Robust Control of Drillstring Vibrations: Modeling, Estimation, and Real-Time Considerations

Abstract

1. Introduction

1.1. Drill String Models and Existing Vibration Control Methods

1.2. Proposed Method

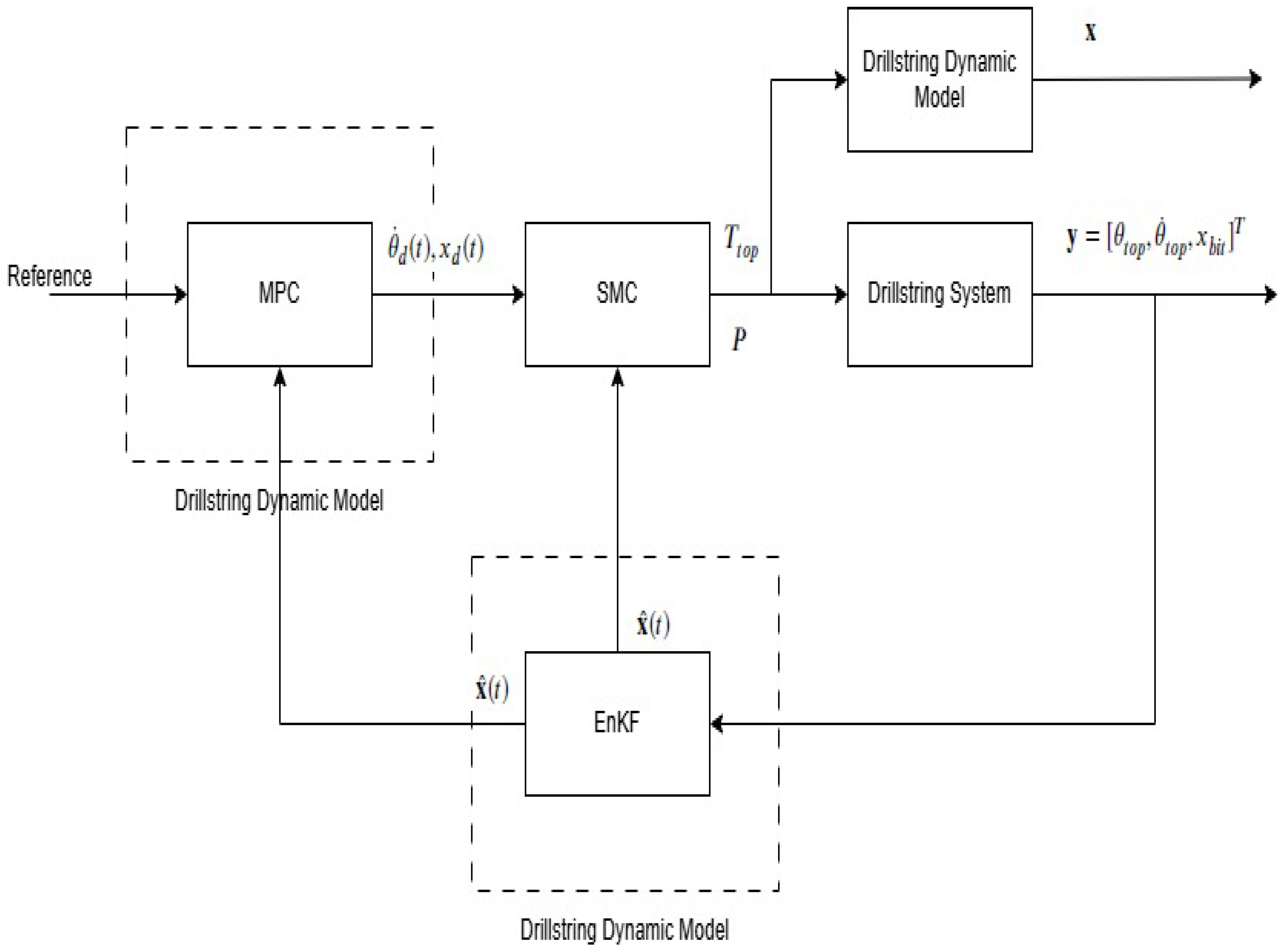

- Ensemble Kalman Filter: for estimating unmeasured states, such as internal friction variables, drill bit velocities, and system parameters, based on partial and noisy sensor data;

- Model Predictive Control: for generating optimal reference trajectories that obey physical and operational constraints, such as actuator torque limits, axial displacement ranges, and speed profiles;

- Sliding Mode Control: for robust low-level tracking of the MPC trajectories with high disturbance rejection and finite-time convergence, particularly suitable for systems with uncertainties and nonlinearities.

