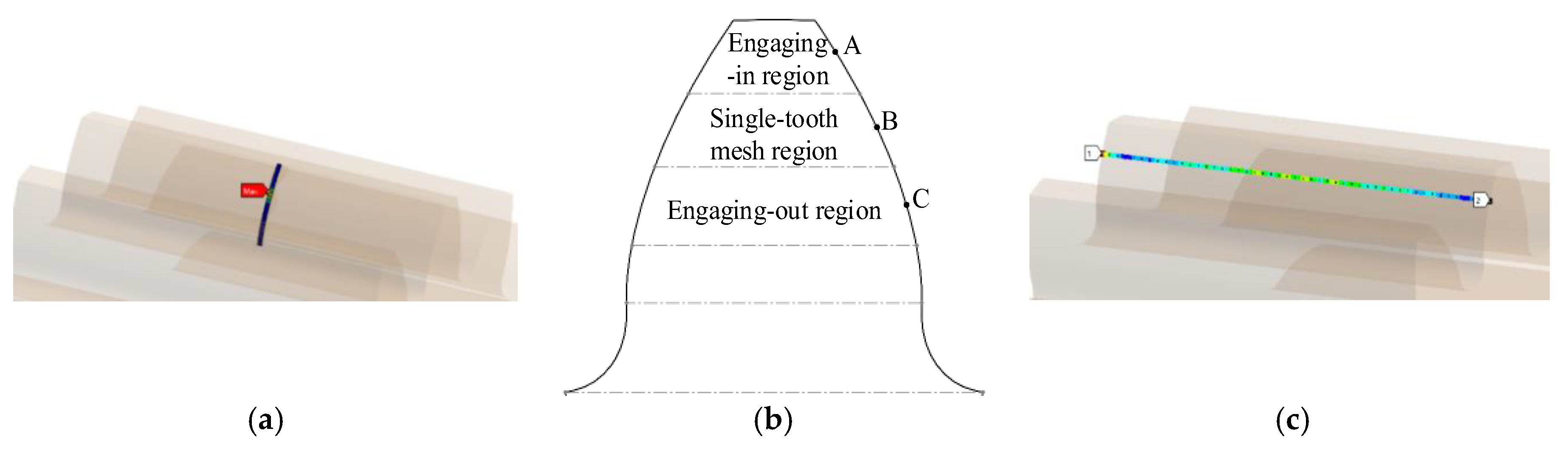

4.1. Meshing and Contact Constraints

4.2. Thermal Analysis

4.3. Contact Stress and Strain Analysis

4.4. Comparative Analysis Between Static and Coupling

5. Actual Performance Analysis of Planetary Gear Set

5.1. Strength Check and Life Analysis

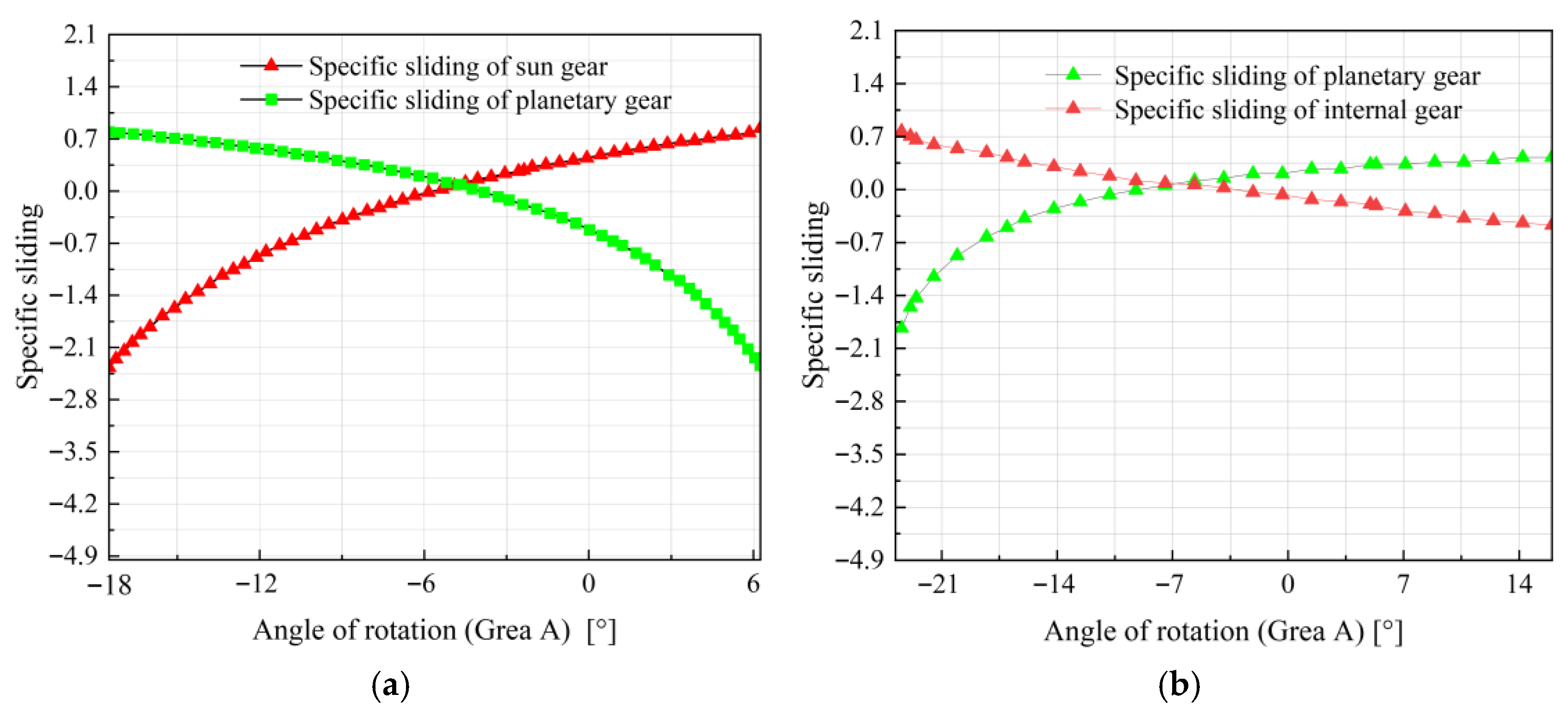

5.2. Slip Rate Analysis

5.3. Transmission Error

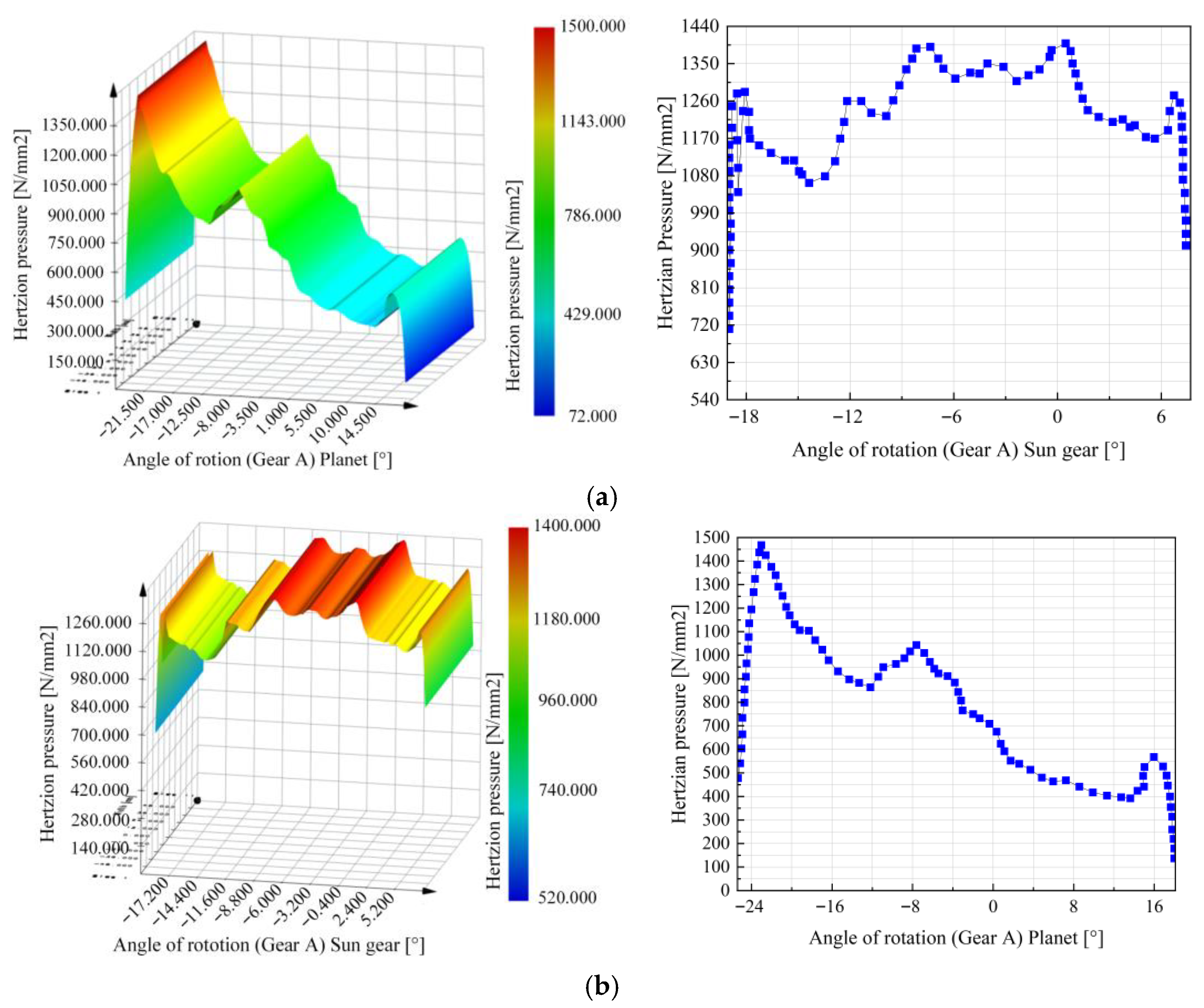

5.4. Stress Analysis

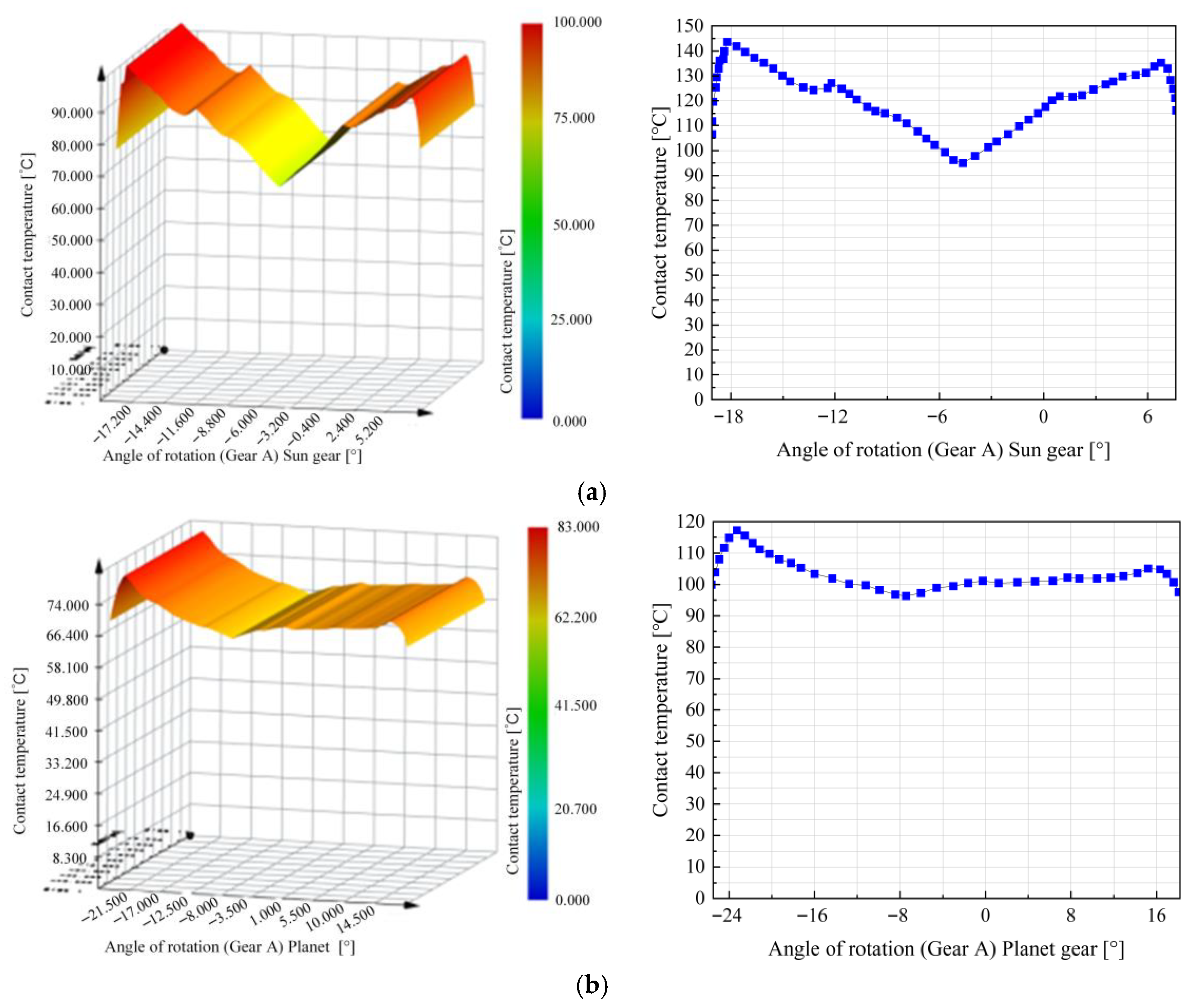

5.5. Contact Temperature

6. Conclusions

- (1)

- The experiment confirmed that the cutting reducer has a high transmission efficiency of 91.3%. The temperature rise