- A comprehensive coupled axial–torsional dynamic model of the drillstring is considered, incorporating stochastic bit–rock interaction and switching behavior between contact and lift-off states. This model captures critical nonlinearities and transient effects observed in real drilling operations.

- A rate-of-penetration (ROP) model is integrated together with a nonlinear friction-based torque-on-bit formulation. These subsystems jointly represent stick–slip oscillations and bit bounce phenomena, enabling realistic reproduction of downhole vibrations.

- A hybrid control architecture is proposed, combining MPC, SMC, and EnKF. The EnKF provides real-time estimation of hidden states and external disturbances; MPC generates constraint-satisfying reference trajectories; and SMC robustly tracks these trajectories under uncertainty and model mismatch.

- A complete simulation framework is constructed, enabling systematic validation of the proposed control strategy. The framework accounts for actuator saturation, sensor noise, and modeling uncertainty, reflecting realistic field constraints.

- Simulation case studies are conducted to demonstrate the robustness, adaptability, and vibration mitigation capabilities of the controller under dynamically varying operating conditions.

2. Drillstring System Modeling

2.1. Axial Vibration Dynamics

2.2. Torsional Vibration Dynamics

- is the inertia matrix;

- is the state vector of angular positions;

- and are the damping and stiffness matrices;

- is the external torque vector;

- is the torque applied at the surface by the top drive;

- is the torque exerted by the rock formation on the drill bit;

2.3. Compact Matrix Form

2.4. Discussions

3. Hybrid Control Design

3.1. Design Motivation

3.2. Notational Consistency for Control Design

- ,

- ,

- P: appears as an input in SMC design

- : appears in equivalent control term of torsional SMC

- , : reference bit trajectories generated by MPC.

3.3. Sliding Mode Control Design

- is the angular velocity tracking error;

- is the actual angular velocity of the drill bit;

- is the desired angular velocity trajectory;

- is a scalar gain that determines the convergence rate.

- is the axial velocity tracking error;

- is the actual drill bit velocity in the axial direction;

- is the desired axial velocity trajectory;

- is a gain for axial sliding dynamics.

- Estimate the maximum expected disturbance from experimental data or conservative system modeling.

- Choose , where is typically 5–10% of the maximum actuator capability.

- Validate the performance through simulation and tune based on observed trade-offs:

- If the system exhibits excessive chattering, reduce k or increase the boundary layer width .

- If convergence to the sliding surface is too slow or weak under disturbance, increase k.

3.4. Model Predictive Control Design

- Q and R are weighting matrices for tracking error and control effort, respectively;

- is a scalar weight penalizing stick–slip severity;

- , defined in [46], represents the Stick–Slip Severity Index at step i, defined as:computed over a local sliding window.

- Torque limits: to ensure actuator safety and feasibility;

- Axial displacement limits: to prevent excessive mechanical stresses;

- Velocity and acceleration bounds: Constraints on and to avoid abrupt transitions and protect structural integrity.

- State soft constraints: Slack variables can be included for flexible enforcement, with corresponding penalties in the objective function;

- Input bounds: P and are restricted within operational ranges to prevent actuator saturation and excessive wear.

4. Ensemble Kalman Filter Design

4.1. Measurements

4.2. EnKF Equations

5. Hybrid Control Framework

- EnKF state estimation: The EnKF processes real-time sensor data and estimates the current system state vector , including velocities and internal states;

- MPC trajectory generation: The MPC uses estimated from EnKF as its starting point to solve a constrained optimization problem over a prediction horizon N. The resulting optimal reference trajectories and their derivatives are computed;

- Reference delivery: The predicted reference trajectory is sent to the SMC as the target to track at time t;

- SMC control synthesis: The SMC computes control inputs and P based on the predicted sliding surfaces and , and outputs the signal to the actuators at time t.

- Robust tracking and stability: SMC enforces convergence to reference trajectories even under bounded uncertainties and unmodeled nonlinearities such as bit-rock interactions and friction hysteresis;

- Constraint-aware optimization: MPC optimizes trajectories under hard constraints (torque, displacement, rate) and soft constraints (vibration suppression, smoothness), ensuring safe and efficient operation;

- Delay and disturbance mitigation: Predictive planning in MPC combined with state forecasting allows real-time delay compensation. The SMC switching law handles abrupt disturbances with high responsiveness;

- Separation of roles: The outer MPC layer shapes long-term behavior and respects system limits, while the inner SMC ensures fast and stable error correction in real time.

- SMC gains must be selected to ensure fast convergence without excessive chattering. Gains should exceed the maximum disturbance estimate by a safety margin;

- MPC horizon N and weight matrices determine optimization fidelity versus computational load. Longer horizons improve foresight, while higher penalty weights suppress excessive actuation;

- Boundary layer width in SMC should reflect actuator resolution and delay robustness. A wider boundary layer reduces chattering but may increase steady-state error.

- SMC controller: Runs at high frequency (e.g., 1–2 Hz) to provide immediate reaction to state deviations;

- MPC optimizer: Executes at a lower frequency (e.g., 0.01–0.1 Hz), suitable for online quadratic programming solvers or convex approximations;

- EnKF estimator: Runs synchronously with sensor data acquisition (e.g., 1–2 Hz), updating state predictions for both control modules.

6. Practical Considerations

6.1. Handling Data Quality Issues

- Sensor fusion from redundant measurements (e.g., multiple encoders or accelerometers);

- Online monitoring of data quality metrics and automatic reconfiguration of EnKF gains;

- Transition to more robust estimation methods such as the Unscented Kalman Filter (UKF) or particle filters for nonlinear and uncertain environments;

- Periodic recalibration and health checks of sensors during drilling pauses or transitions.

6.2. Adaptive Inputs Adjustment Under Vibration Detection

- If , the nominal setpoints are used;

- If , the system begins ramping down and increasing damping gain in the SMC;

- If , the system reduces WOB (if controllable) and switches to a vibration mitigation mode.

7. Case Study and Results

- Open-loop (No Control): Constant surface torque and WOB inputs are applied without any feedback control;

- Sliding Mode Control Only: A robust SMC tracks fixed references for the rotational velocity;

- MPC–SMC Hybrid Control: MPC optimizes time-varying reference trajectories, while SMC robustly tracks these references.