is more obvious under high loading conditions where the maximum temperature can reach 94 °C. The planetary gear set is thermally stable and functions well at low speeds without load. However, the highest temperature measurement of 70.8 °C at the intermediate shaft of the planetary gear set may indicate the risk of localized overheating. It is recommended to upgrade the lubrication method from splash lubrication to targeted forced circulation, with fixed high-pressure nozzles arranged at the exit of the meshing zone to utilize high-speed oil flow for removing accumulated heat.

- (2)

- A FEM model for thermal analysis of the planetary gear set is developed with the thermal boundary conditions including the heat transfer coefficient and heat flux being obtained theoretically. The greatest temperature is observed to occur at the planetary gear with a magnitude of 111.21 °C, and the maximum deformation of 0.11413 mm is located at the internal gear, showing the potential of lubrication failure and excessive wear. In engineering practice, synthetic lubricating oils with a high viscosity index should be selected to maintain sufficient oil-film thickness and strength under high temperatures, thereby protecting the high-temperature meshing regions of the planetary gears and internal ring gear.

- (3)

- A thermal–structural coupling model of the planetary gear set is developed. It is found that the temperature of the planetary gear is the highest, followed by the sun gear and the internal gear. Moreover, the thermal load and deformation are more distinct. The thermal stress of the planetary gear set is 11.5% higher than that of the pure static simulation, and the deformation is increased by 38.4%. This quantitative result provides a direct basis for structural design. To counteract the influence of thermal deformation, pre-compensation modification techniques can be adopted to implement tip relief and crowning on the sun gear and planetary gears.