7.1. Simulation Setup

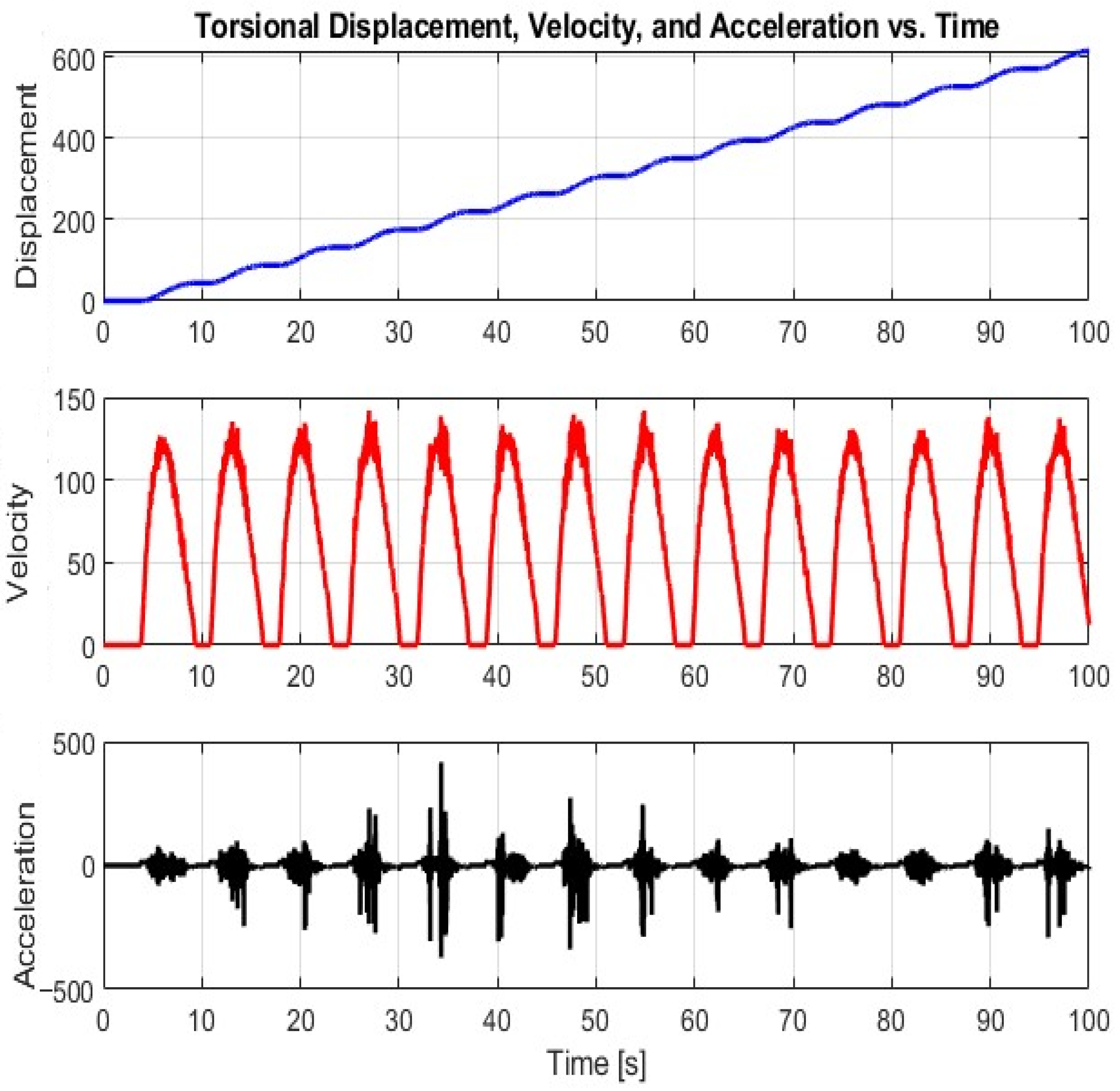

7.2. Open-Loop Behavior: Severe Stick–Slip

| Parameters | Values |

|---|---|

| Young’s Modulus (E) | 220 GPa |

| Poisson’s Ratio () | 0.29 |

| Shear Modulus (G) | 85.3 GPa |

| Density () | 7800 kg/m3 |

| Pipe Outer Radius | 70 mm |

| Pipe Inner Radius | 59.5 mm |

| Collar Outer Radius | 70 mm |

| Collar Inner Radius | 38 mm |

| Pipe Length | 4733.6 m |

| Collar Length | 466.4 m |

| Bit Mass | 66.9 kg |

| Equivalent Bit Radius () | 0.0961 m |

| Friction Coefficient () | 0.4 |

| Number of Borehole Waves () | 4000 |

| Axial Damping Coefficients () | 0.15, 0.15 |

| Torsional Damping Coefficients () | 0.30, 0.30 |

| Sampling Time () | 0.01 s |

| Surface Stall Torque () | 10,000 Nm |