- (4)

- The strength calculation and dynamic contact analysis of the planetary gear set are carried out using the KISSsoft (2022) software. Through analysis, the slip rate of the external meshing gear pair is large, and the transmission error fluctuates frequently, indicating the likelihood of the gear transmission instability and wear resistance. Thus, appropriate meshing angles and modifications should be adopted. Additionally, the contact temperature of the planetary gear set is obvious with load; therefore, it is necessary to use better lubrication and gear oil for heat dissipation. Therefore, to ensure reliability under extreme operating conditions, greater thermal backlash should be reserved in the tolerance design to accommodate tooth-thickness expansion at high temperatures and prevent gear jamming and shaft-locking failures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Z.; Li, J.; Du, W.; Zhao, S.; Li, X.; Zhu, F.; Ren, H. A High-Accuracy Position and Orientation Measurement Method for Bolter-Miner Based on Double-Screen Visual Target. Measurement 2024, 225, 114011. [Google Scholar] [CrossRef]

- Ji, X.; Yang, Y.; Qu, Y.; Jiang, H.; Wu, M. Health Diagnosis of Roadheader Based on Reference Manifold Learning and Improved K-Means. Shock. Vib. 2021, 2021, 6311795. [Google Scholar] [CrossRef]

- Park, C.I. Influence of Tooth Profile and Surface Roughness on Wear of Spur Gears Considering Temperature. J. Mech. Sci. Technol. 2023, 37, 5297–5306. [Google Scholar] [CrossRef]

- Farshad, N.; Ali, M.R. Concurrent Impact of Chipping and Pitting Damages in a Locomotive Power Transmission System. J. Mech. Sci. Technol. 2022, 36, 3791–3800. [Google Scholar] [CrossRef]

- Qin, X.; Pang, R.; Zhao, X.; Li, F. Fracture Failure Analysis of Internal Teeth of Ring Gear Used in Reducer of Coal Mining Machine. Eng. Fail. Anal. 2018, 84, 70–76. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, Y.; Yu, M.; Yu, D.; Lv, J.; Yin, J.; Liu, J.; Wu, R. Triboelectric Sensor for Planetary Gear Fault Diagnosis Using Data Enhancement and CNN. Nano Energy 2022, 103, 107804. [Google Scholar] [CrossRef]

- Zhou, C.; Xing, M.; Wang, H.; Hu, B. A Novel Thermal Network Model for Predicting the Contact Temperature of Spur Gears. Int. J. Therm. Sci. 2021, 161, 106703. [Google Scholar] [CrossRef]

- Hu, X.; Chen, J.; Wu, M.; Wang, J. Thermal Analysis of Herringbone Gears Based on Thermal Electrohydrodynamic Lubrication Considering Surface Roughness. Energies 2021, 14, 8564. [Google Scholar] [CrossRef]

- Roda-Casanova, V.; Gonzalez-Perez, I. Investigation of the Effect of Contact Pattern Design on the Mechanical and Thermal Behaviors of Plastic-Steel Helical Gear Drives. Mech. Mach. Theory 2021, 164, 104401. [Google Scholar] [CrossRef]

- Li, W.; Zhai, P.; Ding, L. Analysis of Thermal Characteristic of Spur/Helica Gear Transmission. J. Therm. Sci. Eng. Appl. 2019, 11, 021003. [Google Scholar] [CrossRef]

- Lan, W.; Fan, S.; Fan, S. Effects of Gear Structural Parameters on Unsteady-State Temperature Field of Large Transmission Ratio Gear and Tooth Root Thermal Stress. Appl. Math. Model. 2022, 108, 701–723. [Google Scholar] [CrossRef]

- Zhang, T.; Lin, T.; Xiang, Y. Analytical Investigation of Thermal-Fluid Iterative Coupling and Parametric Influences in Oil-Jet Lubricated Double-Helical Planetary Gear Transmissions. Aerosp. Sci. Technol. 2025, 169, 111405. [Google Scholar] [CrossRef]

- Bi, X.; Wang, J.; Mo, R. Nonlinear Dynamic Characteristics of Wind Power Concentric Planetary-Face Gear System with Elastic Lubrication and Friction Considering Thermal Effect under Random Wind Load. Front. Phys. 2024, 12, 1505956. [Google Scholar] [CrossRef]

- Yu, Z.; Sun, Z.; Zhang, S.; Wang, J. The Coupled Thermal-Structural Resonance Reliability Sensitivity Analysis of Gear-Rotor System with Random Parameters. Sustainability 2023, 15, 255. [Google Scholar] [CrossRef]

- Yao, G.; Liu, G.; Su, J.; Yang, H.; Jin, M.; Wei, X. Analysis of the Effect of Three-Dimensional Topology Modification on Temperature Field and Thermal Deformation of Internal Helical Gears Pair. Appl. Sci. 2025, 15, 6244. [Google Scholar] [CrossRef]

- Živković, P.; Milutinović, M.; Tica, M.; Trifković, S.; Čamagić, I. Reliability Evaluation of Transmission Planetary Gears “Bottom-up” Approach. Eksploat. I Niezawodn. Maint. Reliab. 2023, 25, 1. [Google Scholar] [CrossRef]

- Li, M.; Luo, Y.; Xie, L. Fatigue Reliability Prediction Method of Large Aviation Planetary System Based on Hierarchical Finite Element. Metals 2022, 12, 1785. [Google Scholar] [CrossRef]

- Alkarkhi, N.; Stojanovic, N.; Al-Zubaidi, S.; Jweeg, M.; Aljibori, H.; Abed, A.; Abdullah, O. Experimental Investigation of Thermal Effect on the Frictional Characteristics of HCC Friction Clutch Material. Tribol. Ind. 2024, 46, 141–150. [Google Scholar] [CrossRef]

- Muratović, E.; Muminović, A.J.; Gierz, Ł.; Smailov, I.; Sydor, M.; Delić, M. An Analysis of the Tribological and Thermal Performance of PVDF Gears in Correlation with Wear Mechanisms and Failure Modes Under Different Load Conditions. Coatings 2025, 15, 800. [Google Scholar] [CrossRef]

- Cao, H.-R.; Wei, C.; Chen, X. Physical Model-Driven Performance Degradation Analysis of Planetary Gearboxes. J. Reliab. Sci. Eng. 2025, 1, 025302. [Google Scholar] [CrossRef]

- Capelli, F.; Riba, J.-R.; Sanllehí, J. Finite Element Analysis to Predict Temperature Rise Tests in High-Capacity Substation Connectors. IET Gener. Transm. Distrib. 2017, 11, 2283–2291. [Google Scholar] [CrossRef]

- Rogkas, N.; Pelekis, M.; Manios, A.; Anastasiadis, A.; Vasileiou, G.; Tsoukalis, A.; Manopoulos, C.; Spitas, V. Design, Simulation and Multi-Objective Optimization of a Micro-Scale Gearbox for a Novel Rotary Peristaltic Pump. Micromachines 2023, 14, 2099. [Google Scholar] [CrossRef] [PubMed]

- Bergstedt, E.; Lin, J.; Olofsson, U. Influence of Gear Surface Roughness on Pitting and Micropitting Life. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2020, 234, 4953–4961. [Google Scholar] [CrossRef]

- Irsel, G. Bevel Gears Strength Calculation: Comparison ISO, AGMA, DIN, KISSsoft and ANSYS FEM Methods. J. Chin. Soc. Mech. Eng. 2022, 43, 315–323. [Google Scholar]

- JB/T 5558-2015; Test method of Reduction (Increase) Gear Unites. China Machinery Industry Press: Beijing, China, 2015.

- Xia, R.; Chen, Y.; Feng, Y. A Method to Measure Thermal Conductivity of Vacuum Insulation Panel Using Enhanced Extreme Learning Machine Model. J. Therm. Sci. 2020, 29, 623–631. [Google Scholar] [CrossRef]

- Lu, F.; Yuan, L.; Zhao, Z.; Wang, C.; Bao, H. Parameter Design Method for the Heat Transfer Performance of a Fan-Driven Gearbox under Planetary Gear Opening and Oil-Return Conditions. J. Mech. Sci. Technol. 2021, 35, 4169–4178. [Google Scholar] [CrossRef]

- ISO/TS 6336-20/21; Calculation of Load Capacity of Gears—Part 20/21: Technical Specifications for Specific Application Scenarios. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 6336:2019; Calculation of Load Capacity of Gears. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO/TR 13989-2:2000; Gears—Wear and Damage—Part 2: Technical Report on Wear Assessment Methods. International Organization for Standardization: Geneva, Switzerland, 2000.