| Base Surface RPM | 60 RPM |

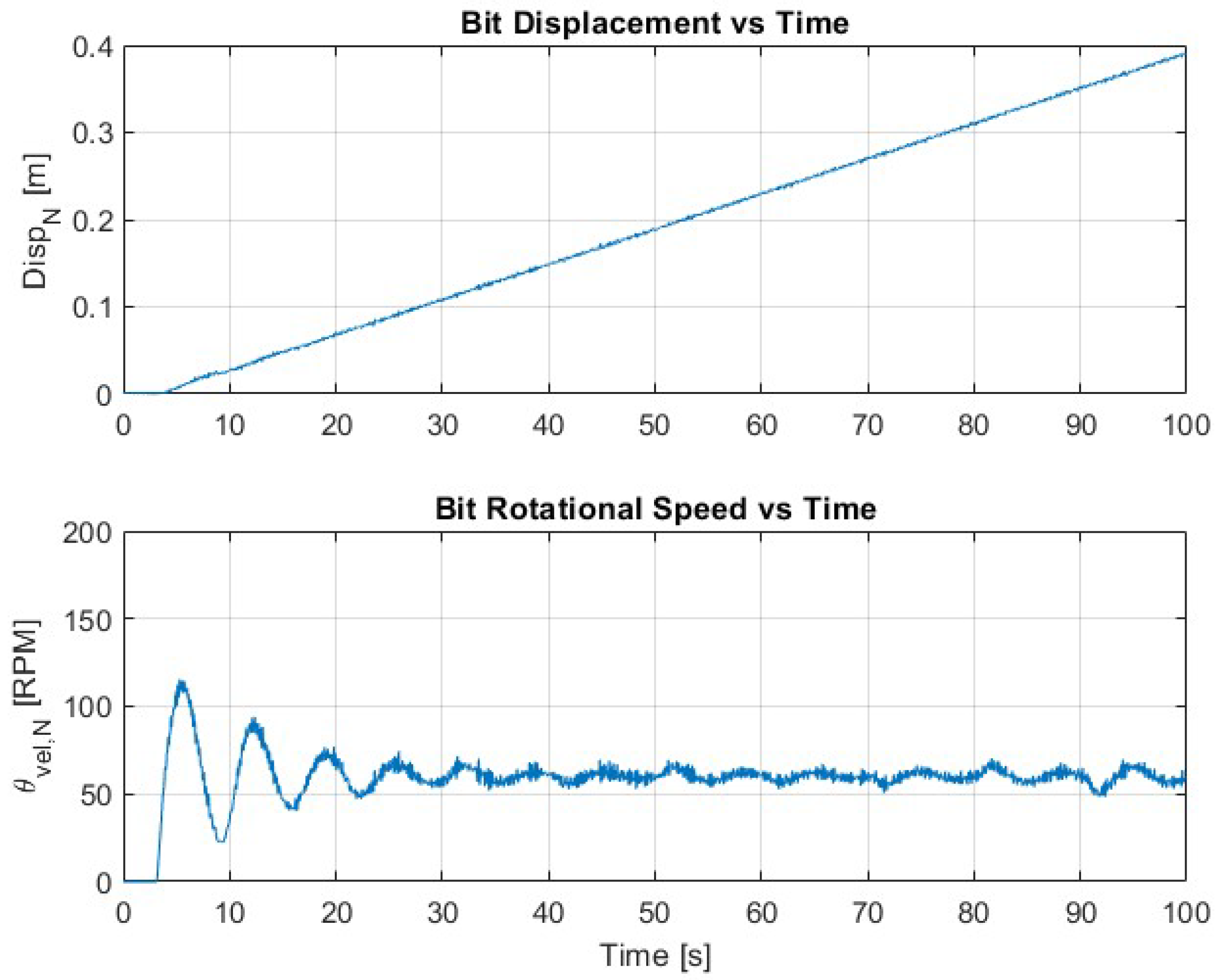

7.3. SMC Performance: Partial Suppression

7.4. MPC–SMC Hybrid Control: Optimal Performance

7.5. Discussion

8. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Detournay, E.; Richard, T.; Shepherd, M. Drilling response of drag bits: Theory and experiment. Int. J. Rock Mech. Min. Sci. 2008, 45, 1347–1360. [Google Scholar] [CrossRef]

- Ritto, T.; Escalante, M.; Sampaio, R.; Rosales, M. Drill-string horizontal dynamics with uncertainty on the frictional force. J. Sound Vib. 2013, 332, 145–153. [Google Scholar] [CrossRef]

- Kamel, J.M.; Yigit, A.S. Modeling and analysis of stick-slip and bit bounce in oil well drillstrings equipped with drag bits. J. Sound Vib. 2014, 333, 6885–6899. [Google Scholar] [CrossRef]

- Liu, X.; Vlajic, N.; Long, X.; Meng, G.; Balachandran, B. Coupled axial-torsional dynamics in rotary drilling with state-dependent delay: Stability and control. Nonlinear Dyn. 2014, 78, 1891–1906. [Google Scholar] [CrossRef]

- Ghasemloonia, A.; Geoff Rideout, D.; Butt, S.D. A review of drillstring vibration modeling and suppression methods. J. Pet. Sci. Eng. 2015, 131, 150–164. [Google Scholar] [CrossRef]

- Aarsnes, U.J.F.; Aamo, O.M. Linear stability analysis of self-excited vibrations in drilling using an infinite dimensional model. J. Sound Vib. 2016, 360, 239–259. [Google Scholar] [CrossRef]

- Bakhtiari-Nejad, F.; Hosseinzadeh, A. Nonlinear dynamic stability analysis of the coupled axial-torsional motion of the rotary drilling considering the effect of axial rigid-body dynamics. Int. J. Non-Linear Mech. 2017, 88, 85–96. [Google Scholar] [CrossRef]

- Aarsnes, U.J.F.; Shor, R.J. Torsional vibrations with bit off bottom: Modeling, characterization and field data validation. J. Pet. Sci. Eng. 2018, 163, 712–721. [Google Scholar] [CrossRef]

- de Moraes, L.P.; Savi, M.A. Drill-string vibration analysis considering an axial-torsional-lateral nonsmooth model. J. Sound Vib. 2019, 438, 220–237. [Google Scholar] [CrossRef]

- Rajabali, F.; Moradi, H.; Vossoughi, G. Coupling analysis and control of axial and torsional vibrations in a horizontal drill string. J. Pet. Sci. Eng. 2020, 195, 107534. [Google Scholar] [CrossRef]

- Choe, Y.M.; Jin, H.S.; Kim, G.S.; Ri, K.S.; Yu, K.S.; Ri, H.G. Axial-torsional mode correlation analysis of a drill string system with non-smooth characteristics. J. Pet. Sci. Eng. 2022, 218, 110870. [Google Scholar] [CrossRef]

- Tian, J.; Tang, L.; Yang, Y.; Dai, L.; Xiong, C. Drill string dynamics and experimental study of constant torque and stick-slip reduction drilling tool. Pet. Sci. Technol. 2024, 42, 407–427. [Google Scholar] [CrossRef]

- Volpi, L.; Cayeux, E.; Time, R. Whirling dynamics of a drill-string with fluid–structure interaction. Geoenergy Sci. Eng. 2024, 232, 212423. [Google Scholar] [CrossRef]

- Haghgouei, H.; Lavrov, A.; Nermoen, A. Effect of drill string lateral vibrations on wellbore stability and optimal mud pressure determination. Geoenergy Sci. Eng. 2025, 247, 213691. [Google Scholar] [CrossRef]

- Clayer, F.; Vandiver, J.K.; Lee, H.Y. The Effect of Surface and Downhole Boundary Conditions on the Vibration of Drillstrings. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990; p. SPE–20447–MS. [Google Scholar] [CrossRef]

- Patil, A.P.; Teodoriu, C. Model Development of Torsional Drillstring and Investigating Parametrically the Stick-Slips Influencing Factors. J. Energy Resour. Technol. 2013, 135, 013103. [Google Scholar] [CrossRef]

- Cunha, A.; Soize, C.; Sampaio, R. Computational modeling of the nonlinear stochastic dynamics of horizontal drillstrings. Comput. Mech. 2015, 56, 849–878. [Google Scholar] [CrossRef]

- Wang, X.; Chen, P.; Rui, Z.; Jin, F. Modeling Friction Performance of Drill String Torsional Oscillation Using Dynamic Friction Model. Shock Vib. 2017, 2017, 1–14. [Google Scholar] [CrossRef]

- Tengesdal, N.K.; Holden, C.; Pedersen, E. Component-Based Modeling and Simulation of Nonlinear Drill-String Dynamics. J. Offshore Mech. Arct. Eng. 2021, 144, 021801. [Google Scholar] [CrossRef]