- Peng, S.; Ma, Z.; Chen, B.; Qin, S.-L.; Wang, S.-Y. Theoretical and Experimental Investigation on Internal Gear Pair with Small Sliding Ratio. J. Cent. South. Univ. 2018, 25, 831–842. [Google Scholar] [CrossRef]

| Nominal Power (kw) | 170 |

|---|---|

| Nominal torque (N·m) | 42,513.36 |

| Tooth number Z1, Z2, Z3 (-) | 18, 14, 47 |

| Displacement factor x1, x2, x3 (-) | 0.28, 0.39, 0.48 |

| Tooth addendum coefficient ha/hf (-) | 1.0 |

| Tooth width (mm) | 102 |

| Material density ρ1, ρ2, ρ3 (kg/m3) | 7830, 7830, 7850 |

| Elastic modulus (Pa) | 2.06 × 1011 |

| Center distance (mm) | 182.5 |

| Poisson’s Ratio (-) | 0.3 |

| Specific heat c1, c2, c3 (J/(kg·K)) | 485, 485, 460 |

| Coefficient of linear expansion (m/°C) | 1.15 × 10−5 |

| Pressure angle (rad) | 20 |

| Thermal conductivity λ1, λ2, λ3 (W/(m·°C)) | 50/50/44 |

| Number | Power (kw) | Frequency |

|---|---|---|

| 1 | 85 | 15% |

| 2 | 170 | 30% |

| 3 | 255 | 35% |

| 4 | 340 | 15% |

| 5 | 374 | 5% |

| Input Items (Calculation with Load Spectrum) | Factor |

|---|---|

| Contact ratios (Sun—Planets) εαm, εβ, εγm | 1.221, 0.000, 1.227 |

| Contact ratios (Planets—Internal gear) εαm, εβ, εγm | 1.466, 0.000, 1.466 |

| Actual tip circle (mm) of Sun, Planets, Internal gear | 224.449, 182.936, 506.661 |

| Root safety of Sun, Planets, Internal gear | 1.982, 1.579, 1.911 |

| Flank safety of Sun, Planets, Internal gear | 0.905, 1.001, 1.190 |

| Safety against scuffing (integral temperature) of Sun, Planets, Internal gear | 1.616, 1.616, 3.229 |

| Safety against scuffing (flash temperature) of Sun, Planets, Internal gear | 1.634, 1.634, 6.261 |

| Required safety for tooth root—SFmin | 1.400 |

| Required safety for tooth flank—SHmin | 1.000 |

| Required service life (h) | 10,000.000 |

| Service life—Hatt (h) | 8783.500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Zhang, W.; Wang, C.; Yuan, J.; Ye, F.; Shi, L.; Wang, D. Thermal Behavior and Operation Characteristic of the Planetary Gear for Cutting Reducers. Appl. Sci. 2025, 15, 13219. https://doi.org/10.3390/app152413219

Shen J, Zhang W, Wang C, Yuan J, Ye F, Shi L, Wang D. Thermal Behavior and Operation Characteristic of the Planetary Gear for Cutting Reducers. Applied Sciences. 2025; 15(24):13219. https://doi.org/10.3390/app152413219

Chicago/Turabian StyleShen, Jiahe, Wenyu Zhang, Chengjian Wang, Jianming Yuan, Fangping Ye, Lubing Shi, and Daibing Wang. 2025. "Thermal Behavior and Operation Characteristic of the Planetary Gear for Cutting Reducers" Applied Sciences 15, no. 24: 13219. https://doi.org/10.3390/app152413219

APA StyleShen, J., Zhang, W., Wang, C., Yuan, J., Ye, F., Shi, L., & Wang, D. (2025). Thermal Behavior and Operation Characteristic of the Planetary Gear for Cutting Reducers. Applied Sciences, 15(24), 13219. https://doi.org/10.3390/app152413219