- Castello, D.; Ritto, T. ABC for model selection and parameter estimation of drill-string bit-rock interaction models and stochastic stability. J. Sound Vib. 2023, 547, 117537. [Google Scholar] [CrossRef]

- Weijun, N.; Guohao, Y.; Chengyun, M.; Gang, L.; Fei, M.; Kai, Z. Research on the influence factors of hydraulic oscillator on drag reduction efficiency in horizontal well drilling. Meas. Control 2024, 57, 871–878. [Google Scholar] [CrossRef]

- Karkoub, M.; Zribi, M.; Elchaar, L.; Lamont, L. Robust μ-synthesis controllers for suppressing stick-slip induced vibrations in oil well drill strings. Multibody Syst. Dyn. 2010, 23, 191–207. [Google Scholar] [CrossRef]

- Hong, L.; Girsang, I.P.; Dhupia, J.S. Identification and control of stick–slip vibrations using Kalman estimator in oil-well drill strings. J. Pet. Sci. Eng. 2016, 140, 119–127. [Google Scholar] [CrossRef]

- Lin, W.; Chavez, J.P.; Liu, Y.; Yang, Y.; Kuang, Y. Stick-slip suppression and speed tuning for a drill-string system via proportional-derivative control. Appl. Math. Model. 2020, 82, 487–502. [Google Scholar] [CrossRef]

- Pavković, D.; Deur, J.; Lisac, A. A torque estimator-based control strategy for oil-well drill-string torsional vibrations active damping including an auto-tuning algorithm. Control Eng. Pract. 2011, 19, 836–850. [Google Scholar] [CrossRef]

- Pehlivantürk, C.; Chen, D.; van Oort, E. Torsional drillstring vibration modelling and mitigation with feedback control. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, The Hague, The Netherlands, 14–16 March 2017; OnePetro: Richardson, TX, USA, 2017. [Google Scholar] [CrossRef]

- Tian, J.; Zhou, Y.; Yang, L.; Hu, S. Analysis of stick-slip reduction for a new torsional vibration tool based on PID control. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2020, 234, 82–94. [Google Scholar] [CrossRef]

- Sharma, A.; Srivastava, S.; Teodoriu, C.; Stan, M. Experimental Comparison of PID Based RPM Control for Long Horizontal vs. Vertical Drillstring. Preprints 2021. [Google Scholar] [CrossRef]

- Hichem, Z.A.; Hamza, A.; Mohamed, D.Z.; Madjid, K. PID-Based Kalman Filter Controller Design Stick-Slip Vibrations Suppression in Drill String Systems. In Proceedings of the 2024 2nd International Conference on Electrical Engineering and Automatic Control (ICEEAC), Setif, Algeria, 12–14 May 2024; pp. 1–716. [Google Scholar] [CrossRef]

- Hu, S.; Lu, C.; Wu, M.; He, Z.; Song, H.; Li, W. Fuzzy PID control for suppressing stick-slip vibration of drill-string system. In Proceedings of the 2022 China Automation Congress (CAC), Xiamen, China, 25–27 November 2022; pp. 5454–5459. [Google Scholar] [CrossRef]

- Meddah, S.; Doghmane, M.Z.; Tadjer, S.A.; Bougueroua, M.; Saighi, O. Fractional-order PID controller design for strongly coupled high-frequency axial–torsional vibrations in drill string system. Int. J. Dyn. Control 2025, 13, 94. [Google Scholar] [CrossRef]

- Liu, Y. Control of a class of multibody underactuated mechanical systems with discontinuous friction using sliding-mode. Trans. Inst. Meas. Control 2018, 40, 514–527. [Google Scholar] [CrossRef]

- Vaziri, V.; Kapitaniak, M.; Wiercigroch, M. Suppression of drill-string stick–slip vibration by sliding mode control: Numerical and experimental studies. Eur. J. Appl. Math. 2018, 29, 805–825. [Google Scholar] [CrossRef]

- Barjini, A.H.; Khoshnazar, M.; Moradi, H. Design of a sliding mode controller for suppressing coupled axial & torsional vibrations in horizontal drill strings using Extended Kalman Filter. J. Sound Vib. 2024, 586, 118477. [Google Scholar] [CrossRef]

- Sadeghimehr, R.; Nikoofard, A.; Khaki Sedigh, A. Predictive-based sliding mode control for mitigating torsional vibration of drill string in the presence of input delay and external disturbance. J. Vib. Control 2020, 27, 2432–2450. [Google Scholar] [CrossRef]

- Zribi, F.; Sidhom, L.; Krama, A.; Gharib, M. Enhancement of drill string system operations with adaptive robust controller and hardware in-the-loop validation. J. Sound Vib. 2023, 556, 117716. [Google Scholar] [CrossRef]

- Soimu, A.; Stinga, F. Predictive control of torsional drillstring vibrations. In Proceedings of the 2016 20th International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 13–15 October 2016; pp. 796–799. [Google Scholar] [CrossRef]

- Wang, X.; Ni, H.; Wang, R. Feasibility study of nonlinear model predictive control in mitigating stick slip in drilling. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 621, p. 012150. [Google Scholar] [CrossRef]

- Cruz Neto, H.; Trindade, M. Control of drill string torsional vibrations using optimal static output feedback. Control Eng. Pract. 2023, 130, 105366. [Google Scholar] [CrossRef]

- Cobern, M.E.; Perry, C.A.; Barbely, J.A.; Burgess, D.E.; Wassell, M.E. Drilling Tests of an Active Vibration Damper. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 20–22 February 2007. [Google Scholar] [CrossRef]

- Chen, J.; Liao, H.; Liu, Y.; Guan, Z. Vibration Analysis of Drill-String with Downhole Shock Absorption Intensifier; SSRN: Rochester, New York, 2024. [Google Scholar]

- Velychkovych, A.; Mykhailiuk, V.; Andrusyak, A. Evaluation of the Adaptive Behavior of a Shell-Type Elastic Element of a Drilling Shock Absorber with Increasing External Load Amplitude. Vibration 2025, 8, 60. [Google Scholar] [CrossRef]

- Wang, L.; Gou, W.; Wang, J.; Zhou, Z. Anti-Vibration Method for the Near-Bit Measurement While Drilling of Pneumatic Down-the-Hole Hammer Drilling. Appl. Sci. 2024, 14, 8565. [Google Scholar] [CrossRef]

- Chen, J.; Liao, H.; Zhang, Y.; Liang, H.; Liu, C.; Qi, D. A torsional-axial vibration analysis of drill string endowed with kinematic coupling and stochastic approach. J. Pet. Sci. Eng. 2021, 198, 108157. [Google Scholar] [CrossRef]

- Chen, J.; Yang, L.; Huang, Q.; Zhang, W.; Qiao, J.; Zhang, X.; Jiang, D. Dynamic analysis of drill string vibration enhanced by neural network based models. Geoenergy Sci. Eng. 2025, 246, 213618. [Google Scholar] [CrossRef]

- Hegde, C.; Millwater, H.; Gray, K. Classification of drilling stick slip severity using machine learning. J. Pet. Sci. Eng. 2019, 179, 1023–1036. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, D.; Chen, J. Robust Control of Drillstring Vibrations: Modeling, Estimation, and Real-Time Considerations. Appl. Sci. 2025, 15, 13137. https://doi.org/10.3390/app152413137

Sui D, Chen J. Robust Control of Drillstring Vibrations: Modeling, Estimation, and Real-Time Considerations. Applied Sciences. 2025; 15(24):13137. https://doi.org/10.3390/app152413137

Chicago/Turabian StyleSui, Dan, and Jingkai Chen. 2025. "Robust Control of Drillstring Vibrations: Modeling, Estimation, and Real-Time Considerations" Applied Sciences 15, no. 24: 13137. https://doi.org/10.3390/app152413137

APA StyleSui, D., & Chen, J. (2025). Robust Control of Drillstring Vibrations: Modeling, Estimation, and Real-Time Considerations. Applied Sciences, 15(24), 13137. https://doi.org/10.3390/app152413137